CN113043219A - Mounting device for automatic target replacement in inertial confinement fusion - Google Patents

Mounting device for automatic target replacement in inertial confinement fusion Download PDFInfo

- Publication number

- CN113043219A CN113043219A CN202110298519.2A CN202110298519A CN113043219A CN 113043219 A CN113043219 A CN 113043219A CN 202110298519 A CN202110298519 A CN 202110298519A CN 113043219 A CN113043219 A CN 113043219A

- Authority

- CN

- China

- Prior art keywords

- target

- inertial confinement

- confinement fusion

- positioning surface

- rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000004927 fusion Effects 0.000 title claims abstract description 26

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 28

- 239000010959 steel Substances 0.000 claims abstract description 28

- 238000009434 installation Methods 0.000 abstract description 11

- 238000002474 experimental method Methods 0.000 abstract description 5

- 238000000034 method Methods 0.000 description 2

- 241000282414 Homo sapiens Species 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008685 targeting Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B27/00—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for

- B25B27/14—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for assembling objects other than by press fit or detaching same

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Connection Of Plates (AREA)

Abstract

The invention provides an installation device for automatic target replacement in inertial confinement fusion, and belongs to the field of experimental equipment. The problem of different targets be difficult to accurate, install fast during current inertial confinement fusion experiment is solved. The target holder comprises a target seat and a target holder which are connected in a matched mode, the target seat comprises a positioning sleeve, a steel ball, a spring and an adjusting screw, a connecting and positioning surface is arranged on the axis of the positioning sleeve, a plurality of threaded holes are uniformly distributed in the positioning sleeve along the radial direction, the threaded holes penetrate through the connecting and positioning surface, the steel ball is arranged in the threaded hole, the adjusting screw is in threaded connection with the threaded holes, the spring is arranged between the steel ball and the adjusting screw and tightly presses the steel ball through the spring, and the target holder comprises a locking nut and a target rod. It is mainly used for automatic target changing of inertial confinement fusion.

Description

Technical Field

The invention belongs to the field of experimental equipment, and particularly relates to an installation device for automatic target replacement in inertial confinement fusion.

Background

Inertial confinement fusion is an effective way for realizing controllable thermonuclear fusion, is an effective way for solving the energy problem faced by human beings, is also a high point of scientific and technological strategy for the competition of developed countries at present, and has great practical significance.

Inertial confinement fusion research needs to carry out a large amount of target practice experiments, and the used target type of experiment is also different according to different physical condition and experiment requirement to the kind is various, and various types of target all have a standard small circle post as the interface, because the diameter of the cylinder pole of interface is the millimeter level, also does not have the locating surface that automatic target changing used on the target pole, and different in size, dress target need be accomplished in a narrow and small space simultaneously, can't be used for the automatic target changing under vacuum condition.

Disclosure of Invention

The invention provides an installation device for automatic target replacement in inertial confinement fusion, aiming at solving the problems in the prior art.

In order to achieve the purpose, the invention adopts the following technical scheme: an installation device for automatic target replacement of inertial confinement fusion comprises a target holder and a target holder which are connected in a matching manner, wherein the target holder comprises a positioning sleeve, a steel ball, a spring and an adjusting screw, a connecting positioning surface is arranged on the axis of the positioning sleeve, a plurality of threaded holes are uniformly distributed on the positioning sleeve along the radial direction, the threaded holes penetrate through the connecting positioning surface, the steel ball is arranged in the threaded hole, the adjusting screw is in threaded connection with the threaded holes, the spring is arranged between the steel ball and the adjusting screw and tightly presses the steel ball through the spring, the target holder comprises a locking nut and a target rod, one end of the target rod is provided with an installation hole matched with a cylindrical rod of a target interface, a plurality of target locking openings are uniformly formed in the radial direction of the installation hole, the outer diameter of the installation hole is provided with threads, the target rod is connected with the locking nut through the threads, and the other, the aligning positioning surface and the connecting positioning surface are matching surfaces, and the target rod is connected with the positioning sleeve in a locking mode.

Furthermore, the aligning positioning surface and the connecting positioning surface are Morse taper surfaces which are matched with each other.

Furthermore, a closing-up structure is arranged at the intersection of the threaded hole and the connecting and positioning surface, and the steel ball is clamped at the closing-up structure.

Further, the number of the threaded holes is three.

Furthermore, the end part of one side of the adjusting screw is provided with a blind hole, and the spring is placed in the blind hole.

Further, the length of the spring is larger than the depth of the blind hole.

Furthermore, the end part of the mounting hole of the target rod is provided with a locking target conical surface, and the locking target conical surface is matched and connected with the locking nut.

Furthermore, a target positioning surface is arranged in the mounting hole of the target rod.

Furthermore, an operation positioning surface is arranged on the rod body of the target rod.

Furthermore, the number of the lock target openings is four, and the depth of each lock target opening is the same as that of the mounting hole.

Compared with the prior art, the invention has the beneficial effects that: the invention solves the problem that different targets are difficult to accurately and quickly install in the existing inertial confinement fusion experiment, and can realize automatic target replacement for different target types. Different targets can be accurately and quickly arranged on the target holder through the target holder; the target can be automatically aligned and positioned through the target holder. The invention breaks through the traditional thinking, the target is not directly clamped on the target seat, but is clamped on the target clamp holder, and then the target is accurately and quickly clamped on the target seat by utilizing the unique interface design of the clamp holder and the target seat.

According to the invention, the target is arranged on the target holder, and then the target holder is arranged on the target seat, so that the target can be arranged in a laboratory, the target assembly is not limited by space and angle, and the operation difficulty is reduced. The unique interface design of the target holder and the target holder ensures that the target holder can be normally installed into the target holder even if the axes of the target holder and the target holder mounting hole are not completely overlapped but have a certain included angle, thereby improving the target installation fault tolerance rate, reducing the difficulty of the target installation operation and providing a basis for realizing automatic target replacement. The target holder can adapt to different target types, and the target holder can be automatically aligned and positioned by the target base. The target holder is provided with an operation positioning surface of a target loading manipulator. The target seat has the functions of pressing and locking the clamper, preventing the clamper from loosening and keeping the position. The target holder is matched with the target holder and is suitable for realizing automatic target replacement under the vacuum condition.

Drawings

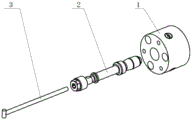

FIG. 1 is a schematic perspective view of an installation device for inertial confinement fusion automatic target replacement according to the present invention;

FIG. 2 is a schematic cross-sectional structure view of a mounting device for inertial confinement fusion automatic target replacement according to the invention;

FIG. 3 is a schematic perspective view of a backing plate according to the present invention;

FIG. 4 is a schematic cross-sectional view of a backing plate according to the present invention;

FIG. 5 is a schematic perspective view of a target holder according to the present invention;

FIG. 6 is a schematic cross-sectional view of a target holder according to the present invention.

1: target holder, 2: target holder, 3: target, 1-1: locating sleeve, 1-2: steel ball, 1-3: spring, 1-4: adjusting screw, 2-1: locking nut, 2-2: target bar, 2-2-1: lock target notch, 2-2-2: locking target conical surface, 2-2-3: targeting and positioning surface, 2-2-4: operation positioning surface, 2-2-5: aligning and positioning surface.

Detailed Description

The technical solution in the embodiments of the present invention will be clearly and completely explained below with reference to the drawings in the embodiments of the present invention.

Referring to fig. 1-6 to illustrate the embodiment, the mounting device for inertial confinement fusion automatic target replacement comprises a target holder 1 and a target holder 2 which are connected in a matching manner, wherein the target holder 1 comprises a positioning sleeve 1-1, a steel ball 1-2, a spring 1-3 and an adjusting screw 1-4, a connecting positioning surface is arranged on the axis of the positioning sleeve 1-1, a plurality of threaded holes are uniformly distributed on the positioning sleeve 1-1 in the radial direction, the threaded holes penetrate through the connecting positioning surface, the steel ball 1-2 is arranged in the threaded holes, the adjusting screw 1-4 is in threaded connection with the threaded holes, the spring 1-3 is arranged between the steel ball 1-2 and the adjusting screw 1-4 and tightly presses the steel ball through the spring 1-3, the target holder 2 comprises a locking nut 2-1 and a target rod 2-2, one end of the target rod 2-2 is provided with a mounting hole matched with the target 3 interface cylindrical rod, a plurality of target locking notches 2-2-1 are uniformly formed in the radial direction of the mounting hole, threads are formed in the outer diameter of the mounting hole, the target rod 2-2 is connected with the locking nut 2-1 through the threads, the other end of the target rod 2-2 is provided with an aligning positioning surface 2-2-5, the aligning positioning surface 2-2-5 and the connecting positioning surface are matching surfaces, and the target rod 2-2 is connected with the positioning sleeve 1-1 in a locking mode.

In the embodiment, the aligning positioning surface 2-2-5 and the connecting positioning surface are Morse taper surfaces which are matched with each other, a closing-up structure is arranged at the intersection of the threaded hole and the connecting positioning surface, the steel ball 1-2 is clamped at the closing-up structure, and the steel ball 1-2 can protrude in the connecting positioning surface; the number of the threaded holes is three, a blind hole is formed in the end portion of one side of each adjusting screw 1-4, the spring 1-3 is placed in the blind hole, the length of the spring 1-3 is larger than the depth of the blind hole, the spring 1-3 is placed between the steel ball 1-2 and the adjusting screw 1-4, finally the adjusting screw 1-4 is screwed in, and the elasticity of the spring 1-3 is adjusted by adjusting the screwing depth of the adjusting screw 1-4.

The whole target rod 2-2 adopts a cylindrical structural design, the end part of a mounting hole of the target rod 2-2 is provided with a target locking conical surface 2-2-2, the target locking conical surface 2-2-2 is matched and connected with a locking nut 2-1, a target mounting positioning surface 2-2-3 is arranged in the mounting hole of the target rod 2-2, the rod body of the target rod 2-2 is provided with an operation positioning surface 2-2-4, the number of target locking openings 2-2-1 is four, and the depth of the target locking openings 2-2-1 is the same as that of the mounting hole.

During assembly, the locking nut 2-1 is firstly screwed into the target rod 2-2 slightly, and only needs to be screwed slightly, but cannot be screwed. Then inserting the interface cylindrical rod of the target into the mounting hole of the target rod 2-2, after the end surface of the interface cylindrical rod of the target is superposed with the target mounting positioning surface 2-2-3 in the target rod 2-2, screwing the locking nut 2-1 on the target rod 2-2, and when the locking nut 2-1 is screwed down, the locking nut 2-1 compresses the target locking conical surface 2-2-2 on the target rod 2-2, so that the mounting hole of the target rod 2-2 is contracted to firmly fix the target on the target holder 2. The target holding end of the target holder 2 with the target is aligned with the mounting hole on the target base 1 and slightly pressed in, the aligning positioning surface 2-2-5 of the target rod 2-2 is a Morse taper surface, the steel ball 1-2 is extruded by the aligning positioning surface 2-2 to force the steel ball 1-2 to retreat into the threaded hole of the positioning sleeve 1-1, when the aligning positioning surface contact point of the steel ball 1-2 and the target rod 2-2 crosses the highest point of the cutting conical surface of the target rod 2-2 and enters the next reverse Morse taper surface, the steel ball 1-2 is ejected out and the elasticity of the steel ball 1-2 acts on the Morse taper surface of the target rod 2-2, so that the target rod 2-2 obtains axial component force, the target holder 2 is firmly locked in the target base 1, because the Morse taper surface on the target base 1 and the Morse taper surface of the target rod 2-2 on the target holder 2 are matching, therefore, the target holder 2 realizes automatic centering and positioning under the action of the axial force of the steel balls 1-2; the Morse taper hole on the axis of the positioning sleeve 1-1 is wide outside and narrow inside, and the Morse taper surface of the target rod 2-2 target-loading end of the target holder 2 is thin in the front and thick in the back, so that the target holder 2 can be easily loaded in the target loading process, the fault-tolerant rate of the target loading is greatly improved, and the target loading operation is simpler and quicker.

The installation device for the inertial confinement fusion automatic target replacement provided by the invention is described in detail, a specific example is applied in the description to explain the principle and the implementation mode of the invention, and the description of the embodiment is only used for helping to understand the method and the core idea of the invention; meanwhile, for a person skilled in the art, according to the idea of the present invention, there may be variations in the specific embodiments and the application scope, and in summary, the content of the present specification should not be construed as a limitation to the present invention.

Claims (10)

1. A mounting device for inertial confinement fusion automatic target replacement is characterized in that: the device comprises a target seat (1) and a target holder (2) which are connected in a matching manner, wherein the target seat (1) comprises a positioning sleeve (1-1), steel balls (1-2), a spring (1-3) and an adjusting screw (1-4), a connecting and positioning surface is arranged on the axis of the positioning sleeve (1-1), a plurality of threaded holes are uniformly distributed in the positioning sleeve (1-1) along the radial direction, the threaded holes penetrate through the connecting and positioning surface, the steel balls (1-2) are arranged in the threaded holes, the adjusting screw (1-4) is in threaded connection with the threaded holes, the spring (1-3) is arranged between the steel balls (1-2) and the adjusting screw (1-4) and tightly presses the steel balls through the spring (1-3), the target holder (2) comprises a locking nut (2-1) and a target rod (2-2), one end of the target rod (2-2) is provided with a mounting hole matched with the interface cylindrical rod of the target (3), a plurality of target locking notches (2-2-1) are uniformly formed in the radial direction of the mounting hole, threads are formed in the outer diameter of the mounting hole, the target rod (2-2) is connected with the locking nut (2-1) through the threads, the other end of the target rod (2-2) is provided with an aligning positioning surface (2-2-5), the aligning positioning surface (2-2-5) and the connecting positioning surface are matching surfaces, and the target rod (2-2) is connected with the positioning sleeve (1-1) in a locking mode.

2. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: the aligning positioning surface (2-2-5) and the connecting positioning surface are Morse taper surfaces which are matched with each other.

3. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: a closing-up structure is arranged at the intersection of the threaded hole and the connecting and positioning surface, and the steel ball (1-2) is clamped at the closing-up structure.

4. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: the number of the threaded holes is three.

5. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: the end part of one side of the adjusting screw (1-4) is provided with a blind hole, and the spring (1-3) is placed in the blind hole.

6. The mounting device for inertial confinement fusion auto-exchange targets of claim 5, wherein: the length of the spring (1-3) is larger than the depth of the blind hole.

7. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: the end part of the mounting hole of the target rod (2-2) is provided with a lock target conical surface (2-2-2), and the lock target conical surface (2-2-2) is connected with a locking nut (2-1) in a matching way.

8. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: and a target positioning surface (2-2-3) is arranged in the mounting hole of the target rod (2-2).

9. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: an operation positioning surface (2-2-4) is arranged on the rod body of the target rod (2-2).

10. The mounting device for inertial confinement fusion auto-exchange targets of claim 1, wherein: the number of the lock target openings (2-2-1) is four, and the depth of the lock target openings (2-2-1) is the same as that of the mounting holes.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110298519.2A CN113043219A (en) | 2021-03-19 | 2021-03-19 | Mounting device for automatic target replacement in inertial confinement fusion |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110298519.2A CN113043219A (en) | 2021-03-19 | 2021-03-19 | Mounting device for automatic target replacement in inertial confinement fusion |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113043219A true CN113043219A (en) | 2021-06-29 |

Family

ID=76513907

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110298519.2A Pending CN113043219A (en) | 2021-03-19 | 2021-03-19 | Mounting device for automatic target replacement in inertial confinement fusion |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113043219A (en) |

Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002047865A1 (en) * | 2000-12-15 | 2002-06-20 | Tosoh Smd, Inc. | Friction fit target assembly for high power sputtering operation |

| CN2572099Y (en) * | 2002-10-14 | 2003-09-10 | 廖善赞 | Pipe connector |

| WO2011146113A1 (en) * | 2010-05-17 | 2011-11-24 | Innoven Energy Partners | Icf targets and chambers |

| CN102486941A (en) * | 2010-12-06 | 2012-06-06 | 中国科学院西安光学精密机械研究所 | Simulated Target Positioning Device |

| CN102672289A (en) * | 2012-04-06 | 2012-09-19 | 浙江大学 | Central spindle capable of automatically centring and tapping internal screw thread |

| WO2014133623A2 (en) * | 2012-12-13 | 2014-09-04 | Lawrence Livermore National Security, Llc | Fusion target projectile accelerator |

| CN204361044U (en) * | 2015-02-05 | 2015-05-27 | 厦门理工学院 | A kind of screw lamp holder gluing stationary fixture |

| CN107429726A (en) * | 2015-03-27 | 2017-12-01 | 肖特兄弟公司 | Double load path closure systems |

| US20180111237A1 (en) * | 2016-10-26 | 2018-04-26 | Creative Engineering Solutions, Inc. | Adjustable Depth Magnetic Device |

| CN108534674A (en) * | 2018-04-18 | 2018-09-14 | 哈尔滨工业大学 | A kind of ICF targets assembly parameter measurement multiple degrees of freedom precision movement platform device |

| CN208495854U (en) * | 2018-06-19 | 2019-02-15 | 常州市莱赫润机械有限公司 | Roll drilling equipment |

| CN109676361A (en) * | 2018-12-20 | 2019-04-26 | 大连长丰实业总公司 | It is a kind of to be cut a conversion equipment with defencive function |

| CN209264262U (en) * | 2018-12-11 | 2019-08-16 | 西安工业大学 | Impact type torque loading experimental apparatus |

| CN210702936U (en) * | 2019-10-11 | 2020-06-09 | 东莞市阿巴斯精密传动科技有限公司 | Clamping device with adjustable center |

| CN112440150A (en) * | 2019-09-02 | 2021-03-05 | 江苏海博工具产业研究院有限公司 | Metal cutting tool for high-speed cutting |

| CN212661870U (en) * | 2020-04-22 | 2021-03-09 | 杨懿涵 | Femoral bone drill for knee arthroscopic ligament reconstruction surgery |

-

2021

- 2021-03-19 CN CN202110298519.2A patent/CN113043219A/en active Pending

Patent Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002047865A1 (en) * | 2000-12-15 | 2002-06-20 | Tosoh Smd, Inc. | Friction fit target assembly for high power sputtering operation |

| CN2572099Y (en) * | 2002-10-14 | 2003-09-10 | 廖善赞 | Pipe connector |

| WO2011146113A1 (en) * | 2010-05-17 | 2011-11-24 | Innoven Energy Partners | Icf targets and chambers |

| CN102486941A (en) * | 2010-12-06 | 2012-06-06 | 中国科学院西安光学精密机械研究所 | Simulated Target Positioning Device |

| CN102672289A (en) * | 2012-04-06 | 2012-09-19 | 浙江大学 | Central spindle capable of automatically centring and tapping internal screw thread |

| WO2014133623A2 (en) * | 2012-12-13 | 2014-09-04 | Lawrence Livermore National Security, Llc | Fusion target projectile accelerator |

| CN204361044U (en) * | 2015-02-05 | 2015-05-27 | 厦门理工学院 | A kind of screw lamp holder gluing stationary fixture |

| CN107429726A (en) * | 2015-03-27 | 2017-12-01 | 肖特兄弟公司 | Double load path closure systems |

| US20180111237A1 (en) * | 2016-10-26 | 2018-04-26 | Creative Engineering Solutions, Inc. | Adjustable Depth Magnetic Device |

| CN108534674A (en) * | 2018-04-18 | 2018-09-14 | 哈尔滨工业大学 | A kind of ICF targets assembly parameter measurement multiple degrees of freedom precision movement platform device |

| CN208495854U (en) * | 2018-06-19 | 2019-02-15 | 常州市莱赫润机械有限公司 | Roll drilling equipment |

| CN209264262U (en) * | 2018-12-11 | 2019-08-16 | 西安工业大学 | Impact type torque loading experimental apparatus |

| CN109676361A (en) * | 2018-12-20 | 2019-04-26 | 大连长丰实业总公司 | It is a kind of to be cut a conversion equipment with defencive function |

| CN112440150A (en) * | 2019-09-02 | 2021-03-05 | 江苏海博工具产业研究院有限公司 | Metal cutting tool for high-speed cutting |

| CN210702936U (en) * | 2019-10-11 | 2020-06-09 | 东莞市阿巴斯精密传动科技有限公司 | Clamping device with adjustable center |

| CN212661870U (en) * | 2020-04-22 | 2021-03-09 | 杨懿涵 | Femoral bone drill for knee arthroscopic ligament reconstruction surgery |

Non-Patent Citations (3)

| Title |

|---|

| 史贵权: "《机械毕业设计指导》", 31 December 1984 * |

| 孙立宁等: "ICF靶支撑定位机器人系统研究", 《强激光与粒子束》 * |

| 宫霞霞等: "放射性靶管切割机设计", 《机械设计与制造》 * |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113043219A (en) | Mounting device for automatic target replacement in inertial confinement fusion | |

| CN108436123B (en) | Anchor clamps suitable for quick clamping of thin wall part | |

| CN212121708U (en) | Self-centering and tensioning type clamp | |

| CN211601728U (en) | Rapid docking device for rocket gun launching control signal detection | |

| CN111941109A (en) | Positioning and clamping device for high-precision space vertical hole turning | |

| CN110444354B (en) | Flange mounting structure and insulating pillar | |

| CN209811747U (en) | Quick clamping device of top | |

| CN111360556A (en) | Clamping fixture for outer barrel parts | |

| CN218252954U (en) | Blind hole part turning self-centering clamp | |

| CN219004632U (en) | Clamp for numerical control lathe | |

| CN111964609A (en) | Coaxiality detection device for flange connecting hole in barrel flange and tool thereof | |

| CN216177531U (en) | Self-positioning clamping device for friction welding of bearing sleeve | |

| CN110459729B (en) | Pole for battery and preparation method thereof | |

| CN217253409U (en) | Quick clamping gear hobbing tool | |

| CN115507252B (en) | Equipment self-locking device under weightless environment | |

| CN217096648U (en) | Processing tool for oil return hole in side wall of cylindrical piston component | |

| CN216127116U (en) | Positioning mechanism for automobile clamp | |

| CN220005148U (en) | Quick clamping mechanism | |

| CN211916028U (en) | Push rod assembly press-fitting mechanism | |

| CN215470682U (en) | Eccentric ejector block device for enabling linear guide rail to be close to reference vertical face | |

| CN218181182U (en) | Optical element clamp | |

| CN219767477U (en) | Clamp for machining upper hole of arc surface | |

| CN215146824U (en) | Dynamic balance clamp for sleeve fork | |

| CN221313075U (en) | Heat exchange tube and tube plate welding positioning mandrel for heat exchanger | |

| CN219818946U (en) | Lower bushing lathe tool |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20210629 |

|

| RJ01 | Rejection of invention patent application after publication |