CN1431496A - Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system - Google Patents

Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system Download PDFInfo

- Publication number

- CN1431496A CN1431496A CN03112800.9A CN03112800A CN1431496A CN 1431496 A CN1431496 A CN 1431496A CN 03112800 A CN03112800 A CN 03112800A CN 1431496 A CN1431496 A CN 1431496A

- Authority

- CN

- China

- Prior art keywords

- difference

- gas

- passage

- space

- score

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 40

- 230000008859 change Effects 0.000 title claims description 14

- 238000011156 evaluation Methods 0.000 title abstract description 3

- 239000007789 gas Substances 0.000 title description 37

- 230000008569 process Effects 0.000 claims abstract description 8

- 238000012545 processing Methods 0.000 claims abstract description 7

- 238000013139 quantization Methods 0.000 claims description 7

- 238000010606 normalization Methods 0.000 claims description 6

- 230000010355 oscillation Effects 0.000 claims description 5

- 230000003321 amplification Effects 0.000 claims description 4

- 238000003199 nucleic acid amplification method Methods 0.000 claims description 4

- 238000007789 sealing Methods 0.000 claims description 3

- 230000005764 inhibitory process Effects 0.000 claims description 2

- 238000001914 filtration Methods 0.000 claims 1

- 238000005259 measurement Methods 0.000 abstract description 10

- 239000000203 mixture Substances 0.000 abstract description 6

- 230000035945 sensitivity Effects 0.000 abstract description 6

- 238000002604 ultrasonography Methods 0.000 abstract description 2

- 230000003213 activating effect Effects 0.000 abstract 1

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 230000002277 temperature effect Effects 0.000 description 2

- 230000032683 aging Effects 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000004868 gas analysis Methods 0.000 description 1

- 239000008246 gaseous mixture Substances 0.000 description 1

- 230000008676 import Effects 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 230000010365 information processing Effects 0.000 description 1

- 230000010363 phase shift Effects 0.000 description 1

- 238000013441 quality evaluation Methods 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- 230000009897 systematic effect Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

Images

Landscapes

- Investigating Or Analyzing Materials By The Use Of Ultrasonic Waves (AREA)

Abstract

The invention belongs to the gas measurement area and sensor technique area. The system includes the transducer of air medium, the module for activating and receiving the ultrasound signal, the analog signals process module and the terminal process system of microcomputer for control and evaluation. The difference method (phase difference and frequency difference) is adopted in the system as the key part of processing analog signals to solve the measurement errors brought by the measuring sensitivity and temperatures. The variant phase locked loop constituted by phase difference system increases the measuring accuracy and sensitivity greatly. The invention is workable in all density range of gas composition.

Description

One, technical field

The invention belongs to gas analysis fields of measurement and sensor technical field.Relate to the intelligent surveying instrument that gas trace changes, and relate to the system that the technical feature of FEEDBACK CONTROL and corresponding device is made assessment.

Two, background technology

Sound propagation velocity in any gas is the function of gas temperature and gas composition.After the influence that the elimination temperature is brought in the measuring system, measurement data is only relevant with gas componant.

When gaseous mixture is 2 kinds of gas compositions, and the velocity of sound of 2 kinds of gas compositions is inequality, and the variation of measuring the velocity of sound this moment just can draw wherein a kind of variation of trace relatively of gas.Therefore accurately measure the velocity of sound, can become a kind of effective means of analytical gas composition.

The method of the comparatively practical measurement velocity of sound has following several in the prior art:

1, interferometer mode: this method is according to the sound wave superposition principle, and is synthetic and when crest, trough occurring, measure the position of peak valley when incident wave and reflection wave, just determines the acoustic propagation time.Its precision generally is no more than 10

-2~10

-3

2, relative method: it is the phase place of comparison incident wave signal and receiving transducer output signal, calculates the acoustic propagation time.

3, impulse method:, calculate the velocity of sound by the needed time of measurements and calculations known distance to tested gas transponder pulse acoustic signals.It can be divided into pulse Hui Mingfa again, superimposed pulses method, pulse matching method etc.

All there is certain shortcoming in above measuring method under specified conditions such as real-time, scene: interferometer mode realizes measuring automatically relatively difficulty, system complex.Phase-comparison method and impulse method measuring accuracy are lower, generally 10

-3About.Impulse method also is subjected to the restriction of air transducer frequency band.The forward position of pulse signal and back are longer along the time, except that directly influencing the precision, measure the restriction that minor increment also is subjected to the blind area.

More than three kinds of method maximums be problematic in that the error that temperature effect is brought can not finely solve.Storage " temperature~speed " data compare method if adopt in advance, and then the influence that variation brought because of territorial environment can't overcome.

Three, summary of the invention

1, goal of the invention

The object of the invention provides a kind of not temperature influence and obtains the little change real-time measurement system of highly sensitive gas.And form automatic control and intelligent management evaluating system according to resulting data.

2, technical scheme

The technical scheme that solves goal of the invention is to adopt method of difference measuring system and a microcomputer terminal disposal system

A basic element of character of method of difference measuring system is that two spaces postpone passage.It is made up of emission, two pairs of air dielectric transducers of reception.One of them passage seals at the scene, and what it touched is still unchanged gas.The then blow-by of another passage, little change gas produces little change of the velocity of sound at this.During work, two channel temperatures are identical, and temperature-responsive is also identical, subtract each other by two paths of signals behind the difference channel, and final output signal only reflects the information that gas content changes, and Temperature Influence then is suppressed.

The method of difference measuring system is divided into the phase differential point-score, the difference on the frequency point-score.

Differential networks output quantity after the binary channels is the phase differential point-score when being phase signal.Phase differential has been represented twin-channel mistiming.This system is postponed parts such as passage, phase difference device, loop filter, voltage controlled oscillator and power splitter and forms by two spaces.Two spaces postpone passages and link to each other with the phase difference device respectively, link to each other with voltage controlled oscillator through loop filter, are connected with power splitter and constitute phase-locked loop.As everyone knows, phase-locked loop is a kind of closed loop automatic control system of tracking signal phase place.Tracking performance and technical complexity that its is unique and accurate, the satellite that the is mainly used in space industry orbit determination of testing the speed, survey of deep space etc.In very high communication of performance requirement and precision measurement system, also use it sometimes.

When it is used in native system twin-channel phase differential is followed the tracks of.It is a kind of phase-locked loop of variation, and when cyclic system locking in a single day, the frequency of voltage controlled oscillator output is the function of little change gas time delay.Twin-channel distance that the space postpones is fixed, and the velocity of sound equals distance divided by the time, so it can obtain the velocity of sound data of high precision.

It requires air transducer working frequency range height, and when conditions such as mechanical system can satisfy, sensitivity reached 10

-7

When the differential networks output quantity after the binary channels is the difference on the frequency signal, then be the difference on the frequency point-score.It is postponed parts such as passage, amplifier, frequency differential device and loop filter and forms by two spaces.Two spaces postpone passage and form the closed loop vibration with two amplifiers respectively.Oscillation frequency has reflected that respectively the space postpones the gas speed of sound of passage 1 and passage 2, and oscillation frequency is the function of time delay, also is the function of gas temperature, gas componant.By difference engine, wave filter is eliminated temperature effect.Its difference frequency signal output is the function of the little change of gas.

Difference measurement obtains little change information, through signal Processing, and FEEDBACK CONTROL and equipment evaluation constituted microcomputer terminal of the present invention disposal system.

Method of difference is measured little change information of output earlier through normalized, makes it provide the content value of percent by volume according to gas with various.Native system generally all is that a certain gas content value is given to preestablish, and will controls automatically according to this setting value in the actual operation process.At this moment, with default simulated value digital quantization.Compare with measuring the normalized signal that obtains then, and obtain power amplification, remove to control corresponding gear train and carry out FEEDBACK CONTROL in power control output stage.This feedback closed loop system has guaranteed the precision control to gas content.

When the content of gas is that when reason caused, generally it was the function of time for the leakage (perhaps aging) of affiliated machinery and equipment.This moment, terminal processing system was differentiated to normalized signal.The time differential result data can be used as the performance parameter of device systems.Output print stores or equipment is reported to the police.

3, beneficial effect

Gas trace provided by the invention changes mensuration, analysis process system has following advantage compared with prior art:

(1), caused interference of temperature and measuring error have been eliminated by system.

(2), the measuring accuracy height, highly sensitive, applied range.

When frequency was 100kHz, adopting the sensitivity of difference on the frequency point-score was 10

-4~10

-5

When frequency is 500kHz when above, adopting the sensitivity of phase differential point-score is 10

-7

The gas trace that can measure concentration range and be 0~100% o'clock changes.(3), system can the constitution equipment quality evaluation system.(4), system can constitute feedback control system.(5), system can measure SF

6, O

2, H

2, methane, trace such as inert gas changes.As long as it is inequality to satisfy the velocity of sound of 2 kinds of gas compositions.

Simultaneously, the parameter of native system and design must require and environmental baseline changes accordingly and debugs according to gas with various.

Four, description of drawings

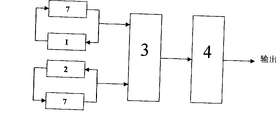

The ultrasonic trace of Fig. 1 method of difference changes to be measured and the control evaluating system

The mixed gas space of 1-sealing postpones passage, 2-mixed gas space postpones passage, 3-double passage differential device, 4-loop filter, 5-voltage controlled oscillator, 6-power splitter, the processing of 8-normalization method, 9-differential, the assessment of 10-performance parameter, the simulated value digital quantization of 11-, 12-comparison, 13-power amplification output;

Fig. 2 difference on the frequency point-score measuring system

1,2,3,4 is identical with Fig. 1

The 7-amplifier

Five, embodiment

The figure elements in the system of the present invention and the block diagram of signal Processing all are known and obtainable software except the binary channels space postpones 1,2.

The enforcement of embodiment 1 phase difference method system

The basic element of character of native system is that two spaces postpone passage 1,2, it is to receive two pairs of air dielectric transducers by emission to constitute, the phase versus frequency response charac t of two pairs of air transducers must be consistent, and two pairs of transducers must be parallel when installing, the temperature of two passages is identical, the temperature-responsive response is also identical, and passage 1 is used sylphon seal, to eliminate the stress of temperature.Passage 1,2 is connected with difference engine 3 respectively, the phase signal of output passes through loop filter 4, links to each other with voltage controlled oscillator 5, be connected with power splitter 6 again, power splitter output two-way same signal imports seal channel 1 and passage 2 respectively into, and whole closed-loop system constitutes a variation phase-locked loop, when in a single day loop locks, voltage controlled oscillator output is the function of the little change of gas, Temperature Influence then has been subjected to inhibition, owing to got rid of the interference of temperature, has improved the precision of measuring greatly.

Implementation process is with SF

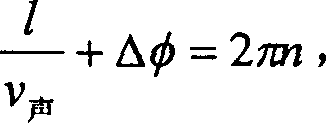

6The gas trace is changed to example and constitutes frequency differential mensuration control system.The double-channel signal of difference engine input is the variation of frequency.When the amplifier by lag line (promptly 1,2,7) constitutes the closed loop vibration: must satisfy four conditions with optimal way in debugging with in selecting:

Amplitude conditions: amplifier gain must be greater than the loss and the loss sum of air ultrasound transducer.

Sound is the gas speed of sound.ΔΦ is the phase shift of gas transducer.

The single-mode oscillation condition:

Δ F is the bandwidth of gas transducer.τ for the emission, receiving transducer it

Between time delay.

The high stable oscillating condition:

F is the closed loop oscillation frequency, and τ is the delay between emission, the receiving transducer

Time.

Begin at systematic survey, when binary channels starting condition and incomplete equating: can will impel data storing to go into microcomputer,

In calculating process, eliminate.

At the laboratory simulation in-site measurement, adopt in the known volume air and inject equal amounts of S F one by one

6Method can be surveyed SF

6The sensitivity that trace changes is 4 * 10

-5

The enforcement of embodiment 2 microcomputer terminal disposal systems

The microcomputer terminal disposal system is made of information processing, FEEDBACK CONTROL, evaluating system, it is that the signal of " differential system " (voltage controlled oscillator 5 in the phase differential point-score and loop filter 4 in the difference on the frequency point-score) output is handled 8 by normalization method, compare 12 with the simulated value digital quantization 11 of predefined a certain gas, and obtain amplifying in power control output 13, remove to control gear train then and carry out FEEDBACK CONTROL; Another road is the signal by normalized 8, differentiates 9, to the performance parameter 10 of time diffusion result data as the assessment apparatus system, reports to the police to this parameter output print storage or to equipment.

Claims (5)

1, a kind of method of difference ultrasonic gas trace changes mensuration and control evaluating system, it is characterized in that it comprises method of difference measuring system and microcomputer terminal disposal system, and method of difference is measured and is divided into phase differential point-score and difference on the frequency point-score again; The phase differential point-score is measured by parts such as space delay passage 1,2, difference engine 3, loop filter 4, voltage controlled oscillator 5 and power splitters 6 and is formed.The space postpones passage 1,2 and is connected with difference engine 3 respectively, links to each other with voltage controlled oscillator 5 through loop filter 4, is connected with power splitter 6, and constitutes the phase-locked loop that makes a variation; The difference on the frequency point-score is measured by parts such as space delay passage 1,2, difference engine 3, loop filter 4 and amplifiers 7 and is formed, the space postpones passage 1,2 and links to each other with amplifier 7 respectively, constitute two groups of oscillating loops, be connected with difference engine 3 respectively, be connected with loop filter again; The microcomputer terminal disposal system is made up of normalization method processing 8, differential 9, performance parameter assessment 10, simulated value digital quantization 11, comparison 12 and power amplification output 13 etc., normalization method handle 8 relatively 12 is connected with differential 9 respectively, differential 9 links to each other with performance parameter assessment 10, simulated value digital quantization with relatively 12 link to each other, compare 12 and export 13 with power amplification again and be connected.

2, method of difference ultrasonic gas trace according to claim 1 changes mensuration and control evaluating system, two spaces that it is characterized in that the method for difference measuring system postpone logical 1 and 2, form by emission, two pairs of air dielectric transducers of reception, wherein passage 1 sealing, what it touched is still unchanged gas, passage 2 blow-by, little change gas produces the little change of the velocity of sound at this.Subtract each other by difference engine 3 back two-way information, the signal that enters voltage controlled oscillator 5 outputs behind loop filter 4 only reflects the information that gas content changes, and Temperature Influence then has been subjected to inhibition.

3, method of difference ultrasonic gas trace according to claim 1 changes to be measured and the control evaluating system, it is characterized in that the mixed gas space that the phase differential point-score is measured by sealing postpones passage 1, it is respectively to be connected with difference engine 3 that the mixed gas space postpones passage 2, enter voltage controlled oscillator 5 after 4 filtering of difference engine 3 output phase difference signals process loop filter, link to each other with power splitter 6 again, power splitter 6 output two-way same signals enter two spaces respectively and postpone passage 1,2 closed-loop systems that form constitute the phase-locked loop of a variation, when in a single day loop locked, the frequency of voltage controlled oscillator 5 outputs was the function of little change gas time delay.

4, method of difference ultrasonic gas trace according to claim 1 changes mensuration and control evaluating system, it is characterized in that the difference on the frequency point-score postpones passage 1,2 by the space and vibrates with the closed loop that amplifier 7 constitutes respectively, oscillation frequency has reflected that respectively the space postpones passage 1 and the space postpones the gas speed of sound of passage 2, in difference engine 3, obtain their difference frequency signal, be the function of the little change of gas through the difference frequency signal of loop filter 4 outputs.

5, method of difference ultrasonic gas trace according to claim 1 changes mensuration and control evaluating system, it is characterized in that handle the microcomputer terminal is little change information via normalization method processing 8 of method of difference being measured output, when providing the simulated value digital quantization 11 that a certain gas preestablishes content, then the signal of normalized 8 and simulated value digital quantization 11 process is compared 12, and obtain amplifying in power control output 13, remove to control gear train and carry out FEEDBACK CONTROL; Normalization method is handled 8 information, differentiate 9, the time differential result data is as the performance parameter 10 of assessment apparatus system, and this parameter output print stores or equipment is reported to the police.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB031128009A CN1174245C (en) | 2003-01-30 | 2003-01-30 | Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB031128009A CN1174245C (en) | 2003-01-30 | 2003-01-30 | Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1431496A true CN1431496A (en) | 2003-07-23 |

| CN1174245C CN1174245C (en) | 2004-11-03 |

Family

ID=4790308

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB031128009A Expired - Fee Related CN1174245C (en) | 2003-01-30 | 2003-01-30 | Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1174245C (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101813673A (en) * | 2010-05-07 | 2010-08-25 | 河海大学常州校区 | Acoustic signal processing device and method for detecting concentration of trace binary-component gas |

| CN101502460B (en) * | 2004-03-22 | 2011-04-06 | 爱尔康公司 | Method of controlling a surgical system based on a load on the cutting tip of a handpiece |

| CN102323444A (en) * | 2011-10-12 | 2012-01-18 | 雷立 | Method for measuring flow velocity of fluid by ultrasonic method |

| CN101646937B (en) * | 2007-01-26 | 2013-05-01 | 法国国家电力企业 | Method for measuring the pressure and/or molar mass of a gas in a housing, and corresponding measurement assembly |

| CN105829882A (en) * | 2013-10-02 | 2016-08-03 | 雅马哈精密科技株式会社 | Filter element |

| CN113189196A (en) * | 2021-04-09 | 2021-07-30 | 哈尔滨理工大学 | Gas concentration detection method based on ultrasonic phase difference technology |

| CN116953073A (en) * | 2023-07-31 | 2023-10-27 | 广州安成电子科技有限公司 | Gas measurement system and method based on ultrasonic transducer |

-

2003

- 2003-01-30 CN CNB031128009A patent/CN1174245C/en not_active Expired - Fee Related

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101502460B (en) * | 2004-03-22 | 2011-04-06 | 爱尔康公司 | Method of controlling a surgical system based on a load on the cutting tip of a handpiece |

| CN101646937B (en) * | 2007-01-26 | 2013-05-01 | 法国国家电力企业 | Method for measuring the pressure and/or molar mass of a gas in a housing, and corresponding measurement assembly |

| CN101813673A (en) * | 2010-05-07 | 2010-08-25 | 河海大学常州校区 | Acoustic signal processing device and method for detecting concentration of trace binary-component gas |

| CN102323444A (en) * | 2011-10-12 | 2012-01-18 | 雷立 | Method for measuring flow velocity of fluid by ultrasonic method |

| CN105829882A (en) * | 2013-10-02 | 2016-08-03 | 雅马哈精密科技株式会社 | Filter element |

| CN105829882B (en) * | 2013-10-02 | 2019-06-21 | 雅马哈精密科技株式会社 | The check device and inspection method of sealed package product |

| CN113189196A (en) * | 2021-04-09 | 2021-07-30 | 哈尔滨理工大学 | Gas concentration detection method based on ultrasonic phase difference technology |

| CN113189196B (en) * | 2021-04-09 | 2024-02-20 | 哈尔滨理工大学 | Method for detecting gas concentration based on ultrasonic phase difference technology |

| CN116953073A (en) * | 2023-07-31 | 2023-10-27 | 广州安成电子科技有限公司 | Gas measurement system and method based on ultrasonic transducer |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1174245C (en) | 2004-11-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Seybert | Two‐sensor methods for the measurement of sound intensity and acoustic properties in ducts | |

| CN201348624Y (en) | Multi-channel surface acoustic wave chemical sensing device | |

| CN100451666C (en) | Improved method and apparatus for measuring stability of frequency of time domain signal | |

| CN101539589B (en) | Detecting method of vehicle GPS velocimeter | |

| CN1821727A (en) | Optical fiber acoustic sensor | |

| CN1174245C (en) | Difference method for measuring change of ultrasonic gases in microscale and its control and evaluation system | |

| CN1189725C (en) | Laser vibration detestion method and its equipment | |

| CN101299031A (en) | Method for detecting automobile tail gas based on gas sensor array | |

| CN101726539A (en) | Method for testing gas concentration by using surface acoustic wave device | |

| CN109186693B (en) | Self-adaptive ultrasonic echo signal detection circuit | |

| CN101387702B (en) | Phase inspecting method for phase laser range finder | |

| CN1719277A (en) | Detection system of space position and its detection method | |

| CN1222768C (en) | Calibrating NOx-sensor | |

| CN103075981B (en) | A kind of ultrasonic thickness test method | |

| CN105738470B (en) | A kind of sonic surface wave gas sensors | |

| CN1595170A (en) | Self-mixed intervention Doppler velometer based on two-frequency laser | |

| CN1645036A (en) | Self-mixed interference displacement sensor based on two-way laser | |

| CN111060920B (en) | Method for eliminating Doppler error of frequency modulation continuous wave laser ranging system | |

| CN2890861Y (en) | Optical fiber acoustic sensor | |

| CN102128806A (en) | Gas detection method used for infrared gas analyzer | |

| CN1635387A (en) | Driver of resonant transducer and signal collector | |

| CN106209290A (en) | A kind of propagation delay time and transmission range measure system and method | |

| CN111474551A (en) | FPGA-based laser phase ranging system and method | |

| Payne et al. | The laser ranging system for the GBT | |

| CN113189196B (en) | Method for detecting gas concentration based on ultrasonic phase difference technology |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |