Three-turn Synchronous Tying Automatic Paper Money Bundling Machine

Technical field

The present invention relates to the bank note bundle paper money device of bank and financial institution, particularly a kind of Three-turn Synchronous Tying Automatic Paper Money Bundling Machine.

Background technology

At present, bank all will carry out a thousand sheets to all kinds of bank note every day ties up, and this also becomes the routine of the important and standard in the banking business.It is to the degree that compresses after tying up, and the width of strapping and quality all have normalized standard.Because when handing-over, all be to calculate with the bale of bank note between each business department of bank, the number of bank note is not checked in each bale.So, the quality of bill binding is just essential.

During manual in the past tying up, can't avoid that the internal staff of bank defalcates in the thousand sheets bank note operation process, individual serious accident of extraction happens occasionally from tie up, and is difficult to trace responsibility.In recent years, automatic money packer has obtained widely using, because normalized mechanical compaction and taked heat to melt bonding special-purpose strapping, and then the phenomenon that is defalcated in bank inside greatly reduces.

Take hold-down mechanism in the existing paper money binding machine mostly, the sending to of orbit determination formula, belt tensioner winding mechanism and add the pressure zone location, heat merges, pressure is sticking, cut off band mechanism forms, with what send that the taut band winding mechanism matches is the special use storage tep reel of hot sticky band, mechanism finish at every turn tie up together must through compressing, transmitting-receiving belt and bonding, cut off each procedure.Because being vertical two horizontal three roads, Central Bank's standard of tying up ties up, so after per pass was tied up, a mechanism that needs to carry the coin bundle rotated 90 ° or 180 ° and ties up to finish three roads.Owing to tie up and all will repeat to compress transmitting-receiving belt, press sticking and the cut-out operation, also wasted energy greatly at every turn owing to repeat to compress for three times.Compress through computer control thrust basically identical down, but owing to driving error, or the pressure that factor such as transmission track delay often causes per pass to tie up is inconsistent, causes the carefully and neatly done degree of uniformity of pack of paper ticket bad, presentation quality is poor at every turn.Since in pressing sticking mechanism carry out three roads tie up bonding voluntarily design plan be 3 bonding, do not have association between longitudinal and transverse the tying up, thereby the finished product that causes tying up at present still has the possibility of taking out coin after compacted, and this is the existing improved problem of urgent need of present automatic money packer.

In addition, existing paper money binding machine is earlier flatiron to be placed between horizontal vertical two strappings carrying out when bonding, after heat is melted flatiron is extracted out.Exert pressure in the above, glue and cut, by hold-down mechanism again so that horizontal vertical strapping is bonding.Long, the also very numerous rope of operation of this bonding time.Have again, existing paper money binding machine, frame is vertical placement.Because each singly is bundled in the place of tying up projection is all arranged, after a plurality of single bundles vertically are stacked together, will occur unevenly, be easy to fall down.So existing paper money binding machine need so exist danger with hand steered when bundle paper money when bundle paper money, can be pressed onto hand.

Summary of the invention

The object of the present invention is to provide the Three-turn Synchronous Tying Automatic Paper Money Bundling Machine that a kind of bundling quality is good, avoid individual extraction.

The objective of the invention is to be achieved through the following technical solutions:

The present invention is provided with frame and control unit in outer cover, hold-down mechanism, sticking mechanism, forward (FWD) mechanism down are installed on the frame, the bottom of outer cover is provided with the band roller, bundle paper money band on the band roller is inserted in the paper money binding machine by forward (FWD) mechanism, hold-down mechanism, down sticking mechanism and forward (FWD) mechanism by in the control unit by being stored in the programming control of setting in the micro controller system, hold-down mechanism, sticking mechanism, forward (FWD) mechanism down from top to bottom are installed on the described frame successively, be provided with sticking mechanism above the upper plate compressing of hold-down mechanism, a side of frame is fixed with the face amount adjusting mechanism.

30~60 ° of described frame tiltables; Described hold-down mechanism comprises clamping motor, worm reduction gear, screw rod, nut and compresses upper plate, worm reduction gear is connected the mouth of clamping motor, is provided with nut in the worm reduction gear, and screw rod inserts nut, and be connected with nut, be fixed with in the lower end of screw rod and compress upper plate; Described sticking mechanism comprises direct current gear reduction motor, motor gear, upper right sticking cam, upper right sticking gear, idle wheel, upper left sticking gear, upper left sticking cam, motor gear is connected the input end of direct current gear reduction motor, motor gear, upper right sticking gear, idle wheel and upper left sticking gear are in transmission connection successively, the coaxial side that is located at upper right sticking gear of upper right sticking cam, the coaxial side that is located at upper left sticking gear of upper left sticking cam, be equipped with push rod below upper right sticking cam and upper left sticking cam, the below of two push rods is established and is connected with sticking flatiron; Described down sticking mechanism comprises vertically sticking cutting mechanism, the laterally sticking cutting mechanism of a right laterally sticking cutting mechanism and a left side, vertically sticking cutting mechanism comprises vertical camshaft, vertical leader tape cam, two directions are cut strap cam in length and breadth, vertical heading tape cam, vertical leader tape axle sleeve, two directions are cut the tape spool cover in length and breadth, the vertical heading tape axle sleeve and first flatiron, vertical leader tape cam, two directions are cut strap cam and are installed in successively on vertical camshaft with vertical heading tape cam in length and breadth, three cams by bearing respectively with vertical leader tape axle sleeve, two directions are cut the tape spool cover in length and breadth, vertically the heading tape axle sleeve is connected, and first flatiron is packed in length and breadth two directions and cuts tape spool and put; Right laterally sticking cutting mechanism comprises right transverse cam axle, right laterally leader tape cam, right laterally heading tape cam, right laterally leader tape axle sleeve, right laterally heading tape axle sleeve, two directions are cut strap cam in length and breadth, two directions are cut the tape spool cover and first flatiron in length and breadth, right transverse cam axle is provided with vertically camshaft is vertical, right laterally leader tape cam and right laterally heading tape cam are installed on the right transverse cam axle, and two cams are connected with the horizontal leader tape axle sleeve in the right side, right laterally heading tape axle sleeve respectively by bearing; The laterally sticking cutting mechanism in a left side comprises left transverse cam axle, a left side is the leader tape cam laterally, strap cam is laterally cut on a left side, a left side is the heading tape cam laterally, a left side is the leader tape axle sleeve laterally, the tape spool cover is laterally cut on a left side, a left side is the heading tape axle sleeve and second flatiron laterally, left side transverse cam axle is provided with vertically camshaft is vertical, a left side is the leader tape cam laterally, strap cam is laterally cut on a left side, a left side laterally heading tape cam is installed on the left transverse cam axle successively, three cams by bearing respectively with the horizontal leader tape axle sleeve in a left side, the tape spool cover is laterally cut on a left side, a left side laterally heading tape axle sleeve is connected, and second flatiron is packed in a left side and laterally cuts tape spool and put; Described face amount adjusting mechanism comprises horizontal face amount adjusting mechanism and vertical face amount adjusting mechanism, and both are by the bevel gear synchronization action; Described horizontal face amount adjusting mechanism comprises horizontal face amount adjustment support and installs horizontal face amount adjustment baffle plate thereon, horizontal face amount adjusting shaft, laterally face amount adjustment cam is installed on the horizontal face amount adjusting shaft, laterally face amount adjustment cam is packed on the horizontal face amount adjustment baffle plate, laterally a side of face amount adjustment cam is provided with roller, and horizontal face amount adjustment cam is adjusted baffle plate by roller with horizontal face amount and is connected; Described vertical face amount adjusting mechanism comprises vertical face amount adjustment support and installs vertical face amount adjustment baffle plate thereon, vertical face amount adjusting shaft, vertically face amount adjustment cam is installed on the horizontal face amount adjusting shaft, vertically face amount adjustment cam is packed on vertical face amount adjustment baffle plate, vertically a side of face amount adjustment cam is provided with roller, and vertical face amount adjustment cam is adjusted baffle plate by roller with vertical face amount and is connected; Laterally be provided with bevel gear between face amount adjusting shaft and the vertical face amount adjusting shaft, vertically an end of face amount adjusting shaft is fixed with the face amount bidding quotation, and the face amount bidding quotation is provided with face amount and adjusts handle; Four point of crossings of these paper money binding machine one vertical two horizontal three road strappings can bond fully, form seven spot gluings.

Advantage of the present invention and good effect are:

Safety of operation, tie up centering.Paper money binding machine of the present invention, 30~60 ° of its frame tiltables.In when operation, put into and treat bundled bank notes, laterally can manage automatically, remove manual arranging process from, vertically be provided with pin simultaneously, put into behind the bank note with hand with bank note and pin be close to can guarantee one indulge two horizontal tie up entirely on the center.

2. bundling quality is good, has avoided individual extraction.The present invention is adding sticking mechanism on the upper plate of hold-down mechanism, bonding to adapt to the needs of tying up in three roads and to increase the intersection point place of horizontal vertical interband, formed the cross bonding of horizontal vertical strapping, form seven spot gluings, thereby improved the quality of tying up greatly, effectively prevented to take out to open and lose the generation of opening.

3. tie paper money time weak point, operation is simple.The present invention is that vertical two horizontal three roads are tied up simultaneously, has saved the time of bundle paper money; Three roads bundle paper money carries out simultaneously, need not to rotate the bank note bundle, has also simplified bundle paper money operation.

Description of drawings

Fig. 1 is an integral structure scheme drawing of the present invention;

Fig. 2 is the scheme drawing of pinch device of the present invention;

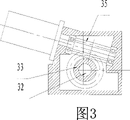

Fig. 3 is the birds-eye view of Fig. 2;

Fig. 4 is sticking schematic representation of apparatus under the present invention;

Fig. 5 vertically glues the scheme drawing of cutting apparatus for the present invention;

Fig. 6 is the laterally right scheme drawing that glues cutting apparatus of the present invention;

Fig. 7 is the laterally left scheme drawing that glues cutting apparatus of the present invention;

Fig. 8 is the scheme drawing of face amount setting device of the present invention;

Fig. 9 is the scheme drawing of longitudinal baffle component in the face amount setting device of the present invention;

Figure 10 is the scheme drawing of transverse baffle component in the face amount setting device of the present invention;

Figure 11 is one of sticking schematic representation of apparatus in the present invention;

Figure 12 is two of sticking schematic representation of apparatus in the present invention.

The specific embodiment

The invention will be further described below in conjunction with accompanying drawing.

As shown in Figure 1, the present invention is provided with frame 2 and control unit in outer cover 1, hold-down mechanism 3, sticking mechanism 5, forward (FWD) mechanism 7 down from top to bottom are installed on the frame 2 successively, the bottom of outer cover 1 is provided with band roller 6, bundle paper money band on the band roller 6 is inserted in the paper money binding machine by forward (FWD) mechanism, hold-down mechanism 3, down sticking mechanism 5 and forward (FWD) mechanism 7 by in the control unit by being stored in the programming control of setting in the micro controller system, be provided with sticking mechanism 4 above the upper plate 34 compressing of hold-down mechanism 3, a side of frame 2 is fixed with face amount adjusting mechanism 8.30~60 ° of frame 2 tiltables, the optimum tilt angle is 45 °.

As Fig. 2, shown in Figure 3, hold-down mechanism 3 comprises clamping motor 31, worm reduction gear 35, screw rod 32, nut 33 and compresses upper plate 34, worm reduction gear 35 is connected the mouth of clamping motor 31, be provided with nut 33 in the worm reduction gear 35, screw rod 32 inserts nut 33, and be connected with nut 33, be fixed with in the lower end of screw rod 32 and compress upper plate 34.

As Figure 11, shown in Figure 12, go up sticking mechanism 4 and comprise direct current gear reduction motor 47, motor gear 46, upper right sticking cam 44, upper right sticking gear 45, idle wheel 43, upper left sticking gear 42, upper left sticking cam 41, motor gear 46 is connected the input end of direct current gear reduction motor 47, motor gear 46, upper right sticking gear 45, idle wheel 43 and upper left sticking gear 42 are in transmission connection successively, upper right sticking cam 44 coaxial sides that are located at upper right sticking gear 45, upper left sticking cam 41 coaxial sides that are located at upper left sticking gear 42, the below that is equipped with push rod 48, two push rods 48 below upper right sticking cam 44 and upper left sticking cam 41 is established to be connected with and is glued flatiron 49.

As shown in Figure 4 to 7, sticking down mechanism 5 comprises vertically sticking cutting mechanism, the laterally sticking cutting mechanism of a right laterally sticking cutting mechanism and a left side, vertically sticking cutting mechanism comprises vertical camshaft 54, vertical leader tape cam 511, two directions are cut strap cam 512 in length and breadth, vertical heading tape cam 513, vertical leader tape axle sleeve 514, two directions are cut tape spool cover 515 in length and breadth, the vertical heading tape axle sleeve 516 and first flatiron 517, vertical leader tape cam 511, two directions are cut strap cam 512 and are installed in successively on vertical camshaft 54 with vertical heading tape cam 513 in length and breadth, three cams by bearing respectively with vertical leader tape axle sleeve 514, two directions are cut tape spool cover 515 in length and breadth, vertically heading tape axle sleeve 516 is connected, and first flatiron 517 is packed in length and breadth two directions and cuts on the tape spool cover 515; Right laterally sticking cutting mechanism comprises right transverse cam axle 57, right laterally leader tape cam 521, right laterally heading tape cam 522, right laterally leader tape axle sleeve 523, right laterally heading tape axle sleeve 524, two directions are cut strap cam 512 in length and breadth, two directions are cut tape spool cover 515 and first flatiron 517 in length and breadth, right transverse cam axle 57 and vertically camshaft 54 vertical settings, right laterally leader tape cam 521 and right laterally heading tape cam 522 are installed on the right transverse cam axle 57, and two cams are connected with the horizontal leader tape axle sleeve 523 in the right side, right laterally heading tape axle sleeve 524 respectively by bearing; The laterally sticking cutting mechanism in a left side comprises left transverse cam axle 56, a left side is leader tape cam 531 laterally, strap cam 532 is laterally cut on a left side, a left side is heading tape cam 533 laterally, a left side is leader tape axle sleeve 534 laterally, tape spool cover 535 is laterally cut on a left side, a left side is the heading tape axle sleeve 536 and second flatiron 537 laterally, left side transverse cam axle 56 and vertically camshaft 54 vertical settings, a left side is leader tape cam 531 laterally, strap cam 532 is laterally cut on a left side, a left side laterally heading tape cam 533 is installed on the left transverse cam axle 56 successively, three cams by bearing respectively with the horizontal leader tape axle sleeve 534 in a left side, tape spool cover 535 is laterally cut on a left side, a left side laterally heading tape axle sleeve 536 is connected, and second flatiron 537 is packed in a left side and laterally cuts on the tape spool cover 535.

As Fig. 8~shown in Figure 10, face amount adjusting mechanism 8 comprises horizontal face amount adjusting mechanism and vertical face amount adjusting mechanism, and both are by bevel gear 84 synchronization actions.Laterally the face amount adjusting mechanism comprises horizontal face amount adjustment support 814 and installs horizontal face amount adjustment baffle plate 811 thereon, horizontal face amount adjusting shaft 813, laterally face amount adjustment cam 812 is installed on the horizontal face amount adjusting shaft 813, laterally face amount adjustment cam 812 is packed on the horizontal face amount adjustment baffle plate 811, the side that horizontal face amount is adjusted cam 812 is provided with roller 85, and horizontal face amount adjustment cam 812 is adjusted baffle plate 811 by roller 85 with horizontal face amount and is connected; Described vertical face amount adjusting mechanism comprises vertical face amount adjustment support 824 and installs vertical face amount adjustment baffle plate 821 thereon, vertical face amount adjusting shaft 823, vertically face amount adjustment cam 822 is installed on the horizontal face amount adjusting shaft 823, vertically face amount adjustment cam 822 is packed on vertical face amount adjustment baffle plate 821, the side that vertical face amount is adjusted cam 822 is provided with roller 85, and vertical face amount adjustment cam 822 is adjusted baffle plate 821 by roller 85 with vertical face amount and is connected; Laterally be provided with bevel gear 84 between face amount adjusting shaft 813 and the vertical face amount adjusting shaft 823, vertically an end of face amount adjusting shaft 823 is fixed with face amount bidding quotation 86, and face amount bidding quotation 86 is provided with face amount and adjusts handle 83.

Working process of the present invention is:

At first carry out the face amount adjustment.To treat that the pack of paper coin is placed on the work top of face amount adjusting mechanism 8, rotate face amount and adjust handle 83, make the corresponding face amount scale on its aligning face amount bidding quotation 86.When rotating face amount adjustment handle 83, vertically face amount adjusting shaft 823 rotates thereupon, and then the vertical face amount that drives on it is adjusted cam 822 rotations.Vertically face amount is adjusted cam 822 and is promoted roller 85, adjusts four-bar mechanism 82 by vertical face amount and makes vertical face amount adjust vertical limit that baffle plate 821 leans against bank note, and bank note is vertically alignd.When vertically face amount adjusting shaft 823 rotates, by bevel gear 84 horizontal face amount adjusting shaft 813 is rotated synchronously, and then the horizontal face amount that drives on it is adjusted cam 812 rotations.Laterally face amount is adjusted cam 812 and is promoted roller 85, adjusts four-bar mechanism 81 by horizontal face amount and makes horizontal face amount adjust the widthwise edge that baffle plate 811 leans against bank note, makes the bank note lateral alignment.

Then bank note is compressed.Clamping motor 31 energising backs drive worm reduction gear 35 work.Nut 33 in the worm reduction gear 35 rotates under the drive of worm reduction gear 35, and then make and be mated bonded assembly screw rod 32 and move down, be pressed on the bank note by the upper plate 34 that compresses that is packed in screw rod 32 lower ends, bank note applied 1000 kilograms pressure (institute's applied pressure is by the power decision of clamping motor).

Following sticking operation.As shown in Figure 5, vertically strapping 55 at first passes vertical leader tape axle sleeve 514, cross each other axle sleeve after, guided to the top of vertical leader tape axle sleeve 514 by vertical conduction band groove 51, under programming control, halt.At this moment, the vertical camshaft of motor-driven 54 rotates, and then drives vertical leader tape cam 511 rotations, promote vertical leader tape axle sleeve 514 rise with strapping 55 take the lead withstand.Strapping 55 is pressed and forward (FWD) direction counteragent under the drive of motor then, and strapping 55 is tightened up.The vertical camshaft 54 of motor-driven rotates once more, drives vertical heading tape cam 513 rotations, promotes vertical heading tape axle sleeve 516 risings magnetic tape trailer is compressed.Strap cam 512 rotations are cut in vertical camshaft 54 drives that are rotated further two directions in length and breadth, and 517 risings of tape spool cover 515 and first flatiron are cut in promotion two directions in length and breadth, and elder generation scalds strapping and glues, and cuts off then, finishes vertically and ties up.As shown in Figure 6, laterally strapping 55 at first passes right laterally leader tape axle sleeve 523, and after crossing each other axle sleeve, is directed to the right laterally top of leader tape axle sleeve 523 by right laterally conduction band groove 52, halts under programming control.At this moment, the right transverse cam axle 57 of motor-driven rotates, and then drives right laterally leader tape cam 521 rotations, promote right laterally leader tape axle sleeve 523 rise with strapping 55 take the lead withstand.Strapping 55 is pressed and forward (FWD) direction counteragent under the drive of motor then, and strapping 55 is tightened up.The right transverse cam axle 57 of motor-driven rotates once more, drives right horizontal heading tape cam 522 rotations, promotes right laterally heading tape axle sleeve 524 risings magnetic tape trailer is compressed.The vertical camshaft 54 that rotates synchronously drives in length and breadth two directions and cuts strap cam 512 rotations, and two directions are cut tape spool cover 515 and first flatiron 517 and promoted to rise in length and breadth, makes two band bondings and cuts off, and finishes the right side and laterally ties up.As shown in Figure 7, laterally strapping 55 at first passes laterally leader tape axle sleeve 534 of a left side, and after crossing each other axle sleeve, a quilt left side laterally conduction band groove 53 is directed to the laterally top of leader tape axle sleeve 534, a left side, halts under programming control.At this moment, motor-driven left side transverse cam axle 56 rotates, and then drives laterally leader tape cam 531 rotations of a left side, promote a left side laterally leader tape axle sleeve 534 rise with strapping 55 take the lead withstand.Strapping 55 is pressed and forward (FWD) direction counteragent under the drive of motor then, and strapping 55 is tightened up.Motor-driven left side transverse cam axle 56 rotates once more, drives left horizontal heading tape cam 533 rotations, promotes horizontal heading tape axle sleeve 536 risings in a left side magnetic tape trailer is compressed.The left transverse cam axle 56 that is rotated further drives a left side and laterally cuts strap cam 532 rotations, and 537 risings of tape spool cover 535 and second flatiron are laterally cut on a promotion left side, strapping is scalded glue earlier, cut off then, finish a left side and laterally tie up.

Go up sticking operation.47 work of direct current gear reduction unit drive motor gear 46 rotations.Motor gear drives upper right sticking gear 45, idle wheel 43, upper left sticking gear 42 rotations successively.Upper right sticking gear 45 drives the upper right sticking cam coaxial with it 44 rotations, upper left sticking gear 42 drives the upper left sticking cam coaxial with it 41 rotations, by push rod 48 sticking flatiron 49 is moved down, four point of crossings of one vertical two horizontal strappings are bondd fully, finish the cross bonding, form seven spot gluings.

What the present invention had realized that vertical two horizontal three roads tie up finishes synchronously, tie up smooth, operating speed and improve, and the phenomenon of opening of taking out that prevents takes place.