CN113233166A - Material pushing and conveying device for various marine engine cylinder bodies - Google Patents

Material pushing and conveying device for various marine engine cylinder bodies Download PDFInfo

- Publication number

- CN113233166A CN113233166A CN202110525234.8A CN202110525234A CN113233166A CN 113233166 A CN113233166 A CN 113233166A CN 202110525234 A CN202110525234 A CN 202110525234A CN 113233166 A CN113233166 A CN 113233166A

- Authority

- CN

- China

- Prior art keywords

- translation

- roll table

- pushing

- material pushing

- marine engine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/74—Feeding, transfer, or discharging devices of particular kinds or types

- B65G47/82—Rotary or reciprocating members for direct action on articles or materials, e.g. pushers, rakes, shovels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G13/00—Roller-ways

- B65G13/02—Roller-ways having driven rollers

- B65G13/06—Roller driving means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G43/00—Control devices, e.g. for safety, warning or fault-correcting

- B65G43/08—Control devices operated by article or material being fed, conveyed or discharged

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F7/00—Lifting frames, e.g. for lifting vehicles; Platform lifts

- B66F7/02—Lifting frames, e.g. for lifting vehicles; Platform lifts with platforms suspended from ropes, cables, or chains or screws and movable along pillars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F7/00—Lifting frames, e.g. for lifting vehicles; Platform lifts

- B66F7/28—Constructional details, e.g. end stops, pivoting supporting members, sliding runners adjustable to load dimensions

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Structural Engineering (AREA)

- Automatic Assembly (AREA)

Abstract

The invention provides a material pushing and conveying device for various marine engine cylinder bodies, and belongs to the field of conveying devices. The problem of the inside work piece of current marine engine cylinder body cleaning station carry and translation lift transport difficulty is solved. It includes translation roll table frame, linear guide, pushing equipment, roll table mechanism and lifts the mechanism, the translation roll table frame sets up on linear guide, translation roll table frame links to each other with translation servo motor, moves along linear guide through translation servo motor drive translation roll table frame, set up pushing equipment and roll table mechanism on the translation roll table frame, pushing equipment links to each other with material pushing conveyer motor, roll table mechanism links to each other with roll table conveyer motor, it links to each other with roll table mechanism to lift the mechanism, drives roll table mechanism through lifting the mechanism and removes along vertical direction. The conveying device is mainly used for conveying workpieces.

Description

Technical Field

The invention belongs to the field of conveying devices, and particularly relates to a material pushing and conveying device for various marine engine cylinder bodies.

Background

The roll table is the equipment commonly used on the transfer chain, and when carrying material weight and volume great, the material has very big difficulty in the inside transport of cleaning station, because the organism of material and the required water volume of turbulent flow washing, the volume of organism and the sealed water pressure of organism needs corresponding increase when weight is great. When the machine body is conveyed inside the turbulent flow cleaning station, the sealing of the transmission part of the machine body is very difficult.

Disclosure of Invention

The invention provides a material pushing and conveying device for various marine engine cylinder bodies, which aims to solve the problems in the prior art.

In order to achieve the purpose, the invention adopts the following technical scheme: the utility model provides a material pushing and conveying device for multiple marine engine cylinder block, it includes translation roll rack, linear guide, pushing equipment, roller mechanism and lift mechanism, the translation roll rack sets up on linear guide, translation roll rack links to each other with translation servo motor, moves along linear guide through translation servo motor drive translation roll rack, set up pushing equipment and roller mechanism on the translation roll rack, pushing equipment links to each other with material pushing and conveying motor, roller mechanism links to each other with roller conveying motor, lift mechanism links to each other with roller mechanism, drive roller mechanism along vertical direction through lifting equipment and removing.

Furthermore, a material pushing detection switch is arranged on the material pushing mechanism.

Furthermore, a workpiece in-place detection switch is arranged on the translation roller bed frame.

Furthermore, the lifting mechanism comprises a lifting motor and a transmission chain, and the lifting motor is connected with the roller way mechanism through the transmission chain.

Furthermore, the lifting motor is arranged on the translation roller way frame, and a lifting detection switch is arranged on the translation roller way frame.

Furthermore, the translation servo motor is connected with the translation rack.

Furthermore, the pushing material conveying motor is connected with the pushing material mechanism through a chain.

Compared with the prior art, the invention has the beneficial effects that: the invention solves the problem that the conveying and the translation lifting conveying of the workpieces in the cleaning station of the existing marine engine cylinder body are difficult. An unpowered roller way is selected in the large-sized cylinder turbulent flow cleaning machine body, a transmission structure is omitted, and the material is conveyed by using an external translation, lifting and material pushing roller way. The conveying mode of the cylinder body is changed, and conveying of the workpieces in the cleaning station is achieved through the pushing and pulling modes. The roller way structure inside the cleaning machine body is changed into an unpowered roller way through the conveying of the structure to the workpiece, so that the problems of conveying of the workpiece in the cleaning station and sealing of the machine body are solved. And the conveying functions of horizontal translation, vertical lifting and the like of the workpiece are realized.

Drawings

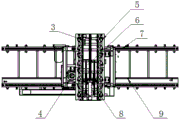

FIG. 1 is a schematic front view of a material pushing and conveying device for various marine engine cylinders according to the present invention;

FIG. 2 is a schematic cross-sectional view taken along line A-A of FIG. 1 in accordance with the present invention;

FIG. 3 is a schematic cross-sectional view taken along line B-B of FIG. 1 in accordance with the present invention;

the automatic pushing and feeding device comprises a 1-translation roller way frame, a 2-pushing conveying motor, a 3-pushing detection switch, a 4-translation servo motor, a 5-workpiece in-place detection switch, a 6-roller way conveying motor, a 7-linear guide rail, an 8-pushing mechanism, a 9-translation rack, a 10-lifting motor, an 11-lifting detection switch and a 12-roller way mechanism.

Detailed Description

The technical solution in the embodiments of the present invention will be clearly and completely explained below with reference to the drawings in the embodiments of the present invention.

The embodiment is described with reference to fig. 1-3, and the material pushing and conveying device for various marine engine cylinder blocks comprises a translation roller way frame 1, a linear guide rail 7, a material pushing mechanism 8, a roller way mechanism 12 and a lifting mechanism, wherein the translation roller way frame 1 is arranged on the linear guide rail 7, the translation roller way frame 1 is connected with a translation servo motor 4, the translation roller way frame 1 is driven by the translation servo motor 4 to move along the linear guide rail 7, the translation roller way frame 1 is provided with the material pushing mechanism 8 and the roller way mechanism 12, the material pushing mechanism 8 is connected with the material pushing and conveying motor 2, the roller way mechanism 12 is connected with the roller way conveying motor 6, the lifting mechanism is connected with the roller way mechanism 12, and the roller way mechanism 12 is driven by the lifting mechanism to move along the vertical direction.

This embodiment be provided with on the pushing equipment 8 and push away material detection switch 3, be provided with the work piece detection switch 5 that targets in place on translation roller rack 1, it includes lift motor 10 and drive chain to lift the mechanism, it links to each other with roller mechanism 12 through drive chain to lift motor 10, it sets up on translation roller rack 1 to lift motor 10, be provided with on translation roller rack 1 and lift detection switch 11, translation servo motor 4 links to each other with translation rack 9, material pushing and conveying motor 2 passes through the chain and links to each other with pushing equipment 8.

Materials are conveyed to the mechanism through a feeding roller way, a motor drives the roller shaft to rotate, and after the materials are stopped, a detection switch sends a signal, and the roller way conveying motor 6 stops; the translation servo motor 4 is started, the workpiece is conveyed to a corresponding station position according to a program, and the translation servo motor 4 stops after the workpiece is conveyed to the position; the lifting motor 10 is started, the rotating chain is driven by the driving shaft to realize the lifting and descending functions of the workpiece, the workpiece is adjusted to the corresponding feeding height of the station, and the lifting detection switch 11 has a signal after the workpiece is in place; the roller way conveying motor 6 rotates to convey the workpiece to a material pushing position, the material pushing detection switch 3 has a signal, the material pushing cylinder extends out to connect the workpiece with the material pushing mechanism 8, and the material pushing conveying motor 2 is started to drive the material pushing mechanism 8 to push out or pull out the workpiece through a chain.

The present invention provides a material pushing and conveying device for various marine engine cylinder blocks, which is described in detail above, and the principle and the implementation of the present invention are explained in the present document by applying specific examples, and the description of the above examples is only used to help understanding the method of the present invention and the core idea thereof; meanwhile, for a person skilled in the art, according to the idea of the present invention, there may be variations in the specific embodiments and the application scope, and in summary, the content of the present specification should not be construed as a limitation to the present invention.

Claims (7)

1. A push away material conveyor that is used for multiple marine engine cylinder block which characterized in that: it includes translation roll table frame (1), linear guide (7), pushing equipment (8), roller mechanism (12) and lifts the mechanism, translation roll table frame (1) sets up on linear guide (7), translation roll table frame (1) links to each other with translation servo motor (4), moves along linear guide (7) through translation servo motor (4) drive translation roll table frame (1), set up pushing equipment (8) and roller mechanism (12) on translation roll table frame (1), pushing equipment (8) link to each other with material pushing conveyor motor (2), roller mechanism (12) link to each other with roller conveyor motor (6), it links to each other with roller mechanism (12) to lift the mechanism, removes along vertical direction through lifting mechanism drive roller mechanism (12).

2. A material pushing and conveying device for various marine engine blocks according to claim 1, characterized in that: and the material pushing mechanism (8) is provided with a material pushing detection switch (3).

3. A material pushing and conveying device for various marine engine blocks according to claim 1, characterized in that: and a workpiece in-place detection switch (5) is arranged on the translation roller way frame (1).

4. A material pushing and conveying device for various marine engine blocks according to claim 1, characterized in that: the lifting mechanism comprises a lifting motor (10) and a transmission chain, and the lifting motor (10) is connected with the roller way mechanism (12) through the transmission chain.

5. A push material delivery device for marine engine blocks according to claim 4, wherein: the lifting motor (10) is arranged on the translation roller way frame (1), and a lifting detection switch (11) is arranged on the translation roller way frame (1).

6. A material pushing and conveying device for various marine engine blocks according to claim 1, characterized in that: and the translation servo motor (4) is connected with the translation rack (9).

7. A material pushing and conveying device for various marine engine blocks according to claim 1, characterized in that: the pushing material conveying motor (2) is connected with the pushing material mechanism (8) through a chain.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110525234.8A CN113233166A (en) | 2021-05-13 | 2021-05-13 | Material pushing and conveying device for various marine engine cylinder bodies |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110525234.8A CN113233166A (en) | 2021-05-13 | 2021-05-13 | Material pushing and conveying device for various marine engine cylinder bodies |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113233166A true CN113233166A (en) | 2021-08-10 |

Family

ID=77134232

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110525234.8A Pending CN113233166A (en) | 2021-05-13 | 2021-05-13 | Material pushing and conveying device for various marine engine cylinder bodies |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113233166A (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004284704A (en) * | 2003-03-20 | 2004-10-14 | Daifuku Co Ltd | Article conveyance device |

| CN103754543A (en) * | 2014-01-28 | 2014-04-30 | 中国联合工程公司 | Piano type stacker device |

| US9327952B1 (en) * | 2011-11-10 | 2016-05-03 | Amazon Technologies, Inc. | Cart for moving items |

| CN106586354A (en) * | 2016-11-01 | 2017-04-26 | 南京理工大学 | Storage and fetching device used for heavy stacker |

| CN107954171A (en) * | 2017-12-12 | 2018-04-24 | 湖州银轴智能装备有限公司 | Change electric transport system |

| CN208898121U (en) * | 2018-10-09 | 2019-05-24 | 长春知和智能包装设备有限公司 | Shifting apparatus for stacking machine |

| CN209635163U (en) * | 2018-09-28 | 2019-11-15 | 浙江今跃机械科技开发有限公司 | A kind of pipeline equipped with pusher |

| CN112429453A (en) * | 2020-12-07 | 2021-03-02 | 昆船智能技术股份有限公司 | Heavy-load stacker |

-

2021

- 2021-05-13 CN CN202110525234.8A patent/CN113233166A/en active Pending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004284704A (en) * | 2003-03-20 | 2004-10-14 | Daifuku Co Ltd | Article conveyance device |

| US9327952B1 (en) * | 2011-11-10 | 2016-05-03 | Amazon Technologies, Inc. | Cart for moving items |

| CN103754543A (en) * | 2014-01-28 | 2014-04-30 | 中国联合工程公司 | Piano type stacker device |

| CN106586354A (en) * | 2016-11-01 | 2017-04-26 | 南京理工大学 | Storage and fetching device used for heavy stacker |

| CN107954171A (en) * | 2017-12-12 | 2018-04-24 | 湖州银轴智能装备有限公司 | Change electric transport system |

| CN209635163U (en) * | 2018-09-28 | 2019-11-15 | 浙江今跃机械科技开发有限公司 | A kind of pipeline equipped with pusher |

| CN208898121U (en) * | 2018-10-09 | 2019-05-24 | 长春知和智能包装设备有限公司 | Shifting apparatus for stacking machine |

| CN112429453A (en) * | 2020-12-07 | 2021-03-02 | 昆船智能技术股份有限公司 | Heavy-load stacker |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112224884B (en) | Vertical overturning and conveying device for glass substrates | |

| CN104944139A (en) | Jacking transfer-machine | |

| CN201941239U (en) | Automatic thermoprinting machine | |

| CN211619318U (en) | Automatic loading and unloading device | |

| CN113233166A (en) | Material pushing and conveying device for various marine engine cylinder bodies | |

| CN210553557U (en) | Drying mode of automatic printing machine and conveying device thereof | |

| CN209937153U (en) | Automatic plate feeding device for hot press | |

| CN207329634U (en) | A kind of dedicated roller conveyor of carpenter | |

| CN217747782U (en) | Metal workpiece surface coating device | |

| CN108946084A (en) | A kind of glass turnover device | |

| CN212193646U (en) | Automatic rubber plug beating equipment for tubular piles | |

| CN215176956U (en) | Automatic snatch device of lithium cell material sagger | |

| CN214989743U (en) | Steel mould hoist and mount transfer device for road construction | |

| CN208916187U (en) | A kind of glass turnover device | |

| CN211970631U (en) | Rotating mechanism for door plate conveying | |

| CN115783419A (en) | Automatic case sealer of water activity sticky tape | |

| CN212018307U (en) | Automatic feeding device in spraying production line | |

| CN208731342U (en) | Automatic pot carrying machine suitable for azlocillin sodium for injection production | |

| CN210025672U (en) | Full-automatic grouting production equipment for insulating bricks | |

| CN113135405A (en) | Panel material loading platform with automated inspection specification | |

| CN208166544U (en) | HuoXiangZhengQiShui empty bottle reversing mechanism | |

| CN210312206U (en) | Triaxial translation handling device | |

| CN216324057U (en) | Automatic transfer mechanism of part box | |

| CN216735922U (en) | Jacking transfer machine | |

| CN219030633U (en) | Right-angle transfer mechanism for material frame |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20210810 |

|

| RJ01 | Rejection of invention patent application after publication |