CN115993401B - Calibration system for grouting saturation measuring equipment - Google Patents

Calibration system for grouting saturation measuring equipment Download PDFInfo

- Publication number

- CN115993401B CN115993401B CN202310286234.6A CN202310286234A CN115993401B CN 115993401 B CN115993401 B CN 115993401B CN 202310286234 A CN202310286234 A CN 202310286234A CN 115993401 B CN115993401 B CN 115993401B

- Authority

- CN

- China

- Prior art keywords

- clamping

- reinforcement

- detection box

- hole

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A90/00—Technologies having an indirect contribution to adaptation to climate change

- Y02A90/30—Assessment of water resources

Landscapes

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

- Investigating Or Analyzing Materials By The Use Of Ultrasonic Waves (AREA)

Abstract

The invention discloses a calibration system for grouting saturation measuring equipment, which relates to the field of detection data calibration, and comprises a reinforcement, a first detection box and a second detection box, wherein the reinforcement sequentially horizontally penetrates through the side walls of the first detection box and the second detection box; the middle part of the bottom plate is provided with a through hole, the middle part of the cover plate is provided with a guide hole, and the outer wall of the lower end of the clamping cylinder is hinged with two supporting legs; the reinforcement is the reinforcing bar that is equipped with a plurality of ribs on the outer wall, and a plurality of ribs are the spiral distribution, and a plurality of clamping parts form a clamping area that is used for the centre gripping reinforcement in the centre gripping section of thick bamboo. The clamping assembly is adopted to ensure that the reinforcement is positioned at the center of the first detection box and the second detection box, so that the signal transmitted by the initial end of the reinforcement can be ensured to be uniformly transmitted into the second detection box when the detection test is carried out by the existing detection equipment, the generation of relatively complex and irregular reflected waves is avoided, and the detection precision is improved.

Description

Technical Field

The invention relates to the technical field of saturation measurement, in particular to a calibration system for grouting saturation measurement equipment.

Background

The reinforcement support technology is used as an active support technology and is widely applied to various engineering fields such as water conservancy and hydropower, railway and highways, buildings, underground facilities and the like, but the reinforcement support belongs to a hidden engineering, so that the construction quality is difficult to be checked by adopting visual means. In the existing reinforcement supporting quality testing technology, different manufacturers develop equipment according to different metering modes, and respectively popularize different standard specifications, so that the unified standard specification is not used for carrying out magnitude tracing on grouting compactness; in practical engineering application, grouting fullness indexes are only qualitative indexes, and cannot be unified due to the fact that technical capabilities of equipment on the market are good and uneven, and quantification of the indexes cannot be achieved.

Disclosure of Invention

The present invention aims to provide a calibration system for grouting saturation measuring equipment, so as to solve the above problems.

The invention is realized by the following technical scheme:

the calibrating system for grouting saturation measuring equipment comprises a reinforcing member, a first detecting box and a second detecting box, wherein the first detecting box and the second detecting box are arranged side by side;

the second detection box is internally provided with a clamping assembly for fastening the reinforcement, the clamping assembly comprises a clamping cylinder, a bottom plate and a cover plate, wherein the bottom plate and the cover plate are used for sealing two ends of the clamping cylinder, a through hole is formed in the middle of the bottom plate, a guide hole coaxial with the through hole is formed in the middle of the cover plate, the through hole and the guide hole are used for horizontally penetrating the reinforcement, and two support legs are hinged to the outer wall of the lower end of the clamping cylinder;

the end face of the bottom plate, which is opposite to the cover plate, is provided with a plurality of guide grooves which are communicated end to end, a positive geometric plane figure is formed after the guide grooves are communicated, and the cover plate is provided with a plurality of limit holes which are uniformly distributed along the direction of the guide Kong Qiexian and correspond to the guide grooves respectively; the device comprises a guide groove, a limiting hole, a plurality of pin columns, a clamping plate, a reinforcing member, a plurality of ribs, a clamping area and a plurality of clamping parts, wherein the pin columns are in sliding fit with the guide groove and the limiting hole;

the first detection box and the second detection box are respectively poured with concrete slurry through the first through hole and the second through hole.

In the prior art, since the quality judgment in the reinforcement supporting engineering cannot form a unified standard, the quantification of grouting saturation cannot be realized, in this regard, the applicant research and development relates to a detection device which is applied to the measurement and evaluation of grouting saturation, namely whether the reinforcement quality detection equipment meets the requirements or not is evaluated through the measurement of a plurality of standard components, if three standard components (the compaction degree of the three standard components is 40%, 60% and 80% respectively) are adopted, the compaction degree of the reinforcement quality detection equipment is used for measuring the compaction degree of the reinforcement quality detection equipment, a receiving sensor of the quality detection equipment is firstly fixed at the exposed reinforcement of the end head of the standard component, an excitation device is used for perpendicularly acting on the reinforcement end head, elastic waves generated by excitation can be transmitted in the standard component along the knocking direction, the compaction degree value of the standard component is obtained after the reflected wave signals received by the receiving sensor are calculated and processed in a host computer of the quality detection equipment, and the compaction degree error of the quality detection equipment can be obtained after the compaction degree error of the standard component is compared with the standard value which is pre-compacted in advance; if the detection result of the standard component exceeds the maximum allowable error value of the quality detection equipment, the detection equipment does not meet the requirement; when the standard component is prepared, a first detection box and a second detection box with equal height and different lengths are firstly processed, the first detection box and the second detection box are placed side by side for the reinforcing member to horizontally pass through, and a first through hole and a second through hole which are arranged at the tops of the first detection box and the second detection box are used for injecting concrete slurry into the standard component after the reinforcing member is placed, and the standard component with corresponding compactness degree is obtained after the concrete slurry is completely solidified; it should be noted that, when the standard component is tested for the first time, the length of the first detection box is generally 200mm, the length of the second detection box is 600mm, the distance between the first detection box and the second detection box is 1200mm, at this time, the reinforcement completely penetrates through the first detection box and then horizontally extends to the side wall of the second detection box, then penetrates through one side wall of the second detection box and then extends to the inside of the second detection box, and the end part of the reinforcement does not penetrate through the other side wall of the second detection box, but leaves a distance with the inner side wall of the second detection box, and as the reinforcement positioned in the second detection box does not have a support before grouting, the joints between the reinforcement and the second detection box and the reinforcement and the first detection box are welded, therefore, before grouting concrete slurry or after grouting the concrete slurry, the free end of the reinforcement positioned in the second detection box is easily deformed to a certain extent, the detection test is performed by using the mass detection equipment without using the later stage, namely, the signal transmitted by the initial end part of the reinforcement is not uniformly transmitted to the second reinforcement, namely, the detection equipment cannot be affected by the quality detection equipment is more complicated, and the quality detection equipment cannot be affected; for this, to being located the inside reinforcement part of the relatively great second detection case of horizontal length, this technical scheme adopts dedicated clamping assembly to carry out corresponding spacing and support to the reinforcement, ensures that the reinforcement is in the positive center department of first detection case and second detection case all the time, does not influence the normal removal and the test use of reinforcement simultaneously.

The specific working principle of the clamping action of the reinforcement is as follows:

the top parts of the first detection box and the second detection box are closed except for grouting holes respectively, before concrete slurry is injected, the reinforcing parts firstly need to penetrate through two opposite side walls of the first detection box and one side wall of the second detection box in sequence, and as the first detection box is relatively short, the reinforcing parts can well realize centering penetration and simultaneously the first detection box can also stably support the reinforcing parts; in the second detection box, the clamping assembly is fixed on the inner wall of the bottom of the second detection box in advance, the reinforcing steel bar with the spiral ribs is selected as the reinforcing steel bar, the reinforcing steel bar penetrates through the side wall of the second detection box and then gradually enters the guide hole on the cover plate, the axes of the guide hole and the through hole are adjusted in advance, after the end part of the reinforcing steel bar passes through the clamping area formed by surrounding the end parts of the plurality of clamping plates, the ribs on the reinforcing steel bar can drive the clamping plates to rotate until the clamping area is attached to the outer wall of the reinforcing steel bar and the reinforcing steel bar can not move continuously, the pin end parts on the clamping plates reach the limit positions of the limit holes, at the moment, the clamped outer wall of the reinforcing steel bar is extruded by the plurality of clamping plates, and the clamping plates are limited by the mutual limitation between the clamping plates and the ribs, the stress along the radial direction of the reinforcing steel bar is directly transmitted to the bottom of the second detection box by the supporting legs, so that the horizontal state of the reinforcing steel bar can be ensured before grouting, and the stability of the reinforcing steel bar can be ensured when the reinforcing steel bar is impacted during grouting or the internal stress generated during the grouting, and the quality detection equipment is still stable, and the factors except the measurement precision of the quality detection equipment are reduced.

In the rest test process, the length of the second detection box is gradually adjusted, so that the distance between the second detection box and the first detection box is reduced, if the length of the first detection box is increased to 400mm, the distance between the first detection box and the second detection box is respectively reduced to 800mm and 400mm when the length of the second detection box is 800mm or 1200mm, and at the moment, the second detection box also needs to be supported and limited by the clamping assembly.

The clamping part comprises a guide plate in a trapezoid shape, the clamping plate is in an isosceles triangle shape, the bottom edge of the clamping plate is equal in length and is connected with the upper bottom edge of the guide plate, a plurality of rollers are obliquely arranged on the end face where the lower bottom edge of the guide plate is located, the inclination angles of the rollers are identical to the rotation direction of the ribs of the reinforcing member, the pin column is rotationally arranged at a position close to one waist of the clamping plate, a limiting groove is formed in the end face where the other waist of the clamping plate is located, one end of the limiting groove is open, the other end of the limiting groove is closed, and the open end of the limiting groove extends to the lower bottom edge of the guide plate;

the thickness of the guide plate is gradually decreased from the pin column to the axis of the through hole;

in the initial state, in two adjacent clamping plates, the roller on one clamping plate can enter the inside of the limiting groove along the open end of the limiting groove on the other clamping plate; and the areas of clamping areas formed by the lower bottom edges of the guide plates in a surrounding way can be used for the rib of the reinforcement and the roller to be matched with each other. Further, the technical scheme is to further limit the specific constitution of the clamping area, namely, by arranging the clamping plate and the guide plate with specific shapes, the matching between the components forming the clamping area is smoother, and the technical scheme is as follows: after the end part of the reinforcement enters the guide hole, the forward projection area of the guide hole is larger than the forward projection area of the clamping area, namely, the reinforcement can smoothly pass through the guide hole, when the rib on the outer wall of the reinforcement is matched with the roller on the side wall where the lower bottom edge of the guide plate is located, the rib on the outer wall of the reinforcement can extrude the roller along with the linear motion of the reinforcement, the roller and the rib which are obliquely arranged in the same direction can drive the guide plate to rotate, one end of the pin moves along the guide groove and the other end of the pin moves along the limit position of the limit hole, after the end part of the pin contacts with the limit position of the limit hole, the roller on each guide plate is bonded with the outer wall of the reinforcement at the same time, so that the roller cannot move continuously (including the motion along the radial direction and the axial direction of the reinforcement), and the guide plate is driven to reversely rotate when the reinforcement is retreated, so that the extrusion contact of the roller to the outer wall of the reinforcement is relieved. In the technical scheme, limiting grooves with open ports are formed in the side walls of the same side of the clamping plates and the guide plates which are connected with each other, namely, after the two adjacent clamping plates move relatively, if a clamping area becomes smaller, a plurality of rollers positioned on the same guide plate are gradually covered by the limiting grooves after passing through the open ends of the other limiting grooves adjacent to the rollers; conversely, when the clamping area becomes large, the rollers on the same guide plate are exposed again from the limiting groove. And the thickness of the guide plate is gradually decreased from the pin column to the axis of the through hole, namely, before the end part of the reinforcement enters the through hole, the inclined surface of the guide plate can guide the reinforcement to move towards the axis of the clamping area, so that the fixed supporting progress of the reinforcement is quickened.

Still include the linkage board, open on the terminal surface that the deflector lower base was located has the joint groove, be equipped with on the lateral wall of linkage board with joint groove complex joint board, open on the other lateral wall of linkage board has a plurality of inclined setting's constant head tank, open respectively on the relative inner wall of constant head tank has the shaft hole, is equipped with the pivot respectively on two terminal surfaces of roller, and the pivot rotates to set up in the shaft hole, the part of roller outstanding in the constant head tank. As the size of the reinforcement is smaller, the size of the roller matched with the reinforcement is smaller, the installation mode of the roller is set to be detachably and movably connected, if the linkage plate is used as an installation carrier of the roller, the linkage plate is formed by splicing two identical strip plates, the opposite side walls of the two strip plates are respectively provided with a cylindrical groove and a shaft hole in an inclined state, the two cylindrical grooves can be spliced to form a complete positioning groove for the installation of the roller, the side walls of the two strip plates opposite to the guide holes are respectively provided with a side plate, the two side plates can be spliced to form a clamping plate matched with the clamping groove, the outer wall of one strip plate is provided with an inclined guide surface matched with the inclined surface of the guide plate, and when the roller is assembled, the spliced clamping plate is inserted into the clamping groove by respectively placing two rotating shafts of the roller in the two shaft holes.

The outer diameter of the roller decreases along the axis thereof in the direction approaching the guide hole. Further, the outer diameter of the roller decreases along the axis of the roller towards the direction close to the guide hole, so that the end part of the reinforcement starts to extrude the roller only after entering the through hole, the axial displacement of the reinforcement is increased, enough contact points between the rollers and the reinforcement are ensured, and the supporting stability of the reinforcement is improved.

An elastic pad is arranged at the bottom of the positioning groove, and the inner diameter of the shaft hole is larger than the outer diameter of the rotating shaft; in the initial state, the outer wall of the large-diameter section of the roller is contacted with the elastic pad, and a gap is reserved between the outer wall of the small-diameter section of the roller and the elastic pad. Further, in the process that the reinforcement moves towards the inside of the through hole, the rib is firstly contacted with the outer wall of the small-diameter section of the roller, and the contact area of the rib and the small-diameter section of the roller is smaller, so that the interaction force generated between the rib and the roller is smaller, the inner diameter of the shaft hole is larger than the outer diameter of the rotating shaft, a gap exists between the end face of the rotating shaft positioned on the small-diameter end of the roller and the hole bottom of the corresponding shaft hole, the small-diameter section of the roller subjected to extrusion moves towards the direction close to the elastic pad until the rib is contacted with the outer wall of the large-diameter section of the roller, the elastic pad starts to be extruded after the whole roller is stressed to deform, and meanwhile, the continuous movement of the reinforcement drives the linkage plate, the guide plate and the clamping plate to rotate together; because the rib is the heliciform, exist the clearance between two adjacent turns of ribs promptly, when the outer wall of roller is not direct with rib outermost wall department contact, the effort that elastic pad recovery deformation produced then can drive the roller and resume the normal position, drive the outer wall of partial roller and direct with the regional contact of non-rib on reinforcing bar surface promptly, the clamping effect of clamping area to the reinforcement reaches the best this moment, the impact of producing when pouring concrete slurry or the stress that produces when concrete is dry, can't be in the radial of reinforcement or axial to its stability influence.

The support leg comprises a support upper section and a support lower section, the support upper section is hinged with the outer wall of the clamping cylinder, a screw rod coaxial with the support upper section is arranged on the lower end face of the support upper section, and an inner screw hole matched with the screw rod is formed in the upper end face of the support lower section. Preferably, the upper support section and the lower support section are matched with the screw rod through the inner screw holes, whether the height of the axis of the repeated checking clamping area is consistent with a preset standard or not can be judged, and if the height is not consistent with the preset standard, the center position of the movable second detection box of the first detection box is not met.

The lower end face of the lower support section is provided with a round backing plate parallel to the horizontal plane. Preferably, the lower end of the lower support section is provided with a circular base plate, when the reinforcement penetrates through the first detection box and then enters the second detection box, the axis of the clamping area is calibrated and adjusted in advance according to the height value of the reinforcement from the ground, so that the reinforcement cannot be centered with the clamping area, and the reinforcement entering the second detection box is prevented from being locally bent or cannot penetrate through.

Compared with the prior art, the invention has the following advantages and beneficial effects:

1. the special clamping assembly is adopted to correspondingly limit and support the reinforcement, so that the reinforcement is always positioned at the right center of the first detection box and the second detection box, normal movement of the reinforcement is not influenced, and detection tests are carried out by using the quality detection equipment in the later stage, so that signals transmitted by the initial end of the reinforcement can be ensured to be uniformly transmitted to the second detection box along the reinforcement, namely, more complex and irregular reflected waves are prevented from being generated, and the detection precision of the quality detection equipment is improved;

2. the thickness of the guide plate in the invention is gradually decreased from the pin column to the axis of the through hole, namely, before the end part of the reinforcement enters the through hole, the inclined surface of the guide plate can guide the reinforcement to move towards the axis of the clamping area, so that the fixed supporting progress of the reinforcement is quickened;

3. according to the invention, the upper support section and the lower support section are matched with the screw rod through the inner screw holes, whether the height of the axis of the repeated checking clamping area is consistent with a preset standard or not can be checked, and if the height of the axis of the repeated checking clamping area is consistent with the preset standard, the center position of the movable second detection box of the first detection box is not met.

Drawings

The accompanying drawings, which are included to provide a further understanding of embodiments of the invention and are incorporated in and constitute a part of this application, illustrate embodiments of the invention. In the drawings:

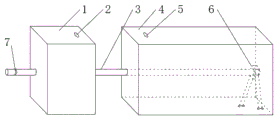

FIG. 1 is a schematic diagram of the structure of the present invention;

FIG. 2 is a schematic view of a clamping assembly;

FIG. 3 is a schematic view of a structure of a limiting plate;

FIG. 4 is a schematic structural view of a reinforcement member;

FIG. 5 is a schematic diagram of a positioning slot;

FIG. 6 is a longitudinal cross-sectional view of the clamping plate;

FIG. 7 is a second construction diagram of the present invention in embodiment 2;

fig. 8 is a schematic view of a third configuration of the present invention in embodiment 2.

The reference numerals are represented as follows: 1-first detection box, 2-first through hole, 3-reinforcement, 31-rib, 4-second detection box, 5-second through hole, 6-clamping component, 61-apron, 62-bottom plate, 63-spacing hole, 64-round pin post, 65-clamping plate, 66-deflector, 67-clamping area, 68-support lower section, 69-support upper section, 610-screw rod, 611-backing plate, 612-internal thread hole, 613-roller, 614-spacing groove, 615-guiding groove, 616-linkage plate, 617-shaft hole, 618-positioning groove, 619-clamping plate, 620-rotating shaft, 621-elastic pad, 7-receiving sensor.

Detailed Description

For the purpose of making apparent the objects, technical solutions and advantages of the present invention, the present invention will be further described in detail with reference to the following examples and the accompanying drawings, wherein the exemplary embodiments of the present invention and the descriptions thereof are for illustrating the present invention only and are not to be construed as limiting the present invention.

Example 1

As shown in fig. 1 to 6, the embodiment includes a reinforcement 3, a first detection box 1 and a second detection box 4 arranged side by side, a first through hole 2 is formed at the top of the first detection box 1, a second through hole 5 is formed at the top of the second detection box 4, the reinforcement 3 sequentially horizontally penetrates through the side walls of the first detection box 1 and the second detection box 4, and the horizontal length of the first detection box 1 is smaller than the horizontal length of the second detection box 4;

the second detection box 4 is internally provided with a clamping assembly 6 for fastening the reinforcement 3, the clamping assembly 6 comprises a clamping cylinder, a bottom plate 62 and a cover plate 61, wherein the bottom plate 62 and the cover plate 61 are used for sealing two ends of the clamping cylinder, a through hole is formed in the middle of the bottom plate 62, a guide hole coaxial with the through hole is formed in the middle of the cover plate 61, the through hole and the guide hole are used for horizontally penetrating the reinforcement 3, and two support legs are hinged on the outer wall of the lower end of the clamping cylinder;

a plurality of guide grooves 615 which are communicated end to end are formed on the end surface of the bottom plate 62, which is opposite to the cover plate 61, a positive geometric plane figure is formed after the guide grooves 615 are communicated, and a plurality of limit holes 63 which are uniformly distributed along the direction of the guide Kong Qiexian and correspond to the guide grooves 615 are formed on the cover plate 61; the steel reinforcement 3 is a steel reinforcement with a plurality of ribs 31 on the outer wall, the ribs 31 are spirally distributed, and a clamping area 67 for clamping the steel reinforcement 3 can be formed in the clamping cylinder around the circumference of the through hole by the aid of the clamping parts;

the first detection box 1 and the second detection box 4 are respectively poured with concrete slurry through the first through hole 2 and the second through hole 5. Preferably, the reinforcement is a Φ22 hot rolled steel; and a plurality of round holes are uniformly formed in the cover plate 61, so that concrete can smoothly enter the clamping cylinder to fill the inside of the clamping cylinder during pouring.

Preferably, after the plurality of guide grooves 615 are communicated, a regular hexagon is formed, that is, the number of the guide grooves 615 is 6, and the number of the limiting holes 63 is 6.

The specific working principle of the clamping action on the reinforcement 3 is as follows:

the top parts of the first detection box 1 and the second detection box 4 are closed except for the grouting holes respectively, before concrete slurry is injected, the reinforcement 3 firstly needs to penetrate through two opposite side walls of the first detection box 1 and one side wall of the second detection box 4 in sequence, and the reinforcement 3 can well realize centering penetration and simultaneously the first detection box 1 can stably support the reinforcement 3 because of the relatively short first detection box 1; in the second detection box 4, the clamping assembly 6 is fixed on the inner wall of the bottom of the second detection box 4 in advance, the reinforcement 3 is selected to be a reinforcement bar with a spiral rib 31, the reinforcement bar penetrates through the side wall of the second detection box 4 and then gradually enters into the guide hole on the cover plate 61, the axes of the guide hole and the through hole are pre-adjusted, after the end part of the reinforcement 3 passes through the clamping area 67 formed by the surrounding of the end parts of the clamping plates 65, the rib 31 on the reinforcement 3 can drive the clamping plates 65 to move in a rotating manner until the clamping area 67 is attached to the outer wall of the reinforcement 3 and the reinforcement 3 cannot move continuously, meanwhile, the end parts of the pin 64 on the clamping plates 65 reach the limit position of the limit hole 63, at this time, the clamped outer wall of the reinforcement 3 is extruded by the clamping plates 65, and meanwhile, the mutual limitation between the clamping plates 65 and the rib 31 is limited, the stress on the radial direction of the reinforcement 3 is directly transmitted to the bottom of the second detection box 4 by the support legs, so that the reinforcement 3 can be ensured to keep the horizontal state before grouting, and the reinforcement 3 can be ensured to be impacted during grouting or the internal stress generated when slurry is dry, the quality of the concrete is still reduced, and the quality of the measurement device is still stable, and the quality of the measurement device is influenced.

The specific configuration of the clamping area 67 is further defined in this embodiment, that is, by providing the clamping plate 65 and the guide plate 66 with specific shapes, the fitting between the components forming the clamping area 67 is smoother, which is specifically as follows:

the clamping part comprises a guide plate 66 in a trapezoid shape, the clamping plate 65 is in an isosceles triangle shape, the bottom edge of the clamping plate 65 is equal in length and is connected with the upper bottom edge of the guide plate 66, a plurality of rollers 613 are obliquely arranged on the end face where the lower bottom edge of the guide plate 66 is located, the inclination angles of the rollers 613 are the same as the rotation direction of the rib 31 of the reinforcing member 3, the pin 64 is rotationally arranged at a position close to one waist of the clamping plate 65, a limiting groove 614 is formed in the end face where the other waist of the clamping plate 65 is located, one end of the limiting groove 614 is open, the other end of the limiting groove 614 is closed, and the open end of the limiting groove 614 extends to the lower bottom edge of the guide plate 66;

the thickness of the guide plate 66 decreases from the pin 64 to the axis of the through hole;

in the initial state, in two adjacent clamping plates 65, the roller 613 on one clamping plate 65 can enter the inside of the limiting groove 614 along the open end of the limiting groove 614 on the other clamping plate 65; and the area of the nip 67 defined by the lower edges of the plurality of guide plates 66 allows the rib 31 of the reinforcing member 3 to be engaged with the roller 613.

In this embodiment, at the end of the stiffener 3 where the receiving sensor 7 is not provided, the end face thereof is spaced apart from the rib 31 closest thereto, so that this section is referred to as the active section of the stiffener 3; after the movable section firstly enters the guide hole, the forward projection area of the guide hole is larger than that of the clamping area 67, namely the movable section can smoothly pass through the guide hole; at this time, because the clamping cylinder is horizontally placed, the axes of the clamping cylinders are parallel to the horizontal plane, the limiting holes 63 which play a role in limiting the pin 64 are uniformly arranged along the tangential direction of the guiding holes, and the plurality of limiting holes 63 are guaranteed to be in rotationally symmetrical distribution, because the adjacent two guiding plates 66 are in contact with each other, when no acting force applied along the circumferential direction of the guiding holes is generated, the clamping area 67 formed by the surrounding of the lower bottom edges of the plurality of guiding plates 66 can keep the initial state of the clamping area 67 and can allow the movable section to pass through, until the rib 31 is in contact with the roller 613 on the side wall where the lower bottom edges of the guiding plates 66 are located, as the stiffener 3 continues to perform linear motion, the rib 31 on the outer wall can transmit the acting force to the corresponding guiding plates 66 and the clamping plate 65 (the cooperation between the spiral rib 31 and the inclined roller 613 is like the meshing between an external gear and an annular gear), so that the roller 613 and the rib 31 which are arranged in the same direction can drive the guiding plates 66 to rotate, and one end of the pin 64 moves along the guiding groove 615 and the other end of the clamping area along the limiting hole 63 moves along the limiting position of the limiting hole 63, and when the end of the pin 64 and the end of the limiting plate are in contact with the roller 613 on the inner bottom edge of the guiding plate 66, and the inner gear 3 can not move along the axial direction of the corresponding stiffener 3 (when the stiffener 3 continues to move along the axial direction and the limiting section 3 is completed; when the reinforcement 3 retreats, the guide plate 66 is driven to reversely rotate so as to release the extrusion contact of the roller 613 on the outer wall of the reinforcement 3.

In this embodiment, a limiting groove 614 with an open port is formed on the same side wall of the two adjacent clamping plates 65 and the two adjacent guiding plates 66, that is, after the two adjacent clamping plates 65 move relatively, if the clamping area 67 becomes smaller, a plurality of rollers 613 on the same guiding plate 66 are gradually covered by the limiting groove 614 after passing through the open end of the other limiting groove 614 adjacent to the two adjacent clamping plates 65; conversely, when the nip 67 becomes larger, the rollers 613 on the same guide plate 66 are again exposed from the limiting groove 614. The thickness of the guide plate 66 decreases from the pin 64 toward the axis of the through hole, that is, the inclined surface of the guide plate 66 guides the movable section of the reinforcement member 3 to move toward the axis of the holding area 67 before the movable section of the reinforcement member 3 enters the through hole, so as to accelerate the progress of the fixed support of the reinforcement member 3.

The present embodiment further includes a linkage plate 616, a clamping slot is formed on an end face where a lower bottom edge of the guide plate 66 is located, a clamping plate 619 matched with the clamping slot is disposed on a side wall of the linkage plate 616, a plurality of inclined positioning slots 618 are formed on another side wall of the linkage plate 616, shaft holes 617 are formed on inner walls opposite to the positioning slots 618 respectively, rotary shafts 620 are respectively disposed on two end faces of the roller 613, the rotary shafts 620 are rotatably disposed in the shaft holes 617, and parts of the roller 613 protrude out of the positioning slots 618.

Preferably, because the size of the reinforcement 3 is smaller, and the size of the roller 613 matched with the reinforcement 3 is smaller, the installation mode of the roller 613 is set to be in detachable movable connection, for example, the linkage plate 616 is used as an installation carrier of the roller 613, the linkage plate 616 is formed by splicing two identical strip-shaped plates, the opposite side walls of the two strip-shaped plates are respectively provided with a cylindrical groove and a shaft hole 617 in an inclined state, the two cylindrical grooves can be spliced to form a complete positioning groove 618 for installing the roller 613, the side walls of the two strip-shaped plates opposite to the guide holes are respectively provided with a side plate, the two side plates can be spliced to form a clamping plate 619 matched with the clamping groove, the outer wall of one strip-shaped plate is provided with an inclined guide surface matched with the inclined surface of the guide plate 66, and when in assembly, the spliced clamping plate 619 can be inserted into the clamping groove by respectively placing the two rotating shafts 620 of the roller 613 in the two shaft holes.

The outer diameter of the roller 613 decreases along the axis thereof in a direction approaching the guide hole, so that the ribs 31 on the outer wall of the roller 613 start to press the roller 613 after the end of the reinforcement 3 enters the through hole, thereby increasing the displacement of the reinforcement 3 in the axial direction, ensuring enough contact points between the roller 613 and the reinforcement 3 and improving the supporting stability of the reinforcement 3.

As a further optimization of this embodiment, an elastic pad 621 is disposed at the bottom of the positioning groove 618, and the inner diameter of the shaft hole 617 is larger than the outer diameter of the shaft 620; in the initial state, the outer wall of the large diameter section of the roller 613 is in contact with the elastic pad 621, and a gap is left between the outer wall of the small diameter section of the roller 613 and the elastic pad 621.

In the process that the reinforcement 3 moves towards the through hole, the rib 31 is firstly contacted with the outer wall of the small diameter section of the roller 613, and the contact area of the rib 31 and the roller 613 is smaller, so that the interaction force generated between the rib 31 and the roller 613 is smaller, the inner diameter of the shaft hole 617 is larger than the outer diameter of the shaft 620, a space exists between the end face of the shaft 620 positioned on the small diameter end of the roller 613 and the hole bottom of the shaft hole 617 corresponding to the end face, and the small diameter section of the roller 613 can move towards the direction close to the elastic pad 621 until the rib 31 is contacted with the outer wall of the large diameter section of the roller 613, the roller 613 begins to extrude the elastic pad 621 to deform after being integrally stressed, and meanwhile, the continuous movement of the reinforcement 3 can drive the linkage plate 616, the guide plate 66 and the clamping plate 65 to rotate together; because the ribs 31 are spiral, that is, gaps exist between two adjacent turns of ribs 31, when the outer wall of the roller 613 is not directly contacted with the outermost wall of the ribs 31, the acting force generated by the elastic pad 621 in the recovery deformation drives the roller 613 to recover to the original position, that is, the outer wall of part of the roller 613 is directly contacted with the non-rib area on the surface of the reinforcing steel bar, at the moment, the clamping effect of the clamping area 67 on the reinforcing steel bar 3 is optimal, and no matter the impact produced when concrete slurry is poured or the stress produced when concrete is dried, the stability of the reinforcing steel bar 3 cannot be influenced in the radial direction or the axial direction.

Preferably, the upper support section 69 and the lower support section 68 are matched with the screw 610 through the inner screw holes, so that whether the height of the axis of the clamping area 67 is consistent with the preset standard or not can be repeatedly checked, if so, the required central position of the movable second detection box 4 of the first detection box 1 is reached.

Preferably, a circular pad 611 is disposed at the lower end of the support lower section 68, so that when the reinforcement 3 penetrates through the first detection box 1 and then enters the second detection box 4, the axis of the clamping area 67 is calibrated and adjusted in advance according to the height value of the reinforcement 3 from the ground, so as to prevent the reinforcement 3 from being unable to be centered with the clamping area 67, and avoid the reinforcement 3 entering the second detection box 4 from being locally bent or unable to penetrate.

Example 2

In this embodiment, when three standard components pass the quality detection device test, grouting densities are respectively 40%, 60% and 80% as shown in fig. 1, 7 and 8;

in fig. 1, i.e. when the standard component (grouting compactness is 40%) is tested for the first time, the length of the first detection box is generally 200mm, the length of the second detection box 4 is 600mm, the interval between the equal heights of the first detection box 1 and the second detection box 4 is 1200mm, at this time, the reinforcing member 3 extends horizontally to the side wall of the second detection box 4 after penetrating through the first detection box 1 completely, then extends to the inside after penetrating through one side wall of the second detection box 4, and the end part of the reinforcing member 3 does not penetrate through the other side wall of the second detection box 4, but leaves an interval with the inner side wall of the second detection box 4, and the reinforcing member 3 positioned in the second detection box 4 is supported and limited by the clamping component 6 before grouting;

in fig. 7, i.e. when the standard (60% of grouting compactness) is tested for the second time, the length of the first detection box 1 is increased to 400mm, the length of the second detection box 4 is 800mm, the distance between the first detection box 1 and the second detection box 4 is 600mm, and the reinforcement 3 positioned in the second detection box 4 is supported and limited by the clamping assembly 6 after reaching the preset position;

in fig. 8, i.e. when the standard (grouting compactness 80%) is tested for the third time, the length of the first detection box 1 is increased to 400mm, the length of the second detection box 4 is 1200mm, the distance between the first detection box 1 and the second detection box 4 is 400mm, the length of the reinforcement 3 inside the second detection box 4 in the unsupported state is the largest, and the reinforcement 3 is supported and limited by the clamping assembly 6 after reaching the preset position.

And after the reinforcement is supported and fastened each time, the connection part between the reinforcement 3 and the outer walls of the first detection box 1 and the second detection box 4 is welded and fixed, the grouting process is carried out through the first through hole 2 and the second through hole 5 until the injected concrete slurry is completely dried, and then the reinforcement quality detection equipment is used for testing the concrete slurry.

When the three standard components are used for measuring the compactness of the reinforcement quality detection equipment, firstly, a receiving sensor 7 of the quality detection equipment is fixed on the reinforcement 3 exposed on the side wall of the first detection box 1, an excitation device is used for vertically acting on the end head of the reinforcement 3, elastic waves generated by excitation can propagate in the first detection box 1 and the second detection box 4 along the knocking direction, reflected wave signals received by the receiving sensor 7 are calculated and processed in a host computer of the quality detection equipment, the compactness value of the standard component is obtained, and the compactness error of the quality detection equipment can be obtained after the compactness value is compared with the standard value set by the standard component; if the detection result of the standard component exceeds the maximum allowable error value of the quality detection equipment, the detection equipment does not meet the requirement.

The foregoing description of the embodiments has been provided for the purpose of illustrating the general principles of the invention, and is not meant to limit the scope of the invention, but to limit the invention to the particular embodiments, and any modifications, equivalents, improvements, etc. that fall within the spirit and principles of the invention are intended to be included within the scope of the invention.

Claims (5)

1. A calibration system for grouting saturation measuring equipment, including reinforcement (3) and first detection case (1), second detection case (4) that set up side by side first detection case (1) top is opened there is first through-hole (2), and it has second through-hole (5), its characterized in that to open at second detection case (4) top: the reinforcement (3) sequentially horizontally penetrates through the side walls of the first detection box (1) and the second detection box (4), the horizontal length of the first detection box (1) is smaller than that of the second detection box (4), and a receiving sensor (7) is arranged on the outer wall of the end part, far away from the second detection box (4), of the reinforcement (3);

the inside of the second detection box (4) is provided with a clamping assembly (6) for fastening the reinforcement (3), the clamping assembly (6) comprises a clamping cylinder, a bottom plate (62) and a cover plate (61) which are used for sealing two ends of the clamping cylinder, a through hole is formed in the middle of the bottom plate (62), a guide hole coaxial with the through hole is formed in the middle of the cover plate (61), the through hole and the guide hole are both used for horizontally penetrating the reinforcement (3), and two support legs are hinged on the outer wall of the lower end of the clamping cylinder;

a plurality of guide grooves (615) which are communicated end to end are formed in the end face of the bottom plate (62) which is opposite to the cover plate (61), a positive geometric plane figure is formed after the guide grooves (615) are communicated, and a plurality of limit holes (63) which are uniformly distributed along the direction of the guide Kong Qiexian and respectively correspond to the guide grooves (615) are formed in the cover plate (61); the novel steel bar clamping device comprises a steel bar, and is characterized by further comprising a plurality of pin columns (64) which are in sliding fit with the guide grooves (615) and the limiting holes (63), wherein one ends of the pin columns (64) are arranged in the guide grooves (615) and the other ends of the pin columns are arranged in the limiting holes (63), clamping plates (65) are fixed on the outer wall of each pin column (64), clamping parts are arranged on the side wall, opposite to the axis of the guide holes, of each clamping plate (65), the outer wall of each reinforcing member (3) is provided with a plurality of ribs (31), the ribs (31) are distributed in a spiral mode, and a clamping area (67) for clamping the reinforcing member (3) can be formed in a clamping cylinder around the circumference of the through hole;

the clamping part comprises a guide plate (66) in a trapezoid shape, the clamping plate (65) is in an isosceles triangle shape, the bottom edge of the clamping plate (65) is equal in length and is connected with the upper bottom edge of the guide plate (66), a plurality of rollers (613) are obliquely arranged on the end face where the lower bottom edge of the guide plate (66) is located, the inclination angle of the rollers (613) is the same as the rotation direction of a rib (31) of the reinforcing member (3), the pin (64) is rotationally arranged at the position where one waist close to the clamping plate (65) is located, a limiting groove (614) is formed in the end face where the other waist of the clamping plate (65) is located, one end of the limiting groove (614) is open, the other end of the limiting groove (614) is closed, and the open end of the limiting groove (614) extends to the position where the lower bottom edge of the guide plate (66) is located;

the thickness of the guide plate (66) is gradually reduced from the pin (64) to the direction of the axis of the through hole;

in the initial state, in two adjacent clamping plates (65), a roller (613) on one clamping plate (65) can enter the inside of the limiting groove (614) on the other clamping plate (65) along the open end of the limiting groove; the area of a clamping area (67) formed by the surrounding of the lower bottom edges of the guide plates (66) can be used for the rib (31) of the reinforcement (3) to be matched with the roller (613);

still including linkage board (616), it has joint groove to open on the terminal surface that base is located under deflector (66), be equipped with on the lateral wall of linkage board (616) with joint groove complex joint board (619), it has constant head tank (618) that a plurality of slopes set up to open on the other lateral wall of linkage board (616), it has shaft hole (617) to open respectively on the inner wall that constant head tank (618) are relative, be equipped with pivot (620) on two terminal surfaces of roller (613) respectively, and pivot (620) rotate and set up in shaft hole (617), the part of roller (613) outstanding in constant head tank (618).

2. A calibration system for a grouting saturation measuring apparatus according to claim 1, wherein: the outer diameter of the roller (613) decreases in a direction approaching the guide hole along the axis thereof.

3. A calibration system for a grouting saturation measuring apparatus according to claim 2, wherein: an elastic pad (621) is arranged at the bottom of the positioning groove (618), and the inner diameter of the shaft hole (617) is larger than the outer diameter of the rotating shaft (620); in the initial state, the outer wall of the large-diameter section of the roller (613) is in contact with the elastic pad (621), and a gap is reserved between the outer wall of the small-diameter section of the roller (613) and the elastic pad (621).

4. A calibration system for a grouting saturation measuring apparatus according to claim 1, wherein: the support leg comprises a support upper section (69) and a support lower section (68), wherein the support upper section (69) is hinged with the outer wall of the clamping cylinder, a screw rod (610) coaxial with the support upper section (69) is arranged on the lower end face of the support upper section (69), and an inner screw hole matched with the screw rod (610) is formed in the upper end face of the support lower section (68).

5. A calibration system for a grouting saturation measuring apparatus according to claim 4, wherein: a circular pad (611) parallel to the horizontal plane is arranged on the lower end surface of the support lower section (68).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310286234.6A CN115993401B (en) | 2023-03-23 | 2023-03-23 | Calibration system for grouting saturation measuring equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310286234.6A CN115993401B (en) | 2023-03-23 | 2023-03-23 | Calibration system for grouting saturation measuring equipment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115993401A CN115993401A (en) | 2023-04-21 |

| CN115993401B true CN115993401B (en) | 2023-05-30 |

Family

ID=85995312

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310286234.6A Active CN115993401B (en) | 2023-03-23 | 2023-03-23 | Calibration system for grouting saturation measuring equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115993401B (en) |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020135484A1 (en) * | 2018-12-25 | 2020-07-02 | 浙江大学 | Device and method for detecting density of grouts in connecting structure of steel sleeve |

| CN215574516U (en) * | 2021-05-14 | 2022-01-18 | 重庆合信检验认证有限公司 | Concrete permeability detection device |

| CN115047065A (en) * | 2022-01-26 | 2022-09-13 | 福建船政交通职业学院 | Method, device and equipment for correcting impact of knocking force in beating method |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106153448B (en) * | 2016-06-29 | 2019-06-04 | 燕山大学 | A kind of fixture of sheet coupon stretching and cyclic compressive load test |

| CN210375938U (en) * | 2019-08-16 | 2020-04-21 | 辽宁有色勘察研究院有限责任公司 | Direct tensile test device suitable for cultural relic rock tensile strength |

| CN112945718A (en) * | 2019-12-10 | 2021-06-11 | 陈伟清 | Tensile strength detection device for leather production |

| CN110987688B (en) * | 2019-12-24 | 2020-11-13 | 江苏润祁项目管理有限公司 | Surface performance detection device for new material research and development convenient to avoid slippage |

| JP7406429B2 (en) * | 2020-03-27 | 2023-12-27 | 大和ハウス工業株式会社 | Support jig |

| US11326865B2 (en) * | 2020-04-28 | 2022-05-10 | Mitutoyo Corporation | Rotating chromatic range sensor system with calibration objects and method |

| CN111398038B (en) * | 2020-04-29 | 2021-05-14 | 中铁二十局集团有限公司 | Elastic modulus tester |

| CN111766144A (en) * | 2020-06-30 | 2020-10-13 | 扬州市远望橡胶有限公司 | Rubber fender fatigue strength testing arrangement |

| CN111946372B (en) * | 2020-07-06 | 2021-06-18 | 青岛市地铁六号线有限公司 | Grouting device for high-coagulability grouting material |

| CN111983036A (en) * | 2020-09-01 | 2020-11-24 | 覃晓军 | Ultrasonic rebound surveying equipment for road and bridge of civil engineering and application method thereof |

| CN112727102A (en) * | 2021-01-06 | 2021-04-30 | 中国化学工程第十一建设有限公司 | Concrete pouring flow guide device and construction method of sewage treatment water tank |

| CN214843953U (en) * | 2021-06-02 | 2021-11-23 | 青岛捷诺电子有限公司 | Detection device for mobile phone data line |

| CN215375249U (en) * | 2021-06-25 | 2021-12-31 | 郑州大学 | Concrete filled steel tube void detection test piece |

| CN215574208U (en) * | 2021-09-09 | 2022-01-18 | 武汉诚源宏景制管有限公司 | Anti deformation performance detection device of slip casting pipe |

| CN216847204U (en) * | 2021-12-29 | 2022-06-28 | 中国水利水电第十二工程局有限公司 | Experimental positioner of dynamic elasticity modulus |

| CN216695834U (en) * | 2021-12-29 | 2022-06-07 | 南宝树脂(佛山)有限公司 | Semi-automatic tensile testing equipment for laboratory |

| CN114608976A (en) * | 2022-03-05 | 2022-06-10 | 盱眙国联建设工程质量检测有限公司 | Concrete test block strength detection device and detection method |

| CN114425750B (en) * | 2022-04-06 | 2022-06-10 | 四川省公路规划勘察设计研究院有限公司 | Fastening clamp for testing mechanical properties of reinforcing steel bars |

| CN115016034B (en) * | 2022-06-01 | 2022-11-25 | 中国科学院地质与地球物理研究所 | Calibration method of measurement while drilling device |

-

2023

- 2023-03-23 CN CN202310286234.6A patent/CN115993401B/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020135484A1 (en) * | 2018-12-25 | 2020-07-02 | 浙江大学 | Device and method for detecting density of grouts in connecting structure of steel sleeve |

| CN215574516U (en) * | 2021-05-14 | 2022-01-18 | 重庆合信检验认证有限公司 | Concrete permeability detection device |

| CN115047065A (en) * | 2022-01-26 | 2022-09-13 | 福建船政交通职业学院 | Method, device and equipment for correcting impact of knocking force in beating method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115993401A (en) | 2023-04-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110779811B (en) | Rainfall seepage and blasting vibration coupling simulation soft rock shear rheology test system | |

| CN115993401B (en) | Calibration system for grouting saturation measuring equipment | |

| CN108871893B (en) | Method for preparing soil body by soil body preparation device for on-site soil body direct shear test | |

| CN211505032U (en) | Building engineering concrete structure intensity detection device | |

| CN115855375B (en) | Water conservancy foundation leakage detection positioning device and application method thereof | |

| CN219284847U (en) | Boiler pipeline joint water pressure test fixture | |

| CN106017398A (en) | Cylinder coaxiality automatic detection machine with controllable compacting force | |

| CN216410120U (en) | Mounting device of multipoint displacement meter | |

| CN117029751A (en) | Engineering detection device for pile foundation hole fixed-point monitoring | |

| CN212358401U (en) | Sediment thickness detection device before bored concrete pile becomes stake | |

| CN215574223U (en) | High-adaptation type clamp for concrete pressure testing machine | |

| CN209513484U (en) | A kind of build concrete metope hardness tester | |

| CN220433751U (en) | Be used for leading oblique throwing to prop limit bearing capacity detection device | |

| CN220854473U (en) | Simple rigid confining pressure device suitable for common pressure testing machine | |

| CN219221991U (en) | Bridge water level detector | |

| CN207623143U (en) | The intelligent experimental rig that a kind of detection soil body horizontal direction tension is split | |

| CN211697433U (en) | Inverted sample preparation device for measuring adhesion between special curved surface and soil interface | |

| CN113155382A (en) | Movable bridge deflection detection device | |

| CN221124066U (en) | FRP stock tensile testing arrangement | |

| CN220058119U (en) | Pile end foundation detection frame | |

| CN214538912U (en) | Mortar strength detector for supervision | |

| CN216900041U (en) | Concrete strength detection device for railway construction | |

| CN214121104U (en) | Building ground beam template size measuring device | |

| CN221523507U (en) | Geotechnical engineering inclinometer pipe | |

| CN113075024B (en) | Explosion test system for porous digital dynamic caustic test |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |