CN112093566A - Lack material early warning equipment based on film unreels at uniform velocity - Google Patents

Lack material early warning equipment based on film unreels at uniform velocity Download PDFInfo

- Publication number

- CN112093566A CN112093566A CN202011127989.4A CN202011127989A CN112093566A CN 112093566 A CN112093566 A CN 112093566A CN 202011127989 A CN202011127989 A CN 202011127989A CN 112093566 A CN112093566 A CN 112093566A

- Authority

- CN

- China

- Prior art keywords

- early warning

- unwinding

- accommodating cavity

- conductive

- follow

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H43/00—Use of control, checking, or safety devices, e.g. automatic devices comprising an element for sensing a variable

- B65H43/02—Use of control, checking, or safety devices, e.g. automatic devices comprising an element for sensing a variable detecting, or responding to, absence of articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H16/00—Unwinding, paying-out webs

- B65H16/02—Supporting web roll

- B65H16/06—Supporting web roll both-ends type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2553/00—Sensing or detecting means

- B65H2553/20—Sensing or detecting means using electric elements

- B65H2553/25—Contact switches

Landscapes

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

Abstract

The invention relates to a material shortage early warning device based on film constant-speed unwinding, which comprises: the device comprises a support frame, an unreeling roller, an unreeling driving device and a material shortage early warning device; the unwinding roller is rotatably arranged on the support frame, and the unwinding driving device is arranged on the support frame; the material shortage early warning device further comprises an early warning driving power supply and an LED early warning lamp, and the LED early warning lamp is connected with the early warning driving power supply after being connected with the conductive switch contact group in series. The invention relates to a material shortage early warning device based on constant-speed film unwinding, which is characterized in that when the unwinding of a plastic film of an unwinding roller is about to be finished, a lamp is turned on to realize material shortage early warning so as to remind workers to change materials in time, and therefore, the production and processing efficiency of the plastic film is improved.

Description

Technical Field

The invention relates to the technical field of plastic film production and processing, in particular to material shortage early warning equipment based on uniform-speed film unwinding.

Background

Plastic film is a very long, wide film structure that is typically stored by being wound onto a roll. When the novel paper roll needs to be used, the novel paper roll is unreeled out for use in a roll unreeling mode.

However, in the existing plastic film production line, in the process of unwinding and processing the film, the plastic film unwinding of the unwinding roller can be known to be finished when no plastic film arrives at the processing station. At the moment, the processing station can only be paused, and the reloading worker at the unreeling station is informed to reload. And after the material changing worker changes the material again, the plastic film is restored to the normal unreeling state again, and when the plastic film is conveyed to the processing station again, the processing station can restore to the normal processing state again. However, the processing station can only pause the processing operation from the time when the processing station finds that the plastic film is not supplied to the processing station to the time when the plastic film is completely replaced and is conveyed to the processing station. This results in inefficient production and processing of the plastic film.

The invention aims to research equipment capable of pre-warning material shortage when a plastic film is about to be unreeled so as to remind workers of replacing materials in time, and therefore the efficiency of plastic film production and processing is improved.

Disclosure of Invention

The invention aims to overcome the defects in the prior art and provides the material shortage early warning device based on the constant-speed film unwinding.

The purpose of the invention is realized by the following technical scheme:

the utility model provides a lack material early warning equipment based on film unreels at the uniform velocity, includes: the device comprises a support frame, an unreeling roller, an unreeling driving device and a material shortage early warning device;

the unwinding roller is rotatably arranged on the support frame, and the unwinding driving device is arranged on the support frame; the unwinding driving device indirectly drives the unwinding roller to rotate by pulling the plastic film at a constant speed so as to realize constant-speed unwinding of the plastic film;

the short-of-material early warning device comprises: the follow-up rotary table, the follow-up rotary column, the conductive switch contact group, the switch conducting piece and the false alarm prevention blocking piece; the follow-up turntable is rotatably arranged on the support frame and is connected with the unreeling roller; the follow-up rotary column is connected with the follow-up rotary disc;

the follow-up rotary column is provided with an accommodating cavity, and the conductive switch contact group is arranged on the bottom wall of the accommodating cavity; the switch conducting piece is arranged in the accommodating cavity in a sliding mode; the false alarm preventing blocking piece is arranged on the side wall of the accommodating cavity through a first spring, and the switch conducting piece is abutted against or separated from the false alarm preventing blocking piece;

the switch conducting piece is provided with a conducting surface, and the conducting surface of the switch conducting piece is abutted against or separated from the conducting switch contact group; the conductive switch contact group comprises two conductive contacts, and the conductive contacts are connected with the bottom wall of the accommodating cavity through a second spring;

the material shortage early warning device further comprises an early warning driving power supply and an LED early warning lamp, and the LED early warning lamp is connected with the early warning driving power supply after being connected with the conductive switch contact group in series.

In one embodiment, a first inclined guide surface is arranged at one end, close to the conductive surface, of the switch conducting piece, and an inclined mating surface is arranged on the false alarm prevention blocking piece and abuts against or separates from the first inclined guide surface.

In one embodiment, the number of the false alarm prevention blocking members is multiple, and the multiple false alarm prevention blocking members are arranged on the same plane at equal intervals along the inner wall of the accommodating cavity.

In one embodiment, the number of the false alarm preventing barriers is two, and the two false alarm preventing barriers are oppositely arranged along the side wall of the accommodating cavity.

In one embodiment, a through groove is formed in the side wall of the follow-up rotary column, and the through groove is communicated with the accommodating cavity and the outside of the follow-up rotary column.

In one embodiment, the early warning driving power supply is fixed on a panel of the follow-up turntable; or the follow-up turntable is provided with an accommodating cavity, and the early warning driving power supply is fixed in the accommodating cavity.

In one embodiment, the material shortage early warning device further comprises a buzzer, and the buzzer is connected with the LED early warning lamp in series.

In one embodiment, the LED early warning lamp is arranged on a panel of the follow-up turntable.

In one embodiment, the second spring is arranged on the bottom wall of the containing cavity through a conductive connecting piece, and the conductive connecting piece is in conductive connection with the conductive contact through the second spring; the conductive connecting piece penetrates through the bottom wall of the accommodating cavity and then is connected with the LED early warning lamp in series.

In one embodiment, the unwinding driving device includes: the unwinding device comprises an unwinding driving motor, an unwinding driving rotating shaft and a free rotating shaft, wherein the unwinding driving rotating shaft is in driving connection with the unwinding driving motor and is rotatably arranged on the supporting frame; the free rotating shaft is rotatably arranged on the supporting frame, and the free rotating shaft is matched with the unreeling driving rotating shaft to clamp and transmit the plastic film.

According to the material shortage early warning device based on the constant-speed film unwinding, when the unwinding of the plastic film of the unwinding roller is about to be finished, the lamp is turned on, the material shortage early warning is realized, so that a worker is reminded to change the material in time, and the production and processing efficiency of the plastic film is improved.

Drawings

In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the drawings needed to be used in the embodiments will be briefly described below, it should be understood that the following drawings only illustrate some embodiments of the present invention and therefore should not be considered as limiting the scope, and for those skilled in the art, other related drawings can be obtained according to the drawings without inventive efforts.

Fig. 1 is a schematic structural diagram (one) of a material shortage early warning device based on uniform-speed unwinding of a film;

fig. 2 is a structural schematic diagram (two) of the short-feeding early warning device based on the uniform-speed unwinding of the film;

fig. 3 is a schematic structural diagram (iii) of the short-feeding early warning device based on uniform-speed unwinding of the film;

fig. 4 is a schematic diagram of the plastic film unwinding state of the short-run early warning device based on uniform-speed unwinding of the film shown in fig. 1;

FIG. 5 is a schematic structural diagram of the short-feeding warning device shown in FIG. 1;

FIG. 6 is a schematic view of a part of the material shortage warning device shown in FIG. 5;

FIG. 7 is another schematic view of FIG. 6;

FIG. 8 is a cross-sectional view of FIG. 5;

FIG. 9 is an enlarged view of a portion of FIG. 8 at A;

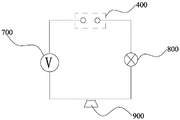

fig. 10 is a circuit connection diagram of the material shortage warning device shown in fig. 1.

Detailed Description

To facilitate an understanding of the invention, the invention will now be described more fully with reference to the accompanying drawings. Preferred embodiments of the present invention are shown in the drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete.

It will be understood that when an element is referred to as being "secured to" another element, it can be directly on the other element or intervening elements may also be present. When an element is referred to as being "connected" to another element, it can be directly connected to the other element or intervening elements may also be present. The terms "vertical," "horizontal," "left," "right," and the like as used herein are for illustrative purposes only and do not represent the only embodiments.

Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. The terminology used herein in the description of the invention is for the purpose of describing particular embodiments only and is not intended to be limiting of the invention. As used herein, the term "and/or" includes any and all combinations of one or more of the associated listed items.

As shown in fig. 1, fig. 2 and fig. 3, the present invention discloses a material shortage warning device 10 based on film constant speed unwinding, which includes: the device comprises a support frame 20, an unreeling roller 30, an unreeling driving device 40 and a material shortage early warning device 50. The unwinding roller 30 is rotatably disposed on the supporting frame 20, and the unwinding driving device 40 is disposed on the supporting frame 20. The unwinding driving device 40 indirectly drives the unwinding roller 30 to rotate by pulling the plastic film 100 at a constant speed, so as to realize that the plastic film 100 is unwound at a constant speed.

As shown in fig. 4 and 5, specifically, the material shortage warning device 50 includes: the follow-up rotary table 200, the follow-up rotary column 300, the conductive switch contact group 400, the switch conducting piece 500 and the false alarm prevention blocking piece 600. The follow-up turntable 200 is rotatably arranged on the support frame 20 and is connected with the unreeling roller 30; the follower post 300 is connected to the follower rotary plate 200. As shown in fig. 5, 6, 7, 8 and 9, the follower rotary post 300 has a cavity 310, and the conductive switch contact set 400 is disposed on the bottom wall 320 of the cavity 310. The switch conducting member 500 is slidably disposed in the receiving cavity 310. The false alarm preventing member 600 is disposed on the sidewall 330 of the receiving cavity 310 through the first spring 610, and the switch conducting member 500 is abutted against or separated from the false alarm preventing member 600. The switch conducting member 500 has a conductive surface 510, and the conductive surface 510 of the switch conducting member 500 is abutted against or separated from the conductive switch contact group 400. The conductive switch contact set 400 includes two conductive contacts 410, and the conductive contacts 410 are connected to the bottom wall 320 of the receiving cavity 310 by a second spring 420.

As shown in fig. 10, the material shortage warning device 50 further includes a warning driving power supply 700 and an LED warning lamp 800, and the LED warning lamp 800 is connected to the warning driving power supply 700 after being connected in series with the conductive switch contact group 400.

Specifically, as shown in fig. 8 and 9, a first inclined guide surface 520 is provided at one end of the switch conductive member 500 close to the conductive surface 510, the anti-misinformation stopper 600 is provided with an inclined mating surface 620, and the inclined mating surface 620 is mated with the first inclined guide surface 520. An end of the switch conducting member 500 away from the conductive surface 510 is provided with a second inclined guide surface 530. The sidewall 330 of the receiving cavity 310 has a receiving groove 333, and the first spring 610 is received in the receiving groove 333.

As shown in fig. 8, specifically, the number of the false alarm prevention blocking members 600 is plural, and the plural false alarm prevention blocking members 600 are disposed on the same plane at equal intervals along the inner wall of the accommodating cavity 310, so that the blocking and limiting of the switch conducting member 500 by the false alarm prevention blocking member 600 are more stable.

Specifically, as shown in fig. 8, a receiving groove 333 is opened in the side wall 330 of the receiving cavity 310, and the first spring 610 is received in the receiving groove 333.

As shown in fig. 8, specifically, the number of the false alarm preventing barriers 600 is two, and the two false alarm preventing barriers 600 are oppositely disposed along the sidewall 330 of the receiving cavity 310.

As shown in fig. 5 and 8, in detail, the sidewall 330 of the follower post 300 is provided with a through groove 340, and the through groove 340 communicates the accommodating cavity 310 and the outside of the follower post 300.

Specifically, the follower rotary plate 200 has a receiving cavity (not shown) in which the warning driving power supply 700 is fixed. Of course, the warning driving power supply 700 may be fixed to the panel of the follower turntable 200.

As shown in fig. 6, an LED early warning lamp 800 is provided on the panel of the follower turntable 200.

As shown in fig. 10, the alarm device 50 further includes a buzzer 900, and the buzzer 900 is connected in series with the LED warning light 800.

As shown in fig. 8 and 9, the conductive connector 430 is disposed on the bottom wall 320 of the receiving cavity 310, and the conductive connector 430 is electrically connected to the conductive contact 410 through the second spring 420. The conductive connecting member 430 penetrates through the bottom wall 320 of the accommodating cavity 310 and is connected with the LED early warning lamp 800 in series. It should be noted that the conductive connecting member 430 can be connected in series with the LED early warning lamp 800 through a wire.

As shown in fig. 4, the driving device 40 includes: unreel driving motor 401, unreel driving shaft 402 and free pivot 403, unreel driving shaft 402 and unreel driving motor 401 drive and be connected, and unreel driving shaft 402 and rotate the setting on support frame 20. The free rotation shaft 403 is rotatably disposed on the supporting frame 20, and the free rotation shaft 403 cooperates with the unreeling driving rotation shaft 402 to clamp and transmit the plastic film 100.

The operation principle of the short-feeding warning device 10 based on the constant-speed unwinding of the film is described below (please refer to fig. 1 to 10):

the plastic film 100 unreeled from the unreeling roller 30 passes through the unreeling driving rotating shaft 402 and the free rotating shaft 403; the unreeling driving motor 401 drives the unreeling driving rotating shaft 402 to rotate at a constant speed, and at the moment, the unreeling driving rotating shaft 402 and the free rotating shaft 403 form clamping and conveying actions on the plastic film 100, so that the plastic film 100 is pulled to move at a constant speed; in the process, the unwinding roller 30 continuously rotates under the pulling of the plastic film 100 and unwinds the plastic film 100 at a constant speed;

it should be noted that, since the plastic film 100 is unreeled at a constant speed, when the remaining amount of the plastic film 100 wound on the unreeling roller 30 is large, the overall diameter of the unreeling roller 30 wound together with the plastic film 100 is large, and at this time, the speed of rotation of the unreeling roller 30 is slow; with the plastic film 100 being continuously unreeled, the overall diameter of the unreeling roller 30 wound together with the plastic film 100 is gradually reduced, and in order to maintain the constant speed unreeling of the plastic film 100, the speed of rotation of the unreeling roller 30 is faster and faster; when the residual amount of the plastic film 100 wound on the unwinding roller 30 is small, the overall diameter of the unwinding roller 30 wound together with the plastic film 100 is small, and at this time, the unwinding roller 30 rotates at a high speed;

in addition, it should be noted that the unwinding roller 30 drives the follower turntable 200 to rotate together when rotating; that is, when the rotation speed of the unwinding roller 30 is slow, the rotation speed of the follower turntable 200 is slow; when the rotation speed of the unwinding roller 30 is high, the rotation speed of the follow-up turntable 200 is high; since the follow-up rotary column 300 is connected with the follow-up rotary disc 200, the follow-up rotary column 300 rotates along with the follow-up rotary disc 200;

when the remaining amount of the plastic film 100 wound around the unwinding roller 30 is large, the unwinding roller 30 rotates at a low speed; at this time, under the action of centrifugal force, the switch conducting piece 500 abuts against the false alarm prevention blocking piece 600 and rotates along with the following rotary column 300; it should be particularly noted that, at this time, the first inclined guiding surface 520 contacts the inclined mating surface 620, and the anti-mis-alarm blocking member 600 forms a certain blocking effect on the switch conducting member 500, so as to prevent the switch conducting member 500 from directly sliding to the bottom wall 320 of the accommodating cavity 310 under the action of centrifugal force to trigger the pre-alarm of missing material by mistake;

with the plastic film 100 being continuously unreeled, the remaining amount of the plastic film 100 wound around the unreeling roller 30 is smaller and smaller, and the rotating speed of the unreeling roller 30 is faster and faster, so that the centrifugal force applied to the switch conducting piece 500 is larger and larger, that is, the force of the switch conducting piece 500 against the false alarm prevention blocking piece 600 is larger and larger;

when the rotation speed of the unwinding roller 30 continues to be increased until the centrifugal force applied to the switch conducting member 500 is enough to break the blocking force of the false alarm preventing blocking member 600, the switch conducting member 500 crosses the false alarm preventing blocking member 600 and abuts against the conductive switch contact group 400, that is, the conductive surface 510 of the switch conducting member 500 abuts against the two conductive contacts 410 of the conductive switch contact group 400 at the same time, and at this time, the conductive surface 510 of the switch conducting member 500 conducts the two conductive contacts 410 of the conductive switch contact group 400; since the LED early warning lamp 800 is connected to the early warning driving power supply 700 after being connected in series with the conductive switch contact group 400, the early warning driving power supply 700, the conductive switch contact group 400, the LED early warning lamp 800 and the buzzer 900 form a closed loop at this time, so that the LED early warning lamp 800 lights up and the buzzer 900 sounds an alarm to realize the material shortage early warning prompt;

it should be noted that, due to the structural design that the inclined mating surface 620 of the anti-false-alarm blocking member 600 and the anti-false-alarm blocking member 600 are connected with the side wall 330 of the accommodating cavity 310 through the first spring 610, on one hand, a certain blocking is formed on the switch conducting member 500, so that when the unwinding roller 30 rotates at a slow speed, the switch conducting member 500 cannot abut against the conductive switch contact group 400, thereby avoiding false alarm; on the other hand, when the rotation speed of the unwinding roller 30 is fast enough and the centrifugal force applied to the switch conducting member 500 is large enough, the first spring 610 is continuously compressed under the acting force of the switch conducting member 500, and the anti-misinformation blocking member 600 moves towards the direction close to the side wall 330 of the accommodating cavity 310, so that a sufficient space is provided for the passage of the switch conducting member 500 and the switch conducting member 500 smoothly passes over the anti-misinformation blocking member 600; the engagement of the inclined engagement surface 620 with the first inclined guide surface 520 further ensures that the switch conducting member 500 smoothly passes over the false alarm prevention stopper 600; on the other hand, when the switch conducting piece 500 crosses the false alarm preventing blocking piece 600, the false alarm preventing blocking piece 600 is reset towards the direction close to the central axis of the accommodating cavity 310 under the action of the elastic restoring force of the first spring 610, so that the switch conducting piece 500 is limited, the conducting surface 510 of the switch conducting piece 500 is stably abutted against the two conducting contacts 410, the material shortage early warning loop of the material shortage early warning device 50 is stably conducted, and the material shortage early warning device 50 enters a stable material shortage early warning state;

it should be further described that the two conductive contacts 410 are connected to the bottom wall 320 of the accommodating cavity 310 through the second springs 420, so that the second springs 420 provide an elastic force for the conductive contacts 410, so that the conductive contacts 410 have a tendency to approach the conductive surface 510, so that the conductive contacts 410 and the conductive surface 510 stably abut against each other, thereby realizing stable conduction of the conductive switch contact set 400, further ensuring stable conduction of the short-of-charge warning loop of the short-of-charge warning device 50, and enabling the short-of-charge warning device 50 to enter a stable short-of-charge warning state;

it should be noted that the sidewall 330 of the follow-up rotary column 300 is provided with a through groove 340, and the through groove 340 communicates the accommodating cavity 310 and the exterior of the follow-up rotary column 300; after the worker finishes replacing the materials, the material shortage early warning prompt of the material shortage early warning device 50 needs to be removed, at this time, the worker only needs to extend a finger into the receiving cavity 310 through the penetrating groove 340, and dial down the switch conducting piece 500, so that the switch conducting piece 500 is separated from the false alarm prevention blocking piece 600;

it should be noted that the matching of the first inclined guiding surface 520 and the inclined matching surface 620, the matching of the second inclined guiding surface 530 and the anti-misinformation stopper 600, and the connection of the anti-misinformation stopper 600, the first spring 610 and the receiving groove 333 form a close matching relationship; due to the structural design, on one hand, the false alarm prevention blocking piece 600 provides enough space for avoiding the switch conducting piece 500, so that the switch conducting piece 500 smoothly passes over the false alarm prevention blocking piece 600; on the other hand, when the worker resets manually, the false alarm prevention blocking member 600 again avoids the switch conducting member 500 when the switch conducting member 500 resets, so that the switch conducting member 500 is more smoothly reset to be separated from the false alarm prevention blocking member 600; on the other hand, when the switch conducting piece 500 crosses the false alarm preventing blocking piece 600, the false alarm preventing blocking piece 600 is reset towards the direction close to the central axis of the accommodating cavity 310 under the action of the elastic restoring force of the first spring 610, so that the switch conducting piece 500 is limited, the conducting surface 510 of the switch conducting piece 500 is stably abutted against the two conducting contacts 410, the material shortage early warning loop of the material shortage early warning device 50 is stably conducted, and the material shortage early warning device 50 enters a stable material shortage early warning state;

it should be noted that if the warning prompt for material shortage is performed by simply lighting the lamp, the worker may easily neglect and fail to see the light in time; therefore, sound early warning is further carried out through the buzzer 900, and it is ensured that the worker receives the material shortage early warning prompt in time and carries out material replacement processing in time, so that the production and processing efficiency of the plastic film 100 is improved.

The above-mentioned embodiments only express several embodiments of the present invention, and the description thereof is more specific and detailed, but not construed as limiting the scope of the invention. It should be noted that, for a person skilled in the art, several variations and modifications can be made without departing from the inventive concept, which falls within the scope of the present invention. Therefore, the protection scope of the present patent shall be subject to the appended claims.

Claims (10)

1. The utility model provides a lack material early warning equipment based on film unreels at uniform velocity which characterized in that includes: the device comprises a support frame, an unreeling roller, an unreeling driving device and a material shortage early warning device;

the unwinding roller is rotatably arranged on the support frame, and the unwinding driving device is arranged on the support frame;

the short-of-material early warning device comprises: the follow-up rotary table, the follow-up rotary column, the conductive switch contact group, the switch conducting piece and the false alarm prevention blocking piece; the follow-up turntable is rotatably arranged on the support frame and is connected with the unreeling roller; the follow-up rotary column is connected with the follow-up rotary disc;

the follow-up rotary column is provided with an accommodating cavity, and the conductive switch contact group is arranged on the bottom wall of the accommodating cavity; the switch conducting piece is arranged in the accommodating cavity in a sliding mode; the false alarm preventing blocking piece is arranged on the side wall of the accommodating cavity through a first spring, and the switch conducting piece is abutted against or separated from the false alarm preventing blocking piece;

the switch conducting piece is provided with a conducting surface, and the conducting surface of the switch conducting piece is abutted against or separated from the conducting switch contact group; the conductive switch contact group comprises two conductive contacts, and the conductive contacts are connected with the bottom wall of the accommodating cavity through a second spring;

the material shortage early warning device further comprises an early warning driving power supply and an LED early warning lamp, and the LED early warning lamp is connected with the early warning driving power supply after being connected with the conductive switch contact group in series.

2. The material shortage early warning device based on film constant-speed unwinding as claimed in claim 2, wherein a first inclined guide surface is arranged at one end, close to the conductive surface, of the switch conducting piece, an inclined fitting surface is arranged on the false alarm prevention blocking piece, and the inclined fitting surface abuts against or is separated from the first inclined guide surface;

one end of the switch conducting piece, which is far away from the conducting surface, is provided with a second inclined guiding surface; the second inclined guide surface abuts against or separates from the false alarm prevention blocking piece;

an accommodating groove is formed in the side wall of the accommodating cavity, and the first spring is accommodated in the accommodating groove.

3. The short-material early warning device based on film constant-speed unwinding as claimed in claim 2, wherein the number of the false alarm prevention blocking members is multiple, and the multiple false alarm prevention blocking members are arranged on the same plane at equal intervals along the inner wall of the accommodating cavity.

4. The short-feeding early warning device based on film constant-speed unwinding as claimed in claim 2, wherein the number of the false alarm prevention blocking members is two, and the two false alarm prevention blocking members are oppositely arranged along the side wall of the accommodating cavity.

5. The short-material early warning device based on film constant-speed unwinding as claimed in claim 4, wherein a through groove is formed in a side wall of the follow-up rotary column, and the through groove is communicated with the accommodating cavity and the outside of the follow-up rotary column.

6. The material shortage early warning device based on the uniform-speed unwinding of the thin film as claimed in claim 5, wherein the early warning driving power supply is fixed on a panel of the follow-up turntable; or the follow-up turntable is provided with an accommodating cavity, and the early warning driving power supply is fixed in the accommodating cavity.

7. The material shortage early warning device based on film constant-speed unwinding as claimed in claim 5, wherein the material shortage early warning device further comprises a buzzer, and the buzzer is connected in series with the LED early warning lamp.

8. The material shortage early warning device based on film constant-speed unwinding as claimed in claim 5, wherein the LED early warning lamp is arranged on a panel of the follow-up turntable.

9. The short-material early warning device based on film constant-speed unwinding is characterized in that the second spring is arranged on the bottom wall of the accommodating cavity through a conductive connecting piece, and the conductive connecting piece is in conductive connection with the conductive contact through the second spring; the conductive connecting piece penetrates through the bottom wall of the accommodating cavity and then is connected with the LED early warning lamp in series.

10. The short-material early warning device based on film constant-speed unwinding as claimed in claim 2, wherein the unwinding driving device comprises: the unwinding device comprises an unwinding driving motor, an unwinding driving rotating shaft and a free rotating shaft, wherein the unwinding driving rotating shaft is in driving connection with the unwinding driving motor and is rotatably arranged on the supporting frame; the free rotating shaft is rotatably arranged on the supporting frame, and the free rotating shaft is matched with the unreeling driving rotating shaft to clamp and transmit the plastic film.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011127989.4A CN112093566A (en) | 2020-10-21 | 2020-10-21 | Lack material early warning equipment based on film unreels at uniform velocity |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011127989.4A CN112093566A (en) | 2020-10-21 | 2020-10-21 | Lack material early warning equipment based on film unreels at uniform velocity |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112093566A true CN112093566A (en) | 2020-12-18 |

Family

ID=73784815

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011127989.4A Withdrawn CN112093566A (en) | 2020-10-21 | 2020-10-21 | Lack material early warning equipment based on film unreels at uniform velocity |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112093566A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102428633A (en) * | 2009-03-10 | 2012-04-25 | 霍姆斯解决方案有限公司 | Improvements in and relating to braking mechanisms |

| US20140367508A1 (en) * | 2013-06-18 | 2014-12-18 | Hewlett-Packard Development Company, L.P. | Monitoring a media roll mounted in a printing apparatus |

| CN108313836A (en) * | 2017-12-29 | 2018-07-24 | 国网山东省电力公司嘉祥县供电公司 | A kind of cable reel installation and application method |

| CN109911704A (en) * | 2019-02-28 | 2019-06-21 | 江苏斯德雷特通光光纤有限公司 | A kind of protective device for optical fiber screening process anti-whip |

-

2020

- 2020-10-21 CN CN202011127989.4A patent/CN112093566A/en not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102428633A (en) * | 2009-03-10 | 2012-04-25 | 霍姆斯解决方案有限公司 | Improvements in and relating to braking mechanisms |

| US20140367508A1 (en) * | 2013-06-18 | 2014-12-18 | Hewlett-Packard Development Company, L.P. | Monitoring a media roll mounted in a printing apparatus |

| CN108313836A (en) * | 2017-12-29 | 2018-07-24 | 国网山东省电力公司嘉祥县供电公司 | A kind of cable reel installation and application method |

| CN109911704A (en) * | 2019-02-28 | 2019-06-21 | 江苏斯德雷特通光光纤有限公司 | A kind of protective device for optical fiber screening process anti-whip |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1178566A (en) | Antitwisting device. | |

| CA2110663A1 (en) | Device for displaying a series of advertisements in a display window | |

| MXPA97003572A (en) | Semiautomatic distributor of labels without recubrimie | |

| CN112093566A (en) | Lack material early warning equipment based on film unreels at uniform velocity | |

| CN114879323B (en) | Laser connection recognition device of optical fiber connector and application thereof | |

| CN112278934A (en) | Early warning equipment for realizing multi-stage material shortage alarm based on uniform-speed film unwinding | |

| CN117416784B (en) | Box sealing adhesive tape production rolling equipment | |

| CN109941843B (en) | Data line storage device | |

| CN214204184U (en) | Data line storage barrel | |

| WO2018058460A1 (en) | Electronic apparatus | |

| CN112278973A (en) | Plastic film unwinding mechanism based on compressing roller realizes lacking material alarm | |

| CN112093567A (en) | Early warning device for realizing multistage material change alarm stepless switching based on film constant-speed unwinding | |

| CN111986854B (en) | Wire and cable equipment disconnection automatic stop control device | |

| CN211010660U (en) | Campus intelligent monitoring device | |

| GB1507150A (en) | Cartridges for web material | |

| CN219058028U (en) | Coating machine coiling mechanism | |

| US1222376A (en) | Attachment for telephones. | |

| US3590182A (en) | Article feeder and delivery mechanism having a shutoff switch | |

| CN115367513B (en) | Film roll mechanism for integrated machine for making and supporting | |

| CN221008374U (en) | Handheld alarm device with GPS positioning function | |

| TWI778834B (en) | Feeder for plastic belt | |

| CN218333481U (en) | Adhesive tape use detection mechanism and bushing winding and adhesive wrapping machine with same | |

| CN218611088U (en) | Steel wire seat and clamp | |

| CN221565354U (en) | Winding drum structure for film production | |

| CN110510193B (en) | Automatic label throwing device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication |

Application publication date: 20201218 |

|

| WW01 | Invention patent application withdrawn after publication |