CN113385131A - Reation kettle is used in aqueous adhesive production - Google Patents

Reation kettle is used in aqueous adhesive production Download PDFInfo

- Publication number

- CN113385131A CN113385131A CN202110675961.2A CN202110675961A CN113385131A CN 113385131 A CN113385131 A CN 113385131A CN 202110675961 A CN202110675961 A CN 202110675961A CN 113385131 A CN113385131 A CN 113385131A

- Authority

- CN

- China

- Prior art keywords

- groups

- inner cylinder

- main body

- reaction kettle

- aqueous adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/18—Stationary reactors having moving elements inside

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/0006—Controlling or regulating processes

- B01J19/0013—Controlling the temperature of the process

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/0053—Details of the reactor

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Accessories For Mixers (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

- Mixers With Rotating Receptacles And Mixers With Vibration Mechanisms (AREA)

Abstract

The invention discloses a reaction kettle for producing a water-based adhesive, which relates to the technical field of water-based adhesive production equipment and comprises a main body, a top cover, a motor arranged at the center of the top of the main body and a main shaft connected with the output end of the motor, wherein the inner side of the main body is provided with an inner cylinder matched with the main body. Four groups of reciprocating screw rods rotate, the lifting mechanism is driven to slide up and down in a reciprocating manner when the four groups of reciprocating screw rods rotate, and when the four groups of reciprocating screw rods slide up and down, the matching gears in the four groups of reciprocating screw rods are meshed with the racks to rotate, the reels on two sides of the matching gears drive the two groups of rigid ropes, the lifting block and the disturbance sheet which are connected with the tail ends of the rigid ropes and are positioned at the bottom end in the inner cylinder to ascend, so that the disturbance sheet does axial lifting motion in the inner cylinder.

Description

Technical Field

The invention relates to the technical field of water-based adhesive production equipment, in particular to a reaction kettle for producing a water-based adhesive.

Background

The water adhesive is mainly dried or bonded by absorbing water on the surface, raw solid starch in the adhesive is gelatinized on a paste line to absorb water, the bonding time is about several seconds to one minute, and the water is gradually absorbed by surrounding air and paper fibers.

During production of the water-based adhesive, solid adipic acid is manually put into a reaction kettle at normal temperature, then diethylene glycol and ethylene glycol are conveyed into a stirring pot by a pump, after the materials are fed once, the materials are slowly heated and stirred to carry out esterification reaction, polycondensation reaction is carried out when the temperature of the materials reaches eighty ℃, and after the reaction is finished, the materials are cooled to thirty ℃ and then discharged to obtain a polyurethane semi-finished product, wherein heating and cooling are needed in the production process of the water-based adhesive.

In the prior art, when the aqueous adhesive is stirred and produced in a reaction kettle, the track of the stirring rod is single, the prior art only has the radial rotating stirring effect on the adhesive, and the stirring and mixing means is single, so that the aqueous adhesive cannot be stirred uniformly, the production time of the aqueous adhesive is prolonged, and the working efficiency is greatly reduced.

Disclosure of Invention

Based on the above, the invention aims to provide a reaction kettle for producing a water-based adhesive, so as to solve the technical problem that the stirring track of the stirring rod in the reaction kettle is single during stirring in the prior art.

In order to achieve the purpose, the invention provides the following technical scheme: a reaction kettle for producing a water-based adhesive comprises a main body, a top cover, a motor arranged at the center of the top of the main body and a main shaft connected with the output end of the motor, wherein an inner cylinder matched with the main body is arranged on the inner side of the main body, a top plate is connected between the top of the inner cylinder and the top cover, and transmission shafts extending to the position between the main body and the inner cylinder are movably connected at four corners inside the top plate;

the main shaft is connected with a group of transmission shafts through a synchronous belt, the bottoms of four groups of transmission shafts are connected with reciprocating screw rods, the bottoms of four groups of reciprocating screw rods are provided with planetary gears, the bottom end of the outer side of the inner cylinder is movably connected with a main gear meshed with the four groups of planetary gears, the outer sides of the four groups of reciprocating screw rods are provided with lifting mechanisms attached to the inner wall of the main body and the outer wall of the inner cylinder, and each lifting mechanism comprises a sliding frame, a matched gear, a rack, a scroll and a rigid rope;

the carriage is connected with the inside rotation of reciprocal lead screw swing joint and carriage and is connected with the cooperation gear, inner tube outer wall four corners department all is provided with the rack with cooperation gear matched with, cooperation gear both sides all are provided with the spool, the inside bottom four corners department of inner tube all is provided with the elevator, and four groups all connect through the rigidity rope between elevator and eight groups of spools, four groups the elevator inboard is provided with four groups of disturbance pieces.

Through adopting above-mentioned technical scheme, four reciprocal lead screws of group all rotate, and four reciprocal lead screws of group drive elevating system when rotating and carry out reciprocal slip from top to bottom, when sliding from top to bottom, make its inside cooperation gear engagement rack rotate, the spool of cooperation gear both sides drives two sets of rigidity ropes and its end-to-end connection be located the inside bottom of inner tube elevator and disturbance piece and rises, make the disturbance piece be axial elevating movement inside the inner tube, from this, not only the stirring rod is radial rotation inside the inner tube, the disturbance piece still is axial reciprocal elevating movement inside the inner tube simultaneously, and then the orbit pluralism that mixes the adhesive stirring, it is more even to make adhesive stirring mix the reaction.

The invention is further arranged in such a way that the output end of the motor is connected with a main shaft which penetrates through the top plate and extends into the inner cylinder, the main shaft is connected with the top plate through a bearing, the two sides of the main shaft extending to the bottom of the inner cylinder are fixedly connected with stirring rods positioned at the bottoms of the four groups of disturbance pieces, and the stirring rods are attached to the inner wall of the inner cylinder.

Through adopting above-mentioned technical scheme, the main shaft that the motor bottom is connected carries out radial rotation stirring to the adhesive in the inner tube, and the motor provides holistic power.

The invention is further provided that the bottom of the main gear is fixedly connected with a connecting ring, the bottom of the connecting ring is fixedly connected with a rotating ring, and a plurality of groups of blades positioned between the main body and the inner cylinder are uniformly arranged on the outer side of the rotating ring.

Through adopting above-mentioned technical scheme, the master gear is when rotating, drives the rotating ring through the clamping ring of its bottom and rotates, and then makes the rotatory suction that produces of the multiunit blade that the rotating ring outside evenly set up, and the blade is breathed in from the multiunit fresh air inlet that the main part surface set up, and the blade then can be with between outside air suction main part and the inner tube, and the air that flows plays a cooling effect to the inner tube.

The invention is further arranged in that a plurality of groups of vertically arranged air inlet holes are annularly distributed in the main body, the top of the outer side of the main body is fixedly provided with a connecting ring, a plurality of groups of heating rods positioned at the inner side of the air inlet holes are uniformly and vertically arranged on the inner wall of the main body, and the connecting ring is connected with the plurality of groups of heating rods through leads.

By adopting the technical scheme, because the heating rods are arranged on the inner sides of the plurality of groups of air inlet holes, the entering air flow drives the hot air flow generated by the heating rods to enter between the main body and the inner cylinder, so that the hot air flow heats the inner cylinder.

The invention is further arranged in that the bottom end of the inner wall of the main body is fixedly connected with support rings matched with the connecting shafts of the four groups of planetary gears, and grooves matched with the connecting shafts of the planetary gears are arranged at four corners inside the support rings.

Through adopting above-mentioned technical scheme, the support ring plays and rotates spacing supporting role to planetary gear, makes four group planetary gear more stable when rotating, can not take place to rock the phenomenon of skew.

The invention is further arranged in such a way that the bottom of the main body is connected with the bottom of the inner cylinder through a bottom plate, the edge positions in the bottom plate are all provided with clearance grooves, and the central position of the bottom of the inner cylinder is provided with a liquid discharge pipe penetrating through the bottom plate.

By adopting the technical scheme, the main body and the inner barrel are connected into a whole by the bottom plate, and the liquid discharge pipe is convenient for discharging the stirred and mixed aqueous adhesive.

The invention is further provided with a feeding pipe which penetrates through the top cover and the top plate and extends into the inner cylinder, and the top end in the feeding pipe is provided with an opening and closing plate.

Through adopting above-mentioned technical scheme, the inlet pipe can be to the inside solid material that adds of inner tube.

The invention is further provided that one end of the top cover, which is positioned at two sides of the feeding pipe, is provided with a liquid injection pipe which penetrates through the top cover and the top plate and extends into the inner cylinder, and the top of the liquid injection pipe is provided with a control valve.

By adopting the technical scheme, the liquid injection pipe can add liquid materials into the inner barrel.

The invention is further arranged in such a way that a supporting frame matched with the motor is arranged at the central position of the top cover and positioned at the outer side of the motor, mounting frames are arranged at four corners of the outer side of the main body, and mounting holes are formed in the mounting frames.

By adopting the technical scheme, the support frame plays a role in supporting and fixing the motor, and the mounting frame plays a role in integrally fixing and mounting the motor.

In summary, the invention mainly has the following beneficial effects:

1. the invention radially rotates and stirs the adhesive in the inner cylinder through a main shaft connected with the bottom of a motor, one of four groups of transmission shafts is driven to rotate through a synchronous belt, the transmission shaft drives a reciprocating screw rod and a planetary gear to rotate, the planetary gear drives a main gear to rotate, the main gear drives the other three groups of planetary gears to rotate, so that the four groups of reciprocating screw rods all rotate, a lifting mechanism is driven to vertically reciprocate when the four groups of reciprocating screw rods rotate, a matching gear in the four groups of reciprocating screw rods is meshed with a rack to rotate when the four groups of reciprocating screw rods vertically slide, reels on two sides of the matching gear drive two groups of rigid ropes, a lifting block and a disturbing sheet which are connected with the tail ends of the rigid ropes and are positioned at the bottom end in the inner cylinder to ascend, and the disturbing sheet axially moves in the inner cylinder, therefore, the stirring rod radially rotates in the inner cylinder, meanwhile, the disturbance piece also performs axial reciprocating lifting motion in the inner cylinder, so that the stirring and mixing track of the adhesive is diversified, and the stirring and mixing reaction of the adhesive is more uniform;

2. when the main gear rotates, the connecting ring at the bottom of the main gear drives the rotating ring to rotate, so that a plurality of groups of blades uniformly arranged on the outer side of the rotating ring rotate to generate suction force, the blades suck air from a plurality of groups of air inlet holes arranged on the surface of the main body, and because the heating rods are arranged on the inner sides of the plurality of groups of air inlet holes, the entering air flow drives hot air generated by the heating rods to enter between the main body and the inner cylinder, so that the hot air heats the inner cylinder, and if the heating rods are stopped to heat, the blades can suck outside air into between the main body and the inner cylinder, and the flowing air plays a role in cooling the inner cylinder.

Drawings

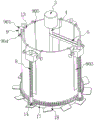

FIG. 1 is an exploded view of the present invention;

FIG. 2 is a cross-sectional view of the present invention;

FIG. 3 is a schematic diagram of the internal structure of the present invention from a first perspective;

FIG. 4 is a schematic diagram of the internal structure of the present invention from a second perspective;

FIG. 5 is a partial exploded view of the present invention;

FIG. 6 is a partial schematic view of the present invention;

FIG. 7 is a schematic overall structure diagram of a first perspective of the present invention;

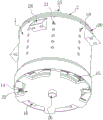

fig. 8 is a schematic overall structure diagram of a second viewing angle of the present invention.

In the figure: 1. a main body; 2. a top cover; 3. a motor; 4. a main shaft; 5. a synchronous belt; 6. a top plate; 7. a drive shaft; 8. a reciprocating screw rod; 9. a lifting mechanism; 901. a carriage; 902. a mating gear; 903. a rack; 904. a reel; 905. a rigid cord; 10. a lifting block; 11. a disturbance plate; 12. a stirring rod; 13. an inner barrel; 14. a planetary gear; 15. a main gear; 16. a connecting ring; 17. a rotating ring; 18. a blade; 19. an air inlet hole; 20. a connecting ring; 21. a heating rod; 22. a base plate; 23. a support ring; 24. a feed pipe; 25. a liquid injection pipe; 26. a liquid discharge pipe; 27. a support frame; 28. and (7) mounting frames.

Detailed Description

The technical solution in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are illustrative only for the purpose of explaining the present invention, and are not to be construed as limiting the present invention.

The following describes an embodiment of the present invention based on its overall structure.

A reaction kettle for producing water-based adhesives is disclosed, as shown in figure 1, figure 2, figure 3, figure 4 and figure 5, comprising a main body 1, a top cover 2, a motor 3 arranged at the center of the top and a main shaft 4 connected with the output end of the motor, an inner cylinder 13 matched with the main body 1 is arranged at the inner side of the main body 1, a top plate 6 is connected between the top of the inner cylinder 13 and the top cover 2, a transmission shaft 7 extending to the position between the main body 1 and the inner cylinder 13 is movably connected at four corners inside the top plate 6, the output end of the motor 3 is connected with the main shaft 4 penetrating through the top plate 6 and extending to the inside of the inner cylinder 13, the main shaft 4 is connected with the top plate 6 through a bearing, the two sides of the main shaft 4 extending to the bottom of the inner cylinder are fixedly connected with stirring rods 12 positioned at the bottoms of the four groups of disturbance pieces 11, the stirring rods 12 are attached to the inner wall of the inner cylinder 13, the spindle 4 connected with the bottom of the motor 3 drives two groups of stirring rods 12 to radially rotate and stir the adhesive in the inner cylinder 13;

the main shaft 4 is connected with a group of transmission shafts 7 through a synchronous belt 5, the bottoms of the four groups of transmission shafts 7 are connected with reciprocating screw rods 8, the bottoms of the four groups of reciprocating screw rods 8 are provided with planetary gears 14, the bottom end of the outer side of the inner cylinder 13 is movably connected with a main gear 15 meshed with the four groups of planetary gears 14, the main gear 15 drives the other three groups of planetary gears 14 to rotate under the rotation of the group of planetary gears 14, then the four groups of lifting mechanisms 9 can complete the movement process, the outer sides of the four groups of reciprocating screw rods 8 are provided with lifting mechanisms 9 attached to the inner wall of the main body 1 and the outer wall of the inner cylinder 13, and each lifting mechanism 9 comprises a sliding frame 901, a matching gear 902, a rack 903, a reel 904 and a rigid rope 905;

the sliding frame 901 is movably connected with the reciprocating screw rod 8, the sliding frame 901 is rotatably connected with a matching gear 902, four corners of the outer wall of the inner cylinder 13 are provided with racks 903 matched with the matching gear 902, two sides of the matching gear 902 are provided with reels 904, four corners of the inner bottom end of the inner cylinder 13 are provided with lifting blocks 10, the four groups of lifting blocks 10 are connected with eight groups of reels 904 through rigid ropes 905, four groups of disturbance pieces 11 are arranged inside the four groups of lifting blocks 10, when the lifting mechanism 9 slides up and down, the matching gear 902 inside the lifting mechanism is meshed with the racks 903 to rotate, the reels 904 at two sides of the matching gear 902 drive the two groups of rigid ropes 905, the lifting blocks 10 which are connected with the tail ends and are located at the inner bottom end of the inner cylinder 13 and the disturbance pieces 11 to ascend, and descend axially inside the inner cylinder 13.

Referring to fig. 1, 2 and 3, the bottom of the main gear 15 is fixedly connected with a connecting ring 16, the bottom of the connecting ring 16 is fixedly connected with a rotating ring 17, the outer side of the rotating ring 17 is uniformly provided with a plurality of groups of blades 18 positioned between the main body 1 and the inner cylinder 13, a plurality of groups of vertically arranged air inlet holes 19 are annularly distributed in the main body 1, the top of the outer side of the main body 1 is fixedly provided with a connecting ring 20, the inner wall of the main body 1 is uniformly and vertically provided with a plurality of groups of heating rods 21 positioned at the inner side of the air inlet holes 19, and the connecting ring 20 is connected with the plurality of groups of heating rods 21 through wires, according to the structure, when the water-based adhesive stirred by the inner cylinder 13 is heated, the connecting ring 20 connected with external power supply equipment is electrified and started, so that the plurality of groups of heating rods 21 are electrified and heated, and because the connecting ring 16 at the bottom of the main gear 15 drives the rotating ring 17 to rotate, so that the plurality of groups of blades 18 uniformly arranged at the outer side of the rotating ring 17 rotate to generate suction force, the blades 18 suck air from a plurality of groups of air inlet holes 19 arranged on the surface of the main body 1, and the entering air flow drives hot air generated by the heating rod 21 to enter between the main body 1 and the inner cylinder 13, so that the hot air flows heat the inner cylinder 13, and further heat is provided for the water-based adhesive during stirring and mixing reaction.

Referring to fig. 1 and 2, the bottom end of the inner wall of the main body 1 is fixedly connected with support rings 23 matched with the connecting shafts of the four groups of planetary gears 14, and four corners inside the support rings 23 are all provided with grooves matched with the connecting shafts of the planetary gears 14.

Referring to fig. 1, 2, 7 and 8, the bottom of the main body 1 is connected with the bottom of the inner cylinder 13 through a bottom plate 22, the edge of the bottom plate 22 is provided with a clearance groove, the center of the bottom of the inner cylinder 13 is provided with a liquid discharge pipe 26 penetrating through the bottom plate 22, the middle of the top end of the top cover 2 is provided with a feed pipe 24 penetrating through the top cover 2 and the top plate 6 and extending into the inner cylinder 13, the top end of the feed pipe 24 is provided with a opening and closing plate, the top end of the top cover 2 is provided with a liquid injection pipe 25 penetrating through the top cover 2 and the top plate 6 and extending into the inner cylinder 13 at two sides of the feed pipe 24, and the top of the liquid injection pipe 25 is provided with a control valve, by the arrangement of the above structures, the bottom plate 22 connects the main body 1 and the inner cylinder 13 into a whole, the liquid discharge pipe 26 is convenient for discharging the stirred and mixed aqueous adhesive, the liquid injection pipe 25 can be used for adding liquid material into the inner cylinder 13, the feed pipe 24 can feed solid materials into the inner drum 13.

Referring to fig. 1, 7 and 8, a supporting frame 27 matched with the motor 3 is arranged at the central position of the top cover 2 and located at the outer side of the motor 3, mounting frames 28 are arranged at four corners of the outer side of the main body 1, and mounting holes are arranged in the mounting frames 28.

The working principle of the invention is as follows: when the stirring device is used, a power supply is switched on, solid adipic acid is manually put into the inner cylinder 13 through the feeding pipe 24, then diethylene glycol and ethylene glycol are respectively injected into the inner cylinder 13 through the two groups of liquid injection pipes 25, the motor 3 is started at the moment, the output end of the motor 3 is connected with the main shaft 4 extending into the inner cylinder 13, and the main shaft 4 drives the two groups of stirring rods 12 to stir, mix and react materials;

one side of the main shaft 4 drives one group of transmission shafts 7 of the four groups of transmission shafts 7 to rotate through a synchronous belt 5, one group of transmission shafts 7 drives the reciprocating screw rods 8 and the planetary gears 14 to rotate, the group of planetary gears 14 drives the main gear 15 to rotate, and the main gear 15 drives the other three groups of planetary gears 14 to rotate, so that the four groups of reciprocating screw rods 8 all rotate in the same direction, and the four groups of reciprocating screw rods 8 drive the lifting mechanism 9 to slide up and down in a reciprocating manner when rotating;

when the lifting mechanism 9 slides up and down, the matching gear 902 inside the lifting mechanism is meshed with the rack 903 to rotate, and the reels 904 at the two sides of the matching gear 902 drive the two groups of rigid ropes 905, the lifting block 10 connected with the tail end of the rigid ropes and positioned at the bottom end inside the inner cylinder 13 and the disturbance sheet 11 to ascend, so that the disturbance sheet 11 does axial lifting motion inside the inner cylinder 13;

therefore, the stirring rod 12 does radial rotation in the inner cylinder 13, and the disturbance piece 11 also does axial reciprocating lifting motion in the inner cylinder 13, so that the stirring and mixing tracks of the adhesive are diversified, and the stirring and mixing reaction of the adhesive is more uniform;

further, when the plurality of sets of lifting blocks 10 move downwards from the top end of the inner cylinder 13, the reel 904 rotates reversely to release the rigid rope 905 wound on the outer side of the reel 904, and simultaneously, the lifting blocks 10 move towards the bottom end of the inner cylinder 13 under the action of self gravity, and the combined weight of the lifting blocks 10 and the disturbance sheet 11 is far greater than the sum of buoyancy and resistance inside the water-based adhesive;

when the aqueous adhesive to be stirred in the inner cylinder 13 needs to be heated, the connecting ring 20 connected with external power supply equipment is electrified and started, so that a plurality of groups of heating rods 21 are electrified and heated, and when the main gear 15 rotates, the connecting ring 16 at the bottom of the main gear drives the rotating ring 17 to rotate, so that a plurality of groups of blades 18 uniformly arranged on the outer side of the rotating ring 17 rotate to generate suction force, the blades 18 suck air from a plurality of groups of air inlet holes 19 arranged on the surface of the main body 1, and the entering air flow drives hot air generated by the heating rods 21 to enter between the main body 1 and the inner cylinder 13, so that the hot air flows heat the inner cylinder 13, and further the water-based adhesive can be provided with heat during stirring and mixing reaction;

if the connection ring 20 and the heating rod 21 are stopped to be electrified and heated, the blades 18 can suck outside air between the main body 1 and the inner cylinder 13, and the flowing air plays a role in cooling the inner cylinder 13, that is, the flowing air flow has a better cooling effect than static air scattered on the outer side of the inner cylinder 13, so that heat emitted from the outer surface of the inner cylinder 13 can be more quickly taken out from the bottom space between the main body 1 and the inner cylinder 13, and the cooling effect of the water-based adhesive is further improved;

finally, the aqueous adhesive after the stirring, mixing and reaction is discharged out of the inner cylinder 13 through the liquid discharge pipe 26, and is collected and reused by using an external collection device.

Although embodiments of the present invention have been shown and described, it is intended that the present invention should not be limited thereto, that the particular features, structures, materials or characteristics described may be combined in any suitable manner in any one or more embodiments or examples, and that modifications, substitutions, variations or the like, which are not inventive and may be made by those skilled in the art without departing from the principle and spirit of the present invention and without departing from the scope of the claims.

Claims (9)

1. The utility model provides a reation kettle is used in production of waterborne adhesive, includes main part (1), top cap (2), motor (3) and main shaft (4) that its output is connected of top central point department installation, its characterized in that: an inner cylinder (13) matched with the main body (1) is arranged on the inner side of the main body (1), a top plate (6) is connected between the top of the inner cylinder (13) and the top cover (2), and four corners in the top plate (6) are movably connected with transmission shafts (7) extending between the main body (1) and the inner cylinder (13);

the main shaft (4) is connected with a group of transmission shafts (7) through a synchronous belt (5), the bottoms of the four groups of transmission shafts (7) are connected with reciprocating screw rods (8), the bottoms of the four groups of reciprocating screw rods (8) are provided with planetary gears (14), the bottom end of the outer side of the inner cylinder (13) is movably connected with a main gear (15) meshed with the four groups of planetary gears (14), the outer sides of the four groups of reciprocating screw rods (8) are provided with lifting mechanisms (9) attached to the inner wall of the main body (1) and the outer wall of the inner cylinder (13), and each lifting mechanism (9) comprises a sliding frame (901), a matched gear (902), a rack (903), a reel (904) and a rigid rope (905);

carriage (901) and reciprocal lead screw (8) swing joint and the inside swivelling joint of carriage (901) are connected with cooperation gear (902), inner tube (13) outer wall four corners department all is provided with rack (903) with cooperation gear (902) matched with, cooperation gear (902) both sides all are provided with spool (904), inner tube (13) inside bottom four corners department all is provided with elevator (10), four groups all connect through rigidity rope (905) between elevator (10) and eight groups of spool (904), four groups elevator (10) inboard is provided with four groups of disturbance pieces (11).

2. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: the output end of the motor (3) is connected with a main shaft (4) which runs through the top plate (6) and extends to the inner part of the inner barrel (13), the main shaft (4) and the top plate (6) are connected through a bearing, the main shaft (4) extends to the two sides of the bottom of the inner barrel, is fixedly connected with stirring rods (12) which are located at the bottoms of the four groups of disturbance pieces (11), and the stirring rods (12) are attached to the inner wall of the inner barrel (13).

3. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: the bottom of the main gear (15) is fixedly connected with a connecting ring (16), the bottom of the connecting ring (16) is fixedly connected with a rotating ring (17), and a plurality of groups of blades (18) positioned between the main body (1) and the inner cylinder (13) are uniformly arranged on the outer side of the rotating ring (17).

4. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: the utility model discloses a hot blast stove, including main part (1), main part (1) inside annular distribution has air inlet (19) of the vertical range of multiunit, main part (1) outside top is fixed and is provided with clamping ring (20), main part (1) inner wall is even vertically provided with multiunit and is located air inlet (19) inboard heating rod (21), and connects through the wire between clamping ring (20) and multiunit heating rod (21).

5. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: the bottom end of the inner wall of the main body (1) is fixedly connected with support rings (23) matched with connecting shafts of the four groups of planetary gears (14), and grooves matched with the connecting shafts of the planetary gears (14) are formed in four corners inside the support rings (23).

6. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: the bottom of the main body (1) is connected with the bottom of the inner cylinder (13) through a bottom plate (22), clearance grooves are formed in the edge positions inside the bottom plate (22), and a liquid discharge pipe (26) penetrating through the bottom plate (22) is arranged in the center position of the bottom of the inner cylinder (13).

7. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: top cap (2) top one end intermediate position department is provided with and runs through top cap (2), roof (6) and extend to inside inlet pipe (24) of inner tube (13), and the inside top of inlet pipe (24) is provided with the board that opens and shuts.

8. The reaction kettle for producing the aqueous adhesive according to claim 7, wherein: top cap (2) top one end is located inlet pipe (24) both sides and all is provided with and runs through top cap (2), roof (6) and extend to annotate liquid pipe (25) inside inner tube (13), and annotates liquid pipe (25) top and be provided with control flap.

9. The reaction kettle for producing the aqueous adhesive according to claim 1, wherein: top cap (2) top central point department of putting is provided with support frame (27) with motor (3) matched with in the motor (3) outside, main part (1) outside four corners department all is provided with mounting bracket (28), and inside all being provided with the mounting hole of mounting bracket (28).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110675961.2A CN113385131A (en) | 2021-06-18 | 2021-06-18 | Reation kettle is used in aqueous adhesive production |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110675961.2A CN113385131A (en) | 2021-06-18 | 2021-06-18 | Reation kettle is used in aqueous adhesive production |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113385131A true CN113385131A (en) | 2021-09-14 |

Family

ID=77621802

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110675961.2A Pending CN113385131A (en) | 2021-06-18 | 2021-06-18 | Reation kettle is used in aqueous adhesive production |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113385131A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113815115A (en) * | 2021-09-23 | 2021-12-21 | 江西中一梦园住宅工业有限公司 | Aerated concrete raw material mixing energy-saving temperature-regulating pouring stirring tank |

| CN116440760A (en) * | 2023-03-14 | 2023-07-18 | 广东美味源香料股份有限公司 | Paste gelatinizing device and beef monosodium glutamate paste gelatinizing processing method |

| CN118179428A (en) * | 2024-05-20 | 2024-06-14 | 盘锦迪宝催化剂技术有限公司 | High-nickel catalyst preparation device and preparation technology thereof |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB988855A (en) * | 1960-05-10 | 1965-04-14 | Crawford And Russell Inc | Material treatment apparatus |

| CN109200983A (en) * | 2018-10-18 | 2019-01-15 | 方期洲 | A kind of highly effective reaction kettle for accelerating radiating rate |

| CN110692755A (en) * | 2019-11-11 | 2020-01-17 | 福安市木尔文电子有限公司 | Domestic automatic tea frying machine |

| CN210097682U (en) * | 2019-06-17 | 2020-02-21 | 江西睿达新能源科技有限公司 | Reation kettle is used in production of ternary cathode material |

-

2021

- 2021-06-18 CN CN202110675961.2A patent/CN113385131A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB988855A (en) * | 1960-05-10 | 1965-04-14 | Crawford And Russell Inc | Material treatment apparatus |

| CN109200983A (en) * | 2018-10-18 | 2019-01-15 | 方期洲 | A kind of highly effective reaction kettle for accelerating radiating rate |

| CN210097682U (en) * | 2019-06-17 | 2020-02-21 | 江西睿达新能源科技有限公司 | Reation kettle is used in production of ternary cathode material |

| CN110692755A (en) * | 2019-11-11 | 2020-01-17 | 福安市木尔文电子有限公司 | Domestic automatic tea frying machine |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113815115A (en) * | 2021-09-23 | 2021-12-21 | 江西中一梦园住宅工业有限公司 | Aerated concrete raw material mixing energy-saving temperature-regulating pouring stirring tank |

| CN116440760A (en) * | 2023-03-14 | 2023-07-18 | 广东美味源香料股份有限公司 | Paste gelatinizing device and beef monosodium glutamate paste gelatinizing processing method |

| CN116440760B (en) * | 2023-03-14 | 2023-09-22 | 广东美味源香料股份有限公司 | Paste gelatinizing device and beef monosodium glutamate paste gelatinizing processing method |

| CN118179428A (en) * | 2024-05-20 | 2024-06-14 | 盘锦迪宝催化剂技术有限公司 | High-nickel catalyst preparation device and preparation technology thereof |

| CN118179428B (en) * | 2024-05-20 | 2024-07-19 | 盘锦迪宝催化剂技术有限公司 | High-nickel catalyst preparation device and preparation technology thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113385131A (en) | Reation kettle is used in aqueous adhesive production | |

| CN210875106U (en) | Brake block batching mixing arrangement | |

| CN209772557U (en) | Gluing device in production of decorative film | |

| CN109046063A (en) | A kind of chemical liquid raw material blending device | |

| CN211514492U (en) | Coaxial anisotropic stirring reaction device | |

| CN209780162U (en) | Wall brushing device | |

| CN114504995B (en) | Stirring device for feed production | |

| CN201872043U (en) | Multifunctional full-automatic crystal grinding and polishing machine | |

| CN216384912U (en) | Drying device is used in production of thick terephthalic acid | |

| CN108328233A (en) | A kind of screw feeding device that rimless combination type permanent-magnet linear synchronous motor directly drives | |

| CN108927874A (en) | A kind of bamboo charcoal fiber production equipment with anti-resurgence function | |

| CN209885691U (en) | Asphalt mixing device | |

| CN208086646U (en) | A kind of screw feeding device that rimless combination type permanent-magnet linear synchronous motor directly drives | |

| CN208302653U (en) | A kind of high efficiency dye mixing arrangement | |

| CN220387028U (en) | Drying equipment of film coater | |

| CN219441686U (en) | Caustic soda feeding device for preparing sodium acetate | |

| CN219168308U (en) | Stirring mixing arrangement convenient to clearance | |

| CN214131630U (en) | Ventilative type polyurethane reation kettle pan feeding mechanism for plastic course | |

| CN206008710U (en) | A kind of new overhead finely tunes boosting jet type open type reactor | |

| CN211246593U (en) | A two stirred tank reactor for producing protection glue auxiliary agent | |

| CN215353457U (en) | High-efficient mixing apparatus is used in hot melt adhesive production | |

| CN214826774U (en) | Production lifting machine for coating | |

| CN220496341U (en) | Glue reaction kettle | |

| CN215353387U (en) | Release agent reation kettle | |

| CN216654318U (en) | Production agitating unit of thick dioctyl terephthalate |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20210914 |

|

| RJ01 | Rejection of invention patent application after publication |