CN112583476B - Optical network terminal and optical fiber testing method - Google Patents

Optical network terminal and optical fiber testing method Download PDFInfo

- Publication number

- CN112583476B CN112583476B CN201910926846.0A CN201910926846A CN112583476B CN 112583476 B CN112583476 B CN 112583476B CN 201910926846 A CN201910926846 A CN 201910926846A CN 112583476 B CN112583476 B CN 112583476B

- Authority

- CN

- China

- Prior art keywords

- optical

- signal

- test

- electrical signal

- laser

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04B—TRANSMISSION

- H04B10/00—Transmission systems employing electromagnetic waves other than radio-waves, e.g. infrared, visible or ultraviolet light, or employing corpuscular radiation, e.g. quantum communication

- H04B10/07—Arrangements for monitoring or testing transmission systems; Arrangements for fault measurement of transmission systems

- H04B10/075—Arrangements for monitoring or testing transmission systems; Arrangements for fault measurement of transmission systems using an in-service signal

- H04B10/079—Arrangements for monitoring or testing transmission systems; Arrangements for fault measurement of transmission systems using an in-service signal using measurements of the data signal

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04B—TRANSMISSION

- H04B10/00—Transmission systems employing electromagnetic waves other than radio-waves, e.g. infrared, visible or ultraviolet light, or employing corpuscular radiation, e.g. quantum communication

- H04B10/50—Transmitters

- H04B10/501—Structural aspects

- H04B10/503—Laser transmitters

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04J—MULTIPLEX COMMUNICATION

- H04J14/00—Optical multiplex systems

- H04J14/02—Wavelength-division multiplex systems

- H04J14/0201—Add-and-drop multiplexing

- H04J14/0202—Arrangements therefor

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04Q—SELECTING

- H04Q11/00—Selecting arrangements for multiplex systems

- H04Q11/0001—Selecting arrangements for multiplex systems using optical switching

- H04Q11/0062—Network aspects

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04Q—SELECTING

- H04Q11/00—Selecting arrangements for multiplex systems

- H04Q11/0001—Selecting arrangements for multiplex systems using optical switching

- H04Q11/0062—Network aspects

- H04Q11/0067—Provisions for optical access or distribution networks, e.g. Gigabit Ethernet Passive Optical Network (GE-PON), ATM-based Passive Optical Network (A-PON), PON-Ring

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04Q—SELECTING

- H04Q11/00—Selecting arrangements for multiplex systems

- H04Q11/0001—Selecting arrangements for multiplex systems using optical switching

- H04Q11/0062—Network aspects

- H04Q2011/0079—Operation or maintenance aspects

- H04Q2011/0083—Testing; Monitoring

Landscapes

- Engineering & Computer Science (AREA)

- Computer Networks & Wireless Communication (AREA)

- Physics & Mathematics (AREA)

- Signal Processing (AREA)

- Electromagnetism (AREA)

- Optics & Photonics (AREA)

- Optical Communication System (AREA)

Abstract

The application discloses an optical network terminal, an optical fiber testing method and a terminal, and belongs to the technical field of optical networks. The optical network terminal only comprises the processing component and the optical component, and the optical component only comprises the first transceiver unit without comprising a plurality of units only having receiving or transmitting functions, namely, the optical component provided by the embodiment of the application has fewer components, so that the manufacturing process is relatively simple, and the manufacturing cost of the optical component can be reduced.

Description

Technical Field

The present application relates to the field of optical network technologies, and in particular, to an optical network terminal, an optical fiber testing method, and a terminal.

Background

In order to reduce the maintenance cost of bandwidth access, a Passive Optical Network (PON) may be used for bandwidth access, and during operation and maintenance of the PON, an Optical Network Terminal (ONT) in the PON network may be used to test an optical fiber in the PON, so as to determine whether the optical fiber in the PON has a fault according to a test result.

In order to implement a test in the ONT, an optical module in the ONT may include a plurality of units, where each unit is configured to have a different function, and taking the optical module composed of the units 1 to 4 as an example, when performing the test, the unit 1 receives a first target electrical signal for the test, performs an electrical-to-optical conversion on the first target electrical signal, obtains a first target optical signal, and transmits the first target optical signal to an optical fiber. When the optical fiber transmits the first target optical signal, the optical fiber reflects the reflected signal of the first optical signal to the unit 2, and then the unit 2 performs photoelectric conversion on the received reflected signal to obtain a second target electrical signal, outputs the second target electrical signal to the sampling component in the ONT, performs sampling processing on the second target electrical signal by the sampling component, and tests the optical fiber based on the sampling result. When the test is not performed, the unit 3 receives a third target electrical signal output by a Media Access Control (MAC) processor of the ONT, performs electro-optical conversion on the third target electrical signal to obtain a second target optical signal, and transmits the second target optical signal to the second directional optical fiber. When the optical fiber connected to the ONT transmits the third target optical signal to the ONT, the unit 4 receives the third target optical signal, performs photoelectric conversion on the third target optical signal to obtain a third target electrical signal, sends the third target electrical signal to the MAC processor, and the MAC processor processes the third target electrical signal.

Since the optical module at least includes four units such as the units 1 to 4, the manufacturing process of the optical module is very complicated to manufacture the four units into one optical module, which results in high manufacturing cost of the optical module.

Disclosure of Invention

The embodiment of the application provides an optical network terminal, an optical fiber testing method and a terminal, which can reduce the manufacturing cost of an optical component. The technical scheme is as follows:

in a first aspect, an optical network terminal is provided, where the optical network terminal includes an optical component and a processing component, where the processing component is configured to output a first electrical signal to the optical component, where the first electrical signal includes a test electrical signal for testing or a non-test electrical signal for carrying service data;

the optical assembly comprises a first transceiver unit, and the first transceiver unit is connected with the processing assembly;

the first transceiver unit is configured to receive the first electrical signal output by the processing component, perform electrical-to-optical conversion on the first electrical signal to obtain a first optical signal with a first wavelength, and transmit the first optical signal to an optical fiber connected to the optical network terminal, and the first transceiver unit is further configured to receive a second optical signal with the first wavelength returned by the optical fiber, perform electrical-to-optical conversion on the second optical signal to obtain a second electrical signal, and output the second electrical signal to the processing component.

The optical network terminal in the above manner only includes the processing component and the optical component, and the optical component only includes the first transceiver unit, and does not need to include a plurality of units having only receiving or transmitting functions, that is, the optical component provided in the embodiment of the present application has fewer components, so that the manufacturing process is relatively simple, and the manufacturing cost of the optical component can be reduced.

In one possible implementation, the first transceiver unit includes a first laser and a first detector;

the first laser is used for receiving the first electric signal output by the processing assembly, performing electro-optical conversion on the received first electric signal to obtain a first optical signal, and transmitting the first optical signal;

the first detector is arranged on an emission optical path of the first laser and is used for transmitting the first optical signal;

the first detector is further configured to receive a second optical signal with the first wavelength returned by the optical fiber, perform photoelectric conversion on the second optical signal to obtain a second electrical signal, and output the second electrical signal to the processing component.

In a possible implementation manner, the first detector is further configured to detect the first optical signal and output a third electrical signal, and the processing component detects whether the first laser is faulty or not according to the third electrical signal.

Based on the possible implementation manner, the processing component detects whether the first laser fails according to the fourth electrical signal, so that the processing component of the optical network terminal can directly monitor the first laser without manual monitoring, and the maintenance cost of the optical network terminal is reduced.

In one possible implementation, the first transceiver unit includes a second laser, a coupler, and a second detector;

the second laser is used for receiving the first electric signal output by the processing component, performing electro-optical conversion on the received first electric signal to obtain a first optical signal, and transmitting the first optical signal;

the coupler is arranged on an emitting light path of the second laser, and the coupler is used for transmitting the first optical signal and reflecting the second optical signal;

the second detector is arranged on a reflected light path of the coupler, and is used for performing photoelectric conversion on the second optical signal to obtain a second electric signal, and outputting the second electric signal to the processing component.

In a possible implementation manner, the optical assembly further includes a second receiving unit, the second receiving unit is configured to detect an optical signal with a second wavelength transmitted through the optical fiber and output a fourth electrical signal, and the processing assembly detects whether the optical fiber is faulty or not according to the fourth electrical signal.

Based on the possible implementation manner, the processing component detects whether the optical fiber has a fault according to the fourth electrical signal, so that whether the optical fiber has the fault can be directly monitored by the processing component of the optical network terminal without manual monitoring, and the maintenance cost of the optical network terminal is reduced.

In one possible implementation, the optical assembly further comprises a first wavelength division multiplexer;

the first wavelength division multiplexer is disposed on an optical path of the first transceiver unit, and the first wavelength division multiplexer is configured to transmit the first optical signal and reflect the second optical signal.

In one possible implementation, the processing component includes a processor and a sampling unit;

the processor is configured to output the first electrical signal to the first transceiver unit, and output a sampling instruction to the sampling unit, where the sampling instruction is used to instruct to sample the second electrical signal;

the sampling unit is used for receiving the second electric signal output by the first transceiving unit, sampling the second electric signal according to the sampling instruction to obtain a sampling result, and testing the optical fiber based on the sampling result.

In a second aspect, an optical network terminal is provided, where the optical network terminal includes an optical component and a processing component, and the processing component is configured to output, to the optical component, a test electrical signal for testing or a non-test electrical signal for carrying service data;

the optical assembly comprises a first transmitting unit and a third receiving unit, and the first transmitting unit and the third receiving unit are both connected with the processing assembly;

the first transmitting unit is configured to receive the test electrical signal output by the processing component, perform electro-optical conversion on the test electrical signal to obtain a test optical signal with a third wavelength, and output the test optical signal to an optical fiber connected to the optical network terminal;

the first transmitting unit is further configured to receive the non-test electrical signal output by the processing component, perform electro-optical conversion on the non-test electrical signal to obtain a non-test optical signal with a first wavelength, and output the non-test optical signal to an optical fiber connected to the optical network terminal;

the third receiving unit is configured to receive the target optical signal of the third wavelength returned by the optical fiber, perform photoelectric conversion on the target optical signal to obtain a target electrical signal, and output the target electrical signal to the processing component.

The optical network terminal in the above manner only includes the processing component and the optical component, and the optical component only includes the first transmitting unit and the third receiving unit, and does not need to include a plurality of units having only receiving or transmitting functions, that is, the optical component provided in the embodiment of the present application has fewer components, and the manufacturing process thereof is relatively simple, so that the manufacturing cost of the optical component can be reduced.

In one possible implementation, the first transmission unit includes a third laser, a fourth laser, and a second wavelength division multiplexer;

the third laser is used for receiving the test electrical signal output by the processing assembly, performing electro-optical conversion on the received test electrical signal to obtain the test optical signal, and transmitting the test optical signal;

the fourth laser is used for receiving the non-test electrical signal output by the processing assembly, performing electro-optical conversion on the received non-test electrical signal to obtain a non-test optical signal, and transmitting the non-test optical signal;

the second wavelength division multiplexer is disposed on an emission optical path of the third laser and an emission optical path of the fourth laser, the second wavelength division multiplexer is configured to transmit the test optical signal and the non-test optical signal and reflect the target optical signal, and the third receiving unit is disposed on a reflection optical path of the second wavelength division multiplexer.

In one possible implementation, the first transmission unit includes a fifth laser and a sixth laser;

the fifth laser is used for receiving the test electrical signal output by the processing assembly, performing electro-optical conversion on the received test electrical signal to obtain the test optical signal, and transmitting the test optical signal;

the sixth laser is arranged on the emitting light path of the fifth laser, and the sixth laser is used for transmitting the test light signal;

the sixth laser is further configured to receive the non-test electrical signal output by the processing component, perform electro-optical conversion on the received non-test electrical signal to obtain the non-test optical signal, and emit the non-test optical signal.

In one possible implementation, the first transmission unit includes a seventh laser;

the seventh laser is used for receiving the test electric signal or the non-test electric signal output by the processing component;

the seventh laser is further configured to perform electro-optical conversion on the received test electrical signal to obtain the test optical signal, and emit the test optical signal;

the seventh laser is further configured to perform electro-optical conversion on the received non-test electrical signal to obtain the non-test optical signal, and to emit the non-test optical signal.

In one possible implementation, the third receiving unit includes a filter and a third detector;

the filter is used for receiving the optical signal, filtering the received optical signal to obtain the target optical signal, and transmitting the target optical signal to the third detector;

the third detector is arranged on a transmission light path of the filter, and is used for receiving the target optical signal transmitted by the filter, performing photoelectric conversion on the received target optical signal to obtain a target electrical signal, and outputting the target electrical signal to the processing component.

In a possible implementation manner, the optical module further includes an optical splitter, where the optical splitter is disposed on a transmission optical path of the optical fiber, and the optical splitter is configured to receive an optical signal, split the optical signal according to a preset splitting ratio to obtain a first split optical signal corresponding to the first transmitting unit and a second split optical signal corresponding to the third receiving unit, output the first split optical signal to the first transmitting unit, and output the second split optical signal to the third receiving unit.

In a possible implementation manner, the third receiving unit is further configured to receive a target optical signal with a third wavelength, and output a fifth electrical signal, and the processing component detects whether the optical fiber is faulty according to the fifth electrical signal.

In the possible mode, the processing assembly detects whether the optical fiber has a fault according to the sixth electric signal without manual monitoring, so that the maintenance cost is reduced.

In one possible implementation, the processing component includes a processor and a sampling unit;

the processor is used for outputting the test electric signal and the non-test electric signal to the first transmitting unit and outputting a sampling instruction to the sampling unit, wherein the sampling instruction is used for instructing the sampling processing of the target electric signal;

the sampling unit is used for receiving the target electric signal output by the third receiving unit, sampling the target electric signal according to the second sampling instruction to obtain a sampling result, and testing the optical fiber based on the sampling result.

In a third aspect, an optical fiber testing method is provided, which is applied to an optical network terminal, where the optical network terminal includes an optical component and a processing component, the optical component includes a first transceiver unit, and the method includes:

the processing component outputs a test electrical signal to the first unit, wherein the test electrical signal is used for indicating to test an optical fiber connected with the network terminal;

the first transceiver unit receives the test electrical signal, performs electro-optical conversion on the test electrical signal to obtain a test optical signal with a first wavelength, and outputs the test optical signal to the optical fiber;

when the test optical signal is transmitted in the optical fiber, the optical fiber returns a second optical signal with the first wavelength to a first transceiver unit;

the first transceiver unit receives the second optical signal, performs photoelectric conversion on the second optical signal to obtain a second electrical signal, and outputs the second electrical signal to the processing assembly;

the processing component tests the optical fiber based on the second electrical signal.

The method can directly use the first transceiver unit and the processing component in the optical network terminal to complete the test process of the optical fiber, and does not need to use equipment except the PON to test the optical fiber in the PON, thereby simplifying the detection process and reducing the detection cost.

In one possible implementation, the optical assembly further includes a second receiving unit, and the method further includes:

the optical fiber transmits optical signals with a second wavelength to the second receiving unit;

the second receiving unit receives the optical signal, performs photoelectric conversion on the optical signal to obtain a sixth electrical signal, and outputs the sixth electrical signal to the processing assembly.

In a fourth aspect, an optical fiber testing method is provided, which is applied to an optical network terminal, where the optical network terminal includes an optical component and a processing component, the optical component includes a first transmitting unit and a third receiving unit, and the method includes:

the processing component outputs a test electrical signal to the first transmitting unit, wherein the test electrical signal is used for indicating that an optical fiber connected with the network terminal is tested;

the first transmitting unit receives the test electrical signal, performs electro-optical conversion on the test electrical signal to obtain a test optical signal with a third wavelength, and transmits the test optical signal to the optical fiber;

when the test optical signal is transmitted in the optical fiber, the optical fiber returns the target optical signal of the third wavelength to the third receiving unit;

the third receiving unit receives the target optical signal, performs photoelectric conversion on the target optical signal to obtain a target electrical signal, and outputs the target electrical signal to the processing assembly;

the processing component tests the optical fiber based on the target electrical signal.

According to the method, the first transmitting unit, the third receiving unit and the processing assembly in the optical network terminal can be directly used for completing the test process of the optical fiber, and equipment except the PON is not needed for testing the optical fiber in the PON, so that the detection process is simplified, and the detection cost is reduced.

In one possible implementation, the optical assembly further includes a second receiving unit, and the method further includes:

the optical fiber transmits optical signals with a second wavelength to the second receiving unit;

the second receiving unit receives the optical signal, performs photoelectric conversion on the optical signal to obtain a sixth electrical signal, and outputs the sixth electrical signal to the processing assembly.

In a fifth aspect, there is provided an optical fiber testing method applied to an optical network terminal including an optical component, the method including:

outputting a test electrical signal to the optical component, performing electro-optical conversion on the test electrical signal by the optical component to obtain a first target test optical signal with a target wavelength, and outputting the first target test optical signal to an optical fiber connected with the optical network terminal, wherein the test electrical signal is used for indicating to test the optical fiber;

receiving a target test electrical signal output by the optical component, wherein the target test electrical signal is obtained by performing photoelectric conversion on a second target test optical signal with the target wavelength returned by the optical fiber by the optical component;

testing the optical fiber based on the target test electrical signal.

The method can directly use the optical component and the processing component in the optical network terminal to complete the test process of the optical fiber, and does not need to use equipment except the PON to test the optical fiber in the PON, thereby simplifying the detection process and reducing the detection cost.

In one possible implementation, before outputting the test electrical signal light to the optical component, the method further includes:

and testing the optical assembly so that the optical assembly performs electro-optical conversion on the test electrical signal to obtain a first target test optical signal with a target wavelength, and performing photoelectric conversion on a second target test optical signal with the target wavelength returned by the optical fiber.

Based on the possible implementation manner, by performing test setting before starting testing, the influence on the first test target optical signal can be reduced, and the precision of the test result can be further improved.

In a sixth aspect, a terminal is provided, where the optical network terminal includes a processor and a memory, where the memory stores at least one instruction, and the instruction is loaded by the processor and executed to implement the operations performed by the optical fiber testing method according to the fifth aspect or any one of the optional manners of the fifth aspect.

Drawings

In order to more clearly illustrate the technical solutions in the embodiments of the present application, the drawings needed to be used in the description of the embodiments are briefly introduced below, and it is obvious that the drawings in the following description are only some embodiments of the present application, and it is obvious for those skilled in the art to obtain other drawings based on these drawings without creative efforts.

Fig. 1 is a schematic diagram of an optical network terminal according to an embodiment of the present application;

fig. 2 is a schematic structural diagram of a first transceiver unit according to an embodiment of the present disclosure;

fig. 3 is a schematic structural diagram of a first transceiver unit according to an embodiment of the present disclosure;

fig. 4 is a schematic structural diagram of an optical network terminal according to an embodiment of the present application;

fig. 5 is a schematic structural diagram of an optical network terminal according to an embodiment of the present application;

fig. 6 is a schematic structural diagram of a terminal according to an embodiment of the present application;

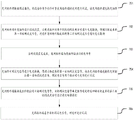

FIG. 7 is a flow chart of a method for testing optical fibers according to an embodiment of the present disclosure;

fig. 8 is a schematic diagram of a PON system according to an embodiment of the present application;

FIG. 9 is a flow chart of a method for testing optical fibers according to an embodiment of the present disclosure;

fig. 10 is a flowchart of an optical fiber testing method according to an embodiment of the present application.

Detailed Description

To make the objects, technical solutions and advantages of the present application more clear, embodiments of the present application will be described in further detail below with reference to the accompanying drawings.

Fig. 1 is a schematic diagram of an optical network terminal according to an embodiment of the present disclosure, referring to fig. 1, the optical network terminal includes an optical component 101 and a processing component 102, where the processing component 102 is configured to output a first electrical signal to the optical component 101, where the first electrical signal includes a test electrical signal for testing or a non-test electrical signal for carrying service data, where the test electrical signal is used to instruct to test an optical fiber connected to the optical network terminal, and the non-test electrical signal is any electrical signal output by the processing component 102 except the test electrical signal, and the test electrical signal and the non-test electrical signal are both electrical signals, where the electrical signal may be a current signal or a voltage signal, and a form of the electrical signal is not specifically limited in the embodiment of the present disclosure.

The optical assembly 101 comprises a first transceiver unit 11, and the first transceiver unit 11 is connected with the processing assembly 102;

the first transceiver unit 11 is configured to receive the first electrical signal output by the processing component, perform electrical-to-optical conversion on the first electrical signal to obtain a first optical signal with a first wavelength, and transmit the first optical signal to an optical fiber connected to the optical network terminal, and the first transceiver unit 11 is further configured to receive a second optical signal with the first wavelength returned by the optical fiber, perform optical-to-electrical conversion on the second optical signal to obtain a second electrical signal, and output the second electrical signal to the processing component 102.

The working principle of the optical network terminal may be as follows: the processing component 102 outputs a first electrical signal to the first transceiver unit 11, when the first transceiver unit 11 receives the first electrical signal, performs photoelectric conversion on the first electrical signal to obtain a first optical signal with a first wavelength, and outputs the first optical signal to an optical fiber connected to an optical network terminal, when the first optical signal is transmitted in the optical fiber, the optical fiber scatters or reflects the first optical signal under the influence of the material of the optical fiber, so that the optical fiber returns a second optical signal with the first wavelength to the first transceiver unit 11, when the first transceiver unit 11 receives the second optical signal, performs photoelectric conversion on the second optical signal to obtain a second electrical signal, and outputs the second electrical signal to the processing component 102, and the processing component 102 processes the second electrical signal.

In some embodiments, the optical assembly further includes a second receiving unit 12, the second receiving unit 12 is connected to the processing assembly 102, and the second receiving unit 12 is configured to receive an optical signal with a second wavelength transmitted through an optical fiber, perform photoelectric conversion on the optical signal to obtain a sixth electrical signal, and output the sixth electrical signal to the processing assembly 102. The output interface of the second receiving unit 12 is connected to the first input interface of the processor assembly 102, and the output interface of the second receiving unit 12 is used for outputting the sixth electrical signal to the first input interface of the processor assembly 102. When the normal service is performed, the optical fiber may transmit an optical signal with a second wavelength to the optical network terminal, where the optical signal with the second wavelength may be any optical signal transmitted by the PON to the optical network terminal through the optical fiber; when the optical signal with the second wavelength is received by the second receiving unit of the optical network terminal, the second receiving unit performs photoelectric conversion on the optical signal to obtain a sixth electrical signal, and outputs the sixth electrical signal to the first input interface of the processing component 102 through the output interface of the second receiving unit 12, and the processing component 102 processes the sixth electrical signal.

As can be known from the operation principle of the optical network terminal, the wavelengths of the first optical signal and the second optical signal passed by the first transceiver unit 11 are both the first wavelength, that is, the wavelengths of the first optical signal corresponding to the test electrical signal and the first optical signal corresponding to the non-test electrical signal are both the first wavelength, where the first wavelength may be 13110nm or 1270nm, and the wavelength of the optical signal transmitted by the optical fiber to the optical network terminal may be the second wavelength, where the second wavelength is 1490nm or 1577 nm.

In some embodiments, the optical component 101 further includes a first Wavelength Division Multiplexer (WDM) 103, the first WDM13 is disposed on the optical path of the first transceiver unit 11, and the first WDM13 is configured to transmit the first optical signal and reflect the second optical signal.

Considering that the optical module 101 may output the first optical signal to the optical fiber and may also receive the optical signal from the optical fiber, in order to indicate the transmission direction of each optical signal passing through the optical module 101, the optical signal output by the optical module 101 to the optical fiber may be referred to as an uplink signal, and the optical signal received by the optical module 101 from the optical fiber may be referred to as a downlink signal, where the wavelength of the uplink signal may be referred to as an uplink wavelength and the wavelength of the downlink signal may be referred to as a downlink wavelength.

Considering that both the first transceiver unit 11 and the second receiver unit 12 can receive the signal from the optical fiber, but the wavelengths of the optical signals received by the two units are different, in order to allow the two units to receive the optical signals required by the two units, the second receiver unit 12 may be disposed on the reflected light path of the first WDM13, and the first WDM13 is further configured to reflect the optical signal of the second wavelength transmitted by the optical fiber to the second receiver unit 12, so that the second receiver unit 12 converts the optical signal of the second wavelength into a sixth electrical signal.

Specifically, when the first WDM13 transmits the first optical signal emitted from the first transceiver unit 11 to the optical fiber, reflects the second optical signal returned through the optical fiber to the first transceiver unit 11, and reflects the optical signal of the second wavelength transmitted through the optical fiber to the second receiver unit 12. It should be noted that, the first WDM13 may transmit the first optical signal to the optical fiber according to the first transmittance, reflect the second optical signal to the first transceiver 11 according to the first reflectance, and transmit the optical signal with the second wavelength to the second receiver 12 according to the second reflectance, and the first transmittance, the first reflectance, and the second reflectance are not specifically limited in this embodiment of the application.

The optical network terminal may further include an optical interface 103, and the optical interface 103 is connected to the optical fiber and disposed on an optical path of the first WDM13 so that the first WDM13 can transmit the first optical signal to an incoming optical fiber through the optical interface 103 and transmit the optical signal to the first WDM13 through the optical interface 103.

The above is a description of the connection mode between each component of the entire optical network terminal and the function of each component, and the following description is made on the internal structure of the optical component 101 in order to further embody the operation principle of the optical component 101.

As can be seen, the first transceiver unit 11 is a unit integrating transceiver function, and for further explaining a specific structure and an operating principle of the first transceiver unit 11, refer to a schematic structural diagram of the first transceiver unit 11 provided in the embodiment of the present application shown in fig. 2, where the first transceiver unit 11 includes a first laser 111 and a first detector 113;

the first laser 111 is configured to receive a first electrical signal output by the processing component 102, perform electro-optical conversion on the received first electrical signal to obtain a first optical signal, and transmit the first optical signal;

a first detector 113 is disposed on an emission optical path of the first laser 111, the first detector 113 being for transmitting the first optical signal;

the first detector 113 is further configured to receive a second optical signal with the first wavelength returned through the optical fiber, perform photoelectric conversion on the second optical signal to obtain a second electrical signal, and output the second electrical signal to the processing component 102.

The connection between the first transceiver unit 11 and the processing component 13 may be as follows: an input interface of the first laser 111 is connected with a first output interface of the processing component 102, and the input interface of the first laser 111 is used for receiving a first electrical signal output by the first output interface; the output interface of the first detector 113 is connected to the second input interface of the processing component, and the output interface of the first detector 113 is used for outputting the second electrical signal to the second input interface.

The operating principle of the first transceiving unit 11 may be: the processing component 102 outputs a first electrical signal to an input interface of the first laser 111 through the first output interface, and after the first laser 111 receives the first electrical signal, performs electro-optical conversion on the first electrical signal to obtain a first optical signal, and transmits the first optical signal to the first detector 113, where because the first detector 113 is disposed on a transmission light path of the first laser 111, the first detector 113 may obtain the first optical signal transmitted by the first laser 111, and transmit the obtained first optical signal to the optical fiber; when the optical fiber returns the second optical signal to the first detector 113, the first detector 113 performs photoelectric conversion on the second optical signal to obtain a second electrical signal, and outputs the second electrical signal to the second input interface of the processing component 102 through the output interface of the first detector 113.

The first laser 111 may be a distributed feedback laser (DFB), or may also be an External Modulation Laser (EML), and the first detector 113 may be a Photodetector (PD), or may also be another detector for photoelectric conversion, where the first laser 111 and the first detector 113 are not specifically limited in this embodiment of the application.

It should be noted that, when the first laser 111 has a forward bias voltage with a first preset value (the positive electrode voltage of the first laser 111 is higher than the negative electrode voltage), the first laser 111 may convert the first electrical signal into the first optical signal, thereby completing the electrical-to-optical conversion of the first electrical signal. When the first detector 113 has a negative bias voltage of a second preset value (the negative voltage of the first detector 113 is higher than the positive voltage), the first detector 113 may convert the second optical signal into a second electrical signal, thereby completing the photoelectric conversion of the second optical signal.

In some embodiments, the optical network terminal may further include a first bias voltage control circuit, where the first bias voltage control circuit may be connected to the first laser 111 and the first detector 113, and the first bias voltage control circuit is configured to provide a first preset value of positive bias voltage for the first laser 111 and provide a second preset value of negative bias voltage for the first detector 113. The first bias voltage control circuit may be packaged in the processing component 102 or the optical component 101, or may be an independent component other than the processing component 102 and the optical component 101.

Since the first detector 113 is not only configured to transmit the first optical signal but also configured to perform photoelectric conversion on the second optical signal, and the optical fiber can only receive the optical signal and cannot receive the electrical signal, when the first detector 113 receives the first optical signal, the first bias voltage control circuit may provide a negative bias voltage or a positive bias voltage smaller than a second preset value for the first detector 113 to prevent the first detector 113 from performing photoelectric conversion on the first optical signal. Specifically, the first bias voltage control circuit may provide a negative bias voltage or a positive bias voltage smaller than a second preset value for the first detector 113 before the processing component 102 sends the first electrical signal, and after a first preset time period, the first bias voltage control circuit provides the negative bias voltage of the second preset value for the first detector 113, where the first preset time period is a difference between a time when the processing component 102 sends the first electrical signal and a time when the first detector 113 receives the second optical signal. In addition, when the first detector 113 performs photoelectric conversion on the second optical signal, the first bias voltage control circuit may provide the first laser 111 with a positive bias voltage or a negative bias voltage smaller than a first preset value, so as to reduce the influence of the first laser 111 on the first detector 113.

It should be noted that the first detector 113 is further configured to detect the first optical signal and output a third electrical signal, and the processing component 102 detects whether the first laser 111 fails according to the fourth electrical signal. The first optical signal is a signal generated by the first laser 111, and thus parameters such as the transmission power and the extinction ratio of the first optical signal can reflect whether the first laser 111 is faulty, for example, when the transmission power of the first optical signal is too small or too large, or when the extinction ratio of the first optical signal is too small or too large, it indicates that the first laser 111 is faulty. Considering that the first detector 113 transmits the first optical signal, when the first detector 113 transmits the first optical signal, the first optical signal may be detected, the magnitude of the transmission power and the magnitude of the extinction ratio of the first optical signal may be detected, the third electrical signal may be used to indicate the magnitude of the transmission power and the magnitude of the extinction ratio of the first optical signal, and the fourth electrical signal may be output to the processing component 102, and the processing component 102 may detect whether the first laser 111 fails according to the fourth electrical signal.

Similarly, the second receiving unit 12 is further configured to detect an optical signal with a second wavelength transmitted through the optical fiber, and output a fourth electrical signal, and the processing component 102 detects whether the optical fiber fails according to the fourth electrical signal. The optical signal with the second wavelength is an optical signal transmitted by an optical fiber, and considering that the second receiving unit 12 receives the optical signal transmitted by the optical fiber, after the second receiving unit 12 receives the optical signal, the received optical signal is detected to obtain a fourth electrical signal, the fourth electrical signal is used for indicating a loss condition of the optical signal during transmission in the optical fiber, and the fourth electrical signal is output to the processing component 102, and the processing component 102 detects whether the optical fiber fails according to the loss condition of the optical signal indicated by the fourth electrical signal during transmission in the optical fiber.

In some embodiments, the first transceiver unit 11 may use the coupler 114 to distinguish optical signals in different directions in consideration of different transmission directions of the first optical signal and the second optical signal, and for further explaining a specific structure and an operation principle of such first transceiver unit 11, refer to a schematic structural diagram of the first transceiver unit 11 provided in the embodiment of the present application shown in fig. 3, where the first transceiver unit 11 includes the second laser 112, the coupler 114, and the second detector 116;

the second laser 112 is configured to receive the first electrical signal output by the processing component 102, perform electro-optical conversion on the received first electrical signal, obtain a first optical signal, and emit the first optical signal;

a coupler 114 is disposed on the emitted optical path of the second laser 112, the coupler 114 being configured to transmit the first optical signal and reflect the second optical signal;

a second detector 116 is disposed on the reflected light path of the coupler 114, the second detector 116 is configured to perform photoelectric conversion on the second optical signal to obtain a second electrical signal, and the second detector 116 is configured to output the second electrical signal to the processing assembly 102.

The connection mode of the first transceiver unit and the processing component may be: an input interface of the second laser 112 is connected with the first output interface of the processing component 102, and the input interface of the second laser 112 is used for receiving the first electrical signal output by the first output interface; the output interface of the second detector 116 is connected to the second input interface of the processing component, and the output interface of the second detector 116 is configured to output the second electrical signal to the second input interface.

The operating principle of the first transceiver unit 11 is as follows: the processing component 102 outputs a first electrical signal to an input interface of the second laser 112 through the first output interface, and after the second laser 112 receives the first electrical signal, performs electro-optical conversion on the received first electrical signal to obtain a first optical signal, and transmits the first optical signal to the coupler 114, and since the coupler 114 is located on a transmission optical path of the second laser 112, the coupler 114 may obtain the first optical signal transmitted by the second laser 112 and transmit the obtained first optical signal to an optical fiber; after the first optical fiber returns the second optical signal to the coupler 114, the coupler 114 reflects the second optical signal to the second detector 116, and since the second detector 116 is located on a reflected light path of the coupler 114, the second detector 116 can obtain the second optical signal reflected by the coupler 114, perform photoelectric conversion on the obtained second optical signal, obtain a second electrical signal, and output the second electrical signal to the second input interface of the processing component 102 through the output interface of the coupler 114.

It should be noted that when the second laser 112 has a forward bias voltage with a first preset value, the second laser 112 may also convert the first electrical signal into a first optical signal, thereby completing the electrical-to-optical conversion of the first electrical signal. When the second detector 116 has a negative bias voltage of a second predetermined value, the second detector 116 may also convert the second optical signal into a second electrical signal, thereby completing the photoelectric conversion of the second optical signal.

The first bias voltage control circuit may further control the voltage of the second laser 112 and the voltage of the second detector 116, and since the second laser 112 and the second detector 116 are not on the same optical path and have no mutual influence, the first bias voltage control circuit may continuously provide the first preset value of the positive bias voltage for the second laser 112 and continuously provide the second preset value of the negative bias voltage for the second detector 116.

It should be noted that the coupler 114 may be an optical splitter or a circulator, when the coupler 114 is an optical splitter, the coupler 114 may partially transmit the first optical signal or partially reflect the second optical signal, and when the coupler 114 is a circulator, the coupler 114 may completely transmit the first optical signal or completely reflect the second optical signal, that is, the coupler 114 may transmit the first optical signal with a third transmittance and reflect the second optical signal with a third reflectance. The coupler 114, the second transmittance, and the third reflectance are not particularly limited in the embodiments of the present application.

In some embodiments, the optical component 101 may further include an amplifying unit, where the amplifying unit is configured to receive the second electrical signal output by the first transceiver 101, perform current/voltage conversion on the received second electrical signal to obtain a first voltage signal, amplify the first voltage signal into a second voltage signal, output the second voltage signal to the processing component 102, and test the optical fiber by the processing component 102 based on the second voltage signal.

In some embodiments, the amplifying unit may include a trans-impedance amplifier (TIA) and at least one amplifier, where the TIA is configured to receive the second electrical signal output by the first transceiver unit 101, perform current/voltage conversion on the first electrical signal to obtain a first voltage signal, and output the first voltage signal to the at least one amplifier; the at least one amplifier is configured to amplify the first voltage signal into a second voltage signal and output the second amplified signal to the processing component 102.

The specific connection structure in the amplification unit may be: an input interface of the TIA is connected with an output interface of the first transceiver unit 11, and is configured to receive a second electrical signal output by the first transceiver unit 101;

at least one amplifier is sequentially connected in series to obtain an amplifier group, an output interface of the TIA is connected with an input interface of a first amplifier in the amplifier group, and the output interface of the TIA is used for outputting a first voltage signal to the input interface of the first amplifier in the amplifier group; the output interface of the last amplifier in the amplifier group is connected to the second input interface of the processing component 102, and the output interface of the last amplifier in the amplifier group is used for outputting the second voltage signal to the second input interface of the processing component 102.

The above is a description of the specific structure of the optical assembly 101, and the following description of the internal structure of the processing assembly 102 is started:

in some embodiments, the processing component 102 comprises a processor 21 and a sampling unit 22;

the processor 21 is configured to output a first electrical signal to the first transceiver unit 11, and output a sampling instruction to the sampling unit 22, where the sampling instruction is used to instruct to perform sampling processing on the second electrical signal;

the sampling unit 22 is configured to receive the second electrical signal output by the first transceiver unit 11, perform sampling processing on the second electrical signal according to the sampling instruction, obtain a sampling result, and test the optical fiber based on the sampling result.

In some embodiments, when the optical assembly comprises the second receiving unit 12, the processor 21 is further configured to receive a sixth electrical signal output by the second receiving unit 12. The connection structure within the process component 102 can be: a first output interface of the processor 21 is connected to an input interface of the first transceiver unit 11, and is configured to output a first electrical signal to the input interface of the first transceiver unit 11; a second output interface of the processor 21 is connected to the first input interface of the sampling unit 22, and is configured to output a sampling instruction to the first input interface of the sampling unit 22; a second input interface of the sampling unit 22 is connected to an output interface of the first transceiver unit 11, and is configured to receive a second electrical signal output by the output interface of the first transceiver unit 11; the input interface of the processor 21 is connected to the output interface of the second receiving unit 12, and is configured to receive the sixth electrical signal output by the output interface of the second receiving unit 12. It should be noted that the sampling unit may be an analog to digital converter (ADC), and the ADC may perform sampling processing on the second electrical signal.

The operating principle of the processing component 102 may be: the processor 21 outputs a first electrical signal to the input interface of the first transceiver unit 11 through the first output interface of the processor 21, so that the first transceiver unit 11 can perform electro-optical conversion on the first electrical signal and output the converted first optical signal to the optical fiber; the processor 21 outputs a sampling instruction to the first input interface of the sampling unit 22 through the second output interface of the processor 21, and the sampling instruction carries the length of the optical fiber to be tested and the sampling time, so that after the sampling unit 22 receives the second electrical signal, the second electrical signal can be sampled according to the length of the optical fiber carried in the sampling instruction and the sampling time, and the optical fiber is tested based on the sampling result. The sampling time may include the time at which sampling begins and the duration of the sampling. The sampling unit 22 may sample the second electrical signal according to the length of the optical fiber carried in the sampling instruction and the sampling time, where the process of sampling the second electrical signal may be: and sampling the second electric signal at the sampling start time included in the sampling time, and terminating the sampling when the length of the optical fiber corresponding to the second electric signal is greater than the length of the optical fiber carried in the sampling instruction, or terminating the sampling when the sampling duration exceeds the sampling duration included in the sampling time. When the output interface of the second receiving unit inputs the sixth electrical signal to the input interface of the processor 21, the processor 21 processes the sixth electrical signal.

In some embodiments, the processor 21 may include a master processor 211 and a slave processor 212, wherein the master processor 211 is configured to output a test instruction to the slave processor 212, and the test instruction is configured to instruct the slave processor 212 to output a test electrical signal;

the slave processor 212 is configured to receive the test instruction output by the master processor 211, output a test electrical signal to the first transceiver unit 11, and output a sampling instruction to the sampling unit 22.

In some embodiments, the processing component 102 further includes a storage unit 23, which is configured to receive a sampling instruction and a storage instruction output from the processor 212, and send the sampling instruction to the sampling unit, where the storage instruction is configured to store the sampling result uploaded by the sampling unit 22 and the test result. If the sampling unit 22 only samples the second electrical signal to obtain a sampling result, but does not test the optical fiber based on the sampling result, after the sampling unit 22 samples the second electrical signal, the sampling unit 22 outputs the sampling result to the storage unit 23, the storage unit 23 stores the current sampling result, and outputs the stored sampling result to the slave processor 212, and the slave processor 212 tests the optical fiber based on the sampling result. When storing the sampling result, the storage unit 23 may store the current sampling result and the optical fiber identifier identifying the optical fiber in an associated manner, so as to represent the sampling result during the test of the optical fiber. If the sampling unit 22 tests the optical fiber based on the sampling result, after the sampling unit tests the optical fiber, the sampling unit 22 outputs the sampling result and the test result to the storage device, the storage unit 23 stores the current sampling result and the current test result, and the storage unit 23 may store the current sampling result, the current test result, and the optical fiber identifier identifying the optical fiber in an associated manner to represent the sampling result and the test result during the optical fiber test.

In some embodiments, the processing assembly 102 further includes a Laser Diode Driver (LDD) 24, the LDD24 is configured to receive the non-test electrical signal output by the main processor 211 and the test electrical signal output by the processor 212, output a first electrical signal to the first transceiver unit 11, and activate the first transceiver unit 11 to convert the first electrical signal into a first optical signal.

In some embodiments, the processing component 102 further includes a Limiting Amplifier (LA) 25, where the LA 25 is configured to receive the sixth electrical signal output by the second receiving unit 12, amplify the sixth electrical signal, and send the amplified sixth electrical signal to the main processor 211, and the main processor 211 processes the amplified sixth electrical signal.

The internal connection structure of the process component 102 may be: the first output interface of the master processor 211 is connected with the first input interface of the slave processor 212, and the first output interface of the master processor 211 is used for outputting a test instruction to the first input interface of the slave processor 212; a first output interface of the slave processor 212 is connected to a first input interface of the LDD24, the first output interface of the slave processor 212 being for outputting a test electrical signal to the first input interface of the LDD 24; a second output interface of the main processor 211 is connected to a second input interface of the LDD24, and the second output interface of the main processor 211 is used for outputting a non-test electrical signal to the second input interface of the LDD 24; an output interface of the LDD24 is connected to an input interface of the first transceiver unit 11, and the output interface of the LDD24 is used for outputting a first electrical signal to the input interface of the first transceiver unit 11; a second output interface of the slave processor 212 is connected to the input interface of the storage unit 23, and the second output interface of the slave processor 212 is configured to output the test instruction and the storage instruction to the input interface of the storage unit 23; a transceiving interface of the storage unit 23 is connected with a transceiving interface of the sampling unit 22, and the transceiving interface of the storage unit 23 is used for outputting a sampling instruction to the transceiving interface of the sampling unit 22 and receiving a sampling result and a test result output by the transceiving interface of the sampling unit 22; an input interface of the sampling unit 22 is connected with an output interface of the first transceiver unit 11, and the input interface of the sampling unit 22 is used for receiving a second electrical signal output by the output interface of the first transceiver unit 11; an input interface of LA 25 is connected to the output interface of the second receiving unit 12, the input interface of LA 25 is configured to receive the sixth electrical signal output by the output interface of the second receiving unit 12, an output interface of LA 25 is connected to the input interface of the main processor 211, and the output interface of LA 25 is configured to output the amplified sixth electrical signal to the input interface of the main processor 211.

At this time, the working principle of the processing component 102 may be: the master processor 211 outputs a test instruction to the first input interface of the slave processor 212 through the first output interface of the master processor 211, where the test instruction may carry a length of an optical fiber to be tested, a test time, and a test mode, where the test time may be a time when the slave processor 212 sends a test electrical signal, and the test mode refers to any mode of testing an optical fiber; when receiving the test instruction, the slave processor 212 outputs a test electrical signal to the first input interface of the LDD24 through the first output interface of the slave processor 212 at the test time carried by the test instruction; the main processor 211 outputs a non-test electrical signal to a second input interface of the LDD24 through a second output interface of the main processor 211; after the LDD24 receives the first electrical signal (test electrical signal or non-test electrical signal); the LDD24 outputs a first electrical signal to the input interface of the first transceiver 11 through the output interface of the LDD24, and activates the first transceiver 11 to convert the first electrical signal into a first optical signal, so that the first transceiver 11 outputs the first optical signal to the optical fiber; after receiving the test instruction, the slave processor 212 further outputs the test instruction and the storage instruction to the input interface of the storage unit 23 through the second output interface of the slave processor 212, and the storage unit 23 outputs the sampling instruction to the transceiving interface of the sampling unit 22 through the transceiving interface of the storage unit 23; after receiving the sampling instruction, the sampling unit 22 waits for receiving the second electrical signal output by the first transceiving unit 11; after the input interface of the sampling unit 22 receives the second electrical signal output by the output interface of the first transceiving unit 11, the sampling unit 22 samples the second electrical signal according to the length and sampling time of the optical fiber carried in the sampling instruction, and tests the optical fiber based on the sampling result; when the input interface of LA 25 receives the sixth electrical signal output by the output interface of second receiving unit 12, LA 25 amplifies the first electrical signal to obtain an amplified sixth electrical signal, LA 25 outputs the amplified sixth electrical signal to the input interface of main processor 211 through the output interface of LA 25, and when the main processor 211 receives the amplified sixth electrical signal, the amplified sixth electrical signal is processed.

The optical network terminal provided by the embodiment of the application only comprises the processing component and the optical component, and the optical component only comprises the first transceiver unit, and does not need to comprise a plurality of units only having receiving or transmitting functions, that is, the optical component provided by the embodiment of the application has fewer components, so that the manufacturing process is relatively simple, and the manufacturing cost of the optical component can be reduced.

The optical component 101 in the optical network terminal includes a first transceiver unit 11 integrating transceiver functions, and in some embodiments, the optical component 101 may further include a unit integrating emission, see fig. 4, which illustrates a schematic structural diagram of the optical network terminal provided in this embodiment of the present application, where the optical network terminal includes an optical component 401 and a processing component 402, and the processing component 402 is configured to output a test electrical signal for testing or a non-test electrical signal for carrying service data to the optical component 401;

the optical assembly 401 includes a first transmitting unit 41 and a third receiving unit 42, and both the first transmitting unit 41 and the third receiving unit 42 are connected to the processing assembly 402;

the first transmitting unit 41 is configured to receive the test electrical signal output by the processing component 402, perform electro-optical conversion on the test electrical signal to obtain a test optical signal with a third wavelength, and output the test optical signal to an optical fiber connected to the optical network terminal;

the first transmitting unit 41 is further configured to receive the non-test electrical signal output by the processing component 402, perform electro-optical conversion on the non-test electrical signal to obtain a non-test optical signal with a first wavelength, and output the non-test optical signal to an optical fiber connected to the optical network terminal;

the third receiving unit 42 is configured to receive the target optical signal with the third wavelength returned through the optical fiber, perform photoelectric conversion on the target optical signal to obtain a target electrical signal, and output the target electrical signal to the processing component 402.

The third wavelength may be 1650nm, and the third wavelength is not limited in the embodiments of the present application. The working principle of the optical network terminal at this time is as follows: when an optical fiber is tested, the processing component 402 outputs a test electrical signal to the first transmitting unit 41, when the first transmitting unit 41 receives the test electrical signal, the test electrical signal is subjected to electro-optical conversion to obtain a test optical signal with a third wavelength, and the test optical signal is output to the optical fiber connected to the optical network terminal, when the optical fiber transmits the test optical signal, the optical fiber scatters or reflects the test optical signal under the influence of the material of the optical fiber, so that the optical fiber returns a target optical signal with the third wavelength to the third receiving unit 42, when the third receiving unit 42 receives the target optical signal, the target optical signal is subjected to electro-optical conversion to obtain a target electrical signal, and the target electrical signal is output to the processing component 402; when the test is not performed, the processing component 402 outputs a non-test electrical signal to the first transmitting unit 41, and when the first transmitting unit 41 receives the non-test electrical signal, performs electro-optical conversion on the non-test electrical signal to obtain a non-test optical signal with a first wavelength, and outputs the non-test optical signal to an optical fiber connected to the optical network terminal, where the non-test optical signal is transmitted in the optical fiber.

In some embodiments, the optical assembly further includes a second receiving unit 12, and since the second receiving unit 12 is described above, the second receiving unit 12 is not described in detail in this embodiment of the present application.

To facilitate the transmission of optical signals between the optical package 401 and the optical fiber, in some embodiments, the optical package 401 further comprises a third wavelength division multiplexer 43;

a third wavelength division multiplexer 43 is disposed on the transmission optical path of the first transmission unit 41, the third wavelength division multiplexer 43 is configured to transmit the test optical signal and the non-test optical signal transmitted by the first transmission unit 41 to the optical fiber, reflect the optical signal transmitted through the optical fiber to the second reception unit 12, and reflect the target optical signal returned through the optical fiber to the third reception unit 42;

the second receiving unit 12 is disposed on a first reflected light path of the optical signal transmitted by the optical fiber reflected by the third wavelength division multiplexer 43, and the third receiving unit 42 is disposed on a second reflected light path of the target optical signal reflected by the third wavelength division multiplexer 43.

In some embodiments, the optical assembly 401 further includes an optical splitter 44, where the optical splitter 44 is disposed on the transmission optical path of the optical fiber, and the optical splitter 44 is configured to receive the optical signal, split the optical signal according to a preset splitting ratio to obtain a first split signal corresponding to the first transmitting and receiving unit 14 and a second split signal corresponding to the third receiving unit 42, output the first split signal to the first transmitting unit, and output the second split signal to the third receiving unit.

It should be noted that, when the third wavelength division multiplexer 43 is not arranged before the optical splitter 44, the optical signal may include an optical signal of the second wavelength, a target optical signal of the third wavelength, and a fourth optical signal of the first wavelength, where the fourth optical signal is an optical signal returned by the optical fiber when the optical fiber transmits a non-test optical signal of the first wavelength. When the third wavelength division multiplexer 43 is disposed in front of the optical splitter 44, the third wavelength division multiplexer 43 reflects the optical signal with the second wavelength to the second receiving unit 12, and transmits the target optical signal with the third wavelength and the fourth optical signal with the first wavelength to the optical splitter 44, at this time, the optical signal received by the optical splitter 44 may include the target optical signal with the third wavelength and the fourth optical signal with the first wavelength, and of course, the optical signal from the optical fiber may also be an optical signal with another wavelength, and therefore, the optical signal received by the optical splitter 44 may also receive an optical signal with another wavelength. When the optical signal received by the optical splitter 44 receives the optical signal, the received optical signal is split according to a preset splitting ratio to obtain a first split optical signal corresponding to the first transmitting and receiving unit 14 and a second split optical signal corresponding to the third receiving unit 42, and the first split optical signal is output to the first transmitting unit and the second split optical signal is output to the third receiving unit. Wherein the preset splitting ratio may be 9: 1, the preset splitting ratio is not specifically limited in the embodiment of the present application.

Since the second split optical signal may include optical signals of other wavelengths in addition to the target optical signal of the third wavelength, and the third receiving unit 42 only needs to process the target optical signal, in some embodiments, the third receiving unit 42 includes a filter 421 and a third detector 422;

the filter 421 is configured to receive the optical signal, filter the received optical signal to obtain a target optical signal, and output the target optical signal to the third detector 422;

the third detector 422 is disposed on the transmission optical path of the filter, and the third detector 422 is configured to receive the target optical signal transmitted by the filter, perform photoelectric conversion on the received target optical signal to obtain a target electrical signal, and output the target electrical signal to the processing component 401.

When the third detector 422 has a negative bias voltage of a third predetermined value, the third detector 422 may convert the target optical signal into a target electrical signal, thereby completing the photoelectric conversion of the target optical signal. In some embodiments, the optical network terminal may further include a second bias voltage control circuit, which may provide a third preset value of negative bias voltage to the third detector 422 so that the third detector 422 may convert the target optical signal into the target electrical signal. The first bias voltage control circuit may be packaged in the processing component 402 or the optical component 401, or may be an independent component other than the processing component 402 and the optical component 401.

In some embodiments, the third receiving unit 42 is further configured to receive the target optical signal with the third wavelength, and output a fifth electrical signal, and the processing component 402 detects whether the optical fiber has a fault according to the fifth electrical signal. Specifically, after the third receiving unit 42 receives the target optical signal, the received target optical signal is detected to obtain a fifth electrical signal, the fifth electrical signal is used to indicate a loss condition of the target optical signal during transmission in the optical fiber, and the fifth electrical signal is output to the processing component 402, and the processing component 402 detects whether the optical fiber fails according to the loss condition of the target optical signal indicated by the fifth electrical signal during transmission in the optical fiber.

Since the first transmitting unit 41 not only needs to perform the electro-optical conversion on the test electrical signal to obtain the test optical signal, but also needs to perform the electro-optical conversion on the non-test electrical signal to obtain the non-test optical signal, and the wavelengths of the test optical signal and the non-test optical signal are different, the first transmitting unit 41 may include two lasers, one laser is used to perform the electro-optical conversion on the test electrical signal to obtain the test optical signal, and the other laser is used to perform the electro-optical conversion on the non-test electrical signal to obtain the non-test optical signal.

In some embodiments, the two lasers may be located on different optical paths, and in one possible implementation, the first transmission unit 41 includes a third laser 411, a fourth laser 413, and a second wavelength division multiplexer 415;

the third laser 411 is configured to receive the test electrical signal output by the processing component 402, perform electro-optical conversion on the received test electrical signal, obtain a test optical signal, and emit the test optical signal;

the fourth laser 413 is configured to receive the non-test electrical signal output by the processing component 402, perform electro-optical conversion on the received non-test electrical signal, obtain a non-test optical signal, and emit the non-test optical signal;

a second wavelength division multiplexer 415 is disposed on an emission optical path of the third laser 411 and an emission optical path of the fourth laser 413, the second wavelength division multiplexer 415 is configured to transmit the test optical signal and the non-test optical signal and reflect the target optical signal, and the third receiving unit 42 is disposed on a reflection optical path of the second wavelength division multiplexer 415.

The connection between the first transmitting unit 401 and the processing module 402 may be as follows: an input interface of the third laser 411 is connected with the first output interface of the processing component 402, and the input interface of the third laser 411 is used for receiving the test electrical signal output by the first output interface of the processing component 402; an input interface of the fourth laser 413 is connected to the second output interface of the processing component 402, and an input interface of the fourth laser 413 is configured to receive the non-test electrical signal output by the second output interface of the processing component 402.