CN113600097B - Preparation method of asymmetric gemini imidazoline phosphate surfactant - Google Patents

Preparation method of asymmetric gemini imidazoline phosphate surfactant Download PDFInfo

- Publication number

- CN113600097B CN113600097B CN202110824766.1A CN202110824766A CN113600097B CN 113600097 B CN113600097 B CN 113600097B CN 202110824766 A CN202110824766 A CN 202110824766A CN 113600097 B CN113600097 B CN 113600097B

- Authority

- CN

- China

- Prior art keywords

- acid

- phosphate

- ammonium

- imidazoline

- chloro

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004094 surface-active agent Substances 0.000 title claims abstract description 52

- DZXSOSQSLWSODC-UHFFFAOYSA-N 4,5-dihydro-1h-imidazole;phosphoric acid Chemical compound C1CN=CN1.OP(O)(O)=O DZXSOSQSLWSODC-UHFFFAOYSA-N 0.000 title claims abstract description 36

- 238000002360 preparation method Methods 0.000 title claims abstract description 7

- -1 3-chloro-2-hydroxyl propyl phosphate ammonium Chemical compound 0.000 claims abstract description 55

- MTNDZQHUAFNZQY-UHFFFAOYSA-N imidazoline Chemical compound C1CN=CN1 MTNDZQHUAFNZQY-UHFFFAOYSA-N 0.000 claims abstract description 55

- 239000007864 aqueous solution Substances 0.000 claims abstract description 52

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 33

- 230000002194 synthesizing effect Effects 0.000 claims abstract description 26

- 238000005804 alkylation reaction Methods 0.000 claims abstract description 20

- 239000003513 alkali Substances 0.000 claims abstract description 9

- 238000010438 heat treatment Methods 0.000 claims description 46

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 44

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 claims description 40

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 36

- 239000000194 fatty acid Substances 0.000 claims description 36

- 229930195729 fatty acid Natural products 0.000 claims description 36

- 238000003756 stirring Methods 0.000 claims description 34

- 150000004665 fatty acids Chemical class 0.000 claims description 31

- POULHZVOKOAJMA-UHFFFAOYSA-N dodecanoic acid Chemical compound CCCCCCCCCCCC(O)=O POULHZVOKOAJMA-UHFFFAOYSA-N 0.000 claims description 27

- BRLQWZUYTZBJKN-UHFFFAOYSA-N Epichlorohydrin Chemical compound ClCC1CO1 BRLQWZUYTZBJKN-UHFFFAOYSA-N 0.000 claims description 22

- 229910052757 nitrogen Inorganic materials 0.000 claims description 22

- 229910000147 aluminium phosphate Inorganic materials 0.000 claims description 20

- LFVGISIMTYGQHF-UHFFFAOYSA-N ammonium dihydrogen phosphate Chemical compound [NH4+].OP(O)([O-])=O LFVGISIMTYGQHF-UHFFFAOYSA-N 0.000 claims description 20

- 229910000387 ammonium dihydrogen phosphate Inorganic materials 0.000 claims description 20

- 235000019837 monoammonium phosphate Nutrition 0.000 claims description 20

- RPNUMPOLZDHAAY-UHFFFAOYSA-N Diethylenetriamine Chemical group NCCNCCN RPNUMPOLZDHAAY-UHFFFAOYSA-N 0.000 claims description 16

- 239000002253 acid Substances 0.000 claims description 16

- 239000005639 Lauric acid Substances 0.000 claims description 14

- WWZKQHOCKIZLMA-UHFFFAOYSA-N octanoic acid Chemical compound CCCCCCCC(O)=O WWZKQHOCKIZLMA-UHFFFAOYSA-N 0.000 claims description 13

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid Chemical compound CCCCCCCC\C=C/CCCCCCCC(O)=O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 claims description 13

- 229920000768 polyamine Polymers 0.000 claims description 13

- 238000009833 condensation Methods 0.000 claims description 12

- 230000005494 condensation Effects 0.000 claims description 12

- GHVNFZFCNZKVNT-UHFFFAOYSA-N decanoic acid Chemical compound CCCCCCCCCC(O)=O GHVNFZFCNZKVNT-UHFFFAOYSA-N 0.000 claims description 12

- 238000000034 method Methods 0.000 claims description 12

- 238000010992 reflux Methods 0.000 claims description 12

- 238000007363 ring formation reaction Methods 0.000 claims description 12

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 claims description 10

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 claims description 10

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 claims description 10

- 239000005642 Oleic acid Substances 0.000 claims description 10

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 claims description 10

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 claims description 10

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 claims description 6

- LRWZZZWJMFNZIK-UHFFFAOYSA-N 2-chloro-3-methyloxirane Chemical compound CC1OC1Cl LRWZZZWJMFNZIK-UHFFFAOYSA-N 0.000 claims description 5

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 claims description 5

- 235000021360 Myristic acid Nutrition 0.000 claims description 5

- TUNFSRHWOTWDNC-UHFFFAOYSA-N Myristic acid Natural products CCCCCCCCCCCCCC(O)=O TUNFSRHWOTWDNC-UHFFFAOYSA-N 0.000 claims description 5

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical compound OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 claims description 5

- 235000011114 ammonium hydroxide Nutrition 0.000 claims description 5

- 150000007530 organic bases Chemical class 0.000 claims description 5

- TWJNQYPJQDRXPH-UHFFFAOYSA-N 2-cyanobenzohydrazide Chemical compound NNC(=O)C1=CC=CC=C1C#N TWJNQYPJQDRXPH-UHFFFAOYSA-N 0.000 claims description 4

- 238000004519 manufacturing process Methods 0.000 claims description 4

- OYHQOLUKZRVURQ-NTGFUMLPSA-N (9Z,12Z)-9,10,12,13-tetratritiooctadeca-9,12-dienoic acid Chemical compound C(CCCCCCC\C(=C(/C\C(=C(/CCCCC)\[3H])\[3H])\[3H])\[3H])(=O)O OYHQOLUKZRVURQ-NTGFUMLPSA-N 0.000 claims description 2

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 claims description 2

- 238000002156 mixing Methods 0.000 claims description 2

- 235000021313 oleic acid Nutrition 0.000 claims description 2

- 238000006243 chemical reaction Methods 0.000 abstract description 41

- 238000005260 corrosion Methods 0.000 abstract description 26

- 230000007797 corrosion Effects 0.000 abstract description 24

- 230000005764 inhibitory process Effects 0.000 abstract description 16

- 229910052751 metal Inorganic materials 0.000 abstract description 9

- 239000002184 metal Substances 0.000 abstract description 9

- 230000029936 alkylation Effects 0.000 abstract description 7

- 238000005516 engineering process Methods 0.000 abstract description 7

- 238000011161 development Methods 0.000 abstract description 6

- 239000002994 raw material Substances 0.000 abstract description 4

- 238000011031 large-scale manufacturing process Methods 0.000 abstract description 3

- 238000005536 corrosion prevention Methods 0.000 abstract 2

- 238000001816 cooling Methods 0.000 description 10

- 238000004821 distillation Methods 0.000 description 10

- 235000020778 linoleic acid Nutrition 0.000 description 9

- OYHQOLUKZRVURQ-IXWMQOLASA-N linoleic acid Natural products CCCCC\C=C/C\C=C\CCCCCCCC(O)=O OYHQOLUKZRVURQ-IXWMQOLASA-N 0.000 description 9

- OYHQOLUKZRVURQ-HZJYTTRNSA-N Linoleic acid Chemical compound CCCCC\C=C/C\C=C/CCCCCCCC(O)=O OYHQOLUKZRVURQ-HZJYTTRNSA-N 0.000 description 8

- 229910000975 Carbon steel Inorganic materials 0.000 description 7

- 239000010962 carbon steel Substances 0.000 description 7

- BGGDRACWOICIIC-KVVVOXFISA-N dodecanoic acid;(z)-octadec-9-enoic acid Chemical compound CCCCCCCCCCCC(O)=O.CCCCCCCC\C=C/CCCCCCCC(O)=O BGGDRACWOICIIC-KVVVOXFISA-N 0.000 description 7

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 6

- 239000002585 base Substances 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- 238000010521 absorption reaction Methods 0.000 description 5

- 239000003112 inhibitor Substances 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 4

- 238000009736 wetting Methods 0.000 description 4

- 229910019142 PO4 Inorganic materials 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 239000003054 catalyst Substances 0.000 description 3

- PYVNUZAVACSANL-UHFFFAOYSA-N dodecanoic acid;octanoic acid Chemical compound CCCCCCCC(O)=O.CCCCCCCCCCCC(O)=O PYVNUZAVACSANL-UHFFFAOYSA-N 0.000 description 3

- 239000000693 micelle Substances 0.000 description 3

- 239000010452 phosphate Substances 0.000 description 3

- 238000003786 synthesis reaction Methods 0.000 description 3

- WIBJWDHQQRFQQO-KVVVOXFISA-N (z)-octadec-9-enoic acid;octanoic acid Chemical compound CCCCCCCC(O)=O.CCCCCCCC\C=C/CCCCCCCC(O)=O WIBJWDHQQRFQQO-KVVVOXFISA-N 0.000 description 2

- GVNVAWHJIKLAGL-UHFFFAOYSA-N 2-(cyclohexen-1-yl)cyclohexan-1-one Chemical compound O=C1CCCCC1C1=CCCCC1 GVNVAWHJIKLAGL-UHFFFAOYSA-N 0.000 description 2

- BQACOLQNOUYJCE-FYZZASKESA-N Abietic acid Natural products CC(C)C1=CC2=CC[C@]3(C)[C@](C)(CCC[C@@]3(C)C(=O)O)[C@H]2CC1 BQACOLQNOUYJCE-FYZZASKESA-N 0.000 description 2

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- 239000004254 Ammonium phosphate Substances 0.000 description 2

- 101150065749 Churc1 gene Proteins 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- 102100038239 Protein Churchill Human genes 0.000 description 2

- 229910000148 ammonium phosphate Inorganic materials 0.000 description 2

- 235000019289 ammonium phosphates Nutrition 0.000 description 2

- 125000004429 atom Chemical group 0.000 description 2

- UKWIGEGTQKXANU-KVVVOXFISA-N decanoic acid;(z)-octadec-9-enoic acid Chemical compound CCCCCCCCCC(O)=O.CCCCCCCC\C=C/CCCCCCCC(O)=O UKWIGEGTQKXANU-KVVVOXFISA-N 0.000 description 2

- ZNVQTOIZKHNIMD-UHFFFAOYSA-N decanoic acid;4,5-dihydro-1h-imidazole Chemical compound C1CN=CN1.CCCCCCCCCC(O)=O ZNVQTOIZKHNIMD-UHFFFAOYSA-N 0.000 description 2

- NYVNRFYXFHTPAP-UHFFFAOYSA-N decanoic acid;tetradecanoic acid Chemical compound CCCCCCCCCC(O)=O.CCCCCCCCCCCCCC(O)=O NYVNRFYXFHTPAP-UHFFFAOYSA-N 0.000 description 2

- MNNHAPBLZZVQHP-UHFFFAOYSA-N diammonium hydrogen phosphate Chemical compound [NH4+].[NH4+].OP([O-])([O-])=O MNNHAPBLZZVQHP-UHFFFAOYSA-N 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 238000002329 infrared spectrum Methods 0.000 description 2

- 229940049918 linoleate Drugs 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 125000002950 monocyclic group Chemical group 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 238000011056 performance test Methods 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 2

- 150000003242 quaternary ammonium salts Chemical class 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 125000005471 saturated fatty acid group Chemical group 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- SCYULBFZEHDVBN-UHFFFAOYSA-N 1,1-Dichloroethane Chemical compound CC(Cl)Cl SCYULBFZEHDVBN-UHFFFAOYSA-N 0.000 description 1

- LRNAABWLSPKFBS-UHFFFAOYSA-N 1-(4,5-dihydroimidazol-1-yl)dodecan-1-one Chemical compound CCCCCCCCCCCC(=O)N1CCN=C1 LRNAABWLSPKFBS-UHFFFAOYSA-N 0.000 description 1

- VILCJCGEZXAXTO-UHFFFAOYSA-N 2,2,2-tetramine Chemical compound NCCNCCNCCN VILCJCGEZXAXTO-UHFFFAOYSA-N 0.000 description 1

- VLRGXXKFHVJQOL-UHFFFAOYSA-N 3-chloropentane-2,4-dione Chemical compound CC(=O)C(Cl)C(C)=O VLRGXXKFHVJQOL-UHFFFAOYSA-N 0.000 description 1

- FLHWLBNLXDWNJC-UHFFFAOYSA-N 4,5-dihydroimidazole-1-sulfonic acid Chemical compound OS(=O)(=O)N1CCN=C1 FLHWLBNLXDWNJC-UHFFFAOYSA-N 0.000 description 1

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 229910001369 Brass Inorganic materials 0.000 description 1

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 1

- NIPNSKYNPDTRPC-UHFFFAOYSA-N N-[2-oxo-2-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)ethyl]-2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidine-5-carboxamide Chemical compound O=C(CNC(=O)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F)N1CC2=C(CC1)NN=N2 NIPNSKYNPDTRPC-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 150000003863 ammonium salts Chemical group 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001804 emulsifying effect Effects 0.000 description 1

- 238000003912 environmental pollution Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- XBUFCZMOAHHGMX-UHFFFAOYSA-N hydroxylamine;phosphoric acid Chemical compound ON.ON.ON.OP(O)(O)=O XBUFCZMOAHHGMX-UHFFFAOYSA-N 0.000 description 1

- 125000002636 imidazolinyl group Chemical group 0.000 description 1

- 150000007529 inorganic bases Chemical class 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000003345 natural gas Substances 0.000 description 1

- 125000004433 nitrogen atom Chemical group N* 0.000 description 1

- 125000002801 octanoyl group Chemical group C(CCCCCCC)(=O)* 0.000 description 1

- 229940049964 oleate Drugs 0.000 description 1

- 239000003209 petroleum derivative Substances 0.000 description 1

- 125000004437 phosphorous atom Chemical group 0.000 description 1

- KCXFHTAICRTXLI-UHFFFAOYSA-N propane-1-sulfonic acid Chemical compound CCCS(O)(=O)=O KCXFHTAICRTXLI-UHFFFAOYSA-N 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 238000001953 recrystallisation Methods 0.000 description 1

- 238000007670 refining Methods 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 239000003549 soybean oil Substances 0.000 description 1

- 235000012424 soybean oil Nutrition 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- 239000003784 tall oil Substances 0.000 description 1

- FAGUFWYHJQFNRV-UHFFFAOYSA-N tetraethylenepentamine Chemical compound NCCNCCNCCNCCN FAGUFWYHJQFNRV-UHFFFAOYSA-N 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 229960001124 trientine Drugs 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F9/00—Compounds containing elements of Groups 5 or 15 of the Periodic Table

- C07F9/02—Phosphorus compounds

- C07F9/06—Phosphorus compounds without P—C bonds

- C07F9/08—Esters of oxyacids of phosphorus

- C07F9/09—Esters of phosphoric acids

- C07F9/091—Esters of phosphoric acids with hydroxyalkyl compounds with further substituents on alkyl

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- Molecular Biology (AREA)

Abstract

The invention discloses a preparation method of an asymmetric gemini imidazoline phosphate surfactant, which comprises the following steps: step one, synthesizing an asymmetric gemini imidazoline intermediate: secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution: step three, alkylation reaction: according to the invention, organic alkali is used for replacing inorganic alkali, 3-chloro-2-hydroxyl propyl ammonium phosphate is not easy to hydrolyze during alkylation, the asymmetrical gemini imidazoline phosphate salt surfactant obtained by directly reacting 3-chloro-2-hydroxyl propyl ammonium phosphate aqueous solution has good water solubility, more excellent corrosion inhibition performance on metal, safe and environment-friendly raw materials, simple reaction process, high yield and atom utilization rate, suitability for industrial large-scale production, accordance with the green development direction of the current corrosion prevention technology, and forcefully promotes the development and innovation of the corrosion prevention technology in China.

Description

Technical Field

The invention belongs to the technical field of surfactants, and particularly relates to a preparation method of an asymmetric gemini imidazoline phosphate surfactant.

Background

Metal corrosion is one of the main causes of equipment life shortening, resulting in production down-time and environmental pollution. Practice proves that the corrosion inhibitor is used in various metal corrosion protection methods, is a method with simple and convenient process, low cost and strong applicability, and is widely applied to the industries of petroleum and natural gas exploitation and refining, machinery, chemical industry, energy and the like. The imidazoline ring is a five-membered ring, wherein two nitrogen atoms and phosphorus atoms can provide lone electron pairs to form coordination bonds with an empty orbit of an iron atom, so that the adsorption capacity between corrosion inhibitor molecules and metal is enhanced, imidazoline surfactant molecules are stably adsorbed on the surface of the metal, and the imidazoline surfactant has excellent corrosion inhibition performance on carbon steel, brass, aluminum alloy and the like. Imidazoline corrosion inhibitors have been used in large scale and large scale, but have the problems of poor water solubility, short protection period and the like.

The imidazoline gemini surfactant is divided into a symmetrical type and an asymmetrical type, and the symmetrical imidazoline gemini surfactant is relatively simple in synthesis process, easy to prepare and more in research. Compared with the symmetrical double quaternary ammonium salt, the asymmetric double quaternary ammonium salt has better performance due to the special structure and particularly shows good corrosion inhibition performance in the field of metal corrosion. However, the synthesis process is complex and still in the starting stage, and the synthesis method reported in the prior research has the defects of high raw material toxicity, serious material waste, poor environmental protection, serious lack of economy and incapability of large-scale industrialization.

The patent application with publication number CN112047886a synthesizes oleic acid imidazoline using oleic acid and amine. The patent application with the publication number of CN111995578A uses oleic acid to react with diethylenetriamine to synthesize a monocyclic imidazoline intermediate, and then the monocyclic imidazoline intermediate is mixed with dichloroethane to carry out a coupling reaction to obtain a gemini imidazoline intermediate. Such imidazoline corrosion inhibitors generally have poor water solubility and limited application range.

Disclosure of Invention

Aiming at the technical problems that the imidazoline surfactant in the prior art has poor water solubility and short metal corrosion inhibition protection period, the recrystallization purification period of 3-chloro-2-hydroxyl ammonium propionate phosphate ester is very long, a large amount of organic solvent is needed, and the like, the invention aims to provide a preparation method of the asymmetric gemini imidazoline phosphate ester surfactant, which has simple process, does not use organic solvent, and does not contain organic base.

In order to achieve the purpose, the technical scheme adopted by the invention is as follows:

the first aspect of the invention provides a preparation method of an asymmetric gemini imidazoline phosphate surfactant, which comprises the following steps:

step one, synthesizing an asymmetric gemini imidazoline intermediate:

under the protection of nitrogen, adding C 8 ~C 18 Mixing fatty acid, organic polyamine and phosphoric acid, heating to 100-200 deg.C (preferably 140 deg.C) under vacuum negative pressure of 1500-30000 Pa (preferably 13000-20000 Pa), reacting for 2-10 h (preferably 2-3 h), and adding C 12 ~C 18 The fatty acid is heated up to 130-250 ℃ in a gradient way (preferably 160-180 ℃, more preferably 170 ℃), reacted for 1-8 h (preferably 3-4 h), and then heated up to 220-250 ℃ for cyclization reaction until no water is evaporated out, so as to obtain an asymmetric gemini imidazoline intermediate;

the phosphoric acid accounts for C 8 ~C 18 Fatty acids, organic polyamines, C 12 ~C 18 The mass percentage of the total mass of the fatty acid and the phosphoric acid is 0.01 to 1 percent;

said C is 8 ~C 18 Fatty acid, C 12 ~C 18 The molar ratio of the fatty acid to the organic polyamine is (0.9-1.1): (0.9-1.1): (0.3 to 1.5);

the organic polyamine is at least one of diethylenetriamine, triethylene tetramine and tetraethylene pentamine;

said C is 8 ~C 18 The fatty acid is one of oleic acid, linoleic acid, myristic acid and lauric acid;

said C is 12 ~C 18 The fatty acid is lauric acid,One of n-decanoic acid and n-octanoic acid;

said C is 8 ~C 18 Fatty acids with said C 12 ~C 18 The fatty acid is not the same fatty acid at the same time;

secondly, synthesizing 3-chloro-2-hydroxypropionate ammonium aqueous solution:

dissolving ammonium dihydrogen phosphate in water, wherein the mass ratio of the ammonium dihydrogen phosphate to the water is 1 (5-20) (preferably 1 (5-12)), stirring and heating to 60-100 ℃ (preferably 75-85 ℃), and then dropwise adding epoxy chloropropane to react for 1-6 h (preferably 3-5 h) under the condition of condensation reflux to obtain a transparent 3-chloro-2-hydroxypropyl ammonium phosphate aqueous solution;

the molar ratio of the ammonium dihydrogen phosphate to the epoxy chloropropane is (1-2) to 1;

step three, alkylation reaction:

adding the asymmetric gemini imidazoline intermediate and organic base obtained in the first step into the transparent 3-chloro-2-hydroxypropionate ammonium aqueous solution in the second step, stirring and heating to 50-95 ℃, and reacting for 1-10 h (preferably 3-5 h) to obtain the asymmetric gemini imidazoline phosphate surfactant;

the molar ratio of the asymmetric gemini imidazoline intermediate, the 3-chlorine-2 hydroxyl propyl ammonium phosphate and the organic alkali is 1 (1.1-3) to 0.5-3;

the organic alkali is ammonia water, monoethanolamine, diethanolamine or triethanolamine.

The structural formula of the main component of the asymmetric gemini imidazoline phosphate surfactant is as follows:

wherein R is 1 Is C 12 ~C 18 Fatty acid alkyl radical, R 2 Is C 12 ~C 18 A fatty acid alkyl group;

said C is 12 ~C 18 The fatty acid alkyl group is one of the following groups:

oleic acid alkyl group: CH (CH) 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 -

Linoleate alkyl group: CH (CH) 3 (CH 2 ) 4 CH=CHCH 2 CH=CH(CH 2 ) 7 -

saturated fatty acid group: CH (CH) 3 (CH 2 ) 14- CH 3 (CH 2 ) 16- 。

In the first step, the acid value of the asymmetric gemini imidazoline intermediate is 0.2-3 mg KOH/g, and preferably 0.5-2.6 mg KOH/g.

In the first step, the gradient temperature rise is performed at the temperature rise rate of 5-25 ℃/h.

In the first step, phosphoric acid is C 8 ~C 18 Fatty acids, organic polyamines, C 12 ~C 18 The mass percentage of the total mass of the fatty acid and the phosphoric acid was 0.2%.

In the first step, C 8 ~C 18 Fatty acid, C 12 ~C 18 The molar ratio of the fatty acid to the organic polyamine is 1:1 (1.01-1.1).

In the first step, the organic polyamine is diethylenetriamine.

In the second step, the mol ratio of the ammonium dihydrogen phosphate to the epoxy chloropropane is (1.1-1.2) to 1.

In the third step, the molar ratio of the asymmetric gemini imidazoline intermediate, the 3-chlorine-2 hydroxyl propyl ammonium phosphate and the organic alkali is 1 (1.1-3) to 1.1-2.

Due to the adoption of the technical scheme, the invention has the following advantages and beneficial effects:

according to the invention, organic alkali is used for replacing inorganic alkali, 3-chloro-2-hydroxyl propyl ammonium phosphate is not easy to hydrolyze during alkylation, the asymmetrical gemini imidazoline phosphate salt surfactant obtained by directly reacting 3-chloro-2-hydroxyl propyl ammonium phosphate aqueous solution has good water solubility, more excellent corrosion inhibition performance on metals, safe and environment-friendly raw materials, simple reaction process, high yield and atom utilization rate, suitability for industrial large-scale production, accordance with the green development direction of the current anticorrosion technology, and forcefully promotes the development and innovation of the anticorrosion technology in China.

Drawings

FIG. 1 is an infrared spectrum of an asymmetric gemini imidazoline phosphate surfactant prepared according to example 1 of the present invention.

Detailed Description

In order to more clearly illustrate the invention, the invention is further described below in connection with preferred embodiments. It is to be understood by persons skilled in the art that the following detailed description is illustrative and not restrictive, and is not to be taken as limiting the scope of the invention.

The fatty acid, diethylenetriamine and ammonium dihydrogen phosphate used in the examples of the present invention are all AR, and purchased from Shanghai Tantan science and technology, inc.; ammonium dihydrogen phosphate and epichlorohydrin are both AR and purchased from chemical reagents of national drug group, inc.; carbon steel sheet, A 3 Yangzhou Keli environmental protection facilities, inc.

Example 1

Taking diethylenetriamine as an example, the synthetic route of the invention is as follows:

wherein R is 1 Is C 12 ~C 18 Fatty acid alkyl radical, R 2 Is C 12 ~C 18 Fatty acid alkyl groups.

Oleic acid alkyl group: CH (CH) 3 (CH 2 ) 7 CH=CH(ch 2 ) 7 -

Linoleate alkyl group: CH (CH) 3 (CH 2 ) 4 CH=CHCH 2 CH=CH(CH 2 ) 7 -

saturated fatty acid group: CH (CH) 3 (CH 2 ) 14- CH 3 (CH 2 ) 16- 。

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding oleic acid (1 mol and 282.5 g) and phosphoric acid (1.2 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 13000pa, heating to 140 ℃, reacting for 3h, adding lauric acid (1 mol and 200.3 g), heating to 170 ℃ at a gradient of 20 ℃/h, reacting for 4h, heating to 250 ℃ for cyclization reaction until no water is evaporated after 4h, cooling to 80 ℃, obtaining an oleic lauric acid imidazoline intermediate 532.7 g, and measuring the acid value to be 2.6mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.36 mol and 41.4 g) is dissolved in 269.1 g of water, the temperature is raised to 85 ℃ by stirring, epichlorohydrin (0.3 mol and 27.8 g) is added for reaction for 3 hours under the state of condensation reflux, and the conversion rate of the epichlorohydrin in the solution is determined to be 99.7 percent, thus obtaining the transparent 3-chloro-2-hydroxypropionate ammonium water solution.

Step three, alkylation reaction:

adding the oleic lauric acid imidazoline intermediate (0.15 mol and 79.8 g) prepared in the first step and ammonia water (0.3 mol and 37.5 g) with the mass concentration of 28% into the transparent 3-chloro-2-hydroxypropionic acid ammonium phosphate (0.3 mol) aqueous solution prepared in the second step, stirring and heating to 85 ℃, and reacting for 4 hours to obtain the asymmetric oleic acid lauric acid gemini imidazoline phosphate surfactant aqueous solution, wherein the conversion rate of the oleic acid lauric acid imidazoline intermediate is 95.1%.

The infrared spectrum of the asymmetric oleic acid lauric acid based gemini imidazoline phosphate surfactant is shown in figure 1, wherein 2924cm -1 Nearby isC-H vibration absorption peak; 2854cm -1 Nearby is CH 2 Symmetric stretching vibration of the middle C-H bond; 1644cm -1 The nearby absorption peak is a C = O characteristic absorption peak; 1462cm -1 Nearby is CH 2 Symmetric stretching vibration of the middle C-H bond; 1043cm -1 The vicinity is a characteristic absorption peak of hydroxyl; 934cm -1 The vicinity is a P-O-C bending vibration absorption peak. The characteristics of the functional groups are consistent with the structure of the product, which shows that the asymmetric oleic acid lauric acid based gemini imidazoline phosphate surfactant is successfully synthesized.

Example 2

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.03 mol and 106.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding oleic acid (1 mol and 282.5 g) and phosphoric acid (1.1 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 15000pa, heating to 140 ℃, reacting for 3h, adding n-capric acid (1 mol and 172.3 g), heating at 20 ℃/h in a gradient manner to 170 ℃ for reacting for 4h, heating to 240 ℃ for cyclization reaction, evaporating until no water is removed after 4h, cooling to 80 ℃, obtaining an oleic decanoic imidazoline intermediate 504.5 g, and measuring the acid value to be 2.2mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.36 mol and 41.4 g) is dissolved in 302.8 g of water, the temperature is raised to 80 ℃ by stirring, epichlorohydrin (0.3 mol and 27.8 g) is added for reaction for 3.5 hours under the state of condensation reflux, the conversion rate of the epichlorohydrin is determined to be 99.1 percent, and the transparent 3-chloro-2 hydroxyl propyl ammonium phosphate aqueous solution is obtained.

Step three, alkylation reaction:

adding the oleic acid decanoic acid base imidazoline intermediate (0.15 mol and 75.6 g) and the monoethanolamine (0.3 mol and 18.3 g) prepared in the first step into the transparent 3-chloro-2-hydroxy propyl ammonium phosphate (0.3 mol) aqueous solution prepared in the second step, stirring and heating to 80 ℃, and reacting for 4 hours to obtain the asymmetric oleic acid decanoic acid base gemini imidazoline phosphate surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 95.2%.

Example 3

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.03 mol and 106.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding oleic acid (1 mol and 282.5 g) and phosphoric acid (1.1 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 20000pa, heating to 140 ℃, reacting for 3h, adding n-octanoic acid (1 mol and 144.2 g), heating to 170 ℃ in a gradient manner at 20 ℃/h, reacting for 3h, heating to 230 ℃ for cyclization reaction until water is evaporated out after 4h, cooling to 80 ℃, obtaining an octocaprylic imidazoline oleate intermediate 476.2 g, and measuring the acid value to be 2.3mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxypropionate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.36 mol and 41.4 g) is dissolved in 344.1 g of water, the temperature is raised to 75 ℃ by stirring, epichlorohydrin (0.3 mol and 27.8 g) is added for reaction for 4 hours under the state of condensation reflux, the conversion rate of the epichlorohydrin is determined to be 98.8 percent, and the transparent 3-chlorine-2 hydroxyl propyl ammonium phosphate aqueous solution is obtained.

Step three, alkylation reaction:

adding the oleic acid octanoic acid base imidazoline intermediate (0.15 mol, 71.4 g) and triethanolamine (0.3 mol, 44.8 g) prepared in the first step into the transparent 3-chloro-2-hydroxy propyl ammonium phosphate (0.3 mol) aqueous solution prepared in the second step, stirring and heating to 75 ℃, and reacting for 4h to obtain the asymmetric oleic acid octanoic acid base gemini imidazoline phosphate salt surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 94.8%.

Example 4

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding linoleic acid (1 mol and 280.4 g) and phosphoric acid (1.2 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 13000pa, heating to 140 ℃, reacting for 3h, adding lauric acid (1 mol and 200.3 g), heating to 170 ℃ at a gradient of 20 ℃/h, reacting for 4h, heating to 250 ℃ for cyclization reaction until no water is evaporated after 4h, cooling to 80 ℃, obtaining a linoleic acid lauroyl imidazoline intermediate 530.3 g, and measuring the acid value to be 2.3mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.33 mol and 38.0 g) is dissolved in 262.1 g of water, the temperature is raised to 85 ℃ by stirring, epichlorohydrin (0.3 mol and 27.8 g) is added for reaction for 3.5 hours under the state of condensation reflux, the conversion rate of the epichlorohydrin is determined to be 99.2 percent, and the transparent 3-chloro-2 hydroxyl propyl ammonium phosphate aqueous solution is obtained.

Step three, alkylation reaction:

adding 0.15 mol and 79.5 g of linoleic acid lauric acid imidazoline intermediate prepared in the first step and 0.3 mol and 37.5 g of ammonia water with the mass concentration of 28% into the transparent 3-chloro-2-hydroxypropionite ammonium phosphate (0.3 mol) aqueous solution prepared in the second step, stirring and heating to 85 ℃, and reacting for 4 hours to obtain an asymmetric linoleic acid lauric acid gemini imidazoline phosphate surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 95.6%.

Example 5

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-mouth flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding linoleic acid (1 mol and 280.4 g) and phosphoric acid (1.1 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 15000pa, heating to 140 ℃, reacting for 3h, adding n-decanoic acid (1 mol and 172.3 g), heating to 170 ℃ in a gradient manner at 20 ℃/h, reacting for 4h, heating to 240 ℃ for cyclization reaction until no water is evaporated after 4h, cooling to 80 ℃, obtaining a linoleic acid decanoic acid imidazoline intermediate 502.5 g, and measuring the acid value to be 1.6mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxypropionate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.33 mol and 38.0 g) is dissolved in 262.1 g of water, the temperature is raised to 80 ℃ by stirring, epichlorohydrin (0.3 mol and 27.8 g) is added for reaction for 3.5 hours under the state of condensation reflux, the conversion rate of the epichlorohydrin is determined to be 98.5 percent, and the transparent 3-chloro-2 hydroxyl ammonium phosphate aqueous solution is obtained.

Step three, alkylation reaction:

adding 0.15 mol and 75.3 g of linoleic acid decanoyl imidazoline intermediate and 0.3 mol and 18.3 g of monoethanolamine prepared in the first step into the transparent 0.3 mol of 3-chloro-2-hydroxypropionite ammonium phosphate aqueous solution prepared in the second step, stirring and heating to 80 ℃, and reacting for 4 hours to obtain an asymmetric linoleic acid decanoyl gemini imidazoline phosphate salt surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 95.8%.

Example 6

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol, 108.3 g) into a 1L four-mouth flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding linoleic acid (1 mol, 280.4 g) and phosphoric acid (1.1 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 20000pa, heating to 140 ℃, reacting for 3h, adding n-octanoic acid (1 mol, 144.2 g), heating to 170 ℃ in a gradient manner at 20 ℃/h, reacting for 4h, heating to 240 ℃ for cyclization reaction until no water is evaporated after 4h, cooling to 80 ℃, and obtaining an oleoylidine caprylic imidazoline intermediate 474.8 g, wherein the acid value is measured to be 1.2mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.25 mol and 28.5 g) is dissolved in 285.9 g of water, the temperature is raised to 75 ℃ by stirring, epichlorohydrin (0.225 mol and 20.8 g) is added for reaction for 4 hours under the state of condensation reflux, the conversion rate of the epichlorohydrin is determined to be 98.3 percent, and the transparent 3-chlorine-2 hydroxyl propyl ammonium phosphate aqueous solution is obtained.

Step three, alkylation reaction:

adding 0.15 mol and 71.1 g of linoleoic acid octanoyl imidazoline intermediate and 0.225 mol and 33.6 g of triethanolamine into the transparent 0.225 mol aqueous solution of 3-chloro-2-hydroxypropionic acid ammonium phosphate prepared in the second step, stirring and heating to 75 ℃, and reacting for 5 hours to obtain the asymmetric linoleoic acid octanoyl gemini imidazoline phosphate salt surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 96.3%.

Example 7

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding myristic acid (1 mol and 228.4 g) and phosphoric acid (1.0 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 15000pa, heating to 140 ℃, reacting for 3h, adding n-capric acid (1 mol and 172.3 g), heating at 20 ℃/h in a gradient manner to 170 ℃ for reacting for 4h, heating to 230 ℃ for cyclization reaction, evaporating until no water is removed after 4h, cooling to 80 ℃, obtaining myristic decanoic acid imidazoline intermediate 450.3 g, and measuring the acid value to be 1.5mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxypropionate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.25 mol and 28.5 g) is dissolved in 211.1 g of water, the temperature is raised to 80 ℃ by stirring, epichlorohydrin (0.225 mol and 20.8 g) is added for reaction for 3.5 hours under the state of condensation and reflux, the conversion rate of the epichlorohydrin is determined to be 99.2 percent, and the transparent 3-chlorine-2 hydroxyl propyl phosphate ammonium aqueous solution is obtained.

Step three, alkylation reaction:

adding 0.15 mol and 67.5 g of myristic acid decanoic acid base imidazoline intermediate and 28% ammonia water (0.225 mol and 28.2 g) into the transparent 3-chloro-2 hydroxyl propyl ammonium phosphate (0.225 mol) aqueous solution prepared in the second step, stirring and heating to 80 ℃, and reacting for 4 hours to obtain asymmetric myristic acid decanoic acid base gemini imidazoline phosphate surfactant aqueous solution, wherein the conversion rate of imidazoline intermediate is 97.0%.

Example 8

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding myristic acid (1 mol and 228.4 g) and phosphoric acid (1.0 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 20000pa, heating to 140 ℃, reacting for 3h, adding n-octanoic acid (1 mol and 144.2 g), heating at a gradient of 20 ℃/h to 170 ℃ for reacting for 4h, heating to 230 ℃ for cyclization reaction until anhydrous is evaporated after 3.5h, cooling to 80 ℃ to obtain 422.6 g of myristic acid octanoyl imidazoline intermediate, and measuring the acid value to be 0.98mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

ammonium dihydrogen phosphate (0.25 mol, 28.5 g) was dissolved in 234.5 g of water in a 1 l four-necked flask equipped with an electric stirrer, a thermometer and a condenser, and then heated to 75 ℃ under stirring, epichlorohydrin (0.225 mol, 20.8 g) was added under reflux condensation to react for 4.5 hours, and the conversion of epichlorohydrin was determined to be 98.7%, thereby obtaining a transparent aqueous solution of ammonium 3-chloro-2-hydroxypropionate.

Step three, alkylation reaction:

adding 0.15 mol and 63.3 g of the myristic acid octanoyl imidazoline intermediate and 0.225 mol and 13.7 g of monoethanolamine into the transparent 0.225 mol aqueous solution of the 3-chloro-2-hydroxypropionic acid ammonium phosphate prepared in the second step, stirring and heating to 75 ℃, and reacting for 5 hours to obtain the asymmetric myristic acid octanoyl gemini imidazoline phosphate salt surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 97.4%.

Example 9

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding lauric acid (1 mol and 228.4 g) and phosphoric acid (1.0 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 15000pa, heating to 140 ℃, reacting for 2h, adding n-capric acid (1 mol and 172.3 g), heating to 170 ℃ at a gradient of 20 ℃/h, reacting for 3h, heating to 220 ℃ for cyclization reaction until water is evaporated after 3h, cooling to 80 ℃ to obtain a lauric acid decanoyl imidazoline intermediate 422.3 g, and measuring the acid value to be 0.73mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

in a 1L four-mouth bottle provided with an electric stirrer, a thermometer and a condenser, ammonium dihydrogen phosphate (0.224 mol and 25.8 g) is dissolved in 194.0 g of water, the temperature is raised to 80 ℃ by stirring, epichlorohydrin (0.195 mol and 18.0 g) is added for reaction for 3.5 hours under the state of condensation and reflux, the conversion rate of the epichlorohydrin is determined to be 98.9 percent, and the transparent 3-chlorine-2 hydroxyl propyl phosphate ammonium aqueous solution is obtained.

Step three, alkylation reaction:

adding 0.15 mol and 63.3 g of lauric acid decyl imidazoline intermediate and 0.194 mol and 6.8 g of monoethanolamine prepared in the first step into the transparent 0.195 mol of 3-chloro-2-hydroxypropionate ammonium phosphate aqueous solution prepared in the second step, stirring and heating to 80 ℃, and reacting for 5 hours to obtain an asymmetric lauric acid decyl gemini imidazoline phosphate surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 97.0%.

Example 10

Step one, synthesizing an asymmetric gemini imidazoline intermediate:

adding diethylenetriamine (1.05 mol and 108.3 g) into a 1L four-neck flask provided with an electric stirrer, a thermometer, a nitrogen inlet pipe and a reduced pressure distillation device, adding lauric acid (1 mol and 228.4 g) and phosphoric acid (1.0 g) under the conditions of stirring and nitrogen protection, starting a vacuum pump to adjust the vacuum negative pressure of a reaction system to 20000pa, heating to 140 ℃, reacting for 2h, adding n-octanoic acid (1 mol and 144.2 g), heating to 170 ℃ in a gradient manner at 20 ℃/h, reacting for 3h, heating to 220 ℃ for cyclization reaction until no water is evaporated after 2h, cooling to 80 ℃ to obtain a lauric acid octanoic acid based imidazoline intermediate 394.3 g, and measuring the acid value to be 0.58mg KOH/g.

Secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

ammonium dihydrogen phosphate (0.224 mol, 25.8 g) was dissolved in 245.1 g of water in a 1 l four-neck flask equipped with an electric stirrer, a thermometer and a condenser, and then heated to 75 ℃ under stirring, and then epichlorohydrin (0.195 mol, 18.0 g) was added under reflux condensation to react for 4.5 hours, and the conversion of epichlorohydrin was determined to be 98.5%, thereby obtaining a transparent 3-chloro-2-hydroxypropanoate ammonium aqueous solution.

Step three, alkylation reaction:

adding 0.15 mol and 59.1 g of lauric acid caprylic acid imidazoline intermediate (0.15 mol and 29.1 g) and triethanolamine (0.194 mol and 29.1 g) prepared in the first step into the transparent 3-chloro-2-hydroxy propyl ammonium phosphate (0.195 mol) aqueous solution prepared in the second step, stirring and heating to 75 ℃, and reacting for 5 hours to obtain the asymmetric lauric acid caprylic acid gemini imidazoline phosphate salt surfactant aqueous solution, wherein the conversion rate of the imidazoline intermediate is 97.4%.

Comparative example 1

The alkylation was carried out using sodium hydroxide as a catalyst, and the procedure of comparative example was otherwise the same as in example 1.

Comparative example 2

The alkylation was carried out using 3-chloro-2-ylpropanesulfonate in place of 3-chloro-2-hydroxypropanolammonium phosphate, as in example 1.

Example 11

Test of corrosion inhibition performance of asymmetric gemini imidazoline phosphate surfactant

Static weightlessness is adopted to test the corrosion inhibition performance of the asymmetric gemini imidazoline phosphate surfactant in an acid system, and the experimental method comprises the following steps:

a is to be 3 Carbon steel test piece (specification is 50mm multiplied by 25mm multiplied by 2mm, surface area is 28cm 2 ) Respectively immersing the steel plates into 500mL of hydrochloric acid aqueous solution with the mass fractions of 4% and the corrosion inhibitors of 100mg/L, 200mg/L, 300mg/L, 400mg/L and 500mg/L, standing for 4h, taking out, washing, drying, weighing and calculating the corrosion inhibition rate.

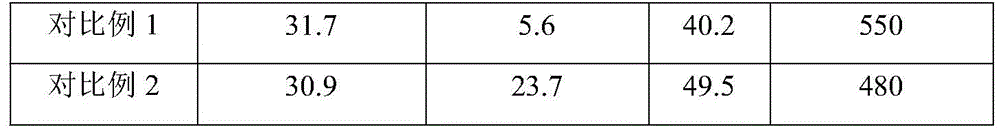

At 90 ℃, as shown in table 1, table 1 is the relationship between the concentration of the asymmetric oleic lauric acid based gemini imidazoline phosphate surfactant prepared in example 1 and the corrosion inhibition rate. With the increase of the concentration of the asymmetrical oleic acid lauric acid based gemini imidazoline phosphate surfactant, the corrosion inhibition rate is gradually improved, the concentration is increased to 300mg/L, and the A is treated 3 The corrosion inhibition rate of the carbon steel sheet is 93.4%, and the carbon steel sheet has a good corrosion inhibition effect on carbon steel. Comparative example 1 asymmetric oleic acid lauric acid based gemini imidazoline phosphate salt was synthesized in the same manner as in example 1 with sodium hydroxide as catalyst in alkylation, and the corrosion inhibition performance was significantly inferior to that of example 1 using ammonia as catalyst. Synthesis of asymmetric oleic acid lauric acid based gemini imidazoline phosphate salt of p-A in acidic System by substituting 3-chloro-2-yl propanesulfonate for 3-chloro-2-hydroxypropanolammonium phosphate in alkylation of p-proportion 2 in the same manner as in example 1 3 The carbon steel sheet has poor corrosion inhibition rate.

According to the asymmetric gemini imidazoline phosphate surfactant provided by the invention, organic base is used for replacing inorganic base, 3-chloro-2-hydroxyl ammonium propionate is not easy to hydrolyze during alkylation, the obtained asymmetric gemini imidazoline phosphate surfactant has good water solubility, is more excellent in corrosion inhibition performance on metal, the used raw materials are safe and environment-friendly, the reaction process is simple, the yield and the atom utilization rate are high, the asymmetric gemini imidazoline phosphate surfactant is suitable for industrial large-scale production, the green development direction of the current anti-corrosion technology is met, and the development and innovation of the anti-corrosion technology in China are powerfully promoted.

TABLE 1 Corrosion inhibition Performance test

The surfactants obtained in the above examples were subjected to performance tests, and the results are shown in table 2.

The wetting time of the asymmetric gemini imidazoline phosphate ester surfactant is tested by referring to corresponding national standards (a method for measuring wetting force of the surfactant GB/T11983-2008): preparing 1000mL of aqueous solution with the effective content of 1% by adopting a standard canvas sheet settling method, flatly placing the standard canvas sheet on the surface of the aqueous solution of the surfactant at a constant temperature of 25.0 +/-0.5 ℃, starting timing, stopping timing when the canvas sheet begins to sink from the liquid surface, repeating the operation for ten times for each sample, taking an average value as the wetting time of the surfactant or the composition, wherein the shorter the time, the better the wetting property is.

The invention discloses a method for testing the emulsibility of an asymmetric gemini imidazoline phosphate surfactant, which comprises the following steps: adding 40mL of tallowimidazoline biquaternary ammonium salt surfactant with the mass fraction of 0.50% and 40mL of soybean oil into a measuring cylinder, violently shaking up and down for 10 times, placing on a horizontal plane for timing, recording the time required for 10mL of water to be separated out, and taking the arithmetic average value of 5 times as the emulsibility test result of tallowimidazoline sulfonate.

The surface tension (mN/m) and critical micelle concentration (mg/L) of the asymmetric gemini imidazoline phosphate ester surfactant of the invention are tested according to GB/T22237-2008. Preparing tall oil acid imidazoline sulfonate aqueous solution with a series of concentrations, carrying out surface tension test on Kruss-K100 at 25 +/-0.1 ℃, then drawing a curve of surface tension changing along with concentration, and determining the surface tension gamma cmc and the critical micelle concentration cmc according to the inflection point of the surface tension changing along with the logarithmic curve of the concentration.

TABLE 2

As can be seen from the data in table 2, the critical micelle concentration cmc of the asymmetric gemini imidazoline phosphate surfactants obtained in examples 1 and 2 is lower, the wettability is better, and the emulsifying performance is more excellent.

Although the present invention has been described with reference to a preferred embodiment, it should be understood that various changes, substitutions and alterations can be made herein without departing from the spirit and scope of the invention as defined by the appended claims.

Claims (6)

1. A preparation method of an asymmetric gemini imidazoline phosphate surfactant is characterized by comprising the following steps:

step one, synthesizing an asymmetric gemini imidazoline intermediate:

under the protection of nitrogen, adding C 8 ~C 18 Mixing fatty acid, organic polyamine and phosphoric acid, heating to 100-200 ℃ under the vacuum negative pressure of 1500-30000 Pa, reacting for 2-10 h, and then adding C 12 ~C 18 The fatty acid is heated up to 130-250 ℃ in a gradient way, reacts for 1-8 h, and then is heated up to 220-250 ℃ for cyclization reaction until no water is evaporated, so as to obtain an asymmetric gemini imidazoline intermediate;

the phosphoric acid accounts for C 8 ~C 18 Fatty acids, organic polyamines, C 12 ~C 18 The mass percentage of the total mass of the fatty acid and the phosphoric acid is 0.01 to 1 percent;

said C is 8 ~C 18 Fatty acid, C 12 ~C 18 The molar ratio of the fatty acid to the organic polyamine is (0.9-1.1): (0.9-1.1): (0.3 to 1.5);

the organic polyamine is diethylenetriamine;

the above-mentionedC 8 ~C 18 The fatty acid is one of oleic acid, linoleic acid, myristic acid and lauric acid;

said C is 12 ~C 18 The fatty acid is one of lauric acid, n-capric acid and n-caprylic acid;

said C is 8 ~C 18 Fatty acids with said C 12 ~C 18 The fatty acid is not the same fatty acid at the same time;

in the first step, the gradient temperature rise is performed at the temperature rise rate of 5-25 ℃/h;

secondly, synthesizing 3-chloro-2-hydroxyl propyl phosphate ammonium aqueous solution:

dissolving ammonium dihydrogen phosphate in water, wherein the mass ratio of the ammonium dihydrogen phosphate to the water is 1 (5-20), stirring and heating to 60-100 ℃, and then dropwise adding epoxy chloropropane for reacting for 1-6 h under the condition of condensation reflux to obtain a transparent 3-chloro-2-hydroxypropyl ammonium phosphate aqueous solution;

the molar ratio of the ammonium dihydrogen phosphate to the epoxy chloropropane is (1-2) to 1;

step three, alkylation reaction:

adding the asymmetric gemini imidazoline intermediate and the organic base obtained in the first step into the transparent 3-chloro-2-hydroxypropionate ammonium aqueous solution in the second step, stirring and heating to 50-95 ℃, and reacting for 1-10 h to obtain the asymmetric gemini imidazoline phosphate surfactant;

the molar ratio of the asymmetric gemini imidazoline intermediate, the 3-chlorine-2 hydroxyl propyl ammonium phosphate and the organic alkali is 1 (1.1-3) to 0.5-3;

the organic alkali is ammonia water, monoethanolamine, diethanolamine or triethanolamine.

2. The process for producing the unsymmetrical gemini imidazoline phosphate ester surfactant of claim 1, wherein in the first step, the acid value of the unsymmetrical gemini imidazoline intermediate is 0.2 to 3mg KOH/g.

3. The process for preparing unsymmetrical gemini imidazoline phosphate ester surfactants according to claim 1, wherein,in the first step, phosphoric acid is C 8 ~C 18 Fatty acids, organic polyamines, C 12 ~C 18 The mass percentage of the total mass of the fatty acid and the phosphoric acid was 0.2%.

4. The process for preparing unsymmetrical gemini imidazoline phosphate ester surfactants according to claim 1, wherein in the first step, C is 8 ~C 18 Fatty acid, C 12 ~C 18 The molar ratio of the fatty acid to the organic polyamine is 1:1 (1.01-1.1).

5. The process for preparing unsymmetrical gemini imidazoline phosphate ester salt surfactants according to claim 1, wherein the molar ratio of ammonium dihydrogen phosphate and epichlorohydrin in the second step is (1.1-1.2): 1.

6. The method for preparing the asymmetrical gemini imidazoline phosphate surfactant according to claim 1, wherein the molar ratio of the asymmetrical gemini imidazoline intermediate, the 3-chloro-2-hydroxypropanoate ammonium and the organic base in the third step is 1 (1.1-3) to 1.1-2.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110824766.1A CN113600097B (en) | 2021-07-21 | 2021-07-21 | Preparation method of asymmetric gemini imidazoline phosphate surfactant |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110824766.1A CN113600097B (en) | 2021-07-21 | 2021-07-21 | Preparation method of asymmetric gemini imidazoline phosphate surfactant |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113600097A CN113600097A (en) | 2021-11-05 |

| CN113600097B true CN113600097B (en) | 2023-02-14 |

Family

ID=78305010

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110824766.1A Active CN113600097B (en) | 2021-07-21 | 2021-07-21 | Preparation method of asymmetric gemini imidazoline phosphate surfactant |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113600097B (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3641871A1 (en) * | 1986-12-08 | 1988-06-09 | Henkel Kgaa | METHOD FOR THE PRODUCTION OF LIQUID AMPHOTENSIDE |

| CA2005568A1 (en) * | 1988-12-15 | 1990-06-15 | Antonio D. Trius | Process for the production of amphoteric surface-active imidazoline derivatives |

| JPH07179888A (en) * | 1993-10-12 | 1995-07-18 | Rhone Poulenc Special Chem Co | Amphoteric acetate surfactant based on high-purity imidazoline and its production |

| CN101365767A (en) * | 2005-11-07 | 2009-02-11 | 斯蒂潘公司 | Polycationic viscoelastic compositions |

| CN107056640A (en) * | 2017-03-27 | 2017-08-18 | 上海发凯化工有限公司 | A kind of double salt-free imidazoline surfactants of alkyl of low bubble and its synthetic method |

| CN112300131A (en) * | 2020-10-30 | 2021-02-02 | 华中科技大学 | Imidazoline corrosion inhibitor with asymmetric terminal group and preparation method and application thereof |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030186834A1 (en) * | 2002-01-09 | 2003-10-02 | Croda, Inc. | Immidazoline quats |

-

2021

- 2021-07-21 CN CN202110824766.1A patent/CN113600097B/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3641871A1 (en) * | 1986-12-08 | 1988-06-09 | Henkel Kgaa | METHOD FOR THE PRODUCTION OF LIQUID AMPHOTENSIDE |

| CA2005568A1 (en) * | 1988-12-15 | 1990-06-15 | Antonio D. Trius | Process for the production of amphoteric surface-active imidazoline derivatives |

| WO1990006912A1 (en) * | 1988-12-15 | 1990-06-28 | Henkel Kommanditgesellschaft Auf Aktien | Process for producing amphoteric surface-active imidazoline derivatives |

| JPH07179888A (en) * | 1993-10-12 | 1995-07-18 | Rhone Poulenc Special Chem Co | Amphoteric acetate surfactant based on high-purity imidazoline and its production |

| US5744063A (en) * | 1993-10-12 | 1998-04-28 | Rhone-Poulenc Inc. | Higher purity imidazoline based amphoacetate surfactants and processes for the preparation thereof |

| CN101365767A (en) * | 2005-11-07 | 2009-02-11 | 斯蒂潘公司 | Polycationic viscoelastic compositions |

| CN107056640A (en) * | 2017-03-27 | 2017-08-18 | 上海发凯化工有限公司 | A kind of double salt-free imidazoline surfactants of alkyl of low bubble and its synthetic method |

| CN112300131A (en) * | 2020-10-30 | 2021-02-02 | 华中科技大学 | Imidazoline corrosion inhibitor with asymmetric terminal group and preparation method and application thereof |

Non-Patent Citations (4)

| Title |

|---|

| A dissymmetric bis-quaternary ammonium salt gemini surfactant as effective inhibitor for Q235 steel in hydrochloric acid;J.Zhang等;《Progress in organic coatings》;20121231;全文 * |

| dsorption of dissymmetric cationic gemini surfactants at silica/water interface;Yuhai Sun;《Surface Science》;20070501;全文 * |

| Effect of the spacer length on the association and adsorption behavior of dissymmetric gemini surfactants;M.Sikirić等人;《Journal of Colloid and Interface Science》;20050115;全文 * |

| Synthesis and properties of dissymmetric gemini surfactants;qun Xu等人;《J. Surfact. Deterg.》;20100526;85页左栏 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113600097A (en) | 2021-11-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103882435B (en) | A kind ofly be applicable to compound corrosion inhibitor of high-temperature strong acid corrosive medium and preparation method thereof | |

| CN108467366B (en) | Thiourea-modified imidazoline derivative corrosion inhibitor and preparation method and application thereof | |

| CN101845019A (en) | Method for synthesizing imidazoline intermediate and cationic derivative thereof | |

| CN111321412B (en) | High-salt-content weak-acid oil field water quality corrosion inhibitor with chloride ion content of more than 5 ten thousand ppm | |

| CN113600097B (en) | Preparation method of asymmetric gemini imidazoline phosphate surfactant | |

| CN108914132A (en) | Sulfide hydrogen oilfield sewage imidazoline inhibitor and preparation method thereof | |

| CN110982508B (en) | Mannich base acidizing corrosion inhibitor and preparation method thereof | |

| CN108440415B (en) | Oil-soluble bis-imidazoline derivative corrosion inhibitor and preparation method and application thereof | |

| CN108486575B (en) | Water-soluble bis-imidazoline derivative corrosion inhibitor and preparation method and application thereof | |

| US10906828B2 (en) | Modified amines useful as scale inhibitors in wet process phosphoric acid production | |

| CN109174465B (en) | Quaternary ammonium salt suitable for flotation | |

| CN109402640B (en) | Corrosion inhibitor and preparation method thereof | |

| CN113430040B (en) | Multifunctional additive for hydraulic support concentrated solution and preparation method thereof | |

| CN109681175B (en) | Method for draining liquid and producing gas by using solid foam drainage agent with pH value response | |

| CN106518770A (en) | Preparation method of novel water soluble and non-salt soluble imidazoline corrosion inhibitor and application | |

| US3010782A (en) | Corrosion inhibiting method and composition | |

| CN115595591A (en) | Glycine derivative corrosion inhibitor and preparation method and application thereof | |

| CN109679610B (en) | Solid foam drainage agent with pH value response, preparation method and application | |

| CN113106457A (en) | Corrosion inhibitor and preparation method thereof | |

| CN109679637B (en) | Method for draining water and producing gas by adopting solid foam water draining agent composition for ultra-deep gas well | |

| CN109679616B (en) | Foam drainage agent with pH value response, preparation method and application | |

| CN108516622B (en) | Carboxyl-terminated hyperbranched polymer scale inhibitor and preparation method and application thereof | |

| CN109679615B (en) | Method for draining water and producing gas by adopting foam water draining agent composition for ultra-deep gas well | |

| CN109679617B (en) | Solid foam drainage agent composition suitable for ultra-deep gas well, preparation method and application | |

| CN111441056A (en) | Didodecyl-dicarboxamide bipyridyl quaternary ammonium salt water-soluble corrosion inhibitor and preparation method and application thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |