CN112795418A - Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof - Google Patents

Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof Download PDFInfo

- Publication number

- CN112795418A CN112795418A CN202011444822.0A CN202011444822A CN112795418A CN 112795418 A CN112795418 A CN 112795418A CN 202011444822 A CN202011444822 A CN 202011444822A CN 112795418 A CN112795418 A CN 112795418A

- Authority

- CN

- China

- Prior art keywords

- tetraurea

- base oil

- grease composition

- detda

- diamine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C273/00—Preparation of urea or its derivatives, i.e. compounds containing any of the groups, the nitrogen atoms not being part of nitro or nitroso groups

- C07C273/18—Preparation of urea or its derivatives, i.e. compounds containing any of the groups, the nitrogen atoms not being part of nitro or nitroso groups of substituted ureas

- C07C273/1809—Preparation of urea or its derivatives, i.e. compounds containing any of the groups, the nitrogen atoms not being part of nitro or nitroso groups of substituted ureas with formation of the N-C(O)-N moiety

- C07C273/1818—Preparation of urea or its derivatives, i.e. compounds containing any of the groups, the nitrogen atoms not being part of nitro or nitroso groups of substituted ureas with formation of the N-C(O)-N moiety from -N=C=O and XNR'R"

- C07C273/1827—X being H

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M115/00—Lubricating compositions characterised by the thickener being a non-macromolecular organic compound other than a carboxylic acid or salt thereof

- C10M115/08—Lubricating compositions characterised by the thickener being a non-macromolecular organic compound other than a carboxylic acid or salt thereof containing nitrogen

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M169/00—Lubricating compositions characterised by containing as components a mixture of at least two types of ingredient selected from base-materials, thickeners or additives, covered by the preceding groups, each of these compounds being essential

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M177/00—Special methods of preparation of lubricating compositions; Chemical modification by after-treatment of components or of the whole of a lubricating composition, not covered by other classes

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2207/00—Organic non-macromolecular hydrocarbon compounds containing hydrogen, carbon and oxygen as ingredients in lubricant compositions

- C10M2207/28—Esters

- C10M2207/283—Esters of polyhydroxy compounds

- C10M2207/2835—Esters of polyhydroxy compounds used as base material

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2215/00—Organic non-macromolecular compounds containing nitrogen as ingredients in lubricant compositions

- C10M2215/10—Amides of carbonic or haloformic acids

- C10M2215/102—Ureas; Semicarbazides; Allophanates

- C10M2215/1026—Ureas; Semicarbazides; Allophanates used as thickening material

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2219/00—Organic non-macromolecular compounds containing sulfur, selenium or tellurium as ingredients in lubricant compositions

- C10M2219/04—Organic non-macromolecular compounds containing sulfur, selenium or tellurium as ingredients in lubricant compositions containing sulfur-to-oxygen bonds, i.e. sulfones, sulfoxides

- C10M2219/044—Sulfonic acids, Derivatives thereof, e.g. neutral salts

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Lubricants (AREA)

Abstract

The invention provides a tetraurea lubricating grease composition prepared from aromatic diamine, which comprises the following components in parts by weight based on the weight of the lubricating grease composition: 85-92% of synthetic base oil, 5-15% of novel tetraurea thickening agent and 0.2-0.5% of antirust agent. The novel tetraurea thickening agent is prepared by the reaction and polymerization of methyl diphenyl diisocyanate (MDI), diethyl toluene diamine (DETDA) and octadecylamine, wherein the molar ratio of the MDI to the DETDA to the octadecylamine is 2: 1: 2. the invention takes polyol ester as base oil, adopts methyl diphenyl diisocyanate (MDI), diethyl toluene diamine (DETDA) and octadecylamine as raw materials to prepare a novel tetraurea thickening agent system by reaction, so that the thickening capability is obviously improved, and the tetraurea thickening agent system has good high temperature resistance, oxidation stability, colloid stability, mechanical stability and extreme pressure wear resistance.

Description

Technical Field

The invention belongs to the technical field of lubricants, and particularly relates to a tetraurea lubricating grease composition prepared from aromatic diamine and a preparation method thereof.

Technical Field

The polyurea thickening agent is a thickening agent with better stability, because the polyurea thickening agent does not contain metal ions, the polyurea thickening agent has no catalytic oxidation effect on base oil in use, and alkyl in the general polyurea-based thickening agent contains aryl, so that the polyurea-based lubricating grease has good radiation resistance and colloid stability, and has a series of excellent service performances such as good pumping property, oxidation resistance, mechanical stability and water resistance, is particularly suitable for lubricating occasions with high temperature, high load, wide speed range and contact with poor media, and is widely applied to industries such as electric appliances, metallurgy, food, paper making, automobiles, airplanes and the like.

Diethyltoluene diamine refers to a mixture of two isomers of diethyltoluene diamine (3, 5-diethyltoluene-2, 4-diamine and 3, 5-diethyltoluene-2, 6-diamine), abbreviated as DETDA. DETDA is mainly used as a polyurethane elastic chain extender, a polyurethane and epoxy resin curing agent, an antioxidant of epoxy resin, a lubricant, an antioxidant of industrial grease and the like. The case of preparing the tetraurea lubricating grease by using DETDA as a tetraurea thickener raw material is not reported at present.

Disclosure of Invention

The invention aims to provide a tetraurea lubricating grease composition prepared from aromatic diamine and a preparation method thereof. The novel tetrapolyurea lubricating grease disclosed by the invention is simple in preparation method, easy to operate, short in production period and good in product using effect.

The invention provides a tetraurea lubricating grease composition prepared from aromatic diamine, which comprises the following components in parts by weight based on the weight of the lubricating grease composition: 85-92% of synthetic base oil, 5-15% of a tetrapolyurea thickening agent and 0.2-0.5% of an antirust agent; wherein the tetraurea thickening agent is prepared by the reaction and polymerization of methyl diphenyl diisocyanate MDI, diethyl toluene diamine DETDA and octadecylamine;

wherein the molar ratio of MDI, DETDA and octadecylamine is 2: 1: 2.

the infrared spectrum of the tetraurea lubricating grease composition prepared by the aromatic diamine is shown in figure 1.

The synthetic base oil is one or more of dipentaerythritol ester, polyol ester, trimellitate and PAO, and the viscosity grade of the base oil is 320 cst.

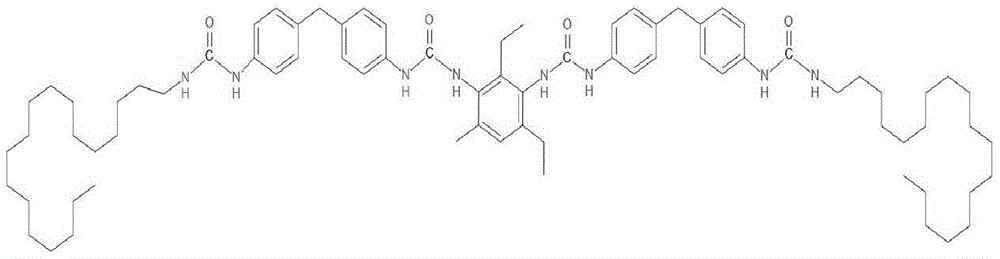

The tetraurea thickener is a mixture of two isomers of diethyltoluenediamine (DETDA), wherein the content of 3, 5-diethyltoluene-2, 4-diamine is 75-82%, and the content of 3, 5-diethyltoluene-2, 6-diamine is 17-24%. The chemical formulas for preparing the two novel tetraurea thickener compounds are respectively as follows:

a novel tetraurea thickener compound prepared from 3, 5-diethyltoluene-2, 4-diamine,

3, 5-diethyltoluene-2, 6-diamine, a novel tetraurea thickener compound.

The antirust agent is at least one of neutral calcium dinonylnaphthalene sulfonate, zinc naphthenate, sodium azelaic acid and sodium nitrite, and the addition amount is 0.2-0.5%.

The preparation method of the tetraurea lubricating grease composition prepared from the aromatic diamine comprises the following specific steps:

1) adding MDI (diphenyl-methane-diisocyanate) into one part of base oil for dissolving at the temperature of 65-70 ℃, and adding DETDA and octadecylamine into the other part of base oil for dissolving at the temperature of 65-70 ℃ for 20-30 min;

2) quickly mixing two parts of base oil dissolved with the tetraurea thickening agent raw material, heating to 95 +/-5 ℃ to perform saponification reaction, wherein the reaction time is 60-90 min;

3) after the reaction is completed, heating to 180-190 ℃ for refining at a high temperature, wherein the heating rate is 2-3 ℃/min, and the refining time is 15-30 min;

4) and stirring and cooling circularly after refining, adding an antirust agent when the temperature is reduced to 70-80 ℃, and performing post-treatment procedures such as grinding, vacuum degassing and the like to obtain the aromatic diamine-prepared tetraurea lubricating grease composition.

In the step 1), the base oil component for dissolving MDI accounts for 45-55% of the total weight of the base oil, and the base oil component for dissolving DETDA and octadecylamine accounts for 45-55% of the total weight of the base oil.

The two parts of base oil dissolved with the raw materials of the tetrapolyurea thickening agent in the step 2) adopt a formula 1: the flow rate is 1-1.1, and the mixture is quickly mixed by an emulsifying machine, and the mixing time is 5-10 min.

The tetraurea lubricating grease prepared from the aromatic diamine prepared by DETDA has strong thickening capacity, and the cone penetration of 12% soap is 264 mm; the high temperature resistance is good, and the loss of the high-temperature baking at 220 ℃ for 4h is 1.89%; the oxidation stability is excellent, and the initial oxidation temperature is 257 ℃; good extreme pressure abrasion resistance, and the experimental no-seizing load PB value of the four-ball machine is 63 kg.

Drawings

FIG. 1: preparing an infrared spectrogram of the tetraurea lubricating grease composition by using the aromatic diamine.

Detailed Description

The following examples are presented to enable one of ordinary skill in the art to more fully understand the present invention and are not intended to limit the scope of the embodiments described herein.

Example 1:

49.3g of MDI were initially charged to 440g of pentaerythritol ester and C6~C16Mixing and heating saturated polyol ester POE320 (Yingkou starfire chemical Co., Ltd.) base oil obtained by reacting fatty acid to 70 ℃ and preserving heat for 30 min; at the same time, 440g POE320 base oil is added with 17.6g DETDA and 53.1g octadecylamine, mixed and heated at 70 ℃ and kept for 30 min.

And then, quickly mixing the two parts of base oil dissolved with the tetraurea thickening agent raw material, heating to 95 ℃ for reaction for 60min, and heating to 180 ℃ after complete reaction for refining for 30 min. Stirring and circulating cooling are carried out after refining is finished, 5g of neutral barium dinonylnaphthalenesulfonate antirust agent is added when the temperature is reduced to 80 ℃, and the aromatic diamine is subjected to post-treatment procedures such as grinding, vacuum degassing and the like to obtain the tetraurea lubricating grease composition 1.

Comparative example 1:

adding 64.1g of MDI into 440g of POE320 base oil, mixing and heating to 70 ℃, and keeping the temperature for 30 min; meanwhile, 440g POE320 base oil is added with 22.8g DETDA and 33.1g octylamine, mixed and heated at 70 ℃ for 30 min.

And then, quickly mixing the two parts of base oil dissolved with the tetraurea thickening agent raw material, heating to 95 ℃ for reaction for 60min, and heating to 180 ℃ after complete reaction for refining for 30 min. Stirring and circulating cooling after refining is completed, adding 5g of neutral barium dinonylnaphthalenesulfonate antirust agent when the temperature is reduced to 80 ℃, and carrying out post-treatment procedures such as grinding, vacuum degassing and the like to obtain the aromatic diamine for preparing the tetraurea lubricating grease composition 2.

Comparative example 2:

firstly, 68.4g of MDI is added into 440g of POE320 base oil, and the mixture is heated to 70 ℃ and is kept warm for 30 min; meanwhile, 440g POE320 base oil is added with 24.4g DETDA and 27.1g cyclohexylamine, and the mixture is heated at 70 ℃ and kept warm for 30 min.

And then, quickly mixing the two parts of base oil dissolved with the raw materials of the tetrapolyurea thickening agent, heating to 95 ℃ for reaction for 60min, and heating to 180 ℃ after complete reaction for refining for 30 min. Stirring and circulating cooling after refining is completed, adding 5g of neutral barium dinonylnaphthalenesulfonate antirust agent when the temperature is reduced to 80 ℃, and carrying out post-treatment procedures such as grinding, vacuum degassing and the like to obtain the aromatic diamine for preparing the tetraurea lubricating grease composition 3.

Table 1: results analysis tables of example 1, comparative example 1 and comparative example 2

From the analysis results in table 1, it can be seen that the tetraurea grease prepared by using the novel tetraurea thickener system of DETDA and octadecylamine has better thickening ability, high temperature resistance, colloid stability, mechanical stability, oxidation stability and extreme pressure wear resistance. In conclusion, the aromatic diamine with excellent performance can be prepared to prepare the tetraurea lubricating grease composition by adopting DETDA as diamine and octadecylamine as monoamine.

The above embodiments are provided for illustrative purposes to enable persons skilled in the art to understand the present invention and implement the present invention, and the protection scope of the present invention is not limited thereby. The invention is within the scope of the claims, unless otherwise indicated herein or clearly indicated by the context of the claims.

Claims (9)

1. The tetraurea lubricating grease composition prepared from aromatic diamine is characterized by comprising the following components in percentage by weight: 85-92% of synthetic base oil, 5-15% of novel tetraurea thickening agent and 0.2-0.5% of antirust agent, wherein the novel tetraurea thickening agent is prepared by the reaction and polymerization of methyl diphenyl diisocyanate MDI, diethyl toluene diamine DETDA and octadecylamine.

2. The grease composition of claim 1, wherein the molar ratio of methyl diphenyl diisocyanate MDI, diethyltoluenediamine DETDA to octadecylamine is 2: 1: 2.

3. the grease composition of claim 1, wherein the synthetic base oil is one or more of dipentaerythritol ester, polyol ester, trimellitate ester, and PAO.

4. The grease composition of claim 1, wherein the diethyltoluenediamine DETDA is a mixture of two isomers of 3, 5-diethyltoluene-2, 4-diamine and 3, 5-diethyltoluene-2, 6-diamine.

5. The grease composition of claim 4, wherein the 3, 5-diethyltoluene-2, 4-diamine content is 75-82% and the 3, 5-diethyltoluene-2, 6-diamine content is 17-24%.

6. The grease composition of claim 1, wherein the rust inhibitor is one or more of neutral calcium dinonylnaphthalenesulfonate, zinc naphthenate, sodium azelate, and sodium nitrite.

7. A method of preparing a grease composition according to any one of claims 1 to 6, characterized in that the method comprises the steps of:

1) adding MDI (diphenyl-methane-diisocyanate) into the base oil for dissolving at 65-70 ℃, and adding DETDA and octadecylamine into the other part of the base oil for dissolving at 65-70 ℃ for 20-30 min;

2) quickly mixing two parts of base oil dissolved with the tetraurea thickening agent raw material, heating to 95 +/-5 ℃ to perform saponification reaction, wherein the reaction time is 60-90 min;

3) after the reaction is completed, heating to 180-190 ℃ for refining at a high temperature, wherein the heating rate is 2-3 ℃/min, and the refining time is 15-30 min;

4) and stirring and cooling circularly after refining, adding an antirust agent when the temperature is reduced to 70-80 ℃, and performing post-treatment procedures such as grinding, vacuum degassing and the like to obtain the aromatic diamine-prepared tetraurea lubricating grease composition.

8. The method for preparing the tetraurea grease composition according to claim 7, wherein the base oil component for dissolving MDI in step 1) accounts for 45-55% of the total weight of the base oil, and the base oil component for dissolving DETDA and octadecylamine accounts for 45-55% of the total weight of the base oil.

9. The method for preparing the tetraurea grease composition from the aromatic diamine according to claim 7, wherein the two parts of the base oil in which the tetraurea thickener is dissolved in the step 2) are 1: the flow rate is 1-1.1, and the mixture is quickly mixed by an emulsifying machine, and the mixing time is 5-10 min.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011444822.0A CN112795418A (en) | 2020-12-08 | 2020-12-08 | Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011444822.0A CN112795418A (en) | 2020-12-08 | 2020-12-08 | Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112795418A true CN112795418A (en) | 2021-05-14 |

Family

ID=75806597

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011444822.0A Pending CN112795418A (en) | 2020-12-08 | 2020-12-08 | Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112795418A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11241084A (en) * | 1998-02-24 | 1999-09-07 | Showa Shell Sekiyu Kk | Urea grease composition |

| CN103484225A (en) * | 2013-08-29 | 2014-01-01 | 中国石油化工股份有限公司 | High-temperature polyurea lubricating grease composition and preparation method thereof |

| CN104011190A (en) * | 2011-12-22 | 2014-08-27 | 国际壳牌研究有限公司 | Grease composition |

| CN105779083A (en) * | 2014-12-16 | 2016-07-20 | 中国科学院兰州化学物理研究所 | Polytetraurea lubricant grease |

| CN109913287A (en) * | 2019-03-28 | 2019-06-21 | 中国石油化工股份有限公司 | Four urea greases of one kind and preparation method |

| CN111303977A (en) * | 2020-03-24 | 2020-06-19 | 青岛中科润美润滑材料技术有限公司 | Lubricating grease for continuous casting machine and preparation method thereof |

-

2020

- 2020-12-08 CN CN202011444822.0A patent/CN112795418A/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11241084A (en) * | 1998-02-24 | 1999-09-07 | Showa Shell Sekiyu Kk | Urea grease composition |

| CN104011190A (en) * | 2011-12-22 | 2014-08-27 | 国际壳牌研究有限公司 | Grease composition |

| CN103484225A (en) * | 2013-08-29 | 2014-01-01 | 中国石油化工股份有限公司 | High-temperature polyurea lubricating grease composition and preparation method thereof |

| CN105779083A (en) * | 2014-12-16 | 2016-07-20 | 中国科学院兰州化学物理研究所 | Polytetraurea lubricant grease |

| CN109913287A (en) * | 2019-03-28 | 2019-06-21 | 中国石油化工股份有限公司 | Four urea greases of one kind and preparation method |

| CN111303977A (en) * | 2020-03-24 | 2020-06-19 | 青岛中科润美润滑材料技术有限公司 | Lubricating grease for continuous casting machine and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102165052B (en) | Lubricant composition and bearing | |

| CN102876434B (en) | Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition | |

| CN102803450B (en) | lubricating oil composition | |

| CN103484225A (en) | High-temperature polyurea lubricating grease composition and preparation method thereof | |

| WO2006090779A1 (en) | Grease composition and bearing | |

| CN103484204A (en) | Lubricating grease containing modified silica component and preparation method of lubricating grease | |

| JP2020083956A (en) | Grease composition and rolling bearing | |

| CN106978236A (en) | A kind of base oil compounding high temperature complex lithium grease and preparation method thereof | |

| CN112375607B (en) | Tetraurea lubricating grease composition and preparation method thereof | |

| CN102827677A (en) | Ashless lubricating grease composition and preparation method thereof | |

| CN108822939B (en) | White lithium-based lubricating grease and preparation method thereof | |

| CN113512453B (en) | Electric automobile hub bearing lubricating grease composition and preparation method thereof | |

| CN101445759B (en) | Ultra high temperature lubricating grease and production method thereof | |

| CN105419906B (en) | A kind of complex lithium grease | |

| CN112795418A (en) | Tetra-urea lubricating grease composition prepared from aromatic diamine and preparation method thereof | |

| CN109233980B (en) | Lubricating grease and preparation method thereof | |

| CN108841430A (en) | A kind of compound urea aluminium-base grease composition and preparation method | |

| CN107955683A (en) | A kind of multifunctional lubricant | |

| CN104312679A (en) | Low-noise lubricating grease and preparation method thereof | |

| CN113493716A (en) | Lubricating grease composition and preparation method thereof | |

| CN105199817A (en) | Low-temperature lithium-calcium bearing lubricating grease and preparation method | |

| CN112522017B (en) | Composite barium-based lubricating grease and preparation method thereof | |

| CN108102773A (en) | A kind of width temperature extreme pressure water-resistant antiwear lubricating grease and preparation method thereof | |

| CN103555397A (en) | Anhydrous calcium-based lubricating grease composition and preparation method thereof | |

| CN103789067A (en) | Copper foil rolling liquid containing oil-soluble nano Cu and preparation method of copper foil rolling liquid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |