CN1171818C - Lead-free fritting enamel for high-grade porcelain - Google Patents

Lead-free fritting enamel for high-grade porcelain Download PDFInfo

- Publication number

- CN1171818C CN1171818C CNB991204050A CN99120405A CN1171818C CN 1171818 C CN1171818 C CN 1171818C CN B991204050 A CNB991204050 A CN B991204050A CN 99120405 A CN99120405 A CN 99120405A CN 1171818 C CN1171818 C CN 1171818C

- Authority

- CN

- China

- Prior art keywords

- lead

- glaze

- porcelain

- frit

- grade

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C8/00—Enamels; Glazes; Fusion seal compositions being frit compositions having non-frit additions

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/089—Glass compositions containing silica with 40% to 90% silica, by weight containing boron

- C03C3/091—Glass compositions containing silica with 40% to 90% silica, by weight containing boron containing aluminium

- C03C3/093—Glass compositions containing silica with 40% to 90% silica, by weight containing boron containing aluminium containing zinc or zirconium

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/097—Glass compositions containing silica with 40% to 90% silica, by weight containing phosphorus, niobium or tantalum

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Glass Compositions (AREA)

Abstract

The present invention provides a lead-free fritted glaze for high-grade household porcelain. Zirconium and litium fritted glaze with wide firing range and good brightness is used, and a large amount of borax is added in the composition, without poisonous minium constituents. The lead-free fritted glaze for high-grade household porcelain has the advantages of scientific and reasonable composition, easy operation, good adaptability of blank glaze, fine and smooth glaze, high brightness, good elasticity, high mechanical strength and good thermal shock stability, is suitable for various kinds of high-grade household porcelain blanks, and can satisfy the requirements of high-grade household porcelain. The lead-free fritted glaze has the lead release quantity of 0.000 ppm, and thoroughly avoids the problem that the lead glaze in porcelain has poison to human bodies.

Description

The present invention relates to a kind of lead-free fritting enamel that is used on the high-grade porcelain.

At present, high-grade porcelain is the lead frit glaze with fritted glaze, make low temperature frit by red lead and borax, silicate minerals, other alkalimetal oxide, because the unique property of lead composition, make the lead frit glaze have characteristics such as fusibility, luminance brightness height, good springiness, physical strength are big, good thermal shock stability, therefore, for these years, the lead frit glaze is extensively being continued to use always.

Along with the continuous development of society, the improving constantly of living standards of the people plumbously caused people's great attention to the harm of human body.Lead composition continues or invades human body frequently, can cause polyneuritis, toxic encephalopthy etc.Stipulate in the GB12651-90 standard that the lead of the ceramic that contacts with food, quantity of cadmium release need less than 7ppm.Therefore, developing a kind of lead-free fritting enamel that can satisfy the high-grade porcelain requirement, is the great difficult problem that people press for solution, is the requirement in epoch.

The object of the present invention is to provide a kind of lead-free fritting enamel for high-grade porcelain, this glaze is formed scientific and reasonable, easy to implement, can satisfy the requirement of high-grade porcelain, has thoroughly exempted in the porcelain lead glaze to the murder by poisoning problem of human body.

Lead-free fritting enamel for high-grade porcelain of the present invention contains SiO

2, Al

2O

3, the weight percent of its its chemical constitution is:

SiO

2 50~70

Al

2O

3 9~14

B

2O

3 1~7

CaO 1~9

MgO 0~4

SrO 0~6

ZnO 0~5

K

2O 0~3

Na

2O 0~3

Li

2O 1~3

P

2O

5 0~6

ZrO

2 1~4

The lead-free fritting enamel for high-grade porcelain of above-mentioned composition, mainly formulated by frit and clay, wherein, the ingredients by weight percentage composition of frit is as follows, and not enough component is by corresponding raw material adjustment, as SiO in the glaze

2Amount by quartz adjustment etc.:

Quartzy 25.00~30.00 feldspars, 12.00~17.00 zircons, 5.00~7.00 boraxs, 13.00~17.00 clays, 12.00~16.00 lime carbonate, 0~8.00 rhombspar, 2.00~3.00 boric acid, 0.5~1 Strontium carbonate powder, 7.00~8.00 Quilonum Retards, 2.00~4.00 bone ashes, 3.00~5.00 zinc oxide 4.00~6.00.

The optimum proportion weight percent of frit consists of:

Quartzy 26.00 feldspars, 15.00 zircons, 6.00 boraxs, 13.34 Longyan clays, 13.00 lime carbonate, 7.00 rhombspars, 3.00 boric acid, 0.66 Strontium carbonate powder, 7.00 Quilonum Retards, 2.00 bone ashes, 3.00 zinc oxide 4.00.

Described lead-free fritting enamel for high-grade porcelain, the weight batching ratio of its glaze is: frit 80~90% quartz 0~10% clay 4~10% porcelain powder 0~16% rhombspar 0~4% Quilonum Retard 0~2% lime borate 0~6%.

Lead-free fritting enamel of the present invention has adopted zirconium, the lithium fritted glaze that firing range is wide, glossiness is good, has added relatively large borax in the composition, in order to improve glaze gloss and temperature flowing, has added a spot of strong fusing assistant.

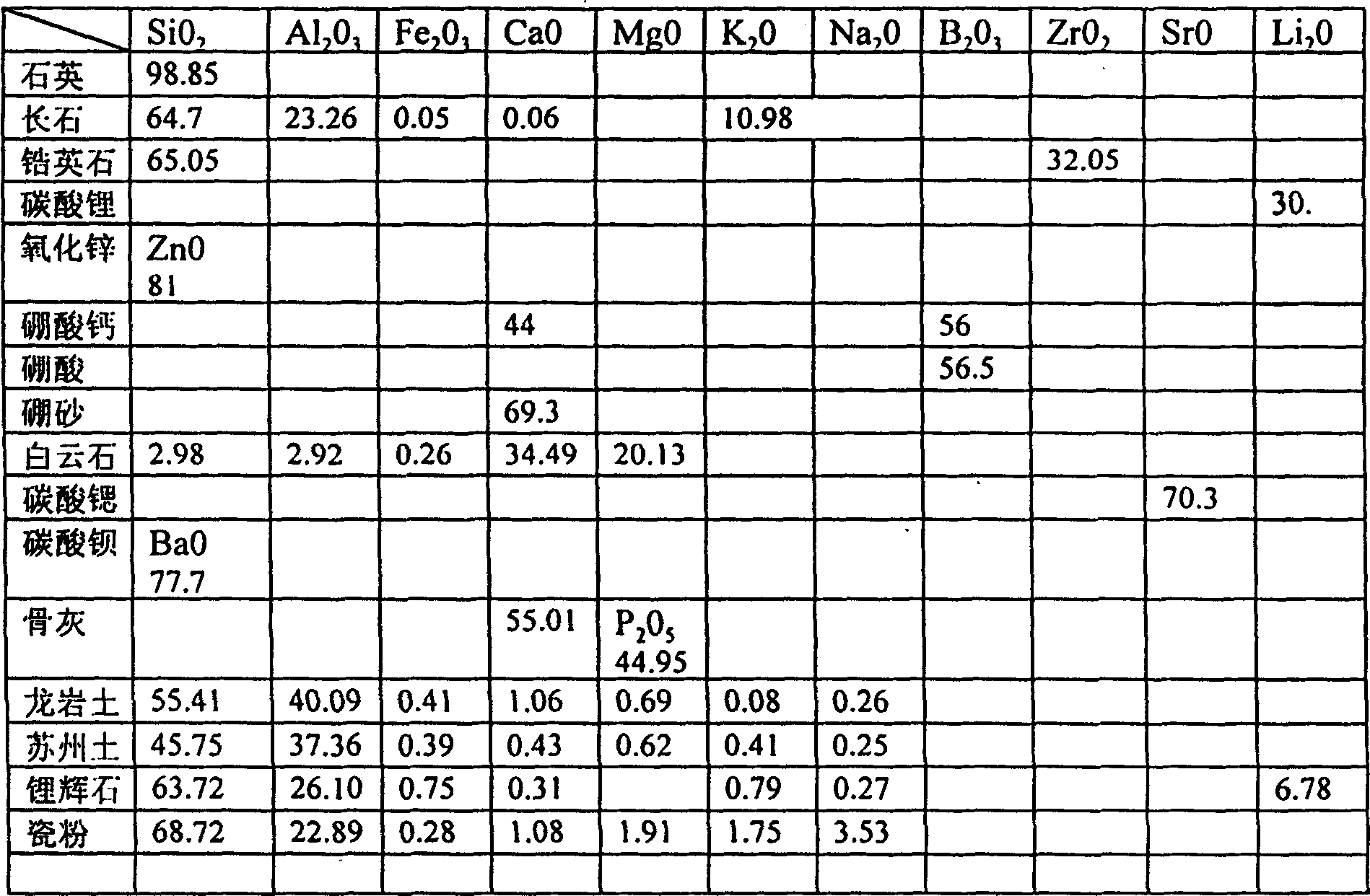

Frit need be at first made in the glaze preparation, and then the preparation glaze.The selection of raw material, use are with common identical, and the raw materials used composition of the present invention sees Table 1.

The first step: with frit raw material proportion ingredient on request, conventional preparation technology prepares frit, 1200~1300 ℃ of melt temperatures by frit.It is standby that frit is pulverized the back.

Second step: frit powder and all the other fecula material are mixed, cooperate preparation glaze such as water reducer, can directly pulverize in ball mill and make standby glaze slip, it is 0.02~0.05% that the glaze slip fineness is controlled at 10000-hole sieve surplus.

Glaze of the present invention high-grade porcelain manufacturing technique requirent and rules use routinely gets final product, and carries out conventional glazing, burns till, and gets finished product.The suitable firing temperature of this leadless glaze is 1160~1200 ℃.

Lead-free fritting enamel for high-grade porcelain of the present invention is formed scientific and reasonablely, easy to implement, and the base glaze adapts to, and is adapted to multiple high-grade porcelain base substrate, as quartz enriched porcelain, high feldspathic porcelain, bone china, steatite ceramic or the like, can satisfy the requirement of high-grade porcelain.Glaze is moist, the luminance brightness height, and transparency is good, good springiness, physical strength is big, and good thermal shock stability, lead release are 0.00ppm, have thoroughly exempted in the porcelain lead glaze to the murder by poisoning problem of human body.

The present invention is further illustrated below in conjunction with embodiment.

Embodiment with the ingredients by weight percentage composition of frit is:

Quartzy 26.00 feldspars, 15.00 zircons, 6.00 boraxs, 13.34 Longyan clays, 13.00 lime carbonate, 7.00 rhombspars, 3.00 boric acid, 0.66 Strontium carbonate powder, 7.00 Quilonum Retards, 2.00 bone ashes, 3.00 zinc oxide 4.00.

Frit fusion process is routinely founded into frit with crucible, and 1200~1300 ℃ of melt temperatures are standby with frit pulverizing back.

Embodiment 1:

Glaze weight proportion: frit 80% porcelain powder 16% Longyan clay 4%

Making 10000-hole sieve glaze wet-milling in ball mill surplus is that 0.02~0.05% glaze slip is standby;

(weight percent consists of: SiO at senior bone china base

240.32 Al

2O

314.65 Fe

2O

30.21CaO 20.64 MgO, 0.94 K

2O 1.35 Na

2O 0.06 P

2O

518.2 TiO

20.05 surplus is conventional impurity) go up glazing after, under 1160~1200 ℃ temperature, burn till, high-grade daily-use bone ash fine porcelain.The fine and smooth light of product glaze, after testing, glossiness>115, whiteness>77, hardness>660Kgf/mm

2, lead release is 0.00ppm.

Embodiment 2:

Glaze weight proportion: frit 84% quartzy 4% Suzhou soil 5% rhombspar 2% Quilonum Retard 1% lime borate 4%

Making 10000-hole sieve glaze wet-milling in ball mill surplus is that 0.02~0.05% glaze slip is standby;

(weight percent consists of SiO at high feldspathic porcelain base

259.33 Al

2O

328.40 Fe

2O

30.35CaO 0.55 MgO, 0.85 K

2O 3.72 Na

2O 5.52 surpluses are conventional impurity) go up glazing after, under 1160~1200 ℃ temperature, burn till, high-grade daily-use feldspathic fine porcelain.Product glaze smoothness, after testing, glossiness>115, hardness>660Kgf/mm

2, lead release is 0.00ppm.

The chemical constitution of embodiment sees Table 2.

Table 1: raw material chemical constitution table (weight percent composition)

The chemical constitution table of table 2, embodiment (weight percent composition)

Claims (4)

1, a kind of lead-free fritting enamel for high-grade porcelain contains SiO

2, Al

2O

3, it is characterized in that the weight percent of its chemical constitution is:

SiO

2 50~70

Al

2O

3 9~14

B

2O

3 1~7

CaO 1~9

MgO 0~4

SrO 0~6

ZnO 0~5

K

2O 0~3

Na

2O 0~3

Li

2O 1~3

P

2O

5 0~6

ZrO

2 1~4

2, lead-free fritting enamel for high-grade porcelain according to claim 1 is characterized in that mainly formulatedly by frit and clay, and wherein, the ingredients by weight percentage composition of frit is as follows, and not enough component is by corresponding raw material adjustment in the glaze:

Quartzy 25.00~30.00 feldspars, 12.00~17.00 zircons, 5.00~7.00 boraxs, 13.00~17.00 clays, 12.00~16.00 lime carbonate, 0~8.00 rhombspar, 2.00~3.00 boric acid, 0.5~1 Strontium carbonate powder, 7.00~8.00 Quilonum Retards, 2.00~4.00 bone ashes, 3.00~5.00 zinc oxide 4.00~6.00.

3, lead-free fritting enamel for high-grade porcelain according to claim 2 is characterized in that the ingredients by weight percentage composition of frit is:

Quartzy 26.00 feldspars, 15.00 zircons, 6.00 boraxs, 13.34 Longyan clays, 13.00 lime carbonate, 7.00 rhombspars, 3.00 boric acid, 0.66 Strontium carbonate powder, 7.00 Quilonum Retards, 2.00 bone ashes, 3.00 zinc oxide 4.00.

4, according to claim 2 or 3 described lead-free fritting enamel for high-grade porcelain, it is characterized in that the weight batching ratio of glaze is: frit 80~90% quartz 0~10% clay 4~10% porcelain powder 0~16% rhombspar 0~4% Quilonum Retard 0~2% lime borate 0~6%.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB991204050A CN1171818C (en) | 1999-12-03 | 1999-12-03 | Lead-free fritting enamel for high-grade porcelain |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB991204050A CN1171818C (en) | 1999-12-03 | 1999-12-03 | Lead-free fritting enamel for high-grade porcelain |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1298844A CN1298844A (en) | 2001-06-13 |

| CN1171818C true CN1171818C (en) | 2004-10-20 |

Family

ID=5281486

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB991204050A Expired - Fee Related CN1171818C (en) | 1999-12-03 | 1999-12-03 | Lead-free fritting enamel for high-grade porcelain |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1171818C (en) |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100357228C (en) * | 2002-07-24 | 2007-12-26 | 唐山惠达陶瓷(集团)股份有限公司 | Sanitary ware with nano self-cleaning enamel and its making process |

| CN100376502C (en) * | 2006-06-14 | 2008-03-26 | 山东硅苑新材料科技股份有限公司 | Leadfree fritted glaze suitable for secondary sintering |

| EP2050725B1 (en) * | 2006-08-07 | 2010-10-13 | Ikebukuro Horo Kogyo Co. Ltd. | Glaze composition for glass lining |

| CN102040374A (en) * | 2009-10-19 | 2011-05-04 | 泉州坤达礼品有限公司 | Lithium-magnesium ceramic fired at low temperature and manufacturing method thereof |

| CN101786795B (en) * | 2009-12-31 | 2014-03-12 | 深圳国瓷永丰源股份有限公司 | Enamel glaze and preparation process thereof |

| CN101857463B (en) * | 2010-06-04 | 2013-06-19 | 深圳市永丰源实业有限公司 | Ceramic glaze and preparation method thereof |

| CN101875567B (en) * | 2010-06-04 | 2013-07-31 | 深圳市永丰源实业有限公司 | Exquisite glaze, exquisite ceramic and preparation process of exquisite ceramic |

| CN101891501A (en) * | 2010-07-13 | 2010-11-24 | 深圳市永丰源实业有限公司 | Lead-free and cadmium-free bone china glaze and preparation process thereof |

| CN102101794B (en) * | 2011-01-20 | 2013-01-16 | 潮州市波士发陶瓷制作有限公司 | Production process of glazed low-temperature bright-red glaze and ceramic products thereof |

| CN102775193B (en) * | 2012-07-30 | 2014-03-26 | 佛山石湾鹰牌陶瓷有限公司 | Ceramic slurry for combining with micro powder |

| CN102826872B (en) * | 2012-08-17 | 2014-01-15 | 广东宏陶陶瓷有限公司 | Formula and preparation method of national flag bright red glazed brick |

| CN103439167B (en) * | 2013-09-11 | 2015-09-16 | 淄博出入境检验检疫局综合技术服务中心 | A kind of preparation method of leaded ceramic glaze standard sample |

| CN103626521B (en) * | 2013-11-30 | 2015-04-22 | 山东省淄博华洋陶瓷有限责任公司 | Frit suitable for color development as well as colored vitreous enamel product and preparation method |

| CN104016720A (en) * | 2014-05-13 | 2014-09-03 | 醴陵陶润实业发展有限公司 | Double-layered crystal glaze and preparation method thereof |

| CN104789222B (en) * | 2015-03-20 | 2016-08-10 | 淄博泰如工业新材料有限公司 | A kind of extraordinary energy luminescent material and production technology thereof |

| CN104829134B (en) * | 2015-03-30 | 2017-12-12 | 佛山市新战略知识产权文化有限公司 | A kind of unleaded glaze of ceramics and preparation method thereof |

| CN105236741B (en) * | 2015-11-05 | 2017-06-20 | 佛山市高明区海帝陶瓷原料有限公司 | A kind of boron split-phase zirconium white frit high and preparation method thereof |

| CN106747660A (en) * | 2015-11-20 | 2017-05-31 | 广东顺祥陶瓷有限公司 | A kind of zinc boron fritted glaze high |

| CN105439532B (en) * | 2015-11-23 | 2018-05-22 | 黄亚奇 | A kind of high-performance pottery and preparation method thereof |

| CN107673611B (en) * | 2017-10-25 | 2023-03-28 | 福建省德化县福金兴陶瓷有限责任公司 | Whitening glaze and preparation process thereof |

| CN108191235A (en) * | 2018-03-15 | 2018-06-22 | 河南城建学院 | A kind of Bone China Glaze, glaze slip and preparation method |

| CN111499419B (en) * | 2020-04-28 | 2022-03-29 | 广东华星陶瓷有限公司 | Preparation method of red lead-free bone china |

| CN112028605A (en) * | 2020-09-08 | 2020-12-04 | 福建省德化县腾艺陶瓷有限公司 | Jade white porcelain prepared from modified metakaolin and preparation process thereof |

| CN112897883A (en) * | 2021-02-07 | 2021-06-04 | 孙正斌 | Preparation method of pearl bone china glaze water |

| CN113788620B (en) * | 2021-11-16 | 2022-03-22 | 佛山欧神诺陶瓷有限公司 | Ceramic dry grain glaze and crystal diamond flashing ceramic tile and preparation method thereof |

-

1999

- 1999-12-03 CN CNB991204050A patent/CN1171818C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN1298844A (en) | 2001-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1171818C (en) | Lead-free fritting enamel for high-grade porcelain | |

| EP0452065B1 (en) | Glaze compositions | |

| CN100376502C (en) | Leadfree fritted glaze suitable for secondary sintering | |

| EP1971559B1 (en) | Glaze compositions | |

| CN1186282C (en) | Lead- and zinc-free transparent fritted glaze | |

| US5009709A (en) | Strong dental porcelain and method for its manufacture | |

| CA2466620C (en) | Opalescent glass-ceramic product | |

| IE910662A1 (en) | Glass composition | |

| CN110078371B (en) | Low-melting glass composition with excellent water resistance | |

| CN100345786C (en) | Low melting point, low expanding coefficient solder glass seal powder and its preparing method | |

| JPH05339029A (en) | Zinc-containing, lead-and cadmium-free glass frits, production thereof and production of decorative coating material | |

| JP3800256B2 (en) | Insulating glass composition | |

| NZ207278A (en) | Glaze for dental porcelain ceramic | |

| US4883777A (en) | Sealing glass composition with filler containing Fe and W partially substituted for Ti in PbTiO3 filler | |

| CN101050059A (en) | Covering layer without lead, cadmium of pigment without lead on ceramic glaze, and preparation method | |

| CN1472155A (en) | Leadless enamel blocks | |

| CN1253395C (en) | High glossiness leadless glaze for porcelain | |

| KR20100058335A (en) | Lead-free glass frit composition for use in sealing | |

| EP0404501B2 (en) | Overglaze colors for pottery and a method of manufacture thereof | |

| JP2001080934A (en) | Material for plasma display panel and glass powder | |

| JP2574556B2 (en) | Glaze composition and glaze method | |

| GB2301100A (en) | Glass flux composition | |

| JPH03170346A (en) | Glass composition and insulator using the same | |

| JP4174894B2 (en) | Transparent dielectric material for front glass plate of plasma display panel | |

| RU2807593C1 (en) | Glass filler for filling and restoration dental materials |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C06 | Publication | ||

| PB01 | Publication | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20041020 Termination date: 20100104 |