CN115637147A - Light-emitting material and light-emitting device - Google Patents

Light-emitting material and light-emitting device Download PDFInfo

- Publication number

- CN115637147A CN115637147A CN202211326602.7A CN202211326602A CN115637147A CN 115637147 A CN115637147 A CN 115637147A CN 202211326602 A CN202211326602 A CN 202211326602A CN 115637147 A CN115637147 A CN 115637147A

- Authority

- CN

- China

- Prior art keywords

- compound

- light

- substituted

- formula

- unsubstituted

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000463 material Substances 0.000 title claims abstract description 142

- 150000001875 compounds Chemical class 0.000 claims abstract description 106

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 30

- 229910052739 hydrogen Inorganic materials 0.000 claims description 30

- 239000001257 hydrogen Substances 0.000 claims description 30

- 229910052805 deuterium Inorganic materials 0.000 claims description 29

- YZCKVEUIGOORGS-OUBTZVSYSA-N Deuterium Chemical compound [2H] YZCKVEUIGOORGS-OUBTZVSYSA-N 0.000 claims description 24

- 150000002431 hydrogen Chemical class 0.000 claims description 24

- 125000001072 heteroaryl group Chemical group 0.000 claims description 23

- 125000003118 aryl group Chemical group 0.000 claims description 16

- 229910052757 nitrogen Inorganic materials 0.000 claims description 15

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 claims description 15

- 125000004093 cyano group Chemical group *C#N 0.000 claims description 14

- 239000002019 doping agent Substances 0.000 claims description 12

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 claims description 11

- 229910052731 fluorine Inorganic materials 0.000 claims description 11

- 239000011737 fluorine Substances 0.000 claims description 11

- 230000005525 hole transport Effects 0.000 claims description 11

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 10

- 229910052799 carbon Inorganic materials 0.000 claims description 10

- 125000000217 alkyl group Chemical group 0.000 claims description 8

- -1 cyano, methyl Chemical group 0.000 claims description 8

- 125000005259 triarylamine group Chemical group 0.000 claims description 8

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 6

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 claims description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 5

- 125000001624 naphthyl group Chemical group 0.000 claims description 5

- 239000001301 oxygen Substances 0.000 claims description 5

- 229910052760 oxygen Inorganic materials 0.000 claims description 5

- 229910052717 sulfur Inorganic materials 0.000 claims description 5

- 239000011593 sulfur Substances 0.000 claims description 5

- 125000006755 (C2-C20) alkyl group Chemical group 0.000 claims description 4

- 125000006736 (C6-C20) aryl group Chemical group 0.000 claims description 4

- IEQIEDJGQAUEQZ-UHFFFAOYSA-N phthalocyanine Chemical group N1C(N=C2C3=CC=CC=C3C(N=C3C4=CC=CC=C4C(=N4)N3)=N2)=C(C=CC=C2)C2=C1N=C1C2=CC=CC=C2C4=N1 IEQIEDJGQAUEQZ-UHFFFAOYSA-N 0.000 claims description 4

- 125000006835 (C6-C20) arylene group Chemical group 0.000 claims description 3

- 125000003785 benzimidazolyl group Chemical class N1=C(NC2=C1C=CC=C2)* 0.000 claims description 3

- LKKPNUDVOYAOBB-UHFFFAOYSA-N naphthalocyanine Chemical class N1C(N=C2C3=CC4=CC=CC=C4C=C3C(N=C3C4=CC5=CC=CC=C5C=C4C(=N4)N3)=N2)=C(C=C2C(C=CC=C2)=C2)C2=C1N=C1C2=CC3=CC=CC=C3C=C2C4=N1 LKKPNUDVOYAOBB-UHFFFAOYSA-N 0.000 claims description 3

- 150000004866 oxadiazoles Chemical class 0.000 claims description 3

- 150000004033 porphyrin derivatives Chemical class 0.000 claims description 3

- 125000001567 quinoxalinyl group Chemical class N1=C(C=NC2=CC=CC=C12)* 0.000 claims description 3

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 18

- 238000002347 injection Methods 0.000 description 16

- 239000007924 injection Substances 0.000 description 16

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 15

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 12

- 230000000903 blocking effect Effects 0.000 description 10

- 238000006243 chemical reaction Methods 0.000 description 9

- 230000015572 biosynthetic process Effects 0.000 description 8

- 238000003786 synthesis reaction Methods 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 7

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 6

- MVPPADPHJFYWMZ-UHFFFAOYSA-N chlorobenzene Chemical compound ClC1=CC=CC=C1 MVPPADPHJFYWMZ-UHFFFAOYSA-N 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 229910000027 potassium carbonate Inorganic materials 0.000 description 6

- 239000007787 solid Substances 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000001308 synthesis method Methods 0.000 description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 4

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N diphenyl Chemical compound C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 4

- 239000011541 reaction mixture Substances 0.000 description 4

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 239000012300 argon atmosphere Substances 0.000 description 3

- 239000011575 calcium Substances 0.000 description 3

- 239000012043 crude product Substances 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 230000002035 prolonged effect Effects 0.000 description 3

- UWRZIZXBOLBCON-VOTSOKGWSA-N (e)-2-phenylethenamine Chemical compound N\C=C\C1=CC=CC=C1 UWRZIZXBOLBCON-VOTSOKGWSA-N 0.000 description 2

- QENGPZGAWFQWCZ-UHFFFAOYSA-N 3-Methylthiophene Chemical compound CC=1C=CSC=1 QENGPZGAWFQWCZ-UHFFFAOYSA-N 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- YTPLMLYBLZKORZ-UHFFFAOYSA-N Thiophene Chemical compound C=1C=CSC=1 YTPLMLYBLZKORZ-UHFFFAOYSA-N 0.000 description 2

- 229940058303 antinematodal benzimidazole derivative Drugs 0.000 description 2

- HFACYLZERDEVSX-UHFFFAOYSA-N benzidine Chemical compound C1=CC(N)=CC=C1C1=CC=C(N)C=C1 HFACYLZERDEVSX-UHFFFAOYSA-N 0.000 description 2

- 235000010290 biphenyl Nutrition 0.000 description 2

- 239000004305 biphenyl Substances 0.000 description 2

- 125000000609 carbazolyl group Chemical group C1(=CC=CC=2C3=CC=CC=C3NC12)* 0.000 description 2

- 238000004440 column chromatography Methods 0.000 description 2

- 150000004985 diamines Chemical class 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 238000004128 high performance liquid chromatography Methods 0.000 description 2

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 2

- VVVPGLRKXQSQSZ-UHFFFAOYSA-N indolo[3,2-c]carbazole Chemical compound C1=CC=CC2=NC3=C4C5=CC=CC=C5N=C4C=CC3=C21 VVVPGLRKXQSQSZ-UHFFFAOYSA-N 0.000 description 2

- 229960005544 indolocarbazole Drugs 0.000 description 2

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 125000002827 triflate group Chemical group FC(S(=O)(=O)O*)(F)F 0.000 description 2

- 239000011787 zinc oxide Substances 0.000 description 2

- GLGNXYJARSMNGJ-VKTIVEEGSA-N (1s,2s,3r,4r)-3-[[5-chloro-2-[(1-ethyl-6-methoxy-2-oxo-4,5-dihydro-3h-1-benzazepin-7-yl)amino]pyrimidin-4-yl]amino]bicyclo[2.2.1]hept-5-ene-2-carboxamide Chemical compound CCN1C(=O)CCCC2=C(OC)C(NC=3N=C(C(=CN=3)Cl)N[C@H]3[C@H]([C@@]4([H])C[C@@]3(C=C4)[H])C(N)=O)=CC=C21 GLGNXYJARSMNGJ-VKTIVEEGSA-N 0.000 description 1

- BCKWPWFSMVGPRC-UHFFFAOYSA-N 2-bromo-3-phenylpyridine Chemical class BrC1=NC=CC=C1C1=CC=CC=C1 BCKWPWFSMVGPRC-UHFFFAOYSA-N 0.000 description 1

- CRJISNQTZDMKQD-UHFFFAOYSA-N 2-bromodibenzofuran Chemical compound C1=CC=C2C3=CC(Br)=CC=C3OC2=C1 CRJISNQTZDMKQD-UHFFFAOYSA-N 0.000 description 1

- NMWSKOLWZZWHPL-UHFFFAOYSA-N 3-chlorobiphenyl Chemical compound ClC1=CC=CC(C=2C=CC=CC=2)=C1 NMWSKOLWZZWHPL-UHFFFAOYSA-N 0.000 description 1

- GILHQTJWHIURJL-UHFFFAOYSA-N 9h-carbazol-2-ylboronic acid Chemical compound C1=CC=C2C3=CC=C(B(O)O)C=C3NC2=C1 GILHQTJWHIURJL-UHFFFAOYSA-N 0.000 description 1

- 229910016036 BaF 2 Inorganic materials 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 241000284156 Clerodendrum quadriloculare Species 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910052688 Gadolinium Inorganic materials 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 229910019015 Mg-Ag Inorganic materials 0.000 description 1

- 101100030361 Neurospora crassa (strain ATCC 24698 / 74-OR23-1A / CBS 708.71 / DSM 1257 / FGSC 987) pph-3 gene Proteins 0.000 description 1

- 229920001609 Poly(3,4-ethylenedioxythiophene) Polymers 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- YZCKVEUIGOORGS-IGMARMGPSA-N Protium Chemical compound [1H] YZCKVEUIGOORGS-IGMARMGPSA-N 0.000 description 1

- 241000720974 Protium Species 0.000 description 1

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical group C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229910006404 SnO 2 Inorganic materials 0.000 description 1

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 1

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Natural products C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- 229910001508 alkali metal halide Inorganic materials 0.000 description 1

- 150000008045 alkali metal halides Chemical class 0.000 description 1

- 229910052977 alkali metal sulfide Inorganic materials 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 239000011651 chromium Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 229940125758 compound 15 Drugs 0.000 description 1

- 229920001940 conductive polymer Polymers 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- UIWYJDYFSGRHKR-UHFFFAOYSA-N gadolinium atom Chemical compound [Gd] UIWYJDYFSGRHKR-UHFFFAOYSA-N 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- ACGUYXCXAPNIKK-UHFFFAOYSA-N hexachlorophene Chemical compound OC1=C(Cl)C=C(Cl)C(Cl)=C1CC1=C(O)C(Cl)=CC(Cl)=C1Cl ACGUYXCXAPNIKK-UHFFFAOYSA-N 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- GKOZUEZYRPOHIO-UHFFFAOYSA-N iridium atom Chemical compound [Ir] GKOZUEZYRPOHIO-UHFFFAOYSA-N 0.000 description 1

- 229910052747 lanthanoid Inorganic materials 0.000 description 1

- 150000002602 lanthanoids Chemical group 0.000 description 1

- 239000011133 lead Substances 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 238000004020 luminiscence type Methods 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- KDLHZDBZIXYQEI-UHFFFAOYSA-N palladium Substances [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920000767 polyaniline Polymers 0.000 description 1

- 229920000128 polypyrrole Polymers 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- TYJJADVDDVDEDZ-UHFFFAOYSA-M potassium hydrogencarbonate Chemical compound [K+].OC([O-])=O TYJJADVDDVDEDZ-UHFFFAOYSA-M 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 230000000171 quenching effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000010898 silica gel chromatography Methods 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910052938 sodium sulfate Inorganic materials 0.000 description 1

- 235000011152 sodium sulphate Nutrition 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 125000001424 substituent group Chemical group 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229930192474 thiophene Natural products 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

- 239000011135 tin Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

- GPPXJZIENCGNKB-UHFFFAOYSA-N vanadium Chemical compound [V]#[V] GPPXJZIENCGNKB-UHFFFAOYSA-N 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 229910052727 yttrium Inorganic materials 0.000 description 1

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- YVTHLONGBIQYBO-UHFFFAOYSA-N zinc indium(3+) oxygen(2-) Chemical compound [O--].[Zn++].[In+3] YVTHLONGBIQYBO-UHFFFAOYSA-N 0.000 description 1

Images

Landscapes

- Electroluminescent Light Sources (AREA)

Abstract

The present disclosure provides a light emitting material and a light emitting device. The luminescent material comprises a host material and a doping material, wherein the doping material comprises a compound with a structural formula shown as a formula 1 or a formula 2. The present disclosure can improve the life span of the light emitting device.

Description

Technical Field

The present disclosure relates to the field of display technologies, and in particular, to a light emitting material and a light emitting device.

Background

With the improvement of living standard, the OLED light emitting device attracts more and more attention. The OLED light-emitting device has a series of advantages of all-solid-state structure, self luminescence, high response speed, high brightness, full viewing angle, flexible display and the like. The QLED light-emitting device has the advantages of narrow light-emitting spectrum, adjustable light-emitting wavelength and the like. However, the lifetime of current light emitting devices is low.

Disclosure of Invention

An object of the present disclosure is to provide a light emitting material and a light emitting device, which can improve the lifetime of the light emitting device.

According to an aspect of the present disclosure, there is provided a light emitting material including a host material and a dopant material including a compound having a structural formula shown in formula 1 or formula 2:

wherein, X 1 Selected from oxygen, sulfur, nitrogen, and carbon;

R 1 -R 8 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl and substituted or unsubstituted heteroaryl, wherein R is 1 -R 6 At least one of which is not hydrogen;

ring A is phenyl, naphthyl and nitrogen-containing heteroaryl;

Ar 1 、Ar 2 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl and substituted or unsubstituted heteroaryl, wherein Ar is 1 And Ar 2 At least one of which is deuterium substituted aryl or heteroaryl.

further, the dopant material includes a compound having the following structural formula:

further, the deuterated compound of the structural formula shown in the formula 1 or the formula 2 has a deuterated proportion of 8-20%.

Further, the host material includes an N-type material and a P-type material, and the N-type material includes a compound having a structural formula shown in formula 3 or formula 4:

wherein, X 2 、X 3 Selected from nitrogen and carbon;

Y 1 -Y 3 each independently selected from nitrogen and carbon, and Y 1 -Y 3 At least one of which is nitrogen;

Ar 3 -Ar 7 each independently selected from hydrogen, deuterium, a C6 to C20 substituted or unsubstituted aryl group and a C5 to C20 substituted or unsubstituted heteroaryl group, wherein Ar 3 -Ar 7 At least one of which is deuterium substituted phenyl;

L 1 、L 2 each independently selected from a single bond and a C6 to C30 aryl or heteroaryl group.

further, the N-type material comprises a compound having the following structural formula:

further, the deuterated compound of the structural formula shown in the formula 3 or the formula 4 has a deuterated proportion of 5-30%.

Further, the deuteration ratio in the doping material and the main body material is more than or equal to 3%.

Further, the host material includes an N-type material and a P-type material, and the P-type material includes a compound having a structural formula shown in formula 5:

wherein L is 3 、L 4 Selected from the group consisting of a single bond, C6-C20 arylene, and C5-C20 heteroarylene;

Ar 8 -Ar 10 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted C2-C20 alkyl, substituted or unsubstituted C6-C20 aryl, and substituted or unsubstituted C5-C30 heteroaryl.

Further, the P-type material comprises a compound having the following structural formula:

according to an aspect of the present disclosure, there is provided a light emitting device including:

an anode and a cathode disposed opposite to each other;

a light-emitting layer disposed between the anode and the cathode, the light-emitting layer comprising the light-emitting material;

a hole transport layer disposed between the anode and the light emitting layer;

and the electron transport layer is arranged between the cathode and the light-emitting layer.

Further, the material of the hole transport layer is selected from phthalocyanine derivatives, naphthalocyanine derivatives, porphyrin derivatives, benzidine type triarylamine, styrylamine type triarylamine, and diamine type triarylamine.

Further, the material of the electron transport layer is selected from benzimidazole derivatives, oxadiazole derivatives and quinoxaline derivatives.

Light-emitting material and light-emitting device of the present disclosure, ar 1 And Ar 2 At least one of the two is deuterium substituted aryl or heteroaryl, so that the stability of the material can be improved, and the service life of the device can be prolonged.

Drawings

Fig. 1 is a schematic view of a light emitting device of an embodiment of the present disclosure.

Description of the reference numerals: 1. an anode; 2. a hole injection layer; 3. a hole transport layer; 4. an electron blocking layer; 5. a light emitting layer; 6. a hole blocking layer; 7. an electron transport layer; 8. an electron injection layer; 9. and a cathode.

Detailed Description

Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, like numbers in different drawings represent the same or similar elements unless otherwise indicated. The embodiments described in the following exemplary embodiments do not represent all embodiments consistent with the present disclosure. Rather, they are merely examples of devices consistent with certain aspects of the present disclosure, as detailed in the appended claims.

The terminology used in the present disclosure is for the purpose of describing particular embodiments only and is not intended to be limiting of the disclosure. Unless otherwise defined, technical or scientific terms used herein should have the same meaning as commonly understood by one of ordinary skill in the art to which this disclosure belongs. The use of "first," "second," and similar terms in the description and claims does not indicate any order, quantity, or importance, but rather is used to distinguish one element from another. Also, the use of the terms "a" or "an" and the like do not denote a limitation of quantity, but rather denote the presence of at least one. "plurality" or "a number" means two or more. Unless otherwise indicated, "front", "rear", "lower" and/or "upper" and the like are for convenience of description and are not limited to one position or one spatial orientation. The word "comprising" or "comprises", and the like, means that the element or item listed as preceding "comprising" or "includes" covers the element or item listed as following "comprising" or "includes" and its equivalents, and does not exclude other elements or items. As used in this disclosure and the appended claims, the singular forms "a", "an", and "the" are intended to include the plural forms as well, unless the context clearly indicates otherwise. It should also be understood that the term "and/or" as used herein refers to and encompasses any and all possible combinations of one or more of the associated listed items.

In the related art, an OLED light emitting device capable of emitting green light includes a light emitting layer including a host material and a dopant material. The doping material adopts a phosphorescence doping material, and can reach 100% of exciton utilization rate. However, phosphorescence may result in quenching due to long lifetime of triplet excitons, resulting in lower device lifetime, which in turn leads to lower lifetime of light emitting devices.

The disclosed embodiments provide a luminescent material. The luminescent material may include a host material and a dopant material. The host material may include an N-type material and a P-type material. The N-type material is an electron transport main body material, and the P-type material is a hole transport main body material. The doping material may include a compound having a structural formula shown in formula 1 or formula 2:

wherein, X 1 Selected from oxygen, sulfur, nitrogen, and carbon; r 1 、R 2 、R 3 、R 4 、R 5 、R 6 、R 7 、R 8 Each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl, and substituted or unsubstituted heteroaryl; wherein R is 1 、R 2 、R 3 、R 4 、R 5 、R 6 At least one of which is not hydrogen; ring A is phenyl, naphthyl and nitrogen-containing heteroaryl; ar (Ar) 1 、Ar 2 Each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl and substituted or unsubstituted heteroaryl, wherein Ar is 1 And Ar 2 At least one of which is deuterium substituted aryl or heteroaryl.

Luminescent Material of embodiments of the present disclosure, ar 1 And Ar 2 At least one of the two is deuterium-substituted aryl or heteroaryl, so that molecular vibration can be reduced, the stability of the material can be improved, and the service life of the device can be prolonged.

The following describes the luminescent material of the embodiments of the present disclosure in detail:

X 1 selected from oxygen, sulfur, nitrogen, and carbon. For example, the X 1 Is oxygen or sulfur.

R 1 、R 2 、R 3 、R 4 、R 5 、R 6 、R 7 、R 8 Each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl, and substituted or unsubstituted heteroaryl. Herein, hydrogen may also be referred to as "protium", and deuterium is an isotope of hydrogen. The substituted or unsubstituted aryl group may be phenyl, biphenyl, naphthyl, or the like. R is 1 、R 2 、R 3 、R 4 、R 5 、R 6 、R 7 、R 8 May be identical to each other or, of course, may be different from each other. Furthermore, R 1 、R 2 、R 3 、R 4 、R 5 、R 6 At least one of which is not hydrogen. Further, R 1 、R 2 、R 3 、R 4 、R 5 、R 6 、R 7 、R 8 Each independently selected from hydrogen, cyano, methyl, phenyl and

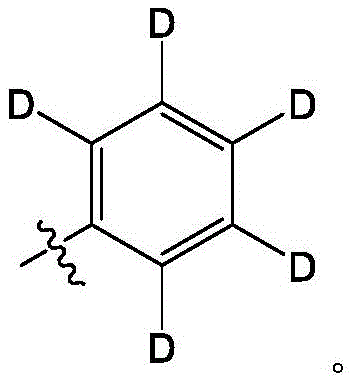

Ar 1 、Ar 2 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl, and substituted or unsubstituted heteroaryl. The substituted or unsubstituted aryl group may be phenyl, biphenyl, naphthyl, or the like. Ar (Ar) 1 、Ar 2 May be identical to each other or, of course, may be different from each other. Wherein Ar is 1 And Ar 2 At least one of which is deuterium substituted aryl or heteroaryl. Further, ar 1 、Ar 2 Each independently selected from hydrogen, cyano andsaidThe "D" in (A) is deuterium as described above.

The deuteration ratio in the compound of the structural formula shown in formula 1 or formula 2 may be 8% to 20%, for example, 8%, 10%, 13%, 16%, 20%, etc.

For example, the dopant material may include a compound having the following structural formula:

the compound having the structure shown in the formula 1 can be a compound G-13, a compound G-14, a compound G-15, a compound G-16 or a compound G-17. The compound having a structure represented by formula 2 may be compound G-1, compound G-2, compound G-3, compound G-4, compound G-5, compound G-6, compound G-7, compound G-8, compound G-9, compound G-10, compound G-11, compound G-12, compound G-18, compound G-19 or compound G-20.

Synthesis method of compound G-1

(1) Synthesis of intermediate G1c

Compound G1a (3-cyano-dibenzofuran-8-ylboronic acid) (12.7g, 60mmol) and compound G1b (4-deuterated phenyl-2-bromopyridine) (10.6G, 60mmol) were added to the flask over catalyst Pd (PPh 3) 4 (0.7g, 0.6 mmol) and K 2 CO 3 (25g, 200mmol) and degassed with nitrogen. The reaction mixture was heated to reflux for 15 hours and then cooled to room temperature. Extracted with dichloromethane and dried over sodium sulfate. After removal of the solvent, the crude product was purified by column chromatography using dichloromethane to yield 13.4g of crude product. The crude product was crystallized from hexane to give 12.1G (73% yield) of pure product (intermediate G1 c). The product was confirmed by NMR and HPLC (purity 99.1%).

(2) Synthesis of Compound G-1

Intermediate G1c (12.1g, 40mmol), compound G1d (iridium complex, OTf on the right represents triflate) (39.1g, 40mmol) and 1500ml ethanol were added to the flask and heated to reflux under nitrogen for 24h. After the reaction was cooled, it was filtered through celite. Purification by column chromatography gave compound 15 as a pale yellow solid (9.7g, 24.3% yield). The product was confirmed by NMR and HPLC (purity 99.2%).

In addition, the doping material may be a phosphorescent material. Further, the doped material is a green phosphorescent material. The phosphorescent material may be a phosphorescent electroluminescent material.

The above-mentioned N-type material may include a compound having a structural formula shown in formula 3 or formula 4:

wherein, X 2 、X 3 Selected from nitrogen and carbon. Y is 1 、Y 2 、Y 3 Each independently selected from nitrogen and carbon, and Y 1 、Y 2 、Y 3 At least one of which is nitrogen. L is 1 、L 2 Each independently selected from a single bond and a C6 to C30 aryl or heteroaryl group. Ar (Ar) 3 -Ar 7 Each independently selected from hydrogen, deuterium, a C6 to C20 substituted or unsubstituted aryl group and a C5 to C20 substituted or unsubstituted heteroaryl group, wherein Ar 3 -Ar 7 At least one of which is deuterium substituted phenyl. Further, ar 3 -Ar 7 Each independently selected from hydrogen, deuterium, phenyl andthe N-type material contains azine units and is due to Ar 3 -Ar 7 At least one of the two is deuterium substituted phenyl, so that the stability of the material can be improved, and the service life of the device can be prolonged.

In addition, the deuterated ratio in the compound of the structural formula shown in formula 3 or formula 4 is 5% to 30%, for example, 5%, 10%, 18%, 20%, 23%, 27%, 30%, and the like.

For example, the N-type material includes a compound having the following structural formula:

the compound with the structure shown in the formula 3 can be a compound N-2, a compound N-5, a compound N-9, a compound N-10, a compound N-11, a compound N-12, a compound N-13, a compound N-14, a compound N-15, a compound N-16, a compound N-17 or a compound N-18. The compound with the structure shown in the formula 4 can be a compound N-1, a compound N-3, a compound N-4, a compound N-6, a compound N-7 or a compound N-8.

Synthesis method of compound N-1

(1) Synthesis of intermediate N-1c

Under an argon atmosphere, the compound N-1a [ indolocarbazole (8.7 g,20 mmol) ], chlorobenzene (5.0 g,20 mmol), and potassium carbonate (5.3 g, 30 mmol) were added to dimethylformamide (45 mL), and the reaction was stirred at 100 ℃ for 8 hours. Water was added to the reaction solution to precipitate a solid, which was washed with methanol to obtain intermediate N-1c (9.3 g, yield 86%).

(2) Synthesis of Compound N-1

Intermediate N-1c (9.3 g, 15 mmol), compound N-1d (7.4 g, 15 mmol) and potassium carbonate (3.8 g,24 mmol) were added to dimethylformamide (50 mL) and the reaction was heated and stirred at 100 ℃ for 8 hours. Water was added to the reaction mixture to precipitate a solid, which was washed with methanol to obtain Compound N-1 (10.1 g, yield 83%, purity 96.3%).

Synthesis method of compound N-2

(1) Synthesis of intermediate N-2c

Under an argon atmosphere, compound N-2a (indolocarbazole (8.7 g,20 mmol)), chlorobenzene (5.0 g,20 mmol), and potassium carbonate (5.3 g, 30 mmol) were added to dimethylformamide (45 mL), and the reaction was stirred with heating at 100 ℃. Intermediate N-2c (9.4 g, yield 87%) was obtained.

(2) Synthesis of Compound N-2

Intermediate N-2c (9.4 g, 15 mmol), compound N-2d (7.4 g, 15 mmol) and potassium carbonate (3.8 g,24 mmol) were added to dimethylformamide (50 mL) and the reaction was heated and stirred at 100 ℃ for 8 hours. Water was added to the reaction solution to precipitate a solid, which was washed with methanol to obtain Compound N-2 (9.8 g, yield 81%, purity 95.9%).

The P-type material may include a compound having a structural formula as shown in formula 5:

wherein L is 3 、L 4 Selected from the group consisting of a single bond, C6-C20 arylene, and C5-C20 heteroarylene;

Ar 8 -Ar 10 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted C2-C20 alkyl, substituted or unsubstituted C6-C20 aryl, and substituted or unsubstituted C5-C30 heteroaryl.

Further, ar10 may be a substituted or unsubstituted carbazolyl group and a substituted or unsubstituted dibenzofuranyl group.

Wherein Ar is 8 -Ar 10 When present, the substituent may be selected from hydrogen, deuterium, C2-C20 alkyl, C6-C20 aryl, and C5-C20 heteroaryl.

The P-type material contains a carbazole structure, can increase hole injection, can improve hole-electron balance, and further improves efficiency and device service life.

For example, the P-type material may include a compound having the following structural formula:

in the light emitting material, the ratio of the amount of the substance of the P-type material to the amount of the substance of the N-type material may be 7/3 to 3/7, but the present disclosure is not limited thereto. In addition, the mass ratio of the dopant material to the host material may be 8/92 to 12/88. In addition, the deuterated ratio in the doped material and the host material can be greater than or equal to 3%, such as 3%, 5%, 6%, and the like, so as to improve the stability of the luminescent material.

Synthesis method of compound P-1

Chlorobenzene (5.3 g,24 mmol), the compound P-1c (9.6 g, 12 mmol), and potassium carbonate (3.8 g,20 mmol) were added to dimethylformamide (40 mL), and the reaction was stirred at 100 ℃ for 8 hours. Water was added to the reaction mixture to precipitate a solid, which was washed with methanol to obtain Compound P-1 (8.5 g, yield 85%, purity 96.2%).

Synthesis method of compound P-2

(1) Synthesis of intermediate P-2c

Under an argon atmosphere, a compound P-2a (9H-carbazole-2-boronic acid (7 g,20 mmol)), a compound P-2b (2-bromodibenzofuran (5.4 g,20 mmol)), tetrakis (triphenylphosphine) palladium (0.21 g, 0.2 mmol), and an aqueous potassium carbonate solution (20 mL) were added to toluene (50 mL), and the mixture was heated and stirred at 80 ℃ for 8 hours. The sample obtained after separation and filtration was purified by silica gel column chromatography to obtain intermediate P-2c (9.9 g, yield 75%).

(2) Synthesis of Compound P-2

1-phenyl-3-chlorobenzene (7.9 g,24 mmol), intermediate P-2c (9.9 g, 12 mmol), and potassium carbonate (3.8 g,20 mmol) were added to dimethylformamide (40 mL), and the reaction was stirred at 100 ℃ for 8 hours. Water was added to the reaction mixture to precipitate a solid, which was washed with methanol to obtain Compound P-2 (8.3 g, yield 83%, purity 95.4%).

The disclosed embodiments also provide a light emitting device. As shown in fig. 1, the light emitting device may include an anode 1, a cathode 9, and a light emitting layer 5, wherein:

the anode 1 and the cathode 9 are disposed opposite to each other. The light-emitting layer 5 is provided between the anode 1 and the cathode 9. The light-emitting layer 5 contains the light-emitting material described in any of the above embodiments.

The luminescent material contained in the luminescent device of the embodiment of the present disclosure is the same as the luminescent material in the embodiment of the luminescent material, and therefore, the luminescent device has the same beneficial effects, and the details of the present disclosure are not repeated herein.

The anode 1 may include a material having a large work function. Specific examples of the anode 1 material include: metals such as nickel, platinum, vanadium, chromium, copper, zinc and gold or alloys thereof; metal oxides such as zinc oxide, indium Tin Oxide (ITO), and Indium Zinc Oxide (IZO); combined metals and oxides, e.g. ZnO: al or SnO 2 Sb; or a conductive polymer such as poly (3-methylthiophene), poly [3,4- (ethylene-1,2-dioxy) thiophene](PEDT), polypyrrole and polyaniline, but are not limited thereto. Indium Tin Oxide (ITO) is preferred as the anode 1.

The cathode 9 may comprise a material having a small work function. Specific examples of the material of the cathode 9 include: metals such as magnesium, calcium, sodium, potassium, titanium, indium, yttrium, lithium,Gadolinium, aluminum, silver, tin, and lead or alloys thereof; or a multilayer material such as LiF/Al, liq/Al, liO 2 Al, liF/Ca, liF/Al and BaF 2 But not limited thereto,/Ca. A metal electrode comprising an Mg-Ag alloy is preferably included as the cathode 9.

The light emitting device may further include a hole injection layer 2 and a hole transport layer 3. The hole injection layer 2 may be provided between the anode 1 and the light emitting layer 5, and the hole transport layer 3 may be provided between the hole injection layer 2 and the light emitting layer 5. In addition, the light emitting device may further include an electron blocking layer 4. The electron blocking layer 4 may be provided between the hole transport layer 3 and the light emitting layer 5. The material of the hole transport layer 3 may be selected from phthalocyanine derivatives, naphthalocyanine derivatives, porphyrin derivatives, benzidine triarylamine, styrylamine and diamine triarylamine. The material of the hole injection layer 2 may be selected from benzidine derivatives, starburst arylamine compounds, phthalocyanine derivatives, and polyazatriphenylene compounds. The material of the electron blocking layer 4 may be selected from diamine type triarylamine and styrene amine type triarylamine.

Further, the light emitting device may further include an electron injection layer 8, an electron transport layer 7, and a hole blocking layer 6. The electron injection layer 8 may be disposed between the cathode 9 and the light emitting layer 5, the electron transport layer 7 may be disposed between the electron injection layer 8 and the light emitting layer 5, and the hole blocking layer 6 may be disposed between the electron transport layer 7 and the light emitting layer 5. The material of the electron transport layer 7 may be selected from benzimidazole derivatives, oxadiazole derivatives, and quinoxaline derivatives. The material of the electron injection layer 8 may be selected from alkali metal sulfides and alkali metal halides.

Examples of the production of the light-emitting device of this embodiment mode are given below.

Example 1

Cleaning and drying an ITO substrate prepared in advance, wherein the glass plate with the ITO is used as an anode of a light-emitting device; a hole injection layer, a hole transport layer, an electron blocking layer, a light emitting layer, a hole blocking layer, an electron transport layer, an electron injection layer, a cathode, and a light extraction layer (CPL) are sequentially deposited on one side of the anode by vapor deposition. The thickness of the hole injection layer was 10nm, and the material thereof was compound M1 in table 1. The thickness of the hole transport layer was 110nm, and the material thereof was compound M2 in table 1. The thickness of the electron blocking layer was 30nm, and the material thereof was compound M6 in table 1. The thickness of the hole-blocking layer was 5nm, and the material thereof was compound M3 in table 1. The thickness of the electron transport layer is 30nm, the materials of the electron transport layer comprise a Liq material and a compound M4 in the table 1, and the rate ratio of the Liq material to the compound M4 in the evaporation process is 1:1. The thickness of the electron injection layer is 1nm, and the material of the electron injection layer is lanthanide metal Yb. The light extraction layer had a thickness of 65nm and the material was compound M5 in Table 1. The cathode is an MgAg electrode, and the thickness of the cathode is 13nm. The thickness of the light-emitting layer was 35nm. The P-type material in the main material of the luminescent layer is the compound P-1; the N-type material in the main material of the luminescent layer is the compound N-2; the doping material of the light-emitting layer is the compound G-1, and the mass ratio of the host material to the guest material is 92/8.

TABLE 1

Example 2

A light-emitting device was fabricated by the same fabrication method as in example 1, except that the dopant material was formed of the above-described compound G-16.

Comparative example 1

A light emitting device was manufactured using the same manufacturing method as example 1 except that the doping material was formed of the compound M9 in table 2 below.

Comparative example 2

A light emitting device was manufactured using the same manufacturing method as example 1 except that the N-type material in the host material was formed of the compound M7 in the following table 2.

Comparative example 3

A light emitting device was fabricated by the same fabrication method as example 1, except that the N-type material in the host material was formed of the compound M7 in the following table 2, the P-type material in the host material was formed of the compound M8, and the dopant material was formed of the above-described compound M9.

TABLE 2

The performance of the prepared light emitting device was tested by the present disclosure, and the results are shown in table 3.

TABLE 3

| Device with a metal layer | Luminescent layer material | voltage/V | Efficiency/cd/cm 2 | Life/h |

| Example 1 | P-1:N-2:G-1 | 100% | 106% | 141% |

| Example 2 | P-1:N-2:G-16 | 100% | 106% | 135% |

| Comparative example 1 | P-1:N-2:M9 | 100% | 102% | 121% |

| Comparative example 2 | P-1:M7:G-1 | 100% | 104% | 113% |

| Comparative example 3 | M8:M7:M9 | 100% | 100% | 100% |

In table 3, the voltage, efficiency and life data were set to 100% with the data of comparative example 3 as a reference. It is understood that the efficiency and lifetime of the light emitting device of the present embodiment are improved.

Although the present disclosure has been described with reference to preferred embodiments, it will be understood by those skilled in the art that various changes may be made and equivalents may be substituted for elements thereof without departing from the scope of the present disclosure.

Claims (15)

1. A light-emitting material comprising a host material and a dopant material, wherein the dopant material comprises a compound having a structural formula shown in formula 1 or formula 2:

wherein, X 1 Selected from oxygen, sulfur, nitrogen, and carbon;

R 1 -R 8 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl and substituted or unsubstituted heteroaryl, wherein R is 1 -R 6 At least one of which is not hydrogen;

ring A is phenyl, naphthyl and nitrogen-containing heteroaryl;

Ar 1 、Ar 2 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted alkyl, substituted or unsubstituted aryl and substituted or unsubstituted heteroaryl, wherein Ar is 1 And Ar 2 At least one of which is deuterium substituted aryl or heteroaryl.

5. the light-emitting material according to claim 1, wherein the compound of the structural formula represented by formula 1 or formula 2 has a deuteration ratio of 8% to 20%.

6. The luminescent material according to claim 1, wherein the host material comprises an N-type material and a P-type material, and the N-type material comprises a compound having a structural formula shown in formula 3 or formula 4:

wherein, X 2 、X 3 Selected from nitrogen and carbon;

Y 1 -Y 3 each independently selected from nitrogen and carbon, and Y 1 -Y 3 At least one of which is nitrogen;

Ar 3 -Ar 7 each independently selected from hydrogen, deuterium, a C6 to C20 substituted or unsubstituted aryl group and a C5 to C20 substituted or unsubstituted heteroaryl group, wherein Ar 3 -Ar 7 At least one of which is deuterium substituted phenyl;

L 1 、L 2 each independently selected from a single bond and a C6 to C30 aryl or heteroaryl group.

9. the light-emitting material according to claim 6, wherein the compound of the structural formula represented by formula 3 or formula 4 has a deuteration ratio of 5% to 30%.

10. The light-emitting material according to claim 6 or 9, wherein a ratio of deuteration in the dopant material and the host material is 3% or more.

11. The luminescent material according to claim 1, wherein the host material comprises an N-type material and a P-type material, and the P-type material comprises a compound having a structural formula shown in formula 5:

wherein L is 3 、L 4 Selected from the group consisting of a single bond, C6-C20 arylene, and C5-C20 heteroarylene;

Ar 8 -Ar 10 each independently selected from hydrogen, deuterium, fluorine, cyano, substituted or unsubstituted C2-C20 alkyl, substituted or unsubstituted C6-C20 aryl, and substituted or unsubstituted C5-C30 heteroaryl.

13. a light emitting device, comprising:

an anode and a cathode disposed opposite to each other;

a light-emitting layer provided between the anode and the cathode, the light-emitting layer containing the light-emitting material according to any one of claims 1 to 12;

a hole transport layer disposed between the anode and the light emitting layer;

and the electron transport layer is arranged between the cathode and the light-emitting layer.

14. The light-emitting device according to claim 13, wherein a material of the hole-transporting layer is selected from the group consisting of phthalocyanine derivatives, naphthalocyanine derivatives, porphyrin derivatives, benzidine-type triarylamines, styrylamine-type triarylamines, and diamine-type triarylamines.

15. The light-emitting device according to claim 14, wherein the material of the electron transport layer is selected from a benzimidazole derivative, an oxadiazole derivative, and a quinoxaline derivative.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211326602.7A CN115637147A (en) | 2022-10-27 | 2022-10-27 | Light-emitting material and light-emitting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211326602.7A CN115637147A (en) | 2022-10-27 | 2022-10-27 | Light-emitting material and light-emitting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115637147A true CN115637147A (en) | 2023-01-24 |

Family

ID=84946414

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211326602.7A Pending CN115637147A (en) | 2022-10-27 | 2022-10-27 | Light-emitting material and light-emitting device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115637147A (en) |

Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102421772A (en) * | 2010-04-20 | 2012-04-18 | 出光兴产株式会社 | Bicarbazole derivative, material for organic electroluminescent element, and organic electroluminescent element using same |

| CN111518139A (en) * | 2019-02-01 | 2020-08-11 | 北京夏禾科技有限公司 | Organic luminescent material containing cyano-substituted ligand |

| CN113024566A (en) * | 2021-01-28 | 2021-06-25 | 陕西莱特光电材料股份有限公司 | Nitrogen-containing compound, electronic element comprising same and electronic device |

| CN113603696A (en) * | 2021-08-04 | 2021-11-05 | 吉林奥来德光电材料股份有限公司 | Blue light fluorescence doping compound and application thereof |

| WO2022031036A1 (en) * | 2020-08-06 | 2022-02-10 | 주식회사 엘지화학 | Organic light emitting device |

| CN114106056A (en) * | 2021-12-02 | 2022-03-01 | 北京燕化集联光电技术有限公司 | Metal organic light-emitting material and application thereof in OLED device |

| CN114105992A (en) * | 2021-06-18 | 2022-03-01 | 陕西莱特迈思光电材料有限公司 | Nitrogen-containing compound, and organic electroluminescent device and electronic device comprising same |

| CN114456174A (en) * | 2021-12-16 | 2022-05-10 | 陕西莱特迈思光电材料有限公司 | Nitrogen-containing compound, and electronic component and electronic device comprising same |

| CN114516890A (en) * | 2020-11-18 | 2022-05-20 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN114605473A (en) * | 2020-12-09 | 2022-06-10 | 北京夏禾科技有限公司 | Phosphorescent organic metal complex and device thereof |

| CN114621199A (en) * | 2020-12-11 | 2022-06-14 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN115057892A (en) * | 2022-06-29 | 2022-09-16 | 北京云基科技有限公司 | Metal organic complex and application thereof |

| CN115215906A (en) * | 2021-04-21 | 2022-10-21 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN115398661A (en) * | 2020-07-15 | 2022-11-25 | 株式会社Lg化学 | Organic light emitting device |

| CN115448958A (en) * | 2022-11-09 | 2022-12-09 | 吉林奥来德光电材料股份有限公司 | Organic metal compound, organic electroluminescent device containing organic metal compound and application of organic metal compound |

| US20220399517A1 (en) * | 2021-02-26 | 2022-12-15 | Universal Display Corporation | Organic electroluminescent materials and devices |

-

2022

- 2022-10-27 CN CN202211326602.7A patent/CN115637147A/en active Pending

Patent Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102421772A (en) * | 2010-04-20 | 2012-04-18 | 出光兴产株式会社 | Bicarbazole derivative, material for organic electroluminescent element, and organic electroluminescent element using same |

| CN111518139A (en) * | 2019-02-01 | 2020-08-11 | 北京夏禾科技有限公司 | Organic luminescent material containing cyano-substituted ligand |

| CN115398661A (en) * | 2020-07-15 | 2022-11-25 | 株式会社Lg化学 | Organic light emitting device |

| WO2022031036A1 (en) * | 2020-08-06 | 2022-02-10 | 주식회사 엘지화학 | Organic light emitting device |

| CN114516890A (en) * | 2020-11-18 | 2022-05-20 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN114605473A (en) * | 2020-12-09 | 2022-06-10 | 北京夏禾科技有限公司 | Phosphorescent organic metal complex and device thereof |

| CN114621199A (en) * | 2020-12-11 | 2022-06-14 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN113024566A (en) * | 2021-01-28 | 2021-06-25 | 陕西莱特光电材料股份有限公司 | Nitrogen-containing compound, electronic element comprising same and electronic device |

| US20220399517A1 (en) * | 2021-02-26 | 2022-12-15 | Universal Display Corporation | Organic electroluminescent materials and devices |

| CN115215906A (en) * | 2021-04-21 | 2022-10-21 | 北京夏禾科技有限公司 | Organic electroluminescent material and device thereof |

| CN114105992A (en) * | 2021-06-18 | 2022-03-01 | 陕西莱特迈思光电材料有限公司 | Nitrogen-containing compound, and organic electroluminescent device and electronic device comprising same |

| CN113603696A (en) * | 2021-08-04 | 2021-11-05 | 吉林奥来德光电材料股份有限公司 | Blue light fluorescence doping compound and application thereof |

| CN114106056A (en) * | 2021-12-02 | 2022-03-01 | 北京燕化集联光电技术有限公司 | Metal organic light-emitting material and application thereof in OLED device |

| CN114456174A (en) * | 2021-12-16 | 2022-05-10 | 陕西莱特迈思光电材料有限公司 | Nitrogen-containing compound, and electronic component and electronic device comprising same |

| CN115057892A (en) * | 2022-06-29 | 2022-09-16 | 北京云基科技有限公司 | Metal organic complex and application thereof |

| CN115448958A (en) * | 2022-11-09 | 2022-12-09 | 吉林奥来德光电材料股份有限公司 | Organic metal compound, organic electroluminescent device containing organic metal compound and application of organic metal compound |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110467536B (en) | Nitrogen-containing compound, organic electroluminescent device, and photoelectric conversion device | |

| US20140091295A1 (en) | Mixtures of organic emissive semiconductors and matrix materials, their use and electronic components comprising said materials | |

| CN112321587B (en) | Organic compound, electroluminescent material and application thereof | |

| CN113121367B (en) | Organic electroluminescent compound and preparation method and application thereof | |

| CN101508649A (en) | Novel organic electroluminescent compounds and organic electroluminescent device using the same | |

| KR20180116342A (en) | Material for organic electroluminescence device | |

| CN109336834A (en) | A kind of aryl amine derivatives and its organic electroluminescence device | |

| CN110041366B (en) | Indenonanthracene derivative compound and application thereof | |

| KR20140125061A (en) | An organoelectro luminescent compound and an organoelectroluminescent device using the same | |

| CN113816979B (en) | Organic compound and electroluminescent application thereof | |

| CN113735891A (en) | Organic compound and application thereof | |

| CN111662312A (en) | Compound, thermally activated delayed fluorescence material and application thereof | |

| US20170040546A1 (en) | Novel compound and organic electronic device using the same | |

| CN115304566A (en) | Luminescent auxiliary material and preparation method and application thereof | |

| CN115521214A (en) | Organic compound, and electronic element and electronic device comprising same | |

| CN111718322B (en) | Compound, display panel and display device | |

| CN112707908B (en) | Organic electronic material and application thereof | |

| CN110526900A (en) | Electroluminescent organic material and device | |

| CN112759524A (en) | Aromatic amine derivative and organic electroluminescent device thereof | |

| CN111518123A (en) | Compound, thermally activated delayed fluorescence material and application thereof | |

| CN114437108B (en) | N-containing spiro organic compound and application thereof in organic light-emitting device and panel | |

| CN110963989A (en) | Compound with xanthene as core and application thereof | |

| CN111662306B (en) | OLED organic electroluminescent compound and main material of light-emitting layer | |

| CN111423450B (en) | Compound, display panel and display device | |

| CN115637147A (en) | Light-emitting material and light-emitting device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |