CN114768312A - Domestic sewage treatment device - Google Patents

Domestic sewage treatment device Download PDFInfo

- Publication number

- CN114768312A CN114768312A CN202210310474.0A CN202210310474A CN114768312A CN 114768312 A CN114768312 A CN 114768312A CN 202210310474 A CN202210310474 A CN 202210310474A CN 114768312 A CN114768312 A CN 114768312A

- Authority

- CN

- China

- Prior art keywords

- electric telescopic

- sewage treatment

- domestic sewage

- cleaning

- driving mechanism

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000010865 sewage Substances 0.000 title claims abstract description 28

- 230000007246 mechanism Effects 0.000 claims abstract description 94

- 238000004140 cleaning Methods 0.000 claims abstract description 51

- 230000010405 clearance mechanism Effects 0.000 claims description 12

- 239000007921 spray Substances 0.000 claims description 9

- 238000009434 installation Methods 0.000 claims description 6

- 238000004062 sedimentation Methods 0.000 description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 239000012535 impurity Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 230000000149 penetrating effect Effects 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 1

- 208000035473 Communicable disease Diseases 0.000 description 1

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 1

- 241000700605 Viruses Species 0.000 description 1

- XKMRRTOUMJRJIA-UHFFFAOYSA-N ammonia nh3 Chemical compound N.N XKMRRTOUMJRJIA-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 150000001720 carbohydrates Chemical class 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 244000000010 microbial pathogen Species 0.000 description 1

- 230000035764 nutrition Effects 0.000 description 1

- 235000016709 nutrition Nutrition 0.000 description 1

- 230000003071 parasitic effect Effects 0.000 description 1

- 244000052769 pathogen Species 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 239000013049 sediment Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 239000002351 wastewater Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D21/00—Separation of suspended solid particles from liquids by sedimentation

- B01D21/0006—Settling tanks provided with means for cleaning and maintenance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D21/00—Separation of suspended solid particles from liquids by sedimentation

- B01D21/02—Settling tanks with single outlets for the separated liquid

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Cleaning By Liquid Or Steam (AREA)

Abstract

The invention discloses a domestic sewage treatment device which comprises a supporting plate, wherein an angle adjusting mechanism is installed at the bottom of the supporting plate, a first driving mechanism is installed at the bottom of the angle adjusting mechanism, a second driving mechanism is arranged at the bottom of the first driving mechanism, first cleaning mechanisms are installed on two sides of the second driving mechanism, and a second cleaning mechanism is installed at the bottom of the second driving mechanism.

Description

Technical Field

The invention relates to a treatment device, in particular to a domestic sewage treatment device.

Background

Domestic sewage is wastewater discharged in daily life of residents and mainly comes from residential buildings and public buildings, such as houses, institutions, schools, hospitals, shops, public places, industrial enterprise toilets and the like. The pollutants contained in the domestic sewage are mainly organic matters (such as protein, carbohydrate, fat, urea, ammonia nitrogen and the like) and a large amount of pathogenic microorganisms (such as parasitic ova, enteroinfectious viruses and the like). Organic matters existing in domestic sewage are extremely unstable and easily become rotten to generate offensive odor. Bacteria and pathogens propagate in large quantities by taking organic matters in domestic sewage as nutrition, and can cause epidemic of infectious diseases. Therefore, domestic sewage must be treated before it is discharged.

The existing sewage treatment technology is to carry out technical treatment on domestic sewage through a primary sedimentation tank and a secondary sedimentation tank, and after the sedimentation tank works under long-time load, the bottom of the tank and the inner wall often form a large amount of impurity precipitates and attachments, and the impurities bring inconvenience to the treatment of sewage and also influence the treatment effect of sewage. Therefore, a convenient cleaning device is urgently needed to regularly clean the sedimentation tank for domestic sewage treatment.

Disclosure of Invention

1. Technical problem to be solved by the invention

The invention aims to provide a domestic sewage treatment device to solve the problems of the background technology, namely, after a sedimentation tank works under a load for a long time, a large amount of impurity sediments and attachments are formed on the bottom and the inner wall of the sedimentation tank, and the impurities bring inconvenience to the sewage treatment and influence the sewage treatment effect. Therefore, a convenient cleaning device is urgently needed to regularly clean the sedimentation tank for domestic sewage treatment.

2. Technical scheme

In order to achieve the purpose, the invention provides the following technical scheme: the utility model provides a domestic sewage treatment device, includes the backup pad, the bottom central authorities of backup pad install angle adjustment mechanism, the first actuating mechanism of angle adjustment mechanism's bottom installation, first actuating mechanism's bottom is equipped with second actuating mechanism, the first clearance mechanism of second actuating mechanism's both sides installation, second clearance mechanism is installed to second actuating mechanism's bottom.

Preferably, angle adjustment mechanism includes the carousel, the carousel bearing is installed the bottom of backup pad, the central authorities of carousel are equipped with the through hole, the first motor of bottom central detachable mounting of backup pad, first pivot is connected to the drive end of first motor, the first telescopic link of bottom installation of first pivot, the bottom of first telescopic link is connected first actuating mechanism.

Preferably, the first telescopic rod comprises a first connecting rod, the first connecting rod is connected with a second connecting rod in a sliding mode, limiting blocks are symmetrically arranged in the center of the outer wall of the first connecting rod, limiting grooves are formed in the inner wall of the second connecting rod, and the limiting blocks are connected with the limiting grooves in a sliding mode.

Preferably, the first driving mechanism comprises a connecting frame which is cross-shaped, second electric telescopic rods are symmetrically installed in the center of the top of the connecting frame, and one end of each second electric telescopic rod is connected with the bottom of the supporting plate.

Preferably, the second driving mechanism comprises a supporting frame, the supporting frame is fixedly installed at the bottom of the connecting frame, second motors are symmetrically installed on one side of the inner wall of the supporting frame, the driving end of each second motor is connected with a first screw shaft, the first screw shafts penetrate through connecting blocks in a threaded mode, the connecting blocks are connected to the other side of the supporting frame in a rotating mode, and the connecting blocks are connected to two sides of the inner wall of the supporting frame in a sliding mode.

Preferably, first clearance mechanism includes third electric telescopic handle, two the third electric telescopic handle symmetry is installed one side of carriage, two first clearance piece is connected to third electric telescopic handle's one end, one side of first clearance piece is equipped with the clearance line.

Preferably, the second cleaning mechanism comprises fourth electric telescopic rods, the four fourth electric telescopic rods are symmetrically arranged at the bottom of the connecting block, the driving end of each fourth electric telescopic rod is connected with the second cleaning block, and the bottom of the second cleaning block is provided with the cleaning grains.

Preferably, the bottom center of backup pad is equipped with gap clearance mechanism, gap clearance mechanism includes the conveyer pipe, the one end of conveyer pipe is run through the backup pad extends and connects the pond, the conveyer pipe runs through first clearance piece connects high-pressure spray gun, high-pressure spray gun sets up in running through the groove, it is in to run through the groove setting the inside of first clearance piece.

3. Advantageous effects

Compared with the prior art, the invention has the beneficial effects that:

1. the first cleaning mechanism is driven to move by the first driving mechanism, the rotation of the first cleaning mechanism is adjusted by the angle adjusting mechanism, the four walls of the sedimentation tank are cleaned, and the second cleaning mechanism is driven by the second driving mechanism to clean the bottom of the sedimentation tank;

2. according to the invention, the high-pressure spray gun is driven to operate, the water in the water tank is pumped through the conveying pipe, the sprayed water is added, gaps around the sedimentation tank are cleaned, and the cleaning range of the device on the sedimentation tank is improved.

Drawings

FIG. 1 is a schematic view of the structure of the present invention;

FIG. 2 is a schematic view of the turntable structure of the present invention;

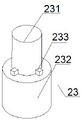

FIG. 3 is a schematic view of a first telescopic rod according to the present invention;

FIG. 4 is a schematic structural view of a second driving mechanism, a first cleaning mechanism and a second cleaning mechanism according to the present invention;

FIG. 5 is a schematic view of a high pressure lance according to the present invention. .

In the figure: 1. a support plate; 2. an angle adjusting mechanism; 21. a turntable; 22. a through hole; 23. a first telescopic rod; 231. a first connecting rod; 232. a second connecting rod; 233. a limiting block; 3. a first drive mechanism; 31. a connecting frame; 32. a second electric telescopic rod; 4. a second drive mechanism; 41. a support frame; 42. a second motor; 43. a first screw shaft; 44. connecting blocks; 5. a first cleaning mechanism; 51. a third electric telescopic rod; 52. a first cleaning block; 6. a second cleaning mechanism; 61. a fourth electric telescopic rod; 62. a second cleaning block; 7. a gap cleaning mechanism; 71. a delivery pipe; 72. a high pressure spray gun.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. The components of embodiments of the present invention generally described and illustrated in the figures herein may be arranged and designed in a wide variety of different configurations. Thus, the following detailed description of the embodiments of the present invention, as presented in the figures, is not intended to limit the scope of the invention, as claimed, but is merely representative of selected embodiments of the invention. All other embodiments, which can be derived by a person skilled in the art from the embodiments of the present invention without making any creative effort, shall fall within the protection scope of the present invention.

In an embodiment, referring to fig. 1-5, the present invention provides a technical solution: a domestic sewage treatment device comprises a supporting plate 1, wherein an angle adjusting mechanism 2 is arranged in the center of the bottom of the supporting plate 1, a first driving mechanism 3 is arranged at the bottom of the angle adjusting mechanism 2, a second driving mechanism 4 is arranged at the bottom of the first driving mechanism 3, first cleaning mechanisms 5 are arranged on two sides of the second driving mechanism 4, and a second cleaning mechanism 6 is arranged at the bottom of the second driving mechanism 4;

obviously, install this device through many support columns on the sedimentation tank, remove through first actuating mechanism 3 drive first clearance mechanism 5, adjust the rotation of first clearance mechanism 5 through angle adjustment mechanism 6 simultaneously, clear up the four walls of sedimentation tank, clear up the bottom of sedimentation tank through second actuating mechanism 4 drive second clearance mechanism 6.

Considering that the periphery of the sedimentation tank needs to be cleaned, and the first cleaning mechanisms 5 are arranged on two sides of the second driving mechanism 4, so that an angle adjusting mechanism 2 is needed for angle adjustment, a preferred scheme is provided, wherein the angle adjusting mechanism 2 comprises a rotary disc 21, the rotary disc 21 is mounted at the bottom of the support plate 1 through a bearing, a through hole 22 is formed in the center of the rotary disc 21, a first motor is detachably mounted at the center of the bottom of the support plate 1, the driving end of the first motor is connected with a first rotating shaft, a first telescopic rod 23 is mounted at the bottom of the first rotating shaft, and the bottom of the first telescopic rod 23 is connected with the first driving mechanism 3;

obviously, by driving the first motor to operate, the first telescopic rod 23 is rotated to further drive the first driving mechanism 3 to rotate, so that the second driving mechanism 4 drives the first cleaning mechanism 5 to rotate, and the other two sides of the sedimentation tank to which the first cleaning mechanism 5 is rotated are cleaned.

Considering that the first driving mechanism 3 needs to drive the first cleaning mechanism 5 to move up and down to clean the inner wall of the sedimentation tank, the angle adjusting mechanism 2 cannot influence the operation of the first driving mechanism 3 and cannot influence the adjustment of the angle adjusting mechanism 2, a preferable scheme is provided, the first telescopic rod 23 comprises a first connecting rod 231, the first connecting rod 231 is slidably connected with a second connecting rod 232, limiting blocks 233 are symmetrically arranged in the center of the outer wall of the first connecting rod 231, a limiting groove is arranged on the inner wall of the second connecting rod 232, and the limiting blocks 233 are slidably connected with the limiting groove;

obviously, through with the first connecting rod 231 sliding connection second connecting rod 232, restrict through restriction piece 233 for when the first connecting rod 231 rotates, can drive the second connecting rod 231 and rotate, and then drive first actuating mechanism 3 and rotate, do not influence the operation of angle adjustment mechanism 2, when first actuating mechanism 3 moves simultaneously, can make first clearance mechanism 5 reciprocate, eliminate the influence through first connecting rod 231 sliding connection second connecting rod 232.

In view of the requirement that the first cleaning mechanism 5 needs to be driven by the first driving mechanism 3 to move up and down, a preferable scheme is provided, the first driving mechanism 3 comprises a connecting frame 31, the connecting frame 31 is in a cross shape, second electric telescopic rods 32 are symmetrically installed in the center of the top of the connecting frame 31, and one end of each second electric telescopic rod 32 is connected with the bottom of the supporting plate 1;

obviously, the second driving mechanism 4 is made to move up and down by controlling the plurality of second electric telescopic rods 32 to operate simultaneously, so as to drive the first cleaning mechanism 5 to move up and down.

Considering that the second driving mechanism 4 needs to control the second cleaning mechanism 6 to move, a preferable scheme is provided, where the second driving mechanism 4 includes a supporting frame 41, the supporting frame 41 is fixedly installed at the bottom of the connecting frame 31, second motors 42 are symmetrically installed on one side of the inner wall of the supporting frame 41, a driving end of each second motor 42 is connected to a first screw shaft 43, the first screw shafts 43 extend through a connecting block 44 in a spiral manner and are connected to the other side of the supporting frame 41 in an extending and rotating manner, and the connecting block 44 is connected to two sides of the inner wall of the supporting frame 41 in a sliding manner;

obviously, the second motor 42 is controlled to operate simultaneously in the same direction and at the same frequency, so that the connecting block 44 moves in the supporting frame 41, and further drives the second cleaning mechanism 6 to move, and the bottom of the sedimentation tank is cleaned.

Considering that the first cleaning mechanism 5 needs to clean the inner wall of the sedimentation tank around, a preferable scheme is provided, the first cleaning mechanism 5 includes third electric telescopic rods 51, two third electric telescopic rods 51 are symmetrically installed at one side of the supporting frame 41, one ends of the two third electric telescopic rods 51 are connected with a first cleaning block 52, the first cleaning block 52 is slidably connected with the connecting frame 31, and cleaning grains are arranged at one side of the first cleaning block 52;

obviously, through controlling the third electric telescopic handle 51 to stretch, make first clearance piece 52 remove, contact with the inner wall of sedimentation tank, through driving the operation of second electric telescopic handle 32, control first clearance piece 52 and reciprocate, clear up the inner wall of sedimentation tank.

In view of cleaning the bottom of the sedimentation tank by the second cleaning mechanism 6, a preferable scheme is provided, the second cleaning mechanism 6 comprises fourth electric telescopic rods 61, two fourth electric telescopic rods 61 are symmetrically arranged at the bottom of the connecting block 44, the driving end of each fourth electric telescopic rod 61 is connected with a second cleaning block 62, and the bottom of each second cleaning block 62 is provided with the cleaning grains;

obviously, stretch through controlling fourth electric telescopic handle 61 for second clearance piece 62 carries out the downstream, makes second clearance piece 62 contact with the bottom of sedimentation tank, then through controlling two second motors 42 operations, makes connecting block 44 remove, and then drives second clearance piece 62 and remove, realizes clearing up the bottom of sedimentation tank.

Considering that gaps on the inner wall of the periphery of the sedimentation tank are not easy to clean, a preferable large scheme is provided, a gap cleaning mechanism 7 is arranged in the center of the bottom of the support plate 1, the gap cleaning mechanism 7 comprises a conveying pipe 71, one end of the conveying pipe 71 penetrates through the support plate 1 and extends to be connected with a water tank, the conveying pipe 71 penetrates through the first cleaning block 52 and is connected with a high-pressure spray gun 72, the high-pressure spray gun 72 is arranged in a penetrating groove, and the penetrating groove is arranged inside the first cleaning block 52;

obviously, the high-pressure spray gun 72 is controlled to operate, water is pumped out of the water pool through the delivery pipe 71, the water is pressurized, and gaps on the inner wall of the periphery of the sedimentation tank are cleaned under high pressure.

The above description is only for the specific embodiments of the present invention, but the scope of the present invention is not limited thereto, and any person skilled in the art can easily think of the changes or substitutions within the technical scope of the present invention, and should fall within the scope of the present invention.

Claims (8)

1. The utility model provides a domestic sewage treatment device which characterized in that: the automatic angle adjusting device comprises a supporting plate (1), a bottom central mounting angle adjusting mechanism (2) of the supporting plate (1), a bottom mounting first driving mechanism (3) of the angle adjusting mechanism (2), a second driving mechanism (4) is arranged at the bottom of the first driving mechanism (3), first cleaning mechanisms (5) are mounted on two sides of the second driving mechanism (4), and a second cleaning mechanism (6) is mounted at the bottom of the second driving mechanism (4).

2. The domestic sewage treatment apparatus according to claim 1, wherein: angle adjustment mechanism (2) are including carousel (21), carousel (21) bearing installation is in the bottom of backup pad (1), the central authorities of carousel (21) are equipped with through hole (22), the first motor of bottom central authorities demountable installation of backup pad (1), first pivot is connected to the drive end of first motor, first telescopic link (23) are installed to the bottom of first pivot, the bottom of first telescopic link (23) is connected first actuating mechanism (3).

3. The domestic sewage treatment apparatus according to claim 2, wherein: the first telescopic rod (23) comprises a first connecting rod (231), the first connecting rod (231) is connected with a second connecting rod (232) in a sliding mode, limiting blocks (233) are symmetrically arranged in the center of the outer wall of the first connecting rod (231), limiting grooves are formed in the inner wall of the second connecting rod (232), and the limiting blocks (233) are connected with the limiting grooves in a sliding mode.

4. The domestic sewage treatment apparatus according to claim 1, wherein: first actuating mechanism (3) are including link (31), link (31) are cross, the top central symmetry installation second electric telescopic handle (32) of link (31), every the one end of second electric telescopic handle (32) is connected the bottom of backup pad (1).

5. The domestic sewage treatment apparatus according to claim 4, wherein: the second driving mechanism (4) comprises a supporting frame (41), the supporting frame (41) is fixedly installed at the bottom of the connecting frame (31), second motors (42) are symmetrically installed on one side of the inner wall of the supporting frame (41), the driving end of each second motor (42) is connected with a first screw shaft (43), the first screw shafts (43) penetrate through connecting blocks (44) in a spiral mode, the connecting blocks are connected to the other side of the supporting frame (41) in an extending and rotating mode, and the connecting blocks (44) are connected to two sides of the inner wall of the supporting frame (41) in a sliding mode.

6. The domestic sewage treatment apparatus according to claim 5, wherein: first clearance mechanism (5) include third electric telescopic handle (51), two third electric telescopic handle (51) symmetry is installed one side of carriage (41), two first clearance piece (52) is connected to the one end of third electric telescopic handle (51), one side of first clearance piece (52) is equipped with the clearance line.

7. The domestic sewage treatment apparatus according to claim 6, wherein: the second cleaning mechanism (6) comprises fourth electric telescopic rods (61), the four fourth electric telescopic rods (61) are symmetrically arranged at the bottom of the connecting block (44), the driving ends of the fourth electric telescopic rods (61) are connected with second cleaning blocks (62), and cleaning grains are arranged at the bottoms of the second cleaning blocks (62).

8. The domestic sewage treatment apparatus according to claim 7, wherein: the bottom center of backup pad (1) is equipped with gap clearance mechanism (7), gap clearance mechanism (7) are including conveyer pipe (71), the one end of conveyer pipe (71) is run through backup pad (1), extend and connect the pond, conveyer pipe (71) are run through high-pressure spray gun (72) are connected in first clearance piece (52), high-pressure spray gun (72) set up and are running through in the groove, it is in to run through the groove setting the inside of first clearance piece (52).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210310474.0A CN114768312A (en) | 2022-03-28 | 2022-03-28 | Domestic sewage treatment device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210310474.0A CN114768312A (en) | 2022-03-28 | 2022-03-28 | Domestic sewage treatment device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114768312A true CN114768312A (en) | 2022-07-22 |

Family

ID=82426027

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210310474.0A Pending CN114768312A (en) | 2022-03-28 | 2022-03-28 | Domestic sewage treatment device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114768312A (en) |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1501480A (en) * | 1974-08-19 | 1978-02-15 | Fux K | Settling apparatus including sludge removal means |

| KR101796201B1 (en) * | 2017-03-30 | 2017-11-10 | 주식회사 가나엔텍 | Water Maintenance System with Bad Small Eliminating Function |

| CN210384951U (en) * | 2019-06-21 | 2020-04-24 | 四川中喻环境治理有限公司 | Sewage floater cleaning device that municipal administration sewage treatment plant used |

| CN210786345U (en) * | 2019-07-25 | 2020-06-19 | 绍兴上虞科元自保温墙体材料有限公司 | Sedimentation tank cleaning device for sewage treatment |

| CN211215561U (en) * | 2019-11-08 | 2020-08-11 | 青岛汇鑫混凝土有限公司 | Waste water circulating system convenient to clearance |

| CN211383937U (en) * | 2019-07-17 | 2020-09-01 | 宁波大学 | Sludge scraping device for sewage treatment |

| CN111648615A (en) * | 2020-06-12 | 2020-09-11 | 倪旭军 | Deformation adaptive wall dust shoveling device of water-spraying type self-cleaning mechanism |

| CN211611750U (en) * | 2020-01-06 | 2020-10-02 | 上海环科淙达水务有限公司 | Sludge impoundment bottom cleaning device |

| CN211676462U (en) * | 2019-12-21 | 2020-10-16 | 重庆中明港桥环保有限责任公司 | Sludge discharge device for wastewater treatment |

| WO2021004200A1 (en) * | 2019-07-10 | 2021-01-14 | 中广核研究院有限公司 | Curved surface foreign matter removal device |

| CN112354223A (en) * | 2021-01-15 | 2021-02-12 | 山东锦绣山河环境工程有限公司 | Environment-friendly self-adaptive adjustment type sedimentation tank mud scraper |

| CN212818326U (en) * | 2020-07-06 | 2021-03-30 | 安徽九辰环境科技有限公司 | Sedimentation tank cleaning device for sewage treatment |

| CN215137198U (en) * | 2021-06-22 | 2021-12-14 | 余庆丰 | A sedimentation tank cleaning device for rural sewage treatment |

| CN215841782U (en) * | 2021-09-15 | 2022-02-18 | 鄂尔多斯市碧清源环保科技有限责任公司 | A driving mud scraper for drenching dry water mud sedimentation tank |

| CN216062130U (en) * | 2021-01-11 | 2022-03-18 | 贵州省福帝能塑业有限公司 | Sewage treatment purifies uses sedimentation tank cleaning device |

-

2022

- 2022-03-28 CN CN202210310474.0A patent/CN114768312A/en active Pending

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1501480A (en) * | 1974-08-19 | 1978-02-15 | Fux K | Settling apparatus including sludge removal means |

| KR101796201B1 (en) * | 2017-03-30 | 2017-11-10 | 주식회사 가나엔텍 | Water Maintenance System with Bad Small Eliminating Function |

| CN210384951U (en) * | 2019-06-21 | 2020-04-24 | 四川中喻环境治理有限公司 | Sewage floater cleaning device that municipal administration sewage treatment plant used |

| WO2021004200A1 (en) * | 2019-07-10 | 2021-01-14 | 中广核研究院有限公司 | Curved surface foreign matter removal device |

| CN211383937U (en) * | 2019-07-17 | 2020-09-01 | 宁波大学 | Sludge scraping device for sewage treatment |

| CN210786345U (en) * | 2019-07-25 | 2020-06-19 | 绍兴上虞科元自保温墙体材料有限公司 | Sedimentation tank cleaning device for sewage treatment |

| CN211215561U (en) * | 2019-11-08 | 2020-08-11 | 青岛汇鑫混凝土有限公司 | Waste water circulating system convenient to clearance |

| CN211676462U (en) * | 2019-12-21 | 2020-10-16 | 重庆中明港桥环保有限责任公司 | Sludge discharge device for wastewater treatment |

| CN211611750U (en) * | 2020-01-06 | 2020-10-02 | 上海环科淙达水务有限公司 | Sludge impoundment bottom cleaning device |

| CN111648615A (en) * | 2020-06-12 | 2020-09-11 | 倪旭军 | Deformation adaptive wall dust shoveling device of water-spraying type self-cleaning mechanism |

| CN212818326U (en) * | 2020-07-06 | 2021-03-30 | 安徽九辰环境科技有限公司 | Sedimentation tank cleaning device for sewage treatment |

| CN216062130U (en) * | 2021-01-11 | 2022-03-18 | 贵州省福帝能塑业有限公司 | Sewage treatment purifies uses sedimentation tank cleaning device |

| CN112354223A (en) * | 2021-01-15 | 2021-02-12 | 山东锦绣山河环境工程有限公司 | Environment-friendly self-adaptive adjustment type sedimentation tank mud scraper |

| CN215137198U (en) * | 2021-06-22 | 2021-12-14 | 余庆丰 | A sedimentation tank cleaning device for rural sewage treatment |

| CN215841782U (en) * | 2021-09-15 | 2022-02-18 | 鄂尔多斯市碧清源环保科技有限责任公司 | A driving mud scraper for drenching dry water mud sedimentation tank |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108383288A (en) | A kind of sanitary sewage disposal agitation and filtration device and application method | |

| CN208440407U (en) | A kind of sanitary sewage disposal agitation and filtration device | |

| CN217027245U (en) | Device for removing bottom mud of sewage tank | |

| CN114768312A (en) | Domestic sewage treatment device | |

| CN209138069U (en) | A kind of cleaning shoe | |

| CN111498984A (en) | High-efficient sewage microorganism sewage treatment plant | |

| CN208071419U (en) | A kind of biochemistry pool | |

| CN212292996U (en) | Domestic sewage treatment integrated device | |

| CN210313583U (en) | Adjustable sewage treatment equipment | |

| CN215559435U (en) | Purification tank for integrated sewage treatment | |

| CN108786216B (en) | Domestic sewage treatment equipment of family | |

| CN220951351U (en) | Urban sewage treatment device | |

| CN221701293U (en) | Liftable sewage treatment aeration device | |

| CN111995192A (en) | Integrated sewage treatment equipment | |

| CN216606526U (en) | Sewage treatment pond pool wall cleaning device | |

| CN116495876B (en) | Sewage treatment device | |

| CN221333800U (en) | Sewage treatment device for hospital | |

| CN221440389U (en) | Sewage filtering device for industrial sewage discharge | |

| CN213265758U (en) | A purifier for domestic sewage | |

| CN218945798U (en) | Production device of composite carbon source | |

| CN220345220U (en) | Sewage treatment solid-liquid separation device | |

| CN209128264U (en) | A kind of biomembrane treatment tank | |

| CN220986304U (en) | Aerator for sewage treatment | |

| CN214115080U (en) | Efficient microorganism curing equipment for sewage treatment | |

| CN211712835U (en) | Domestic sewage treatment device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |