CN115214381A - Control method and device of driving motor, computer equipment and readable storage medium - Google Patents

Control method and device of driving motor, computer equipment and readable storage medium Download PDFInfo

- Publication number

- CN115214381A CN115214381A CN202210898003.6A CN202210898003A CN115214381A CN 115214381 A CN115214381 A CN 115214381A CN 202210898003 A CN202210898003 A CN 202210898003A CN 115214381 A CN115214381 A CN 115214381A

- Authority

- CN

- China

- Prior art keywords

- power

- motor

- state

- maximum

- vehicle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L15/00—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles

- B60L15/20—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles for control of the vehicle or its driving motor to achieve a desired performance, e.g. speed, torque, programmed variation of speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/42—Drive Train control parameters related to electric machines

- B60L2240/421—Speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/42—Drive Train control parameters related to electric machines

- B60L2240/423—Torque

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/72—Electric energy management in electromobility

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

The present application relates to a control method, a control apparatus, a computer device, a storage medium, and a computer program product for driving a motor. The method comprises the following steps: acquiring vehicle data of an electric vehicle carrying a driving motor; calculating by using vehicle data to obtain power parameters of the driving motor, and identifying the current driving state and slope slipping state of the electric vehicle; the power parameters comprise total maximum power, required power and backup power; then, determining the maximum available power and the minimum available power of the driving motor in the corresponding running state and the slope slipping state based on the total maximum power, the required power and the backup power; and finally, controlling the driving motor by using the maximum available power and the minimum available power. By adopting the method, the phenomena of over-discharge and over-charge of the driving motor can be avoided, the safety of the vehicle is ensured, and the dynamic property and the economical efficiency of the whole vehicle are improved.

Description

Technical Field

The present application relates to the field of automotive technologies, and in particular, to a method, an apparatus, a computer device, a computer-readable storage medium, and a computer program product for controlling a driving motor.

Background

With the continuous deterioration of the environment and the rapid shortage of energy, various products using clean energy are being developed at an increasing speed, and among them, electric vehicles, as new energy vehicles, are being widely researched and used worldwide due to their advantages of no pollution, low noise, high energy efficiency, energy diversification, etc.

In the motor control of the electric vehicle, the discharge capacity and the charge capacity of the battery pack are preset with limit values, and the discharge power of the battery pack is usually used to subtract the consumed power of accessories and is used as the maximum discharge power allowed to be used by the motor; the charging power of the battery pack minus the power consumed by the accessory is used as the minimum charging power allowed by the motor. However, when the whole electric vehicle is in a driving state, if the limit on the discharge power of the motor is too large, the battery may be over-discharged, and if the limit is too small, the dynamic performance of the whole electric vehicle may be affected; when the whole vehicle is in a recovery state, if the limit of the charging power of the motor is too small, the battery may be overcharged, and if the limit is too large, the economy of the whole vehicle may be affected.

Therefore, the current control method for the charging and discharging power of the motor of the electric vehicle has the defect that the safety and the economy cannot be realized.

Disclosure of Invention

In view of the above, it is necessary to provide a control method, a control apparatus, a computer device, a computer-readable storage medium, and a computer program product of a drive motor that can solve the above-described problems.

In a first aspect, the present application provides a control method of a drive motor. The method comprises the following steps: acquiring vehicle data of an electric vehicle carrying a driving motor; calculating by using vehicle data to obtain a power parameter of a driving motor, and identifying the current driving state and the slope sliding state of the electric vehicle; the power parameters comprise total maximum power, required power and backup power, the total maximum power is used for representing the maximum total power of the driving motor in a corresponding driving state, and the backup power is used for representing the residual power of the total maximum power after the required power is consumed; determining the maximum available power and the minimum available power of the driving motor in the corresponding driving state and the slope slipping state based on the total maximum power, the required power and the backup power; the drive motor is controlled using the maximum available power and the minimum available power.

In one embodiment, the vehicle data comprises gear state, vehicle speed, accelerator pedal depth and motor speed value of the electric vehicle; the method for identifying the current driving state and the slope slipping state of the electric automobile comprises the following steps: in a corresponding gear state, monitoring the magnitude relation between the rotating speed value of the motor and a preset rotating speed value so as to identify the current slope sliding state of the electric automobile; and monitoring the change relation between the speed and the depth of the accelerator pedal in the time dimension so as to identify the current driving state of the electric automobile.

In one embodiment, the drive motor comprises a front motor and a rear motor; wherein, under corresponding gear state, the big or small relation of monitoring motor speed value and predetermineeing the rotational speed value to discernment electric automobile current smooth slope state includes: when the gear state is a forward gear state, identifying that the electric automobile is in a first-class slope state at present in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a first preset rotating speed value; or under the condition that the gear state is a reverse gear state, identifying that the electric automobile is in a second type of slope slipping state at present in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a second preset rotating speed value; or when the electric automobile is not in the first type slope slipping state and the second type slope slipping state currently, the electric automobile is identified to be in the non-slope slipping state currently.

In one embodiment, the driving state includes a relatively stationary state, a driving state, and a recovery state; wherein, monitoring the speed of a motor vehicle and the accelerator pedal degree of depth relation of change under the time dimension to discernment electric automobile current driving state includes: responding to the change of the speed and the depth of the accelerator pedal along with the time to continuously maintain the initial values, and then the current running state of the electric automobile is a relative static state; or continuously maintaining a non-initial value or increasing in response to the change of the vehicle speed and the depth of the accelerator pedal along with the time, wherein the current running state of the electric vehicle is a driving state; or responding to the continuous reduction of the vehicle speed and the change of the accelerator pedal depth along with the time, and then the current running state of the electric vehicle is a recovery state.

In one embodiment, the vehicle data further includes a permitted discharge power and a permitted charge power of the battery pack, an accessory power; the sum maximum power includes a sum maximum discharge power and a sum maximum charge power; wherein, utilize vehicle data calculation to obtain driving motor's power parameter, include: calculating the difference between the allowable discharge power and the accessory power to obtain the sum of the maximum discharge power; and calculating a difference between the allowable charging power and the accessory power to obtain a summed maximum charging power.

In one of the embodiments, the vehicle data further includes required torque, efficiency, and rotational speed values of the front motor, and required torque, efficiency, and rotational speed values of the rear motor; wherein, utilize the vehicle data calculation to obtain driving motor's power parameter, include: calculating a quotient value of a product of the required torque and the rotating speed value of the front motor which dynamically changes along with the running state and the required torque of the front motor to obtain the required power of the front motor which correspondingly dynamically changes; and calculating a quotient value of a product of the required torque and the rotating speed value of the rear motor which are dynamically changed along with the driving state and the required torque of the rear motor in real time to obtain the required power of the rear motor which is correspondingly dynamically changed.

In one embodiment, the backup power comprises a discharge backup power and a charge backup power corresponding to a hill-slip condition; wherein, utilize the vehicle data calculation to obtain driving motor's power parameter, include: responding to the condition that the electric automobile is in the non-slope-slipping state, calculating the difference value between the sum maximum discharge power and the required power of the front motor and the required power of the rear motor to obtain the discharge reserve power in the non-slope-slipping state, and calculating the difference value between the sum maximum charging power and the required power of the front motor and the required power of the rear motor to obtain the charge reserve power in the non-slope-slipping state; or responding to the situation that the electric automobile is in a slope slipping state, calculating the difference value between the negative value of the total maximum discharging power and the required power of the front motor and the required power of the rear motor to obtain the discharging backup power in the slope slipping state, and calculating the difference value between the negative value of the total maximum charging power and the required power of the front motor and the required power of the rear motor to obtain the charging backup power in the slope slipping state.

In one embodiment, determining the maximum available power and the minimum available power of the drive motor in the respective driving state and the hill-slip state comprises: calculating a sum of a preset ratio of a sum of a maximum charging power, a discharge backup power and a required power in response to the electric vehicle being in a driving state to determine a maximum available power and a minimum available power of the front motor and a maximum available power and a minimum available power of the rear motor; or in response to the electric vehicle being in a recovery state, calculating a sum of a preset ratio of the sum of the maximum discharge power, the charge backup power and the required power to determine the maximum available power and the minimum available power of the front motor and the maximum available power and the minimum available power of the rear motor.

In one embodiment, the vehicle data further includes a battery pack voltage; wherein, the control of the driving motor by using the maximum available power and the minimum available power comprises the following steps: respectively calculating quotient values of the maximum available power and the minimum available power of the front motor and the battery pack voltage in preset proportion to determine the maximum current limit value and the minimum current limit value of the front motor in the corresponding slope state, and respectively calculating quotient values of the maximum available power and the minimum available power of the rear motor and the battery pack voltage in preset proportion to determine the maximum current limit value and the minimum current limit value of the rear motor in the corresponding slope state; adjusting the torque limit value of the front motor by using the maximum current limit value and the minimum current limit value of the front motor so as to control the front motor; and controlling the rear motor by using the torque limit value of the motor after the adjustment of the maximum current limit value and the minimum current limit value of the rear motor.

In one embodiment, the method further comprises: acquiring environmental data and historical vehicle data of the electric automobile; determining a predicted current limit value of the driving motor in a corresponding driving state and a slope slipping state according to current vehicle data, environment data and historical vehicle data; and adjusting the torque limit value of the driving motor in real time by using the predicted current limit value so as to control the electric automobile.

In a second aspect, the present application also provides a control apparatus for driving a motor. The apparatus comprises: the vehicle data acquisition module is used for acquiring vehicle data of an electric vehicle carrying a driving motor; the vehicle data processing module is used for calculating and obtaining power parameters of the driving motor by using vehicle data; the power parameters comprise total maximum power, required power and backup power, the total maximum power is used for representing the maximum total power of the driving motor in a corresponding driving state, and the backup power is used for representing the residual power of the total maximum power after the required power is consumed; the vehicle state identification module is used for identifying the current driving state and the slope slipping state of the electric vehicle by using the vehicle data; the motor available power processing module is used for determining the maximum available power and the minimum available power of the driving motor in the corresponding running state and the slope slipping state based on the total maximum power, the required power and the backup power; and the motor control module is used for controlling the driving motor by utilizing the maximum available power and the minimum available power.

In a third aspect, the present application also provides a computer device. The computer device comprises a processor and a memory connected with the processor, wherein the memory is stored with program data, and the processor calls the program data stored in the memory to execute the control method of the driving motor.

In a fourth aspect, the present application further provides a computer-readable storage medium. The computer-readable storage medium has stored therein program instructions that, when executed by a processor, implement the control method of the drive motor as described above.

In a fifth aspect, the present application further provides a computer program product. The computer program product has stored therein a computer program which, when executed by a processor, implements the control method of the drive motor as described above.

The control method of the driving motor, the control device of the driving motor, the computer equipment, the storage medium and the computer program product are characterized in that vehicle data of an electric vehicle loaded with the driving motor are obtained; then, calculating by utilizing vehicle data to obtain a power parameter of a driving motor, and identifying the current driving state and the slope sliding state of the electric automobile; the power parameters comprise total maximum power, required power and backup power, the total maximum power is used for representing the maximum total power of the driving motor in a corresponding driving state, and the backup power is used for representing the residual power of the total maximum power after the required power is consumed; then, based on the total maximum power, the required power and the backup power, the maximum available power and the minimum available power of the corresponding driving motor are determined by utilizing the current driving state and the slope slipping state of the electric automobile, so that the phenomena of over-discharge and over-charge of the driving motor can be avoided, and the safety of the automobile is ensured; and finally, the maximum available power and the minimum available power are utilized to control the driving motor, the full play of the capability of the driving motor can be ensured, and the dynamic property and the economical efficiency of the whole vehicle are improved within the range of the maximum available power and the minimum available power.

Drawings

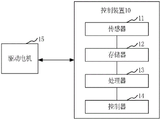

Fig. 1 is a schematic application scenario diagram of an embodiment of a control method for a driving motor provided in the present application;

fig. 2 is a schematic application scenario diagram of another embodiment of a control method for a driving motor provided in the present application;

FIG. 3 is a schematic flow chart diagram illustrating an embodiment of a method for controlling a driving motor provided herein;

FIG. 4 is a model diagram illustrating an embodiment of the present application for identifying the current driving status of an electric vehicle;

FIG. 5 is a schematic flow chart diagram illustrating another embodiment of a method for controlling a drive motor provided herein;

FIG. 6 is a schematic structural diagram of an embodiment of a control apparatus for a driving motor provided in the present application;

fig. 7 is a schematic structural diagram of an embodiment of an electronic device provided in the present application;

FIG. 8 is a schematic block diagram of an embodiment of a computer apparatus provided in the present application;

fig. 9 is a schematic structural diagram of an embodiment of a computer-readable storage medium provided in the present application.

Detailed Description

In order to make the objects, technical solutions and advantages of the present application more apparent, the present application is described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are for purposes of illustration and not limitation, and that specific details are set forth such as particular system structures, procedures, techniques, etc. in order to provide a thorough understanding of the present application.

Reference in the specification to "an embodiment" means that a particular feature, process, or characteristic described in connection with the embodiment can be included in at least one embodiment of the specification. The appearances of the phrase in various places in the specification are not necessarily all referring to the same embodiment, nor are separate or alternative embodiments mutually exclusive of other embodiments. It is explicitly and implicitly understood by one skilled in the art that the embodiments described herein may be combined with other embodiments.

The steps in the embodiments of the present application are not necessarily processed according to the described step sequence, and may be optionally rearranged in a random manner, or steps in the embodiments may be deleted, or steps in the embodiments may be added according to requirements.

Referring to fig. 1, fig. 1 is a schematic view of an application scenario of an embodiment of a control method for a driving motor according to the present application, and the control method for a driving motor according to some embodiments of the present application may be applied to an application environment of a control device 10 for a driving motor 15 mounted on an electric vehicle. The control device 10 may include, among other things, several and several sensors 11, a memory 12, a processor 13, and a controller 14.

In one embodiment, the plurality of sensors 11 may include a three-axis gyroscope, an angular velocity sensor, an angle sensor, a motion sensor, and the like, for collecting in real time corresponding vehicle data generated by the electric vehicle based on the posture operation of the driver.

In one embodiment, processor 13 may also be referred to as a CPU (Central Processing Unit). The processor 13 may be an electronic chip having signal processing capabilities. The Processor 13 may also be a general purpose Processor, a Digital Signal Processor (DSP), an Application Specific Integrated Circuit (ASIC), a Field Programmable Gate Array (FPGA) or other Programmable logic device, discrete Gate or transistor logic, discrete hardware components. A general purpose processor may be a microprocessor or the processor may be any conventional processor or the like. In addition, the processor 13 may be commonly implemented by an integrated circuit chip.

In one embodiment, the memory 12 may be a memory bank, a TF card, or the like, and may store all information in the control device 10, including all vehicle data entered, raw data, computer programs, intermediate operational results, and final operational results, all stored in the memory 12. It stores and retrieves information according to the location specified by the processor 13. With the memory 12, the control device 10 has a memory function to ensure normal operation. The memory 102 of the control device 10 may be classified into a main memory (internal memory) and an auxiliary memory (external memory) according to the purpose, and may be classified into an external memory and an internal memory. The external memory is usually a magnetic medium, an optical disk, or the like, and can store information for a long period of time. The memory refers to a storage component on the main board, which is used for storing data and programs currently being executed, but is only used for temporarily storing the programs and the data, and the data is lost when the power is turned off or the power is cut off.

In one embodiment, the controller 14 (controller) refers to a master command device that controls the starting, speed regulation, braking, and reversing of the drive motor 15 by changing the wiring of the master circuit or control circuit and changing the resistance value in the circuit in a predetermined sequence. Which is comprised of a program counter, an instruction register, an instruction decoder, a timing generator, and an operation controller, controller 14 is capable of coordinating and directing the operation of the entire computer system in control apparatus 10.

In one embodiment, the control device 10 may load an application program, program data, and operating system that may include various applications, such as a Web browser, a middle tier application, a relational database management system (RDBMS), and the like, being executed by the electric vehicle. As an example, the operating system of an electric vehicle may include versions of Microsoft WindowsAppleAnd/or Linux operating system, various business or classOperating systems (including but not limited to various GNU/Linux operating systems, google)OS, etc.) and/or mobile operating systems, such asPhone、OS、OS、An OS operating system, and other operating systems.

In one application scenario, first, the sensor 11 collects at least a part of vehicle data generated on the electric vehicle based on the driving state of the vehicle in real time, the memory 12 acquires and stores the at least part of vehicle data, and the memory 12 stores the intrinsic vehicle data of the electric vehicle in itself. Then, the processor 13 receives the vehicle data in the memory 12 and performs data processing to obtain a corresponding data processing result. Finally, the controller 14 is communicatively connected to the driving motor 15 and the processor 13 by a communication network (e.g., a data bus, an ethernet, a cellular network, a bluetooth, a wireless hotspot, a wired wire, etc.) to obtain a data processing result of the vehicle data and generate corresponding control data, so as to control the driving motor 15 by using the control data.

Referring to fig. 2, fig. 2 is a schematic view of an application scenario of another embodiment of the control method for a driving motor according to the present application, and the control method for a driving motor according to some embodiments of the present application may be applied to an application environment of a control system 20 of an electric vehicle. The control system 20 may include a Broadcast Transmitter 21 (BT) installed in an electric vehicle, a plurality of communication base stations 22 distributed in a driving area of the electric vehicle, a satellite 23, and a server 24.

In an application scenario, firstly, the broadcast transmitter 21 acquires vehicle data on the electric vehicle in real time and converts the vehicle data into a corresponding broadcast message, the broadcast transmitter 21 transmits the broadcast message to the communication base station 22 closest to the broadcast transmitter in a short-distance communication manner, and the communication base station 22 receives the broadcast message and forwards the broadcast message to the communication satellite 23 to analyze the broadcast message, so as to obtain original vehicle data and positioning information of the electric vehicle. Then, the satellite 23 sends the original vehicle data and the positioning information of the electric vehicle to the server 24 for data processing and corresponding logic judgment to generate corresponding control data, and the server 24 transmits the control data back to the electric vehicle through the original communication path to control a driving motor on the electric vehicle.

Referring to fig. 3, fig. 3 is a schematic flowchart of an embodiment of a method for controlling a driving motor according to the present disclosure, where the method is applied to a control device of the driving motor for example, and it can be understood that the method may also be applied to a control system of an electric vehicle, or applied to a control system including the control device and a server, and implemented by interaction between the control device and the server. In this embodiment, the control method includes the steps of:

step S11: vehicle data of an electric vehicle equipped with a drive motor is acquired.

In one embodiment, the control device receives vehicle data transmitted by the electric vehicle in real time using a communication network (e.g., data bus, ethernet, cellular network, bluetooth, etc.).

In an embodiment, the electric vehicle may be a pure electric vehicle in the automobile field (e.g., a new energy vehicle such as a hydrogen energy vehicle, a sodium battery vehicle, a lithium battery vehicle, etc.), a hybrid vehicle, an extended range vehicle, a trolley bus, etc., which are not specifically limited herein, and a driving motor of the electric vehicle may be controlled by a current conducted on the electric vehicle.

In one embodiment, the driving motor mounted on the electric vehicle may be any one of a concentrated driving motor, a wheel-side driving motor, and a hub driving motor.

As an example, the concentrated driving motor may be mounted in an electric vehicle in a dual driving mode, and provide driving capability or recovery capability for front and rear wheels thereof, respectively. The wheel-side driving motor can drive the wheel-side reducer through a permanent magnet synchronous motor technology so as to provide speed reduction and torque increase for the electric automobile to drive wheels of the electric automobile.

In one embodiment, the vehicle data of the electric vehicle may include dynamic vehicle data on the electric vehicle and may also include static vehicle data on the electric vehicle.

As one example, the dynamic vehicle data is dynamic data in which an electric vehicle executes a corresponding travel instruction based on a driver's driving operation on the electric vehicle and generates a corresponding change following a change in a vehicle travel state. For example, dynamic vehicle data may include vehicle speed, drive motor torque, accelerator pedal depth, brake pedal depth, and the like.

As an example, the static vehicle data is inherent data or fixed parameters set based on a production engineer when the electric vehicle is shipped from the factory. For example, the static vehicle data may include discharge power and charge power allowed by the battery pack, operating efficiency of the driving motor, and the like.

Step S12: and calculating power parameters of the driving motor by using the vehicle data, and identifying the current driving state and the slope slipping state of the electric vehicle.

In one embodiment, the control device may identify the current driving state and the slope slipping state of the electric vehicle by using the current vehicle data of the electric vehicle and an associated preset algorithm or preset standard. The current driving state of the electric vehicle may include a driving state, a recovery state and a stationary state. The current slope state of the electric automobile can comprise a slope state and a slope state.

As an example, the control device determines whether the current relevant vehicle data of the electric vehicle exceeds, does not reach or is equal to some set index parameters according to a preset reference standard (such as a preset reference parameter threshold), so as to identify the current driving state and the slope slipping state of the electric vehicle.

As an example, the control device inputs the current vehicle data of the electric vehicle into some preset program algorithm (such as a computer model for comparing data changes or sizes) to perform state recognition, so as to recognize the current driving state and the current slope state of the electric vehicle.

In one embodiment, the control device may utilize current vehicle data and associated data processing methods of the electric vehicle to calculate current power parameters of the drive motor. Wherein the power parameters of the drive motor comprise at least a total maximum power, a required power and a backup power.

As an example, the total maximum power is used to represent the maximum total power of the driving motor in the corresponding driving state, and if the maximum power that the driving motor can output in the driving state is A1, A1 is the maximum total power of the driving motor in the driving state. The power demand is used to characterize the desired output power of the driver for the drive motor in the respective driving state. The backup power is used for representing the residual power of the sum maximum power after the required power is consumed, and if the maximum sum power of the driving motor is A1 and the required power of a driver is A2, the backup power of the driving motor is A1-A2.

Step S13: and determining the maximum available power and the minimum available power of the driving motor under the corresponding driving state and the slope slipping state based on the total maximum power, the required power and the backup power.

In one embodiment, the control device calculates the maximum available power and the minimum available power of the drive motor from the sum of the maximum power, the required power and the backup power according to the relevant data processing method and by combining the current driving state and the hill-climbing state of the electric vehicle.

In one embodiment, the maximum available power is the maximum power that the driving motor can release in the current driving state and the downhill state, and the minimum available power is the minimum power that the driving motor can release in the current driving state and the downhill state, that is, the range of power that the driving motor can release is between the maximum available power and the minimum available power. Wherein, under different driving state and the state of sloping, the power range that the driving motor can release can be different.

Step S14: the drive motor is controlled using the maximum available power and the minimum available power.

In one embodiment, the control device converts the maximum available power and the minimum available power into corresponding maximum current and minimum current using the associated data processing method, and transmits the available current within the range of the maximum current and the minimum current to the driving motor so that the driving motor outputs a corresponding amount of torque, thereby controlling the operation of the driving motor.

In one implementation scenario, the control device receives vehicle data transmitted by the electric vehicle in real time by way of a data bus. The control device identifies that the electric automobile is in a driving state and a non-slope-slipping state at present, and the current total maximum power A1, the required power A2 and the backup power A3 of the driving motor by using the current vehicle data and a preset computer model. Then, the control device calculates the maximum available power A4 and the minimum available power A5 of the driving motor in the driving state and the non-slip state by using the total maximum power A1, the required power A2 and the backup power A3. Finally, the control device converts the maximum available power A4 and the minimum available power A5 into a corresponding maximum current A6 and a corresponding minimum current A7, and transmits a current A8 to the driving motor (wherein, the maximum current A6 is more than the current A8 is more than the minimum current A7), so that the driving motor outputs a torque A9 with a corresponding magnitude, thereby controlling the driving motor to operate under the torque A9.

In the control method of the driving motor, on one hand, the maximum available power and the minimum available power of the corresponding driving motor are determined according to the current driving state and the slope slipping state of the electric automobile, so that the phenomena of over-discharge and over-charge of the driving motor can be avoided, and the safety of the automobile is ensured; on the other hand, the driving motor is controlled by utilizing the maximum available power and the minimum available power, the full play of the capability of the driving motor can be ensured, and the dynamic property and the economical efficiency of the whole vehicle are improved within the range of the maximum available power and the minimum available power.

It will be understood by those skilled in the art that in the method of the present invention, the order of writing the steps does not imply a strict order of execution and any limitations on the implementation, and the specific order of execution of the steps should be determined by their function and possible inherent logic.

In some specific embodiments, the process of controlling the driving motor by the control device further includes a process of recognizing a state of the vehicle, sequentially calculating a total maximum power, a required power, a backup power, an available power limit, and a current limit of the front motor and the rear motor, and then controlling the driving motor based on the current limit.

In some embodiments, the electric vehicle is mounted with several kinds and several sensors, and after the electric vehicle generates corresponding dynamic vehicle data based on the driving operation of the driver, the sensors can collect the dynamic vehicle data in real time and transmit the dynamic vehicle data to the control device. The electric vehicle is also equipped with a storage device for storing static vehicle data unique to the electric vehicle, and the storage device is connected to the control device in a communication manner and transmits the static vehicle data to the control device.

In some embodiments, the vehicle data of the electric vehicle acquired by the control device may include a gear state and a motor speed value of the electric vehicle. The motor rotating speed value is the current rotating speed value of the driving motor, and the gear state can comprise a forward gear and a reverse gear.

In one embodiment, the control device identifying the current roll state of the electric vehicle may include: and in the corresponding gear state, monitoring the magnitude relation between the rotating speed value of the motor and a preset rotating speed value so as to identify the current slope sliding state of the electric automobile.

In one embodiment, the driving motor comprises a front motor and a rear motor, that is, the electric vehicle in the present application can perform a dual-motor all-wheel drive in a manner that the front motor and the rear motor jointly provide torque.

In one embodiment, the front motor and the rear motor may adopt motors with the same power, that is, the front motor is responsible for front-drive driving, and the rear motor is responsible for rear-drive driving, so as to increase the torque and power of the electric vehicle, and achieve an effect of "1+1= 2".

In another embodiment, the front motor and the rear motor may adopt a power splitting mode, that is, the front motor is mainly responsible for driving, and the rear motor is mainly responsible for generating electricity. The double-motor drive can repeatedly utilize the high-efficiency working area, and can achieve the effect of energy recovery.

In another embodiment, the front motor and the rear motor can be controlled simultaneously by using motors with different powers, namely, the front motor is responsible for controlling a high-speed area, and the rear motor is responsible for controlling a low-speed area. Through the mode, the front motor and the rear motor are kept in an efficient working range, and the efficiency of the whole vehicle is improved in an all-round mode.

In one embodiment, the identifying of the current roll state of the electric vehicle by the control device may specifically include: when the gear state is a forward gear state, identifying that the electric automobile is currently in a first type of slope state in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a first preset rotating speed value; or under the condition that the gear state is a reverse gear state, identifying that the electric automobile is in a second type of slope slipping state at present in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a second preset rotating speed value; or when the electric automobile is not in the first type slope slipping state and the second type slope slipping state currently, the electric automobile is identified to be in the non-slope slipping state currently.

As an example, when the gear state of the electric vehicle is forward, the rotation speed nfront of the front electric machine and the rotation speed nrear of the rear electric machine are both less than a preset first preset rotation speed value nneg, which is a negative value, indicating that the vehicle is rolling backwards. When the gear state of the electric vehicle is a reverse gear, when the rotation speed nfront of the front motor and the rotation speed nrear of the rear motor are both greater than a preset second preset rotation speed value npos, the vehicle is indicated to roll forward, wherein the second preset rotation speed value nneg is a positive value. When the electric vehicle is either one of the vehicle forward-rolling or the vehicle backward-rolling, it is determined that the electric vehicle is in the state of rolling on a slope at that time, and this is indicated by bvehvs =1. When the electric vehicle is not in the state that the vehicle rolls forward or rolls backward, the electric vehicle is determined not to be in the state of rolling down the slope at the moment, and the result is represented by bvehivvs = -1.

In one embodiment, the control device recognizing the current driving state of the electric vehicle may include: and monitoring the change relation between the speed and the depth of the accelerator pedal in the time dimension so as to identify the current driving state of the electric automobile.

In one embodiment, the current driving state of the electric vehicle includes a relatively stationary state, a driving state, and a recovery state. The relative stationary state is used to indicate that the electric vehicle is stationary relative to the ground at this time. The driving state is used to indicate that the driving motor of the electric vehicle is in a discharging process, i.e., consuming energy. The recovery state is used to indicate that the drive motor of the electric vehicle is in a charging process, i.e., energy is being recovered.

In one embodiment, the identifying of the current driving state of the electric vehicle by the control device may specifically include: responding to the change of the speed and the depth of the accelerator pedal along with the time to continuously maintain the initial values, and then the current running state of the electric automobile is a relative static state; or continuously maintaining a non-initial value or increasing in response to the change of the vehicle speed and the depth of the accelerator pedal along with the time, wherein the current running state of the electric vehicle is a driving state; or responding to the continuous reduction of the vehicle speed and the change of the accelerator pedal depth along with the time, and then the current running state of the electric vehicle is a recovery state.

As an example, please refer to fig. 4, wherein fig. 4 is a schematic model diagram of an embodiment of the present application for identifying a current driving state of an electric vehicle. The driving state model of the change of the speed and the depth of the accelerator pedal of the electric automobile along with the time is represented by a function Sp, and the influence factors of the model comprise the speed V and the depth h of the accelerator pedal of the electric automobile. As shown in fig. 2, if the vehicle speed V and the accelerator pedal depth h of the electric vehicle are continuously maintained at 0 between T1 and T2 with the lapse of time, the current driving state of the electric vehicle recognized by the control device is a relatively stationary state within the time range T1 to T2. The vehicle speed V and the accelerator pedal depth h of the electric vehicle keep rising state between T2 and T3 along with the time, and the current running state of the electric vehicle identified by the control device is a driving state in the time range from T2 to T3. The vehicle speed V and the accelerator pedal depth h of the electric vehicle keep descending state between T3 and T4 along with the time, and the current running state of the electric vehicle identified by the control device is a recovery state in the time range from T3 to T4.

In some embodiments, the vehicle data of the electric vehicle acquired by the control device further includes the allowable discharge power and allowable charge power of the battery pack, and the accessory power. The allowable discharge power is used for representing the maximum discharge power of the battery pack designed to output to the driving motor when the electric automobile is in a driving state; the allowable charging power is used for representing the maximum charging power which is output to the driving motor by the design of the battery pack when the electric automobile is in a recovery state. The accessory power is used for representing the sum of all power consumed by other power components except the driving motor when the electric automobile is in a driving state or a recovery state.

In some embodiments, the sum maximum power of the driving motors includes a sum maximum discharge power and a sum maximum charge power. The total maximum discharge power is used for representing the maximum discharge power which can be jointly output by the front motor and the rear motor when the electric automobile is in a driving state; the total maximum charging power is used for representing the maximum charging power which can be jointly output by the front motor and the rear motor when the electric automobile is in a recovery state.

In one embodiment, the calculating the power parameter of the driving motor by the control device using the vehicle data may specifically include: calculating the difference between the allowable discharge power and the accessory power to obtain the sum of the maximum discharge power; and calculating a difference between the allowable charging power and the accessory power to obtain a summed maximum charging power.

As an example, the allowable discharge power (denoted by BMSPwrChg) of the battery pack is a positive value, the allowable charge power (denoted by BMSPwrChg) of the battery pack is a negative value, and the accessory power of the electric vehicle is denoted by AccPwr, so that the total maximum discharge power commonly available to the front motor and the rear motor of the driving motor is DCUPwrmax = BMSPwrChg-AccPwr, and the total maximum charge power commonly available to the front motor and the rear motor of the driving motor is DCUPwrmin = BMSPwrChg-AccPwr.

In some embodiments, the vehicle data of the electric vehicle acquired by the control device further includes required torque, efficiency, and rotation speed values of the front motor, and required torque, efficiency, and rotation speed values of the rear motor. The required torque of the front motor and the required torque of the rear motor are used for representing the output torque of the front motor and the rear motor expected by a driver corresponding to the driving operation when the driver performs the driving operation.

In one embodiment, the calculating the power parameter of the driving motor by the control device using the vehicle data may specifically include: calculating a quotient value of a product of a required torque and a rotating speed value of the front motor which dynamically changes along with the running state and the efficiency of the front motor with a preset proportion to obtain required power of the front motor which correspondingly dynamically changes; and calculating the quotient of the product of the required torque and the rotating speed value of the rear motor which dynamically changes along with the driving state and the efficiency of the rear motor with the preset proportion in real time to obtain the required power of the rear motor which correspondingly dynamically changes.

As an example, the vehicle data obtained by the control device includes that the front motor has an inherent driving efficiency Efffront, the rear motor has an inherent driving efficiency Effrear, the current rotation speed nfont of the front motor, the current rotation speed nrear of the rear motor, the current required torque tqreqfont of the front motor, the current required torque tqreqreqrear of the rear motor, and the factory-set required power proportionality constant of the electric vehicle is 9550 (in other embodiments, any other proportionality constant may be used, and is not specifically limited herein), so that the required power of the front motor is dcuelcpwrreqfont = (nfont:)/9550/Efffront, and the required power of the rear motor is dcuelcprrer = (nreqreqreqrefront)/9550/effear.

In one embodiment, the power parameter of the driving motor calculated by the control device by using the vehicle data may include a backup power of the driving motor, wherein the backup power may also specifically include a discharge backup power and a charge backup power in a corresponding slope state of the electric vehicle.

In one embodiment, the backup power is used to represent the remaining power of the sum of the maximum powers after consuming the required power, and if the maximum sum discharge power of the driving motor is A1 and the required power of the driver is A2, the backup discharge power of the driving motor is A1-A2.

In one embodiment, the calculating the power parameter of the driving motor by the control device using the vehicle data may specifically include: and calculating the difference value of the sum maximum discharge power, the required power of the front motor and the required power of the rear motor to obtain the discharge reserve power in the non-slip state, and calculating the difference value of the sum maximum charge power, the required power of the front motor and the required power of the rear motor to obtain the charge reserve power in the non-slip state.

In another embodiment, the calculating the power parameter of the driving motor by the control device using the vehicle data may specifically include: and in response to the situation that the electric automobile is in a slope slipping state, calculating the difference value between the negative value of the total maximum discharging power and the required power of the front motor and the required power of the rear motor to obtain the discharging backup power in the slope slipping state, and calculating the difference value between the negative value of the total maximum charging power and the required power of the front motor and the required power of the rear motor to obtain the charging backup power in the slope slipping state.

As an example, when the whole vehicle of the electric vehicle is in a non-slope-slipping state, the slope slipping state is recorded as bvehvs =0, when the whole vehicle of the electric vehicle is in a slope slipping state, the slope slipping state is recorded as bvehvs =1, the maximum total discharge power of the driving motor is dcupwrrmax, the maximum total charge power is DCUPwrmin, the required power of the front motor is DCUElcPwrReqfront, the required power of the rear motor is DCUElcPwrReqrear, then the discharge backup power of the electric vehicle in the non-slope state is SBPwrDchg = dcuprwrrmax-dcuelwrreqfront-DCUElcPwrReqrear, and the charge backup power is sbpwrrg = dcuplwrqrewrmjn-dcuelprered; and the discharge reserve power of the electric automobile in a slope slipping state is SBPwrdcchg = -1 DCUPwrmin-DCUELCPwrReqfron-DCUELCPwrReqrear, and the charge reserve power is SBPwrchg = -1 DCUPwrmin-DCUELCPwrReqfron-DCUELCPwrReqrear.

In one embodiment, the control device may specifically determine the maximum available power and the minimum available power of the drive motor in the respective driving state and the downhill state based on the total maximum power, the required power and the backup power, and may include: calculating a sum of a preset ratio of a sum of a maximum charging power, a discharge backup power and a required power in response to the electric vehicle being in a driving state to determine a maximum available power and a minimum available power of the front motor and a maximum available power and a minimum available power of the rear motor; or in response to the electric vehicle being in a recovery state, calculating a sum of a preset ratio of the sum of the maximum discharge power, the charge backup power and the required power to determine the maximum available power and the minimum available power of the front motor and the maximum available power and the minimum available power of the rear motor.

As an example, when the entire electric vehicle is in a driving state, the driving state is written as bRecpAct =0, when the entire electric vehicle is in a recovery state, the recovery state is written as bRecpAct =1, the required electric power of the front motor is dcuelpwrreqfront, the required electric power of the rear motor is dcuelpwrreqrreat, the total maximum charging power of the driving motors is DCUPwrmin, the total maximum discharging power is dcuprrmax, the discharge backup power of the driving motors is SBPwrDchg, and the charge backup power is sbpwrch, on the one hand, when the electric vehicle is in the driving state, the maximum available power of the front motor is dcuprmavarrmin = dcweront =2, the maximum available power of the rear motor is rexarfrost + SBPwrDchg/2, and the minimum available power of the front motor is dcupravlront = dcweruplrmrmin = dcwerdcweruplmar/dcwerdcwerdcwerdcwerdcwerdcwergrurgprr + sbpwrderg/2. On the other hand, when the electric vehicle is in the recovery state, the maximum available power of the front motor is DCUPwrMaxAvailfront = dcupwrrmax/2, the minimum available power of the front motor is DCUPwrMinAvailfront = DCUElcPwrReqfront + sbpwrchag/2, the maximum available power of the rear motor is DCUPwrMaxAvailrear = dcuewrreqrreqrear + sbpwrchag/2, and the minimum available power of the rear motor is dcuepwrrmaxavailrear = dcuewrreqrreqrear + sbpwrchag/2.

In one embodiment, the controlling means controlling the driving motor using the maximum available power and the minimum available power may specifically include: the maximum available power and the minimum available power of the front motor in preset proportion are respectively calculated with the quotient of the battery pack voltage to determine the maximum current limit value and the minimum current limit value of the front motor in the corresponding slope state, and the maximum available power and the minimum available power of the rear motor in preset proportion are respectively calculated with the quotient of the battery pack voltage to determine the maximum current limit value and the minimum current limit value of the rear motor in the corresponding slope state. Then, the torque limit value of the front motor is adjusted by using the maximum current limit value and the minimum current limit value of the front motor so as to control the front motor; and controlling the rear motor by using the torque limit value of the motor after the adjustment of the maximum current limit value and the minimum current limit value of the rear motor.

As an example, when the electric vehicle is in the non-slip state, the maximum current limit of the front motor is DCUIdcMaxfront = DCUPwrMaxAvailfront/BMSVolt, the minimum current limit is dcuidccminfront = DCUPwrMaxAvailfront/BMSVolt, the maximum current limit of the rear motor is dcuidcuidccmaxreal = DCUPwrMaxAvailfront/BMSVolt, and the minimum current limit is dcuidcuidcuidccminreal = DCUPwrMaxAvailfront/BMSVolt. When the electric automobile is in a slope state, the maximum current limit value of the front motor is DCUIdcMaxfront = -1 × DCUPwrMinAvailailfront/BMSVolt, the minimum current limit value is DCUIdcMaxinorfront = -1 × DCUPwrMaxAvailailfront/BMSVolt, the maximum current limit value of the rear motor is DCUIdcMaxreal = -1 × DCUPwrMinrAvailailfront/BMSVolt, and the minimum current limit value is DCUIdCMAxreal = -1 × DCUPwrMaxalfront/BMSVolt.

In one embodiment, after acquiring the maximum current limit and the minimum current limit of the front motor and the rear motor, the control device calculates the maximum torque limit and the minimum torque limit of the front motor corresponding to the maximum current limit and the minimum current limit of the front motor and the maximum torque limit and the minimum torque limit of the rear motor corresponding to the maximum current limit and the minimum current limit of the rear motor by using a preset iterative algorithm.

As an example, the maximum torque limits of the front motor of the electric vehicle are P1 and the minimum torque limit P2, and P1 > P2, the maximum torque limits of the rear motor are P3 and the minimum torque limit P4, and P3 > P4, the front motor may output any torque output in the range of P1 to P2 based on the driving operation of the driver to control the front motor of the electric vehicle, and the rear motor may output any torque output in the range of P3 to P4 based on the driving operation of the driver to control the rear motor of the electric vehicle.

In another embodiment, after acquiring the maximum current limit value and the minimum current limit value of the front motor and the rear motor, the control device calculates the optimal output current of the front motor within the maximum current limit value and the minimum current limit value by using a preset optimal strategy model, converts the optimal output current into the optimal output torque corresponding to the front motor to control the front motor of the electric vehicle, calculates the optimal output current of the rear motor within the maximum current limit value and the minimum current limit value, and converts the optimal output current into the optimal output torque corresponding to the rear motor to control the rear motor of the electric vehicle.

As an example, the preset optimal strategy model may be a pre-trained reinforcement learning neural network, which learns a plurality of current limit ranges to be trained and accumulated feedback values obtained by corresponding driving motors under preset driving operation, so as to obtain optimal target output torque ranges of different action strategies (i.e. optimal output torques) under each initial state value and termination state value (i.e. maximum current limit value and minimum current limit value). Wherein each target output torque within the range of target output torques represents an optimal output torque.

As an example, the reinforcement learning neural network sets the initial amount of each action policy at the initial state value to Px = (x 1N, x 2N.. Once, xn), and the initial amount at the termination state value to Py = (y 1N, y 2N.. Once, yn), where Px and Py are action policies, the initial amount at the xnn maximum current limit, the initial amount at the ynn minimum current limit, xi ∈ [ li, hi ], or yi ∈ [ li, hi ] is the initial amount of the i-th action policy, and there are N ∈ N total initial amounts that need to be learned. The reinforcement learning neural network takes different action strategies and the cumulative feedback value of the current limit value to be trained is rt = score (st + 1) -score (st), wherein the cumulative feedback value sets the step size of each parameter adjustment to be 1, namely a = (± 1, ± 1,...., ± 1,. For each parameter adjustment), and score sets a comprehensive optimal target output torque range determined by engineers for the current feedback value, and any feasible feedback value in the range can be used as a target output torque.

In one embodiment, the control device may further obtain environmental data of the electric vehicle when the electric vehicle is currently running and historical vehicle data stored in the storage device; according to the collected current vehicle data, the collected environmental data and the collected historical vehicle data, the predicted current limit values of the driving motor in the corresponding running state and the slope slipping state are determined; and the torque limit value of the driving motor is adjusted in real time by using the predicted current limit value so as to control the electric automobile.

As an example, the environmental data collected by the corresponding sensors of the electric vehicle is recorded and saved as a data set D, the historical vehicle data previously stored by the electric vehicle is saved as a data set S, the vehicle data collected by the corresponding sensors of the electric vehicle is recorded and saved as a data set P, the current driving state of the electric vehicle is brrecpact = Ri, and the current hill-climbing state of the electric vehicle is bveivs = Vi, the control device inputs the data set D, the data set S, the state brrecpact = Ri, and the state bveivs = Vi into a corresponding logic control program or a neural network model (e.g., RNN, LSTM, etc. based on the Attention) to perform the predicted output of the current limit, to output the predicted current limit I1 of the front motor driving the motor and the predicted current limit I2 of the rear motor, and converts the predicted current limit I1 into a corresponding predicted output torque N1 to control the front motor of the electric vehicle, and converts the predicted current limit I2 into a corresponding predicted output torque N2 to control the rear motor of the electric vehicle.

Referring to fig. 5, fig. 5 is a schematic flowchart of another embodiment of a control method for a driving motor provided in the present application, where the method is applied to a control device for a driving motor for example, and it can be understood that the method can also be applied to a control system for a four-wheel drive vehicle (i.e., an electric vehicle), or a control system including a control device and a server, and is implemented through interaction between the control device and the server. In this embodiment, the control method includes the steps of:

first, the control device acquires relevant parameters of the vehicle in real time, and the relevant parameters comprise: s1, discharging power BMSPwrrCg, charging power BMSPwrCg and battery pack voltage BMSVolt, which are allowed to be used by a battery pack; s2, rotating speeds nfront and nrear of front and back driving motors; s3, vehicle speed v and accelerator pedal depth app of the whole vehicle; s4, the power AccPwr of the whole vehicle accessory; s5, torque requests TqReqfront and TqReqrear for front and rear motors are carried out; s6, efficiencies of front and rear motors corresponding to different speeds and torques are Efffront and Effrear; s7, recognizing the vehicle driving recovery state: bRecpAct =0 represents that the vehicle is in a driving state, and bRecpAct =1 represents that the vehicle is in a recovery state; and S8, vehicle gear information DrvGear.

Further, the control device identifies a hill-drop condition of the vehicle: s1, when a gear DrvGear is a forward gear and the rotating speeds nfront and nrear of front and rear motors are both smaller than a negative value nneg, the vehicle is indicated to slide backwards; s2, when the gear DrvGear is a reverse gear and the rotating speeds nfront and nrear of the front and rear motors are both larger than a certain positive value npos, the vehicle is indicated to roll forward; and S3, when either condition of the S1 and the S2 is met, determining that the vehicle is in a slope slipping state, namely bVehIvs =1.

Still further, the control device calculates the maximum discharge power available to the motor and the maximum charge power available to the motor, where the maximum discharge power is the discharge power allowed to be used by the battery pack minus the power of the accessories of the vehicle, that is: DCUPwrmax = BMSPwrDchg-AccPwr; the maximum charging power is the charging power allowed by the battery pack minus the power of accessories of the whole vehicle, namely: DCUPwrmin = BMSPwrChg-AccPwr. Wherein, because the discharge power is a positive value, and the charge power is a negative value, DCUPwrmin is used to represent the maximum available charge power of the motor.

Then, since the torque requests of the front and rear electric machines of the four-wheel drive are adjusted in real time according to the running state of the vehicle, the current limits of the front and rear electric machines should be changed accordingly. Wherein, the current limits of the motor before and after calculation can be calculated through the following steps:

s1, calculating the required electric power of a motor before and after: DCUElcPwrReqfront = (nfront:tqreqfront)/9550/Efffront, and DCUElcPwrReqrear = (nrear:tqreqrear)/9550/effear.

S2, calculating the backup power of the battery, wherein when the vehicle is in a slope slipping state, the total available discharge power and the total available charge power of the motor need to be subjected to reversing operation to match the real discharge and charge effects of the front motor and the rear motor, so that the power of the front motor and the rear motor is limited, and the backup power of the battery can be calculated through the following steps:

s21, when the whole vehicle does not slide down the slope, namely bVehIvs =0,

discharge reserve power SBPwrDchg = DCUPwrmax-DCUElcPwrReqfront-DCUElcPwrReqrear;

charging backup power SBPwrChg = DCUPwrmin-DCUElcPwrReqfront-DCUElcPwrReqrear.

S22, when the whole vehicle slides down a slope, namely bVehiVs =1,

discharge reserve power SBPwrrDchg = -1 × DCUPwrmin-DCUElcPwrReqfront-DCUElcPwrReqrear;

charging backup power SBPwrChg = -1 × dcupwrrmax-DCUElcPwrReqfront-DCUElcPwrReqrear.

Further, the control device calculates the maximum available power and the minimum available power of the front motor and the rear motor respectively according to the driving or recovery state of the whole vehicle at present and by using the calculated backup power, and the control device specifically comprises the following steps:

s1, when the whole vehicle is in a driving state, namely bRecpAct =0,

front motor maximum available power DCUPwrMaxAvailfront = DCUElcPwrReqfront + SBPwrDchg/2,

the front motor minimum available power DCUPwrMinAvailfront = DCUPwrmin/2,

rear motor maximum available power dcupwrmaxavailreal = DCUElcPwrReqrear + SBPwrDchg/2,

rear motor minimum available power dcupwrminavailreal = DCUPwrmin/2;

s2, when the whole vehicle is in a recovery state, namely bRecpAct =1,

front motor maximum available power DCUPwrMaxAvailfront = DCUPwrmax/2,

front motor minimum available power DCUPwrMinAvailfront = DCUElcPwrReqfront + SBPwrChg/2,

rear motor maximum available power DCUPwrMaxAvailrear = DCUPwrmax/2,

rear motor minimum available power dcupwrminavailreal = DCUElcPwrReqrear + SBPwrChg/2.

Further, the control device calculates the maximum and minimum current limits of the front and rear motors according to the maximum and minimum available powers of the front and rear motors, which may specifically be implemented by the following steps:

s1, when the vehicle does not slide on a slope and bVehiVs = 0:

DCUIdcMaxfront=DCUPwrMaxAvailfront/BMSVolt;

DCUIdcMinfront=DCUPwrMinAvailfront/BMSVolt;

DCUIdcMaxrear=DCUPwrMaxAvailrear/BMSVolt;

DCUIdcMinrear=DCUPwrMinAvailrear/BMSVolt。

s2, when the vehicle slips down a slope and bVehiVs = 1:

DCUIdcMaxfront=-1*DCUPwrMinAvailfront/BMSVolt;

DCUIdcMinfront=-1*DCUPwrMaxAvailfront/BMSVolt;

DCUIdcMaxrear=-1*DCUPwrMinAvailrear/BMSVolt;

DCUIdcMinrear=-1*DCUPwrMaxAvailrear/BMSVolt。

finally, the control device controls the front motor and the rear motor according to the calculated maximum and minimum current values of the front motor and the rear motor, dynamically adjusts the capacity limit ratio of the front motor and the rear motor, and outputs any torque output within the range of the capacity limit ratio of the front motor and the rear motor based on the driving operation of the driver so as to control the front motor and the rear motor of the electric automobile.

It should be understood that, although the steps in the flowcharts related to the embodiments described above are shown in sequence as indicated by the arrows, the steps are not necessarily performed in sequence as indicated by the arrows. The steps are not performed in the exact order shown and described, and may be performed in other orders, unless explicitly stated otherwise. Moreover, at least a part of the steps in the flowcharts related to the embodiments described above may include multiple steps or multiple stages, which are not necessarily performed at the same time, but may be performed at different times, and the execution order of the steps or stages is not necessarily sequential, but may be performed alternately or alternately with other steps or at least a part of the steps or stages in other steps.

Based on the same inventive concept, the embodiment of the present application further provides a control device of a driving motor for implementing the control method of the driving motor. The implementation scheme for solving the problem provided by the device is similar to the implementation scheme recorded in the method, so specific limitations in the following embodiments of the control device for one or more driving motors can be referred to the limitations on the control method for the driving motor, and are not described herein again.

Referring to fig. 6, fig. 6 is a schematic structural diagram of an embodiment of a control apparatus for a driving motor provided in the present application, where the control apparatus 100 for a driving motor includes: a vehicle data acquisition module 110, a vehicle data processing module 120, a vehicle status identification module 130, a motor available power processing module 140, and a motor control module 150, wherein:

the vehicle data acquisition module 110 is used for acquiring vehicle data of an electric vehicle equipped with a driving motor.

In certain embodiments, the vehicle data acquisition module 110 receives vehicle data transmitted by the electric vehicle in real time using a communication network (e.g., data bus, ethernet, cellular network, bluetooth, etc.).

The vehicle data processing module 120 is configured to calculate a power parameter of the driving motor by using the vehicle data. The power parameters comprise total maximum power, required power and backup power, the total maximum power is used for representing the maximum total power of the driving motor in the corresponding driving state, and the backup power is used for representing the residual power of the total maximum power after the required power is consumed.

In certain embodiments, the vehicle data further includes an allowed discharge power and an allowed charge power of the battery pack, accessory power; the summed maximum power includes a summed maximum discharge power and a summed maximum charge power.

In one embodiment, the vehicle data processing module 120 further comprises: a total maximum power calculation submodule for calculating a difference between the allowable discharge power and the accessory power to obtain the total maximum discharge power; and calculating a difference between the allowed charging power and the accessory power to obtain the summed maximum charging power.

In some embodiments, the vehicle data further includes torque, efficiency and speed values required of the front electric machine, and torque, efficiency and speed values required of the rear electric machine.

In one embodiment, the vehicle data processing module 120 further comprises: the required power calculation submodule is used for calculating a quotient value of the product of the required torque and the rotating speed value of the front motor which dynamically changes along with the running state and the required torque of the front motor so as to obtain the required power of the front motor which correspondingly dynamically changes; and calculating the quotient of the product of the required torque and the rotating speed value of the rear motor which dynamically changes along with the driving state and the required torque of the rear motor in real time to obtain the required power of the rear motor which correspondingly dynamically changes.

In certain embodiments, the backup power includes a discharge backup power and a charge backup power corresponding to the downhill state.

In one embodiment, the vehicle data processing module 120 further comprises: a backup power calculation submodule, configured to calculate, in response to that the electric vehicle is in the non-slope-slipping state, a difference between the total maximum discharge power and a required power of the front motor and a required power of the rear motor to obtain a discharge backup power in the non-slope-slipping state, and calculate a difference between the total maximum charge power and a required power of the front motor and a required power of the rear motor to obtain a charge backup power in the non-slope-slipping state; or responding to the situation that the electric automobile is in the slope slipping state, calculating the difference value between the negative value of the sum maximum discharging power and the required power of the front motor and the required power of the rear motor to obtain the discharging backup power in the slope slipping state, and calculating the difference value between the negative value of the sum maximum charging power and the required power of the front motor and the required power of the rear motor to obtain the charging backup power in the slope slipping state.

The vehicle state identification module 130 is configured to identify a current driving state and a hill-drop state of the electric vehicle by using the vehicle data.

In some embodiments, the vehicle data includes gear state, vehicle speed, accelerator pedal depth, and motor speed values of the electric vehicle.

In one embodiment, the vehicle state identification module 130 further comprises:

and the slope state monitoring submodule is used for monitoring the magnitude relation between the rotating speed value of the motor and a preset rotating speed value under the corresponding gear state so as to identify the current slope state of the electric automobile.

And the driving state monitoring submodule is used for monitoring the variation relation of the speed and the depth of the accelerator pedal in the time dimension so as to identify the current driving state of the electric automobile.

In one embodiment, the drive motor includes a front motor and a rear motor; the slip state monitoring submodule is also used for:

under the condition that the gear state is a forward gear state, identifying that the electric automobile is currently in a first type of slope state in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a first preset rotating speed value; or under the condition that the gear state is a reverse gear state, in response to the fact that the motor rotating speed values of the front motor and the rear motor are both larger than a second preset rotating speed value, the electric automobile is identified to be in a second-type slope slipping state; or when the electric automobile is not in the first type slope slipping state and the second type slope slipping state currently, identifying that the electric automobile is in a non-slope slipping state currently.

In one embodiment, the driving state includes a relatively stationary state, a driving state, and a recovery state; the driving state monitoring submodule is also used for:

responding to the change of the vehicle speed and the accelerator pedal depth along with time to continuously maintain initial values, and then the current running state of the electric vehicle is a relative static state; or responding to the change of the vehicle speed and the accelerator pedal depth along with time to continuously maintain a value which is not the initial value or is increased, and then the current running state of the electric vehicle is a driving state; or responding to the continuous reduction of the vehicle speed and the accelerator pedal depth along with the change of time, and then the current running state of the electric vehicle is a recovery state.