Disclosure of Invention

The invention aims to provide a Zr-B-N nano composite coating with high hardness and high toughness and a preparation method thereof.

In order to achieve the purpose, the technical scheme adopted by the invention is as follows:

a Zr-B-N nano composite coating with high hardness and high toughness is prepared on a metal, alloy or ceramic material substrate, and a CrN transition layer is deposited between the Zr-B-N nano composite coating and the substrate; wherein the Zr-B-N nano composite coating comprises an amorphous BN phase and ZrB2A crystalline phase.

The Zr-B-N nano composite coating, ZrB2The phase grows preferentially along the (001) crystal face.

The critical load between the Zr-B-N nano composite coating and the substrate is more than 41N, the coating hardness is more than 41GPa, the average friction coefficient of the coating is less than 0.69, and the wear rate of the coating is less than1.2×10-14m3/N·m。

The Zr-B-N nano composite coating is obtained by depositing on the surface of a substrate by adopting a pulse direct current magnetron sputtering technology, and specifically comprises the following steps:

(1) evaporating a metal Cr target by utilizing an arc ion plating technology, and carrying out ion bombardment cleaning on the surface of the matrix;

(2) introducing high-purity Ar and N2And H2Depositing a CrN transition layer by using the mixed gas, and closing a Cr target power supply after the deposition is finished;

(3) in high purity Ar, N2And H2In the mixed atmosphere, ZrB is sputtered by using a pulse direct current magnetron sputtering technology2And (4) carrying out reaction deposition on the Zr-B-N nano composite coating.

Before the ion bombardment cleaning in the step (1), glow discharge cleaning is firstly carried out, and the specific process is as follows: the background of the vacuum chamber is vacuumized to 3.0 x 10-3Pa or below, then introducing high-purity argon and loading-800V direct-current bias to perform glow discharge cleaning on the surface of the substrate, wherein the working pressure is kept at 1.5Pa, and the glow discharge cleaning time is 15 min.

In the step (1), the ion bombardment cleaning process comprises the following steps: introducing 100sccm of argon flow into the vacuum chamber, and maintaining the working pressure at 6.0 × 10-1And Pa, starting an arc ion plating power supply, adjusting the average output current to 90A, controlling the metal Cr target to be subjected to arc striking, keeping the output voltage at 18-25V and the bias voltage at-800V, and performing ion bombardment cleaning for 8 min.

In the step (2), the process of depositing the CrN transition layer is as follows: the bias voltage of the substrate is adjusted to-150V, and high-purity Ar and N are introduced into the vacuum chamber2And H2Maintaining the gas flow ratio (N)2+H2)/(Ar+N2+H2) 4/5, the working pressure is controlled to be 9.0 x 10-1Pa, depositing a CrN transition layer for 10min, and then closing a Cr target power supply.

In the step (3), the process of depositing the Zr-B-N coating is as follows: introducing high-purity Ar and N into the vacuum chamber2And H2Maintaining the gas flow ratio (N)2+H2)/(Ar+N2+H2) 1/11 working pressureEmphasis is placed on 6.0X 10-1Pa, turning on a pulse direct-current magnetron sputtering power supply to control ZrB2Starting the target, wherein the output power is 0.8kW, the target current is 2.5-2.8A, the duty ratio is 50%, the bias voltage of the matrix is kept at-150V, and the Zr-B-N coating is deposited just opposite to the target; the deposition time is determined according to the coating thickness requirement.

In the process of depositing the CrN transition layer in the step (2), the target base distance is kept at 280mm, and the deposition temperature is 400 ℃; in the Zr-B-N coating deposition process in the step (3), the target base distance is 75mm, and the deposition temperature is 400 ℃.

In the coating deposition process in the step (2) and the step (3), N is in the vacuum chamber2And H2The gas volume ratio of (3) is 9: 1.

The design mechanism of the invention is as follows:

the invention adopts the pulse direct current magnetron sputtering technology to deposit the Zr-B-N nano composite coating on the surface of the metal or alloy substrate in the reducing atmosphere, and further improves the toughness and the friction performance on the premise of ensuring the hardness of the coating. The invention realizes that a large amount of two-phase (amorphous and nanocrystalline) interfaces are utilized to block the initiation and expansion of microcracks, thereby improving the toughness of the coating. And the introduction of the reducing reaction gas removes residual oxygen impurities in the vacuum chamber through reduction reaction, and inhibits the oxygen oxide from damaging the performance of the coating.

The invention adopts the pulse direct current magnetron sputtering technology to deposit the Zr-B-N nano composite coating on the metal or alloy matrix, and in order to improve the bonding strength between the coating and the matrix, before the deposition of the Zr-B-N coating, the arc ion plating technology is firstly used for bombarding and cleaning the matrix, and then a CrN transition layer with the thickness of about 300nm is deposited, thereby playing the role of buffering the internal stress. In order to increase the content of hard phase in the coating, a compound ZrB is selected2The target is used as a pulse direct current magnetron sputtering target in the reaction gas N2Mixed with a proper amount of reducing gas H2Removing residual oxygen impurities and N in the coating chamber by reduction reaction in the coating process2Mixed with oxygen impurities, optimizes the deposition process and inhibits the amorphous B in the coating2O3The damage of the O element to the amorphous layer is reduced, and the purity and the hardness of the coating are improved; doping the coating with a proper amount of N elementTo form the amorphous BN phase, the nanocomposite structure is utilized to improve the toughness of the coating. The reaction gas flow and the sputtering power of the target are strictly controlled during film coating, and the Zr-B-N nano composite coating with compact structure, high hardness and high toughness is prepared.

The invention has the following advantages:

1. the Zr-B-N coating developed by the invention has stable chemical performance, does not react with common chemical corrosion media, and has good corrosion resistance. The amorphous BN phase and the nanocrystalline interface in the coating can effectively prevent the initiation and the expansion of microcracks, and the toughness of the coating is greatly improved.

2. The Zr-B-N coating developed by the invention has higher hardness and elastic modulus and excellent wear resistance. The introduction of the reducing atmosphere improves the purity of the coating and reduces the damage of oxygen oxide to the hardness of the coating.

3. The Zr-B-N coating developed by the invention has good impact load resistance and can be used in the fields of high-speed cutting and dry cutting.

4. The Zr-B-N prepared by the invention has uniform thickness and compact structure, and is well combined with the matrix.

5. The Zr-B-N coating developed by the invention has the advantages of simple preparation process, good repeatability, wide application range and strong practicability.

Detailed Description

The present invention is further illustrated by the following examples.

Example 1

This example is a mirror polished single crystalThe Zr-B-N coating is deposited on the Si sheet (the (100) crystal face), and the size of the substrate is 50mm multiplied by 10mm multiplied by 0.7 mm. Before coating, the substrate is ultrasonically cleaned in alcohol solution for 20 minutes, then is dried by high-purity nitrogen, and is placed on a sample rack in a vacuum chamber opposite to the target. The coating process is carried out on a V-TECH AS610 type pulse direct current magnetron sputtering coating machine, an arc ion plating cathode is also arranged on the coating machine, and the target material is respectively selected from a metal Cr target and a compound ZrB2Target (purity is 99.9 wt.%), metal Cr target is used for ion bombardment cleaning of substrate surface and deposition of CrN transition layer, compound ZrB2The target is used for depositing the Zr-B-N coating; high-purity Ar (purity 99.999%) and high-purity N are respectively used as working gas and reaction gas2+H2(gas volume ratio N2:H2=9:1)。

The background of the vacuum chamber is first vacuumized to 3.0X 10-3Pa, introducing argon gas to carry out glow discharge cleaning on the surface of the sample, keeping the working pressure at 1.5Pa, loading-800V direct current bias voltage, and carrying out discharge cleaning for 15 min; then, the flow rate of argon gas was reduced to emphasize the working pressure to 6.0X 10-1Pa, starting an arc ion plating power supply, controlling the metal Cr target to be in arc striking, controlling the average output current to be 90A, the output voltage to be 18-25V, keeping the bias voltage to be-800V, and performing bombardment cleaning for 8 min; then, the bias voltage is reduced to-150V, and N is introduced2And H2Mixed gas (gas volume ratio N)2:H29:1), maintaining the gas flow ratio (N)2+H2)/(Ar+N2+H2) 4/5, the working pressure is adjusted to 9.0 × 10-1Pa, depositing a CrN transition layer for 10min, keeping the target base distance at 280mm, and depositing at 400 ℃; then the Cr target power supply is turned off, and the gas flow ratio in the vacuum chamber is adjusted to (N)2+H2)/(Ar+N2+H2) Control throttle emphasizes operating pressure to 6.0 × 10 ═ 1/11-1Pa, simultaneously starting a pulse direct-current power supply, outputting power of 0.8kW, target current of 2.5-2.8A and duty ratio of 50%, and controlling ZrB2Starting the target glow, and beginning to face the target material to deposit the Zr-B-N coating, wherein the target base distance is 75mm, and the substrate bias voltage is still-150V; continuously coating for 60 min.

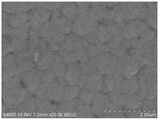

The surface appearance and the cross-sectional appearance of the Zr-B-N coating are shown in figures 1 and 21, the tissue structure of the coating surface is uniform and compact, and no large particles or liquid drops appear. According to the section morphology of the Zr-B-N coating (figure 2), the internal structure of the coating has no obvious columnar crystal, and the interface combination between the coating/a transition layer/a matrix is good. FIG. 3 shows the results of X-ray diffraction analysis of a Zr-B-N coating prepared by the process of this example, the coating consisting essentially of polycrystalline ZrB2Phase composition of ZrB of (001) plane2The phase diffraction peak is strongest and is the preferential growth direction of the coating. No diffraction peak related to N element is found, according to the analysis of element valence state, the N element mainly exists in an amorphous BN phase to form a composite structure of an amorphous layer wrapping nanocrystalline, and the existence of a two-phase (amorphous and nanocrystalline) interface can prevent the initiation and expansion of microcrack, so that the toughness of the coating is improved.

Example 2

This example was a 30mm x 3mm substrate of mirror polished YG8 cemented carbide with Zr-B-N coating deposited thereon. The substrate is firstly ground and polished by metallographic abrasive paper, then is sequentially ultrasonically cleaned by acetone, a degreasing agent, ultrapure water and an alcohol solution, is blow-dried by high-purity nitrogen, and is placed on a sample rack in a vacuum chamber opposite to the target. The deposition process and process parameters were the same as in example 1.

FIG. 4 is a hardness test result of a Zr-B-N coating deposited on a hard alloy substrate. The coating hardness test value fluctuation is small and changes within the range of 39-43 GPa, the average value of 5 measurements is 41.9 +/-1.2 GPa, and the coating hardness is high. The bonding strength of the coating and the substrate was tested by a scratch method, the radius of the tip of a diamond scribe was 200 μm, the normal load was gradually increased from 0N to 80N at a rate of 2.67N/s, the length of the scratch was 15mm, and the test speed was 0.5 mm/s. Selecting different positions for testing for 5 times, and taking an average value, wherein the critical load of the Zr-B-N coating is 41.3 +/-0.7N, the figure 5 shows the scratch appearance on the Zr-B-N coating after the scratch test, the position of the coating completely stripped from the matrix can be identified from the figure, and the grey area is the residual coating and the white area is the hard alloy matrix after the energy spectrum analysis. FIG. 6 is a plot of the coefficient of friction of a Zr-B-N coating against a 6mm diameter alumina ceramic ball, under test conditions: normal load of 2N, sliding speed of 0.1m/s, dry frictionThe rotary motion, the grinding scar orbit radius is 9 mm. From the friction coefficient curve, the average friction coefficient at the stable friction stage was calculated to be 0.69, and the average wear rate of the Zr-B-N coating layer was 1.12X 10-14m3The coating prepared by the method has good frictional wear performance.