CN1274260C - Coating device with rod and handle part connected by hinge and coating material - Google Patents

Coating device with rod and handle part connected by hinge and coating material Download PDFInfo

- Publication number

- CN1274260C CN1274260C CNB031427618A CN03142761A CN1274260C CN 1274260 C CN1274260 C CN 1274260C CN B031427618 A CNB031427618 A CN B031427618A CN 03142761 A CN03142761 A CN 03142761A CN 1274260 C CN1274260 C CN 1274260C

- Authority

- CN

- China

- Prior art keywords

- spreader

- bar

- handle component

- spreader according

- epitheca

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D40/00—Casings or accessories specially adapted for storing or handling solid or pasty toiletry or cosmetic substances, e.g. shaving soaps or lipsticks

- A45D40/26—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball

- A45D40/262—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like

- A45D40/265—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like connected to the cap of the container

- A45D40/267—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like connected to the cap of the container comprising a wiper

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D40/00—Casings or accessories specially adapted for storing or handling solid or pasty toiletry or cosmetic substances, e.g. shaving soaps or lipsticks

- A45D40/26—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball

Landscapes

- Coating Apparatus (AREA)

- Brushes (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Cosmetics (AREA)

Abstract

The present invention provides an applicator comprising: a handle member; a stem connected via a hinge to the handle member; and an applicator element disposed at a first end of the stem and configured to apply makeup on keratinous fibers; the stem including a maneuverable portion enabling the direction in which it points relative to the handle member to be modified, the maneuverable portion extending at least in part between the hinge and a second end of the stem opposite from its first end.

Description

Technical field

The present invention relates to a kind of cosmetic applicator, this spreader comprises: handle component; Bar, this bar links to each other with this handle component by hinge; And the spreader element, this spreader arrangements of elements is at an end of bar.

Background technology

Disclose such spreader in U.S. Patent No. 6026823, it is suitable for being coated with cosmetics.

Other spreader is disclosed in US5328282, US2173959, US4396029, US5435328, FR2701196, US4165755, FR1395217, US4428388, US3185291 and US4370989.

In above-mentioned application, FR1395217 discloses a kind of nail polish spreader with inflatable bladder portion (capsule).This capsule portion comprises flexible portion and rigid element, and this rigid element comprises screw thread, and this screw thread makes it can be screwed on the bottleneck of flask.Can be fixed on for the flexible portion of sphere or bellow-shaped on the brush, and the user can be pushed away brush downwards by pushing away this flexible portion downwards, thereby make this brush can arrive the bottom of flask, and whisk off a little, so that effectively pick up the pigment that has deposited, thereby they are got back in the suspension.

The also known spreader that comprises the spreader element with non-linear longitudinal axis is in particular for being coated on cosmetics on eyelashes or the eyebrow.Because the shape of this spreader element, will be very difficult when this spreader element inserts in the container when loading cosmetics by strigil.Should insert for fear of overslaugh, must can not be too big by the spreader element with respect to its formed angle of bar of supporting.Unfortunately, for example, may wish that the spreader element tilts more with respect to bar owing to the reason of human engineering aspect and/or in order to carry out more kinds of cosmetics.

Summary of the invention

Main purpose of the present invention provides a kind of spreader, and in particular for the spreader of lip, eyelid, eyebrow, eyelashes or hair, this spreader more meets human engineering and/or can obtain new dressing effect.

To achieve these goals, in one aspect, the invention provides a kind of spreader, this spreader comprises:

Handle component;

Bar, this bar links to each other with this handle component by hinge;

Spreader element, this spreader arrangements of elements be at first end of bar, and be arranged to cosmetics are coated on the cutin fiber, for example eyelashes, eyebrow or hair; And

Operation part, this operation part can change the direction that this bar points to respect to handle component, extends between second end of described operation part at least partially in hinge and bar, and second end of this bar is relative with first end of bar.

Such spreader can change the direction that the spreader element points to respect to handle component in use, so that make non-vanishing degree angle between the axis of the axis of spreader element and bar, but when introducing spreader in the container, can not have any problem, this container is equipped with the cosmetics that are used to be coated with, and provide strigil, because such insertion for example can be carried out when bar is substantially on the axis at handle component.When the spreader element was the non-linear shape, the inclination angle between spreader element and the handle component can increase in use, did not need to make the spreader element to have simultaneously and hindered the inclination angle that is inserted into action in the container.Bar tilts with respect to handle component, and this also can make handle component face further away from each other when eyelashes or eyebrow are made up, thereby can more easily cosmetics be coated on eyelashes or the eyebrow under the vertical substantially situation of the axis of bar.

On the other hand, the invention provides a kind of spreader, this spreader comprises:

Handle component;

Bar, this bar links to each other with this handle component by hinge, this hinge be arranged to anti-stopping bar at the hinge place with respect to handle component carry out perceptible axially and/or be displaced sideways;

The spreader element of any kind, this spreader arrangements of elements is at first end of bar; And

Operation part, this operation part can change the direction that this bar points to respect to handle component, and described operation part can be extended between second end at least partially in hinge and bar, and second end of this bar is relative with first end of bar.

Bar at the hinge place with respect to handle component without any perceptible axially and/or be displaced sideways, this makes the spreader element can be accurately positioned in the position that will be coated with cosmetics.

On the other hand, the invention provides a kind of spreader, this spreader comprises:

Handle component;

Bar, this bar links to each other with this handle component by the hinge in the handle component;

The spreader element of any kind, this spreader arrangements of elements is at first end of bar; And

Operation part, this operation part can change the direction that this bar points to respect to handle component, and described operation part can be extended between second end at least partially in hinge and bar, and second end of this bar is relative with first end of bar.

In handle component, this makes spreader compacter with hinge arrangement, and is easier to hand.

In the example of spreader manufactured according to the present invention, handle component can comprise female body.

Handle component can comprise body, and operation part is passed an end of this body.At described end, this body can have end wall, and this end wall has opening, and operation part is passed this opening.This end wall can be the basic shape of outwards protruding.

Above-mentioned opening can comprise at least one slit, and this slit can be used for the motion of pilot operationp part.Preferably, this slit can extend at least a portion of side surface of handle component.For example, this opening can have at least two slits, and the longitudinal axis of these two slits is basic vertical mutually.Slit can have the edge, and at least one difficult point that passes through in the moving process of operation part has for example been determined by at least one projection in this edge.Preferably, should can more easily operation part be held in a predetermined position than difficult point.

Spreader for example its end wall can comprise at least one reference marker, scale for example, thereby the direction that the easier identification bar of user is pointed to respect to handle component.

Operation part can comprise lid, and this lid is arranged to cover handle component to small part.For example, this lid can have substantially towards the recessed face of handle component.

Operation part can be covered by epitheca to small part, and the epitheca of at least one flexible region is for example arranged.Particularly, this flexible region can comprise bellows.

Operation part can be covered by epitheca fully.

Epitheca can be entirely flexibility, is for example made by elastomer, and this elastomer is nitrile, ethylene propylene diene rubber monomer (EPDM), silicone or latex for example, and this is not to limit for example.

Epitheca also can be added on the handle component, and perhaps in a version, it can form one with handle component by molded, for example is formed on this handle component by injection moulding.

The profile of epitheca can be axially symmetry, for example on its at least a portion of length, circular cross-section is arranged.

The profile of epitheca can be carried out advantageous version along one or more directions.For example this epitheca can have the rectangle cross section on its at least a portion of length.

Epitheca can have wall, and this wall can have certain thickness.For example, this epitheca has the identical order of magnitude at the wall thickness of some position with the wall thickness of handle component at least.

Epitheca can also have thicker wall relatively, especially when this epitheca is made by cellular material.

For example, epitheca can comprise foam-plastic blocks, and this foam-plastic blocks has recess, perhaps has slit at least, and second end of bar inserts in this recess or the slit.Such piece is for example by heat-sealing or be fixed on by bonding agent on the end of body of handle component.

Epitheca can help airtight container, and spreader places on this container when not using.

Hinge can comprise brake, so that brake bar is with respect to the motion of handle component.No matter with respect to the position of handle component how this bar, this brake can apply brake force.In a kind of version, can select, brake can only just apply brake force when bar is at least one precalculated position with respect to handle component.

Hinge can be made in many ways, and for example it makes the bar can be around an axle, two axles or unlimited a plurality of motions.

For example, hinge can comprise ball-and-socket joint, and this ball-and-socket joint can have rigidity or flexible seat.Can select better contact between seal member that rigid holder for example can be by making bar and the container and seal this container better.

In a kind of version, hinge can comprise pin, metallic pin for example, and bar can rotate around this metallic pin.Also can select, this bar can comprise the cylindrical section as pivot.

Hinge also can comprise at least one flexible wall, for example coils, and bar passes this flexible wall, and described wall extends between bar and handle component.In one embodiment, hinge comprises at least one deformable material piece, foam-plastic blocks for example, and bar passes this deformable material piece.

Spreader can be arranged to like this, and after user's releasing operation part, bar continues to point to the direction that is formed by the user.

Also can select, spreader can comprise elastic reseting part, and this elastic reseting part is suitable for making this bar be back to the sensing predetermined direction when user's release lever, for example so that make the axial alignment of its axis and handle component.Reset components for example can be made of the element that constitutes hinge.This reset components also can be made of above-mentioned epitheca.

Bar can comprise seal member, and the sealing parts are arranged to the mode of the basic sealing surface against container, and spreader is contained on this container when not using.For example, seal member can comprise dish and/or frustum part.

The spreader element can have longitudinal axis, and this longitudinal axis can be chosen as linearity.

The spreader element can have longitudinal axis, and the axis of this longitudinal axis and bar forms non-zero angle.This non-zero angle is formed near between the axis of the boom end of spreader element and the spreader element proximal axis partly near this bar.This non-zero angle also is formed near between the axis of the boom end of spreader element and the spreader member distal end axis partly away from this bar.

The spreader element can be non-linear, and perhaps bar and spreader element do not need whole along single linear axis extension.Under these circumstances, for example spreader element and bar can extend in a plane, and bar can rotate in described plane.The rotational plane that the longitudinal axis of spreader element also can leave bar extends.

The spreader element can comprise the bristle and/or the tooth of horizontal expansion, that is to say, perpendicular to the longitudinal axis of spreader element.

The spreader element can comprise that eyebrow covers with paint or varnish, and especially, brush has core, and this core is formed by two metal wire branches twisted together, and bristle substantially radially stretches out from this core.

The spreader element can also comprise comb, and this comb is arranged to cosmetics are coated on the cutin fiber, for example eyelashes or eyebrow.

The spreader element for example can be formed with serration.

The spreader element for example can be made by the injection of plastic material.

In alternate embodiment, the spreader element can comprise paintbrush type brush, for example is used to be coated with the brush of nail polish.

The spreader element can comprise foamed plastics, sponge, felt, flocking (flocked) end part, for example is arranged to cosmetics are coated on lip or the eyelid.The spreader element can carry out flocking.

The spreader element is suitable for keeping cosmetics by capillarity.

The present invention also provides the packing and the spreader device of cosmetics, and this device comprises container and the above-mentioned spreader that holds cosmetics.

This spreader can be arranged to seal this container.

This container can comprise strigil, and this strigil can be used for making bar turn back to the position of tilt angle of zero when being put back into spreader on the container.

Container and spreader can be arranged to prevent that the bar of spreader from rotating with respect to container when this spreader is arranged on this container.

The hermetically enclosed of container can obtain by sealing device, the sealing device by the axial-movement along hinge be arranged in above the hinge, around the hinge or below the hinge.

The present invention also provides cosmetics has been coated on method on the part of health or face, especially is coated on eyelashes and the eyebrow, the method is characterized in that it may further comprise the steps:

Make the spreader element that cosmetics are housed, this spreader element is at first end of bar, this bar with have the handle component of axis to be articulated and connected; And

By on operation part, manually applying the thrust of direction perpendicular to the axis of handle component, thereby change the direction that bar points to respect to handle component, this operation part is near second end of bar, and second end of this bar is relative with first end bar, that the spreader element is housed.

Be arranged to cosmetics are coated on cutin fiber for example on eyelashes and/or the eyebrow time when the spreader element, this method may further comprise the steps:

Be in the basic horizontal position at bar, and be in this cutin fiber is made up under the situation at first inclination angle with respect to handle component, described first inclination angle for example is a zero degree; And

Be in basic upright position at bar, and be in this cutin fiber is made up under the situation at second inclination angle with respect to handle component, described second inclination angle is different with first inclination angle.

By below reading to the detailed description of non-limiting examples and in conjunction with the accompanying drawings, can understand the present invention better.

Description of drawings

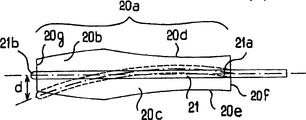

Fig. 1 is the axial cutaway view that is used for cosmetics are coated to the apparatus of the present invention on eyelashes or the eyebrow;

Fig. 2 has represented the view of spreader after bar rotates with respect to handle component of the device of Fig. 1;

View when Fig. 3 has represented that the spreader of Fig. 2 is used for make-up eyelash, its king-rod is oriented vertical substantially;

View when Fig. 4 has represented that the spreader of Fig. 2 is used for make-up eyelash, its king-rod is oriented basic horizontal;

Fig. 5 and 6 is views of two examples that expression is suitable for use as the brush of spreader element, and this brush is expressed as the state before their chip bending;

Fig. 7 is the view that is similar to Fig. 1, is illustrated in the situation when the spreader element is made of the brush with linear longitudinal axis in the device;

Fig. 8 to 11 has represented the various embodiment of other spreader;

Figure 12 A has represented the part of bent stick;

Figure 12 B is the cutaway view that comprises the spreader element of serration;

Figure 13 to 15 has represented how to form the various embodiment of hinge;

Figure 16 is a kind of part side view of spreader of another embodiment of the present invention;

Figure 17 is the side view of the arrow XVII along Figure 16 when seeing;

Figure 18 and 19 is the views that are similar to Figure 17, has represented various embodiment;

Figure 20 to 27 is views of the spreader part of other example of expression;

Figure 28 is the cutaway view along the XVIII of Figure 27;

Figure 29 to 31 has represented other example of hinge; And

Figure 32 has represented to have the embodiment of the hinge of serration.

The specific embodiment

Fig. 1 represented to be used for cosmetics P for example mascara be coated on device 1 on eyelashes or the eyebrow, this device comprises: spreader 2, this spreader 2 is from expression in Fig. 2 and 3; And container 3, this container is equipped with cosmetics P, and spreader 2 can be fixed in the mode of not leaking substantially on this container 3 when not in use.Usually, as shown in Figure 1, this container 3 can have threaded neck 4, and the strigil 5 that is fixed on these threaded neck 4 inside is arranged, and this strigil is made by elastomer, and for example can comprise the flexible lip of basic conical in shape.

In the example shown, the handle component 7 that spreader 2 includes the linear bar 6 of axis X and axis Y is arranged, this handle component 7 also as the closing cover of container 3, therefore have internal thread 8, and this internal thread 8 is arranged to can be screwed on the bottleneck 4.

In this example, seat 11 determines that by the wall 12 of handle component this wall 12 links to each other with the medial flange 13 of body 14 on the top.

Usually, this brush can comprise core, and this core is formed by two metal wire branches twisted together, and bristle substantially radially stretches out from this core.

When spreader is arranged on the container, can therefore not have the danger that the user makes finger dirty with under the situation that part in this container of insertion of bar contacts not changing bar 6 direction pointed with respect to handle component 7.

In addition, the operation part 18 of bar 6 can make the user recognize in coating can to change the spreader element direction pointed with respect to handle component on the operation part 18 by acting on during cosmetics.

When the coating cosmetics, can operate this bar with a hand.

Brush also can have the core of non-linear, shown in the example among Fig. 1 to 3, linear core is perhaps arranged, as shown in Figure 7.

Guarantee that preferably spreader element 20 and bar 6 are not to extend along identical straight line, guarantee that especially this spreader element has curved longitudinal axis.

In the example of Fig. 1 to 3, brush 20 has snake core, and this core 21 links to each other with this bar along the axis X direction substantially near the proximal part 21a of bar, the direction Z of the far-end 21b of core 21 sensing simultaneously and axis X angulation i.

Be formed at angle between the axis Y of direction Z and handle component 7 corresponding to the summation of angle i and ii, therefore, can cosmetics be coated on the eyelashes, as shown in Figure 3 up the time at the bar of spreader.

When the bar of the spreader by was up made up, the angle between bar and the handle component can be very big, so that can make handle component away from face, thus easier coating cosmetics.

When using spreader under the situation of bar basic horizontal, the direction that bar points to can become zero angle with the axis of handle component substantially, for example as shown in Figure 4.

Spreader can be arranged to like this, and after releasing operation part 18, bar keeps its direction pointed, and like this, the user need not exert pressure on operation part in order to keep this bar to tilt and continue with respect to the axis of handle component.

In a kind of version, as described below, spreader can be arranged to like this, and after releasing operation part 18, bar returns, so that with respect to the orientation of its axis predetermined direction of handle component.

When spreader is arranged on the container, bar and the cooperating of seal member 9 and container when suitable, especially carry out perceptible inclination with preventing operation part 18 cooperating of strigil parts 5 with respect to handle component, this is with for example the described device of French Patent (FRP) No.1395217 is different.

These figure have represented before the chip bending and two brush blanks before in core 21 insertion rods.

Can see, in insertion rod before, in each example, core 21 all substantially be a linearity.

Dotted line is represented the shape of core after carrying out bending.

In the example of Fig. 5, blank has case surface, and this case surface becomes two frusto-conical shape around its longitudinal axis.

The total length of the part 20a that can adorn bristle of brush for example is about 26 millimeters (mm).The maximum gauge of blank can be less times greater than 7mm, and its end diameter can be near 4mm.The total length of core 21 for example can be less times greater than 35mm.

The free end of core can depart from the axis certain distance d of the linear segment in the insertion rod, for example should can be about 4.5mm apart from d.

Before chip bending, the overall shape of the blank of Fig. 6 may be substantially of fish shape, have the anterior 20b of basic frustoconical and the body 20c of circular symmetry, the longitudinal cross-section of this body 20c is determined by two relative curved edge 20d and 20e, these two edge 20d and 20e are outside spill, and the radius of curvature of about 52mm is arranged respectively.Brush for example is about 7.5mm at the diameter of transverse plane 20f vicinity, back, for example is 5mm at its diameter of preceding transverse plane 20g vicinity.The blank of Fig. 6 forms final brush by the chip bending that bristle is housed that makes it, so that the constant curvature radius of about 53mm is arranged, shown in example among the figure.

As shown in Figure 6, the brush that bristle is housed can be formed with smaller angle with respect to the axis of the part in the insertion rod 6 in the end near the part place in the insertion rod.What therefore, the free end portion of core departed from for example can be about 2.4mm apart from d.

Can also use spreader element with flocking end part 30, for example being used for eyelid makes up, as shown in Figure 8, perhaps use spreader element with flocking end part 40, be used for lip and make up, as shown in Figure 9, perhaps use the spreader element of brush 50 with paintbrush form, be used for being coated with nail polish, as shown in figure 10 to nail.Can also use comb 60, as shown in figure 11.Particularly, in patent application EP1169941, EP1070465, EP1070468, EP1070467, introduced other example of non-limiting comb.It also can adopt felt point or foam, shown in Figure 12 A.

In the figure, it is whole for linear to see that bar 6 does not need, and for example can comprise elbow part 6a.

When observing in the cross section, the spreader element can comprise serration, and shown in Figure 12 B, and it can form by the injection molded material.

Also can select, various spreader elements can extend along the straight line identical with bar.

In the example of Fig. 1 to 3, for example by moulding of plastics materials, the operation part 18 of bar 6 forms one with the remainder of bar.

The hinge that bar 6 is linked to each other with handle component 7 can be made of the parts on the remainder that is installed in handle component 7, as shown in figure 14.In the figure, can see that seat 11 is formed in the parts 63, these parts 63 for example are fixed on the remainder 64 of handle component by fixing.

In Figure 14, can also see that the opening in handle component 7 determines that by the edge of outwards dispersing 65 operation part 18 is passed this opening and stretched out.

The wall 12 of having determined the seat 11 of ball-and-socket joint for example can extend in the outside of handle component 7 at least in part, as shown in figure 15.

At an axial end, handle component 7 can have end wall 69, and as shown in figure 16, this end wall 69 has one or more slits, and operation part 18 is passed this slit.

In the example of Figure 16, end wall 69 has two slits 70 and 71, and the axle F1 of each slit 70,71 is vertical mutually with F2, and the width of this slit equals the diameter of operation part 18 substantially, when bar 6 tilted with respect to handle component 7, described operation part can be moved in slit.

In the example shown, end wall 69 is outside substantially convex.At least one above-mentioned slit (for example two slit 70 and 71) can comprise at least one projection 73, for example a pair of respect to one another protruding 73, so that produce the point that makes operation part 18 be difficult to pass through, thereby can help this operation part 18 is held in a predetermined position, for example in position against the axial termination of a slit.

Therefore, in the example of Figure 18, the user can make operation part 18 be in five precalculated positions one, be center and four end positions, when this center, this operation part 18 is in the intersection point place between slit 70 and 71, and bar 6 is zero with respect to the gradient of axis Y substantially, and this operation part 18 is when being in four end positions each, and operation part 18 is against an axial termination of respective slots.By owing to the difficult point that passes through that exists projection 73 to produce, can between center and end position, change the position.

For example, when wishing that bar 6 is merely able to when single axis rotates, 7 of handle components need a slit 70, as shown in figure 19.

When bar only rotated in a plane, the spreader element can have the crooked longitudinal axis that extends in described plane.

Handle component can have at least one reference marker 77, and this reference number 77 makes the user can be familiar with the position of this operation part 18 with respect to handle component.For example, handle component can have a plurality of scales.

Figure 20 has represented epitheca 80, and this epitheca 80 is by making on the part 81 with the Overmolded body at handle component 7 of elastomer.

For example, epitheca can be formed with fold 82, and as shown in figure 21, this fold 82 for example constitutes bellows, and this bellows makes epitheca that flexibility along all directions be arranged, so that can action bars 6.

In the example of Figure 20 and 21, the outer shape of epitheca is roughly the axis Y circular symmetry of thorny shank spare 7, but, also can select, for one or more preferred orientations of determining that operation part can be moved, epitheca is had be not the shape of circular symmetry, this does not exceed scope of the present invention yet.

For example, Figure 22 has represented to have two apparent surfaces' 91 epitheca 90, and these two surfaces 91 are the plane substantially, and the user can exert pressure on these two surfaces, so that change the gradient of bar 6 with respect to handle component 7.

Also can select, a surface 91 can comprise information, so that the prompting user exerts pressure on it.

When the epitheca shown in employing Figure 22, this epitheca can be useful on the shape of limit rod 6 around the angular displacement of single axis.

In the example of Figure 22, epitheca 90 impels bar to rotate around the axis K that is basically parallel to surface 91 along the flexibility on the moving direction M (perpendicular to surface 91) of operation part 18, and epitheca 90 will prevent that along the big hardness on the axis K direction axis that this bar winds perpendicular to axis K from rotating.

The seat of ball-and-socket joint can be formed by the wall that forms one with epitheca, and this wall is by forming with the epitheca identical materials is molded, for example in order to prevent the mobile of bar by the bigger frictional force of generation.

For example, Figure 23 has represented an example of epitheca 100, and this epitheca 100 has bottom 94, and this bottom 94 snaps on the flange 95 that is fixed on handle component.Seat 11 has been determined in this bottom 94, and the spherical part 10 of bar 6 is included in this seat 11.

Also can select, the epitheca that is engaged on the operation part 18 can unfixing with respect to handle component part.

Suitable is, epitheca can constitute elastic reseting part, is used to make bar to turn back to zero gradient position when static.

Epitheca also can comprise the cellular material piece on the body that is fixed on handle component.

For example, Figure 24 has represented the sheath that is made of elastically deformable ground foam-plastic blocks 102, and this foam-plastic blocks 102 is fixed on the end wall 104 of handle component by one side 103 by heat-sealing or by bonding agent.

This piece 102 comprises recess 105, and this recess 105 outwards is opened on the face 103, and operation part 18 is loaded in this recess 105.

In a kind of version, recess 105 can be replaced by one or more slits 106, two of cross-over configuration slits for example, as shown in figure 25.

Epitheca can for example link to each other with handle component by the film hinge, as shown in figure 26 by making with the handle component identical materials.

The figure shows epitheca 108, this epitheca 108 is made one by molded with handle component 7, and links to each other with handle component by film hinge 107.

The central area of film hinge 107 disconnects, so that operation part 18 can be passed through.

Other device that is different from ball-and-socket joint also can be used to form hinge between bar and the handle component.

For example, Figure 27 and 28 has represented to comprise for example hinge of metallic pin of pin 110, and this pin 110 has axis T, bar 6 is engaged on this pin 110, and bar 6 for example can comprise amplifier section 111, and this amplifier section 111 has the plane surface that is basically perpendicular to axis T, and be installed with opening 112, so that pin 110 is passed through.This pin can be fixed in the radially phase coupled columns bolt 113 of handle component.Handle component can comprise the outer cover 114 that for example is made of metal, and this outer cover 114 is fixed on the body 115 of handle component, and it also is used for pin 110 is remained in the post bolt 113.

As shown in figure 29, for example can also make the hinge of bar replace spherical part by cylindrical section 116, so that make bar be merely able to rotate around the axis W of described cylindrical section, this axis normal is extended in the axis X of bar.Cylindrical section 116 can be contained in its axial end in the shell 117, this shell 117 can snap in cylindrical section 116 with time in the respective openings of convenient operation part 18 insertion handle components and is fixed in the shell 117 towards termination 15 openings of handle component.

Hinge also can utilize wall or the piece made by deformable material to make.

For example, Figure 30 has represented to comprise that cellular material is the piece 120 of elastically deformable foamed plastics, and this piece 120 is for example by sealing or be fixed on by bonding agent the inside of handle component body.Bar 6 passes the opening 121 in the piece 120, this opening 121 is slit for example, and piece 120 can have the projection 123 and 124 of the both sides that are arranged in piece 120, and these projections are enough big,, piece 120 can be remained between them so that when changing its pointing direction with convenient user's action bars 6.

Also can use the simple dish of for example being made by elastomer 130, as shown in figure 31, this dish for example seals in flange 131 handle component, around opening, and operation part 18 is stretched out by this opening.

Insert spherical part 10 in the seat 11, bar for example serration of projection 135 can be arranged, shown in figure 32, be used for cooperating, so that the motion of brake bar and/or can make this bar more easily static in one or more predetermined angular position place maintenance with complementary projection 136 on the wall 12 that is formed at seat.In a kind of version, convex part 135 and 136 can be replaced by at least one elastomeric material edge, so that produce additional frictional force between bar and handle component.

Certainly, the present invention is not limited to the foregoing description.The feature of each embodiment for example can combination with one another, so that constitute new embodiment of the present invention.

Should be known in that in whole specification the meaning that wording " comprises " is " comprising at least one ", unless carry out opposite explanation specially.

Spreader manufactured according to the present invention does not need to use with container, and this spreader inserts in this container when not using.For example, the spreader element can be loaded onto cosmetics by contacting with cosmetics.

Claims (49)

1. a spreader is characterized in that, comprising:

Handle component (7);

Bar (6), this bar links to each other with this handle component by hinge; And

Spreader element (20; 60), this spreader arrangements of elements is at first end of bar, and is arranged to and cosmetics can be coated on the cutin fiber;

This bar comprises operation part (18), and this operation part can change the direction that this bar points to respect to handle component, extends between second end of described operation part at least partially in hinge and bar, and second end of this bar is relative with first end.

2. spreader according to claim 1 is characterized in that: this hinge be arranged to anti-stopping bar at the hinge place with respect to handle component carry out perceptible axially and/or be displaced sideways.

3. spreader according to claim 1 is characterized in that: this handle component (7) is arranged for sealing one container (3).

4. spreader according to claim 3 is characterized in that: this handle component comprises female skirt.

5. spreader according to claim 1 is characterized in that: it comprises at least one reference marker (77), and this reference marker makes the user can discern the direction that bar (6) points to respect to handle component (7).

6. spreader according to claim 1 is characterized in that: this handle component comprises body (14), and described operation part (18) is passed an end of this body.

7. spreader according to claim 1 is characterized in that: an end place of this body has end wall (69), and this end wall has opening, and operation part is passed this opening.

8. spreader according to claim 7 is characterized in that: this opening comprises at least one slit (70,71).

9. spreader according to claim 8 is characterized in that: this opening comprises at least two slits (70,71), and the longitudinal axis of these two slits (F1, F2) is basic vertical mutually.

10. spreader according to claim 8 is characterized in that: in this slit (70,71) one of them comprises at least one edge (73) at least, at least one difficult point that passes through in the moving process of operation part (18) has been determined at this edge.

11. spreader according to claim 7 is characterized in that: this end wall (69) has the shape of protruding towards the outside substantially.

12. spreader according to claim 1 is characterized in that: this operation part comprises lid (66), and this lid is arranged to cover to small part handle component (7).

13. spreader according to claim 12 is characterized in that: this lid can have substantially towards the recessed face (67) of the body of handle component.

14. spreader according to claim 1 is characterized in that: this operation part (18) to small part by epitheca (80; 90; 100; 102; 108) cover, this epitheca has at least one flexible region.

15. spreader according to claim 14 is characterized in that: the flexible region of epitheca comprises bellows (82).

16. spreader according to claim 14 is characterized in that: operation part (18) is covered by epitheca fully.

17. spreader according to claim 14 is characterized in that: this epitheca is entirely flexibility.

18. spreader according to claim 14 is characterized in that: this epitheca is made by elastomer.

19. spreader according to claim 14 is characterized in that: this epitheca is contained on the handle component.

20. spreader according to claim 14 is characterized in that: this epitheca (80; 108) by molded and form one with handle component.

21. spreader according to claim 20 is characterized in that: this epitheca links to each other with handle component (7) by film hinge (107).

22. spreader according to claim 14 is characterized in that: this epitheca (80) has the circular cross-section at least a portion of its length.

23. spreader according to claim 14 is characterized in that: this epitheca (90) has the rectangle cross section at least a portion of its length.

24. spreader according to claim 23 is characterized in that: this epitheca (102) comprises foam-plastic blocks.

25. spreader according to claim 14 is characterized in that: this epitheca helps airtight container, and spreader places on this container when not using.

26. spreader according to claim 1 is characterized in that: this spreader is arranged to like this, and after user's releasing operation part, bar continues to point to the direction that is formed by the user.

27. spreader according to claim 1 is characterized in that: this hinge comprises brake (135,136), is used to brake the motion of this bar with respect to handle component.

28. spreader according to claim 27 is characterized in that: no matter with respect to the position of handle component how this bar, this brake all applies brake force.

29. spreader according to claim 27 is characterized in that: this brake (135,136) only just applies brake force when bar is at least one precalculated position with respect to handle component.

30. spreader according to claim 1 is characterized in that: this hinge comprises ball-and-socket joint (10,11).

31. spreader according to claim 30 is characterized in that: the seat of this joint (11) is a rigidity.

32. spreader according to claim 1 is characterized in that: this hinge comprises pin (110), and bar (6) can rotate around this pin.

33. spreader according to claim 1 is characterized in that: this hinge comprises at least one deformable wall, and bar passes this deformable wall, and this wall extends between bar and handle component.

34. spreader according to claim 33 is characterized in that: this deformable wall comprises dish (130).

35. spreader according to claim 1 is characterized in that: this hinge comprises at least one deformable material piece (120), and bar passes this deformable material piece.

36. spreader according to claim 35 is characterized in that: this deformable material is a foam-plastic blocks.

37. spreader according to claim 1 is characterized in that: this bar comprises cylindrical section (116), and this cylindrical section is as pivot.

38. according to the described spreader of claim 37, it is characterized in that: this bar comprises seal member (9), and the sealing parts are arranged to the surface engagement with the mode of basic sealing and container (3), and spreader is contained on this container when not using.

39. spreader according to claim 1 is characterized in that: this spreader element has longitudinal axis, and this longitudinal axis is not a linear.

40. spreader according to claim 1 is characterized in that: this spreader element (20) has longitudinal axis, and the axis of this longitudinal axis and bar (X) forms non-zero angle (i).

41. spreader according to claim 1 is characterized in that: this spreader element comprises bristle or the tooth perpendicular to the longitudinal axis extension of spreader element.

42. according to the described spreader of claim 41, it is characterized in that: this spreader element is that eyebrow is covered with paint or varnish.

43. according to the described spreader of claim 40, it is characterized in that: this spreader element comprises comb (60), and this comb is arranged to cosmetics are coated at least one of eyelashes or eyebrow.

44. a device that is used to pack and be coated with cosmetics, this device comprise container and the spreader as claimed in claim 1 that holds cosmetics.

45. according to the described device of claim 44, it is characterized in that: this spreader is arranged to seal this container.

46. according to claim 44 or 45 described devices, it is characterized in that: this container comprises strigil (5).

47. according to the described device of claim 44, it is characterized in that: this container and spreader are arranged to prevent that the bar of spreader from rotating with respect to container when this spreader is arranged on this container.

48. one kind is used for cosmetics are coated on method on the part of health or face, it is characterized in that, may further comprise the steps:

Make spreader element (20) that cosmetics are housed, this spreader element is at first end of bar (6), this bar with have the handle component (7) of axis (Y) to be articulated and connected; And

By on operation part (18), manually applying the thrust of direction perpendicular to the axis (Y) of handle component, thereby change the direction that bar (6) points to respect to handle component, this operation part is near second end of bar, and second end of this bar is relative with first end that this bar is equipped with the spreader element.

49. according to the described method of claim 48, it is characterized in that, may further comprise the steps:

Be in the basic horizontal position at bar, and be in this cutin fiber is made up under the situation at first inclination angle with respect to handle component, described first inclination angle is a zero degree; And

Be in basic upright position at bar, and be in this cutin fiber is made up under the situation at second inclination angle with respect to handle component, described second inclination angle is different with first inclination angle.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0207060A FR2840515B1 (en) | 2002-06-07 | 2002-06-07 | APPLICATOR COMPRISING A ROD CONNECTED BY A JOINT TO A GRIPPING MEMBER |

| FR0207060 | 2002-06-07 | ||

| FR0207061A FR2840516B1 (en) | 2002-06-07 | 2002-06-07 | APPLICATOR COMPRISING A ROD CONNECTED BY A JOINT TO A GRIPPING MEMBER |

| FR0207061 | 2002-06-07 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1470204A CN1470204A (en) | 2004-01-28 |

| CN1274260C true CN1274260C (en) | 2006-09-13 |

Family

ID=29551395

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB031427618A Expired - Fee Related CN1274260C (en) | 2002-06-07 | 2003-06-06 | Coating device with rod and handle part connected by hinge and coating material |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1369055B1 (en) |

| JP (1) | JP3825422B2 (en) |

| KR (1) | KR100583751B1 (en) |

| CN (1) | CN1274260C (en) |

| DE (1) | DE60330623D1 (en) |

| ES (1) | ES2337889T3 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100708878B1 (en) * | 2006-08-30 | 2007-04-18 | 백운 | A cosmetic bottle |

| US8096306B2 (en) * | 2006-07-12 | 2012-01-17 | Albea Services | Molded plastic mascara brush |

| FR2939619B1 (en) * | 2008-12-15 | 2011-02-11 | Oreal | APPLICATOR FOR APPLYING A PRODUCT ON KERATINIC MATERIAL. |

| JP2012232162A (en) * | 2012-07-31 | 2012-11-29 | Hiroaki Takashima | Mascara tool |

| US20140332027A1 (en) * | 2013-05-09 | 2014-11-13 | HCT Group Holdings Limited | Cosmetic implement with polyhedral applicator |

| FR3034968B1 (en) * | 2015-04-15 | 2019-06-14 | L'oreal | JOINT MECHANISM OF A COSMETIC PRODUCT APPLICATION DEVICE, DEVICE, METHOD OF APPLICATION, AND METHOD OF MANUFACTURING THE SAME |

| US20170258203A1 (en) | 2016-03-09 | 2017-09-14 | L'oréal | Systems for applying cosmetic compositions |

| JP6723653B2 (en) * | 2016-09-29 | 2020-07-15 | 株式会社吉野工業所 | Cosmetic container |

| JP7280277B2 (en) * | 2017-11-08 | 2023-05-23 | インジーニアス・インヴェンションズ・インコーポレイテッド | Cosmetic applicator and method of using same |

| JP7309278B2 (en) * | 2019-09-27 | 2023-07-18 | 株式会社吉野工業所 | container with applicator |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2173959A (en) | 1939-02-09 | 1939-09-26 | Victor Metal Products Corp | Applicating apparatus and method |

| FR1395217A (en) | 1964-04-24 | 1965-04-09 | Deformable capsule nail polish applicator allowing the dyes to be suspended before use | |

| US4165755A (en) | 1977-09-26 | 1979-08-28 | Cassai Gino H | Adjustable mascara wand |

| US4396028A (en) | 1982-10-22 | 1983-08-02 | Waggoner Edward S | Suntan lotion applicator device |

| US5328282A (en) | 1993-01-21 | 1994-07-12 | The Procter & Gamble Company | Combined mascara bottle and applicator |

| FR2701196B1 (en) * | 1993-02-09 | 1995-04-21 | Oreal | Make-up or hair product applicator. |

| US5435328A (en) | 1993-09-02 | 1995-07-25 | Grohoske; Joan L. | Toiletry article |

| FR2745271B1 (en) * | 1996-02-23 | 1998-04-30 | Oreal | PACKAGING ALLOWING THE STORAGE AND APPLICATION ON A SUPPORT OF A LIQUID OR PASTE PRODUCT, ESPECIALLY FOR MAKE-UP |

| FR2753056B1 (en) | 1996-09-10 | 1998-10-16 | Oreal | MAKEUP OR CARE PRODUCT APPLICATOR |

| JP2004522651A (en) * | 2000-03-20 | 2004-07-29 | エプリ、ズザンネ | Screw-in lid with brush |

-

2003

- 2003-06-06 DE DE60330623T patent/DE60330623D1/en not_active Expired - Lifetime

- 2003-06-06 EP EP03291362A patent/EP1369055B1/en not_active Expired - Lifetime

- 2003-06-06 ES ES03291362T patent/ES2337889T3/en not_active Expired - Lifetime

- 2003-06-06 CN CNB031427618A patent/CN1274260C/en not_active Expired - Fee Related

- 2003-06-07 KR KR1020030036575A patent/KR100583751B1/en not_active IP Right Cessation

- 2003-06-09 JP JP2003163802A patent/JP3825422B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| KR20030095317A (en) | 2003-12-18 |

| ES2337889T3 (en) | 2010-04-30 |

| EP1369055A2 (en) | 2003-12-10 |

| DE60330623D1 (en) | 2010-02-04 |

| JP3825422B2 (en) | 2006-09-27 |

| JP2004008801A (en) | 2004-01-15 |

| KR100583751B1 (en) | 2006-05-26 |

| EP1369055B1 (en) | 2009-12-23 |

| CN1470204A (en) | 2004-01-28 |

| EP1369055A3 (en) | 2004-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2370192C2 (en) | Container and application device containing wiping element | |

| CN1163178C (en) | Packing and applicating device of applicator and dewatering element having container and according with characters of humanbody | |

| CN1234575C (en) | Means for packaging and applying cosmetics, especially on lips | |

| CN1197506C (en) | Article brush applicator for eyelash, brush applicator system and brushing method | |

| CN1264449C (en) | Applicator with component containing skin coating material | |

| CN1274260C (en) | Coating device with rod and handle part connected by hinge and coating material | |

| CN1245125C (en) | Device for coating substance on eyelash or eyebrow | |

| CN1209990C (en) | Applicator and corollary container | |

| CN101044933A (en) | Applicator and a packaging and applicator device | |

| CN1197507C (en) | Brush applicator of object for brushing eyelash | |

| CN1101165C (en) | Packaging and application device, and reloading element therefor | |

| CN1170497C (en) | Applying device, packing and applying device and method for applying cosmetic substances | |

| CN1868371A (en) | Applicator for applying a composition to the eyelashes and/or the eyebrows | |

| CN1868370A (en) | Applicator and a device for applying a cosmetic | |

| CN1644130A (en) | Device for applying a product | |

| CN1317946A (en) | Device for applying prdoct on hair | |

| CN1714700A (en) | Device for applying a product to keratinous fibres | |

| CN1868369A (en) | Storing and applying device | |

| CN1524474A (en) | Device for storage and application of a cosmetic | |

| CN1307849A (en) | Brush to paint some article onto eyelash | |

| CN1781400A (en) | Container and applicator for applying a product on eyelash or eyebrow, in particular mascara | |

| CN1302576A (en) | Brush applicator of object for brushing eyelash | |

| CN1650772A (en) | Applicator, packaging and applicator device including applicator | |

| US20170311699A1 (en) | Packaging and application device | |

| CN1572177A (en) | Device for packaging and applying a substance, the device including a wiper member |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20060913 Termination date: 20140606 |