CN115561195A - Single-cavity double-comb light source and gas detection system based on same - Google Patents

Single-cavity double-comb light source and gas detection system based on same Download PDFInfo

- Publication number

- CN115561195A CN115561195A CN202211281592.XA CN202211281592A CN115561195A CN 115561195 A CN115561195 A CN 115561195A CN 202211281592 A CN202211281592 A CN 202211281592A CN 115561195 A CN115561195 A CN 115561195A

- Authority

- CN

- China

- Prior art keywords

- comb

- optical

- light source

- gas

- optical fiber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001514 detection method Methods 0.000 title claims abstract description 40

- 230000003287 optical effect Effects 0.000 claims abstract description 147

- 239000013307 optical fiber Substances 0.000 claims abstract description 75

- 238000005086 pumping Methods 0.000 claims abstract description 23

- 238000010521 absorption reaction Methods 0.000 claims description 26

- 230000035559 beat frequency Effects 0.000 claims description 14

- 239000011521 glass Substances 0.000 claims description 12

- 238000004458 analytical method Methods 0.000 claims description 11

- 230000010287 polarization Effects 0.000 claims description 10

- 239000004065 semiconductor Substances 0.000 claims description 10

- 230000009977 dual effect Effects 0.000 claims description 3

- 238000001228 spectrum Methods 0.000 abstract description 24

- 238000005516 engineering process Methods 0.000 abstract description 21

- 239000007789 gas Substances 0.000 description 141

- 238000000034 method Methods 0.000 description 19

- 238000005259 measurement Methods 0.000 description 15

- 210000001520 comb Anatomy 0.000 description 13

- 238000000862 absorption spectrum Methods 0.000 description 11

- 230000035945 sensitivity Effects 0.000 description 11

- 230000003595 spectral effect Effects 0.000 description 11

- 239000006096 absorbing agent Substances 0.000 description 7

- 239000000835 fiber Substances 0.000 description 6

- 238000010586 diagram Methods 0.000 description 5

- 230000003993 interaction Effects 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- 244000126211 Hericium coralloides Species 0.000 description 4

- 235000013405 beer Nutrition 0.000 description 4

- 238000012544 monitoring process Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 230000002457 bidirectional effect Effects 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- 230000004044 response Effects 0.000 description 3

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000002329 infrared spectrum Methods 0.000 description 2

- 238000013021 overheating Methods 0.000 description 2

- 238000004445 quantitative analysis Methods 0.000 description 2

- 238000002310 reflectometry Methods 0.000 description 2

- 230000004043 responsiveness Effects 0.000 description 2

- 238000004088 simulation Methods 0.000 description 2

- 229910052691 Erbium Inorganic materials 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000012824 chemical production Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000001658 differential optical absorption spectrophotometry Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- UYAHIZSMUZPPFV-UHFFFAOYSA-N erbium Chemical group [Er] UYAHIZSMUZPPFV-UHFFFAOYSA-N 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000031700 light absorption Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 230000001902 propagating effect Effects 0.000 description 1

- 238000004451 qualitative analysis Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 239000002341 toxic gas Substances 0.000 description 1

- 238000000041 tunable diode laser absorption spectroscopy Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/17—Systems in which incident light is modified in accordance with the properties of the material investigated

- G01N21/25—Colour; Spectral properties, i.e. comparison of effect of material on the light at two or more different wavelengths or wavelength bands

- G01N21/31—Investigating relative effect of material at wavelengths characteristic of specific elements or molecules, e.g. atomic absorption spectrometry

- G01N21/35—Investigating relative effect of material at wavelengths characteristic of specific elements or molecules, e.g. atomic absorption spectrometry using infrared light

- G01N21/3504—Investigating relative effect of material at wavelengths characteristic of specific elements or molecules, e.g. atomic absorption spectrometry using infrared light for analysing gases, e.g. multi-gas analysis

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/01—Arrangements or apparatus for facilitating the optical investigation

Landscapes

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analysing Materials By Optical Means (AREA)

Abstract

The invention relates to the technical field of gas detection, and discloses a single-cavity double-comb light source, which comprises: the optical fiber laser comprises a pumping light source, a resonant cavity and a gas pool, wherein the pumping light source forms a first optical comb and a second optical comb which have a repeated frequency difference in the resonant cavity, the gas pool is arranged in the resonant cavity, and the first optical comb and the second optical comb respectively pass through the gas pool in an opposite direction and repeat for a plurality of times. The gas detector detects gas through the single-cavity double-light comb light source, solves the problem that the traditional double-light comb spectrum technology needs to lock the cavity of the independent double-light comb, reduces the complexity of the system, reduces the cost and has high practicability.

Description

Technical Field

The invention relates to the technical field of gas detection, in particular to a single-cavity double-comb light source and a gas detection system based on the single-cavity double-comb light source.

Background

The gas detection technology is widely applied to various production scenes at present, and can help maintenance managers to monitor and detect the running condition of equipment. In practical applications such as monitoring the operation of electrical equipment and detecting toxic gases in the environment during chemical production, most of the detected gases have low concentration, so that a high-sensitivity gas monitoring means is required. Because gas molecules have strong absorption in an infrared band and the absorption peak has strong characteristics, the types and the concentrations of the gas molecules can be determined by measuring the absorption spectrum line of the gas, so the method has important application value in the field of gas detection. At present, gas spectrum detection methods include a non-dispersive infrared method, a Fourier transform infrared spectroscopy, a differential optical absorption spectroscopy, a tunable diode laser absorption spectroscopy and the like.

The non-dispersive infrared method utilizes a broad-spectrum light source to detect gas to be detected, filters out a specific infrared band through a narrow-band filter, measures the intensity of infrared light entering an infrared sensor, and selects absorption characteristics to analyze gas molecular components based on the gas. The method has the advantages that the specific gas molecule analysis is rapid and accurate; but the measurement band is narrow, the precision is low, and the complex multi-component gas is difficult to measure.

The fourier transform infrared spectroscopy technology converts an interference pattern of signal light and intrinsic light into an infrared spectrogram through fourier transform, can perform qualitative and quantitative analysis on a measured gas, has high measurement precision and low noise, is commonly used for monitoring atmospheric pollutants, but has low sensitivity, is difficult to detect gas concentration of ppm (parts per million) or below, is limited by mechanical movement speed, and consumes long time for measurement.

The differential optical absorption spectrum is obtained by detecting the narrow-band absorption characteristics of gas and deducing the species and concentration information of trace gas according to the Lambert beer law. The technical equipment is cheap and simple, and the precision is high; however, the method is mainly used for a non-scattering system with uniformly distributed optical media, so that the application range of the method is greatly limited.

The tunable diode laser absorption spectrum technology utilizes a tunable semiconductor laser light source to obtain the absorption spectrum of gas molecules through frequency scanning, and then utilizes the wavelength and height of an absorption peak to obtain information such as the type and concentration of gas. The technology has high sensitivity and resolution, but has slow response speed, limited tuning range of the light source and limited application range.

Therefore, the conventional gas spectrum detection technology generally has the problems of time consumption, low precision, limited detection sensitivity, difficulty in quantitative analysis of multi-component gas and the like.

The femtosecond optical frequency comb has the characteristics of wide frequency spectrum, narrow pulse width, stable repetition frequency and the like, and provides a better choice for high-resolution broadband infrared spectrum measurement. A double-optical comb spectrum gas detection technology is a novel spectrum detection technology developed on the basis of an optical comb technology. The principle is similar to the Fourier transform spectrum technology, and the difference is that two optical frequency combs with a tiny repetition frequency difference are used as a fully static interference light source, and a mechanical movable arm of an interferometer in the Fourier transform spectrum technology is not needed any more, so that the stability, the resolution, the precision and the measurement speed of a measurement system are greatly improved. However, the optical comb has a wide spectrum and low energy of single comb teeth, so that the detection sensitivity of the method is low, and the sensitivity is generally required to be further improved by combining with a cavity enhancement technology. The cavity enhanced infrared optical comb spectrum is characterized in that an optical resonant cavity is used as a gas pool, and light oscillates back and forth in the cavity, so that the effective optical path of gas absorption is increased, and the sensitivity of spectral measurement is improved. The existing double-optical comb spectrum gas detection technology uses two independent optical combs, and noise suppression processing is needed to ensure the coherence of the double optical combs. The technology needs elaborate cavity locking equipment and signal enhancement equipment to carry out cavity locking and signal enhancement processing on the double-optical comb, and the system cost is high. And the double-light comb is sensitive to the external environment, is not beneficial to outdoor use and has the problem of poor practicability.

Disclosure of Invention

The invention aims to provide a single-cavity double-light comb light source, which is used for detecting gas through the single-cavity double-light comb light source, solves the problem that the traditional double-light comb spectrum technology needs to lock a cavity for an independent double-light comb, reduces the system complexity and the cost, and has high practicability.

The technical scheme provided by the invention is as follows: a single cavity dual comb light source comprising: the optical fiber laser comprises a pumping light source, a resonant cavity and a gas pool, wherein the pumping light source forms a first optical comb and a second optical comb which have a repeated frequency difference in the resonant cavity, the gas pool is arranged in the resonant cavity, and the first optical comb and the second optical comb respectively pass through the gas pool in an opposite direction and repeat for a plurality of times.

The working principle and the advantages of the invention are as follows: the method aims at the problems of the existing gas spectrum detection technology in the aspects of measurement resolution, sensitivity, precision, cost and the like. A pumping light source of the single-cavity double-comb light source forms a first optical comb and a second optical comb which have repeated frequency difference in a resonant cavity, and then the first optical comb and the second optical comb directly face each other in the resonant cavity to pass through a gas pool and repeat for a plurality of times. The mode of intracavity reinforcing has been realized through above-mentioned structure, has removed traditional technical means from and has carried out the step and the corresponding equipment of signal reinforcing behind the lock chamber to independent two optical combs, has optimized the structure. In addition, the invention combines the characteristic of high coherence of a single-cavity double-comb mode and an intracavity enhanced structure to further enhance the absorption of gas molecules on the double-optical comb with corresponding wave bands, so that the double-optical comb fully carries the absorption information of a multi-component gas sample, thereby being capable of detecting a weaker absorption spectrum line and improving the detection sensitivity.

The invention analyzes the optical signal after the first optical comb and the second optical comb which have the repeated frequency difference respectively pass through the gas cell in opposite directions and repeat for a plurality of times, thereby obtaining the gas detection result. The single-cavity double-comb mode does not need a second optical comb light source, has high coherence, does not need to inhibit noise processing, and solves the coherence problem of the traditional double-spectrum technology. Therefore, the requirements on cavity locking equipment and technology are reduced, extra cavity locking and frequency control are not needed, the complexity of the system is reduced, the cost is reduced, and the practicability is high.

Further, the resonant cavity comprises a high reflection mirror, an output mirror, a first reflection mirror, a second reflection mirror and a gain medium, wherein the high reflection mirror, the gain medium and the output mirror are sequentially arranged on the same straight line, and the first reflection mirror, the gas pool and the second reflection mirror are sequentially arranged on the same straight line; the pumping light source faces the high-reflection mirror, and is incident to the gain medium through the high-reflection mirror to form a first optical comb and a second optical comb which are opposite in direction; the first optical comb is reflected by the output mirror and the first reflector, passes through the gas pool, and then is reflected by the second reflector and the high-reflection mirror to be incident to the gain medium; the second optical comb is reflected by the high reflecting mirror and the second reflecting mirror and opposite to the first optical comb, passes through the gas pool, and is reflected by the first reflecting mirror and the output mirror to be incident to the gain medium; and the first optical comb and the second optical comb respectively pass through the gas cell in an opposite direction, repeat for a plurality of times and then are ejected out through the output mirror.

Through the resonant cavity structure, the pumping light source generates bidirectional light, the bidirectional light vibrates for multiple times, the double-optical comb is generated after the mode locking, the first optical comb and the second optical comb repeatedly pass through the gas pool after being reflected for multiple times in the cavity and are partially absorbed by gas to be detected, and therefore the optical comb carries fingerprint information of a gas absorption spectrum. The gas pool is arranged in the cavity, so that an extra cavity locking is not needed, the requirement on the external environment is reduced, the high coherence of the single-cavity double-comb and the enhancement in the cavity can play a role in enhancing the interaction between the optical comb and molecules, the sensitivity and the responsiveness of gas detection are increased, and the detection capability of complex multi-component gas in power equipment fault gas is favorably improved.

Further, the center wavelengths of the first optical comb and the second optical comb are 1550nm, and the gain medium is doped bait glass.

The center wavelengths of the first optical comb and the second optical comb are related to the gain medium used by the light source, and the spectrum of the light source needs to cover the absorption peak of the gas to be measured. The single-cavity light source is incident to the gain medium to generate the double optical combs with central wavelengths of 1550nm through stimulated radiation, and the double optical combs exist in the same resonant cavity, so that common-mode noise is effectively inhibited, and high coherence among the optical frequency combs is realized. The erbium-doped glass is used as a gain medium in an optical path and can effectively amplify optical signals.

Further, the resonant cavity comprises a wavelength division multiplexer, a gain medium, a polarization controller, a semiconductor saturable absorber mirror, a first optical fiber coupler, a first optical fiber collimator and a second optical fiber collimator, wherein the first optical fiber collimator, the wavelength division multiplexer, the gain medium, the polarization controller, the semiconductor saturable absorber mirror, the first optical fiber coupler and the second optical fiber collimator are sequentially connected through optical fibers, the pump light source faces the wavelength division multiplexer, and the gas pool is arranged between the first optical fiber collimator and the second optical fiber collimator.

The structure of the gas detection system can be further optimized by conducting optical signals through the optical fiber, the requirements of equipment technology and environment are reduced, and the gas detection system is favorable for being applied to detection of fault gas of outdoor power equipment.

Further, the central wavelength of the pumping light source is 980nm, the wavelength division multiplexer is a 980/1550nm wavelength division multiplexer, and the gain medium is an erbium-doped optical fiber.

The central wavelength of the pump light source is 980nm, the output of the 980nm pump light source is mostly unpolarized light, and a 980/1550nm wavelength division multiplexer is selected for matching with the output optical fiber of the light source. Due to the fact that the interval between 980nm and 1550nm is large, the coupling coefficient difference is large, wavelength division multiplexing of the coupler is easy to achieve, and 980nm light is almost completely coupled into the optical fiber. The erbium-doped fiber is used as a gain medium in the fiber, can effectively amplify optical signals, is compatible with a wavelength division multiplexing system, and has high pumping efficiency and stable working performance.

Further, the gas pool is provided with a gas inlet, a gas outlet and a light-transmitting window.

And introducing the gas to be detected into the gas pool through the gas inlet. And vacuumizing the gas pool through the gas outlet to discharge the original residual sample gas. The optical comb passes through the gas cell through the light-passing window, realizes the detection to gaseous.

The invention also provides a gas detection system based on the single-cavity double-comb light source, which comprises the single-cavity double-comb light source and also comprises: the device comprises a beam combiner, a first photoelectric detector, a second photoelectric detector and an electric signal analysis device, wherein the first optical comb and the second optical comb respectively pass through a gas cell in an opposite direction and repeat for a plurality of times, are subjected to beam combination and beat frequency by the beam combiner and then are split into a first split beam and a second split beam, and the first split beam and the second split beam are respectively received by the first photoelectric detector and the second photoelectric detector; the first photoelectric detector and the second photoelectric detector are respectively electrically connected with the electric signal analysis equipment.

The first optical comb and the second optical comb respectively pass through the gas pool in an opposite direction and repeat for a plurality of times, then are subjected to beam combination and beat frequency through the beam combiner and then are split, optical signals are received by the first photoelectric detector and the second photoelectric detector respectively and are converted into electric signals, and the electric signals are analyzed by the electric signal analysis equipment to obtain a gas detection result. The gas detection system based on the single-cavity double-comb does not need mechanical or spectrum scanning, and the second-level measurement speed of the traditional spectrum method is improved to the millisecond level, so that the quick response and spectrum formation are realized. The beam combiner converts the interaction information of the light frequency and the gas into a radio frequency domain by adopting a beat frequency method, and the information is directly measured by electric signal analysis equipment, so that the difficulty of detecting the spectrum signal is reduced, and the measurement precision is improved.

Furthermore, the beam combiner is a beam combining sheet, an outer light path of the resonant cavity comprises a third reflector, the second optical comb is incident to the beam combining sheet through the third reflector, and the beam combining sheet and the two beams of incident light are placed at an angle of 45 degrees.

The beam combining sheet and two beams of incident light are arranged at an angle of 45 degrees, so that the first optical comb and the second optical comb can be effectively combined into one beam of light through the beam combining sheet, the double combs are used for spatially combining the light beams and reflecting and transmitting the light beams to the two photoelectric detectors, and the light signals after the beam combining is fully received.

Further, the beam combiner is a second optical fiber coupler, the first optical fiber coupler is in optical fiber connection with the second optical fiber coupler, and the second optical fiber coupler is in optical fiber connection with the first photoelectric detector and the second photoelectric detector respectively.

The first optical comb and the second optical comb are respectively output to the second optical fiber coupler through the first optical fiber coupler. The beam is combined and beaten by the second optical fiber coupler and then split into a first split beam and a second split beam, the first split beam and the second split beam are respectively received by the first photoelectric detector and the second photoelectric detector, and a time domain interference signal is collected and converted into an electric signal so as to realize the sufficient reception of the combined beam light signal.

Further, the electric signal analysis equipment comprises a differential amplifier and a frequency spectrograph, wherein the first photoelectric detector and the second photoelectric detector are respectively electrically connected with the differential amplifier, and the differential amplifier is electrically connected with the frequency spectrograph.

Common mode noise of the electric signals of the first photoelectric detector and the second photoelectric detector is suppressed and amplified through a differential amplifier, and the amplified electric signal data is recorded and analyzed by a frequency spectrograph, so that a hyperfine spectrogram of gas molecules, namely a double-optical comb absorption spectrum, is obtained. Compared with an oscilloscope, the frequency spectrograph can directly convert the electric signals into the intensity signals of the frequency domain without Fourier transform.

Drawings

FIG. 1 is a schematic structural diagram of a gas detection system based on a single-cavity double-comb light source according to a first embodiment of the present invention;

FIG. 2 is a schematic diagram of intracavity absorption enhancement of a gas detection system based on a single-cavity double-comb light source according to the present invention;

FIG. 3 is a diagram of optical frequency comb teeth of a double optical comb beat frequency of a gas detection system based on a single-cavity double-comb light source according to the present invention;

FIG. 4 is a beat signal diagram of the beat frequency of the double optical combs of the gas detecting system based on the single-cavity double-comb light source of the present invention;

fig. 5 is a schematic structural diagram of a second embodiment of a gas detection system based on a single-cavity double-comb light source according to the present invention.

Detailed Description

Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only for illustrating the technical solutions of the present invention more clearly, and therefore are only examples, and the protection scope of the present invention is not limited thereby.

It is to be noted that, unless otherwise specified, technical or scientific terms used herein shall have the ordinary meaning as understood by those skilled in the art to which the invention pertains.

The reference numbers in the drawings of the specification include: the device comprises a pumping light source 1, a gas pool 2, a first photoelectric detector 3, a second photoelectric detector 4, a differential amplifier 5, a frequency spectrograph 6, a beam combining sheet 7, a high-reflection mirror 8, an output mirror 9, erbium-doped glass 10, a first reflection mirror 11, a second reflection mirror 12, a third reflection mirror 13, a wavelength division multiplexer 14, an erbium-doped optical fiber 15, a polarization controller 16, a semiconductor saturable absorber 17, a first optical fiber collimator 18, a second optical fiber collimator 19, a first optical fiber coupler 20 and a second optical fiber coupler 21.

The first embodiment is as follows:

as shown in fig. 1, the present embodiment discloses a gas detection system based on a single-cavity double-comb light source, which includes a single-cavity double-comb light source, a gas cell 2, a beam combiner, a first photodetector 3, a second photodetector 4, a differential amplifier 5, and a spectrometer 6.

The single-cavity double-comb light source comprises a pumping light source 1 and a resonant cavity, wherein the resonant cavity comprises a high reflecting mirror 8, an output mirror 9, a first reflecting mirror 11, a second reflecting mirror 12 and a gain medium. The high reflecting mirror 8, the gain medium and the output mirror 9 are sequentially arranged on the same straight line, and the first reflecting mirror 11, the gas cell 2 and the second reflecting mirror 12 are sequentially arranged on the same straight line. The gain medium is arranged between the high reflecting mirror 8 and the output mirror 9, the gas pool 2 is arranged between the first reflecting mirror 11 and the second reflecting mirror 12, and the pumping light source 1 faces the high reflecting mirror 8. The gain medium in this embodiment is erbium doped glass 10.

The central wavelength of the pumping light source 1 is 980nm, the pumping light source 1 forms a first optical comb and a second optical comb which are opposite in direction and have a repetition frequency difference through the erbium-doped glass 10 of the resonant cavity, and the central wavelength of the first optical comb and the central wavelength of the second optical comb are 1550nm.

The gas pool 2 is used for storing trace multi-component gas, is provided with a gas inlet and a gas outlet, and is used for a light-transmitting window for ultra-sensitive infrared spectrum detection.

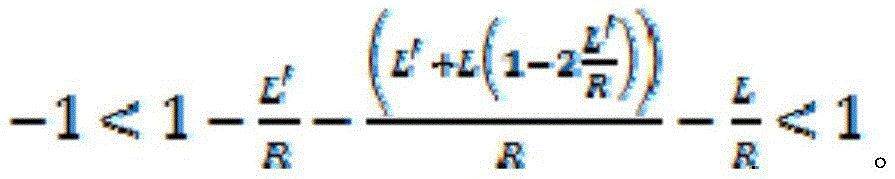

The first mirror 11 and the second mirror 12 are plane mirrors. The annular resonant cavity formed by the four cavity mirrors, namely the high-reflection mirror 8, the output mirror 9, the first reflection mirror 11 and the second reflection mirror 12 allows light in two different directions to propagate in the cavity. The total cavity length of the ring resonator is L (the optical path length of light when propagating in the ring resonator), the curvature radiuses of the high reflecting mirror 8 and the output mirror 9 are both R, the distance between the two mirrors is L', and the total cavity length can be obtained by the stability condition of the resonator:

in this embodiment, the beam combiner is a beam combining plate 7, an external optical path of the resonant cavity includes a third reflector 13, the beam combining plate 7 is disposed on a straight line along the output mirror 9, so that the first optical comb passes through the output mirror 9 and then emits to the beam combining plate 7, the third reflector 13 is disposed on an optical path emitted by the second optical comb through the output mirror 9, and the second optical comb passes through the output mirror 9 and then emits to the beam combining plate 7 after being reflected by the third reflector 13. The beam combining sheet 7 and the two beams of incident light are arranged at an angle of 45 degrees.

The first optical comb and the second optical comb are split into a first split beam and a second split beam after being subjected to beam combination and beat frequency by the beam combiner, the first photoelectric detector 3 and the second photoelectric detector 4 are respectively arranged to receive the first split beam and the second split beam and then are processed by the electric signal analysis equipment, and the electric signal analysis equipment comprises a differential amplifier 5 and a frequency spectrometer 6. The first photodetector 3 and the second photodetector 4 are electrically connected to a differential amplifier 5, respectively, and the differential amplifier 5 is electrically connected to a spectrometer 6. Spectrometer 6 can select for use spectrometer 6 or oscilloscope, adopts spectrometer 6 in this embodiment, can directly convert the intensity signal of electric signal to the frequency domain, need not to carry out Fourier transform.

The implementation process of this embodiment is as follows:

the mixed gas of CH4, CO2, CO, C2H4 and the like is common important characteristic gas in the operation safety monitoring and early warning of the power equipment, and can be used for representing system faults, operation safety and eliminating fault sources. For example, CH4, C2H4 gas corresponds to an oil overheating fault type, CH4, CO2, CO, C2H4 gas corresponds to an oil and paper overheating fault type, and so on. However, the characteristic spectral lines of the gases are distributed in different spectral bands, the absorption is weak, and the gases are difficult to detect simultaneously, wherein the CH4 spectral band is 1630-1750nm, the CO2 spectral band is 1754-1828nm, the C2H4 spectral band is 1510-1540nm, and the CO spectral band is 1578-1585nm.

In this example, mixed gas such as CH4, CO2, CO, and C2H4 is detected.

Firstly, gas to be detected is led into the gas pool 2 through the gas inlet, the gas inlet and the gas outlet are sealed, the gas pool 2 is arranged between the first reflecting mirror 11 and the second reflecting mirror 12, and the gas in the gas pool is uniformly diffused.

The central wavelength of the pump light source 1 is 980nm. The pumping light source 1 forms a first optical comb and a second optical comb which have opposite directions and have a repetition frequency difference through the bait-doped glass 10 of the resonant cavity, the central wavelength of the first optical comb and the central wavelength of the second optical comb are 1550nm, the spectral range is 1300-2000nm, and the repetition frequency is f respectively r1 =100MHz,f r2 =100MHz+1Hz。

Turning on a pumping light source 1, and enabling the light source to enter bait-doped glass 10 through a high-reflection mirror 8 to form a first optical comb and a second optical comb which are opposite in direction; the first optical comb is reflected by the output mirror 9 and the first reflector 11, passes through the gas pool 2, and then is reflected by the second reflector 12 and the high reflector 8 to be incident to the bait-doped glass 10; the second optical comb is reflected by the high reflecting mirror 8 and the second reflecting mirror 12, passes through the gas cell 2 in an opposite direction to the first optical comb (in fig. 1, the solid line arrow indicates the propagation direction of the first optical comb, and the dotted line arrow indicates the propagation direction of the second optical comb), and is reflected by the first reflecting mirror 11 and the output mirror 9 to enter the bait doped glass 10. The first optical comb and the second optical comb are respectively incident to the bait-doped glass 10, then pass through the gas pool 2 after being reflected for multiple times again, and repeat for multiple times until the optical comb completes oscillation in the cavity, and finally are ejected through the output mirror 9. In the process, the pump light generates bidirectional 1550nm light at the position of the bait-doped glass 10, vibrates for many times, and generates a double-light comb after mode locking. The first optical comb and the second optical comb pass through the gas cell 2 for multiple times in the cavity and are partially absorbed by gas to be detected, so that the optical comb carries fingerprint information of a gas absorption spectrum. The gas pool 2 is arranged in the cavity, so that an additional cavity locking is not needed, the requirement on the external environment is reduced, the high coherence of the single-cavity double-comb can achieve the enhancement effect of the interaction of the optical comb and molecules, the sensitivity and the responsiveness of gas detection are increased, and the improvement of the detection capability of complex multi-component gas in power equipment fault gas is facilitated.

The relationship between the absorption of the transmitted light by the gas molecule to be measured and the passing times is shown in FIG. 2, and the final average passing times n B In relation to the precision F of the cavity enhancement, the relationship with the reflectivity of the cavity mirror is:r 2 and r 4 Respectively the reflectivity of the high mirror 8 and the output mirror 9. The change expression of the transmitted light power P caused by the gas to be measured in the cavity is as follows: α (f) is an absorption coefficient, and d is a light absorption path.

In the process, the first optical comb and the second optical comb pass through the gas cell 2 for multiple times in the resonant cavity, collect gas absorption information and respectively emit the gas absorption information through the output mirror 9. The second optical comb is beat-frequency-modulated with the first optical comb on the beam combining plate 7 via the third reflecting mirror 13, and is split into the first split beam and the second split beam again. Wherein the first split beam of light comprises transmitted light of the first optical comb and reflected light of the second optical comb and the second split beam of light comprises reflected light of the first optical comb and transmitted light of the second optical comb. In the process, the first optical comb and the second optical comb are respectively output from an output mirror 9 of the resonant cavity, the second optical comb is reflected on the beam combining sheet 7 through a third reflecting mirror 13 to beat frequency with the first optical comb, and due to different gas absorption peaks, generated beat frequency signals are different, so that simultaneous measurement of a plurality of gas molecule absorption peaks is realized, and then the beat frequency signals are split through the beam combining sheet 7 and respectively incident on the two photoelectric detectors.

The first split beam light and the second split beam light are respectively received by the first photoelectric detector 3 and the second photoelectric detector 4, and time domain interference signals are collected and converted into electric signals. Common-mode noise of the electric signals of the first photoelectric detector 3 and the second photoelectric detector 4 is suppressed and amplified through the differential amplifier 5, the amplified electric signal data is recorded and analyzed through the frequency spectrograph 6, and the frequency spectrograph 6 can directly convert interference signals of double-optical comb beat frequency into intensity signals of frequency domain, so that a hyperfine spectrogram of gas molecules, namely a double-optical comb absorption spectrum, is obtained.

As shown in FIG. 3, the optical comb in this embodiment is an infrared single-cavity dual-optical comb light source, the spectrum range is 1000-14000nm, since the spectrum of the optical comb is distributed with N equally-spaced frequency teeth, N is any integer, and usually N is 10 5 Left and right. Wherein each optical frequency tooth is equivalent to a beam of single longitudinal mode laser, and the frequency of the first comb tooth of the optical comb is f 0 Adjacent frequency tooth spacing of f r Then the absolute frequency of the nth comb is represented as f n =(f 0 +nf r ) Wherein N is more than 0 and less than N, and the solid line of the optical frequency comb teeth is the first optical comb f in FIG. 3 n(1) =f 0 +nf r1 The dotted line is a second optical comb f n(2) =f 0 +nf r2 . In addition, because the double optical combs are generated in the same resonant cavity, the repetition frequencies of the double optical combs are slightly different due to different sequences of the optical devices, so that the double optical combs have good coherence, extra frequency control is not needed, the requirement on a frequency-locked phase-locked system is reduced, and the cost is reduced.

As shown in FIG. 4, the expression of the beat signal of the dual optical comb at the nth comb tooth is f b =|(f 0 +nf r2 )-(f 0 +nf r1 ) L = m Δ f. The zero frequencies of the light sources of the double optical combs are both f 0 The repetition frequencies are respectively f r1 And f r2 And the difference in repetition frequency is Δ f = f r2 -f r1 . The absorption lines follow the Lambert beer law, I (v) = I o (v)exp[-σ(v)Nd]Where I denotes light intensity, v denotes light frequency, N denotes the number concentration of light-absorbing substance molecules, d denotes a light-absorbing path, and σ (v) denotes a medium absorption cross section, and is related to the wavelength of incident light or the like at a constant temperature.

The beat frequency method converts the interaction information of the optical frequency and the gas into a radio frequency domain, thereby greatly reducing the difficulty of detecting the spectral signals. For example, if the optical comb detects a CH4 absorption signal at the nth comb tooth, a frequency f is generated at the corresponding comb tooth b Of beat signals, i.e. f b =n|f n(2) -f n(1) And i | = n Δ f, wherein Δ f is a known quantity, then the radio frequency domain is converted into the optical frequency domain, the gas component information is obtained by comparing the absorption peak positions of corresponding gas molecules through simulation, and the gas concentration is calculated by the Lambert beer law.

After the measurement is finished, the gas pool 2 is vacuumized through the gas outlet, and the original residual sample gas is discharged.

The system for detecting the fault gas in the transformer oil based on the single-cavity double-comb does not need mechanical or spectral scanning, and the second-level measurement speed of the traditional spectrum method is increased to the millisecond level, so that the quick response and the spectrum formation are realized. Through the mode of single chamber double comb, do not need second light comb light source, itself has high coherence, need not to restrain noise processing, has solved the coherence problem that traditional two spectral technique exists. Therefore, the requirements on cavity locking equipment and technology are reduced, extra cavity locking and frequency control are not needed, the complexity of the system is reduced, the cost is reduced, and the practicability is high. In addition, the invention combines the characteristic of high coherence of a single-cavity double-comb mode and an enhanced structure in the cavity, and can further enhance the absorption of gas molecules on the double-optical comb with corresponding wave bands, so that the double-optical comb fully carries the absorption information of a multi-component gas sample, thereby being capable of detecting a weaker absorption spectrum line and improving the detection sensitivity. The structure of the reinforcing in the cavity is used, the requirements on cavity locking equipment, technology and environment are reduced, and the detection of fault gas of outdoor power equipment is facilitated. The beat frequency method is adopted to convert the information of the interaction between the light frequency and the gas into a radio frequency domain, and the information is directly measured by the frequency spectrograph 6 or the oscilloscope, so that the difficulty of detecting the spectrum signal is reduced, and the measurement precision is improved.

Example two:

as shown in fig. 5, the present embodiment is different from the first embodiment in that:

the resonant cavity comprises a wavelength division multiplexer 14, a gain medium, a polarization controller 16, a semiconductor saturable absorber mirror 17, a first optical fiber coupler 20, a first optical fiber collimator 18 and a second optical fiber collimator 19. The first optical fiber collimator 18, the wavelength division multiplexer 14, the gain medium, the polarization controller 16, the semiconductor saturable absorber mirror 17, the first optical fiber coupler 20 and the second optical fiber collimator 19 are sequentially connected by optical fibers. The pump light source 1 faces the wavelength division multiplexer 14, and the gas cell 2 is arranged between the first optical fiber collimator 18 and the second optical fiber collimator 19.

In this embodiment, the beam combiner is a second optical fiber coupler 21, the first optical fiber coupler 20 is in optical fiber connection with the second optical fiber coupler 21, and the second optical fiber coupler 21 is in optical fiber connection with the first photodetector 3 and the second photodetector 4, respectively.

In this embodiment, the gain medium is an erbium-doped fiber 15, the central wavelength of the pumping light source 1 is 980nm, and the wavelength division multiplexer 14 is a 980/1550nm wavelength division multiplexer 14.

The first fiber coupler 20 and the second fiber coupler 21 are both fiber couplers of 2*2.

The rest of the structure is the same as the first embodiment.

The implementation process of this embodiment is as follows:

the pumping light source 1 of which the pumping light source 1 is opened and which is 980nm enters the resonant cavity through the wavelength division multiplexer 14 of which the wavelength is 980/1550nm and is divided into a first optical comb and a second optical comb, wherein the repetition frequencies of the first optical comb and the second optical comb are respectively f r1 =100MHz,f r2 =100MHz+1Hz。

The first optical comb is emitted through the first optical fiber collimator 18 and repeatedly passes through the gas cell 2, is then recoupled into the optical fiber through the second optical fiber collimator 19, and is emitted again through the first optical fiber collimator 18 after passing through the first optical fiber coupler 20, the semiconductor saturable absorber mirror 17, the polarization controller 16 and the erbium-doped optical fiber 15. The second optical comb passes through the polarization controller 16, the semiconductor saturable absorber mirror 17 and the first optical fiber coupler 20, then exits through the second optical fiber collimator 19, passes through the gas cell 2 repeatedly, is re-coupled into the optical fiber through the first optical fiber collimator 18, then passes through the erbium-doped optical fiber 15, and returns to the polarization controller 16 (in fig. 5, the solid line arrow indicates the propagation direction of the first optical comb, and the dotted line arrow indicates the propagation direction of the second optical comb). After passing through the gas cell 2 for multiple times, the first optical comb and the second optical comb are respectively output to the second optical fiber coupler 21 through the first optical fiber coupler 20. The beams are combined and beat-frequency-modulated by the second optical fiber coupler 21 and then split into a first split beam and a second split beam.

The first split beam light and the second split beam light are respectively received by the first photoelectric detector 3 and the second photoelectric detector 4, and time domain interference signals are collected and converted into electric signals. Common-mode noise of the electric signals of the first photoelectric detector 3 and the second photoelectric detector 4 is suppressed and amplified through the differential amplifier 5, the amplified electric signal data is recorded and analyzed through the frequency spectrograph 6, and the frequency spectrograph 6 can directly convert interference signals of double-optical comb beat frequency into intensity signals of frequency domain, so that a hyperfine spectrogram of gas molecules, namely a double-optical comb absorption spectrum, is obtained. And obtaining gas component information by comparing absorption peak positions of corresponding gas molecules in a simulation mode, and calculating the gas concentration according to the Lambert beer law.

After the measurement is finished, the gas pool 2 is vacuumized through the gas outlet, and the original residual sample gas is discharged.

The foregoing are merely exemplary embodiments of the present invention, and no attempt is made to show structural details of the invention in more detail than is necessary for the fundamental understanding of the art, the description taken with the drawings making apparent to those skilled in the art how the several forms of the invention may be embodied in practice with the teachings of the invention. It should be noted that, for those skilled in the art, without departing from the structure of the present invention, several changes and modifications can be made, which should also be regarded as the protection scope of the present invention, and these will not affect the effect of the implementation of the present invention and the practicability of the patent. The scope of the claims of the present application shall be determined by the contents of the claims, and the description of the embodiments and the like in the specification shall be used to explain the contents of the claims.

Claims (10)

1. A single cavity dual comb light source, comprising: the optical fiber laser comprises a pumping light source, a resonant cavity and a gas pool, wherein the pumping light source forms a first optical comb and a second optical comb which have a repeated frequency difference in the resonant cavity, the gas pool is arranged in the resonant cavity, and the first optical comb and the second optical comb respectively pass through the gas pool in an opposite direction and repeat for a plurality of times.

2. The single cavity double comb light source of claim 1, wherein: the resonant cavity comprises a high-reflection mirror, an output mirror, a first reflecting mirror, a second reflecting mirror and a gain medium, wherein the high-reflection mirror, the gain medium and the output mirror are sequentially arranged on the same straight line, and the first reflecting mirror, the gas pool and the second reflecting mirror are sequentially arranged on the same straight line; the pumping light source faces the high-reflection mirror, and is incident to the gain medium through the high-reflection mirror to form a first optical comb and a second optical comb which are opposite in direction; the first optical comb is reflected by the output mirror and the first reflector, passes through the gas pool, and then is reflected by the second reflector and the high-reflection mirror to be incident to the gain medium; the second optical comb is reflected by the high reflecting mirror and the second reflecting mirror and opposite to the first optical comb, passes through the gas pool, and is reflected by the first reflecting mirror and the output mirror to be incident to the gain medium; and the first optical comb and the second optical comb respectively pass through the gas cell in an opposite direction, repeat for a plurality of times and then are ejected out through the output mirror.

3. The single cavity double comb light source of claim 2, wherein: the center wavelengths of the first optical comb and the second optical comb are 1550nm, and the gain medium is erbium-doped glass.

4. The single cavity double comb light source of claim 1, wherein: the resonant cavity comprises a wavelength division multiplexer, a gain medium, a polarization controller, a semiconductor saturable absorption mirror, a first optical fiber coupler, a first optical fiber collimator and a second optical fiber collimator, wherein the first optical fiber collimator, the wavelength division multiplexer, the gain medium, the polarization controller, the semiconductor saturable absorption mirror, the first optical fiber coupler and the second optical fiber collimator are sequentially connected through optical fibers, the pump light source faces the wavelength division multiplexer, and the gas pool is arranged between the first optical fiber collimator and the second optical fiber collimator.

5. The single cavity double comb light source of claim 4, wherein: the central wavelength of the pumping light source is 980nm, the wavelength division multiplexer is a 980/1550nm wavelength division multiplexer, and the gain medium is an erbium-doped optical fiber.

6. The single cavity double comb light source of claim 1, wherein: and the gas pool is provided with a gas inlet, a gas outlet and a light through window.

7. A gas detection system based on a single-cavity double-comb light source, which is characterized by comprising the single-cavity double-comb light source as claimed in any one of claims 1 to 6, and further comprising: the device comprises a beam combiner, a first photoelectric detector, a second photoelectric detector and an electric signal analysis device, wherein the first optical comb and the second optical comb respectively pass through a gas cell in an opposite direction and repeat for a plurality of times, are subjected to beam combination and beat frequency by the beam combiner and then are split into a first split beam and a second split beam, and the first split beam and the second split beam are respectively received by the first photoelectric detector and the second photoelectric detector; the first photoelectric detector and the second photoelectric detector are respectively and electrically connected with the electric signal analysis equipment.

8. The single chamber double comb light source based gas detection system of claim 7, wherein: the beam combiner is a beam combining sheet, an outer light path of the resonant cavity comprises a third reflector, the second light comb is incident to the beam combining sheet through the third reflector, and the beam combining sheet and the two beams of incident light are placed at an angle of 45 degrees.

9. The single chamber double comb light source based gas detection system of claim 7, wherein: the beam combiner is a second optical fiber coupler, the first optical fiber coupler is in optical fiber connection with the second optical fiber coupler, and the second optical fiber coupler is in optical fiber connection with the first photoelectric detector and the second photoelectric detector respectively.

10. The gas detection system based on the single-cavity double-comb light source as claimed in any one of claims 7 to 9, wherein: the electric signal analysis equipment comprises a differential amplifier and a frequency spectrograph, wherein the first photoelectric detector and the second photoelectric detector are respectively and electrically connected with the differential amplifier, and the differential amplifier is electrically connected with the frequency spectrograph.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211281592.XA CN115561195A (en) | 2022-10-19 | 2022-10-19 | Single-cavity double-comb light source and gas detection system based on same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211281592.XA CN115561195A (en) | 2022-10-19 | 2022-10-19 | Single-cavity double-comb light source and gas detection system based on same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115561195A true CN115561195A (en) | 2023-01-03 |

Family

ID=84746997

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211281592.XA Pending CN115561195A (en) | 2022-10-19 | 2022-10-19 | Single-cavity double-comb light source and gas detection system based on same |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115561195A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116625946A (en) * | 2023-05-29 | 2023-08-22 | 电子科技大学 | CMOS frequency comb Fourier transform rotation spectrum detector |

| CN118501095A (en) * | 2024-06-06 | 2024-08-16 | 武汉敢为科技有限公司 | Cavity ring-down system based on dual-optical-path correction and gas measurement method |

-

2022

- 2022-10-19 CN CN202211281592.XA patent/CN115561195A/en active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116625946A (en) * | 2023-05-29 | 2023-08-22 | 电子科技大学 | CMOS frequency comb Fourier transform rotation spectrum detector |

| CN116625946B (en) * | 2023-05-29 | 2024-03-19 | 电子科技大学 | CMOS frequency comb Fourier transform rotation spectrum detector |

| CN118501095A (en) * | 2024-06-06 | 2024-08-16 | 武汉敢为科技有限公司 | Cavity ring-down system based on dual-optical-path correction and gas measurement method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10928313B2 (en) | Optical absorption spectroscopy based gas analyzer systems and methods | |

| US5528040A (en) | Ring-down cavity spectroscopy cell using continuous wave excitation for trace species detection | |

| US8693004B2 (en) | Dual-etalon cavity ring-down frequency-comb spectroscopy with broad band light source | |

| US9759654B2 (en) | Cavity enhanced laser based isotopic gas analyzer | |

| CN110672554B (en) | Random vibration drive ring-down cavity calibration-free gas concentration measurement system | |

| CN115561195A (en) | Single-cavity double-comb light source and gas detection system based on same | |

| US6940600B1 (en) | Apparatus and method for measuring decay in intensity of electromagnetic radiation in multipass spectrometry | |

| CN112525841B (en) | Vibration and gas temperature concentration measuring method based on ring-down cavity | |

| CN111829981B (en) | Gas heterodyne detection device and detection method based on TDLAS | |

| CN110927096A (en) | Mid-infrared gas measurement system based on four-mirror optical feedback | |

| CN109580541B (en) | Optical heterodyne cavity ring-down spectroscopy measurement device and method | |

| Debecker et al. | High-speed cavity ringdown spectroscopy with increased spectral resolution by simultaneous laser and cavity tuning | |

| US6747742B1 (en) | Microspectrometer based on a tunable fabry-perot interferometer and microsphere cavities | |

| CN113552212B (en) | Radial cavity quartz enhanced photoacoustic spectrum sound detector and gas detection device thereof | |

| Winkowski et al. | Optical interference suppression using wavelength modulation | |

| CN112710628A (en) | Ultra-sensitive SF (sulfur hexafluoride) based on broadband double-optical-comb spectrum6Gas decomposition component detection method | |

| CN115524302A (en) | Gas detection method based on single-cavity double-comb light source | |

| Brown et al. | Water-vapor detection using asynchronous THz sampling | |

| Friedrichs | Sensitive absorption methods for quantitative gas phase kinetic measurements. Part 2: Cavity ringdown spectroscopy | |

| CN113777068B (en) | Multiband-cavity enhanced infrared comb spectrum gas detection system | |

| KR102340037B1 (en) | Apparatus and method for identifying for traces gases | |

| CN221803827U (en) | Cavity enhancement intensity calibration-free Raman spectrum gas detection device | |

| CN117451665A (en) | Multiple gas detection device based on cavity ring-down spectroscopy | |

| CN118294019A (en) | Flame diagnosis system and method based on free radical radiation luminescence technology | |

| CN118050343A (en) | Gas detection device based on cavity enhanced Raman spectrum technology |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |