CN113243846A - Surface cleaning apparatus and method of controlling the same - Google Patents

Surface cleaning apparatus and method of controlling the same Download PDFInfo

- Publication number

- CN113243846A CN113243846A CN202110486298.1A CN202110486298A CN113243846A CN 113243846 A CN113243846 A CN 113243846A CN 202110486298 A CN202110486298 A CN 202110486298A CN 113243846 A CN113243846 A CN 113243846A

- Authority

- CN

- China

- Prior art keywords

- surface cleaning

- cleaning

- operating mechanism

- cleaning apparatus

- power

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/29—Floor-scrubbing machines characterised by means for taking-up dirty liquid

- A47L11/30—Floor-scrubbing machines characterised by means for taking-up dirty liquid by suction

- A47L11/302—Floor-scrubbing machines characterised by means for taking-up dirty liquid by suction having rotary tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4002—Installations of electric equipment

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4002—Installations of electric equipment

- A47L11/4005—Arrangements of batteries or cells; Electric power supply arrangements

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4002—Installations of electric equipment

- A47L11/4008—Arrangements of switches, indicators or the like

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4036—Parts or details of the surface treating tools

- A47L11/4041—Roll shaped surface treating tools

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B21/00—Arrangements or duct systems, e.g. in combination with pallet boxes, for supplying and controlling air or gases for drying solid materials or objects

- F26B21/001—Drying-air generating units, e.g. movable, independent of drying enclosure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B21/00—Arrangements or duct systems, e.g. in combination with pallet boxes, for supplying and controlling air or gases for drying solid materials or objects

- F26B21/004—Nozzle assemblies; Air knives; Air distributors; Blow boxes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B21/00—Arrangements or duct systems, e.g. in combination with pallet boxes, for supplying and controlling air or gases for drying solid materials or objects

- F26B21/06—Controlling, e.g. regulating, parameters of gas supply

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

- A47L2201/02—Docking stations; Docking operations

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

- A47L2201/02—Docking stations; Docking operations

- A47L2201/026—Refilling cleaning liquid containers

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Cleaning By Liquid Or Steam (AREA)

Abstract

The present disclosure provides a surface cleaning apparatus comprising: a handle; the handle is arranged on the machine body; the power-on and power-off operating mechanism and/or the power adjusting operating mechanism are/is arranged on the handle and can be triggered by a user; and the water supply operating mechanism is arranged on the handle, and enables the spacing distance between the water supply operating mechanism and the on-off operating mechanism and/or the power adjusting operating mechanism to be larger than a preset value. The present disclosure also provides a method of controlling a surface cleaning apparatus.

Description

Technical Field

The present disclosure relates to a surface cleaning apparatus and a control method thereof.

Background

Today's surface cleaning devices are used for wet cleaning hard floors or short-hair carpets. The device typically has one or more cleaning portions or discs made of a wool material which can be used to scrub tough soils from the floor by the addition of water or a water/cleaner mixture. When the machine is moving over the dirt, the dirt which has been wiped off by the cleaning section and dissolved by the water or water/detergent mixture is sucked up with the cleaning head arranged in the direction of movement of the cleaning section, and in the technique of providing the cleaning tray, the dirt may be directly adsorbed by the cleaning material on the cleaning tray without providing the cleaning head.

However, stubborn stains are generally difficult to clean, and milk stains, fruit juices, sauces and the like are scattered on the floor surface, and after water is evaporated, stubborn stains which are difficult to remove are formed on the cleaning surface. Often, not all of this stubborn dirt is removed by vacuuming during scrubbing, and some of it remains on the floor, reducing the quality of the cleaning.

Existing surface cleaning devices, whether autonomous mobile cleaning devices or handheld cleaning devices, all require the provision of structures such as a sewage tank and a clean water tank to enable cleaning of the surface by hot water.

However, when the surface cleaning apparatus includes a clean water tank, a waste water tank, etc., multiple operating mechanisms are required to perform the different functions of the surface cleaning apparatus. Accordingly, there is a need for a proper arrangement of the operating mechanism of a surface cleaning apparatus to enhance the user experience.

Disclosure of Invention

To solve one of the above technical problems, the present disclosure provides a surface cleaning apparatus and a control method thereof.

According to an aspect of the present disclosure, there is provided a surface cleaning apparatus comprising:

a handle;

the handle is arranged on the machine body;

the power-on and power-off operating mechanism and/or the power adjusting operating mechanism are/is arranged on the handle and can be triggered by a user; and

the water supply operating mechanism is arranged on the handle, and the spacing distance between the water supply operating mechanism and the on-off operating mechanism and/or the power adjusting operating mechanism is larger than a preset value.

A surface cleaning apparatus according to at least one embodiment of the present disclosure, further comprising:

the self-cleaning operating mechanism is arranged on the handle, and the spacing distance between the self-cleaning operating mechanism and the on-off operating mechanism and/or the power adjusting operating mechanism is larger than a preset value.

According to at least one embodiment of the present disclosure, a surface cleaning apparatus, the handle comprises:

a grip portion that a user grips when the user operates the handle.

According to the surface cleaning device of at least one embodiment of the present disclosure, the power-on/off operation mechanism and/or the power-adjusting operation mechanism is located at one end of the holding portion, and the water-feeding operation mechanism and/or the self-cleaning operation mechanism is located at the other end of the holding portion.

According to at least one embodiment of the present disclosure, the surface cleaning apparatus further comprises:

and when the rod part is in a vertical state, the upper end of the holding part is connected with the upper end of the rod part, so that the connecting part of the rod part and the holding part forms the top end of the handle.

In accordance with at least one embodiment of the present disclosure, the water feed operation mechanism and/or the self-cleaning operation mechanism is disposed at or near a top end of the handle.

According to the surface cleaning apparatus of at least one embodiment of the present disclosure, the power on/off operation mechanism and/or the power adjustment operation mechanism is provided at a lower end of the grip portion, and enables a user to grip a portion between the power on/off operation mechanism and/or the power adjustment operation mechanism and the water feeding operation mechanism and/or the self-cleaning operation mechanism.

According to the surface cleaning apparatus of at least one embodiment of the present disclosure, at least one of the power-on/off operation mechanism, the power-adjusting operation mechanism, the water-feeding operation mechanism, and the self-cleaning operation mechanism is triggered by touching, pressing, or pushing.

A surface cleaning apparatus according to at least one embodiment of the present disclosure, further comprising:

a control device for receiving a control signal from at least one of the on/off operating mechanism, the power regulating operating mechanism, the water feed operating mechanism and the self-cleaning operating mechanism and controlling the surface cleaning apparatus in accordance with the control signal.

In accordance with at least one embodiment of the present disclosure, when the surface cleaning apparatus includes a power adjustment operating mechanism and a power on/off operating mechanism, the power adjustment operating mechanism is located below the power adjustment operating mechanism.

According to at least one embodiment of the present disclosure, when the surface cleaning apparatus includes a water feed operation mechanism and a self-cleaning operation mechanism, the self-cleaning operation mechanism is located above the water feed operation mechanism.

A surface cleaning apparatus according to at least one embodiment of the present disclosure, further comprising:

a clean water tank for storing a cleaning liquid before the surface cleaning apparatus cleans a surface to be cleaned;

wherein when the feed water operation mechanism is operated, the clean liquid is allowed to be added to the clean water tank.

A surface cleaning apparatus according to at least one embodiment of the present disclosure, further comprising:

a cleaning assembly for cleaning a surface to be cleaned;

wherein when the self-cleaning operation mechanism is operated, cleaning of the cleaning portion of the cleaning assembly is allowed.

According to at least one embodiment of the present disclosure, the clean water tank supplies the cleaning liquid to the cleaning portion of the cleaning assembly when the cleaning portion of the cleaning assembly is cleaned.

A surface cleaning apparatus according to at least one embodiment of the present disclosure, further comprising: a liquid connector in communication with the clean water tank to provide cleaning liquid to the clean water tank through the liquid connector or to draw out cleaning liquid in the clean water tank to an exterior of the clean water tank.

According to another aspect of the present disclosure, there is provided a method of controlling a surface cleaning apparatus, comprising:

the surface cleaning device detects whether the operating mechanism is triggered; and

when the power on/off operation mechanism is triggered for the first time, the surface cleaning equipment is switched from a power off state to a power on state, and the surface to be cleaned is cleaned in a preset working mode until the power on/off operation mechanism is triggered for the second time, and the surface cleaning equipment is switched from the power on state to the power off state;

wherein the surface cleaning apparatus detects whether the power adjustment operating mechanism is triggered when the surface cleaning apparatus cleans a surface to be cleaned in a predetermined operating mode; when the power adjustment operating mechanism is triggered, the predetermined operating mode is switched to the operating mode selected by the user.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, the surface cleaning apparatus does not detect whether a power adjustment operating mechanism is triggered when the surface cleaning apparatus is in a power-off state.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, the predetermined operation mode is an automatic mode, a powerful mode, or an energy saving mode.

According to the control method of the surface cleaning device of at least one embodiment of the disclosure, when the surface cleaning device is switched from the power-on state to the power-off state, the ground brush motor and the water pump motor of the surface cleaning device are controlled to stop, and the motor assembly of the surface cleaning device is controlled to stop after a preset time.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, when a self-cleaning operation mechanism is triggered, it is determined whether the surface cleaning apparatus is parked at a base station, and when the surface cleaning apparatus is parked at the base station, the surface cleaning apparatus is self-cleaned.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, the base station includes an in-place detection device for detecting whether the surface cleaning apparatus is docked at the base station; when the in-place detection device detects that the surface cleaning equipment stops at the base station, the base station sends information detected by the in-place detection device to the surface cleaning equipment.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, the self-cleaning of the surface cleaning apparatus includes:

causing the base station to dry and/or sanitize the at least one cleaning portion of the surface cleaning apparatus.

According to the control method of the surface cleaning device of at least one embodiment of the disclosure, when the water feeding operation mechanism is triggered, whether the surface cleaning device is stopped at the base station or not is judged, and when the surface cleaning device is stopped at the base station, whether the liquid level in the liquid storage tank of the base station is larger than or equal to a certain preset value or not is judged; and determining whether a liquid level in a cleaning liquid supply portion of the surface cleaning apparatus is less than or equal to a certain preset value; and when the liquid level in the liquid storage tank of the base station is greater than or equal to a certain preset value and the liquid level in the cleaning liquid supply part of the surface cleaning equipment is less than or equal to a certain preset value, adding the cleaning liquid in the liquid storage tank of the base station into the cleaning liquid supply part of the surface cleaning equipment.

According to a control method of a surface cleaning apparatus of at least one embodiment of the present disclosure, in a process of adding a cleaning liquid to a cleaning liquid supply portion of the surface cleaning apparatus, it is determined whether a liquid level in the cleaning liquid supply portion of the surface cleaning apparatus is greater than or equal to a certain preset value, and when the liquid level in the cleaning liquid supply portion of the surface cleaning apparatus is greater than or equal to the certain preset value, the addition of the cleaning liquid to the cleaning liquid supply portion of the surface cleaning apparatus is stopped.

Drawings

The accompanying drawings, which are included to provide a further understanding of the disclosure and are incorporated in and constitute a part of this specification, illustrate exemplary embodiments of the disclosure and together with the description serve to explain the principles of the disclosure.

FIG. 1 is a schematic structural view of a surface cleaning apparatus according to one embodiment of the present disclosure (only the handle is shown).

FIG. 2 is a schematic structural view of a surface cleaning apparatus according to one embodiment of the present disclosure.

FIG. 3 is a schematic view of another angular configuration of a surface cleaning apparatus according to one embodiment of the present disclosure.

FIG. 4 is a schematic structural view (with the fuselage removed) of a surface cleaning apparatus according to one embodiment of the present disclosure.

Fig. 5 is a schematic structural view of a wastewater tank according to an embodiment of the present disclosure.

FIG. 6 is a schematic structural view of a surface cleaning apparatus according to another embodiment of the present disclosure.

Fig. 7 is one of the schematic structural diagrams of a base station of at least one embodiment of the present disclosure.

Fig. 8 is a second schematic structural diagram of a base station according to at least one embodiment of the present disclosure.

Fig. 9 is a third schematic structural diagram of a base station according to at least one embodiment of the present disclosure.

Fig. 10 is one of schematic structural diagrams of a base station of at least one embodiment of the present disclosure.

Fig. 11 is one of partial structural schematic diagrams of a base station of at least one embodiment of the present disclosure.

Fig. 12 is one of partial structural schematic views of a pallet section of a base station according to at least one embodiment of the present disclosure.

Fig. 13 is a second partial configuration diagram of a pallet section of a base station according to at least one embodiment of the present disclosure.

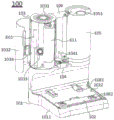

Fig. 14 is one of exploded structural schematic diagrams of a base station of at least one embodiment of the present disclosure.

Fig. 15 is an overall structural schematic diagram of a drying mechanism of a base station according to at least one embodiment of the present disclosure.

Fig. 16 is one of internal structural schematic diagrams of a drying mechanism of a base station of at least one embodiment of the present disclosure.

Fig. 17 is a second schematic internal structural diagram of the drying mechanism of the base station according to at least one embodiment of the present disclosure.

Fig. 18 is a schematic structural view of a water level detection part of a drying mechanism of a base station according to at least one embodiment of the present disclosure.

Fig. 19 is a schematic structural diagram of a method of controlling a surface cleaning apparatus of at least one embodiment of the present disclosure.

Detailed Description

The present disclosure will be described in further detail with reference to the drawings and embodiments. It is to be understood that the specific embodiments described herein are for purposes of illustration only and are not to be construed as limitations of the present disclosure. It should be further noted that, for the convenience of description, only the portions relevant to the present disclosure are shown in the drawings.

It should be noted that the embodiments and features of the embodiments in the present disclosure may be combined with each other without conflict. Technical solutions of the present disclosure will be described in detail below with reference to the accompanying drawings in conjunction with embodiments.

Unless otherwise indicated, the illustrated exemplary embodiments/examples are to be understood as providing exemplary features of various details of some ways in which the technical concepts of the present disclosure may be practiced. Accordingly, unless otherwise indicated, features of the various embodiments may be additionally combined, separated, interchanged, and/or rearranged without departing from the technical concept of the present disclosure.

The use of cross-hatching and/or shading in the drawings is generally used to clarify the boundaries between adjacent components. As such, unless otherwise noted, the presence or absence of cross-hatching or shading does not convey or indicate any preference or requirement for a particular material, material property, size, proportion, commonality between the illustrated components and/or any other characteristic, attribute, property, etc., of a component. Further, in the drawings, the size and relative sizes of components may be exaggerated for clarity and/or descriptive purposes. While example embodiments may be practiced differently, the specific process sequence may be performed in a different order than that described. For example, two processes described consecutively may be performed substantially simultaneously or in reverse order to that described. In addition, like reference numerals denote like parts.

When an element is referred to as being "on" or "on," "connected to" or "coupled to" another element, it can be directly on, connected or coupled to the other element or intervening elements may be present. However, when an element is referred to as being "directly on," "directly connected to" or "directly coupled to" another element, there are no intervening elements present. For purposes of this disclosure, the term "connected" may refer to physically, electrically, etc., and may or may not have intermediate components.

For descriptive purposes, the present disclosure may use spatially relative terms such as "below … …," below … …, "" below … …, "" below, "" above … …, "" above, "" … …, "" higher, "and" side (e.g., as in "side wall") to describe one component's relationship to another (other) component as illustrated in the figures. Spatially relative terms are intended to encompass different orientations of the device in use, operation, and/or manufacture in addition to the orientation depicted in the figures. For example, if the device in the figures is turned over, elements described as "below" or "beneath" other elements or features would then be oriented "above" the other elements or features. Thus, the exemplary term "below … …" can encompass both an orientation of "above" and "below". Further, the devices may be otherwise positioned (e.g., rotated 90 degrees or at other orientations) and the spatially relative descriptors used herein interpreted accordingly.

The terminology used herein is for the purpose of describing particular embodiments and is not intended to be limiting. As used herein, the singular forms "a", "an" and "the" are intended to include the plural forms as well, unless the context clearly indicates otherwise. Furthermore, when the terms "comprises" and/or "comprising" and variations thereof are used in this specification, the presence of stated features, integers, steps, operations, elements, components and/or groups thereof are stated but does not preclude the presence or addition of one or more other features, integers, steps, operations, elements, components and/or groups thereof. It is also noted that, as used herein, the terms "substantially," "about," and other similar terms are used as approximate terms and not as degree terms, and as such, are used to interpret inherent deviations in measured values, calculated values, and/or provided values that would be recognized by one of ordinary skill in the art.

FIG. 1 is a schematic structural view of a surface cleaning apparatus according to one embodiment of the present disclosure (only the handle is shown). FIG. 2 is a schematic structural view of a surface cleaning apparatus according to one embodiment of the present disclosure.

As shown in fig. 1 and 2, a surface cleaning apparatus 800 of the present disclosure is characterized by comprising:

a handle 821;

a switch operating mechanism 840 and/or a power adjustment operating mechanism 850, the switch operating mechanism 840 and/or the power adjustment operating mechanism 850 being provided to the handle 821 and being capable of being triggered by a user; and

and the water supply operating mechanism 860 is arranged on the handle 821, and the spacing distance between the water supply operating mechanism 860 and the on-off operating mechanism 840 and/or the power adjusting operating mechanism 850 is larger than a preset value.

In the present disclosure, the surface cleaning apparatus 800 further comprises:

a self-cleaning operating mechanism 870, wherein the self-cleaning operating mechanism 870 is disposed on the handle 821, and a distance between the self-cleaning operating mechanism 870 and the on/off operating mechanism 840 and/or the power adjusting operating mechanism 850 is greater than a predetermined value.

In an alternative embodiment of the present disclosure, the handle 821 includes:

a grip portion 8212, which the user grips when operating the handle 821.

In this case, referring to the grip portion 8212, the on/off operation means 840 and/or the power adjustment operation means 850 are/is located at one end of the grip portion 8212, and the water supply operation means 860 and/or the self-cleaning operation means 870 are/is located at the other end of the grip portion 8212.

The handle 821 further includes:

a rod portion 8211, an upper end of the holding portion 8212 is connected to an upper end of the rod portion 8211 when the rod portion 8211 is in a vertical state, so that a connecting portion of the rod portion 8211 and the holding portion 8212 forms a top end of the handle 821.

In the present disclosure, the water supply operation mechanism 860 and/or the self-cleaning operation mechanism 870 is disposed at or near the top end of the handle 821.

In contrast, the on/off operating mechanism 840 and/or the power adjustment operating mechanism 850 are disposed at a lower end of the holding portion 8212 and allow a user to hold a portion between the on/off operating mechanism 840 and/or the power adjustment operating mechanism 850 and the water feeding operating mechanism 860 and/or the self-cleaning operating mechanism 870.

In the present disclosure, at least one of the on/off operating mechanism 840, the power regulating operating mechanism 850, the water feed operating mechanism 860, and the self-cleaning operating mechanism 870 is triggered by touching, pressing, or pushing.

In the present disclosure, the surface cleaning apparatus 800 further comprises:

a control device for receiving a control signal from at least one of the on/off operating mechanism 840, the power regulating operating mechanism 850, the water feed operating mechanism 860 and the self-cleaning operating mechanism 870 and controlling the surface cleaning apparatus 800 in accordance with the control signal.

In the present disclosure, when the surface cleaning apparatus 800 includes the power on/off operating mechanism 840 and the power adjustment operating mechanism 850, the power on/off operating mechanism 840 is located below the power adjustment operating mechanism 850.

Also, when the surface cleaning apparatus 800 includes a feed water operator 860 and a self-cleaning operator 870, the self-cleaning operator 870 is positioned above the feed water operator 860.

In the present disclosure, surface cleaning apparatus 800 includes a host 820, wherein handle 821 forms a portion of host 820.

More preferably, the surface cleaning apparatus 800 of the present disclosure comprises:

a cleaning assembly 810, the cleaning assembly 810 comprising a roller 813;

a main unit 820, wherein the main unit 820 is rotatably arranged on the cleaning assembly 810, and when the angle between the main unit 820 and the horizontal plane changes, the roller keeps contact with the surface to be cleaned;

when the included angle between the longitudinal axis of the main unit 820 and the horizontal plane is an acute angle, the projection of the center of gravity of the main unit 820 on the horizontal plane where the contact point of the roller 813 and the surface to be cleaned is located and the distance between the contact point of the roller 813 and the horizontal plane are a first distance D1, the projection of the center of gravity of the handle 821 on the horizontal plane where the contact point of the roller 813 and the surface to be cleaned is located and the distance between the contact point of the roller 813 and the horizontal plane are a second distance D2, and the first distance D1 is smaller than or equal to 1/2 of the second distance D2.

The handle is generally a part above the main body for a user to hold, and the user can control the movement of the main body in four directions, namely front, back, left and right directions by operating the handle. In some particular cases, the user may lift the host from the cleaning surface by lifting the handle.

The center of gravity of the handle generally refers to the point through which the resultant of the gravitational forces of all the component fulcrums passes when the handle is in any orientation. The gravity center of the handle with regular shape and uniform density is the geometric gravity center of the handle, and the gravity center of the handle with irregular shape and uniform density is usually positioned at a certain point in the outer contour range of the handle.

This surface cleaning equipment of disclosure, through the centrobaric linkage design to handle 821 and host computer, the pulling force that bears when using the user reduces, simultaneously, improves clear water tank 823 in clear water's utilization ratio and security to can prevent effectively that sewage from flowing backward.

In the present disclosure, preferably, the host 820 includes:

a waste tank 822 for storing waste water after the surface cleaning apparatus 800 cleans a surface to be cleaned; and

a clean water tank 823 for storing cleaning liquid before the surface cleaning apparatus 800 cleans a surface to be cleaned.

In one embodiment of the present disclosure, when the dirty water tank 822 does not store dirty water and the clean water tank 823 stores clean liquid, the first distance D1 is equal to or less than 1/2 of the second distance D2.

On the other hand, when the sewage tank 822 does not store sewage and the clean water tank 823 does not store cleaning liquid, the first distance D1 is equal to or less than 1/3 of the second distance D2.

As a more preferable implementation form, when the sewage tank 822 does not store sewage and the clean water tank 823 stores clean liquid, the first distance D1 is equal to or less than 1/3 of the second distance D2.

On the other hand, when the sewage tank 822 does not store sewage and the clean water tank 823 does not store cleaning liquid, the first distance D1 is equal to or less than 1/4 of the second distance D2.

In the present disclosure, the clean water tank 823 is also used to provide a cleaning liquid to the cleaning assembly 810 so that the cleaning assembly 810 uses the cleaning liquid to clean the surface to be cleaned.

Preferably, the host 820 further includes:

a body 824, wherein the rod part of the handle 821 is arranged on the body 824 through an extension rod 830;

the sewage tank 822 and the clean water tank 823 are disposed on the body 824, and when the body 824 is in a vertical state, the clean water tank 823 is located above the sewage tank 822.

In the present disclosure, in combination with the positions of the clean water tank 823 and the sewage tank 822, the first distance D1 is decreased when the sewage in the sewage tank 822 is increased, and/or when the clean liquid in the clean water tank 823 is decreased.

In this disclosure, the host 820 further includes:

a connection portion 825, a lower end of the connection portion 825 being rotatably connected to the cleaning assembly 810;

the body 824 is arranged at the connecting portion 825, and the clean water tank 823 is connected with the cleaning assembly 810 through a water pipe to provide cleaning liquid with a preset temperature for the cleaning assembly 810; that is, one end of the water pipe is connected to the clean water tank 823, and the other end of the water pipe may pass through the connection part 825 to be connected to the cleaning assembly 810.

Fig. 5 is a schematic structural view of a wastewater tank according to an embodiment of the present disclosure.

In the present disclosure, as shown in fig. 5, the waste water tank 822 includes:

a case 8221, wherein the case 8221 is disposed at the connection portion 825 and/or the body 824, an upper end of the case 8221 is open, and a suction hole is formed in a bottom wall of the case 8221;

a suction pipe 8222 disposed at the tank body 8221 such that an upper end of the suction pipe 8222 is spaced a predetermined distance from an upper end of the tank body 8221; the lower end of the suction pipe 8222 communicates with the suction hole of the tank 8221 so that the contaminated water sucked through the suction pipe 8222 is stored in the tank 8221.

Preferably, the upper end of the suction pipe 8222 is provided with a non-return valve to prevent sewage from the sewage tank 822 to enter the suction pipe 8222 through the non-return valve.

FIG. 6 is a schematic structural view of a surface cleaning apparatus according to another embodiment of the present disclosure.

Preferably, as shown in fig. 6, the holding portion 8212 and the clean water tank 823 are located on the same side of the rod portion 8211, and in turn, when the surface cleaning apparatus 800 is used, if the surface cleaning apparatus is tilted to one side of the clean water tank 823, the handle 821 can contact the surface to be cleaned first, and the possibility of damage to the clean water tank 823 and the liquid crystal panel disposed above the clean water tank 823 can be effectively reduced.

In this disclosure, the host 820 further includes:

a motor assembly 826, the motor assembly 826 being adapted to generate a negative pressure and to cause the suction tube 8222 to generate a negative pressure to suck in the contaminated water after cleaning the surface to be cleaned.

More preferably, the motor assembly 826 is disposed between the clean water tank 823 and the sewage tank 822.

Moreover, a filtering component can be arranged between the motor component 826 and the sewage tank 822, so that on one hand, the motor component is prevented from being carried out by solid pollutants through the filtering component, and on the other hand, the motor component is also prevented from being carried out by excessive water vapor through the filtering component.

In the present disclosure, the suction pipe 8222 is connected to the cleaning assembly 810 through a connection portion 825 to suck contaminated water after cleaning the surface to be cleaned into the contaminated water tank 822 after supplying the cleaning liquid to the cleaning assembly 810 through the clean water tank 823 and cleaning the surface to be cleaned by the cleaning liquid; that is, the inner cavity of the connection portion 825 is formed as a part of a pipe for pumping sewage into the sewage tank 822.

In this disclosure, the host 820 further includes:

a battery assembly 827 disposed at the body 824, the first distance D1 being changed by disposing the battery assembly 827 at different heights of the body 824.

In the present disclosure, the cleaning assembly 810 includes:

a cleaning part 811, and the clean water tank 823 supplies cleaning liquid to the cleaning part 811, and when the cleaning part 811 rotates, a surface to be cleaned is cleaned.

In the present disclosure, the cleaning assembly 810 further comprises:

a water collecting part 812 disposed at a downstream side of the cleaning part 811 for collecting contaminated water after cleaning a surface to be cleaned, and the water collecting part 812 communicates with a connection part 825 through a pipe to suck the contaminated water collected by the water collecting part 812 into a contaminated water tank 822 when a negative pressure is generated in the suction pipe 8222.

In the present disclosure, at least a portion of the water collecting portion 812 is in contact with the surface to be cleaned when the cleaning assembly 810 cleans the surface to be cleaned, so as to effectively collect the polluted water on the surface to be cleaned to the water collecting portion 812.

In this disclosure, the host 820 further includes:

a liquid connector 828, wherein the liquid connector 828 is communicated with the clean water tank 823 so as to provide cleaning liquid to the clean water tank 823 through the liquid connector 828 or draw out the cleaning liquid in the clean water tank 823 to the outside of the clean water tank 823.

More preferably, the host 820 further includes:

the charging connector 829 is connected to the battery pack 827, so that electric energy is supplied to the battery pack 827 through the charging connector 829.

In the present disclosure, when the water feed operation mechanism is operated, the addition of the cleaning liquid to the clean water tank is allowed; and/or allowing cleaning of a cleaning portion of the cleaning assembly when the self-cleaning operating mechanism is operated.

Preferably, the clean water tank supplies the cleaning liquid to the cleaning portion of the cleaning assembly when the cleaning portion of the cleaning assembly is cleaned.

In the present disclosure, the surface cleaning apparatus 800 is used in conjunction with a base station 100 and thus constitutes a surface cleaning system.

The base station 100 of the present disclosure is explained in detail below with reference to fig. 7 to 18.

In this case, the base station 100 includes:

a base 101, wherein the base 101 has a cavity structure, and a base air inlet part 1013 and a base air outlet part are formed on the base 101; and the number of the first and second groups,

the drying mechanism 109 is disposed in the cavity structure of the base 101, and the drying mechanism 109 heats the airflow entering through the base air inlet 1013 and outputs the heated airflow through the base air outlet.

Wherein the heated airflow output via the base air outlet portion can dry the cleaning portion of the surface cleaning apparatus resting on the base 101.

In the base station of the above embodiment, the base 101 preferably has a base main housing 1011 and a base upper housing 1012, and the base main housing 1011 and the base upper housing 1012 are detachably connected.

With the base station of each of the embodiments described above, it is preferable that the base 101 is provided with a positioning mechanism for positioning the surface cleaning apparatus resting on the base 101.

For the base station of each of the above embodiments, preferably, as shown in fig. 7, one end of the base 101 is formed with a protrusion 1014, and the base air outlet portion is provided on the protrusion 1014.

By providing the base air outlet on the raised portion 1014, the heated air stream can be blown onto the cleaning portion of the surface cleaning apparatus in a more favorable direction, fig. 7 shows the general shape of the raised portion 1014 of one embodiment of the present disclosure, which can be adjusted by one skilled in the art.

For the base station of each of the above embodiments, it is preferable that the protrusion 1014 is formed on the base main housing 1011, and the main housing air-out portion 1015 is formed on the protrusion 1014, and the main housing air-out portion 1015 serves as the base air-out portion.

As shown in fig. 10, since the main housing vent portion 1015 is disposed on the raised portion 1014, the main housing vent portion 1015 is disposed substantially toward the surface cleaning apparatus resting on the base 101.

For the base station of each of the above embodiments, it is preferable that the base station further includes a tray part 102, the housing groove is formed on the base upper housing 1012, the tray part 102 is disposed inside the housing groove of the base upper housing 1012, and the cleaning tank 112 is formed on the tray part 102.

Wherein the tray portion 102 may be as or considered part of the base 101.

As shown in fig. 10, the tray portion 102 is removably disposed within the receiving recess of the base upper housing 1012, and by providing the sink 112 on the tray portion 102, the cleaning portion of the surface cleaning apparatus can be at least partially placed within the sink 112 for draining when the surface cleaning apparatus is docked to the base station 100.

In the base station of each of the above embodiments, it is preferable that the upper surface of the base 101 has an inclination angle with respect to the horizontal plane, and the upper surface of the base 101 is inclined downward from the base air inlet part 1013 side to the base air outlet part side.

The person skilled in the art can set and adjust the tilt angle appropriately.

The upper surface of the base 101 may be constituted by a part of the upper surface of the base upper housing 1012 of the base 101 and a part of the upper surface of the tray portion 102 together, such as the structure of the base 101 shown in fig. 10.

The upper surface of the base 101 may be constituted by the upper surface of the tray portion 102, for example, the structure of the base 101 shown in fig. 14.

As shown in fig. 14, the degree of inclination of the upper surface of the base 101 may be achieved by the degree of inclination of the bearing section 1021 of the tray section 102, for example, by the upper surface of the bearing section 1021 being inclined with respect to a horizontal plane when the tray section 102 is mounted (non-horizontally mounted) on the base 101, that is, when the tray section 102 is placed on a horizontal plane, the upper surface of the bearing section 1021 is not inclined with respect to the horizontal plane, and when the tray section 102 is mounted on the base 101, the upper surface of the bearing section 1021 is inclined with respect to the horizontal plane, thereby achieving the inclination of the upper surface of the base 101.

According to another preferred embodiment of the present disclosure, the bearing portion 1021 of the tray part 102 includes an inclined surface, and in the present embodiment, by setting the upper surface of the bearing portion 1021 as an inclined surface, the above-described inclination of the upper surface of the base 101 is achieved by the inclined surface when the tray part 102 is horizontally mounted on the base 101.

As shown in fig. 7, by providing the upper surface of the base 101 with an inclined angle such that water dripping on the tray portion 102 flows toward the protrusion 1014 when the surface cleaning apparatus is parked at the base station 100, the water dripping on the tray portion 102 can flow toward the cleaning bath 112 of the tray portion 102 according to some embodiments of the present disclosure.

According to a preferred embodiment of the present disclosure, the base upper housing 1012 also has an oblique angle.

In the base station of each of the above embodiments, it is preferable that the base station further includes an air guiding portion 113, and the air guiding portion 113 guides the outlet air of the main casing outlet portion 1015, and guides the outlet air of the main casing outlet portion 1015 to the cleaning tank 112 of the tray portion 102.

By providing the air guide portion 113, the air outlet of the main housing air outlet portion 1015 is guided toward the cleaning tank 112 of the tray portion 102, so that the drying efficiency of the cleaning portion of the surface cleaning apparatus can be improved.

In the base station of each of the above embodiments, the air guide portion 113 preferably includes a plurality of air guide elements 1131, the air guide elements 1131 form an air outlet, and the air outlet of the air guide elements 1131 faces the washing tub 112.

As shown in fig. 11, the plurality of wind guide elements 1131 may be in the form of wind guide sleeves or wind guide pipes, and the wind discharged through the main housing air outlet portion 1015 is guided by the plurality of wind guide elements 1131, so that the wind discharged from the main housing air outlet portion 1015 is guided toward the cleaning tank 112 of the tray portion 102.

In the base station of each of the above embodiments, it is preferable that the air guide portion 113 is provided on the base main housing 1011, or the air guide portion 113 is formed integrally with the base main housing 1011.

In the base station according to each of the above embodiments, it is preferable that the air guide portion 113 is provided on the tray portion 102, or the air guide portion 113 is formed integrally with the tray portion 102.

For the base station of each of the above embodiments, preferably, the tray portion 102 and the base upper housing 1012 are detachably fixedly connected by a magnetic assembly.

As shown in fig. 11, the above-described wind guiding element 1131 forms a substantially downward air outlet, and the air flow passing through the air outlet can be guided to the cleaning tank 112 through a smooth transition portion between the air outlet and the cleaning tank 112. Specifically, in the present embodiment, the air guide element 1131 is provided with the first shielding member 11311, the first shielding member 11311 defines the air outlet as an air outlet facing substantially downward, and the first shielding member 11311 can prevent water droplets from splashing into the air outlet when the cleaning portion is self-cleaning. As shown in fig. 11, each air guiding element 1131 may have two air outlets, or may have three air outlets, each air outlet forms a first blocking piece 11311, and a person skilled in the art can adjust the number of the air outlets of each air guiding element 1131.

According to another preferred embodiment of the present disclosure, in order to improve the wind guiding efficiency, fig. 12 and 13 show another structure of the wind guiding portion 113, in this embodiment, a wind guiding plate 1133 is disposed on the whole of the wind guiding portion 113, a wind outlet is formed below the wind guiding plate 1133, and the wind guiding plate 1133 can enable the wind outlet to face the direction of the cleaning tank 112 or the cleaning portion, so that the airflow can be guided to the cleaning tank 112 or the cleaning portion and flow through the cleaning tank 112 or the cleaning portion.

In the air guide part 113 of the above embodiment, it is preferable that the air guide part 113 includes the adjustment part 1135, and the relative position (rotational position) of the air guide plate 1133 is adjustable by the adjustment part 1135, so that the airflow direction at the air outlet is adjustable.

For the air guiding portion 113 of the above embodiment, preferably, a blocking portion 1134 is disposed at a position close to the air outlet, and the cleaning portion prevents water from flowing into the air outlet during the self-cleaning or drying process to cause a safety hazard.

The air guide plate 1133 of each of the above embodiments may be an elongated plate or an elongated plate having a curved surface, and those skilled in the art can appropriately adjust the structure of the air guide plate 1133.

Preferably, the blocking portion 1134 of each of the above embodiments may also be an elongated plate having a length matched with the air guide plate 1133.

As shown in fig. 14, the tray section 102 is detachably fixedly connected to the base upper housing 1012 by a magnetic assembly, so that the tray section 102 is more easily detached and attached to the base upper housing 1012.

For the base station of each of the above embodiments, preferably, the magnetic assembly includes the magnetic part 114 and the iron block 115, and the magnetic part 114 and the iron block 115 are respectively disposed on the tray part 102 and the base upper housing 1012.

As shown in fig. 14, the number of the magnetic parts 114 may be one or two or more, the number of the iron blocks 115 may be one or two or more, preferably, the magnetic parts 114 and the iron blocks 115 have matching sizes, the magnetic parts 114 may be embedded into the tray part 102, the iron blocks 115 may be embedded into the base upper housing 1012, alternatively, the magnetic parts 114 may be provided on the base upper housing 1012, and the iron blocks 115 may be provided on the tray part 102, and a person skilled in the art may adjust the shapes, the numbers, and the like of the magnetic parts 114 and the iron blocks 115.

For the base station of each of the above embodiments, preferably, the positioning mechanism includes a main positioning portion 1081 and/or a sub-positioning portion 1082.

The primary alignment portion 1081 may be used to align the primary roller of a surface cleaning apparatus roller and the secondary alignment portion 1082 may align the secondary roller of a surface cleaning apparatus roller, it being understood by those skilled in the art that the number and shape of the primary alignment portion 1081 and the secondary alignment portion 1082 may be adjusted to accommodate a surface cleaning apparatus that is compatible with the base station 100, and that the alignment mechanism may include only the primary alignment portion 1081 or only the secondary alignment portion 1082.

For the base station of each of the above embodiments, it is preferable that the drying mechanism 109 has a cavity, the drying mechanism 109 has a drying mechanism air inlet and a drying mechanism air outlet 1093, a blower device 1094 and a heating body 1096 are disposed in the cavity of the drying mechanism 109, the heating body 1096 heats the air flow generated by the blower device 1094, and the heated air flow is output through the drying mechanism air outlet 1093.

The number of the fan devices 1094 may be one or more than two, two fan devices 1094 are shown in fig. 17, according to the embodiment of the present disclosure, a buffer layer or a cushion pad is further sleeved on the fan devices 1094, and the buffer layer or the cushion pad may be in the form of a fan sleeve to buffer the vibration of the fan devices 1094 in the working process; the heating body 1096 may have a suitable shape, and the present disclosure does not particularly limit the shape and size of the heating body 1096, and preferably, the heating body 1096 is elongated or cylindrical.

For the base station of each of the above embodiments, it is preferable that the drying mechanism 109 includes a drying mechanism lower housing 1091 and a drying mechanism upper housing 1092, and the drying mechanism lower housing 1091 and the drying mechanism upper housing 1092 together form a cavity structure of the drying mechanism 109.

For the base station of each of the above embodiments, preferably, the drying mechanism 109 further includes an airflow dispersing plate 1095, and the airflow dispersing plate 1095 disperses the airflow generated by the fan device 1094, so that the heater 1096 can sufficiently heat the dispersed airflow.

For the base station of each of the above embodiments, it is preferable that the airflow dispersion plate 1095 be provided between the fan device 1094 and the heating body 1096.

Preferably, the airflow dispersion plate 1095 is disposed closer to the fan device 1095.

For the base station of each of the above embodiments, it is preferable that the airflow dispersion plate 1095 is a V-shaped plate or a U-shaped plate, the airflow dispersion plate 1095 is formed in an opening shape, and the opening shape faces the heating body 1096.

For the base station of each of the above embodiments, it is preferable that the fan device 1094 is disposed adjacent to or within the air inlet of the drying mechanism.

For the base station of each of the above embodiments, it is preferable that the heater 1096 is fixed inside the cavity of the drying mechanism 109 by the heater fixing portion 1097.

For the base station of each of the above embodiments, it is preferable that the drying mechanism 109 further has a water-blocking portion 1099, and the water-blocking portion 1099 is disposed in the cavity of the drying mechanism 109 and between the heating body 1096 and the drying mechanism outlet 1093 of the drying mechanism 109.

For the base station of each of the above embodiments, it is preferable that the water blocking portion 1099 is in the form of a water bar, and is disposed in parallel with the heating body 1096, and the water blocking portion 1099 is disposed on the inner sidewall of the drying mechanism lower housing 1091.

In the base station of each of the above embodiments, it is preferable that a water storage portion or a water storage area is provided on an inner sidewall of the drying mechanism lower housing 1091, and the water storage portion or the water storage area is located on a side of the water blocking portion 1099 away from the heating body 1096.

As shown in fig. 16 and 17, a water retaining portion 1099 is provided between the water storage portion or the water storage area and the heating body 1096.

In the base station according to each of the above embodiments, it is preferable that a water level detector 1098 is provided in the water storage unit or the water storage area, and the water level detector 1098 generates a trigger signal when the water level in the water storage unit or the water storage area reaches a predetermined water level.

For example, when the surface cleaning apparatus is parked on the base 101 of the base station, since the cleaning portion of the surface cleaning apparatus may be in a dripping state, and the dripping water may enter the cavity of the drying mechanism 109 through the base air outlet portion of the base 101 and the drying mechanism air outlet 1093 of the drying mechanism 109, if the entering water is more, the electric component or other components in the cavity of the drying mechanism 109 may be damaged, by providing the water level detecting portion 1098, the detection of the water level in the water storage portion or the water storage area may be implemented, and when the water level reaches a preset alarm water level or warning water level, the water level detecting portion 1098 generates a trigger signal to remind, for example, by an optical signal or an acoustic signal.

In the base station according to each of the above embodiments, it is preferable that the base station stops the power supply to the drying mechanism based on the trigger signal generated by the water level detector 1098.

For the base station of each of the above embodiments, it is preferable that the water level detecting part 1098 includes the circuit board 10982 and at least two electrode parts 10981 provided on the same side of the circuit board 10982, and the electrode part 10981 has a predetermined distance from the water storage part or the lowest position of the water storage part.

Wherein the preset distance corresponds to the warning water level.

For the base station of each of the above embodiments, it is preferable that the number of the electrode portions 10981 is two and have the same length.

With the base station of each of the above embodiments, it is preferable that the water level detection part 1098 is supported within the water storage part or the water storage area by the support part 1090.

Wherein, the supporting portion 1090 can be in the form of a supporting column or a supporting frame.

For the base station of each of the above embodiments, it is preferable that a liquid storage tank 105 is further included, and the liquid storage tank 105 is used for storing cleaning liquid to supply the cleaning liquid to the surface cleaning apparatus parked at the base station.

For the base station of each of the above embodiments, it is preferable that the base station further includes a storage box 103, and the storage box 103 is configured to store sub-components of the surface cleaning apparatus.

Wherein, sub-components of the surface cleaning apparatus, such as the cleaning brush 801, the cleaning part 811, etc., may be provided with one or more holding structures within the housing box 103 for holding the cleaning brush 801, the cleaning part 811, etc.

For the base station of each of the above embodiments, it is preferable that the storage box 103 has a storage box door 1032, and the storage box door 1032 can be opened and closed.

For the base station of each of the above embodiments, it is preferable that the storage box 103 has the air blowing device 1033 and the storage box air vent part 1031, the air blowing device 1033 can blow air to the inside of the storage box 103 to dry/ventilate the inside of the storage box 103, and the air flow provided by the air blowing device 1033 is output through the storage box air vent part 1031.

With the base station of each of the above embodiments, it is preferable that the housing box air vent 1031 is provided at the top of the housing box 103.

Wherein, the storage box air vent 1031 may be a porous structure, and fig. 8 exemplarily shows a porous form of the storage box air vent 1031.

For the base station of each of the above embodiments, it is preferable that the air blowing device 1033 is provided inside the housing box 103.

For the base station of each of the above embodiments, it is preferable that a filter 1034 is provided inside the housing box 103, and the filter 1034 is used to filter the air flow inside the housing box 103.

Among them, hypa can be used as the filter 1034.

In the base station of the present disclosure, the surface cleaning device may be placed on the base 101 during operation of the surface cleaning device, the drying mechanism 109 is started, and the cleaning portion (e.g., the roller brush) of the surface cleaning device is preheated through the base air outlet portion of the base 101, or the above-described tray portion 102 may be removed, and the cleaning portion of the surface cleaning device may be directly placed on the base upper housing 1012 of the base 101 for preheating.

The base station of the present disclosure may further place the surface cleaning apparatus on the base 101 after the surface cleaning apparatus finishes working, start the drying mechanism 109, and dry the cleaning portion of the surface cleaning apparatus through the base air outlet portion of the base 101.

For the base station of each of the above embodiments, it is preferable that the base station further includes a supporting device 106, the supporting device 106 is disposed on the base 101, and the liquid storage tank 105 and the storage tank 103 are disposed on the supporting device 106.

Wherein the support means 106 may be in the form of a support frame or a support housing.

In fig. 7 to 10, the storage box 103 and the liquid storage box 105 are both cylindrical structures, and those skilled in the art may adjust the shapes of the storage box 103 and the liquid storage box 105.

The top of liquid reserve tank 105 can set up liquid reserve tank liquid feeding portion 1051, and liquid reserve tank liquid feeding portion 1051 can be the form of liquid feeding lid cooperation filling opening.

A handle part can be arranged on the liquid storage tank 105, and the liquid storage tank 105 is detachably connected with the supporting device 106.

Preferably, the base station 100 further has a connector portion 104, the connector portion 104 includes a charging/communication connector and a liquid connector, and the base station 100 further has a connector partition 1041, and the connector partition 1041 partitions the charging/communication connector and the liquid connector.

Through the charging/communication connector, the base station 100 is able to charge the surface cleaning apparatus and to interact with data or signals with the surface cleaning apparatus.

Through the liquid connection, the base station 100 can add liquid to the surface cleaning apparatus or recover the remaining liquid of the surface cleaning apparatus.

Preferably, the base station 100 further has a bidirectional pump device 111, a first pipeline, a second pipeline and a heating device 110, the bidirectional pump device 111 is connected between the liquid storage tank 105 and the first end of the first pipeline, the second end of the first pipeline is connected with the heating device 110, the heating device 110 is connected between the second end of the first pipeline and the first end of the second pipeline, and the second end of the second pipeline is connected with the liquid joint, so that the liquid in the liquid storage tank 105 is supplied to the surface cleaning equipment through the bidirectional pump device 111, the first pipeline, the heating device 110, the second pipeline and the liquid joint in sequence.

The base station 100 further comprises a control device 107, the control device 107 may be in the form of a control chip or a control circuit board, which may be arranged on the support device 106 or within the support device 106.

The control device 107 controls and/or supplies power to the blower device 1094, the heater 1096, the water level detector 1098, the heater 110, the blower device 1033, and the like of the drying mechanism 109.

In the present disclosure, the base station includes an in-place detection means for detecting whether the surface cleaning apparatus 800 is docked at the base station; when the presence detection means detects that the surface cleaning apparatus 800 is docked at a base station, the base station sends information detected by the presence detection means to the surface cleaning apparatus 800.

Fig. 19 is a schematic structural diagram of a method of controlling a surface cleaning apparatus of at least one embodiment of the present disclosure.

According to another aspect of the present disclosure, as shown in fig. 19, the present disclosure provides a method of controlling a surface cleaning apparatus, including:

s102, the surface cleaning equipment 800 detects whether the operating mechanism is triggered; and

s104, when the power on/off operating mechanism 840 is triggered for the first time, the surface cleaning device 800 is switched from the power off state to the power on state, and the surface to be cleaned is cleaned in a preset working mode until the power on/off operating mechanism 840 is triggered for the second time, and the surface cleaning device 800 is switched from the power on state to the power off state;

wherein, S106, when the surface cleaning apparatus 800 cleans the surface to be cleaned in the predetermined operation mode, the surface cleaning apparatus 800 detects whether the power adjustment operation mechanism 850 is triggered; when power adjustment operator 850 is triggered, the predetermined mode of operation is switched to the user-selected mode of operation.

In the present disclosure, it is contemplated that the operating mode cannot be changed when surface cleaning apparatus 800 is in a powered off state, and thus, surface cleaning apparatus 800 does not detect whether power adjustment operating mechanism 850 is triggered when surface cleaning apparatus 800 is in a powered off state.

In this disclosure, the predetermined operation mode is an automatic mode, a powerful mode or an energy saving mode, wherein the predetermined operation mode may be pre-stored in a control device of the surface cleaning apparatus, or may be preset by a user or a common operation mode of the surface cleaning apparatus.

In the present disclosure, when the surface cleaning apparatus 800 is switched from the on state to the off state, the motor that drives the cleaning portion 811 of the surface cleaning apparatus 800 to rotate and the water pump motor that supplies the cleaning liquid to the cleaning portion 811 are controlled to stop; and controls the motor assembly 826 of the surface cleaning apparatus 800 to stop after a predetermined time.

In this disclosure, the method of controlling a surface cleaning apparatus further includes: s202, when the self-cleaning operation mechanism 870 is triggered, S204, determining whether the surface cleaning apparatus 800 is docked at the base station, and S206, when the surface cleaning apparatus 800 is docked at the base station, self-cleaning the surface cleaning apparatus 800.

That is, in the present disclosure, when surface cleaning apparatus 800 is activating self-cleaning, surface cleaning apparatus 800 may be in either a powered-on state or a powered-off state. Wherein when surface cleaning apparatus 800 is in a powered off state and self-cleaning operating mechanism 870 is triggered, surface cleaning apparatus 800 is first brought to a powered on state and surface cleaning apparatus 800 is further brought to a self-cleaning state.

In the present disclosure, the self-cleaning of the surface cleaning apparatus 800 includes:

causing the base station to dry and/or sanitize the at least one cleaning portion of the surface cleaning apparatus.

For example, at least one cleaning portion of the surface cleaning apparatus is driven to rotate at a first speed and is applied with cleaning liquid, the at least one cleaning portion being applied with a suction treatment such that liquid flowing through the at least one cleaning portion is drawn into a sump within the surface cleaning apparatus; and the number of the first and second groups,

after the duration of the above steps reaches a preset time period, or when the liquid amount in the wastewater tank reaches a preset liquid amount, the at least one cleaning part stops being applied with the cleaning liquid and the at least one cleaning part stops being applied with the suction treatment, and the at least one cleaning part is driven to rotate at a second speed, which is lower than the first speed.

In the present disclosure, when the at least one cleaning portion of the surface cleaning apparatus is driven to rotate at the second speed, the drying mechanism of the base station is activated to provide hot dry air and/or a sterilizing gas such as ozone to the at least one cleaning portion of the surface cleaning apparatus.

Wherein a time period during which the cleaning part is rotated at the second speed and a time period during which the drying mechanism provides hot dry air may be set to be the same.

In this disclosure, the method of controlling a surface cleaning apparatus further includes: s302, when the water supply operation mechanism 860 is triggered, S304, judging whether the surface cleaning device 800 is parked at a base station, and when the surface cleaning device 800 is parked at the base station, judging whether the liquid level in a liquid storage tank of the base station is larger than or equal to a certain preset value; and determines whether the liquid level in the cleaning liquid supply portion of the surface cleaning apparatus 800 is less than or equal to a certain preset value; when the liquid level in the tank of the base station is greater than or equal to a predetermined value and the liquid level in the cleaning liquid supply of the surface cleaning apparatus 800 is less than or equal to a predetermined value, S306, add the cleaning liquid in the tank of the base station to the cleaning liquid supply of the surface cleaning apparatus 800.

More preferably, in the process of adding the cleaning liquid to the cleaning liquid supply portion of the surface cleaning apparatus 800, it is determined whether the liquid level in the cleaning liquid supply portion of the surface cleaning apparatus 800 is greater than or equal to a certain preset value S308, and when the liquid level in the cleaning liquid supply portion of the surface cleaning apparatus 800 is greater than or equal to a certain preset value S301, the addition of the cleaning liquid to the cleaning liquid supply portion of the surface cleaning apparatus 800 is stopped.

In the description herein, reference to the description of the terms "one embodiment/mode," "some embodiments/modes," "example," "specific example," or "some examples," etc., means that a particular feature, structure, material, or characteristic described in connection with the embodiment/mode or example is included in at least one embodiment/mode or example of the application. In this specification, the schematic representations of the terms used above are not necessarily intended to be the same embodiment/mode or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments/modes or examples. Furthermore, the various embodiments/aspects or examples and features of the various embodiments/aspects or examples described in this specification can be combined and combined by one skilled in the art without conflicting therewith.

Furthermore, the terms "first", "second" and "first" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance or implicitly indicating the number of technical features indicated. Thus, a feature defined as "first" or "second" may explicitly or implicitly include at least one such feature. In the description of the present application, "plurality" means at least two, e.g., two, three, etc., unless specifically limited otherwise.

It will be understood by those skilled in the art that the foregoing embodiments are merely for clarity of illustration of the disclosure and are not intended to limit the scope of the disclosure. Other variations or modifications may occur to those skilled in the art, based on the foregoing disclosure, and are still within the scope of the present disclosure.

Claims (10)

1. A surface cleaning apparatus, comprising:

a handle;

the handle is arranged on the machine body;

the power-on and power-off operating mechanism and/or the power adjusting operating mechanism are/is arranged on the handle and can be triggered by a user; and

the water supply operating mechanism is arranged on the handle, and the spacing distance between the water supply operating mechanism and the on-off operating mechanism and/or the power adjusting operating mechanism is larger than a preset value.

2. A surface cleaning apparatus as claimed in claim 1, further comprising:

the self-cleaning operating mechanism is arranged on the handle, and the spacing distance between the self-cleaning operating mechanism and the on-off operating mechanism and/or the power adjusting operating mechanism is larger than a preset value;

and/or, the handle comprises:

a grip portion that a user grips when the user operates the handle;

and/or the on-off operation mechanism and/or the power regulation operation mechanism are/is positioned at one end of the holding part, and the water supply operation mechanism and/or the self-cleaning operation mechanism are/is positioned at the other end of the holding part;

and/or, the handle further comprises:

when the rod part is in a vertical state, the upper end of the holding part is connected with the upper end of the rod part, so that the connecting part of the rod part and the holding part forms the top end of the handle;

and/or the water feeding operation mechanism and/or the self-cleaning operation mechanism are/is arranged at the top end of the handle or near the top end of the handle;

and/or the on-off operating mechanism and/or the power adjusting operating mechanism are/is arranged at the lower end of the holding part, and a user holds the part between the on-off operating mechanism and/or the power adjusting operating mechanism and the water feeding operating mechanism and/or the self-cleaning operating mechanism;

and/or at least one of the on-off operating mechanism, the power regulating operating mechanism, the water feeding operating mechanism and the self-cleaning operating mechanism is triggered by touch, press or push;

and/or, further comprising:

a control device for receiving a control signal from at least one of the power-on/off operating mechanism, the power-adjusting operating mechanism, the water-feeding operating mechanism, and the self-cleaning operating mechanism, and controlling the surface cleaning apparatus in accordance with the control signal;

and/or, when the surface cleaning apparatus comprises a power adjustment operating mechanism and a power on/off operating mechanism, the power adjustment operating mechanism is located below the power adjustment operating mechanism;

and/or, when the surface cleaning apparatus comprises a water feed operation mechanism and a self-cleaning operation mechanism, the self-cleaning operation mechanism is located above the water feed operation mechanism.

3. A surface cleaning apparatus as claimed in claim 1 or claim 2, further comprising:

a clean water tank for storing a cleaning liquid before the surface cleaning apparatus cleans a surface to be cleaned;

wherein when the feed water operation mechanism is operated, the addition of the cleaning liquid to the clean water tank is permitted;

and/or, further comprising:

a cleaning assembly for cleaning a surface to be cleaned;

wherein when the self-cleaning operation mechanism is operated, the cleaning part of the cleaning assembly is allowed to be cleaned;

and/or, when the cleaning portion of the cleaning assembly is cleaned, the clean water tank provides cleaning liquid to the cleaning portion of the cleaning assembly;

and/or, further comprising: a liquid connector in communication with the clean water tank to provide cleaning liquid to the clean water tank through the liquid connector or to draw out cleaning liquid in the clean water tank to an exterior of the clean water tank.

4. A method of controlling a surface cleaning apparatus, comprising:

the surface cleaning device detects whether the operating mechanism is triggered; and

when the power on/off operation mechanism is triggered for the first time, the surface cleaning equipment is switched from a power off state to a power on state, and the surface to be cleaned is cleaned in a preset working mode until the power on/off operation mechanism is triggered for the second time, and the surface cleaning equipment is switched from the power on state to the power off state;

wherein the surface cleaning apparatus detects whether the power adjustment operating mechanism is triggered when the surface cleaning apparatus cleans a surface to be cleaned in a predetermined operating mode; when the power adjustment operating mechanism is triggered, the predetermined operating mode is switched to the operating mode selected by the user.

5. The method of claim 4, wherein the surface cleaning apparatus does not detect whether the power adjustment actuator is activated when the surface cleaning apparatus is in a power off state;

and/or the preset working mode is an automatic mode, a powerful mode or an energy-saving mode;