CN114794960B - Cleaning machine receiver and cleaning equipment - Google Patents

Cleaning machine receiver and cleaning equipment Download PDFInfo

- Publication number

- CN114794960B CN114794960B CN202210742835.9A CN202210742835A CN114794960B CN 114794960 B CN114794960 B CN 114794960B CN 202210742835 A CN202210742835 A CN 202210742835A CN 114794960 B CN114794960 B CN 114794960B

- Authority

- CN

- China

- Prior art keywords

- take

- cleaning machine

- storage box

- cable

- box body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L1/00—Cleaning windows

- A47L1/02—Power-driven machines or devices

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/28—Floor-scrubbing machines, motor-driven

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/38—Machines, specially adapted for cleaning walls, ceilings, roofs, or the like

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4002—Installations of electric equipment

- A47L11/4005—Arrangements of batteries or cells; Electric power supply arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/20—External fittings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H75/00—Storing webs, tapes, or filamentary material, e.g. on reels

- B65H75/02—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks

- B65H75/34—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks specially adapted or mounted for storing and repeatedly paying-out and re-storing lengths of material provided for particular purposes, e.g. anchored hoses, power cables

- B65H75/38—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks specially adapted or mounted for storing and repeatedly paying-out and re-storing lengths of material provided for particular purposes, e.g. anchored hoses, power cables involving the use of a core or former internal to, and supporting, a stored package of material

- B65H75/44—Constructional details

- B65H75/4457—Arrangements of the frame or housing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H75/00—Storing webs, tapes, or filamentary material, e.g. on reels

- B65H75/02—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks

- B65H75/34—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks specially adapted or mounted for storing and repeatedly paying-out and re-storing lengths of material provided for particular purposes, e.g. anchored hoses, power cables

- B65H75/38—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks specially adapted or mounted for storing and repeatedly paying-out and re-storing lengths of material provided for particular purposes, e.g. anchored hoses, power cables involving the use of a core or former internal to, and supporting, a stored package of material

- B65H75/44—Constructional details

- B65H75/48—Automatic re-storing devices

- B65H75/486—Arrangements or adaptations of the spring motor

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/34—Handled filamentary material electric cords or electric power cables

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cleaning In General (AREA)

- Storing, Repeated Paying-Out, And Re-Storing Of Elongated Articles (AREA)

Abstract

The invention discloses a cleaning machine storage box and cleaning equipment, wherein the cleaning machine storage box comprises a storage box body, a fixing structure and a cable, wherein the storage box body is used for storing a cleaning machine; the fixing structure is arranged on the storage box body and used for fixing the storage box body with an external object; the cable is connected with receiver body and cleaner respectively. The storage box for the cleaning machine, provided by the technical scheme of the invention, can be used for storing and arranging equipment components such as the cleaning machine and the like, and can also be used as a fixing structure when the cleaning machine is used, so that the cleaning machine is pulled by a cable when the cleaning machine falls, high-altitude falling is prevented, the safety performance of the storage box is improved, and the multifunctional use purpose of the storage box for the cleaning machine is achieved.

Description

Technical Field

The invention relates to the technical field of cleaning equipment, in particular to a storage box of a cleaning machine and cleaning equipment.

Background

It is well known that cleaning equipment (e.g., cleaning machines, floor washers, etc.) is becoming more and more popular with users as it frees up labor and helps clean glass and floors.

The existing cleaning machine storage box is single in function and only used for storing other equipment components such as a cleaning machine and the like after cleaning work is finished. Therefore, in the actual working process of the cleaning machine, the cleaning machine is mostly directly externally connected with a power supply through a power line for supplying power, and in special occasions such as high-altitude operation and the like, a safety rope is additionally arranged to prevent the cleaning machine from falling off at high altitude. Therefore, the cleaning machine is provided with the multi-strand cable, and the multi-strand cable is easy to knot in the using process, so that the winding process is complex, and the problem of overlong winding time is solved.

Disclosure of Invention

The invention provides a storage box of a cleaning machine and cleaning equipment, and aims to solve the problems that the storage box of the existing cleaning machine is single in function and cannot meet the multifunctional requirement of a cleaning machine product.

To achieve the above object, a first aspect of the present invention provides a cleaning machine storage box including:

the storage box body is used for storing the cleaning machine;

the fixing structure is arranged on the storage box body and used for fixing the storage box body with an external object;

a cable connected with the storage box body and the cleaning machine respectively.

In some embodiments, the fixing structure includes at least one suction element, each of which has a suction cavity formed therein, the suction element being provided on the cartridge body for fixing with an external object.

In some embodiments, the at least one sorption element comprises a first sorption element and a second sorption element, the volume of the sorption cavity of the first sorption element being different from the volume of the sorption cavity of the second sorption element.

In some embodiments, the fixing structure further comprises a negative pressure assembly connected to the adsorption element for adjusting a vacuum degree in each adsorption cavity.

In some embodiments, the fixing structure further includes a pressure relief structure, and the pressure relief structure is connected to the adsorption element and is configured to adjust a vacuum degree in each adsorption cavity.

In some embodiments, the fixing structure further includes a drawing structure connected to the suction element for adjusting a vacuum degree in each of the suction chambers.

In some embodiments, the cleaning machine storage box further comprises a connecting rope assembly, and the connecting rope assembly is connected with the storage box body.

In some embodiments, further comprising:

the switch piece is arranged in the storage box body and used for controlling the power-on or the disconnection of the cable;

the connecting rope assembly is used for abutting against or loosening the switch piece.

In some embodiments, the connecting cord assembly comprises: connect the rope and with connect the connecting piece that the rope is connected, the connecting piece can be dismantled with the receiver body and be connected, be equipped with the connecting hole on the box wall of receiver body, the one end of connecting piece is passed the connecting hole is perhaps loosened with the butt the switch spare, the other end of connecting piece is connected connect the rope.

In some embodiments, the cable includes a core, an insulating layer covering an outer surface of the core, and a tensile layer covering an outer surface of the insulating layer.

In some embodiments, a take-up device is further included, the take-up device being located within the cassette body, the take-up device being for taking up the cable and releasing the cable.

In some embodiments, the wire takeup device comprises:

the take-up device body is arranged in the storage box body and used for winding the cable;

the driving piece is connected with the take-up body and used for driving the take-up body to rotate so as to wind the cable.

In some embodiments, a fixed shaft is arranged in the storage box body, and the take-up device body is sleeved on the fixed shaft and is rotationally connected with the fixed shaft;

the driving piece is sleeved between the fixed shaft and the take-up device body, when the take-up device body rotates along a preset direction, the rotation potential energy of the driving piece is increased, and when the driving piece releases the rotation potential energy, the take-up device body rotates along the direction opposite to the preset direction.

In some embodiments, the take-up device further comprises a first ratchet assembly coupled to the take-up body;

when the take-up device body rotates along a preset direction, the take-up device body drives the first ratchet wheel assembly to rotate;

when the take-up device body rotates along the direction opposite to the preset direction, the first ratchet wheel assembly is clamped inside to limit the take-up device body to rotate.

In some embodiments, the first ratchet assembly comprises:

the first ratchet wheel is connected with the take-up body;

the first rotating rod is rotatably connected to the storage box body, a first pawl is formed at one end of the first rotating rod, and the first pawl is meshed with the first ratchet wheel.

In some embodiments, the wire takeup device further includes a second ratchet assembly, and the second ratchet assembly is connected with the wire takeup device body;

when the rotating speed of the take-up body is less than the preset rotating speed, the take-up body drives the second ratchet wheel assembly to rotate;

when the rotating speed of the take-up body is larger than or equal to the preset rotating speed, the second ratchet wheel assembly is clamped inside to limit the rotation of the take-up body.

In some embodiments, the second ratchet assembly comprises:

the second ratchet wheel is connected with the take-up device body;

the second dwang, rotate connect in the receiver body, the one end of second dwang is formed with the second pawl, the second pawl with the second ratchet meshing.

In some embodiments, an adapter is also included;

the winding device comprises a first winding device and a second winding device, the first winding device is wound with a first cable, two ends of the first cable are respectively used for connecting the cleaner with the adapter, the second winding device is wound with a second cable, and two ends of the second cable are respectively used for connecting the adapter and the power supply.

In some embodiments, the first cable includes a first portion and a second portion, the first portion includes a first connection end and a first lead end, the first lead end connects with the adapter; the second part comprises a first fixed end and a first extending end, the first fixed end is fixed on the take-up body of the first take-up device, the first extending end is connected with the cleaning machine, and the second part is wound on the take-up body of the first take-up device or released from the take-up body of the first take-up device along with the rotation of the take-up body of the first take-up device; the first connecting end is rotatably connected with the take-up body of the first take-up device;

and/or the second cable comprises a third part and a fourth part, the third part comprises a second connecting end and a second leading end, and the second leading end is connected with the adapter; the fourth part comprises a second fixed end and a second extending end, the second fixed end is fixed on the take-up body of the second take-up device, the second extending end is connected with the power supply, and the fourth part is wound on the take-up body of the second take-up device or released from the take-up body of the second take-up device along with the rotation of the take-up body of the second take-up device; the second connecting end is rotatably connected with the take-up body of the second take-up device.

In some embodiments, the first wire rewinding device further includes a first conductive member, the first conductive member is disposed on a wire rewinding device body of the first wire rewinding device, the wire rewinding device body of the first wire rewinding device rotates to drive the first conductive member to rotate, the first fixed end is fixedly connected to the first conductive member and electrically connected to the first conductive member, and the first conductive member is rotatably connected to the first connection end;

and/or, the second wire take-up device further comprises a second conductive piece, the second conductive piece is arranged on the wire take-up device body of the second wire take-up device, the wire take-up device body of the second wire take-up device rotates to drive the second conductive piece to rotate, the second fixed end is fixedly connected with the second conductive piece and electrically connected with the second conductive piece, and the second conductive piece is rotatably connected with the second connecting end.

In some embodiments of the present invention, the,

further comprising: the first connecting end is rotationally connected with the first conductive piece through the first electric connecting piece;

and/or, further comprising: and the second connecting end is rotatably connected with the second conductive piece through the second electric connecting piece.

In some embodiments, the cleaning machine storage box further comprises a safe starting system, the safe starting system comprises a control chip and an air pressure sensor electrically connected with the control chip, and the air pressure sensor is communicated with the adsorption element.

In some embodiments, the cartridge body comprises:

the first box body is internally provided with a first containing cavity which is used for containing the take-up device and the adapter;

the second box body is stacked with the first box body, a second containing cavity is formed in the second box body, and the second containing cavity is used for containing the cleaning machine;

the outer surface of the first box body and/or the outer surface of the second box body are/is provided with the fixing structures.

A second aspect of the invention provides a cleaning apparatus comprising a cleaning machine and the cleaning machine storage case according to the first aspect for storing the cleaning machine.

The invention provides a storage box of a cleaning machine and cleaning equipment. Cleaning machine receiver includes the receiver body, and the receiver body is used for accomodating the cleaning machine, sets up fixed knot structure on the receiver body to make the receiver can be fixed on outside stationary plane through this fixed knot structure, wherein, still includes the cable, and the receiver is connected to cable one end, and the cleaning machine is connected to the other end to the cleaning machine power supply. Therefore, the cleaning machine storage box can be used for storing equipment components such as the tidying cleaning machine, when the cleaning machine is used, the storage box can also serve as a fixing structure, so that when the cleaning machine drops, the cleaning machine is pulled through the cable, the high-altitude falling is prevented, the safety performance of the storage box is improved, and the multifunctional use purpose of the storage box of the cleaning machine is achieved.

Drawings

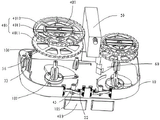

FIG. 1 is a schematic view of a storage box of a cleaning machine according to an embodiment of the present invention;

FIG. 2 is a first schematic view of an installation structure of an absorption structure in a storage box of the cleaning machine of the present invention;

FIG. 3 is a second schematic view of an installation structure of the adsorption structure in the storage box of the cleaning machine of the present invention;

FIG. 4 is a first embodiment of a mounting structure in a storage case of the cleaning machine of the present invention;

FIG. 5 is a second embodiment of a mounting structure in a storage case of the cleaning machine of the present invention;

FIG. 6 shows a third example of a fixing structure in a storage case of the cleaning machine of the present invention;

FIG. 7 is a fourth example of a fixing structure in a storage case of the cleaning machine of the present invention;

FIG. 8 is a schematic view of a portion of the storage box of the cleaning machine of FIG. 7;

FIG. 9 is a schematic view of the cable arrangement in the storage box of the cleaning machine of the present invention;

FIG. 10 is a first partially exploded view of the first storage box take-up device of the cleaning machine of the present invention;

FIG. 11 is a second schematic view of a partially exploded view of the storage box take-up device of the cleaning machine of the present invention;

FIG. 12 is a third schematic view of a partially exploded view of a storage box take-up device of the cleaning machine of the present invention;

FIG. 13 is a schematic diagram illustrating a portion of the first conductive member and the first cable in the embodiment of FIG. 12;

fig. 14 is a schematic structural view illustrating the first conductive member mounted to the wire takeup device body of the first wire takeup device in the embodiment of fig. 12;

FIG. 15 is a schematic structural view of a first electrical connector, a first electrical adapter, and a mounting socket of the embodiment of FIG. 12;

FIG. 16 is a schematic view of an assembly structure of the storage box take-up device of the cleaning machine of the present invention;

fig. 17 is a schematic structural view of a storage box body in the storage box of the cleaning machine of the present invention.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

It should be noted that all directional indicators (such as up, down, left, right, front, back \8230;) in the embodiments of the present invention are only used to explain the relative positional relationship between the components, the motion situation, etc. in a specific posture (as shown in the attached drawings), and if the specific posture is changed, the directional indicator is changed accordingly.

It will also be understood that when an element is referred to as being "secured to" or "disposed on" another element, it can be directly on the other element or intervening elements may also be present. When an element is referred to as being "connected" to another element, it can be directly connected to the other element or intervening elements may also be present.

In addition, the descriptions relating to "first", "second", etc. in the present invention are used for descriptive purposes only and are not to be construed as indicating or implying relative importance or implicitly indicating the number of technical features indicated. Thus, a feature defined as "first" or "second" may explicitly or implicitly include at least one such feature. In addition, technical solutions between the embodiments may be combined with each other, but must be based on the realization of the technical solutions by a person skilled in the art, and when the technical solutions are contradictory to each other or cannot be realized, such a combination should not be considered to exist, and is not within the protection scope of the present invention.

Referring to fig. 1 to 15, a first aspect of the present invention provides a storage box for a cleaning machine, including:

a storage box body 10 for storing the cleaning machine;

the fixing structure 20 is arranged on the storage box body 10, and is used for fixing the storage box body 10 with an external object;

cables connected to the storage box body 10 and the cleaner, respectively.

According to the technical scheme, the storage box of the cleaning machine can be used for storing and arranging equipment components such as the cleaning machine and the like, and can also serve as a fixing structure when the cleaning machine is used, so that when the cleaning machine drops, the cleaning machine is pulled through a cable, high-altitude falling is prevented, the safety performance of the storage box is improved, and the multifunctional use purpose of the storage box of the cleaning machine is achieved. It can be understood that the cleaning machine of the present application may be a cleaning machine that needs to be attached to a surface to be cleaned, such as a window cleaning machine, a wall cleaning machine, a ceiling cleaning machine, etc., or may be a cleaning machine that does not need to be attached to a surface to be cleaned, such as a floor cleaning machine, etc.

In some embodiments, referring to fig. 2 and 3, the fixing structure 20 includes at least one suction element 21, each suction element 21 has a suction cavity formed therein, and the suction element 21 is disposed on the housing case body 10 for fixing with an external object.

In some embodiments, the adsorption element 21 includes: the first adsorption element 211, a first adsorption chamber 2111 is formed in the first adsorption element 211.

In some embodiments, the first suction element 211 is a suction cup, is disposed on the bottom surface of the storage box main body 10, and is made of a soft material, such as silicone, polyvinyl chloride (PVC), thermoplastic Elastomer (TPE), rubber, and the like.

Referring to fig. 2 and 3, in some embodiments, the adsorption element 21 further includes:

and a second adsorption element 212, in which a second adsorption chamber 2121 is formed in the second adsorption element 212, and a volume of the first adsorption chamber 2111 is different from a volume of the second adsorption chamber 2121.

In some embodiments, the second suction element 212 is a suction cup, and is made of a soft material, such as silicone, polyvinyl chloride, thermoplastic elastomer, rubber, and the like.

In some embodiments, the number of the second adsorption elements 212 is plural. The plurality of second adsorption elements 212 are distributed at intervals on both sides of the first adsorption element 211; or a plurality of second adsorption elements 212 are disposed around the first adsorption element 211; or a plurality of second adsorption elements 212 are disposed side by side with the first adsorption element 311.

In some embodiments, the volume of the first adsorption chamber 2111 is greater than the volume of the second adsorption chamber 2121.

In this embodiment, the adsorption cavity is formed in the adsorption element 21, and the storage box body 10 is firmly fixed to an external object by generating a large vacuum degree in the adsorption cavity. Wherein, the difference in height setting range of sucking disc and receiver bottom surface is 3-20mm.

In some embodiments, referring to fig. 2 and 4, in order to achieve a good negative pressure effect in the suction chamber, the fixing structure 20 further includes a negative pressure assembly 203, the negative pressure assembly 203 includes a negative pressure element 2031, and the negative pressure element 2031 is connected to the suction element 21 for adjusting a vacuum degree in the suction chamber.

In some embodiments, the suction channel 213 is disposed on the suction element 21, and the negative pressure element 2031 is communicated with the suction cavity through the suction channel 213. When the storage box of the cleaning machine needs to be used, the negative pressure element 2031 can increase the vacuum degree in the adsorption cavity, so that the adsorption element 21 can be firmly adsorbed on the surface of an object, such as the ground, a desktop or a wall surface. Even if the surface of an object, such as a floor, a table top or a wall, is uneven or has gaps, the vacuum degree in the adsorption cavity can be increased by the negative pressure element 2031, so that the adsorption element 21 can be firmly adsorbed on the uneven or gap object, such as a floor, a table top or a wall. In addition, when the cleaning storage box is not required to be used, the negative pressure member 2031 may reduce the degree of vacuum in each adsorption cavity, and the adsorption member 21 may move with respect to the surface of an object, such as the ground, a table top, or a wall surface, so that the user may also easily move or retract the cleaning machine storage box.

In some embodiments, the negative pressure element 2031 is a negative pressure motor or vacuum pump.

In some embodiments, referring to fig. 2 and 5, the fixing structure 20 further includes a pressure relief structure 204, and the pressure relief structure 204 is connected to the adsorbing element 21 for adjusting a vacuum degree in the adsorbing cavity.

In some embodiments, the pressure relief structure 204 includes a pressure relief valve 2041, the pressure relief valve 2041 is connected to a joint 2043 through a pipeline 2042, and is connected to a pressure relief port 214 on the adsorption element 21 through the joint 2043, and the pressure relief port 214 is communicated with the adsorption cavity.

To control the vacuum in the adsorption chamber via a pressure relief valve 2041. When the cleaner storage box is not needed, the vacuum degree in the adsorption cavity can be reduced through the pressure relief valve 2041. At this time, the suction chamber is communicated with the outside air, and the suction member 21 can be moved relative to the surface of an object such as the floor, the table top or the wall surface, so that the user can easily move or retract the cleaning machine storage case. When the cleaning machine storage box needs to be used, the pressure relief valve 2041 can be closed to increase the vacuum degree in the adsorption cavity. At this time, the adsorption chamber in the adsorption element 21 is isolated from the outside air, and the adsorption element 21 may be adsorbed on the surface of an object, such as the floor, the table top, or the wall surface, by its own weight or by the adsorption element 21.

Further, the suction element 21 may be further connected to a negative pressure element 2031 to increase the vacuum degree in the suction cavity by the negative pressure element 2031.

In some embodiments, referring to fig. 2 and 6, the fixing structure 20 further includes a drawing structure 205, and the drawing structure 205 is connected to the suction element 21 for adjusting the vacuum degree in the suction cavity.

In some embodiments, the drawing structure 205 includes a switch member 2051 rotatably or pressingly provided on a side wall of the cartridge main body 10, a link 215 is provided on the suction member 21, and the switch member 2051 is connected to the link 215 by a rope 2052. So that when the switch element 2051 is rotated, the attached cord 2052 exerts a force on the suction element 21; or the switch element 2051, when pressed, the connected cord 2052 exerts a force on the suction element 21. The rope 2052 may be wound around the switch element 2051, and a pulley and a guide mechanism may be provided to move the rope 2052 along the moving path of the rope 2052.

When the cleaner storage box is not needed, the switch element 2051 can be pulled, and then the adsorption element 21 is pulled, so that the vacuum degree in the adsorption cavity is reduced, at the moment, the adsorption cavity in the adsorption element 21 is communicated with the outside air, and a user can easily move or retract the cleaner storage box and the adsorption element 21. When the cleaning machine storage box is required to be used, the switch element 2051 can be released, so that the adsorption element 21 can be adsorbed on the surface of an object, such as the ground or a table top, or a wall surface.

In some embodiments, referring to fig. 7-8, the fixing structure 20 further includes a connecting rope assembly 206, and the connecting rope assembly 206 is connected with the storage box body 10. To fix the cartridge body 10 by the connecting string assembly 206.

In some embodiments, the storage box further comprises a switch member 70, the switch member 70 is arranged in the storage box body 10, and the switch member 70 is used for controlling the power on or off of the cables; the connecting cord assembly 206 is used to abut or release the switch member 70.

In some embodiments, the connecting string assembly 206 includes: connect rope 2061 and with being connected the connecting piece 2062 that rope 2061 is connected, connecting piece 2062 can dismantle with receiver body 10 and be connected, is equipped with the connecting hole on the box wall of receiver body 10, and the connecting hole is passed with the butt with the one end of connecting piece 2062 or loosens switch spare 70, and connecting rope 2061 is connected to the other end of connecting piece 2062. In fig. 7, the housing case body 10 has a housing hole 108 in a case wall thereof, and the housing hole 108 is configured to receive a plug for connecting an external power source.

In some embodiments, the connecting member 2062 is a threaded bolt, and the connecting string 2061 passes through a through hole of the threaded bolt and is connected to the threaded bolt, which is screwed to the cartridge body 10.

When the connecting string assembly 206 is used, the connecting member 2062 is connected to the storage box body 10; when the connection string assembly 206 is not used, the connector 2062 may be detached from the cartridge main body 10. Compare in the supplementary fixed knot structure that present receiver adopted the sucking disc, connect rope 2061 and can connect on arbitrary fixed object indoor, reduced the limitation that uses the scene to need not to set up the air pump, still the cost is reduced.

In some embodiments, the connecting cord assembly 206 further includes an adjustment assembly 2064;

the adjusting member 2064 is provided with a pair of openings, one end of the connecting cord 2061 sequentially passes through one opening of the adjusting member 2064 and the cord hole of the connecting member 2062 and then passes through the other opening of the adjusting member 2064, and the adjusting member 2064 is used for locking the connecting cord 2061 or loosening the connecting cord 2061 to enable the connecting cord 2061 to be adjusted.

In some embodiments, a hook 2063 is attached to the other end of the connecting cord 2061. The connecting rope 2061 can be connected with an external object through the hook 2063, so that the connection is simple and the use is convenient.

In some embodiments, referring to fig. 2, 7-8, the housing case body 10 is provided with a connecting seat 120 corresponding to the connecting member 2062, the connecting seat 120 is provided with a through hole 121, the switch member 70 is adjacent to the connecting seat 120, and one end of the connecting member 2062 is inserted into the through hole 121 to abut against the switch member 70.

In this embodiment, a switch member 70 is disposed in the storage box body 10, the switch member 70 is electrically connected to a control circuit inside the storage box of the cleaning machine, a power supply circuit for supplying power to the cleaning machine inside the storage box of the cleaning machine is electrically connected to the control circuit, and the control circuit can control the power supply circuit to be turned on or off according to a signal of the switch member 70. When the connector 2062 is connected to the storage case body 10, the switch 70 is abutted or released. Specifically, when the connecting member 2062 abuts against the switch member 70 in the storage box body 10, the power supply circuit in the box body is turned on to supply power to the cleaning machine, and the cleaning machine operates normally; when the connector 2062 releases the switch member 70 in the storage case body 10, the power supply circuit in the case body is disconnected, and the cleaning machine cannot normally operate. So can force the user to install on the box body and connect rope subassembly 206, play the effect of reminding the user to use the cleaning machine safely, and then the security of guarantee cleaning machine use.

In some embodiments, referring to fig. 9, the cable includes a core 301, an insulating layer 302 covering an outer surface of the core 301, and a tensile layer 303 covering an outer surface of the insulating layer 302.

In this embodiment, the core 301 is a copper core, which has a good conductive power supply function. Preferably, the tensile layer 303 is an outermost layer coated by the braided rope, the braided rope has a large tensile resistance (capable of reaching more than 200N without being broken), and meanwhile, the deformation of the braided rope is smaller than that of the inner insulating layer 302 and the copper core, so that the cable is prevented from being damaged in the inner part due to falling and pulling in use, and the cable further plays a role of a safety protection rope of the cleaning machine while supplying power.

Referring to fig. 10 to 12, in order to improve the wire rewinding efficiency, in some embodiments, a wire rewinding device is further included, and the wire rewinding device is located in the storage box body 10 and is used for rewinding the cable and releasing the cable.

In some embodiments, the wire takeup device includes:

the take-up device body 401 is arranged in the storage box body 10 and used for winding the cables;

the driving member 402 is connected to the wire takeup body 401 and is configured to drive the wire takeup body 401 to rotate to wind the cable.

In this embodiment, a containing cavity is provided in the storage box body 10, and the take-up body 401 is provided in the containing cavity. In some preferred embodiments, the wire takeup body 401 is a turntable (the following aspects are all described with the wire takeup body 401 being a turntable) for winding the cable of the cleaning machine and the cartridge body 10. To enable the cables to pass into and out of the magazine body 10, perforations are provided in the magazine body 10 through which the cables pass into and out. Referring to fig. 10 to 12, the rotary table provided in this embodiment includes a first rotary table 4011 and a second rotary table 4012, the first rotary table 4011 and the second rotary table 4012 are spaced and disposed opposite to each other, a spool 4013 for winding a cable is formed between the first rotary table 4011 and the second rotary table 4012, and the spool 4013 is connected to the first rotary table 4011 and the second rotary table 4012 and can rotate along with the first rotary table 4011 and the second rotary table 4012. Driving piece 402 is connected with the carousel, when receiving the line, through driving piece 402 drive carousel antiport for wear out to receiver body 10 the cable via the perforation automatically around rolling up to wrapping post 4013 on, thereby convenience of customers receives the line, promotes user experience. The reverse rotation of the turntable is relative to the rotation direction of the turntable during paying off, for example, the rotation direction of the turntable during paying off is clockwise, and the rotation direction of the turntable during paying off is counterclockwise.

When the cable storage box is required to be paid off for use, a user pulls one end of the cable to enable the rotary disc to rotate in the first direction, and in the rotating process of the rotary disc, the cable on the rotary disc is pulled out from the inner portion of the storage box body 10 through the through hole, so that the paying off operation is completed. When the wire is required to be wound, the turntable is driven by the driving member 402, so that the cable positioned outside the storage box body 10 is wound on the turntable until the cable is completely wound.

In some embodiments, referring to fig. 10-12, the storage box body 10 is provided with a fixing shaft 102, a rotating disc is sleeved on the fixing shaft 102 and is rotatably connected to the fixing shaft 102, and a driving member is sleeved between the fixing shaft 102 and the rotating disc, wherein when the rotating disc rotates in a predetermined direction, the rotational potential energy of the driving member 402 is increased, and when the driving member 402 releases the rotational potential energy, the rotating disc rotates in a direction opposite to the predetermined direction.

In some embodiments, the driving member 402 is preferably a spiral spring having opposite ends connected to the turntable and the stationary shaft 102, respectively.

In this embodiment, the driving member 402 employs a volute spiral spring to store energy, which is used to drive the turntable to rotate when the cable is reeled. When the wire is outgoing, a user pulls one end of the cable to move, the rotary disc drives the volute spiral spring to rotate when rotating along the preset direction, and at the moment, the elastic potential energy of the volute spiral spring is gradually increased; when the wire is wound, the spiral spring is controlled to release elastic potential energy, the turntable can rotate along the reverse direction of the preset direction, and the wire winding is automatically completed.

In some embodiments, a first ratchet assembly is further included and is coupled to the turntable.

In this embodiment, the first ratchet assembly is used to prevent the rotation of the turntable. Specifically, when the turntable rotates along a preset direction, the turntable drives the first ratchet wheel assembly to rotate; when the turntable rotates along the reverse direction of the preset direction, the first ratchet wheel component is clamped inside to limit the rotation of the turntable.

In some embodiments, referring to fig. 10-12, the first ratchet assembly comprises:

the first ratchet wheel is connected with the rotary disc;

the first rotating rod 45 is rotatably connected to the storage box body 10, a first pawl 451 is formed at one end of the first rotating rod 45, and the first pawl 451 is engaged with the first ratchet wheel.

In this embodiment, a first ratchet is connected to the turntable to self-lock the turntable 401 through the first ratchet. In some preferred embodiments, the first ratchet is integrally provided with the rotating disc 401, i.e. the first ratchet teeth 441 are added along the edge of the rotating disc 401. A first pawl 451 for engaging with the first ratchet teeth 441 is formed at one end of the first rotating rod 45, a first rotating shaft 105 is provided on the storage box body 10, the first rotating rod 45 is rotatably connected to the first rotating shaft 105 and is located at the middle position of the first rotating shaft 105, a first elastic reset piece 22 is further provided in the rotating direction of the first rotating rod 45, and the first elastic reset piece 22 is used for driving the first rotating rod 45 to rotate so as to engage the first pawl 451 with the first ratchet teeth 441. At this time, the turntable can only rotate along the first direction, and when the turntable rotates along the direction opposite to the first direction, the first pawl 451 is meshed with the first ratchet teeth 441, wherein the first direction is set as the wire releasing direction, so that the self-locking of the turntable during wire releasing can be realized, the rotation of the turntable during wire releasing is prevented, and a user can stop along with pulling according to the required wire releasing length.

The other end of the first rotating rod 45 opposite to the first pawl 451 is connected to the control button 403 on the storage box body 10, the control button 403 can reciprocate relative to the inside of the storage box body 10, when the cable is taken up, only the control button 403 needs to be pressed, the control button 403 overcomes the elastic action of the first elastic reset piece 22, the first rotating rod 45 is driven to rotate around the first rotating shaft 105, the first pawl 451 is separated from the first ratchet tooth 441, at the moment, the rotating disc can rotate along the second direction under the action of the driving piece 402, wherein the second direction is opposite to the first direction, and therefore automatic winding of the cable is achieved. After the wire is completely collected, the user releases the control button 403, the first rotating rod 45 will be reset to the state that the first pawl 451 is engaged with the first ratchet teeth 441 under the action of the first elastic resetting member 22, and the control button 403 will also be reset under the action of the first rotating rod 45.

In some embodiments, as shown in fig. 10-12, a second ratchet assembly is included,

in the embodiment, the second ratchet wheel assembly is used for the anti-falling function, and specifically, when the rotating speed of the rotating disc is less than the preset rotating speed, the rotating disc drives the second ratchet wheel assembly to rotate; when the rotating speed of the rotating disc is greater than or equal to the preset rotating speed, the second ratchet wheel component is clamped inside to limit the rotation of the rotating disc.

In some embodiments, the second ratchet assembly is similar to the first ratchet assembly, and includes a second ratchet wheel coupled to the turntable and a second rotatable lever 56. Wherein, the second ratchet wheel can also be integrated with the rotary plate, one end of the second rotating rod 56 forms a second pawl 561, and the periphery of the second ratchet wheel is provided with a second ratchet wheel tooth 551 corresponding to the second rotating rod 56.

It should be noted that the functions of the first ratchet assembly and the second ratchet assembly are different, and the first direction and the second direction are used for description, the first ratchet assembly is used for preventing the rotating disc from rotating in the second direction, and the second ratchet assembly is used for preventing the rotating disc from rotating in the first direction in an accelerated manner. Therefore, in the present embodiment, the extending direction of the second ratchet teeth 551 is opposite to the extending direction of the first ratchet teeth 441 to achieve the engagement of the second ratchet teeth 551 with the second pawls 561 and the engagement of the first ratchet teeth 441 with the first pawls 451, respectively. Furthermore, the first ratchet wheel and the second ratchet wheel need to be arranged in a split mode. In a preferred embodiment, a first ratchet wheel is provided integral with the first rotary table 4011 and a second ratchet wheel is provided integral with the second rotary table 4012.

In some embodiments. The second rotating rod 56 is rotatably connected to the second rotating shaft 106, a second elastic reset member 33 is disposed in the rotating direction of the second rotating rod 56, and the second elastic reset member 33 is used for driving the tail end (the opposite end of the pawl) of the second rotating rod 56 to be always in a collision state with the turntable.

It will be appreciated that when the rear end of the second rotating lever 56 collides with the second ratchet wheel, the rear end of the second rotating lever 56 is knocked open, the second rotating lever 56 makes a rotating motion about the second rotating shaft 106, and the second pawl 561 moves toward the second ratchet wheel teeth 551. Therefore, when the unwinding speed is low, the rotation speed of the turntable is lower than the preset rotation speed, and the collision force of the second pawl against the tail end of the second rotating rod 56 is not enough to cause the second pawl 561 to be clamped into the second ratchet teeth 551, so that the wire rewinding device normally unwinds. And when the direction speed is great, the rotating speed of the rotating disc is greater than the preset rotating speed, at the moment, the impact force of the rotating disc is enhanced, under the collision of the second ratchet wheel, the second rotating rod 56 forms a large rotating angle once, the second pawl 561 can be clamped on the second ratchet wheel teeth 551, the rotating disc 401 stops rotating and stops paying off in time, and the risk that the cleaning machine accidentally falls off during high-altitude operation is avoided, wherein the preset rotating speed can be set to be 1m/s or 2m/s or other.

In some embodiments, as shown with reference to fig. 10-12, an adapter 50 is also included;

the take-up device comprises a first take-up device 40 and a second take-up device 41, a first cable 30 is wound on the first take-up device 40, two ends of the first cable 30 are respectively used for connecting the cleaning machine and the adapter 50, a second cable 31 is wound on the second take-up device 41, and two ends of the second cable 31 are respectively used for connecting the adapter 50 and the power supply.

In this embodiment, set up first cable 30 and connect cleaning machine and receiver body 10, second cable 31 connects power and receiver body 10, forms the electricity through adapter 50 in the receiver body 10 between first cable 30 and the second cable 31 and connects to form the route of power to cleaning machine. The adapter 50 serves as a converter for converting the operating current of the cleaner main body.

Referring to fig. 12, in some embodiments, the first cable 30 includes a first portion 304 and a second portion 305, the first portion 304 includes a first connection end and a first termination end, the first termination end is connected to the adapter 50; the second part 305 comprises a first fixed end and a first extending end, the first fixed end is fixed on the take-up body 401 of the first take-up device 40, the first extending end is connected with the cleaning machine, and the second part is wound on the take-up body 401 of the first take-up device 40 or released from the take-up body 401 of the first take-up device 40 along with the rotation of the take-up body 401; the first connecting end is rotatably connected with the take-up body 401 of the first take-up device 40. And/or the second cable 31 comprises a third part and a fourth part (not shown in the figures), the third part comprising a second connection end and a second terminating end, the second terminating end being connected with the adapter; the fourth part comprises a second fixed end and a second extending end, the second fixed end is fixed on the take-up body of the second take-up device 41, the second extending end is connected with the power supply, and the fourth part is wound on the take-up body of the second take-up device 41 or released from the take-up body of the second take-up device 41 along with the rotation of the take-up body of the second take-up device 41; the second connecting end is rotatably connected with the take-up body of the second take-up 41.

Based on the fact that the first cable 30 and the second cable 31 have the same structure, the first cable 30 is taken as an example for the explanation of the present embodiment. Wherein the second part 305 of the first cable 30 is fixed to the take-up body 401 of the first take-up 40, i.e. the turntable, by a first fixed end. Such that the extended end of the second portion 305 of the first cable 30 is wound onto or released from the turntable as the turntable rotates. The second part is the cable between the turntable and the cleaning machine. Further, the first portion 304 is provided with a first connection end rotatably connected with the take-up body 401 of the first take-up 40, wherein during winding or releasing of the second portion 305, the first portion 304 is based on the rotational connection relationship between the first connection end and the turntable, the first portion 304 is not influenced by the rotation of the turntable, i.e. is not wound on the turntable, and is always connected with the turntable during the rotation of the turntable, so that an electrical connection path is formed between the first portion 304 and the second portion 305 of the first cable 30 further based on an electrical connection structure on the turntable. Similarly, an electrical connection path is formed between the third portion and the fourth portion of the second cable 31. Therefore, when the second extending end of the second cable 31 is connected to the power source, the first extending end of the first cable 30 is connected to the cleaning machine, and the first terminating end of the first cable 30 and the second terminating end of the second cable are connected to the adapter 50, a conductive path from the power source to the cleaning machine can be formed.

Referring to fig. 12-14, in some embodiments, the first wire rewinding device 40 further includes a first conductive member 200, the first conductive member 200 is disposed on a wire rewinding device body 401 of the first wire rewinding device 40, the wire rewinding device body 401 of the first wire rewinding device 40 rotates to drive the first conductive member 200 to rotate, a first fixed end is fixedly connected to the first conductive member 200 and electrically connected to the first conductive member 200, and the first conductive member 200 is rotatably connected to the first connection end;

and/or the second wire rewinding device 41 further includes a second conductive member (not shown), the second conductive member is disposed on the wire rewinding device body 401 of the second wire rewinding device 41, the wire rewinding device body of the second wire rewinding device 41 rotates to drive the second conductive member to rotate, the second fixed end is fixedly connected to the second conductive member and electrically connected to the second conductive member, and the second conductive member is rotatably connected to the second connection end.

In this embodiment, the first conductive member 200 in the first cable 30 is described. The first conductive member 200 is detachably connected to the wire take-up body 401 of the first wire take-up device 40. In some examples, the first conductive member 200 is formed with at least one connection protrusion 2001, the take-up body 401 of the first take-up device 40 is formed with at least one connection hole, and each connection protrusion 2001 is fixedly connected to a connection hole.

In this embodiment, the first conductive member 200 is fixedly connected to the connection hole through the connection protrusion 2001 thereof, and is further detachably connected to the wire rewinding device body 401 of the first wire rewinding device 40. Alternatively, the coupling projection 2001 has a hook shape, and the coupling hole corresponds to a through hole. When the first conductive member 200 is connected to the first wire winding device body 401 of the first wire winding device 40, the connecting protrusion 2001 is hooked on the edge of the connecting hole through the connecting hole, and the first conductive member 200 is stably connected to the connecting hole. The number of the connecting protrusions 2001 is the same as the number of the connecting holes, and the connecting protrusions 2001 correspond to the positions of the connecting holes, for example, four connecting protrusions 2001 are provided on the first conductive member 200 along the circumferential direction thereof, four connecting holes are correspondingly provided on the wire takeup body 401 of the first wire takeup device 40, and four connecting protrusions 2001 are correspondingly fixedly connected to the four connecting holes.

Referring to fig. 12 to 14, in some embodiments, the first conductive member 200 is provided with an electrical connection port, and the first fixing end is provided with an electrical plug terminal, which is plugged into the electrical connection port; or the like, or a combination thereof,

the first conductive component 200 includes a first conductive component 210 and a second conductive component 220, the first conductive component 210 has a first electrical connection port 2002a, and the second conductive component 220 has a second electrical connection port 2002b; the first fixed end is provided with a first electrical plug terminal 66a and a second electrical plug terminal 66b, the first electrical plug terminal 66a being plugged to the first electrical connection port 2002a, the second electrical plug terminal 66b being plugged to the second electrical connection port 2002b.

In this embodiment, the first conductive member 200 may be one, the first conductive member 200 is provided with an electrical connection port, the first fixed end is provided with an electrical connection terminal adapted to the electrical connection port, and the second portion 305 is connected to the electrical connection port through the electrical connection terminal, and is further fixed and electrically connected to the first conductive member 200. The number of the first conductive members 200 may also be two, and the first conductive member 210 and the second conductive member 220 respectively correspond to the positive electrode and the negative electrode. The first conductive part 210 has a first electrical connection port 2002a, the second conductive part 220 has a second electrical connection port 2002b, the first fixing end has a first electrical plug terminal 66a adapted to the first electrical connection port 2002a, and a second electrical plug terminal 66b adapted to the second electrical connection port 2002b, the first cable 30 is plugged into the first electrical connection port 2002a through the first electrical plug terminal 66a, and then fixed and electrically connected to the first conductive part 210, and plugged into the second electrical connection port 2002b through the second electrical plug terminal 66b, and then fixed and electrically connected to the second conductive part 220.

The electrical connection port may be a sheet structure extending from the first conductive member 200 to mate with the electrical plug terminal to realize plug connection. Optionally, the electrical plug terminal is a pogo terminal. The first cable 30 is inserted into the electric connection port of the first conductive piece 200 through the electric insertion terminal, and no line body welding is needed, so that rapid assembly can be realized, the assembly time is reduced, and the assembly efficiency is improved.

Corresponding to the above embodiment, when the first conductive members 200 include the first conductive part 210 and the second conductive part 220, the first conductive part 210 and the second conductive part 220 are both formed with connecting protrusions 2001 for being respectively and fixedly connected to connecting holes correspondingly formed in the wire rewinding device body 401 of the first wire rewinding device 40.

In some embodiments, referring to fig. 12 to 14, a cavity 404 is formed between the first rotating disc 4011 and the second rotating disc 4012, and a wire passing hole 405 communicated with the cavity 404 is formed in a cavity wall of the cavity 404;

the first conductive member 200 is mounted on one side of the first rotary table 4011, which faces away from the second rotary table 4012, the electrical connection port is accommodated in the cavity 404, and the electrical plug terminal passes through the wire through hole 405 and is plugged into the electrical connection port; or, the first conducting part 210 and the second conducting part 220 are installed on one side of the first rotary table 4011 opposite to the second rotary table 4012, the first electrical connection port 2002a and the second electrical connection port 2002b are both accommodated in the cavity 404, the first electrical plug terminal 66a is inserted into the first electrical connection port 2002a through the wire passing hole 405, and the second electrical plug terminal 66b is inserted into the second electrical connection port 2002b through the wire passing hole 405;

in some embodiments, further comprising: the first connecting end is rotatably connected with the first conductive piece 200 through the first electric connecting piece;

and/or, further comprising: and a second electrical connector (not shown) through which the second connection end is rotatably connected to the second conductive member.

In this embodiment, the first electrical connector is explained. Specifically, in this storage box, the first electrical connector serves as an electrical connector of the power supply line of the storage box body 10, and the first cable 30, the take-up body 401 of the first take-up 40, and the first electrical connector are connected in sequence, thereby realizing energization of the power supply line with the storage box body 10.

In some embodiments, referring to fig. 12 and 15, a mount 101 is provided on the cartridge body 10, and the first electrical connector is fixedly connected to the mount 101.

In this embodiment, the first electric connector is mounted on the mount 101 to be set on the cartridge body 10. Specifically, the mount 101 is detachable from the cartridge body 10. During the assembling process, optionally, the first electrical connector and the mounting seat 101, and the mounting seat 101 and the storage box body 10 can be connected by screws.

In some embodiments, the first electrical connector is formed with a fixing portion fixedly connected to the mounting seat 101 and an elastic grounding portion slidably abutted against the first conductive member 200; or, the first electrical connector includes a first electrical connection portion 310 and a second electrical connection portion 320, the first electrical connection portion 310 is formed with a first fixing portion 3001a and a first elastic grounding portion 3002a, and the second electrical connection portion 320 is formed with a second fixing portion 3001b and a second elastic grounding portion 3002b; the first fixing portion 3001a and the second fixing portion 3001b are fixedly connected to the mounting base 101, the first elastic grounding portion 3002a is in sliding contact with the first conductive portion 210, and the second elastic grounding portion 3002b is in sliding contact with the second conductive portion 220.

In this embodiment, when there is one first conductive member 200, there is one first electrical connector. The first electrical connector is fixedly connected to the mounting base 101 through a fixing portion thereof, and the elastic connecting portion is slidably abutted against the conductive member, so that connection and energization with the first conductive member 200 are realized. When there are two first conductive members 200, including the first conductive part 210 and the second conductive part 220, there are two first electrical connectors, including a first electrical connection part 310 and a second electrical connection part 320. The first electrical connection portion 310 is fixedly connected to the mounting base 101 through the first fixing portion 3001a thereof, and the first elastic connection portion 3002a abuts against the first conductive portion 210 in a sliding manner, so as to realize connection and energization with the first conductive portion 210; the second electrical connection portion 320 is fixedly connected to the mounting base 101 through the second fixing portion 3001b, and the second elastic connection portion 3002b is in sliding contact with the second conductive portion 220, so as to achieve connection and conduction with the second conductive portion 220.

Specifically, when the take-up body 401 of the first take-up device 40 is assembled to the storage box body 10, the elastic grounding portion of the first electrical connector is abutted to the first conductive member 200 and is pressed and deformed by the take-up body 401 of the first take-up device 40 to maintain stable abutment with the first conductive member 200, so as to achieve energization of the first cable 30. Further, the first conductive member 200 is a ring-shaped metal sheet, the first electrical connecting member may be a W-shaped elastic metal sheet, and the first electrical connecting member has two elastic grounding portions, which are respectively located at two sides of the fixing portion and abut against the first conductive member 200 which is the ring-shaped metal sheet. When the wire rewinding device body 401 of the first wire rewinding device 40 rotates, the first conductive member 200 rotates along with the first wire rewinding device, and the first electric connecting member is kept in contact with the first conductive member 200 without power failure.

In some embodiments, referring to fig. 12 and 15, a first electrical transition is also included, electrically connected to the first electrical connector, and the first electrical transition is also connected to the first connection end of the first portion 304 of the first cable 30;

the first electric adapter is attached to the fixing part, and the first electric connection end of the first part 304 is provided with an electric connection terminal which is inserted into the first electric adapter; or, the first electrical adaptor includes a first electrical adaptor portion 410 and a second electrical adaptor portion 420, the first electrical adaptor portion 410 is attached to the first fixing portion 3001a, the second electrical adaptor portion 420 is attached to the second fixing portion 3001b, a first electrical connection terminal 77a and a second electrical connection terminal 77b are disposed at one end of the first portion 304, the first electrical connection terminal 77a is plugged into the first electrical adaptor portion 410, and the second electrical connection terminal 77b is plugged into the second electrical adaptor portion 420.

In this embodiment, a first electrical interposer is used to enable electrical communication between the first portion 304 and the first electrical connector. When the first electric connector is one, the first electric adapter is correspondingly one. The first electrical adaptor is attached to the fixing portion of the first electrical connector, the first connection end of the first portion 304 is provided with an electrical connection terminal, and the first portion 304 is inserted into the first electrical adaptor through the electrical connection terminal and is further fixed and electrically connected with the first electrical adaptor. When the number of the first electrical connectors is two and includes the first electrical connection portion 310 and the second electrical connection portion 320, the number of the first electrical connectors is two, and the first electrical connectors includes a first electrical connector 410 and a second electrical connector 420. The first electrical connector 410 is attached to the first fixing portion 3001a, the second electrical connector 420 is attached to the second fixing portion 3001b, a first electrical connection terminal 77a and a second electrical connection terminal 77b are disposed at one end of the first portion 304 connected to the first electrical connector 410 and the second electrical connector 420, the first portion 304 is connected to the first electrical connector 410 through the first electrical connection terminal 77a, and is further fixed and electrically connected to the first electrical connector 410, and is connected to the second electrical connector 420 through the second electrical connection terminal 77b, and is further fixed and electrically connected to the second electrical connector 420.

To sum up, the first wire take-up device 40 is respectively arranged to take up and pay off the first cable 30, and the second wire take-up device 41 is arranged to take up and pay off the second cable 31. The first wire rewinding device 40 and the second wire rewinding device 41 are structures of the wire rewinding devices provided in the above embodiments, and are not described herein again. Referring to fig. 16, the first wire rewinding device 40 and the second wire rewinding device 41 are respectively located on opposite sides in the cartridge body 10, the first cable 30 is provided with a corresponding first through hole 103 on the cartridge body 10, the second cable 31 is provided with a second through hole 104 on the cartridge body 10, and the first through hole 103 and the second through hole 104 are provided on opposite side walls of the cartridge body 10 to form a linear arrangement of the power source, the cartridge body 10 and the cleaning machine, so that the risk of cross winding of the first cable 30 and the second cable 31 can be reduced. Similarly, in order to control the first wire rewinding device 40 and the second wire rewinding device 41, a first control button and a second control button are respectively arranged on the storage box body 10.

In some embodiments, referring to fig. 10-12, the storage box further includes a safety starting system 60, the safety starting system 60 includes a control chip, and an air pressure sensor 601 electrically connected to the control chip, and the air pressure sensor 601 is communicated with the inside of the suction element 201.

In this embodiment, the safety starting system 60 is used as a mandatory safety control system, and aims to improve the safety awareness of users. Whether the air pressure in the adsorption element 201 can reach the using condition of the cleaning machine or not is detected, in use, the adsorption element 201 needs to be pressed onto a large plane (a floor tile), an adsorption cavity is formed in the adsorption element 201, the storage box body 10 is adsorbed on an external fixed surface, meanwhile, whether a vacuum degree threshold value is reached in the adsorption cavity or not is detected through the air pressure sensor 601, when the vacuum degree is reached, connected equipment can supply electricity to the cleaning machine, the cleaning machine works, and when the vacuum degree is lower than the vacuum degree threshold value, electricity cannot be supplied to the cleaning machine, and the cleaning machine stops working; under the arrangement, the safety awareness of the user can be forcibly improved, and the potential safety hazard is reduced.

Further, a buzzer, an indicator lamp and the like can be arranged to feed back whether the vacuum degree threshold value is reached, the buzzer and the indicator lamp are electrically connected with the control chip to receive instruction information of the control chip, for example, when the vacuum degree threshold value is not reached, the buzzer and the indicator lamp can send warning information to remind a user, and when the vacuum degree threshold value is reached, the buzzer and the indicator lamp normally display.

In some embodiments, referring to fig. 1 and 17, the cartridge body 10 includes: the box comprises a first box body 111, a second box body 112 and a box cover 113, wherein the second box body 112 is arranged with the first box body 111 in a stacking mode, and the box cover 113 is arranged on the second box body 112 in a covering mode so as to seal the box bodies.

In some embodiments, a first receiving cavity is formed in the first case 111 for receiving the wire rewinding device and the adapter 50; in addition, other structural components such as the cable, the negative pressure component 202, the pressure relief structure 204, the pulling mechanism 208, the connecting rope component 209, the switch component 70, the ratchet component, the safety starting system 60, and the like are contained in the first containing cavity or connected to the first box body.

In some embodiments, a second storage cavity is formed in the second box 112, and the second storage cavity is used for storing the cleaning machine, the traveling turntable of the cleaning machine, the cleaning liquid bottle, the safety rope, the remote controller, and the cleaning sheet bottle. In fig. 17, the central, voluminous receiving chamber is used to receive the cleaning machine. The cleaning machine can be a window cleaning machine, a floor cleaning machine, a ceiling cleaning machine, a wall cleaning machine and other cleaning equipment.

In some embodiments, the outer surface of the first container 111 and/or the outer surface of the second container 112 are provided with the fixing structures 20, wherein in one embodiment, the adsorption member 201 is fixed to the outer surface of the first container 111 or the outer surface of the second container 112.

In a second aspect of the present invention, a cleaning apparatus is provided, where the cleaning apparatus includes the cleaning machine storage box provided in the first aspect, and the specific structure of the cleaning machine storage box refers to the foregoing embodiments.

The above description is only a part of or preferred embodiments of the present invention, and neither the text nor the drawings should be construed as limiting the scope of the present invention, and all equivalent structural changes made by using the contents of the present specification and the drawings or directly/indirectly applied to other related technical fields in the spirit of the present invention are included in the scope of the present invention.

Claims (21)

1. A cleaning machine receiver, its characterized in that includes:

the storage box body is used for storing the cleaning machine;

the fixing structure is arranged on the storage box body and used for fixing the storage box body with an external object;

cables which are directly connected with the storage box body and the cleaning machine respectively;

the cable winding device is positioned in the storage box body and used for winding the cable and releasing the cable;

the take-up device comprises: the take-up device body is arranged in the storage box body;

the take-up device further comprises a first ratchet wheel component, and the first ratchet wheel component is connected with the take-up device body;

when the take-up device body rotates along a preset direction, the take-up device body drives the first ratchet wheel assembly to rotate;

when the take-up device body rotates along the direction opposite to the preset direction, the first ratchet wheel assembly is clamped inside to limit the take-up device body to rotate;

the take-up device further comprises a second ratchet wheel component, and the second ratchet wheel component is connected with the take-up device body;

when the rotating speed of the take-up body is less than the preset rotating speed, the take-up body drives the second ratchet wheel assembly to rotate;

when the rotating speed of the take-up body is larger than or equal to the preset rotating speed, the second ratchet wheel assembly is clamped inside to limit the rotation of the take-up body.

2. The cleaning machine storage box of claim 1, wherein the fixing structure includes at least one suction member, each suction member having a suction chamber formed therein, the suction member being provided on the storage box body for fixing with an external object.

3. The cleaning machine storage box according to claim 2, wherein the at least one adsorption element includes a first adsorption element and a second adsorption element, and a volume of an adsorption cavity of the first adsorption element is different from a volume of an adsorption cavity of the second adsorption element.

4. The cleaning machine storage box of claim 2, wherein the securing structure further comprises a negative pressure assembly connected to the suction element for adjusting a vacuum level within each suction chamber.

5. The cleaning machine storage box according to claim 2, wherein the fixing structure further comprises a pressure relief structure, and the pressure relief structure is connected with the adsorption elements and used for adjusting the vacuum degree in each adsorption cavity.

6. The cleaning machine storage box of claim 2, wherein the securing structure further comprises a pull structure connected to the suction element for adjusting a vacuum level within each suction chamber.

7. The cleaning machine storage box of claim 1, further comprising a connection cord assembly connected to the storage box body.

8. The cleaning machine storage box of claim 7, further comprising:

the switch piece is arranged in the storage box body and used for controlling the power-on or the disconnection of the cable;

the connecting rope assembly is used for abutting against or loosening the switch piece.

9. The cleaning machine storage box of claim 8, wherein the connecting cord assembly comprises: connect the rope and with connect the connecting piece that the rope is connected, the connecting piece can be dismantled with the receiver body and be connected, be equipped with the connecting hole on the box wall of receiver body, the one end of connecting piece is passed the connecting hole is perhaps loosened with the butt the switch spare, the other end of connecting piece is connected connect the rope.

10. The cleaning machine storage box of claim 1, wherein the cable includes a core, an insulating layer covering an outer surface of the core, and a tensile layer covering an outer surface of the insulating layer.

11. The cleaning machine storage box of claim 1, wherein the take-up device comprises:

the driving piece is connected with the take-up body and used for driving the take-up body to rotate so as to wind the cable.