CN1875495A - Package structure for optical device - Google Patents

Package structure for optical device Download PDFInfo

- Publication number

- CN1875495A CN1875495A CNA2004800326674A CN200480032667A CN1875495A CN 1875495 A CN1875495 A CN 1875495A CN A2004800326674 A CNA2004800326674 A CN A2004800326674A CN 200480032667 A CN200480032667 A CN 200480032667A CN 1875495 A CN1875495 A CN 1875495A

- Authority

- CN

- China

- Prior art keywords

- resin

- light

- optics

- optical device

- package structure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/47—Structure, shape, material or disposition of the wire connectors after the connecting process

- H01L2224/48—Structure, shape, material or disposition of the wire connectors after the connecting process of an individual wire connector

- H01L2224/4805—Shape

- H01L2224/4809—Loop shape

- H01L2224/48091—Arched

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/47—Structure, shape, material or disposition of the wire connectors after the connecting process

- H01L2224/48—Structure, shape, material or disposition of the wire connectors after the connecting process of an individual wire connector

- H01L2224/481—Disposition

- H01L2224/48151—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/48221—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/48245—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being metallic

- H01L2224/48247—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being metallic connecting the wire to a bond pad of the item

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/15—Details of package parts other than the semiconductor or other solid state devices to be connected

- H01L2924/181—Encapsulation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/19—Details of hybrid assemblies other than the semiconductor or other solid state devices to be connected

- H01L2924/191—Disposition

- H01L2924/19101—Disposition of discrete passive components

- H01L2924/19107—Disposition of discrete passive components off-chip wires

Landscapes

- Led Device Packages (AREA)

Abstract

An LED (6) is mounted to the mounting portion (5) of a lead frame with its light emitting portion facing an opening (5a). A wire (9) connecting the LED (6) with the lead portion (3) of the lead frame is disposed on the LED (6)-mounted side. Light transmitting resin (8) for transmitting an emitted light from the LED (6) is disposed on the side opposite to the LED (6)-mounted side of the lead frame. Low-stress resin (2) for sealing the LED (6) and the wire (9) is disposed on the LED (6)-mounted side of the lead frame. A crack preventing structure is formed by bends (31) provided to the lead portions (3) and bending to the LED (6)-mounted side, parts (21) of the low-stress resin positioned on the side opposite to the LED (6)-mounted side across the bends (31), and the ends (81) of the light transmitting resin in contact with the parts (21) of this low-stress resin.

Description

Technical field

The present invention relates to employed package structure for optical device in abominable relatively temperature environment such as optical communication, illumination, automobile.

Background technology

According to routine, a kind of package structure for optical device has been arranged, wherein CCD optics such as (charge coupled devices) is installed on the device mounting portion of lead frame, the lead portion of optics and lead frame couples together by lead, and seals optics, lead and lead frame (consulting JP2000-173947A) with light-transmissive resin.Make light-transmissive resin approximately form the shape of rectangular parallelepiped protrusion part, its material have gratifying with incide this optics on the relevant transmissison characteristic of light.Upper surface with light-transmissive resin integrally forms lens, makes rays pass through lens incide on the optics.In addition, the lead portion of lead frame is outstanding from the side of light-transmissive resin, and the optics shell is connected to the electrode of regulation by lead portion.

But, in the package structure for optical device of routine, in order to obtain the light transmission features of light-transmissive resin, any filler of no use mixes so that reduce linear expansion coefficient with light-transmissive resin.Therefore, the linear expansion coefficient of light-transmissive resin is the several times of linear expansion coefficient of each material of optics and lead.As a result, such problem is arranged, when package structure for optical device be used in the abominable temperature environment (such as, temperature is spent in the scopes of 105 degree-40 and is changed) time, in light-transmissive resin, can cause the fracture of lead and the breaking-up of optics because of thermal stress.Another problem is that light-transmissive resin can break.

The objective of the invention is to, prevent the fracture of lead and the breaking-up of optics, and prevent breaking of the light-transmissive resin relevant with package structure for optical device.

Summary of the invention

In order to realize this purpose, a kind of package structure for optical device is provided, it comprises:

Optics;

Lead frame, it has mounting portion that optics is installed and the lead portion that is electrically connected to this optics thereon, and this mounting portion has an aperture, and the light of incident or the light that sends from optics can pass through this aperture;

Lead, it is positioned at lead frame and that side of optics is installed and is electrically connected to this optics with lead portion;

First resin is positioned at the opposite side of that side that optics is installed with lead frame, this first resin transmit light;

Second resin, the part of at least the second resin are positioned at that side that lead frame is equipped with optics, and this second resin seals optics and lead and has the linear expansion coefficient lower than first resin; And

Anti-cataclastic structure is used to prevent that first resin from breaking.

According to this structure, in package structure for optical device, second resin that is used to seal optics and lead has the linear expansion coefficient lower than first resin.Therefore, even this structure is used in the relatively large environment of variations in temperature, the thermal stress that is applied on optics and the lead also can be reduced effectively.Therefore, can prevent the problem that optics is destroyed and the problem of wire fracture effectively.

In addition, no matter the linear expansion coefficient of first resin is greater than linear expansion coefficient of lead frame or the like, anti-cataclastic structure all can make and be difficult in first resin break.Therefore, even this structure is used in the relatively large environment of variations in temperature, also can prevent to produce in first resin problem of breaking effectively.

In an example of package structure for optical device, anti-cataclastic structure comprises:

Sweep, it is positioned at the leading part office of lead frame and towards that lateral bending song that optics is installed;

The part of second resin, it is positioned at and the opposite side of that side of optics being installed with respect to sweep; And

The end portion of first resin, it contacts with the part of second resin.

According to present embodiment, in anti-cataclastic structure, sweep is positioned at the lead portion of lead frame and towards that lateral bending song that optics is installed.The part of second resin is positioned at and the opposite side of that side that optics is installed with respect to sweep.The end portion of first resin contacts with the part of second resin.When using this arrangement, can reduce the shearing stress that produced in the end portion of first resin effectively,, also can prevent to produce in first resin problem of breaking effectively even if this structure is used in the relatively large environment of variations in temperature.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises:

Sunk part, it is positioned at the leading part office of lead frame and has a chamber, and this chamber is positioned at a side opposite with that side that optics is installed;

The part of second resin, it is positioned at sunk part inside; And

The end portion of first resin, it contacts with the part of second resin.

According to present embodiment, in anti-cataclastic structure, sunk part is positioned at the lead portion of lead frame and has a chamber, and this chamber is positioned at a side opposite with that side that optics is installed.The part of second resin is positioned at sunk part inside.The end of first resin contacts with the part of second resin.When using this arrangement, can reduce the shearing stress that is produced in the end portion of first resin effectively.As a result, even this structure is used in the relatively large environment of variations in temperature, also can prevent to produce in first resin problem of breaking effectively.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises:

Sweep, it is positioned at the leading part office of lead frame and towards that lateral bending song that optics is installed; And

The end portion of first resin, the justified margin of its end surface and sweep.

According to present embodiment, in anti-cataclastic structure, sweep is positioned at the leading part office of lead frame and towards that lateral bending song that optics is installed.Have the end portion of first resin of end surface and the justified margin of sweep.When using this structure, can reduce the shearing stress that is produced in the end portion of first resin effectively.As a result, even this structure is used in the relatively large environment of variations in temperature, also can prevent to produce in first resin problem of breaking effectively.

In an embodiment of package structure for optical device, the end surface of the end portion of first resin roughly with the flush of sweep, this sweep is positioned at a side opposite with that side that optics is installed.

According to present embodiment, the end surface of the end portion by making first resin roughly flushes with the lead portion of lead frame, just can reduce the shearing stress that is produced in the end portion of first resin.Therefore, can prevent to produce in first resin problem of breaking effectively.

In an embodiment of package structure for optical device, second resin forms by transfer modling.

According to present embodiment, second resin forms by transfer modling.Therefore, can reduce the residual stress that produced with in the second resin-sealed optics and the lead effectively.

In an embodiment of package structure for optical device, second resin does not comprise any release agent.

According to present embodiment, second resin does not comprise any release agent, therefore, can improve bonding between second resin and first resin.

In an embodiment of package structure for optical device, first resin comprises the filler that is used to reduce the first resin linear expansion coefficient.

According to present embodiment, reduce the linear expansion coefficient of first resin by filler, therefore, can reduce linear expansion coefficient poor between second resin and the lead frame.Therefore, can prevent from first resin to produce too much thermal stress, and can prevent the generation of breaking effectively.

Notice that the amount that is mixed into the filler in first resin preferably should make the light transmission of first resin can not reduce largely.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises first resin, first resin has lens component and base portion, this lens component is collected into light that is mapped on this optics or the light that sends from this optics, this base portion and lens component couple together, and base portion has and is not more than 0.5 millimeter thickness.

According to present embodiment, the stress that is focused on the base portion of first resin has reduced.Therefore, can prevent the generation of breaking in first resin effectively.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises first resin, first resin has lens component and base portion, this lens component is collected into the light that is mapped to the light on the optics or sends from optics, this base portion and lens component couple together, and when first resin when the emission of light and incident direction are observed has the little area of area than the mounting portion of lead frame, and base portion has the thickness littler than the thickness of lens component.

According to present embodiment, the stress that focuses on the base portion of first resin has reduced.Therefore, can prevent from effectively in first resin, to produce and break.

In an embodiment of package structure for optical device, second resin has and is positioned at the parts that the opposite side of that side of optics is installed with lead frame, and the parts of second resin are arranged in the part except that part of lead frame of placing first resin at least.

According to present embodiment, the parts of second resin are placed on lead frame that identical side of first resin are installed.Therefore, for example, the parts by using second resin as a reference, this device can be installed on the miscellaneous equipment.Therefore, can obtain can be based on the package structure for optical device of external shape aligned position.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises first resin, this first resin has lens component and base portion, this lens component is collected into the light that is mapped to the light on the optics or sends from optics, this base portion and lens component couple together, and are joined together with lead frame at least with the binder material.

According to present embodiment, under the situation of not using insert molding, from lead frame, form first resin separately, and first resin and lead frame are joined together with the binder material.Therefore, can prevent from when forming first resin, to shrink the generation of the stress that causes because of mold pressing by insert molding.As a result, can prevent from effectively in first resin, to produce and break.

In an embodiment of package structure for optical device, the binder material comprises a kind of resin, and this resin has the glass height also lower than minimum storing temperature.

According to present embodiment, the binder material comprises its glass height resin also lower than minimum storing temperature, and therefore, in the normal environment for use of package structure for optical device, the elasticity of binder material is bigger.Therefore, since can reduce the shearing stress that produces between first resin and lead frame, what so just can prevent from effectively to produce in first resin breaks.Notice that storing temperature means the ambient temperature range that can preserve this resin under the situation that does not apply electric loading, description is arranged in JIS-C7021-B10.

In an embodiment of package structure for optical device, the binder material comprises a kind of resin, and the solidification point of this resin is not less than minimum storing temperature and is not higher than the highest storing temperature.

According to present embodiment, the binder material comprises its solidification point and is not less than minimum storing temperature and is not higher than a kind of like this resin of the highest storing temperature.Therefore, in the solidification process of binder material, can reduce the thermal stress that causes because of curing relatively.Therefore, since the shearing stress that can reduce in being lower than resin to be produced so also can prevent to produce in being lower than resin and break.

In an embodiment of package structure for optical device, anti-cataclastic structure comprises first resin, and

First resin has a plurality of lens components and a plurality of base portion, lens component is collected into the light that is mapped to the light on the optics or sends from optics, base portion extends to each lens component, and a plurality of compound lens part is separated mutually with base portion.

According to present embodiment, the lens component and the base portion of a plurality of combinations are separated from each other, and therefore, can prevent from effectively to produce in first resin and break.

As mentioned above, in package structure for optical device of the present invention, first resin transmits into the light that is mapped to the light on the optics or sends from optics, this first resin is positioned at that side of mounting portion of lead frame, second resin-sealed optics and the lead, this second resin is positioned at the opposite side of mounting portion, and second resin has the linear expansion coefficient lower than first resin.Therefore, even package structure for optical device is used in the relatively large environment of variations in temperature, also can reduce to be applied to the thermal stress on the optics effectively.Therefore, can prevent the problem of optics breaking-up and the problem of wire fracture effectively.

In addition, can prevent to produce in first resin problem of breaking effectively by anti-cataclastic structure, and no matter the linear expansion coefficient of first resin greater than the linear expansion coefficient of lead frame etc., even and this structure to be used in the relatively large environment of variations in temperature situation also like this.

Description of drawings

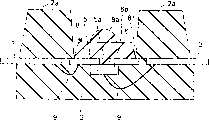

Figure 1A shows the cross-sectional view of the package structure for optical device of first embodiment of the invention;

Figure 1B shows the plane graph of the package structure for optical device of first embodiment;

Fig. 2 shows the cross-sectional view of the package structure for optical device of second embodiment;

Fig. 3 shows the cross-sectional view of the package structure for optical device of the 3rd embodiment;

Fig. 4 shows the cross-sectional view of the package structure for optical device of comparative example;

Fig. 5 shows the cross-sectional view of the package structure for optical device of the 4th embodiment;

Fig. 6 shows the cross-sectional view of the package structure for optical device of the 5th embodiment;

Fig. 7 shows the cross-sectional view of the package structure for optical device of the 6th embodiment;

Fig. 8 shows the cross-sectional view of the package structure for optical device of the 7th embodiment;

Fig. 9 shows the cross-sectional view of package structure for optical device of the modified example of the 5th embodiment;

Description of drawings

By many embodiment the present invention is described now with reference to accompanying drawing.

(first embodiment)

Figure 1A shows the cross-sectional view of the package structure for optical device of the first embodiment of the present invention.Figure 1B shows the plane graph of the package structure for optical device of first embodiment.

In package structure for optical device, be installed in lower surface one side of the mounting portion 5 of lead frame among Fig. 1 as the LED (light-emitting diode) 6 of optics.The light that LED6 sent is positioned at 5 places, mounting portion of lead frame by aperture 5a wherein, and the luminous component of LED 6 faces aperture 5a.LED6 is electrically connected to the lead portion 3 of lead frame by lead 9.Lead 9 is arranged in a side (that side of LED 6 is installed) of mounting portion lead frame.LED 6 and lead 9 are to seal with containing the low stress resin 2 of silicon dioxide as filler.Low stress resin 2 is arranged in a side (that side of LED 6 is installed) of mounting portion 5 lead frames.On the other hand, light-transmissive resin 8 is arranged in the opposite side of that side that LED 6 is installed with the lead frame of mounting portion 5, and has the infiltrative material of light by a kind of light that is sent at LED 6 and constitute.Light-transmissive resin 8 constitutes by integrally forming lens component 8a with base portion 8b, and lens component 8a converges the light that LED 6 is sent, base portion 8b support of lens part 8a.The cross section of base portion 8b be trapezoidal then be rectangle in the plane.Low stress resin 2 is provided by a kind of resin, in adding epoxy resin such as the filler silicon dioxide that linear expansion coefficient is very little, comprises the linear expansion coefficient that reduces this resin on the whole.Light-transmissive resin 8 is to be provided by transparent epoxy resin.

Package structure for optical device has anti-cataclastic structure.Anti-cataclastic structure is by the sweep 31 at lead portion 3 places that are positioned at lead frame, is positioned at the low stress resin part 21 at the opposite side place of that side that LED 6 is installed with respect to sweep 31 and with the end portion 81 of low stress resin part 21 contacted light-transmissive resins and is constituted.The sweep 31 of the lead portion 3 of lead frame is towards that lateral bending song that LED 6 is installed.

In the package structure for optical device of this structure, LED 6 and lead 9 usefulness low stress resins 2 seal, and the linear expansion coefficient of low stress resin 2 has the numerical value that a linear expansion coefficient with the linear expansion coefficient of the LED 6 that is formed by Si (silicon) and GaAs (GaAs) and lead frame and lead is close.Therefore, even if this structure is used in the relatively large environment of variations in temperature, also can reduce to be applied to the thermal stress on LED 6 and the lead 9 effectively.As a result, can prevent the breaking-up problem of LED 6 and the breakage problem of lead 9 effectively.

In addition, since package structure for optical device has anti-cataclastic structure,, also can prevent breaking of light-transmissive resin 8 effectively even so when this structure is used in the relatively large environment of variations in temperature.That is, light-transmissive resin 8 does not mix any filler, and to preserve the gratifying transmissison characteristic at the light of LED 6, therefore, light-transmissive resin 8 has the linear expansion coefficient of the linear expansion coefficient several times that are lead frame and low stress resin 2.But, since the end portion of light-transmissive resin 81 contacts with low stress resin part 21, provide the shearing stress that is produced in the end portion 81 of resin to become so than little with the contacted end portion of the lead portion of lead frame.As a result, can prevent effectively that generation is broken in the light-transmissive resin 8.

In addition, form low stress resin 2 and light-transmissive resin 8 respectively separately, just can produce package structure for optical device at an easy rate by bottom side and top side at lead frame.Promptly, with be to compare by the situation that insert molding forms when the lens of making and be used to converge the light that LED sends by glass by the low stress resin, the required time and efforts such as location of the lens of being made by glass are still less, therefore, can produce low stress resin 2 at an easy rate.In addition, since low stress resin 2 only is positioned at that side that lead frame is equipped with LED 6, only come the situation of sealing wire frame both sides to compare with light-transmissive resin so with in the conventional situation, the flowable of the resin during mold pressing in the metal pattern is more gratifying.Therefore, can prevent to discharge the problem that enters sealing resin.In addition, can under less relatively restriction, be provided for mold pressing metal pattern the door the position.Therefore, by relatively easily carrying out common injection-molding, just can produce package structure for optical device in mode cheaply.

(second embodiment)

Fig. 2 shows the sectional view of the package structure for optical device of second embodiment.

The package structure for optical device of second embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In a second embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.

The anti-cataclastic structure that package structure for optical device had of second embodiment is by the sunk part 32 at lead portion 3 places that are arranged in lead frame, is positioned at the low stress resin part 22 of sunk part 32 and constitutes jointly with the end portion 81 of low stress resin part 22 contacted light-transmissive resins.The sunk part 32 of the lead portion of lead frame has a chamber at an opposite side place with that side that LED 6 is installed.

Even when being used in the relatively large environment of variations in temperature, by means of this anti-cataclastic structure, the package structure for optical device of present embodiment also can prevent breaking of light-transmissive resin 8 effectively.That is,, comprise the shearing stress that is produced in the end portion 81 that reduces light-transmissive resin effectively so since the end portion of light-transmissive resin 81 contacts with low stress resin part 22 in the anti-cataclastic structure.Therefore, no matter the linear expansion coefficient that this resin has is the several times of the linear expansion coefficient of lead frame and low stress resin 2, can prevents from effectively in light-transmissive resin 8, to produce and break.

(the 3rd embodiment)

Fig. 3 shows the sectional view of the package structure for optical device of the 3rd embodiment.

The package structure for optical device of the 3rd embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In the 3rd embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.The anti-cataclastic structure that package structure for optical device had of the 3rd embodiment is to be made of the sweep 33 at lead portion 3 places that are positioned at lead frame and the end portion 81 of light-transmissive resin, and this end portion 81 has the end surface 83 with the justified margin of sweep 33.The sweep 33 of the lead portion of lead frame is towards that lateral bending song that LED 6 is installed.

Even when being used in the relatively large environment of variations in temperature, by means of this anti-cataclastic structure, the package structure for optical device of present embodiment also can prevent breaking of light-transmissive resin 8 effectively.Promptly, the end portion 81 of light-transmissive resin contact with the sweep 33 of lead portion and the end surface 83 of the terminal part office of light-transmissive resin and situation that the edge of sweep 33 in the anti-cataclastic structure is aimed under, can reduce the shearing stress that is produced in the end portion 81 of light-transmissive resin effectively.Therefore, no matter the linear expansion coefficient of light-transmissive resin 8 is several times of the linear expansion coefficient of lead frame and low stress resin 2, can prevents from effectively in light-transmissive resin 8, to produce and break.

In each embodiment, the formation method of light-transmissive resin 8 is not particularly limited.On the other hand, in order to reduce the residual stress in these parts, preferably should be formed for low stress resin 2, lead 9 of sealing LED 6 or the like by transfer modling.

In addition, preferably, should any release agent be used for low stress resin 2.This is because if release agent is used for the low stress resin, then when light-transmissive resin be when after the low stress resin forms, forming again, release agent sometimes can ooze out from the low stress resin and to the bonding adverse influence that causes between low stress resin and the light-transmissive resin.

In addition, what can receive is to be mixed in the light-transmissive resin 8 so that reduce linear expansion coefficient with fillers such as silicon dioxide, and the degree of mixing will make transmissison characteristic (light transmittance) not weakened.When using this arrangement, the shearing stress that can further reduce in the light-transmissive resin to be produced, and can more effectively prevent from light-transmissive resin, to produce and break.

In addition, LED 6 can be another kind of optics, for example, and CCD, VCSEL (vertical cavity surface emitting laser), PD (photodiode) or the like.

In addition, the shape of light-transmissive resin 8 and low stress resin 2 is not limited to the shape of rectangular parallelepiped protrusion part, but can be varied to other shape as required.

In addition, the shape of lead frame can change over other shape as required.For example, mounting portion 5 and lead portion 3 can integrally form, and the lead portion 3 of any number can be provided.

(example)

The package structure for optical device of first to the 3rd embodiment is to spend and produce in the environment of 105 degree and through tested person for-40 in range of temperature.In addition, at the package structure for optical device of first to the 3rd embodiment, come emulation by FEM (Finite Element Method), thereby calculate the shearing stress that under test condition, is produced with computer.In addition, example is tested the package structure for optical device that does not have anti-cataclastic structure of the present invention as a comparison, and carries out the calculating of shearing stress.

Fig. 4 shows the sectional view of the package structure for optical device of comparative example.Package structure for optical device has some assemblies identical with the package structure for optical device of first embodiment, difference is, the lead portion 103 of lead frame is stretched out to the side along the boundary line between light-transmissive resin 8 and the low stress resin 2, and any anti-cataclastic structure is not provided.In the example depicted in fig. 4, identical with first embodiment shown in Figure 1 assembly is denoted by the same reference numerals.

Material and the comparative example used in the process of the optics of producing first to the 3rd embodiment are as follows.That is, the EME6710 that is produced by Sumitomo Bakelite company is used to low stress mold pressing resin 2.In addition, the NT600 that Nitto Denko company is produced is used to light-transmissive resin 8, and the copper alloy KFC that is produced by Kobe Steel company is used to lead frame.Then, low stress resin 2 forms 2 millimeters thickness, and light-transmissive resin 8 forms 1 millimeter thickness, and lead frame forms 0.25 millimeter thickness.Use these building blocks, just produced the shell size and be 6 square millimeters shell mechanism.

Form 1 shows the physical characteristic of the material of building block.

Form 1

| Linear expansion coefficient (ppm/k) | Young's modulus (GPa) | The Poisson ratio | |

| GaAs | 5.9 | 85.5 | 0.55 |

| Si | 2.8 | 187 | 0.25 |

| Au | 14.2 | 78 | 0.44 |

| The Cu alloy | 17 | 128 | 0.35 |

| Luminous resin | 60-70 | 3-3.5 | 0.3 |

| The low stress resin | 8-18 | 15-30 | 0.25-0.3 |

As shown in Table 1, since mixed filler, the linear expansion coefficient of low stress resin 102 has with the copper alloy that is used for lead frame, is used for the gold of lead and is used for the numerical value that the linear expansion coefficient of the Si of LED 6 is close so.On the other hand, light-transmissive resin 108 does not mix any filler so that avoid reducing of light transmission features (this light transmission features is the light that sent at LED 6), and it has the linear expansion coefficient of the several times that are other structural material.

The package structure for optical device of first to the 3rd embodiment and comparative example is to make with the material with physical characteristic shown in the form 1.Shell mechanism is to produce by 2 insertions of low stress resin are molded into the casting mold that also carries out light-transmissive resin 108 in the lead frame that LED6 is installed after this.These package structure for optical device be positioned over range of temperature for-40 spend to 105 the degree environment in stand temperature cycling test.

As a result, in the light-transmissive resin 8 of comparative example, produced and broken.Specifically, in Fig. 4, in the lead portion 103 and low stress resin 8 contacted those parts of the most normal end portion that appears at light-transmissive resin 81 of breaking and lead frame.Secondly, break in lead portion 103 contacted those parts of the end portion 81 that more often appears at light-transmissive resin and lead frame.The shearing stress that is produced in the general main end portion 81 owing to light-transmissive resin of these generations of breaking, it produces former because the difference of each the components linear expansion coefficient that contacts with each other.

On the other hand, in the package structure for optical device of first to the 3rd embodiment, almost do not observe any generation of breaking at end portion 81 places of light-transmissive resin.This is probably owing to having relative less Young's modulus with the end portion 81 contacted low stress resin parts 21 and 22 of light-transmissive resin, although its linear expansion coefficient is different from the light-transmissive resin 8 among first and second embodiment, therefore, the shearing stress that the place, border produces between these resins is less relatively.In addition, in a second embodiment,, can reduce the shearing stress at light-transmissive resin end portion 81 places by locating to form end surface 83 in light-transmissive resin end portion (edge of the sweep 31 of the lead portion of this end portion and lead frame aligns).

According to test result, by forming the lead portion 3 of lead frame, make lead portion only from second resin, stretch out, rather than in first and second embodiment from as the light-transmissive resin of first resin with as stretching out the border between the low stress resin of second resin, just can probably prevent from first resin, to produce too much shearing stress.In addition, by forming the lead portion 3 of lead frame, make the edge of sweep in a second embodiment as the light-transmissive resin of first resin with as the boundary between the low stress resin of second resin, just can probably prevent from first resin, to produce too much shearing stress.

| The shearing stress (MPa) at A place, position | The shearing stress (MPa) at B place, position | |

| Comparative example | 70 | 51 |

| First embodiment | 35.8 | 28 |

| Second embodiment | 35.8 | 28 |

| The 3rd embodiment | 45.8 | 40 |

In form 2, position A be light-transmissive resin 8 with the transverse edge of the lead portion 3 of lead frame and 103 and light-transmissive resin end portion 81 place or light-transmissive resin end portion 81 near low stress resin 2 contacted that part of.Position B be light-transmissive resin 8 with light-transmissive resin end portion 81 place or light-transmissive resin end portion 81 near the lead portion 3 and 103 the transverse center of lead frame contacted that part of.

The simulation result of form 2 is satisfactorily corresponding to the result who carries out the temperature cycling test gained with true things.Produce and the NT600 that is used to make light-transmissive resin 8 has the bending strength of 130MPa by Nitto Denko company.Since the shearing stress of resin normally its bending strength 1/3rd, the shearing strength that can estimate light-transmissive resin 8 so is about 45MPa.Can judge that the shearing stress that goes out when simulation calculation can be easy to produce shear fracture when surpassing the shearing stress of light-transmissive resin.In fact, in comparative example, all substantially exceed 45MPa at position A and B place, in the temperature cycling test process, produced many breaking in the end portion 81 of light-transmissive resin by the shearing stress that simulation calculation obtained.On the other hand, according to first and second embodiment, the shearing stress that obtains by simulation calculation all is lower than 45MPa at position A and B place, in temperature cycling test, does not produce any breaking in the end portion 81 of light-transmissive resin.In addition, although the shearing stress that A place in position obtains by simulation calculation in the 3rd embodiment just over 45MPa, by temperature cycling test, does not produce any breaking in the end portion 81 of light-transmissive resin.

According to these results, what produced in the light-transmissive resin 8 breaks probably owing to the generation of shearing stress greatly, these stress result from the end portion 81 of light-transmissive resin and the lead portion 103 contacted parts of lead frame, especially result from two lateral end being positioned at lead portion 103 and also with low stress resin 2 contacted those parts.In this case, according to package structure for optical device of the present invention, it can reduce the shearing stress at end portion 81 places of light-transmissive resin effectively by means of the anti-result of breaking, and probably can prevent breaking of light-transmissive resin 8 effectively.

(the 4th embodiment)

Fig. 5 shows the sectional view of the package structure for optical device of the 4th embodiment.

The package structure for optical device of the 4th embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In the 4th embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.

The thickness that the thickness of base portion 8b by light-transmissive resin 8 is set to stipulate, thus the anti-cataclastic structure that package structure for optical device had of present embodiment is provided.Notice that base portion 8b is meant that the lens 8a's that is used to support light-transmissive resin 8 is that part of.The thermal stress that is produced in the light-transmissive resin 8 mainly is by caused in the difference of lead frame 3 aspect linear expansion coefficient and the Young's modulus and 5.Particularly, the thickness of the base portion 8b of light-transmissive resin 8 is thick more, lead frame 3 and 5 and light-transmissive resin 8 between the shearing stress that produces just big more, thereby be easy to cause that stress is concentrated and produced breaks in the terminal part office of light-transmissive resin 8.

In this case, be 0.5 millimeter or still less by thickness setting with the base portion 8b of light-transmissive resin 8, just can reduce the shearing stress that is produced in the end portion of light-transmissive resin effectively.That is, be lead frame 3 and 5 and the linear expansion coefficient of low stress resin 2 several times although light-transmissive resin 8 has, by using anti-cataclastic structure, just can prevent from effectively in light-transmissive resin 8, to produce to break.

From the angle that prevents to break, preferably, the thickness of the base portion 8b of light-transmissive resin 8 should approach as much as possible.But, consider the flowable problem of resin during mold pressing, lower limit should preferably be set to about 0.3 millimeter.

(the 5th embodiment)

Fig. 6 shows the sectional view of the package structure for optical device of the 5th embodiment.

The package structure for optical device of the 5th embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In the 5th embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.

Area by making light-transmissive resin 8 provides the anti-cataclastic structure that package structure for optical device had of present embodiment less than the area when the mounting portion 5 of lead frame when the light emission direction of LED 6 is seen.Notice that light-transmissive resin 8 is that the base portion 8b by lens component 8a and support of lens part 8a constitutes, and the area of light-transmissive resin 8 is identical with the area of base portion 8b.The thermal stress that is produced in the light-transmissive resin 8 mainly is by causing in the difference between those of lead frame 3 aspect linear expansion coefficient and the Young's modulus and 5.Particularly, the area of light-transmissive resin 8 is big more, and near the end portion of light-transmissive resin 8, the shearing stress that is produced between resin and lead frame 3 and 5 is just big more, thereby is easy to cause that in the terminal part office of light-transmissive resin 8 stress is concentrated and generation is broken.

In this case, the area by making light-transmissive resin 8 can reduce the shearing stress that is produced in the end portion 81 of light-transmissive resin effectively less than the area of seeing the mounting portion 5 of lead frame from LED 6 light emission directions.That is, be lead frame 3 and 5 and the linear expansion coefficient of the several times of low stress resin 2 no matter light-transmissive resin 8 has, can break by using anti-cataclastic structure to prevent from effectively in light-transmissive resin 8, to produce.

In addition, by the 4th embodiment and the 5th embodiment are combined thickness and the area that reduces light-transmissive resin 8, can more effectively prevent from light-transmissive resin 8, to produce and break.In addition, as shown in Figure 9, when light-transmissive resin 8 is by a plurality of lens component 8a, 8a ... with a plurality of base portion 8b, the 8b that extend to a plurality of lens component 8a ... the time, by the lens component 8a and the base portion 8b of a plurality of combinations disconnected from each other, can more effectively prevent from light-transmissive resin 8, to produce and break.

(the 6th embodiment)

Fig. 7 shows the sectional view of the package structure for optical device of the 6th embodiment.

The package structure for optical device of the 6th embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In the 6th embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.

The package structure for optical device of present embodiment has the anti-cataclastic structure similar to the package structure for optical device of the 5th embodiment.That is, light-transmissive resin 8 is the base portion 8b by lens component 8a and support of lens part 8a, and the area of the area of base portion 8b or light-transmissive resin 8 is less than the area of the mounting portion 5 of lead frame when the light emission direction of LED 6 is seen.In this case since light-transmissive resin 8 be with inevitable minimum dimension form so that make the light transmission of LED 6, such situation is so just arranged, promptly shell mechanism can't be aimed at by the surface of using light-transmissive resin 8.

Therefore, the parts 2a of low stress resin is positioned on the surface of lead frame 3 and 5 (light-transmissive resin 8 is positioned at this side), and is arranged at least except that the present part that part of of light-transmissive resin 8.The surface of parts 2a by using the low stress resin, shell mechanism can be aimed at the equipment that shell mechanism is installed.When low stress resin 2 was molded into lead frame 3 and 5, comparatively suitable was by place a pin etc. in that part of position of serving as light path (wherein placing light-transmissive resin 8), to block the inflow of low stress resin material.

When forming the base portion 8b of light-transmissive resin 8 under the situation about reducing to some extent, can on the surface of that side lead frame 3 of placing light- transmissive resin 8 and 5, form the parts 2a of low stress resin at thickness.Even when the base portion 8b of the light-transmissive resin 8 that reduces to some extent with thickness can't realize position alignment, also can realize the position alignment of shell mechanism by the surface of the parts 2a of low stress resin.

(the 8th embodiment)

Fig. 8 shows the sectional view of the package structure for optical device of the 7th embodiment.

The package structure for optical device of the 7th embodiment is compared with the package structure for optical device of first embodiment, and difference only is the structure of anti-cataclastic structure.In the 7th embodiment, the assembly identical with first embodiment all is denoted by the same reference numerals, and no longer is described in detail.

Except when when the light emission direction of LED 6 is seen beyond the area of area less than the mounting portion 5 of lead frame of light-transmissive resin 8, by joining light-transmissive resin 8 mounting portion 5 of lead frame at least, thereby constituted the anti-cataclastic structure that package structure for optical device had of the 7th embodiment with binder.Light-transmissive resin 8 is that the base portion 8b by lens component 8a and support of lens part 8a constitutes, and joins the mounting portion 5 of lead frame to the bottom of major general's base portion 8b with the binder material.

If light-transmissive resin 8 is made of by insert molding integral body lead frame 3 and 5, residual stress, thermal stress etc. then in light-transmissive resin 8, have been produced, residual stress is attributable to the stress that molding causes, and thermal stress is owing to temperature when light-transmissive resin solidifies the zero hour and the temperature difference between the environment temperature.Residual stress becomes the reason that generation is broken in light-transmissive resin 8.

In this case, according to present embodiment, light-transmissive resin 8 forms separately from lead frame 3 and 5, and with binder material 10 light-transmissive resin 8 is fixed on the mounting portion 5 of lead frame at least.Under this arrangement, have only thermal stress (temperature when solidifying the zero hour and the temperature difference between the environment temperature) to become the reason of residual stress owing to light-transmissive resin, therefore, can reduce in light-transmissive resin 8, to produce the possibility of breaking.In addition, serve as the buffer of stress, just can prevent from effectively in light-transmissive resin 8, to produce to break by making binder material 10.

Specifically, the glass height material that is lower than the minimum storing temperature of optics shell preferably should be used as binder material 10.Under this arrangement, in the home of using package structure for optical device, binder material 10 can form rubbery state.Under this arrangement, can reduce the Young's modulus of binder material 10, therefore, by the fixing lead frame 3 of binder material 10 and 5 and light-transmissive resin 8 between stress difference can weaken.Therefore, focus on the light-transmissive resin 8, just can prevent the generation of breaking effectively by preventing stress effectively.

In addition, by using binder material 10 (its solidification point is not less than the minimum storing temperature of optics shell and is not higher than the highest storing temperature),, can reduce the temperature difference between solidification point and the environment temperature at the setting up period of binder material 10.Therefore, can reduce the thermal stress that when solidifying binder material 10, produced, and can prevent from effectively in light-transmissive resin 8, to produce and break.The solidification point of binder material 10 preferably should have such numerical value, i.e. the numerical value of the minimum storing temperature of optics shell and the arithmetic mean of the numerical value of high storing temperature.

In the 4th to the 7th embodiment, the formation method of light-transmissive resin 8 is not particularly limited.On the other hand, since low stress resin 2 sealing LEDs 6, lead 9 etc. so in order to reduce the residual stress in these parts, preferably should use transfer moudling.

In addition, at low stress resin 2, preferably do not use any release agent.This is because if release agent is used for the low stress resin, then when light-transmissive resin be forming the low stress resin after again formation the time, release agent may ooze out from the low stress resin and to the bonding adverse effect that causes between low stress resin and the light-transmissive resin.

In addition, LED 6 can be another optics, such as, CCD, VCSEL or PD.

In addition, the shape of light-transmissive resin 8 and low stress resin 2 is not limited to the shape of rectangular parallelepiped protrusion part, but can change into other shape as required.

In addition, the shape of lead frame also can become another kind of shape as required.For example, mounting portion 5 and lead portion 3 can integrally constitute, and the lead portion 3 of arbitrary number can be provided.

| Maximum shearing stress (MPa) | |

| First embodiment | 28 |

| The 4th embodiment | 23 |

| The 5th embodiment (each lens all separates with base portion) | 22 |

| The 5th embodiment | 25 |

| The 5th embodiment (thin type) | 20 |

| The 7th embodiment (silicones) | 2 |

| The 7th embodiment (solidification point: 75 ℃) | 14 |

Can find out obviously that from form 3 compare with first embodiment, the package structure for optical device of the 4th, the 5th and the 7th embodiment can allow further to reduce the shearing stress of light-transmissive resin 8.Therefore, can say like this, can prevent from effectively in light-transmissive resin 8, to produce and break.

Claims (16)

1. package structure for optical device, it comprises:

Optics (6);

Lead frame, it has mounting portion (5) that optics (6) are installed and the lead portion that is electrically connected to optics (6) thereon, mounting portion (5) has aperture (5a), incides the light on the optics (6) or the light that sends from optics (6) all passes aperture (5a);

Lead (9), it is positioned at described lead frame and that side of optics (6) is installed and is electrically connected to the have lead portion optics (6) of (3);

First resin (8), it is positioned at the opposite side of that side that optics (6) is installed with described lead frame, and described first resin is a printing opacity;

Second resin (2), at least a portion of described second resin are positioned at that side that described lead frame is equipped with optics (6), and the described second resin-sealed optics (6) and lead (9) also have than the little linear expansion coefficient of described first resin; And

Anti-cataclastic structure (8,21,22,31,32,81) is used to prevent that described first resin from breaking.

2. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises:

Sweep (31), the lead portion (3) that it is positioned at described lead frame are located and towards that lateral bending song that optics (6) is installed;

The part of described second resin (21), it is positioned at and the opposite side of that side that optics (6) is installed with respect to sweep (31); And

The end portion of described first resin (81), it contacts with the described part of described second resin.

3. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises:

Sunk part (32), the lead portion (3) that it is positioned at described lead frame is located and is had a chamber in an opposite side with that side that optics (6) is installed;

Described second resin is positioned at the part (22) of sunk part (32); And

The end portion of described first resin (81), it contacts with the described part (22) of described second resin.

4. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises:

Sweep (31), the lead portion (3) that it is positioned at described lead frame are located and towards that lateral bending song that optics (6) is installed; And

The end portion of described first resin (81), its end surface (83) is aimed at the edge of described sweep.

5. package structure for optical device as claimed in claim 4 is characterized in that,

The end surface of the end portion of described first resin (83) surface general and sweep (31) flushes, and described sweep is positioned at a side opposite with that side that described optics is installed.

6. package structure for optical device as claimed in claim 1 is characterized in that,

Described second resin (2) forms by transfer modling.

7. package structure for optical device as claimed in claim 1 is characterized in that,

Described second resin (2) does not comprise any release agent.

8. package structure for optical device as claimed in claim 1 is characterized in that,

Described first resin (8) comprises the filler of the linear expansion coefficient that is used to reduce described first resin.

9. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises described first resin (8),

Described first resin (8) has lens component (8a) and base portion (8b), described lens component (8a) is used for being collected into light that is mapped on the described optics or the light that sends from described optics, described base portion (8b) extends to described lens component (8a), and

Described base portion (8b) has and is not more than 0.5 millimeter thickness.

10. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises described first resin (8), and

Described first resin (8) has the lens component (8a) of the light that is used for being collected into the light that is mapped on the described optics or sends from described optics and the base portion (8b) that extends to described lens component (8a), and has the area of seeing the mounting portion (5) than described lead frame from the emission or the incident direction of described light and want little area.

11. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises described first resin (8),

Described first resin (8) has the lens component (8a) of the light that is used for being collected into the light that is mapped on the described optics or sends from described optics and the base portion (8b) that extends to described lens component (8a), and have the area of seeing mounting portion (5) from the emission or the incident direction of described light and want little area than described lead frame, and

Described base portion (8b) has than the thickness of described lens component (8a) wants little thickness.

12. as claim 10 or 11 described package structure for optical device, it is characterized in that,

Described second resin (2) has and is positioned at the parts that the opposite side of that side of optics (6) is installed with described lead frame, and the parts of described second resin (2a) are arranged in the parts of the part except that described lead frame is placed first resin (8) that part of at least.

13. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises described first resin (8), and

Described first resin (8) has the lens component (8a) of the light that is used for being collected into the light that is mapped on the described optics or sends from described optics and the base portion (8b) that extends to described lens component (8a), and joins described first resin (8) to described lead frame at least with binder material (10).

14. package structure for optical device as claimed in claim 13 is characterized in that,

Described binder material (10) comprises the resin that a kind of its glass height is lower than minimum storing temperature.

15. package structure for optical device as claimed in claim 13 is characterized in that,

Described binder material (10) comprises a kind of its solidification point and is not less than minimum storing temperature and is not higher than the resin of high storing temperature.

16. package structure for optical device as claimed in claim 1 is characterized in that,

Described anti-cataclastic structure comprises the described resin (8) that is lower than, and

Described first resin (8) has a plurality of lens components (8a) of the light that is used for being collected into the light that is mapped on the described optics or sends from described optics and a plurality of base portion (8b) that extend to each lens component (8a), and lens component of described a plurality of combinations (8a) and base portion (8b) are separated from each other.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP376967/2003 | 2003-11-06 | ||

| JP2003376967 | 2003-11-06 | ||

| JP232371/2004 | 2004-08-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1875495A true CN1875495A (en) | 2006-12-06 |

| CN100454588C CN100454588C (en) | 2009-01-21 |

Family

ID=37484954

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2004800326674A Expired - Fee Related CN100454588C (en) | 2003-11-06 | 2004-10-13 | Package structure for optical device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN100454588C (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9711489B2 (en) | 2013-05-29 | 2017-07-18 | Cree Huizhou Solid State Lighting Company Limited | Multiple pixel surface mount device package |

| US9831393B2 (en) | 2010-07-30 | 2017-11-28 | Cree Hong Kong Limited | Water resistant surface mount device package |

| US10431567B2 (en) | 2010-11-03 | 2019-10-01 | Cree, Inc. | White ceramic LED package |

| CN111197730A (en) * | 2018-11-19 | 2020-05-26 | 东京零件工业股份有限公司 | Lighting device |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3238326B2 (en) * | 1996-07-17 | 2001-12-10 | 株式会社東芝 | Light emitting device |

| JP2002118270A (en) * | 2000-10-06 | 2002-04-19 | Tokai Rika Co Ltd | Optical device and its fabricating method |

| JP2003007946A (en) * | 2001-06-27 | 2003-01-10 | Enomoto Co Ltd | Lead frame for surface-mounting led and manufacturing method thereof |

| US6613597B2 (en) * | 2001-06-29 | 2003-09-02 | Xanoptix, Inc. | Optical chip packaging via through hole |

| TW546857B (en) * | 2001-07-03 | 2003-08-11 | Semiconductor Energy Lab | Light-emitting device, method of manufacturing a light-emitting device, and electronic equipment |

-

2004

- 2004-10-13 CN CNB2004800326674A patent/CN100454588C/en not_active Expired - Fee Related

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9831393B2 (en) | 2010-07-30 | 2017-11-28 | Cree Hong Kong Limited | Water resistant surface mount device package |

| US10431567B2 (en) | 2010-11-03 | 2019-10-01 | Cree, Inc. | White ceramic LED package |

| US9711489B2 (en) | 2013-05-29 | 2017-07-18 | Cree Huizhou Solid State Lighting Company Limited | Multiple pixel surface mount device package |

| CN111197730A (en) * | 2018-11-19 | 2020-05-26 | 东京零件工业股份有限公司 | Lighting device |

| CN111197730B (en) * | 2018-11-19 | 2022-06-17 | 东京零件工业股份有限公司 | Lighting device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN100454588C (en) | 2009-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1212676C (en) | Light source device using LED, and method of producing same | |

| CN1929159A (en) | Semiconductor illumination device | |

| CN100338786C (en) | Semiconductor light emitting device, method for producing the same and reflector for semiconductor light emitting device | |

| CN1215349C (en) | Semiconductor laser module | |

| CN1825644A (en) | High power led housing and fabrication method thereof | |

| JP4683053B2 (en) | Injection mold, semiconductor package molded by the same, and method of manufacturing semiconductor package | |

| JP4934352B2 (en) | High power LED package and high power LED package manufacturing method | |

| JP4211359B2 (en) | Manufacturing method of semiconductor device | |

| CN1825645A (en) | Led housing and fabrication method thereof | |

| CN1251369C (en) | Semiconductor laser unit with laser acceptor to receive monitor laser beam | |

| CN1233045C (en) | Luminescent device | |

| CN1258252C (en) | Semiconductor laser device | |

| CN1190844C (en) | Method for manufacturing optical illuminating device | |

| CN1229766C (en) | Image display unit and prodn. method for image display unit | |

| CN1423347A (en) | Luminance element and making method thereof and lead frame for making said element | |

| CN1574407A (en) | Light emitting device | |

| CN1744335A (en) | Surface mount LED | |

| CN1523681A (en) | Semiconductor light-emitting device, manufacturing method thereof, and electronic image pickup device | |

| US20050236639A1 (en) | Semiconductor light emitting device and fabrication method thereof | |

| CN1692503A (en) | A light-emitting diode | |

| WO2007080742A1 (en) | Method of photoelement resin sealing/molding | |

| CN1287486C (en) | Small antenna and production thereof | |

| CN1728364A (en) | Optical semiconductor device, optical connector and electronic equipment | |

| CN1838441A (en) | Light-emitting device and image reading apparatus | |

| CN1822401A (en) | LED package frame and LED package having the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20090121 Termination date: 20131013 |