CN114442277A - Optical imaging lens - Google Patents

Optical imaging lens Download PDFInfo

- Publication number

- CN114442277A CN114442277A CN202210105853.6A CN202210105853A CN114442277A CN 114442277 A CN114442277 A CN 114442277A CN 202210105853 A CN202210105853 A CN 202210105853A CN 114442277 A CN114442277 A CN 114442277A

- Authority

- CN

- China

- Prior art keywords

- lens

- optical imaging

- optical

- image

- imaging lens

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000012634 optical imaging Methods 0.000 title claims abstract description 244

- 230000003287 optical effect Effects 0.000 claims abstract description 166

- 238000003384 imaging method Methods 0.000 claims description 75

- 101100532514 Arabidopsis thaliana SAG21 gene Proteins 0.000 claims description 9

- 230000004075 alteration Effects 0.000 description 44

- 201000009310 astigmatism Diseases 0.000 description 9

- 238000010586 diagram Methods 0.000 description 6

- 235000013312 flour Nutrition 0.000 description 5

- 230000009286 beneficial effect Effects 0.000 description 4

- 230000035945 sensitivity Effects 0.000 description 3

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000014509 gene expression Effects 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000005286 illumination Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/001—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras

- G02B13/0015—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design

- G02B13/002—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface

- G02B13/0045—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface having five or more lenses

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B30/00—Camera modules comprising integrated lens units and imaging units, specially adapted for being embedded in other devices, e.g. mobile phones or vehicles

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Lenses (AREA)

Abstract

The present application provides an optical imaging lens, sequentially comprising, from an object side to an image side along an optical axis: a first lens having a positive refractive power, an object-side surface of which is convex; a second lens having a refractive power, an image-side surface of which is concave; a third lens having optical power; a fourth lens having an optical power; a fifth lens having a refractive power, an object-side surface of which is convex; a sixth lens having optical power; a seventh lens having optical power; an eighth lens having optical power; and a distance T12 between the first lens and the second lens on the optical axis, a distance T23 between the second lens and the third lens on the optical axis, a distance T34 between the third lens and the fourth lens on the optical axis, and a distance T45 between the fourth lens and the fifth lens on the optical axis satisfy: 1< (T12+ T23+ T34)/T45< 1.5.

Description

Technical Field

The present application relates to the field of optical elements, and more particularly, to an optical imaging lens.

Background

With the gradual maturity of mobile phone camera technology, the common telephoto lens cannot meet the requirement of the consumer for telephoto in daily life, and the total length of the light system needs to be further increased to obtain a larger magnification, which is contrary to the technical development trend of thinning the thickness of the mobile phone. The periscopic telephoto lens has the length direction parallel to the plane direction of the mobile phone, and can break through the limitation of the thickness of the mobile phone on the length of the lens, so that the periscopic lens is more and more widely applied to the zoom mobile phone lens.

However, periscopic lenses require many aspheric lens combinations to meet the final high optical magnification and increasing high pixel requirements, which puts high demands and challenges on the lens structure.

Disclosure of Invention

An aspect of the present disclosure provides an optical imaging lens, sequentially from an object side to an image side along an optical axis, comprising: a first lens having a positive refractive power, an object-side surface of which is convex; a second lens having a refractive power, an image-side surface of which is concave; a third lens having optical power; a fourth lens having an optical power; a fifth lens having a refractive power, an object-side surface of which is convex; a sixth lens having optical power; a seventh lens having optical power; an eighth lens having optical power; and a distance T12 on the optical axis between the first lens and the second lens, a distance T23 on the optical axis between the second lens and the third lens, a distance T34 on the optical axis between the third lens and the fourth lens, and a distance T45 on the optical axis between the fourth lens and the fifth lens satisfy: 1< (T12+ T23+ T34)/T45< 1.5.

In one embodiment of the present application, the maximum effective half aperture DT11 of the object-side surface of the first lens and the half ImgH of the diagonal length of the effective pixel area on the imaging surface of the optical imaging lens satisfy: 0.75< DT11/ImgH <1.

In one embodiment of the present application, a maximum effective half aperture DT52 of an image-side surface of the fifth lens element and a maximum effective half aperture DT61 of an object-side surface of the sixth lens element satisfy: 1< DT52/DT61< 0.8.

In one embodiment of the present application, an on-axis distance SAG21 from an intersection point of an object-side surface of the second lens and the optical axis to a vertex of an effective radius of the object-side surface of the second lens and a center thickness CT2 of the second lens on the optical axis satisfy: 2 is less than or equal to SAG21/CT2< 3.

In one embodiment of the present application, a radius of curvature R3 of an object-side surface of the second lens and a radius of curvature R4 of an image-side surface of the second lens satisfy: 3< (R3+ R4)/(R3-R4) <5.

In an embodiment of the present application, a total effective focal length f of the optical imaging lens and a distance TTL between an object-side surface of the first lens element and an imaging surface of the optical imaging lens on the optical axis satisfy that f/TTL is greater than or equal to 1.

In one embodiment of the present application, the effective focal length f2 of the second lens and the effective focal length f3 of the third lens satisfy: -1.5< f2/f3< -0.8.

In one embodiment of the present application, a combined focal length f678 of the sixth lens element, the seventh lens element and the eighth lens element and a distance TTL on the optical axis from an object-side surface of the first lens element to an imaging surface of the optical imaging lens satisfy: -2.5< f678/TTL < -1.

In one embodiment of the present application, a radius of curvature R9 of an object-side surface of the fifth lens and a radius of curvature R10 of an image-side surface of the fifth lens satisfy 0.8< R9/R10< 1.2.

In one embodiment of the present application, a sum Σ CT of a center thickness CT1 of the first lens on the optical axis and center thicknesses on the optical axis of the respective lenses of the first lens to the eighth lens satisfies 0.3< CT1/∑ CT < 0.5.

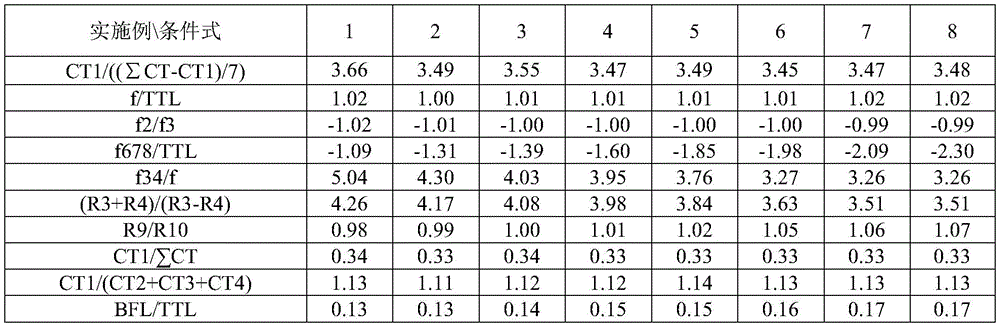

In one embodiment of the present application, a sum Σ CT of a center thickness CT1 of the first lens on the optical axis and center thicknesses Σ CT of the respective lenses of the first lens to the eighth lens on the optical axis satisfies: 3.0< CT1/((∑ CT-CT1)/7) < 4.0.

In one embodiment of the present application, a center thickness CT1 of the first lens on the optical axis, a center thickness CT2 of the second lens on the optical axis, and a center thickness CT3 of the third lens on the optical axis and a center thickness CT4 of the fourth lens on the optical axis satisfy 1< CT1/(CT2+ CT3+ CT4) < 1.5.

In one embodiment of the present application, a distance Tr11r16 between an object-side surface of the sixth lens element and an image-side surface of the eighth lens element on the optical axis and a distance TD between the object-side surface of the first lens element and the image-side surface of the eighth lens element on the optical axis satisfy: 0.2< Tr11r16/TD < 0.3.

In one embodiment of the present application, an on-axis distance SAG61 from an intersection point of an object-side surface of the sixth lens and the optical axis to a vertex of an effective radius of the object-side surface of the sixth lens to the optical axis center thickness CT6 of the sixth lens satisfies: -1.6< SAG61/CT6< -1.

In one embodiment of the present application, an on-axis distance SAG51 from an intersection point of an object-side surface of the fifth lens and the optical axis to an effective radius vertex of the object-side surface of the fifth lens and a center thickness CT5 of the fifth lens on the optical axis satisfy: 0.1< SAG51/CT5< 0.3.

In one embodiment of the present application, an on-axis distance SAG22 from an intersection point of a side surface of the second transparent mirror image and the optical axis to an effective radius vertex of an image side surface of the second lens and an on-axis distance SAG31 from an intersection point of an object side surface of the third lens and the optical axis to an effective radius vertex of an object side surface of the third lens satisfy: 1< SAG22/SAG31< 1.2.

In one embodiment of the present application, a combined focal length f34 of the third lens and the fourth lens and a total effective focal length f of the optical imaging lens satisfy: 3< f34/f < 5.5.

In one embodiment of the present application, a distance T45 between the fourth lens and the fifth lens on the optical axis and a distance T56 between the fifth lens and the sixth lens on the optical axis satisfy: 0.3< T45/T56< 0.6.

In one embodiment of the present application, a distance T67 on the optical axis between the sixth lens and the seventh lens, a distance T78 on the optical axis between the seventh lens and the eighth lens, a central thickness CT6 on the optical axis between the sixth lens, a central thickness CT7 on the optical axis between the seventh lens, and a central thickness CT8 on the optical axis between the eighth lens satisfy: 0.3< (T67+ T78)/(CT6+ CT7+ CT8) < 0.5.

In one embodiment of the present application, a maximum effective half aperture DT42 of an image-side surface of the fourth lens and a maximum effective half aperture DT51 of an object-side surface of the fifth lens satisfy: 10 (DT42-DT51)/DT51 <1.

In one embodiment of the present application, the maximum effective half aperture DT11 of the object-side surface of the first lens and the maximum effective half aperture DT51 of the object-side surface of the fifth lens satisfy: 0.2< (DT11-DT51)/DT11< 0.5.

In one embodiment of the present application, the abbe number V3 of the third lens, the abbe number V5 of the fifth lens, and the abbe number V8 of the eighth lens satisfy: (V3+ V5+ V8)/3< 25.

In one embodiment of the present application, the total effective focal length f of the optical imaging lens and the aperture value Fno of the optical imaging lens satisfy 5mm < f/Fno <6 mm.

Another aspect of the present application provides another optical imaging lens, in order from an object side to an image side along an optical axis, comprising: a first lens having a positive refractive power, an object-side surface of which is convex; a second lens having a refractive power, an image-side surface of which is concave; a third lens having optical power; a fourth lens having an optical power; a fifth lens having a refractive power, an object-side surface of which is convex; a sixth lens having optical power; a seventh lens having optical power; an eighth lens having optical power; and the distance TD between the object side surface of the first lens and the image side surface of the eighth lens on the optical axis and the half ImgH of the diagonal length of the effective pixel area on the imaging surface of the optical imaging lens satisfy: 2< TD/ImgH < 2.5.

In one embodiment of the present application, the maximum effective half aperture DT11 of the object-side surface of the first lens and the half ImgH of the diagonal length of the effective pixel area on the imaging surface of the optical imaging lens satisfy: 0.75< DT11/ImgH <1.

In one embodiment of the present application, a maximum effective half aperture DT52 of an image-side surface of the fifth lens element and a maximum effective half aperture DT61 of an object-side surface of the sixth lens element satisfy: 0.8< DT52/DT61 <1.

In one embodiment of the present application, an on-axis distance SAG21 from an intersection point of an object-side surface of the second lens and the optical axis to a vertex of an effective radius of the object-side surface of the second lens and a center thickness CT2 of the second lens on the optical axis satisfy: 2 is less than or equal to SAG21/CT2< 3.

In one embodiment of the present application, a radius of curvature R3 of an object-side surface of the second lens and a radius of curvature R4 of an image-side surface of the second lens satisfy: 3< (R3+ R4)/(R3-R4) <5.

In an embodiment of the present application, a total effective focal length f of the optical imaging lens and a distance TTL between an object-side surface of the first lens element and an imaging surface of the optical imaging lens on the optical axis satisfy that f/TTL is greater than or equal to 1.

In one embodiment of the present application, the effective focal length f2 of the second lens and the effective focal length f3 of the third lens satisfy: -1.5< f2/f3< -0.8.

In one embodiment of the present application, a combined focal length f678 of the sixth lens element, the seventh lens element and the eighth lens element and a distance TTL on the optical axis from an object-side surface of the first lens element to an imaging surface of the optical imaging lens satisfy: -2.5< f678/TTL < -1.

In one embodiment of the present application, a radius of curvature R9 of an object-side surface of the fifth lens and a radius of curvature R10 of an image-side surface of the fifth lens satisfy 0.8< R9/R10< 1.2.

In one embodiment of the present application, a sum Σ CT of a center thickness CT1 of the first lens on the optical axis and center thicknesses on the optical axis of the respective lenses of the first lens to the eighth lens satisfies 0.3< CT1/∑ CT < 0.5.

In one embodiment of the present application, a center thickness CT1 of the first lens on the optical axis, a center thickness CT2 of the second lens on the optical axis, a center thickness CT3 of the third lens on the optical axis, and a center thickness CT4 of the fourth lens on the optical axis satisfy 1< CT1/(CT2+ CT3+ CT4) < 1.5.

In one embodiment of the present application, a distance Tr11r16 between an object-side surface of the sixth lens element and an image-side surface of the eighth lens element on the optical axis and a distance TD between the object-side surface of the first lens element and the image-side surface of the eighth lens element on the optical axis satisfy: 0.2< Tr11r16/TD < 0.3.

In one embodiment of the present application, an on-axis distance SAG61 from an intersection point of an object-side surface of the sixth lens and the optical axis to a vertex of an effective radius of the object-side surface of the sixth lens to the optical axis center thickness CT6 of the sixth lens satisfies: -1.6< SAG61/CT6< -1.

In one embodiment of the present application, an on-axis distance SAG51 from an intersection point of an object-side surface of the fifth lens and the optical axis to an effective radius vertex of the object-side surface of the fifth lens and a center thickness CT5 of the fifth lens on the optical axis satisfy: 0.1< SAG51/CT5< 0.3.

In one embodiment of the present application, an on-axis distance SAG22 from an intersection point of a side surface of the second transparent mirror image and the optical axis to an effective radius vertex of an image side surface of the second lens and an on-axis distance SAG31 from an intersection point of an object side surface of the third lens and the optical axis to an effective radius vertex of an object side surface of the third lens satisfy: 1< SAG22/SAG31< 1.2.

In one embodiment of the present application, a combined focal length f34 of the third lens and the fourth lens and a total effective focal length f of the optical imaging lens satisfy: 3< f34/f < 5.5.

In one embodiment of the present application, a distance T45 between the fourth lens and the fifth lens on the optical axis and a distance T56 between the fifth lens and the sixth lens on the optical axis satisfy: 0.3< T45/T56< 0.6.

In one embodiment of the present application, a distance T67 between the sixth lens and the seventh lens on the optical axis, a distance T78 between the seventh lens and the eighth lens on the optical axis, a central thickness CT6 of the sixth lens on the optical axis, a central thickness CT7 of the seventh lens on the optical axis, and a central thickness CT8 of the eighth lens on the optical axis satisfy: 0.3< (T67+ T78)/(CT6+ CT7+ CT8) < 0.5.

In one embodiment of the present application, a maximum effective half aperture DT42 of an image-side surface of the fourth lens and a maximum effective half aperture DT51 of an object-side surface of the fifth lens satisfy: 10 (DT42-DT51)/DT51 <1.

In one embodiment of the present application, the maximum effective half aperture DT11 of the object-side surface of the first lens and the maximum effective half aperture DT51 of the object-side surface of the fifth lens satisfy: 0.2< (DT11-DT51)/DT11< 0.5.

In one embodiment of the present application, the abbe number V3 of the third lens, the abbe number V5 of the fifth lens, and the abbe number V8 of the eighth lens satisfy: (V3+ V5+ V8)/3< 25.

In one embodiment of the present application, the total effective focal length f of the optical imaging lens and the aperture value Fno of the optical imaging lens satisfy 5mm < f/Fno <6 mm.

The optical imaging lens adopts a plurality of (for example, eight) lenses, and reasonably distributes the focal power, the surface type, the central thickness of each lens, the on-axis distance between each lens and the like, so that the optical imaging lens has at least one beneficial effect of balancing the aberration generated by the front lens and the rear lens, realizing miniaturization and large aperture and the like while meeting long-focus imaging.

Drawings

Other features, objects, and advantages of the present application will become more apparent from the following detailed description of non-limiting embodiments when taken in conjunction with the accompanying drawings. In the drawings:

fig. 1 shows a schematic structural view of an optical imaging lens according to embodiment 1 of the present application;

fig. 2A to 2D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 1;

fig. 3 is a schematic structural view showing an optical imaging lens according to embodiment 2 of the present application;

fig. 4A to 4D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 2;

fig. 5 is a schematic structural view showing an optical imaging lens according to embodiment 3 of the present application;

fig. 6A to 6D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 3;

fig. 7 is a schematic structural view showing an optical imaging lens according to embodiment 4 of the present application;

fig. 8A to 8D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 4;

fig. 9 is a schematic structural view showing an optical imaging lens according to embodiment 5 of the present application;

fig. 10A to 10D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 5;

fig. 11 is a schematic structural view showing an optical imaging lens according to embodiment 6 of the present application;

fig. 12A to 12D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 6;

fig. 13 is a schematic structural view showing an optical imaging lens according to embodiment 7 of the present application;

fig. 14A to 14D show an axial chromatic aberration curve, an astigmatism curve, a distortion curve, and a chromatic aberration of magnification curve of the optical imaging lens of embodiment 7, respectively;

fig. 15 is a schematic structural view showing an optical imaging lens according to embodiment 8 of the present application;

fig. 16A to 16D show an on-axis chromatic aberration curve, an astigmatic curve, a distortion curve, and a chromatic aberration of magnification curve, respectively, of the optical imaging lens of embodiment 8;

Detailed Description

For a better understanding of the present application, various aspects of the present application will be described in more detail with reference to the accompanying drawings. It should be understood that the detailed description is merely illustrative of exemplary embodiments of the present application and does not limit the scope of the present application in any way. Like reference numerals refer to like elements throughout the specification. The expression "and/or" includes any and all combinations of one or more of the associated listed items.

It should be noted that in this specification, the expressions first, second, third, etc. are used only to distinguish one feature from another, and do not represent any limitation on the features. Thus, the first lens discussed below may also be referred to as the second lens or the third lens without departing from the teachings of the present application.

In the drawings, the thickness, size, and shape of the lens have been slightly exaggerated for convenience of explanation. In particular, the shapes of the spherical or aspherical surfaces shown in the drawings are shown by way of example. That is, the shape of the spherical surface or the aspherical surface is not limited to the shape of the spherical surface or the aspherical surface shown in the drawings. The figures are purely diagrammatic and not drawn to scale.

Herein, the paraxial region refers to a region near the optical axis. If the lens surface is convex and the convex position is not defined, it means that the lens surface is convex at least in the paraxial region; if the lens surface is concave and the concave position is not defined, it means that the lens surface is concave at least in the paraxial region. The surface of each lens closest to the object is called the object side surface of the lens, and the surface of each lens closest to the imaging surface is called the image side surface of the lens.

It will be further understood that the terms "comprises," "comprising," "has," "having," "includes" and/or "including," when used in this specification, specify the presence of stated features, elements, and/or components, but do not preclude the presence or addition of one or more other features, elements, components, and/or groups thereof. Moreover, when a statement such as "at least one of" appears after a list of listed features, the entirety of the listed features is modified rather than modifying individual elements in the list. Furthermore, when describing embodiments of the present application, the use of "may" mean "one or more embodiments of the present application. Also, the term "exemplary" is intended to refer to an example or illustration.

Unless otherwise defined, all terms (including technical and scientific terms) used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs. It will be further understood that terms, such as those defined in commonly used dictionaries, should be interpreted as having a meaning that is consistent with their meaning in the context of the relevant art and will not be interpreted in an idealized or overly formal sense unless expressly so defined herein.

It should be noted that, in the present application, the embodiments and features of the embodiments may be combined with each other without conflict. The present application will be described in detail below with reference to the embodiments with reference to the attached drawings.

The features, principles, and other aspects of the present application are described in detail below.

The optical imaging lens according to an exemplary embodiment of the present application may include, for example, eight lenses having optical powers, i.e., a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens, and an eighth lens. The eight lenses are arranged in order from an object side to an image side along an optical axis. In the first lens to the eighth lens, any two adjacent lenses may have an air space therebetween. The optical imaging lens may further include optical devices (not shown) for deflecting light rays, such as a deflecting prism and a mirror. As an example, the turning prism and the mirror may be disposed between the subject and the first lens.

In an exemplary embodiment, the optical imaging lens may further include at least one diaphragm. The stop may be provided at an appropriate position as needed to control the light-entering amount of the optical imaging lens, for example, between the object side and the first lens.

In an exemplary embodiment, the first lens may have a positive optical power, and the object side surface thereof may be convex and the image side surface thereof may be concave; the second lens can have negative focal power, the image side surface of the second lens is a concave surface, the third lens can have positive focal power, the fourth lens can have negative focal power, the fifth lens can have positive focal power or negative focal power, the image side surface of the fifth lens is a convex surface, the sixth lens can have negative focal power, the seventh lens can have positive focal power or negative focal power, the eighth lens can have positive focal power or negative focal power, and the image pickup effect can be effectively improved by reasonably distributing the positive focal power and the negative focal power of each lens of the optical imaging lens. In addition, the aberration of the optical imaging lens can be balanced by controlling the object-side surface of the first lens element to be convex and the image-side surface of the second lens element to be concave.

In an exemplary embodiment, the optical imaging lens may satisfy 3< f34/f <5.5, where f34 is a combined focal length of the third lens and the fourth lens, and f is a total effective focal length of the optical imaging lens. The optical imaging lens meets the requirement that 3< f34/f <5.5, the contribution amount of the aberration of the third lens and the fourth lens can be controlled, the aberration generated by the front end lens and the aberration generated by the rear end lens are balanced, and the aberration of the optical imaging lens is in a reasonable state.

In an exemplary embodiment, the optical imaging lens may satisfy 2< TD/ImgH <2.5, where TD is a distance on an optical axis from an object side surface of the first lens to an image side surface of the eighth lens, and ImgH is a half of a diagonal length of an effective pixel area on an imaging surface of the optical imaging lens. The optical imaging lens meets the requirement that 2< TD/ImgH <2.5, the size of an effective compression system can be reduced, the ultrathin characteristic of the lens is ensured, and the optical imaging lens is suitable for the miniaturization of a mobile phone camera imaging system. More specifically 2.2< TD/ImgH < 2.5.

In one embodiment of the present application, the optical imaging lens may satisfy 0.75< DT11/ImgH <1, where DT11 is the maximum effective half aperture of the object side surface of the first lens, and ImgH is half the diagonal length of the effective pixel area on the imaging plane of the optical imaging lens. The optical imaging lens meets the condition that DT11/ImgH is less than 1 and the effective radius of the first lens can be effectively controlled within a certain range, so that the marginal light ray transition is more stable, and the processing deterioration caused by overlarge break difference between lenses is avoided.

In one embodiment of the application, the optical imaging lens may satisfy 1< DT52/DT61<0.8, where DT52 is a maximum effective half aperture DT52 of an image side surface of the fifth lens, and DT61 is a maximum effective half aperture of an object side surface of the sixth lens. The optical imaging lens meets the condition that 1< DT52/DT61<0.8, the offset during the processing of the optical imaging lens can be effectively reduced, the edge light transition of the optical imaging lens is normal, and the deflection angle is normal and stable.

In one embodiment of the application, the optical imaging lens can satisfy 2 ≦ SAG21/CT2<3, wherein SAG21 is the distance from the intersection point of the object side surface of the second lens and the optical axis to the effective radius vertex of the object side surface of the second lens on the optical axis, CT2 is the central thickness of the second lens on the optical axis, and the optical imaging lens satisfies 2 ≦ SAG21/CT2<3, so that the incident angle of the principal ray on the object side surface of the second lens can be effectively reduced, and the matching degree of the lens and the chip is improved.

In one embodiment of the present application, the optical imaging lens may satisfy BFL/TTL <0.25, where BFL is a distance on an optical axis from an image-side surface of the eighth lens element to an imaging surface of the optical imaging lens, and TTL is a distance on an optical axis from an object-side surface of the first lens element to the imaging surface of the optical imaging lens. The optical imaging lens meets the BFL/TTL <0.25, and is favorable for an optical system to obtain a better balance between high-quality telephoto image acquisition and module miniaturization, and high-quality telephoto imaging is realized.

In one embodiment of the present application, the optical imaging lens may satisfy 0.9< DT11/DT82<1.2, where DT11 is the maximum effective half aperture of the object side surface of the first lens, and DT51 is the maximum effective half aperture of the image side surface of the eighth lens. The optical imaging lens meets the condition that DT11/DT82 is 0.9< 1.2, the light flux of the lens can be effectively increased, the relative illumination of the marginal field of view is improved, and the optical system has good imaging quality in a dark environment.

In one embodiment of the present application, the optical imaging lens may satisfy 0.9< DT42/DT61<1.2, where DT42 is the maximum effective half aperture of the image-side surface of the fourth lens, and DT51 is the maximum effective half aperture DT51 of the object-side surface of the sixth lens. The optical imaging lens meets 0.9< DT42/DT61<1.2, the outer diameters of the fourth lens and the sixth lens can be restricted, the offset of adjacent lenses is reduced, the manufacturability is improved, and the assembly is consistent.

In an exemplary embodiment, the optical imaging lens may satisfy 0.3< T56/∑ AT <0.6, where T56 is a distance on the optical axis of the fifth lens and the sixth lens, and Σ AT is a sum of distances on the optical axis of each adjacent two lenses of the first lens to the eighth lens. The optical imaging lens meets the requirement that 0.3< T56/∑ AT <0.6, and can reasonably control the distortion range of the system, so that the system has smaller distortion.

In one embodiment of the present application, the optical imaging lens may satisfy 3< (R3+ R4)/(R3-R4) <5, where R3 is a radius of curvature of an object-side surface of the second lens and R4 is a radius of curvature of an image-side surface of the second lens. The optical imaging lens meets the requirement of 3< (R3+ R4)/(R3-R4) <5, the refraction angle of the system light beam on the second lens can be effectively controlled, and the good processing characteristics of the system are realized.

In an embodiment of the application, the optical imaging lens may satisfy that f/TTL is greater than or equal to 1, where f is a total effective focal length f of the optical imaging lens, and TTL is a distance TTL on an optical axis from an object-side surface of the first lens to an imaging surface of the optical imaging lens. The optical imaging lens meets the condition that f/TTL is more than or equal to 1, the telephoto capability of the optical imaging lens can be enhanced, the long-focus characteristic of the lens is met, and the optical imaging lens can be used as a model selection of a periscopic module lens.

In one embodiment of the application, the optical imaging lens can satisfy-1.5 < f2/f3< -0.8, wherein f2 is the effective focal length of the second lens and f3 is the effective focal length of the third lens. The optical imaging lens meets the requirements of-1.5 < f2/f3< -0.8, the deflection angle of light rays can be reduced, and the imaging quality of the optical imaging lens is improved.

In one embodiment of the present application, the optical imaging lens may satisfy-2.5 < f678/TTL < -1, where f678 is a combined focal length f678 of the sixth lens element, the seventh lens element, and the eighth lens element, and TTL is a distance on an optical axis from an object-side surface of the first lens element to an imaging surface of the optical imaging lens. The optical imaging lens meets the requirement that the optical imaging lens is-2.5 < f678/TTL < -1, the total length of a compression system is favorably shortened, the miniaturization of a module is realized, and meanwhile, the light rays of the front five lenses are better converged.

In one embodiment of the present application, the optical imaging lens may satisfy 0.8< R9/R10<1.2, where R9 is a radius of curvature of an object-side surface of the fifth lens and R10 is a radius of curvature of an image-side surface of the fifth lens. The optical imaging lens meets the requirement that 0.8< R9/R10<1.2, the deflection angle of marginal rays of the optical imaging lens can be controlled, and the sensitivity of the optical imaging lens is effectively reduced.

In an embodiment of the present application, the optical imaging lens may satisfy 0.3< CT1/∑ CT <0.5, where CT1 is a central thickness of the first lens on the optical axis, Σ CT is a sum of central thicknesses of the first lens to the eighth lens on the optical axis, and the optical imaging lens satisfies 0.3< CT1/∑ CT <0.5, so that distortion contributions of each field of view of the optical imaging lens can be controlled within a reasonable range, and finally system distortion is within 3%, thereby improving imaging quality.

In one embodiment of the present application, the optical imaging lens may satisfy 3.0< CT1/((∑ CT-CT1)/7) <4.0, where CT1 is the center thickness of the first lens on the optical axis, Σ CT is the sum of the center thicknesses of the respective lenses of the first lens to the eighth lens on the optical axis, and the optical imaging lens satisfies 3.0< CT1/(Σct-CT1)/7) <4.0, so that the distortion contribution amount of each field of view of the optical imaging lens can be controlled within a reasonable range, and finally the system distortion amount is within 3%, thereby improving the imaging quality. More specifically, 3.3< CT1/((∑ CT-CT1)/7) < 3.8.

In one embodiment of the present application, the optical imaging lens may satisfy 1< CT1/(CT2+ CT3+ CT4) <1.5, where CT1 is a central thickness of the first lens on the optical axis, CT2 is a central thickness CT2 of the second lens on the optical axis, CT3 is a central thickness of the third lens on the optical axis, and CT4 is a central thickness of the fourth lens on the optical axis. The optical imaging lens meets the requirements of 1< CT1/(CT2+ CT3+ CT4) <1.5, and is beneficial to better balancing the relation between the miniaturization of the module and the increase of the size of the first lens flange, thereby realizing the assembly in the same direction.

In one embodiment of the present application, the optical imaging lens may satisfy 0.2< Tr11r16/TD <0.3, where Tr11r16 is a distance on an optical axis from an object-side surface of the sixth lens to an image-side surface of the eighth lens, and TD is a distance on an optical axis from an object-side surface of the first lens to an image-side surface of the eighth lens. The optical imaging lens meets the condition that the ratio of Tr11r16/TD is 0.2 to 0.3, the curvature radius and the edge field angle of the ground object side surface of the sixth lens and the image side surface of the eighth lens can be effectively controlled within a certain range, and the sensitivity of the sixth lens and the eighth lens is reduced; meanwhile, the thickness ratio of the sixth lens and the eighth lens is prevented from being too large, and the manufacturability of the lens is improved.

In one embodiment of the application, the optical imaging lens can satisfy-1.6 < SAG61/CT6< -1, wherein SAG61 is the distance on the optical axis from the intersection point of the object side surface of the sixth lens and the optical axis to the effective radius vertex of the object side surface of the sixth lens, and CT6 is satisfied by the center thickness of the sixth lens on the optical axis. The optical imaging lens meets the requirement of-1.6 < SAG61/CT6< -1 >, the incident angle of a chief ray on the object side surface of the sixth lens can be effectively reduced, and the matching degree of the lens and a chip is improved.

In an embodiment of the present application, the optical imaging lens may satisfy 0.1< SAG51/CT5<0.3, where SAG51 is a distance on an optical axis from an intersection point of an object-side surface of the fifth lens and the optical axis to an effective radius vertex of the object-side surface of the fifth lens, CT5 is a center thickness of the fifth lens on the optical axis, and the optical imaging lens satisfies 0.1< SAG51/CT5<0.3, so that an incident angle of a principal ray on a side surface of the fifth lens object can be effectively reduced, and a matching degree between the lens and a chip can be improved.

In one embodiment of the present application, the optical imaging lens may satisfy 1< SAG22/SAG31<1.2, where SAG22 is an on-axis distance from an intersection of an image side surface of the second transparent mirror image and the optical axis to an effective radius vertex of the image side surface of the second lens to SAG31 is an on-axis distance from an intersection of an object side surface of the third lens and the optical axis to an effective radius vertex of an object side surface of the third lens. The optical imaging lens meets 1< SAG22/SAG31<1.2, the miniaturization of the balance module is facilitated, and the spherical aberration of the second lens and the spherical aberration of the third lens are mutually offset.

In one embodiment of the present application, the optical imaging lens may satisfy 1< (T12+ T23+ T34)/T45<1.5, where T12 is a distance between the first lens and the second lens on an optical axis, T23 is a distance between the second lens and the third lens on the optical axis, T34 is a distance between the third lens and the fourth lens on the optical axis, and T45 is a distance between the fourth lens and the fifth lens on the optical axis. The optical imaging lens meets the requirements that 1< (T12+ T23+ T34)/T45<1.5, the field curvature contribution of each field of view can be controlled in a reasonable range, the aberration of the optical imaging lens in an off-axis field of view is small, and therefore the off-axis field of view of the optical imaging lens obtains good imaging quality.

In one embodiment of the present application, the optical imaging lens may satisfy 0.3< T45/T56<0.6, where T45 is a distance between the fourth lens and the fifth lens on the optical axis, and T56 is a distance between the fifth lens and the sixth lens on the optical axis. The optical imaging lens meets the requirement that 0.3< T45/T56<0.6, and can balance the curvature of field generated by the front lens and the curvature of field generated by the rear lens of the optical imaging system, thereby balancing the curvature of field of the optical imaging lens.

In an embodiment of the present application, the optical imaging lens may satisfy 0.3< (T67+ T78)/(CT6+ CT7+ CT8) <0.5, where T67 is a distance between the sixth lens and the seventh lens on an optical axis, T78 is a distance between the seventh lens and the eighth lens on the optical axis, CT6 is a central thickness of the sixth lens on the optical axis, CT7 is a central thickness of the seventh lens on the optical axis, and CT8 is a central thickness of the eighth lens on the optical axis, and the optical imaging lens satisfies 0.3< (T67+ T78)/(CT6+ CT7+ CT8) <0.5, which can reduce an overall length of the optical imaging lens while having good assemblability.

In one embodiment of the present application, the optical imaging lens may satisfy 10 × (DT42-DT51)/DT51<1, where DT42 is the maximum effective half aperture of the image-side surface of the fourth lens and DT51 is the maximum effective half aperture of the object-side surface of the fifth lens. The optical imaging lens meets 10-X (DT42-DT51)/DT51<1, so that marginal rays can smoothly pass through the fourth lens and the fifth lens, and the marginal field imaging quality is improved.

In one embodiment of the present application, the optical imaging lens may satisfy 0.2< (DT11-DT51)/DT11<0.5, where DT11 is the maximum effective half aperture of the object-side face of the first lens and DT51 is the maximum effective half aperture of the object-side face of the fifth lens. The optical imaging lens meets the requirements of 0.2< (DT11-DT51)/DT11<0.5, so that the light of the imaging system can be normally transited, and the deflection angle is normally stable.

In one embodiment of the present application, the optical imaging lens may satisfy (V3+ V5+ V8)/3<25, where V3 is an abbe number of the third lens, V5 is an abbe number of the fifth lens, and V8 is an abbe number of the eighth lens. The optical imaging lens satisfies (V3+ V5+ V8)/3<25, and can effectively control the refractive index difference among the materials of the third lens, the fifth lens and the eighth lens.

In one embodiment of the present application, the optical imaging lens may satisfy 5mm < F/Fno <6mm, where F is a total effective focal length of the optical imaging lens and Fno is a relative F-number of the optical imaging lens. The optical imaging lens meets the requirement that f/Fno is less than 6mm and the system can obtain more light entering amount, thereby realizing large aperture and enabling the shot scenery to be brighter.

The optical imaging lens adopts a plurality of lenses (for example, eight lenses), and has at least one beneficial effect of long focal length, high resolution, miniaturization, large aperture and the like by reasonably distributing the focal power, the surface type, the central thickness of each lens, the on-axis distance between each lens and the like.

In an exemplary embodiment, the optical imaging lens may further include a filter for correcting color deviation and/or a protective glass for protecting a photosensitive element located on an imaging surface.

The optical imaging lens according to the above-described embodiment of the present application may employ a plurality of lenses, for example, eight lenses as described above. By reasonably distributing the focal power, the surface type, the central thickness of each lens, the on-axis distance between each lens and the like, the volume of the optical imaging lens can be effectively reduced, the sensitivity of the optical imaging lens can be reduced, and the processability of the optical imaging lens can be improved, so that the optical imaging lens is more beneficial to production and processing and can be suitable for portable electronic products. The optical imaging lens according to the embodiment of the application also has the advantages that the imaging requirements are met, and meanwhile, the information transmission and the miniaturization between the front-end optical system and the rear-end optical system are realized.

In the embodiment of the present application, at least one of the mirror surfaces of each lens is an aspherical mirror surface, that is, at least one of the object-side surface of the first lens to the image-side surface of the fourth lens is an aspherical mirror surface. The aspheric lens is characterized in that: the curvature varies continuously from the center of the lens to the periphery of the lens. Unlike a spherical lens having a constant curvature from the center of the lens to the periphery of the lens, an aspherical lens has better curvature radius characteristics, and has advantages of improving distortion aberration and improving astigmatic aberration. After the aspheric lens is adopted, the aberration generated during imaging can be eliminated as much as possible, thereby improving the imaging quality. Optionally, at least one of the object side surface and the image side surface of the first lens, the second lens, the third lens and the fourth lens is an aspheric mirror surface. Optionally, the object-side surface and the image-side surface of the second lens, the third lens and the fourth lens are aspheric mirror surfaces.

However, it will be appreciated by those skilled in the art that the number of lenses constituting an optical imaging lens may be varied to achieve the various results and advantages described in the present specification without departing from the claimed subject matter. For example, although eight lenses are exemplified in the embodiment, the optical imaging lens is not limited to include eight lenses. The optical imaging lens may also include other numbers of lenses, if desired.

Specific examples of an optical imaging lens applicable to the above-described embodiments are further described below with reference to the drawings.

Example 1

An optical imaging lens according to embodiment 1 of the present application is described below with reference to fig. 1 to 2D. Fig. 1 shows a schematic structural diagram of an optical imaging lens according to embodiment 1 of the present application.

As shown in fig. 1, the optical imaging lens includes, in order from an object side to an image side along an optical axis: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has positive power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a concave object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has positive power, and has a concave object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has negative power, and has a convex object-side surface S15 and a concave image-side surface S16. Filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

Table 1 shows a basic parameter table of the optical imaging lens of embodiment 1, in which the units of the radius of curvature, the thickness/distance, and the focal length are all millimeters (mm).

TABLE 1

In this embodiment, the total effective focal length f of the optical imaging lens is 8.50mm, the distance TTL between the object-side surface S1 of the first lens element and the imaging surface S19 on the optical axis is 8.30mm, the ImgH, which is half of the diagonal length of the effective pixel area on the imaging surface S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.50.

In the present embodiment, the aspheric surface type x included in the object-side surface and the image-side surface of the lenses of the first lens E1 to the eighth lens E8 may be defined using, but not limited to, the following aspheric surface formula:

wherein x is the rise of the distance from the aspheric surface vertex to the aspheric surface vertex when the aspheric surface is at the position with the height of h along the optical axis direction; c is the paraxial curvature of the aspheric surface, c being 1/R (i.e., paraxial curvature c is the inverse of radius of curvature R in table 1 above); k is a conic coefficient; ai is the correction coefficient of the i-th order of the aspherical surface. Table 2 below shows the high-order term coefficients A that can be used for the aspherical mirror surfaces S1 to S16 in example 14、A6、A8、A10、A12、A14、A16、A18And A20。

| Flour mark | A4 | A6 | A8 | A10 | A12 | A14 | A16 | A18 | A20 |

| S1 | 3.6415E-02 | -1.4080E-02 | 6.2541E-03 | -2.2537E-03 | 5.8306E-04 | -1.0148E-04 | 1.1185E-05 | -7.0419E-07 | 1.9291E-08 |

| S2 | 1.8774E-02 | -7.6328E-03 | 2.4892E-03 | -6.1461E-04 | 1.2088E-04 | -1.9196E-05 | 2.2427E-06 | -1.6203E-07 | 5.2891E-09 |

| S3 | 1.2043E-03 | 3.3376E-03 | -5.9674E-03 | 3.9810E-03 | -1.3882E-03 | 2.8619E-04 | -3.5525E-05 | 2.4809E-06 | -7.5473E-08 |

| S4 | 1.0791E-03 | 1.2886E-02 | -1.4686E-02 | 7.3514E-03 | -1.7687E-03 | 1.7205E-04 | 8.2007E-06 | -3.0978E-06 | 1.8232E-07 |

| S5 | 5.3238E-02 | -1.4077E-02 | 8.8965E-03 | -1.0465E-02 | 6.3870E-03 | -2.0772E-03 | 3.7768E-04 | -3.6243E-05 | 1.4172E-06 |

| S6 | 7.1947E-02 | -1.1331E-02 | 4.0359E-04 | -1.9705E-03 | 5.2763E-04 | 1.4892E-04 | -8.0512E-05 | 1.2123E-05 | -6.3509E-07 |

| S7 | 5.3681E-02 | -4.2229E-03 | -2.4837E-03 | 3.6827E-03 | -2.0742E-03 | 2.9550E-04 | 1.2492E-04 | -4.7027E-05 | 4.4754E-06 |

| S8 | 4.5149E-02 | -4.4831E-02 | 4.3305E-02 | -2.6122E-02 | 1.0915E-02 | -3.2260E-03 | 6.6684E-04 | -8.8590E-05 | 5.5113E-06 |

| S9 | -5.5637E-02 | -1.6639E-03 | -1.2822E-03 | -2.5166E-04 | 9.1441E-04 | -3.3423E-04 | 3.0556E-05 | 4.4916E-06 | -7.4714E-07 |

| S10 | -2.3028E-02 | 4.8279E-03 | -1.5212E-02 | 1.5853E-02 | -6.0912E-03 | -1.1318E-03 | 2.1193E-03 | -7.8186E-04 | 1.0051E-04 |

| S11 | -7.6830E-02 | 2.9927E-02 | 8.6633E-03 | -3.8363E-02 | 3.3107E-02 | -1.4671E-02 | 3.5718E-03 | -4.4900E-04 | 2.3028E-05 |

| S12 | -1.1381E-01 | 8.7790E-02 | -5.1952E-02 | 1.4107E-02 | 1.1062E-03 | -1.9199E-03 | 5.5662E-04 | -7.1727E-05 | 3.5671E-06 |

| S13 | -3.6706E-02 | 7.1855E-02 | -8.0723E-02 | 4.2896E-02 | -1.2859E-02 | 2.3363E-03 | -2.5624E-04 | 1.5597E-05 | -4.0309E-07 |

| S14 | 2.1984E-02 | 4.2679E-02 | -6.8012E-02 | 4.0682E-02 | -1.4106E-02 | 3.0628E-03 | -4.0822E-04 | 3.0325E-05 | -9.5501E-07 |

| S15 | -3.0044E-02 | 1.1750E-02 | -1.4908E-03 | -2.1592E-03 | 1.1216E-03 | -2.3017E-04 | 2.3158E-05 | -1.0879E-06 | 1.7105E-08 |

| S16 | -5.4007E-02 | 1.0782E-02 | -2.8409E-04 | -1.2551E-03 | 5.7751E-04 | -1.3059E-04 | 1.7473E-05 | -1.3278E-06 | 4.3580E-08 |

TABLE 2

Fig. 2A shows an on-axis chromatic aberration curve of the optical imaging lens of embodiment 1, which represents the convergent focus deviation of light rays of different wavelengths after passing through the lens. Fig. 2B shows an astigmatism curve representing a meridional field curvature and a sagittal field curvature of the optical imaging lens of embodiment 1. Fig. 2C shows a distortion curve of the optical imaging lens of embodiment 1, which represents distortion magnitude values corresponding to different image heights. Fig. 2D shows a chromatic aberration of magnification curve of the optical imaging lens of embodiment 1, which represents a deviation of different image heights on the imaging plane after light passes through the lens. As can be seen from fig. 2A to 2D, the optical imaging lens according to embodiment 1 can achieve good imaging quality.

Example 2

An optical imaging lens according to embodiment 2 of the present application is described below with reference to fig. 3 to 4D. In this embodiment and the following embodiments, descriptions of parts similar to those of embodiment 1 will be omitted for the sake of brevity. Fig. 3 shows a schematic structural diagram of an optical imaging lens according to embodiment 2 of the present application.

As shown in fig. 3, the optical imaging lens, in order from an object side to an image side along an optical axis, comprises: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has positive power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a convex object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has positive power, and has a concave object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has negative power, and has a convex object-side surface S15 and a concave image-side surface S16. Filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

In this embodiment, the total effective focal length f of the optical imaging lens is 8.42mm, the distance TTL between the object-side surface S1 of the first lens element and the imaging surface S19 on the optical axis is 8.38mm, the ImgH, which is half the diagonal length of the effective pixel area on the imaging surface S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.55.

Table 3 shows a basic parameter table of the optical imaging lens of embodiment 2, in which the units of the radius of curvature, the thickness/distance, and the focal length are millimeters (mm). Table 4 shows high-order term coefficients that can be used for each aspherical mirror surface in example 2, wherein each aspherical mirror surface type can be defined by formula (1) given in example 1 above.

TABLE 3

| Flour mark | A4 | A6 | A8 | A10 | A12 | A14 | A16 | A18 | A20 |

| S1 | 5.8666E-01 | -6.4808E-02 | 1.2786E-02 | -3.9855E-03 | 1.0406E-03 | -3.3676E-04 | 1.4234E-04 | -5.4467E-05 | 1.4003E-05 |

| S2 | 1.9784E-01 | -2.9457E-02 | 7.0651E-03 | -1.9600E-03 | 5.9291E-04 | -1.0115E-04 | 1.7585E-05 | -3.3052E-06 | 1.2291E-06 |

| S3 | 5.4121E-02 | 1.3803E-02 | 1.4991E-03 | -1.6643E-03 | 6.1495E-04 | 1.4881E-04 | -1.6140E-04 | 5.8075E-05 | -1.1717E-05 |

| S4 | 1.7196E-01 | 1.9392E-02 | -3.1957E-03 | -6.4733E-03 | -4.3797E-04 | 4.7346E-04 | -4.4695E-04 | 5.1633E-05 | -2.5457E-06 |

| S5 | 6.2041E-01 | -7.3644E-02 | 1.4135E-02 | -1.6652E-02 | -5.8659E-03 | -1.3944E-03 | -9.5876E-04 | -1.7311E-04 | 1.2949E-04 |

| S6 | 5.2357E-01 | -1.7254E-01 | 3.5385E-02 | -2.7569E-03 | -4.8747E-03 | 6.3627E-04 | 4.6129E-04 | -1.2530E-04 | -2.3093E-06 |

| S7 | 4.3651E-01 | -2.6310E-02 | 2.1471E-03 | 1.5108E-03 | 2.9781E-04 | -1.5964E-04 | -2.4502E-05 | 3.0860E-05 | 3.9578E-06 |

| S8 | 1.7296E-01 | -8.7701E-04 | 2.6491E-03 | -1.5461E-03 | 3.4834E-04 | -1.6058E-04 | 2.5533E-05 | -4.1907E-06 | 7.4275E-07 |

| S9 | -3.7160E-01 | -1.4731E-03 | 1.8032E-03 | 7.1823E-05 | -1.0276E-04 | 1.0304E-05 | 6.1501E-06 | 3.9097E-07 | -1.0867E-06 |

| S10 | -1.1801E-01 | 3.1744E-02 | 1.3683E-02 | 4.0450E-03 | 1.8059E-03 | 8.4036E-04 | 3.4759E-04 | 1.1623E-04 | 2.5764E-05 |

| S11 | -7.5988E-01 | 2.1224E-02 | 3.5215E-02 | 3.1023E-02 | 8.2467E-03 | 1.6311E-03 | -6.1395E-04 | -1.7551E-04 | 1.9681E-05 |

| S12 | -1.0163E+00 | 1.1979E-01 | -4.1606E-02 | -1.2161E-02 | -1.0511E-02 | 4.4793E-03 | 2.2072E-03 | 2.1013E-03 | 3.8791E-04 |

| S13 | -4.8409E-01 | 1.2652E-01 | -1.2410E-02 | -2.8879E-02 | 1.2524E-02 | 3.5197E-03 | -1.2672E-03 | 1.0020E-03 | -5.8317E-04 |

| S14 | -4.8395E-01 | -9.7023E-02 | 9.9876E-02 | -8.3471E-03 | 2.9316E-02 | -4.2237E-03 | -1.0619E-02 | -6.0623E-03 | -2.2595E-03 |

| S15 | -7.0273E-01 | 1.3250E-01 | -2.0377E-02 | -2.4566E-02 | 7.9062E-03 | 5.0186E-06 | -7.2609E-03 | -2.3077E-03 | 3.2726E-04 |

| S16 | -1.1948E+00 | 2.7129E-01 | -3.0872E-02 | -1.7633E-02 | -3.7331E-03 | 7.2759E-03 | 3.4740E-03 | 1.0733E-03 | 3.3111E-05 |

TABLE 4

Fig. 4A shows an on-axis chromatic aberration curve of the optical imaging lens of embodiment 2, which represents the convergent focus deviation of light rays of different wavelengths after passing through the lens. Fig. 4B shows an astigmatism curve representing meridional field curvature and sagittal field curvature of the optical imaging lens of embodiment 2. Fig. 4C shows a distortion curve of the optical imaging lens of embodiment 2, which represents distortion magnitude values corresponding to different image heights. Fig. 4D shows a chromatic aberration of magnification curve of the optical imaging lens of embodiment 2, which represents the deviation of different image heights on the imaging plane after light passes through the lens. As can be seen from fig. 4A to 4D, the optical imaging lens according to embodiment 2 can achieve good imaging quality.

Example 3

An optical imaging lens according to embodiment 3 of the present application is described below with reference to fig. 5 to 6D. Fig. 5 shows a schematic structural diagram of an optical imaging lens according to embodiment 3 of the present application.

As shown in fig. 5, the optical imaging lens, in order from an object side to an image side along an optical axis, comprises: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has positive power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a convex object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has negative power, and has a concave object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has positive power, and has a convex object-side surface S15 and a concave image-side surface S16. The filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

In this embodiment, the total effective focal length f of the optical imaging lens is 8.52mm, the distance TTL between the object-side surface S1 of the first lens element and the imaging surface S19 on the optical axis is 8.44mm, the ImgH, which is half the diagonal length of the effective pixel area on the imaging surface S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.55.

Table 5 shows a basic parameter table of the optical imaging lens of embodiment 3, in which the units of the radius of curvature, the thickness/distance, and the focal length are all millimeters (mm). Table 6 shows high-order term coefficients that can be used for each aspherical mirror surface in example 3, wherein each aspherical mirror surface type can be defined by formula (1) given in example 1 above.

TABLE 5

| Flour mark | A4 | A6 | A8 | A10 | A12 | A14 | A16 | A18 | A20 |

| S1 | 5.8714E-01 | -6.4777E-02 | 1.2835E-02 | -3.9574E-03 | 1.0494E-03 | -3.3317E-04 | 1.4181E-04 | -5.3314E-05 | 1.4258E-05 |

| S2 | 1.9743E-01 | -2.9630E-02 | 7.0453E-03 | -1.9504E-03 | 5.9826E-04 | -1.0010E-04 | 1.7653E-05 | -3.1764E-06 | 1.2584E-06 |

| S3 | 5.3867E-02 | 1.3967E-02 | 1.4907E-03 | -1.6856E-03 | 6.1405E-04 | 1.4917E-04 | -1.6533E-04 | 5.4178E-05 | -1.0088E-05 |

| S4 | 1.7258E-01 | 1.9010E-02 | -3.0065E-03 | -6.0206E-03 | -3.5036E-04 | 4.0804E-04 | -4.2481E-04 | 6.3605E-05 | 7.4564E-06 |

| S5 | 6.2075E-01 | -7.3579E-02 | 1.4177E-02 | -1.5943E-02 | -5.6989E-03 | -1.5511E-03 | -1.0310E-03 | -2.0307E-04 | 1.2406E-04 |

| S6 | 5.2356E-01 | -1.7266E-01 | 3.4368E-02 | -3.4316E-03 | -5.2724E-03 | 3.8570E-04 | 3.5965E-04 | -9.4516E-05 | 2.1000E-05 |

| S7 | 4.3637E-01 | -2.6514E-02 | 2.2211E-03 | 1.4989E-03 | 2.9859E-04 | -1.4981E-04 | -1.8409E-05 | 2.7799E-05 | 1.3882E-06 |

| S8 | 1.7315E-01 | -8.9317E-04 | 2.5808E-03 | -1.5578E-03 | 3.4329E-04 | -1.6135E-04 | 2.5602E-05 | -4.0514E-06 | 8.4026E-07 |

| S9 | -3.7164E-01 | -1.5611E-03 | 1.6558E-03 | 2.3781E-05 | -1.3285E-04 | 1.7021E-05 | 9.4876E-06 | 1.1304E-06 | -1.1131E-06 |

| S10 | -1.1811E-01 | 3.2738E-02 | 1.3429E-02 | 3.7365E-03 | 1.5758E-03 | 7.4682E-04 | 2.8268E-04 | 8.9936E-05 | 1.5291E-05 |

| S11 | -7.7378E-01 | 2.5870E-02 | 3.2949E-02 | 3.1080E-02 | 8.8895E-03 | 1.8193E-03 | -1.4216E-03 | -1.0081E-03 | -1.9526E-04 |

| S12 | -1.0270E+00 | 1.2172E-01 | -3.9843E-02 | -1.3411E-02 | -9.6044E-03 | 4.6713E-03 | 8.4387E-04 | 1.2263E-03 | 1.0226E-03 |

| S13 | -4.9861E-01 | 1.4417E-01 | -9.4097E-03 | -3.1818E-02 | 1.5945E-02 | 1.4109E-03 | -2.5557E-03 | 2.5578E-03 | 1.6829E-03 |

| S14 | -5.1035E-01 | -8.6798E-02 | 9.1365E-02 | 2.4384E-04 | 2.7536E-02 | -1.8383E-03 | -1.5292E-02 | -5.5257E-03 | -3.2123E-03 |

| S15 | -7.3292E-01 | 1.3726E-01 | -2.7333E-02 | -2.2657E-02 | 6.7447E-03 | 3.1419E-03 | -1.1054E-02 | 3.1611E-03 | 6.4956E-04 |

| S16 | -1.2383E+00 | 2.5556E-01 | -4.9188E-03 | -4.0864E-03 | -8.2128E-04 | 1.4057E-02 | 4.3784E-03 | 1.9641E-03 | 5.2065E-04 |

TABLE 6

Fig. 6A shows on-axis chromatic aberration curves of the optical imaging lens of embodiment 3, which represent the convergent focus deviation of light rays of different wavelengths after passing through the lens. Fig. 6B shows an astigmatism curve representing meridional field curvature and sagittal field curvature of the optical imaging lens of embodiment 3. Fig. 6C shows a distortion curve of the optical imaging lens of embodiment 3, which represents distortion magnitude values corresponding to different image heights. Fig. 6D shows a chromatic aberration of magnification curve of the optical imaging lens of embodiment 3, which represents a deviation of different image heights on the imaging plane after light passes through the lens. As can be seen from fig. 6A to 6D, the optical imaging lens according to embodiment 3 can achieve good imaging quality.

Example 4

An optical imaging lens according to embodiment 4 of the present application is described below with reference to fig. 7 to 8D. Fig. 7 shows a schematic structural diagram of an optical imaging lens according to embodiment 4 of the present application.

As shown in fig. 7, the optical imaging lens, in order from an object side to an image side along an optical axis, comprises: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has positive power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a convex object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has positive power, and has a concave object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has positive power, and has a convex object-side surface S15 and a convex image-side surface S16. Filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

In the present embodiment, the total effective focal length f of the optical imaging lens is 8.66mm, the distance TTL between the object-side surface S1 of the first lens element and the imaging surface S19 on the optical axis is 8.57mm, the ImgH, which is half of the diagonal length of the effective pixel area on the imaging surface S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.60.

Table 7 shows a basic parameter table of the optical imaging lens of embodiment 4, in which the units of the radius of curvature, the thickness/distance, and the focal length are all millimeters (mm). Table 8 shows high-order term coefficients that can be used for each aspherical mirror surface in example 4, wherein each aspherical mirror surface type can be defined by formula (1) given in example 1 above.

TABLE 7

TABLE 8

Fig. 8A shows an on-axis chromatic aberration curve of the optical imaging lens of embodiment 4, which represents the convergent focus deviation of light rays of different wavelengths after passing through the lens. Fig. 8B shows an astigmatism curve representing meridional field curvature and sagittal field curvature of the optical imaging lens of embodiment 4. Fig. 8C shows a distortion curve of the optical imaging lens of embodiment 4, which represents distortion magnitude values corresponding to different image heights. Fig. 8D shows a chromatic aberration of magnification curve of the optical imaging lens of embodiment 4, which represents the deviation of different image heights on the imaging plane after light passes through the lens. As can be seen from fig. 8A to 8D, the optical imaging lens system according to embodiment 4 can achieve good imaging quality.

Example 5

An optical imaging lens according to embodiment 5 of the present application is described below with reference to fig. 9 to 10D. Fig. 9 shows a schematic structural diagram of an optical imaging lens according to embodiment 5 of the present application.

As shown in fig. 9, the optical imaging lens, in order from an object side to an image side along an optical axis, comprises: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has positive power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a convex object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has positive power, and has a convex object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has positive power, and has a convex object-side surface S15 and a convex image-side surface S16. Filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

In this embodiment, the total effective focal length f of the optical imaging lens is 8.73mm, the distance TTL on the optical axis from the object side surface S1 to the image plane S19 of the first lens element is 8.65mm, the ImgH, which is a half of the diagonal length of the effective pixel area on the image plane S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.65.

Table 9 shows a basic parameter table of the optical imaging lens of embodiment 5, in which the units of the radius of curvature, the thickness/distance, and the focal length are all millimeters (mm). Table 9 shows high-order term coefficients that can be used for each aspherical mirror surface in embodiment 5, wherein each aspherical mirror surface type can be defined by the formula (1) given in embodiment 1 above.

TABLE 9

| Spherical surface | A4 | A6 | A8 | A10 | A12 | A14 | A16 | A18 | A20 |

| S1 | 5.8809E-01 | -6.4772E-02 | 1.2775E-02 | -3.9271E-03 | 1.0569E-03 | -3.2002E-04 | 1.2786E-04 | -4.2843E-05 | 1.5936E-05 |

| S2 | 1.9714E-01 | -2.9807E-02 | 7.0772E-03 | -1.9389E-03 | 6.2299E-04 | -9.0153E-05 | 2.1500E-05 | -8.6391E-07 | 1.0141E-06 |

| S3 | 5.3368E-02 | 1.4609E-02 | 1.7064E-03 | -1.5135E-03 | 6.8324E-04 | 2.5829E-04 | -1.4198E-04 | 1.0450E-05 | -2.5081E-06 |

| S4 | 1.7545E-01 | 1.8228E-02 | -2.6731E-03 | -5.2560E-03 | 1.7358E-04 | 5.0272E-04 | -5.8816E-04 | -8.1107E-05 | 4.5882E-05 |

| S5 | 6.1884E-01 | -7.5144E-02 | 1.2660E-02 | -1.5459E-02 | -4.3047E-03 | -1.0606E-03 | -1.1145E-03 | -3.5503E-04 | 1.4041E-04 |

| S6 | 5.2347E-01 | -1.7020E-01 | 3.3988E-02 | -4.4526E-03 | -6.2010E-03 | -4.2078E-04 | -3.1925E-04 | -3.6295E-04 | 4.1682E-05 |

| S7 | 4.3847E-01 | -2.6287E-02 | 2.5399E-03 | 1.6782E-03 | 3.4381E-04 | -1.3717E-04 | 2.4873E-05 | 2.4594E-05 | 1.7425E-06 |

| S8 | 1.7578E-01 | -3.7397E-04 | 2.7634E-03 | -1.5628E-03 | 3.2763E-04 | -1.5633E-04 | 2.4438E-05 | -4.6708E-06 | 1.0097E-06 |

| S9 | -3.7183E-01 | -1.1436E-03 | 1.6441E-03 | -3.7691E-05 | -1.1847E-04 | 1.0769E-05 | 5.6346E-06 | 2.6764E-06 | -1.1079E-06 |

| S10 | -1.2342E-01 | 3.3044E-02 | 1.3223E-02 | 3.7587E-03 | 1.6033E-03 | 7.0766E-04 | 2.5092E-04 | 6.8077E-05 | 9.6666E-06 |

| S11 | -7.8647E-01 | 2.6502E-02 | 3.2644E-02 | 3.0995E-02 | 9.5646E-03 | 1.7274E-03 | -5.2287E-04 | -2.5537E-04 | -1.1986E-05 |

| S12 | -1.0284E+00 | 1.2944E-01 | -3.5177E-02 | -1.6667E-02 | -9.4367E-03 | 1.8599E-03 | 1.0316E-03 | 1.4704E-03 | 1.9247E-04 |

| S13 | -5.4448E-01 | 1.2322E-01 | -3.0807E-03 | -3.8539E-02 | 2.2056E-02 | 2.3816E-04 | -2.1278E-03 | 6.5680E-04 | -9.8192E-04 |

| S14 | -6.3362E-01 | -5.2122E-02 | 8.6978E-02 | -5.4845E-03 | 3.3259E-02 | -6.2393E-03 | -1.2447E-02 | -4.2856E-03 | -1.6432E-03 |

| S15 | -8.1398E-01 | 1.2117E-01 | -2.2945E-02 | -2.9197E-02 | 8.9047E-03 | -1.5623E-03 | -5.3173E-03 | 2.3520E-03 | 1.9647E-03 |

| S16 | -1.1926E+00 | 2.3685E-01 | 1.8120E-02 | 4.6376E-03 | 6.4887E-03 | 8.5758E-03 | 2.2042E-03 | -2.7634E-04 | -1.5712E-04 |

Fig. 10A shows an on-axis chromatic aberration curve of the optical imaging lens of embodiment 5, which represents the convergent focus deviation of light rays of different wavelengths after passing through the lens. Fig. 10B shows an astigmatism curve representing meridional field curvature and sagittal field curvature of the optical imaging lens of embodiment 5. Fig. 10C shows a distortion curve of the optical imaging lens of embodiment 5, which represents distortion magnitude values corresponding to different image heights. Fig. 10D shows a chromatic aberration of magnification curve of the optical imaging lens of embodiment 5, which represents a deviation of different image heights on the imaging surface after light passes through the lens. As can be seen from fig. 10A to 10D, the optical imaging lens according to embodiment 6 can achieve good imaging quality.

Example 6

An optical imaging lens according to embodiment 6 of the present application is described below with reference to fig. 11 to 12D. Fig. 11 shows a schematic structural view of an optical imaging lens according to embodiment 7 of the present application.

As shown in fig. 11, the optical imaging lens, in order from an object side to an image side along an optical axis, comprises: the stop STO, the first lens E1, the second lens E2, the third lens E3, the fourth lens E4, the fifth lens E5, the sixth lens E6, the seventh lens E7, the eighth lens E8, the filter E9, and the image plane S19.

The first lens element E1 has positive power, and has a convex object-side surface S1 and a convex image-side surface S2. The second lens element E2 has negative power, and has a convex object-side surface S3 and a concave image-side surface S4. The third lens element E3 has positive power, and has a convex object-side surface S5 and a concave image-side surface S6. The fourth lens element E4 has negative power, and has a convex object-side surface S7 and a concave image-side surface S8. The fifth lens element E5 has negative power, and has a convex object-side surface S9 and a concave image-side surface S10. The sixth lens element E6 has negative power, and has a convex object-side surface S11 and a concave image-side surface S12. The seventh lens element E7 has positive power, and has a convex object-side surface S13 and a convex image-side surface S14. The eighth lens element E8 has positive power, and has a convex object-side surface S15 and a convex image-side surface S16. The filter E9 has an object side S17 and an image side S18. The light from the object passes through the respective surfaces S1 to S18 in order and is finally imaged on the imaging surface S19.

In this embodiment, the total effective focal length f of the optical imaging lens is 8.84mm, the distance TTL between the object-side surface S1 of the first lens element and the imaging surface S19 on the optical axis is 8.76mm, the ImgH, which is half the diagonal length of the effective pixel area on the imaging surface S19, is 3.15mm, and the aperture value Fno of the optical imaging lens is 1.65.