CN1131676C - Electric smoking system for delivering flavors and methods for making same - Google Patents

Electric smoking system for delivering flavors and methods for making same Download PDFInfo

- Publication number

- CN1131676C CN1131676C CN94102530A CN94102530A CN1131676C CN 1131676 C CN1131676 C CN 1131676C CN 94102530 A CN94102530 A CN 94102530A CN 94102530 A CN94102530 A CN 94102530A CN 1131676 C CN1131676 C CN 1131676C

- Authority

- CN

- China

- Prior art keywords

- cigarette

- proposed

- heating member

- filter

- carrying pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000000391 smoking effect Effects 0.000 title claims abstract description 109

- 239000000796 flavoring agent Substances 0.000 title claims description 56

- 235000019634 flavors Nutrition 0.000 title claims description 56

- 238000000034 method Methods 0.000 title description 21

- 235000019504 cigarettes Nutrition 0.000 claims abstract description 505

- 238000010438 heat treatment Methods 0.000 claims abstract description 330

- 241000208125 Nicotiana Species 0.000 claims abstract description 124

- 235000002637 Nicotiana tabacum Nutrition 0.000 claims abstract description 124

- 238000005485 electric heating Methods 0.000 claims abstract description 21

- 239000000463 material Substances 0.000 claims description 91

- 238000001914 filtration Methods 0.000 claims description 45

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 claims description 28

- 230000004888 barrier function Effects 0.000 claims description 26

- 239000000758 substrate Substances 0.000 claims description 19

- 239000011148 porous material Substances 0.000 claims description 17

- 229920000049 Carbon (fiber) Polymers 0.000 claims description 13

- 239000004917 carbon fiber Substances 0.000 claims description 13

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims description 13

- 230000008859 change Effects 0.000 claims description 12

- 239000002002 slurry Substances 0.000 claims description 11

- 239000012535 impurity Substances 0.000 claims description 9

- 235000007164 Oryza sativa Nutrition 0.000 claims description 8

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims description 8

- 235000009566 rice Nutrition 0.000 claims description 8

- 229910052710 silicon Inorganic materials 0.000 claims description 8

- 239000010703 silicon Substances 0.000 claims description 8

- 239000000835 fiber Substances 0.000 claims description 7

- 238000009940 knitting Methods 0.000 claims description 7

- 238000001035 drying Methods 0.000 claims description 6

- 239000004065 semiconductor Substances 0.000 claims description 6

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims description 3

- 239000011574 phosphorus Substances 0.000 claims description 3

- 229910052698 phosphorus Inorganic materials 0.000 claims description 3

- 238000005507 spraying Methods 0.000 claims description 2

- 231100000749 chronicity Toxicity 0.000 claims 6

- 240000007594 Oryza sativa Species 0.000 claims 2

- 239000006260 foam Substances 0.000 claims 1

- 230000001737 promoting effect Effects 0.000 claims 1

- 235000019505 tobacco product Nutrition 0.000 claims 1

- 210000000689 upper leg Anatomy 0.000 claims 1

- 239000000779 smoke Substances 0.000 abstract description 6

- 239000003205 fragrance Substances 0.000 abstract description 3

- 239000000126 substance Substances 0.000 abstract description 2

- 230000002776 aggregation Effects 0.000 abstract 1

- 238000004220 aggregation Methods 0.000 abstract 1

- 125000003118 aryl group Chemical group 0.000 abstract 1

- 230000000717 retained effect Effects 0.000 abstract 1

- 230000000875 corresponding effect Effects 0.000 description 26

- 230000003287 optical effect Effects 0.000 description 26

- 230000005669 field effect Effects 0.000 description 16

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 14

- 229910052799 carbon Inorganic materials 0.000 description 14

- 229910052751 metal Inorganic materials 0.000 description 13

- 239000002184 metal Substances 0.000 description 13

- 230000000712 assembly Effects 0.000 description 11

- 238000000429 assembly Methods 0.000 description 11

- 238000004519 manufacturing process Methods 0.000 description 11

- 230000004044 response Effects 0.000 description 11

- 239000000853 adhesive Substances 0.000 description 10

- 230000001070 adhesive effect Effects 0.000 description 10

- 239000011248 coating agent Substances 0.000 description 10

- 238000000576 coating method Methods 0.000 description 10

- 235000013599 spices Nutrition 0.000 description 10

- 238000012545 processing Methods 0.000 description 9

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 8

- 230000008901 benefit Effects 0.000 description 7

- 230000015572 biosynthetic process Effects 0.000 description 7

- 238000005520 cutting process Methods 0.000 description 7

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 6

- 241000209094 Oryza Species 0.000 description 6

- 230000001965 increasing effect Effects 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 229910045601 alloy Inorganic materials 0.000 description 5

- 239000000956 alloy Substances 0.000 description 5

- 238000005452 bending Methods 0.000 description 5

- 230000005611 electricity Effects 0.000 description 5

- 238000005516 engineering process Methods 0.000 description 5

- 238000002156 mixing Methods 0.000 description 5

- 238000003466 welding Methods 0.000 description 5

- 239000000080 wetting agent Substances 0.000 description 5

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 4

- 230000000903 blocking effect Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 238000010304 firing Methods 0.000 description 4

- 229910052742 iron Inorganic materials 0.000 description 4

- 238000003698 laser cutting Methods 0.000 description 4

- 238000003754 machining Methods 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 101710089042 Demethyl-4-deoxygadusol synthase Proteins 0.000 description 3

- 239000004411 aluminium Substances 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 230000009286 beneficial effect Effects 0.000 description 3

- 238000004891 communication Methods 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000000284 extract Substances 0.000 description 3

- 239000000416 hydrocolloid Substances 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 239000002304 perfume Substances 0.000 description 3

- 230000035882 stress Effects 0.000 description 3

- 229910000601 superalloy Inorganic materials 0.000 description 3

- 230000007704 transition Effects 0.000 description 3

- 229910000951 Aluminide Inorganic materials 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 2

- 241000208202 Linaceae Species 0.000 description 2

- 235000004431 Linum usitatissimum Nutrition 0.000 description 2

- OJIJEKBXJYRIBZ-UHFFFAOYSA-N cadmium nickel Chemical compound [Ni].[Cd] OJIJEKBXJYRIBZ-UHFFFAOYSA-N 0.000 description 2

- 239000011195 cermet Substances 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000011651 chromium Substances 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 239000003500 flue dust Substances 0.000 description 2

- 239000011737 fluorine Substances 0.000 description 2

- 229910052731 fluorine Inorganic materials 0.000 description 2

- 235000011187 glycerol Nutrition 0.000 description 2

- 206010022000 influenza Diseases 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 230000002045 lasting effect Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 238000012856 packing Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000002035 prolonged effect Effects 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 238000004080 punching Methods 0.000 description 2

- 230000002441 reversible effect Effects 0.000 description 2

- 239000000523 sample Substances 0.000 description 2

- 238000004513 sizing Methods 0.000 description 2

- PYMYPHUHKUWMLA-UHFFFAOYSA-N 2,3,4,5-tetrahydroxypentanal Chemical compound OCC(O)C(O)C(O)C=O PYMYPHUHKUWMLA-UHFFFAOYSA-N 0.000 description 1

- KRKNYBCHXYNGOX-UHFFFAOYSA-K Citrate Chemical compound [O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O KRKNYBCHXYNGOX-UHFFFAOYSA-K 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- 235000014676 Phragmites communis Nutrition 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 239000005030 aluminium foil Substances 0.000 description 1

- 230000003064 anti-oxidating effect Effects 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 238000003763 carbonization Methods 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 230000001413 cellular effect Effects 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 238000003486 chemical etching Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 235000019506 cigar Nutrition 0.000 description 1

- 229940040387 citrus pectin Drugs 0.000 description 1

- 239000009194 citrus pectin Substances 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 238000005538 encapsulation Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 239000002223 garnet Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000011031 large-scale manufacturing process Methods 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 150000002736 metal compounds Chemical class 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 229910052752 metalloid Inorganic materials 0.000 description 1

- 150000002738 metalloids Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 235000010987 pectin Nutrition 0.000 description 1

- 229920001277 pectin Polymers 0.000 description 1

- 239000001814 pectin Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- ULWHHBHJGPPBCO-UHFFFAOYSA-N propane-1,1-diol Chemical class CCC(O)O ULWHHBHJGPPBCO-UHFFFAOYSA-N 0.000 description 1

- 230000010349 pulsation Effects 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 230000011514 reflex Effects 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000012163 sequencing technique Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 238000000967 suction filtration Methods 0.000 description 1

- 230000009182 swimming Effects 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 230000007306 turnover Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/40—Constructional details, e.g. connection of cartridges and battery parts

- A24F40/46—Shape or structure of electric heating means

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D1/00—Cigars; Cigarettes

- A24D1/20—Cigarettes specially adapted for simulated smoking devices

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/20—Devices using solid inhalable precursors

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/70—Manufacture

Landscapes

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

Abstract

In a smoking system of the present invention, an exchangeable cigarette containing tobacco aromatic substances is arranged in a set of electric heating pieces in a cigarette lighter for releasing vapor or smog type tobacco fragrance or other components which are supplied to a smoker. The cigarette and the lighter of the present invention can provide various airflow types passing through the smoking system, and air flows into the cigarette in the transverse direction. The flow types improve the supply of the smog and the fragrance for the smoker, and the aggregation of the vapor or the smog retained in a heating piece zone in the smoke system is reduced.

Description

The present invention relates to the cigarette smoking system and the cigarette that constitute by cigarette and lighter.

We United States Patent (USP) N.5, disclosed a kind of electric smoking article in 060,671, this patent is classified reference as at this.The smoking article that this patent disclosed has one group of disposable electric heating part.The medium with tobacco flavor that contains such as tobacco or the material that extract from tobacco all is housed on each electric heating part.Disposable heater/combinations of perfumes is received such as the such power supply that electric energy is provided of battery or capacitor with according to the smoker and is aspirated this smoking article or push on the control circuit that hand switch drives heating member.Control circuit is designed to each suction and makes one but be not whole heating member startup work at least, and making has certain number of share of stock, the per share material with tobacco flavor (response that for example contains the smog of tobacco flavor or distribute tobacco flavor) that contains some to send the smoker to.Control circuit can prevent that also any one heating member from starting once more, thereby has avoided the tobacco spice above the excessive heat.

Use such article, heater will be thrown away after using up remaining tobacco material.In addition, be electrically connected the plug repeatedly that to stand continuous replacing spices assembly between heater and the battery.

At subsequent application No.08/012 that propose, that now proposed by on February 2nd, 1993 in our 11 days March in 1991, the 799 relevant unsettled U.S. Patent No.s 07/666 that replaced, in 926, disclosed a kind of electric smoking article, it has the part of one a group of reusable heating member and a disposable generation tobacco flavor.This disposable use partly comprises a spices section and a fillter section that couples together with bag end paper or other fixed structure.Yet owing to used reusable heating member, this article some problems that worked together, particularly residual flue dust can accumulate on the heating member and some other long-term structural member that uses of this article.

The objective of the invention is to make problem set forth above to improve.

A kind of embodiment cigarette smoking system of the present invention comprises cigarette and lighter, and its advantage is that the transmission of cigarette improves.The heating member that a kind of advantage that embodies cigarette smoking system of the present invention is a lighter is reusable, makes the volume of disposable use part drop to minimum.

A kind of advantage that embodies system of the present invention is to make flue dust gathering on the heating member of lighter and other member significantly reduce.

A kind of advantage that embodies smoking article of the present invention and manufacture method thereof be easy to manufacture, cost is low, even can produce with the large-scale production speed of modern technologies.

Various embodiments of the present invention can also have the smog of making and fragrance sends the improved advantage of smoker to.

According to the preferred embodiment that embodies one aspect of the invention, provide a kind of and tobacco flavor has been sent to the cigarette that uses in smoker's the cigarette smoking system what contain heater.This cigarette comprises a carrying pipe, and this carrying pipe has at separated first end and second end of making progress that continue, and also has first surface and second surface.First surface has surrounded a chamber between first end and second end, second surface comprises the zone that can be close to heater.Material with tobacco flavor is configured on the first surface of carrying pipe.This cigarette perfumery matter produces tobacco flavor and sends the smoker in the chamber when being subjected to the heater heating.Carrying pipe and cigarette perfumery matter can allow crossflow to enter in the chamber.

Preferred embodiment according to embodying another aspect of the present invention provides a kind of lighter that is used with replaceable cigarette in the cigarette smoking system of tobacco flavor being given the smoker.This lighter comprises that first termination by it receives the heater of a replaceable cigarette.Certain part that this heater has at least to replaceable cigarette provides cross-flow device.One group of electric heating part is housed in heater.Each heating member all has a surface that can abut on the cigarette by crossflow on that part of.The device that drives one or several electric heating part in this group electric heating part also is housed in the lighter, makes in cigarette, to produce the predetermined tobacco flavor of one size.Crossflow produces when the smoker aspirates cigarette in lighter.

Preferred embodiment according to embodying third aspect present invention provides a kind of cigarette smoking system that tobacco flavor is sent to the smoker.This system drives electric heating part work one by one, makes to produce the predetermined tobacco flavor of one size in the chamber of cigarette.

Preferred embodiment according to embodying fourth aspect present invention provides a kind of and tobacco flavor has been sent to the heating member that uses in smoker's the cigarette smoking system.This heating member comprise one first end, second end and one group between first and second ends, be used for increasing the buckled zone of heating member resistance.Heating member is made with resistance material, has first and second surfaces of general arrangement in a plane.Its total length is L, and gross weight is W, and thickness is T.Effective electrical length of heating member is greater than L, and the effective electric sectional area of heating member is then less than the product of W and T.

Preferred embodiment according to embodying fifth aspect present invention provides a kind of in the manufacture method that tobacco flavor is sent to the integrated heating component that uses in smoker's the cigarette smoking system.

According to the method, a slice resistive material is cut into one group of at least at one end interconnective heating member.This sheet material is rolled into a drum.

Illustrate some embodiment that embody various aspects of the present invention below in conjunction with accompanying drawing.In these accompanying drawings:

Fig. 1 is for embodying the perspective schematic view of a cigarette smoking system of the present invention;

Fig. 2 is the perspective schematic view of the partly cut-away of an embodiment cigarette smoking system of the present invention;

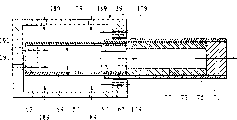

Fig. 3 A is for embodying the side sectional view of a heater of the present invention;

Fig. 3 B can cut open the end-view of getting for the 3B-3B along Fig. 3 A;

Fig. 4 A is for embodying the perspective schematic view of a cigarette of the present invention;

Fig. 4 B cuts open the sectional view of getting for the 4B-4B along Fig. 4 A;

Fig. 5 is for embodying the schematic assembled view of a heater of the present invention;

Fig. 6 is for embodying the perspective view of a heating component of the present invention;

Fig. 7 is for embodying the expansion outline drawing of a heating component of the present invention;

Fig. 8 is for embodying the fragmentary, perspective view of a heating member of the present invention;

Fig. 9 is for embodying the perspective view of a lead assemblies of the present invention;

Figure 10 A is for embodying the side schematic sectional view of a lining of the present invention;

Figure 10 B cuts open the explanatory view of getting for the 10B-10B along Figure 10 A;

Figure 10 C cuts open the explanatory view of getting for the 10C-10C along Figure 10 A;

Figure 11 A is for embodying the side schematic sectional view of a pedestal of the present invention;

Figure 11 B cuts open the explanatory view of getting for the 11B-11B along Figure 11 A;

Figure 11 C is for to cut open the explanatory view of getting along Figure 11 C-11C;

Figure 12 A is for embodying the perspective schematic view of a lining substrate combination member of the present invention;

Figure 12 B cuts open the side schematic sectional view of getting for the 12B-12B along Figure 12 A;

Figure 12 C cuts open the explanatory view of getting for the 12C-12C along Figure 12 A;

Figure 12 D cuts open the explanatory view of getting for the 12D-12D along Figure 12 A;

Figure 13 is the end-view of a ring in the one embodiment of the invention;

Figure 14 A is the perspective schematic view of an end cap in the one embodiment of the invention;

Figure 14 B can cut open the side schematic sectional view of getting for the 14B-14B along Figure 14 A;

Figure 14 C cuts open the explanatory view of getting for the 14C-14C along Figure 14 A;

Figure 14 D cuts open the explanatory view of getting for the 14D-14D along Figure 14 A;

Figure 15 A is for embodying the schematic side elevation of a heating jacket of the present invention;

Figure 15 B cuts open the end-view of getting for the 15B-15B along Figure 15 A;

Figure 16 and 17 is the schematic side elevation of the some parts of a cigarette smoking system, shows the path of air-flow in this cigarette smoking system;

Figure 18 illustrates the electrical schematic diagram that embodies circuit configuration of the present invention;

Figure 19 is for embodying the side schematic sectional view of another cigarette smoking system of the present invention;

Figure 20 is for embodying the side schematic sectional view of another heater of the present invention;

Figure 21 is the perspective schematic view of the equipment of the part of the disposable cigarette of manufacturing Figure 19 cigarette smoking system;

Figure 22 is for embodying a schematic cross sectional views that periphery aspirates embodiment of cigarette smoking system of the present invention;

Figure 23 illustrates the electrical schematic diagram that embodies another kind of circuit configuration of the present invention; And

Figure 24 is the electrical schematic diagram of a timing network of control circuit among Figure 23.

Fig. 1 and 2 shows a kind of cigarette smoking system 21 that comprises a cigarette 23 and a repeatedly used lighter 25 of the present invention.Cigarette can insert the aperture 27 of lighter 25 front ends 29 and 27 take off from the aperture.Cigarette smoking system 21 resembles usual cigarette very much on occupation mode.Cigarette 23 is thrown away having inhaled once or several times, and lighter is then just thrown away after having inhaled quite a lot of cigarettes.

Lighter 25 with casing 31 has front portion 33 and rear portion 35.Power supply 37 into the heating member power supply of heating cigarette 23 is housed in the rear portion 35 of lighter 25.Preferably can opening and close easily by the device such as screw or spring are buckled in rear portion 35, is beneficial to change power supply.The heating member and the circuit arrangement that are electrically connected with power supplys 37 in the rear portion 35 forwardly are housed in 33.Anterior 33 by cooperating and can be inserted into easily on the rear portion 35 such as dovetail joint or female type.The hard heat proof material of casing 31 usefulness is made, and as metal base material, more recommendable is the polymeric substrates material.Casing 31 is made the shape that can cosily be held in smoker's hand, and overall size is 1.5 centimetres of 10.7 cm x, 3.8 cm x.

A certain size power supply 37 provides enough power for the heating member of heating cigarette 23.Power supply 37 is preferably replaceable and chargeable, can contain the device an of electric capacity or a battery and so on.In the preferred embodiment of being introduced, power supply is that an open-circuit voltage is approximately 4.8 volts to 5.6 volts replaceable rechargeable battery (be actually with four nickel-cadmium cells and be in series).Yet the characteristic of power supply 37 will be selected with the situation of other device, particularly heating member of 21 according to smoking system.U.S. Patent No. 5,144,962 have introduced several power supplys that can be used for cigarette smoking system of the present invention, for example rechargeable battery formula power supply and with the repid discharge condenser type electric capacity of battery charge.Therefore this patent is in this row referenced patent.

A heating cigarette 23 is housed in the front portion 33 of lighter, makes cigarette be clipped in columnar heater 39 on the lighter 25 and one control circuit 41 that can send each heating member the heater (not shown in Fig. 1 and 2) surely to from power supply 37.In this preferred embodiment of being introduced, heater 39 comprises 8 radially divided heating members 43, as shown in Figure 3A.These heating members obtain the power supply of power supply 37 one by one under the control of circuit 41,8 zones round cigarette 23 peripheries are heated, so that produce 8 strands of tobacco flavors.Though the number of heating member 43 can not be 8, preferably 8, because nominal has 8 strands on the cigarette of a routine, and 8 heating members are fit to carry out electric control with binary device.

An indicator 51 is housed on the outer surface of lighter 25, preferably is contained on anterior 33, be used to refer to the also surplus several strands of cigarettes of the cigarette 23 that inserts in the lighter and do not have suction.Indicator 51 comprises 7 sections LCDs.In this preferred embodiment, when optical sensor 53 (see figure 2)s detect light beam that it sends from new cigarette 23 front end reflex times that insert, indicator 51 just demonstrates numeral " 8 ".Optical sensor 53 is installed in the lining 49 and the opening 55 in the pedestal 50 of heater 39, as shown in Figure 3A.Optical sensor 53 provides signal to circuit 41, and circuit 41 is added to signal on the indicator 51.Indicator 51 shows on every cigarette 23 of numeral " 8 " expression has 8 strands of cigarettes to inhale, and that is to say, goes back neither one in these heating members 43 and once starts this new cigarette of heating.After cigarette 23 all sucked, indicator 51 showed digital " 0 ".When cigarette 23 when lighter 25 takes off, optical sensor 53 detects less than cigarette 23, indicator 51 is turned off.Optical sensor 23 is adjusted to the state that is not always to send light beam, to reduce the loss of unnecessary power supply 37.The preferred light sensor 51 that is applicable to cigarette smoking system 21 is OPR5005 type optical sensors, by Ao Puteke technology company (OPTEK Technology, Inc., 1215 West Crosby Road, Carrollton, Texas75006) manufacturing.

Above-mentioned optical sensor 53 also can replacing with other form.A mechanical switch (not shown) for example can be installed detect whether cigarette 23 is arranged, a SR (not shown) can be installed, when a new cigarette inserts lighter 25, circuit 41 be resetted, for example make indicator 51 show numeral " 8 ", or the like.The power supply, circuit, puff sensor and the indicator that are applicable to cigarette smoking system 21 of the present invention have introduction in the U.S. Patent No. 5,060,671 of classifying reference as.Passage 47 in lining 49 and heater pedestal 50 and opening 55 are preferably airtight during smoking.

Fig. 4 A and 4B at length show the used preferred cigarette 23 of a cigarette smoking system 21, though this cigarette also can be other desired form, send the smoker to as long as can produce tobacco flavor when heated object 43 heating.Cigarette 23 comprises tobacco volume 57, contain by carrying tobacco cigarette perfumery matter 61 the carrying pipe or send smoke pipe 59 to constitute.Tobacco is rolled up 57 1 ends and wraps on the columniform back airflow filtering device 63, and the other end wraps on the columnar first free stream filter 65.The first free stream filter 65 is tubular filters, and there is a vertical passage 67 in central authorities, and is therefore very little to draw resistance, the air-flow freedom.

Need volume one deck cigarette paper 69 on tobacco volume 57.Can draw together low quantitatively (Unit Weight) paper as the paper bag of cigarette paper 69, preferably have the paper of tobacco spice coating or contain the paper of tobacco, distribute the tobacco flavor of tobacco flavor response with enhancing.The concentrated extracting solution that on cigarette paper 69, can coat concentrated extracting solution or be diluted.Cigarette paper 69 preferably quantitatively hangs down the paper of thin thickness, but enough hot strengths will be arranged, so that machine processing processing.The paper that contains tobacco preferably has following characteristic: quantitatively at 20-25 gram/rice

2Between (relative humidity is 60%), minimum air penetrability is Ke 0-25 Leicester (CORESTA be defined as in pressure difference is 1.0 kPas of next minutes by one square centimeter of material (as paper) be the air capacity of unit with the cubic centimetre), hot strength equals 2000 grams for being wider than for 27 millimeters (1 inches), thickness is the 1.3-1.5 mil, calcium carbonate content is smaller or equal to 5%, and citrate is 0%.The material that is used for making cigarette paper 69 preferably includes the tobacco-containing sheet (mixed fillers of non-cigar type, liquid or liquid gas-solidization and clean stem) more than or equal to 75%.Can add some flax fibers, but amount is exceeded with the hot strength that can be met requirement.Cigarette paper 69 also can be quantitatively to be 15-20 gram/rice

2Common flax fiber paper or have this paper of extract coating.Can add some citrus pectin type adhesives, its amount is not more than 1%.Also can add some glycerine, its amount Ying Yineng obtains the such rigidity of common cigarette paper and exceeds.

The internal diameter of the vertical passage 77 of the best second free stream filter 73 is greater than the internal diameter of the vertical passage 67 of the first free stream filter 65.The internal diameter of vertical passage is preferably between 1 to 4 millimeter, and the internal diameter of vertical passage 77 is preferably between 2 to 6 millimeters.Have found that, passage 67 and 77 internal diameter differences help having cigarette perfumery matter and forming desirable the mixing and mixed flow between the inhaled air during the smog that produces and the smoking outside cigarette 23 in heating, the response of distributing tobacco flavor is improved, and the end of filter 71 can be exposed among the mixing smog more.Heating cigarette perfumery matter and the response of distributing tobacco flavor that produces mainly is vapour phase in chamber 79, and in passage 77 owing to immixture is converted into visible smog.The first free stream filter 65 also can adopt other tobacco flavor that can make gas phase and the air of introducing to produce desirable structure of mixing except adopting the above-mentioned structure that has a vertical passage 67.For example, the first free stream filter can be made a filter form with a large amount of apertures, that is to say that the first free stream filter can be cellular or have the metal plate-like in a series of holes.

The best overwhelming majority of air is that horizontal (radially) is by tobacco volume 57 and cigarette paper 69 rather than vertical by in the back airflow filtering device 63 suction cigarettes 23.Yet as following will the explanation, the airflow filtering device enters after wishing to allow air communication during first strand of cigarette on the smoking volume, can reduce the resistance to suction like this.Be appreciated that vertically air being sucked cigarette 23 can cause and can not make owing to enclose heating member 43 heating tobaccos volumes, 57 smog that produce 79 discharges from the chamber effectively that tobacco is rolled up 57 radial arrangement.It is desirable for the tobacco flavor that is produced now and almost completely depend on the constituent of tobacco volume 57 and the energy of heating member 43.Therefore, except first strand of cigarette, vertically the smaller the better during smoking by that part of air-flow of back airflow filtering device 63.In addition, back airflow filtering device 63 can make the smog stream of exhaust chamber 79 backward for minimum after cigarette perfumery matter 61 obtains heating, to reduce the possibility that the smog that flows out backward from cigarette damages lighter 25 devices.

The carrying pipe of carrying cigarette perfumery matter 61 or send smoke pipe 59 that heating member 43 and cigarette perfumery matter 61 are separated conducts the heat that heating member produced to cigarette perfumery matter 61, and makes that the cigarette of inhaling is unlikely to scatter.The carrying pipe of being recommended 59 comprises non-those carrying pipes of knitting system carbon fiber bed course formation that hot property is stable.The relevant unsettled U.S. Patent application No.07/943 that proposed on September 11st, 1992 same assignee of these carrying pipes has detailed discussion in 747.This patent is classified reference as at this.The best thickness of these bed courses between 0.05 millimeter to 0.11 millimeter, is made up of the non-system carbon fiber of knitting greatly, and it is quantitatively greatly about 6 gram/rice, 2 to 12 gram/rice

2Between, and fibre diameter is greatly between 7 microns to 30 microns.The length of fiber should guarantee that bed course stands suffered tensile stress during the processing.Best, bed course should contain the adhesive that is applicable to electric smoking article (promptly have subjectivity and can accept character).

Other carrying pipe 59 comprises low-quality net metal sieve or multicellular metal foil.For example, can service property (quality) be approximately 5 gram/rice

2To 15 gram/rice

2, line directly is approximately 0.038 millimeter (1.5 mil) metallic screen to 0.076 millimeter (3.0 mil).Another embodiment be thick with a slice be that the metal forming (as aluminium foil) of 0.0064 millimeter (about 0.25 mil) constitutes the carrying pipe, dashing above has a series of diameters to be about 0.3 millimeter to 0.5 millimeter hole, makes that the quality of metal forming is corresponding to reduce 30% to 50%.Best, (promptly not alinement) arranged in the staggered or discontinuous arrangement in the hole on the metal forming, to reduce to leave the lateral heat conduction of cigarette perfumery matter 61.

This metalloid sieve and metal forming can be incorporated in the cigarette 23 by different way.For example: the slurries that (1) will have a tobacco flavor are coated in and will sieve before doing on the band or paper tinsel is stacked on the wet slurries, and (2) will sieve with suitable binding agent or paper tinsel adheres on the substrate or bed course with tobacco flavor.Because the electrical short that uses metal carrying pipe can cause heating member 43 itself to reach between each heating member, this metal carrying pipe does not directly contact with heating member usually.Therefore in the occasion of using metal carrying pipe, be stained with such as the such low weight paper of cigarette paper 69, so that metal carrying pipe 59 insulate with electric heating part 43 in that metal carrying pipe is outer with suitable adhesive.

The tobacco volume of now being recommended 57 is to adopt papermaking process to make.In this technical process, at first water washes tobacco rods.Use in the DDGS last coating operation afterwards.(extraction) baccy fiber that is left is used for constituting base wad.Carbon fiber is dispersed in the water, adds mosanom.Also can add any other hydrocolloid and replace mosanom, as long as this hydrocolloid does not disturb the effect of distributing tobacco flavor, water soluble, and have suitable molecular weight to increase the intensity of tobacco volume 57.Disperse thing to mix this with the slurries and the available spices of the baccy fiber that is extracted.Resulting mixture soak is divided on the fourdrinier wire,, just form a base wad by the remainder of traditional paper machine.The most handy reverse roller coat device that is configured in behind a cylinder that is the Yang Ji drier will wash the side that DDGS that tobacco rods sweeps away is coated in base wad.The ratio of DDGS of tobacco and tobacco particles is preferably between 1: 1 to 20: 1.Slurries also can water or be extruded on the base wad.Perhaps, last coating operation off line is carried out.During the last coating or after, add in the cigarette industry spices commonly used.Add pectin or other hydrocolloid, amount is between 0.1% to 2.0%, to improve the coating character of slurries.

No matter adopt which kind of carrying pipe 59, the cigarette perfumery matter 61 that is configured on this carrying pipe internal surface is wanted to be attached on the surface of carrying pipe, emits tobacco flavor being subjected to heating.These materials comprise in the form of sheets, foamed, gelatinous, also can be the slurries of drying or the spraying slurries of drying.Though these materials not necessarily but the material that preferably contains tobacco or extract from tobacco, this is at U.S. Patent application No.07/943 cited above, more detailed discussion is arranged in 747.

Best, during handling, add such as glycerine or the such wetting agent of propane diols in the tobacco volume 57, its amount is 0.5% to 10% of tobacco volume weight.Wetting agent helps forming visible smog owing to play a part the smog parent.When smoker's ejection contained the smog of tobacco flavor and wetting agent, wetting agent condensed in atmosphere, and the wetting agent of cohesion has just formed the smog of common cigarette.

Because cigarette perfumery matter 61 of the present invention is configured in the surface of carrying pipe 59, therefore can specially change the characteristic of the smoke of sending, make each burst smoke type all have nothing in common with each other.For example, the cigarette perfumery matter 61 of contiguous first heating member 43 can contain first kind of spices, and the cigarette perfumery matter 61 amounts second kind spices all different with type of contiguous second heating member.Therefore, by incomparable inconsistent cigarette perfumery matter is configured in the carrying tube-surface, can make the smoker be drawn onto different smokes selectively.For example, the smoker can locate the long-term relatively heating member that uses of disposable cigarette 23 when cigarette is inserted lighter 25 as required, and like this, a specific heating member just can heat a predetermined portions of the fragrant material of non-consistent cigarette.

In addition, according to the present invention, can be by providing controlled energy to change tobacco flavor selectively to heating member 43.For example, if the energy (as 20 joules) that offers heating member 43 on first greater than the energy that offers second heating member 43 (as 1.5 joules), the temperature that first heating member reached generally will be higher than second temperature that heating member reached so.Therefore, first heating member generally produces than the bigger tobacco flavor of second heating member.Like this, the energy that sends each strand to by change just can be controlled the size of tobacco flavor selectively.

When cigarette 23 inserts in the aperture 27 of lighter 25 front ends 29, cigarette 23 just in abutting connection with or the end inner face 81 of lining 49 in the heater 39 almost, with the passage 47 that communicates with smoking driving sensor 45 and that the opening 55 of optical sensor 53 is installed is adjacent, as shown in Figure 3A.On this position, heating member 43 is close in the chamber 79 of cigarette 23, and second free stream filter 73 of cigarette and filter 71 parts are all stayed outside the lighter 25, each heating member 43 all some footpath is inwardly inclined to one side, in order to cigarette 23 relative lighter 25 are remained on the appropriate location, make heating member directly or by cigarette paper 69 heat to be passed to tobacco volume 57.Therefore, cigarette 23 preferably can push, so that make heating member 43 can compress into the side of cigarette.

Air-flow by cigarette 23 has several modes.For example, in the embodiment of the cigarette shown in Fig. 4 A and the 4B 23, cigarette paper 69 and tobacco volume 57 all are fully ventilative, so that obtain desired draw resistance, make that air horizontal (radially) is by cigarette paper and tobacco volume inflow chamber 79 when the smoker aspirates cigarette.As previously mentioned, Tou Qi back airflow filtering device 69 can be used for making the vertical inflow chamber 79 of air.

Necessary, can on the zone of one or several adjacent cavities 79, open a series of pore (not shown) that penetrate cigarette paper 69 and tobacco volume 57, be beneficial to crossflow and enter chamber 79.Have been found that these pores can improve the response of distributing tobacco flavor and the formation of smog.The density that penetrates the pore of tobacco volume 57 is approximately per 1 to 2 square millimeter 1, and the diameter of each pore is between 0.4 millimeter to 0.7 millimeter, and corresponding Ke Leicester (CORESTA) porosity is between 100 to 500.The air penetrability of cigarette paper 69 is preferably between 100 to 1000 Ke Leicesters.Certainly, desirable in order to obtain such as the such smoking characteristic of draw resistance, also can be with being different from above-described stomatal frequency and relevant hole diameter.

Both pore (not shown) of tobacco volume 57 that also can be by penetrating cigarette paper 69 improve the situation that crossflow enters chamber 79.When this cigarette 23 with this class pore of processing, can earlier cigarette paper 69 and tobacco volume 57 be sticked together punching again, stick together again after also can punching respectively, make the superimposed aligning of each pore.

Fig. 3 A and 3B show a preferred embodiment of heater 39.Fig. 5 shows the view sub-anatomy of the embodiment of a modified heater 39A, and this heater 39A has the member 49A of a combination lining and pedestal.The member 49A of heater 39A has replaced the lining 49 and the pedestal 50 of the heater 39 shown in Fig. 3 A.It is the common function that Fig. 3 A-3B or heater shown in Figure 5 all have to be provided the space that holds cigarette 23 and the heating member 43 of heating cigarette 23 is provided.

By Fig. 3 A and 3B as seen, heater 39 is configured in the aperture 27 of lighter 25.Cigarette 23 enters in the space that is column substantially of heater 39 from the aperture 27 that back airflow filtering device 63 begins to insert lighter 25.Heater 39 comprises: the annular block 83 with openend of admitting cigarette; an available tubular heating member protective sleeve 85; a tubular air flue cover 87; a heating component 89 that comprises some heating members 43; a conductive pin or a common lead assembly 91, and lining 49 as the common lead of each heating member of heating component.The end inner face 81 of lining 49 blocks cigarette 23 in heating device 39 and on the appropriate location, makes heating member 43 be close to the chamber 79 in the cigarette.In heater 38A shown in Figure 5, the end inner face 81A of member 49A blocks cigarette 23 in heater 39A on the appropriate location.

Whole heater 39 is configured in inside basically, by fastening in place with casing 31 tight fits of lighter 25 front portions 33.The front end 29 that the leading edge 93 of block 83 is configured in lighter 25 perhaps stretches out slightly, and an interior chamfering or rounded portion are preferably arranged, and is beneficial to guide cigarette 23 to insert heater 39.Each heating member 43 of heating component 89 and pin assemblies 91 respectively sell 95 all corresponding site is fastened on the outer surface 97 of lining 49 by frictional fit by ring 99 around.The tail end 103 of the tail end 101 of each heating member 43 and two pin 95 is soldered to respectively and blocks on the corresponding pin 104 on the pedestal 50, and these pins 104 stretch out the outer bottom 105 (seeing Fig. 3 B) of pedestal 50 by each hole 107 of pedestal 50, receive on circuit 41 and the power supply 37.Pin 104 should very closely be stuck on the pedestal 50, makes air unlikely by hole 107 inflows.Pin 104 can insert corresponding socket (not shown), makes heating member 39 supported in lighter 25.Receive on the various components from lead or printed circuit cable that socket is drawn.Two other pin 95 provides additional support, and the intensity of pin assemblies 91 is strengthened to some extent.Passage 47 in lining 49 and the pedestal 50 leads to suction driving sensor 45 and detects the optical sensor 53 that whether is inserted with cigarette 23 in the lighter 25.

Similar, in heater 39A shown in Figure 5, the pin assemblies 91 of each heating member 43 of heating component 89 respectively sell 95 all corresponding site is fastened on the outer surface 97A of member 49A by frictional fit by ring 99 around.The tail end 103 of the tail end 101 of each heating member 43 and two pins 95 stretches out the outer bottom 105A of member 49A, so that receive on circuit 41 and the power supply 37.

In profile sheet 11 5, each heating member 43 connects together at the afterbody 117 of tail end 101 by cutting profile sheet 115 mutually, at front end 119 by forming heating component 89 front portions 121 that part of connecting together.Two sidepieces 123 are between afterbody 117 and anterior 121.Though afterbody 117 and sidepiece 123 will cut at last, help during the processing profile sheet 115 being handled.

After having formed profile sheet 115, each heating member 43 all has wide 125 of will be attached to after on the tobacco volume 57 and narrow 127 of will be connected with circuit 41.Need, narrow 127 of each heating member 43 is having lug boss 129 near tail end 101 places, so that be electrically connected with circuit 41 with pin 104 welding or insertion socket (not shown).Summary profile sheet 115 is handled again, had better use laser cutting, at wide 125 snakelike " track " 131 that forms shown in Fig. 6 and 8.Certainly, need, when forming profile sheet 115, just can cut out track 131.

The sheet that cuts is electropolishing in addition preferably, makes the edge slyness of each heating member 43 smooth.The edge slyness of heating member 43 makes cigarette 23 can insert lighter 25 easily, can not hindered.The sheet that cuts twists in a type frame (not shown), forms tubular.Cut rear portion 117 and sidepiece 123, two edges 133 of anterior 121 are welded together, just formed the heating component 89 of an integral body as shown in Figure 6.

The various embodiment of lighter 25 of the present invention are designed to and can send tobacco flavor to smoker effectively under the service condition of standard.Specifically, wish 8 strands of cigarettes with 5 to 13 millimeters, preferably 7 to 10 millimeters smog sends the smoker to, and per share cigarette continues 2 seconds, 35 milliliters.Have been found that in order to reach this purpose heating member 43 should can reach about 200 ℃ to 900 ℃ in that heat is passed under cigarette 23 situations.In addition, heating member 43 should consume about 5 to 40 joules energy, and preferably about 10 to 25 joules, more recommendable is about about 15 joules.If heating member 43 requires lower energy, survey heating member 43 and should more bend towards cigarette 23, to improve thermally conductive relation.

Effective surface area with heating member 43 of the characteristic that requires is approximately 3 square millimeters to 25 square millimeters, and resistance is in Europe, about 0.5 Europe to 3.0.More recommendable is that the resistance of heating member 43 is between Europe, about 0.8 Europe to 2.1.Certainly, heating member resistance also depends on the concrete power supply that is used to provide the essential electric energy of heater 43.For example, it is each embodiment that is supplied with by the nickel-cadmium cell (the open circuit total voltage is 4.8 volts to 5.8 volts) of four serial connections that the heating member resistance that more than exemplifies is suitable for electric energy.Perhaps, if with six or eight batteries of serial connection like this, the resistance of heating member 43 should should be Europe, 3 Europe to 5 or Europe, 5 Europe to 7 mutually so.

Making the material of heating member 43 should be selected, and guarantees reliably repeat switch at least 1800 times and does not break down.Heater 39 preferably can be separated disposal from the lighter 25 that comprises power supply 37 and circuit 41 separately, and lighter 25 preferably can remarket behind the switch more than 3600 times.The heating member material also will be selected according to non-oxidizability and difficult reactivity, not oxidized and unlikelyly reacts with cigarette 23 under the temperature that may run into guaranteeing.Need, oxidation and reaction are further avoided in inertia Heat Conduction Material encapsulation that can heating member 43 usefulness such as suitable ceramic material is such.

According to these criterions, the material of electric heater unit comprises doped semiconductor (as silicon), carbon, stainless steel, titanium, cermet material and the metal alloy such as the alloy of nickeliferous, chromium and iron.Mixing with amount is 5 * 10

18Impurity/centimetre

3To 5 * 10

19Impurity/centimetre

3The resistivity of the silicon semiconductor material of phosphorus impurities should be about 1 * 10 mutually

-2Europe is centimetre to 1 * 10

-3Europe centimetre.This material is correlated with certainly U.S. Patent application No.07/943 row commonly-assigned us for referencial use, has in 505 illustrated.Suitable cermet material comprises 131 carbonization sial and silicon carbide titaniums.Such as the aluminide of nickel and the such anti-oxidation metal compound of aluminide of iron also is suitable material.

Recommendable is to make electric heating part 43 with the heat-resisting alloy with high mechanical properties and high temperature resistance surface degradation.Best, with having high strength and under up to fusing point 80 percent left and right sides temperature, keeping the material of surface-stable to make heating member 43.Some alloys comprise those alloys that are commonly referred to superalloy like this, generally based on nickel, iron or cobalt.Best, the superalloy of making heating member 43 contains aluminium, with the further performance (as non-oxidizability) of improving heating member.A kind of material is this 214 alloy of extra large sodium, can (Haynes International, Inc.of Kokomo Indiana) obtains from Hai Nasi international corporation.It is about 75% nickel, about 16% chromium, about 4.5% aluminium and about 3% iron that this high-temperature material contains weight.

As mentioned above, each heating member 43 of heating component 89 comprises snakelike 131 by one group of interconnective bending (S-shaped substantially) district formation, to increase the effective resistance of each heating member.Snakelike 131 of heating member 43 increased resistance and do not increased the total length of heating member or reduce the cross-sectional width of heating member.Have resistance and be approximately the heating member 43 that Europe, 0.5 Europe to 3, snakelike 131 length is fit to be installed in heater 39 shown in Fig. 3 A and heater 39A shown in Figure 5 N interconnective S shape district preferably arranged, wherein N is approximately 3 to 12, and preferably about 6 to 10.

If snakelike 131 of heating member shown in Figure 8 at first is wide 125 the shape of cutting as shown in Figure 7, make that the width of wide portion is that W1, length are that L1 and thickness are T, then an end 125 of portion ' to the opposite end 125 leniently " resistance be

Wherein p is the resistivity of employed material.After forming snakelike 131, because effective electrical length of heating member 43 increases and cross-sectional area reduces, therefore the resistance of snakelike portion has just increased.For example, after having formed snakelike 131 on the heating member 43, electric current just passes through heating member along path P.Compare with initial electrical length L1, effective electrical length of path P is approximately 9 or 10 and multiply by W1 (for the snakelike district that 5 complete S shape turnovers are arranged).In addition, cross-sectional area is reduced to W2T from W1T.According to the present invention, owing to resistance is proportional to electrical length and is inversely proportional to sectional area, so the all-in resistance increase that reduces all can make heating member 43 of the increase of electrical length and sectional area.

Therefore, in heating member 43, form snakelike 131 and make and on the given area of heating surface (for example for square millimeter to 25 square millimeter), to provide predetermined resistance with the conductive material of smaller size smaller.This feature of the present invention has following three advantages at least.

The first, for certain resistance, constitute heating member 43 with rectangular sheet, its length is longer.Therefore adopt snakelike 131 can make than compact heater 39 and lighter 25 with lower one-tenth is original.

Second, owing in still air, a heating member 43 being heated to the required energy of given operating temperature and along with the increase of the quality of this heating member increases, therefore the capacity usage ratio of snakelike heating member is higher, can provide desired resistance with smaller volume.For example, if the volume of heating member 43 reduces one times, then quality also reduces one times.Like this owing in still air, a heating member 43 is heated to the required energy of given operating temperature and roughly is directly proportional with the quality and the thermal capacity of this heating member, so volume reduce one times just institute's energy requirement reduce one times.This makes heating member 43 have high energy utilization rate.

Less the 3rd advantage of snakelike heating member 43 volumes is relevant with the response time of heating member.Response time be defined as the given energy input of 43 pairs one of a given heating member respond make it temperature from first temperature change to the required time of the second higher temperature.Because the response time of a heating member 43 generally is directly proportional with its volume, therefore can expect a heating member that volume is less, its response time is also shorter.Like this, snakelike heating member 43 is except compact and capacity usage ratio is higher, and it is also very fast to be heated to operating temperature.These characteristics of the present invention provide a more efficiently heating member 43.

Therefore,, just can increase the resistance of heating member by on heating member 43, forming one group tortuous (as serpentine pattern) back and forth, and the sectional area that does not need to increase the length of heating member or reduce heating member.Certainly, also can adopt the pattern that is different from heating member shown in Figure 8 43, be applied in the principle that is embodied in this structure compactness, effective heating member are provided.

Of course, with any suitable method, for example use laser (CO preferably

2Laser), on heating member 43, cut out snakelike 131.Because the physical dimension very little (for example, the furrow width B among Fig. 8 is roughly 0.1 millimeter to 0.25 millimeter magnitude) of snakelike heating member 43, it is more more desirable than other processing method to form snakelike 131 laser cutting for cutting.Because in laser energy is fit to concentrate among a small circle, so laser energy helps general, quick, accurate and automation processing.In addition, compare with other cutting method (as the discharge cutting), Laser Processing had both reduced the inducedstress that produces on the material being cut, and had also reduced the degree that material is influenced by heat (being the amount of oxidized material).Other method of share has discharge cutting, precision stamping, chemical attack and chemical etching etc.Also can form snakelike 131 with the embossing method of routine.Yet, be appreciated that this method is few of attraction for serpentine pattern at least owing to die wear.

Except cut out snakelike heating member 43 with laser, also available laser (preferably yttrium-aluminium-garnet (YAG) laser) links together each device of lighter effectively.For example, heating component 89 and pin assemblies 91 the most handy CO

2Or the YAG laser spot welding together.In addition, the tail end 101 of heating member 43 or lug boss 129 preferably also are laser-welded on the wiring pin 104 or suitable circuit devcie or socket of pedestal 50.Certainly, also can link together with various conventional methods of attachment each device with lighter.

According to the present invention, greatly reduce the possibility that in heating member 43, produces the thermally induced stress damage.As shown in Figure 6, be soldered to the tail end 101 (or lug boss 129) on pin 104 or other circuit or the device and produce hot single-piece heating member 43 of snakelike 131 formation, therefore just need not snakelike of separating is welded together with the end.Have found that such welding can cause producing harmful deformation between the period of heating at heating member.The longitudinal centre line of end 101 or lug boss 129 is preferably aimed at snakelike 131 center line.Find that also the center line misalignment also can produce deformation at heating member between the period of heating.In addition, snakelike 131 two opposite ends 131 ' with 131 are " preferably with the non-snakelike portion of symmetric mode (being that each point is on identical direction) junction heating member 43.Opposite end 131 ' and 131 " symmetry this two ends that can prevent snakelike 131 reverse to two opposite directions between the period of heating at heating member and damage snakelike portion.At snakelike 131 two ends, be in corresponding transition region 137 between non-snakelike of heating member 43 and the end ' and 137 " fall bevel, as shown in Figure 6.The transition region 137 ' 137 that is appreciated that down bevel " has also reduced thermally induced stress.

For fear of outside distortion, each heating member 43 of heating component 89 is all made aduncate shape, as shown in Figure 3A.Curve inwardly and help guaranteeing that heating member 43 and cigarette 23 be close to and good thermo-contact.The interior bending shape of heating member 43 can be realized in many ways.For example, as shown in Figure 6 cartridge heater is put into one have desired in the type frame (not shown) of bending shape be shaped.Best, before heating component 89 is made tubular, heating member 43 is struck out aduncate shape.Heating member 43 aduncate shapes make heating member during heating curve inwardly more owing to extend.This bending is corresponding mild whole snakelike 131 length range planted agent.The transition region 137 of chamfering ' and 137 " can bend than trickleer snakelike 131 severe.The position that the ratio that so just can avoid thermal stress to concentrate on heating member 43 is easier to damage.

Need, can add a ring (not shown) round snakelike 131 of each heating member 43.This ring plays a part a radiator.When snakelike 131 of heating member 43 extended owing to heating, snakelike 131 just was forced to inwardly towards cigarette 23 bendings.

Except that above-mentioned heating component 89, the heater 39 shown in Fig. 3 A also comprises lining 49 and heater pedestal 50.Shown in Figure 10 A-10C, lining 49 has a columniform outer surface 97, and pin 91 and heating member 43 just are fixed on this outer surface 97 by frictional fit by encircling 99.Lining 49 also comprises the cylinder shape inner wall 141 and a diapire 139 that can allow cigarette enter lining.The end inner face 81 of diapire 139 is used for blocking the cigarette 23 unlikely lighter 25 that go deep into more, makes the correctly relative heating member 43 of cigarette 23 locate.On diapire 139, processed the part 47 of the passage 47 that a formation communicates with suction driving sensor 45 '.The hole that center with lining 49 of part 47 ' preferably is parallel, penetrate diapire 139.On diapire 139, also processed a part 55 that constitutes the opening 55 of configuration optical sensor 53 '.First strand pore 143 from the outer surface 97 of lining 49 extend to always opening part 55 '.First strand pore 143 since provide one from the cigarette peripheral region to the additional air flow passage of back airflow filtering device 63 adjacent domains, thereby help during aspirating cigarette 23 for the first time, providing suitable draw resistance.Enter cigarette 23 because tobacco volume 57 and cigarette paper 69 can hinder air-flow before going back the zone that neither one heating member 43 once heated cigarette, therefore first strand of pore 143 back airflow filtering device 63 by cigarette provides air-flow for this zone of heater 39.Back airflow filtering device 63 allows enough air-flows to enter cigarette 23, thus the draw resistance that will run into when draw resistance being lower than do not adopt this structure.Yet, though back airflow filtering device 63 still will guarantee can flow into said flow during first strand of cigarette, should try one's best " closely ", make to remain in after having aspirated cigarette 23 that smog in the chamber 79 is unlikely to enter lighter 25 by back airflow filtering device.Be a groove of opening on the end of pedestal inner surface 157 having inhaled cigarette 23, this groove just becomes airtight after having loaded onto lining 49.Best, part 47 " is to be made of two that open on the diapire 151 vertical and radial holes that join mutually.The part 55 of opening 55 " is opened on diapire 151.Part 47 on the lining 49 ' aim at the part 47 " and 55 " on the pedestal 50 with 55 ' respectively forms passage 47 and opening 55.

Figure 12 A-12D at length shows the member 49A in heater 39A embodiment shown in Figure 5.Member 49A has a cylindrical outer surface 97A, each sell 95 and heating see that 43 99 are fastened on this outer surface 97A by ring.Member 49A also comprises the cylinder shape inner wall 141A and a diapire 139A that can allow cigarette to insert member.The inner surface 81A of diapire 139A is used for blocking cigarette 23, and cigarette 23 relative heating members 43 are correctly located.On member 49A, can also process a first strand of pore (not shown).The passage 47A that is communicated with smoking driving sensor 45 opens on diapire 139A.Passage 47A be one penetrate diapire 139A, with the parallel hole of member 49A center line.As mentioned above, the tail end of the tail end 101 of each heating member 43 and at least two pins 95 extends through the end outer surface 105A of member 49A, is connected with power supply 37 with circuit 41.A flange 109 is arranged on the member 49A, opened two grooves or hole 107A above at least, make the tail end 103 of two pins 95 to pass through, stretch out outside end outer surface 105A.The tail end of heating member 43 curves the shape that conforms to flange 109, extends through end outer surface 105A along flange outer rim 111.Air flue cover 87A cooperates further the tail end 101 with heating member 43 to be fastened on the appropriate location with the outer rim 111 of flange 109.

Except mentioning especially, convenient in order to reference for the purpose of, below mainly be each part at heater 39 shown in Fig. 3 A-3B to the discussion of cigarette smoking system 21.Yet, be appreciated that these discuss also applicable to the embodiment of heater 39A shown in Figure 5 and other embodiment of specifically not indicating and discuss here.As mentioned above, heater can comprise that some other can finish various such as the devices near the such heater function in the space of heating member of heating cigarette are provided.

Figure 13 shows heating member 43 and pin 95 round the outer surface 97 of the lining 49 shown in Fig. 3 A end-view of fastening ring 99 in addition.The internal diameter of ring 99 should be to surround each heating member 43 with assurance, and with frictional fit these heating members 43 is fastened on the columniform outer surface 97.Be used for holding every the cannelure 159 at 90 ° of angles mutually and thicker respectively sell 95 round what ring 99 inner rim was opened, like this, ring 99 just can surround these and sell 95, and they are fastened on the outer surface 97.

First end 161 of air flue cover 87 is received on the pedestal 50, and second end 163 is received on the block 83.On first end 161 of air flue cover 87 ectoloph 165 is arranged, be used for being stuck in the inside groove 167 on the inwall 155 of pedestal 50.Similar, on second end 163 of air flue cover 87 ectoloph 171 is arranged, be used for being stuck in the inside groove 173 on the inner edge 175 of block 83.Air flue cover 87A among the embodiment of heater 39A shown in Figure 5 is different with the embodiment of the air flue cover 87 shown in Fig. 3.On the first end 161A of air flue cover 87A an inside groove 165A is arranged, be used for being stuck on the ectoloph 167A on the outer rim 111 of flange 109 of member 49A.The part of the close tail end 101 of each heating member 43 is between each junction surface of member 49A and air flue cover 87A.As following will in conjunction with Figure 17 further discuss in addition, if require to increase air-flow, some that can open then that one or several radial hole passes heater 39 are overlapped 87 such parts such as air flue, preferably open on the point suitable along some air communication of air flue cover length.

All are all identical for the block 83 of heater 39 shown in Fig. 3 A and the block 83A of heater 39A shown in Figure 5, and 83 the inwall 177 of just blocking a shot is more longer than the inwall 177A of block 83A.The internal diameter of the inwall 177 of block 83 preferably is not more than the external diameter of cigarette 23; Make cigarette when inserting lighter 25, be squeezed with smaller slightly for well, remain on the appropriate location reliably by interference fit.Block 39 inwall 117 is longer to be desirable, and this has increased the support to cigarette 23.For the purpose of illustrating, Figure 14 A-14D shows the structure of block 83A.

Have one group of vertical hole or passage 179A on the block 83A, pass block 83A from the front end 93A of rounding or chamfering to back side 181A, space between cigarette in the heater 39A that is used for that air can be flowed into and holds cigarette 23 and the air flue cover 87 makes horizontal (promptly radially inside) air communication cross near the tobacco volume 57 snakelike 131 of heating member 43.As shown in Figure 3A, in this preferred embodiment of the block 83 of heater 39, hole or passage 179 are doing greatlyyer than close front end 93 places near 181 places, the back side, so that obtain a desired smoking resistance.In another embodiment of block, these vertical holes replace with the cannelure (not shown) of opening at the block inwall.By Figure 14 A-14D as seen, open a circumferential groove 183A overleaf on the 181A, be used for holding and supporting the available protective heaters set 85 shown in Figure 15 A-15B.Heaters set 85 is tubular articles, has first end 185 and second end 187, and these two ends all can be included in the groove 183A.Circumferential groove 183A opens at radius and exceeds on the circumference of hole or passage 179A, so that air introduced heater 39 when the smoker aspirates cigarette 23.

The smoker can take off heaters set 85 and throw away after having inhaled some cigarettes (for example 30 to 60 cigarettes 23), change a new heaters set again.Heaters set 85 prevents that the inwall 169 of air flue cover 87 is subjected to the effect of the residual smog of generation in the zone between heating member 43 and air flue cover.Heaters set 85 has been arranged, and these smog have just acted on the heaters set 85.

The material of the paper that heaters set 85 usefulness are heat-resisting or plastics and so on is made, and is changed after having inhaled some cigarettes 23 by the smoker.Therefore, with have " tube-in-tube " inverted configuration of receiving as the smog barrier tube of the following tobacco spice assembly that will illustrate, the smog barrier tube will be thrown away with the combinations of perfumes that sucks, and the heaters set 85 of this cigarette smoking system 21 then is fit to re-use.Therefore, simplified the manufacturing of cigarette 23, reduced sucking the quantity of material that to discard behind every cigarette.

Figure 16 shows the preferred flux map that forms briefly in heater 39 and cigarette 23 when smoker's suction filtration mouth 71.Because suction at filter tip 71 places, air is inhaled in the heater 39 between air flues cover or the heaters set (in this view not label) by vertical hole or passage 179, cross the heating member (not shown) that contacts with cigarette 23, pass ventilative cigarette paper 69 and tobacco volume and enter in the chamber 79 of cigarette after 57 (or passing top air-vent).Air 79 flows into the vertical passage 67 of the first free stream filter 65 and the vertical passage 77 of the second free stream filter 73 from the chamber, by filter tip 71 to the smoker.The quantity of passage 179 and size are chosen to make the total corpuscle (TPM) that sends the smoker to for best.In this preferred embodiment, on block 83,6 or 8 passages 179 have been opened.

As shown in figure 17, need, provide some other air flues to replace or accessory channel 179, make air enter the chamber 79 of heater 39 inside and cigarette 23.For example, can on heater 39, open one or several radial passage 189 by any vantage point (normally putting) at air flue.Can on heater 39, open several vertical passages 191 by pedestal or pedestal and lining (not shown).In addition, the passage 179 of block on 83 can be aforesaid hole or drive cannelure on the inwall 177 of block 83.As mentioned above, need, when smoker's smoking is rolled up, allow vertical air to flow to back airflow filtering device 63 can adding one on the cigarette into chamber 79.

Need, lighter 25 can comprise a sharpening pipe (not shown) of selecting for use, is installed in the heater 39, is used for piercing through the back airflow filtering device 63 of the cigarette that inserts lighter.Therefore the top end of this pipe can make direct gas flow enter in the chamber 79 when the smoker aspirates cigarette 23 in chamber 79.The sharpening pipe has one or several pore in the guiding end, and these pores are preferably opened on the sidewall of pipe, rather than on the leading end of pipe, so that on the direction that helps making air-flow in the chamber, form whirlpool, obtain high velocity air.This eddy current has improved leaked-in air and the smog of cigarette 23 interior generations and mixing of steam.