CN111980715A - Construction method for breaking shield machine to reach tunnel portal - Google Patents

Construction method for breaking shield machine to reach tunnel portal Download PDFInfo

- Publication number

- CN111980715A CN111980715A CN202010867438.5A CN202010867438A CN111980715A CN 111980715 A CN111980715 A CN 111980715A CN 202010867438 A CN202010867438 A CN 202010867438A CN 111980715 A CN111980715 A CN 111980715A

- Authority

- CN

- China

- Prior art keywords

- pile

- tunnel

- piles

- portal

- tunnel portal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000010276 construction Methods 0.000 title claims abstract description 28

- 238000005520 cutting process Methods 0.000 claims abstract description 34

- 238000007689 inspection Methods 0.000 claims abstract description 24

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 20

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 19

- 239000010959 steel Substances 0.000 claims abstract description 19

- 238000005553 drilling Methods 0.000 claims abstract description 16

- 230000005641 tunneling Effects 0.000 claims abstract description 15

- 239000004567 concrete Substances 0.000 claims abstract description 7

- 229910001294 Reinforcing steel Inorganic materials 0.000 claims description 7

- 239000004568 cement Substances 0.000 claims description 7

- 239000000523 sample Substances 0.000 claims description 7

- 238000000034 method Methods 0.000 claims description 6

- 238000004080 punching Methods 0.000 claims description 2

- 239000002002 slurry Substances 0.000 claims description 2

- 230000003014 reinforcing effect Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 2

- 238000001556 precipitation Methods 0.000 description 2

- 239000002893 slag Substances 0.000 description 2

- 239000002689 soil Substances 0.000 description 2

- 238000009412 basement excavation Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000009435 building construction Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000011440 grout Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011150 reinforced concrete Substances 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D9/00—Tunnels or galleries, with or without linings; Methods or apparatus for making thereof; Layout of tunnels or galleries

- E21D9/06—Making by using a driving shield, i.e. advanced by pushing means bearing against the already placed lining

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- Excavating Of Shafts Or Tunnels (AREA)

Abstract

The invention provides a construction method for breaking a shield machine to reach a tunnel portal, which comprises the following steps: s1, stopping tunneling when the shield tunneling machine reaches a certain distance from the tunnel portal, and drilling a plurality of exploring holes at the determined positions of the tunnel portal; s2, inserting an inspection tube with a valve into the exploratory hole and fixing, opening the valve to inspect the water flow in the tunnel door, S3, erecting an operation platform, and sequentially cutting piles in the tunnel door at the top of each pile along the horizontal direction, wherein the cutting depth of each pile is greater than 1/2 of the diameter of the pile until all the piles are completely cut; s4, completely cutting the piles in the tunnel door at the root of the pile along the same cutting direction as the cutting direction of the step S3, S5, and advancing the shield tunneling machine until the pile in the tunnel door is ejected out of the tunnel door; removing concrete at the top of the pile hole S6; fixing the piles to prevent the piles from moving, cutting the residual steel bars at the tops of the piles until the residual steel bars are completely cut off, and transferring the piles out of the tunnel door until all the piles are completely transferred; and S7, after the residual muck in the tunnel portal is cleaned, the shield machine reaches the tunnel portal and is completely broken.

Description

Technical Field

The invention relates to the technical field of building construction, in particular to a construction method for breaking a shield machine to reach a tunnel portal.

Background

The tunnel portal that the shield arrives generally adopts tunnel portal steel ring and reinforced concrete bored pile structure, and the shield constructs the machine and can't directly pass the pile foundation. The existing arrival portal adopts modes of manual breaking, mechanical breaking, rope saw cutting and the like to chisel piles in the portal.

Artifical abolish need personnel directly to chisel the concrete of stake completely and adopt the flame cutting reinforcing bar at the well head, machinery abolishes needs the excavator directly to chisel the concrete of stake completely and adopts the flame cutting reinforcing bar at the well head, the dregs of both directly falls on the well head, later stage clearance dregs volume is great, the required time is also longer, the cost is higher, rope saw cutting needs to fall into a plurality of regions and the drilling volume is great with the door, every stake needs to be cut into the multistage, the cutting volume is great, the process is comparatively complicated, the cost is higher.

Disclosure of Invention

The invention provides a construction method for breaking a shield machine to reach a tunnel portal, which aims to solve the technical problems in the prior art.

The scheme for solving the technical problems is as follows:

a construction method for breaking a shield machine to a tunnel portal comprises the following steps:

s1, stopping tunneling when the shield tunneling machine reaches a certain distance from the tunnel portal, and drilling a plurality of exploring holes at the determined positions of the tunnel portal;

s2, inserting an inspection tube with a valve into the exploratory hole and fixing, opening the valve to inspect the water flow in the tunnel portal, and if the water flow in the tunnel portal is larger than the reasonable flow range, injecting cement slurry into the tunnel portal through the inspection tube until the water flow is reduced to the reasonable flow range

S3, erecting an operation platform, and sequentially cutting piles in the tunnel door at the top of each pile along the horizontal direction, wherein the cutting depth of each pile is greater than 1/2 of the diameter of the pile until all the piles are completely cut;

s4, completely cutting the piles in the door in sequence at the root of the pile along the same cutting direction as the cutting direction of the step S3 until all the piles are completely cut;

s5, the shield machine tunnels forwards until the pile in the tunnel door is ejected out of the tunnel door; removing concrete on the top of the pile hole until the un-sawn reinforcing steel bars on the top of the pile are completely exposed;

s6; fixing the piles to prevent the piles from moving, cutting the residual steel bars at the tops of the piles until the residual steel bars are completely cut off, and transferring the piles out of the tunnel door until all the piles are completely transferred;

and S7, after the residual muck in the tunnel portal is cleaned, the shield machine reaches the tunnel portal and is completely broken.

Further, in the step S1, when the shield machine reaches 500mm-1000mm of the tunnel portal, the tunneling is stopped.

Further, the step S1 of drilling a plurality of probing holes at the determined positions outside the tunnel door specifically includes: and drawing a vertical intersecting straight line by taking the central point of the portal as an original point, and punching holes at the intersection point of the vertical intersecting straight line and the edge of the portal and the central point of the portal.

Furthermore, the vertical intersecting straight lines are two groups and form a Chinese character 'mi'.

Further, in step S2, inserting an inspection tube with a valve into the probe hole and fixing the tube specifically: and closing a valve of the inspection tube, inserting the valve into the probe hole, fixing the inspection tube by adopting an expansion bolt, and plugging a gap between the inspection tube and the probe hole by using cement.

Further, in step S3, the cut depth of each pile is preferably greater than 1/2 of the diameter of the pile.

Further, the fixing the pile to prevent the pile from moving in step S6 specifically includes: the pile is tied by a rope, and hoisting equipment is adopted to hoist the pile to prevent the pile from sliding.

Further, the step S6 of cutting the remaining steel bars at the top of the pile until the steel bars are completely cut off specifically includes: and cutting the residual reinforcing steel bars on the top of the pile by adopting flame until the residual reinforcing steel bars are completely cut off.

Further, the step S6 of transferring the pile out of the door is specifically: and hoisting the pile to the ground by adopting hoisting equipment.

Furthermore, the hoisting equipment is a gantry crane.

The beneficial effects of the invention at least comprise:

(1) the construction method for breaking the shield machine to the tunnel portal saves the construction period, reduces the project amount of pile cutting, and has good social and economic benefits;

(2) the inspection pipe has the function of a grouting pipe, when the water flow of the portal is large, grouting plugging can be performed through the inspection pipe, and the inspection pipe is safer and more convenient to grout compared with other breaking modes, so that the risk of water burst and sand burst of the portal can be well reduced;

(3) the portal pile pushing device fully utilizes the thrust of the shield tunneling machine to push all the piles in the portal and utilizes the gantry crane to fix the piles, thereby greatly reducing the risk of manual operation.

The invention has simple structure and convenient construction, and the pile is lifted to the ground after being sawn off, thereby greatly reducing the portal slag, shortening the time for breaking the portal and reducing the construction cost.

The foregoing description is only an overview of the technical solutions of the present invention, and in order to make the technical solutions of the present invention more clearly understood and to implement them in accordance with the contents of the description, the following detailed description is given with reference to the preferred embodiments of the present invention and the accompanying drawings. The detailed description of the present invention is given in detail by the following examples and the accompanying drawings.

Drawings

The accompanying drawings, which are included to provide a further understanding of the invention and are incorporated in and constitute a part of this application, illustrate embodiment(s) of the invention and together with the description serve to explain the invention without limiting the invention. In the drawings:

fig. 1 is an arriving portal breaking schematic diagram of a construction method for breaking an arriving portal of a shield tunneling machine according to an embodiment of the present invention;

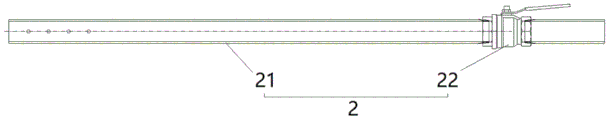

FIG. 2 is a schematic diagram of an inspection tube structure according to an embodiment of the present invention.

Detailed Description

The principles and features of this invention are described below in conjunction with the following drawings, which are set forth by way of illustration only and are not intended to limit the scope of the invention. The invention is described in more detail in the following paragraphs by way of example with reference to the accompanying drawings. Advantages and features of the present invention will become apparent from the following description and from the claims. It is to be noted that the drawings are in a very simplified form and are not to precise scale, which is merely for the purpose of facilitating and distinctly claiming the embodiments of the present invention.

As shown in fig. 1 and 2, the construction method of the embodiment has the greatest characteristic that when the pile is cut, a part of steel bars are reserved at the top of the pile, the pile is pushed down by the thrust of the shield machine, and the whole pile is lifted away from an inlet by a gantry crane, so that the time for breaking the tunnel portal is shortened, and the amount of slag and soil at the wellhead is reduced.

The invention is further explained by combining the attached drawings, and the embodiment is that the shield machine of the subway tunnel construction reaches the receiving construction, wherein the excavation diameter of the shield machine of the tunnel is 6250mm, the outer diameter of a shield segment is 6200mm, and the ring width of the segment is 1500 mm.

After the shield tail of the shield machine enters the reinforcing body, when the cutter head is 500mm-1000mm away from the tunnel portal pile foundation, the tunneling is stopped, and at the moment, the shield machine can keep reasonable soil bin pressure.

The method comprises the steps of marking two groups of vertical intersecting straight lines in a shape like a Chinese character 'mi' on a portal by taking the central point of the portal as an original point, and drilling holes in the portal by adopting a core drilling machine, wherein the positions of the drilling holes are the central point of the portal and the intersecting points of the two groups of vertical intersecting straight lines and the portal steel ring (the two groups of vertical intersecting straight lines are close to the portal steel ring as far as possible, but in order to facilitate drilling, the drilling position needs to slightly deviate towards the central point of the portal steel ring), so that the number of the drilling holes is 9, in the embodiment, the diameter of the drilling holes is 65mm, the depth of the holes is 2500mm, 4 expansion bolts with the diameter of 10mm are arranged on the periphery of the holes, it can be understood that the diameter of the drilling holes can be other values in other embodiments, the diameter value of the drilling holes is related to the diameter of an inspection pipe and the diameter of the portal, and under the common condition.

In this embodiment, as shown in fig. 2, the inspection tube 2 includes a tube body 21 and a valve 22, specifically, in this embodiment, the valve 22 is a ball valve 22, during construction, after the ball valve 22 is closed, the tube body 21 is inserted into the probe hole and fixed by an expansion bolt, and simultaneously, cement is used to seal a gap between the inspection tube 2 and the probe hole. When needing to pay attention, in order to guarantee engineering progress and construction stability, every time beat a trial hole and just install corresponding inspection tube 2 at once to after this inspection tube 2 installation finishes, carry out next trial hole drilling operation again until 9 inspection tubes all install.

Opening the ball valve 22 of the inspection tube 2 to observe the flow and color of the water flow, installing a flowmeter at the opening of the ball valve for accurately measuring the water flow, judging the water flow through the turbidity degree of the water flow for experienced constructors, and directly entering the next step without processing if the clear water and the flow are in a reasonable range; if the water flow is large or the water is turbid, the ball valve is closed, then the grouting pipe is connected, the ball valve is opened again, and then cement grouting is carried out until the water becomes clear or the water flow reaches a reasonable range. It can be understood that, besides the cement grouting method, other measures such as precipitation of precipitation wells can be adopted to reduce the water flow, and as for what measure to reduce the water flow is adopted by the constructor in the actual construction process, the engineering requirements and the construction conditions need to be considered comprehensively, which are routine choices of the technicians in the field, and all of which belong to the protection scope of the present invention, and are not repeated herein.

Next, the pile cutting operation is started: firstly, setting up an operation platform according to the height of a tunnel portal, drawing a line at the top of each pile 1 as shown in figure 1, sequentially cutting the pile from left to right by using a disc saw, and stopping cutting each pile 1 until the diameter of the pile is about 3/4 of the diameter of the pile to form a top cut a; and then the root of the pile 1 is scribed, the disc saw is used for sequentially cutting from left to right, each pile is completely sawed off until all the piles in the portal are cut to form a bottom cut b, wherein the disc saw is used for cutting without raising dust, the portal breaking time is shortened, and the construction cost is effectively reduced.

After the piles 1 in the tunnel portal A are completely cut, the shield machine starts to advance, and continues to advance after the cutter head props the piles until the piles are all pushed down, and the roots of the piles are all removed out of the tunnel portal.

And (3) chiseling concrete at the top of the pile 1 by using a small excavator with a breaking hammer until all the steel bars of the pile 1 are exposed.

The pile is tied by the rope, then the gantry crane is used for hoisting and translating the pile to prevent the pile from sliding, specifically, in order to guarantee the firmness of tying and the stability of the rope, in the embodiment, a steel wire rope with the diameter of 20mm is used for tying the pile, the steel bars at the top of the pile are cut by flame, and after all the steel bars of the pile are cut off, the pile is hoisted to the ground by the gantry crane. And circulating in sequence until all the piles in the tunnel portal are cleaned.

And finally, chiseling the concrete of the left uncut pile in the portal by using a small excavator with a breaking hammer, and cutting the left reinforcing steel bars by using flame to complete the portal breaking.

The foregoing is merely a preferred embodiment of the invention and is not intended to limit the invention in any manner; the present invention may be readily implemented by those of ordinary skill in the art as illustrated in the accompanying drawings and described above; however, those skilled in the art should appreciate that they can readily use the disclosed conception and specific embodiments as a basis for designing or modifying other structures for carrying out the same purposes of the present invention without departing from the scope of the invention as defined by the appended claims; meanwhile, any changes, modifications, and evolutions of the equivalent changes of the above embodiments according to the actual techniques of the present invention are still within the protection scope of the technical solution of the present invention.

Claims (10)

1. A construction method for breaking a shield machine to a tunnel portal is characterized by comprising the following steps:

s1, stopping tunneling when the shield tunneling machine reaches a certain distance from the tunnel portal, and drilling a plurality of exploring holes at the determined positions of the tunnel portal;

s2, inserting an inspection tube with a valve into the exploratory hole and fixing, opening the valve to inspect the water flow in the tunnel portal, and injecting cement slurry into the tunnel portal through the inspection tube if the water flow in the tunnel portal is larger than a reasonable flow range until the water flow is reduced to the reasonable flow range;

s3, erecting an operation platform, and sequentially cutting piles in the tunnel door at the top of each pile along the horizontal direction, wherein the cutting depth of each pile is greater than 1/2 of the diameter of the pile until all the piles are completely cut;

s4, completely cutting the piles in the door in sequence at the root of the pile along the same cutting direction as the cutting direction of the step S3 until all the piles are completely cut;

s5, the shield machine tunnels forwards until the pile in the tunnel door is ejected out of the tunnel door; removing concrete on the top of the pile hole until the un-sawn reinforcing steel bars on the top of the pile are completely exposed;

s6; fixing the piles to prevent the piles from moving, cutting the residual steel bars at the tops of the piles until the residual steel bars are completely cut off, and transferring the piles out of the tunnel door until all the piles are completely transferred;

and S7, after the residual muck in the tunnel portal is cleaned, the shield machine reaches the tunnel portal and is completely broken.

2. The demolition construction method of a shield machine reaching a tunnel portal according to claim 1, characterized in that tunneling is stopped when the shield machine reaches 500mm-1000mm of the tunnel portal in step S1.

3. The breaking construction method for the shield tunneling machine to reach the tunnel portal according to claim 1, wherein the step S1 of drilling a plurality of exploratory holes at the determined positions outside the tunnel portal specifically comprises:

and drawing a vertical intersecting straight line by taking the central point of the portal as an original point, and punching holes at the intersection point of the vertical intersecting straight line and the edge of the portal and the central point of the portal.

4. The demolition construction method according to claim 3 wherein the vertical intersecting lines are two groups and form a "m" shape.

5. The tunnel portal breaking construction method of claim 1, wherein in step S2, inserting an inspection tube with a valve into the exploratory hole and fixing specifically comprises:

and closing a valve of the inspection tube, inserting the valve into the probe hole, fixing the inspection tube by adopting an expansion bolt, and plugging a gap between the inspection tube and the probe hole by using cement.

6. The demolition construction method according to claim 1 wherein each pile cut depth is greater than 1/2 of the pile diameter, preferably each pile cut depth is greater than the pile diameter in step S3.

7. The tunnel portal breaking construction method of the shield tunneling machine according to claim 1, wherein the step S6 of fixing the pile to prevent the pile from moving is specifically as follows:

the pile is tied by a rope, and hoisting equipment is adopted to hoist the pile to prevent the pile from sliding.

8. The demolition construction method for a shield tunneling machine to reach a tunnel portal according to claim 1, wherein the step S6 of cutting the remaining steel bars at the top of the pile until the steel bars are completely cut comprises:

and cutting the residual reinforcing steel bars on the top of the pile by adopting flame until the residual reinforcing steel bars are completely cut off.

9. The method for breaking and constructing the tunnel according to claim 1, wherein the step S6 of transferring the pile out of the tunnel comprises:

and hoisting the pile to the ground by adopting hoisting equipment.

10. The demolition construction method according to claim 1 wherein the hoisting device is a gantry crane.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010867438.5A CN111980715A (en) | 2020-08-25 | 2020-08-25 | Construction method for breaking shield machine to reach tunnel portal |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010867438.5A CN111980715A (en) | 2020-08-25 | 2020-08-25 | Construction method for breaking shield machine to reach tunnel portal |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111980715A true CN111980715A (en) | 2020-11-24 |

Family

ID=73444120

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010867438.5A Pending CN111980715A (en) | 2020-08-25 | 2020-08-25 | Construction method for breaking shield machine to reach tunnel portal |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111980715A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112502729A (en) * | 2020-12-07 | 2021-03-16 | 上海市机械施工集团有限公司 | Method for breaking hole door to enter and exit hole |

| CN113847039A (en) * | 2021-09-30 | 2021-12-28 | 中交(天津)轨道交通工程建设有限公司 | Construction method for breaking pile hole door in SMW (soil mixing wall) construction method in pipe jacking construction |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008013927A (en) * | 2006-07-03 | 2008-01-24 | Nippon Densetsu Kogyo Co Ltd | Pipe jacking method and pipe jacking device |

| CN104847364A (en) * | 2015-05-18 | 2015-08-19 | 中建交通建设集团有限公司 | Construction method of shield and continuous cutting pile foundation for penetrating through residential building group |

| CN111101964A (en) * | 2019-11-18 | 2020-05-05 | 中铁隧道集团二处有限公司 | Construction method for blocking receiving tunnel portal by shield method |

-

2020

- 2020-08-25 CN CN202010867438.5A patent/CN111980715A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008013927A (en) * | 2006-07-03 | 2008-01-24 | Nippon Densetsu Kogyo Co Ltd | Pipe jacking method and pipe jacking device |

| CN104847364A (en) * | 2015-05-18 | 2015-08-19 | 中建交通建设集团有限公司 | Construction method of shield and continuous cutting pile foundation for penetrating through residential building group |

| CN111101964A (en) * | 2019-11-18 | 2020-05-05 | 中铁隧道集团二处有限公司 | Construction method for blocking receiving tunnel portal by shield method |

Non-Patent Citations (1)

| Title |

|---|

| 李维龙: "盾构始发、到达关键施工技术问题分析", <<中国新技术新产品>> * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112502729A (en) * | 2020-12-07 | 2021-03-16 | 上海市机械施工集团有限公司 | Method for breaking hole door to enter and exit hole |

| CN113847039A (en) * | 2021-09-30 | 2021-12-28 | 中交(天津)轨道交通工程建设有限公司 | Construction method for breaking pile hole door in SMW (soil mixing wall) construction method in pipe jacking construction |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110056369B (en) | Construction method for entrance and exit hole of tunnel | |

| CN110821503B (en) | Construction method for main body of ultra-deep shield section air shaft after tunnel advance | |

| CN106837351A (en) | Tunnel karst water detection and treatment method | |

| CN104746517B (en) | A kind of suspension roof support system of total length below artesian head | |

| CN109723443B (en) | Tunnel construction method | |

| CN109707399B (en) | Tunnel exit supporting structure and construction method thereof | |

| CN108643948B (en) | Construction method for shield to penetrate anchor cable area | |

| CN106988750B (en) | Implementation mode of ultra-short-distance underpass of existing station of large-span interval tunnel | |

| CN110107310A (en) | A kind of construction method at tunnel slope hole | |

| CN111997639B (en) | Method for getting rid of trouble and reinforcing and improving geology of TBM construction tunnel bad geology section card machine | |

| CN106836214A (en) | Rotary digging bored concrete pile pile body collapse hole or the construction method of pile bottom sediment mass defect treatment | |

| CN105041322A (en) | Method and system for reinforcing hole for push bench to go in and out | |

| CN111980715A (en) | Construction method for breaking shield machine to reach tunnel portal | |

| CN104452793B (en) | Foam concrete process overhead road of city Bridge Foundation place discards sewage conduct construction technology | |

| CN113216832A (en) | Water-mill drilling construction method for pile hole in karst area | |

| CN107604903A (en) | A kind of miniature steel pipe isolation pile reinforced construction method | |

| CN112942441B (en) | Pre-grouting water-stopping construction method for water-rich powder sand stratum | |

| CN204570696U (en) | Viaduct foundation place discards sewage conduct construction system | |

| CN114526376B (en) | Construction method for stacked wire jacking pipe | |

| CN113982639B (en) | Tunnel lining full-ring dismantling and replacing construction method in unfavorable geological region | |

| CN115596453A (en) | Micro-brush slope tunnel entering method for tunnel long-distance side to pass through accumulation body | |

| CN110485413B (en) | Combined type protection rapid hole forming method for pile foundation of viaduct adjacent to subway | |

| CN220910657U (en) | Horizontal pipe curtain protection structure for gas pipeline | |

| CN104018492A (en) | Bamboo reinforced concrete pile | |

| CN118257604B (en) | Large-scale pile group construction method for shield cutting and grinding |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20201124 |

|

| RJ01 | Rejection of invention patent application after publication |