CN111571014A - Handheld rifle head of adjustable laser of facula - Google Patents

Handheld rifle head of adjustable laser of facula Download PDFInfo

- Publication number

- CN111571014A CN111571014A CN202010539714.5A CN202010539714A CN111571014A CN 111571014 A CN111571014 A CN 111571014A CN 202010539714 A CN202010539714 A CN 202010539714A CN 111571014 A CN111571014 A CN 111571014A

- Authority

- CN

- China

- Prior art keywords

- gun head

- rotor

- head body

- spot

- mirror

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/20—Bonding

- B23K26/21—Bonding by welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/04—Automatically aligning, aiming or focusing the laser beam, e.g. using the back-scattered light

- B23K26/046—Automatically focusing the laser beam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/073—Shaping the laser spot

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Telescopes (AREA)

Abstract

The invention provides a light spot adjustable laser handheld gun head, wherein a collimating mirror is arranged on a collimating mirror base, and the collimating mirror base is inserted into a gun head body through a through hole, so that the collimating mirror base can be conveniently taken out, and the collimating mirror can be replaced; the laser handheld gun head is further provided with the fixing plate and the sleeve, so that the moved spray pipe can be fixed through the fixing plate and the sleeve in the moving process of the spray pipe, and the spray pipe cannot shake; according to the laser handheld gun head, the first wedge-shaped mirror is arranged in the inner rotor, the second wedge-shaped mirror is arranged in the outer rotor, the outer rotor is rotated relative to the inner rotor through adjustment, the first wedge-shaped mirror and the second wedge-shaped mirror are rotated relative to each other, different angle differences are generated between the first wedge-shaped mirror and the second wedge-shaped mirror, the refraction angle of a light path is changed, the light spot can be moved, the size of the light spot is changed, and various welding process requirements can be met.

Description

Technical Field

The invention relates to the technical field of laser processing equipment, in particular to a handheld laser gun head with an adjustable light spot.

Background

Laser in the existing market is more and more widely applied, wherein laser welding is particularly prominent, the working principle of the existing laser gun head is that laser beams are collimated by a collimating lens and then enter a wedge-shaped lens, and then pass through a focusing lens and a protective lens and then laser processing is carried out on a workpiece through a nozzle.

Disclosure of Invention

In view of this, the invention provides a spot-adjustable laser handheld gun head with a collimator lens convenient to replace.

The technical scheme of the invention is realized as follows: the invention provides a laser handheld gun head with an adjustable light spot, which comprises: the gun head comprises a gun head body, a collimating mirror and a collimating mirror base, wherein the collimating mirror is installed on the collimating mirror base, a through hole is formed in the gun head body, and the collimating mirror base is inserted into the gun head body through the through hole.

On the basis of the technical scheme, the collimator base further comprises a bolt, screw holes are formed in the side face of the collimator base and the corresponding positions of the gun head body, and the bolt is in threaded connection with the screw holes so that the collimator base is fixed in the gun head body.

On the basis of the technical scheme, the improved gun head further comprises a spray pipe, wherein the spray pipe is arranged inside the front end of the gun head body and penetrates out of the gun head body, and the spray pipe can move along the gun head body.

Further preferably, the spray gun further comprises a fixing plate and a sleeve, the fixing plate is circumferentially fixed on the periphery of the front end face of the gun head body at intervals, the side face, close to the spray pipe, of the fixing plate is attached to the spray pipe, a first inclined face inclining towards the spray pipe is arranged at the front end of the side face, far away from the spray pipe, of the fixing plate, the sleeve is sleeved on the periphery of the fixing plate and is in threaded connection with the fixing plate, and a second inclined face matched with the first inclined face is arranged on the sleeve in a position corresponding.

Further preferably, a portion of the fixing plate corresponding to the first inclined surface is made of an elastic material.

Further preferred, still include stator, rotor, first wedge mirror and second wedge mirror, stator, rotor all are located rifle head this internal and are located collimating mirror base the place ahead, the rotor can rotate relative to the stator, the rotor includes inner rotor and outer rotor, first wedge mirror is installed in the inner rotor, the second wedge mirror is installed in the outer rotor, the outer rotor cover is established in the inner rotor periphery and inner rotor rotation relatively.

Further preferred, still include first adjusting collar, second adjusting collar and adjust the pole, first adjusting collar is installed in the inner rotor periphery, the second is adjusted the cover and is installed in the outer rotor periphery, first adjusting collar, second adjusting collar tip all are equipped with bevel gear, it installs at rifle head originally internally and is located between first adjusting collar, the second adjusting collar to adjust the pole, adjust the pole both sides respectively with bevel gear engagement, it rotates to drive the relative inner rotor rotation of outer rotor to adjust the pole.

Preferably, the first adjusting sleeve is circumferentially provided with a plurality of positioning holes, each positioning hole is internally provided with a spring, the end part of each spring is fixedly provided with a ball, the second adjusting sleeve is provided with a groove corresponding to the positioning hole, and the end part of each ball can be clamped in the groove.

Further preferably, the inner wall of the gun head body is provided with a mounting hole, the adjusting rod is located in the mounting hole and can move along the mounting hole, and the outer periphery of the adjusting rod is sleeved with a return spring.

Further preferably, the end of the adjusting rod is also provided with a positioning groove.

Compared with the prior art, the laser handheld gun head with the adjustable light spot has the following beneficial effects:

(1) according to the handheld laser gun head with the adjustable light spot, the collimating lens is arranged on the collimating lens base, and the collimating lens base is inserted into the gun head body through the through hole, so that the collimating lens base can be conveniently taken out, and the collimating lens is further replaced;

(2) the laser handheld gun head with the adjustable light spot is further provided with the fixing plate and the sleeve, so that the movable spray pipe can be fixed through the fixing plate and the sleeve in the moving process of the spray pipe, and the spray pipe cannot shake;

(3) according to the spot-adjustable laser handheld gun head, the first wedge-shaped mirror is arranged in the inner rotor, the second wedge-shaped mirror is arranged in the outer rotor, the outer rotor is rotated relative to the inner rotor through adjustment, and the first wedge-shaped mirror and the second wedge-shaped mirror are rotated relative to each other, so that different angle differences are generated between the first wedge-shaped mirror and the second wedge-shaped mirror, the refraction angle of a light path is changed, the spot can be moved, the size of a spot is changed, and various welding process requirements can be met;

(4) according to the laser handheld gun head with the adjustable light spot, the conical gears are arranged on the outer sides of the end parts of the first adjusting sleeve and the second adjusting sleeve, the periphery of the end part of the adjusting rod is respectively meshed with the conical gears on the first adjusting sleeve and the second adjusting sleeve, when the adjusting rod rotates, the first adjusting sleeve and the second adjusting sleeve are driven to rotate relatively, the first wedge-shaped mirror and the second wedge-shaped mirror are further driven to rotate relatively, the refraction angle of a light path is changed, and the first adjusting sleeve and the second adjusting sleeve can be simply and conveniently rotated relatively through the adjusting rod;

(5) the laser handheld gun head with the adjustable light spot is further provided with a spring and a ball, when the first adjusting sleeve rotates relative to the second adjusting sleeve, the spring is compressed, when the first adjusting sleeve rotates relative to the second adjusting sleeve, the spring returns to a natural state when the first adjusting sleeve rotates to the position where the positioning hole is opposite to the other groove, and the ball is clamped in the groove.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to the drawings without creative efforts.

Fig. 1 is a schematic perspective view of a laser handheld gun head with an adjustable light spot according to the present invention;

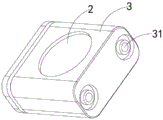

FIG. 2 is a schematic perspective view of a collimator base of the spot-adjustable laser handheld gun head according to the present invention;

FIG. 3 is a schematic perspective view of the connection between the nozzle and the fixing plate according to the present invention;

FIG. 4 is a schematic perspective view of the sleeve of the present invention;

FIG. 5 is a cross-sectional view of a spot adjustable laser torch head of the present invention;

FIG. 6 is an enlarged view of FIG. 5 taken at the circle;

FIG. 7 is a cross-sectional view of the engagement between the adjustment lever of the present invention and the first and second adjustment sleeves;

fig. 8 is a schematic perspective view of the connection of the first adjusting sleeve, the adjusting rod and the cover plate according to the present invention.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be obtained by a person skilled in the art without any inventive step based on the embodiments of the present invention, are within the scope of the present invention.

As shown in fig. 1 to 8, the invention provides a handheld laser gun head with an adjustable light spot, which comprises: the gun head comprises a gun head body 1, a collimating mirror 2, a collimating mirror base 3, a spray pipe 4, a fixing plate 5, a sleeve 6, a stator 7, a rotor 8 and an adjusting rod 9.

The laser welding gun head comprises a gun head body 1 which is a main part of a laser handheld gun head with an adjustable light spot, a collimating lens 2, a focusing lens 12 and a protective lens 13 are obviously arranged in the gun head body 1, laser beams are collimated by the collimating lens 2, pass through a wedge-shaped lens, are focused by the focusing lens 12 and are ejected from a spray pipe 4 of the gun head body 1 through the protective lens 13, and then laser welding processing is carried out on workpieces.

And a collimating mirror 2 for collimating the laser beam.

Collimating mirror base 3, it is used for installing collimating mirror 2, it is concrete, can set up mounting hole collimating mirror 2 on collimating mirror base 3 and install on collimating mirror base 3, in practice, collimating mirror 2 detachable installs on collimating mirror base 3, and seted up a through-hole on rifle head body 1, collimating mirror base 3 is inserted through the through-hole and is located rifle head body 1, so, can install collimating mirror 2 in rifle head body 1, through this kind of mode, can be convenient take out collimating mirror base 3, and then change collimating mirror 2.

The further bolt that still is equipped with, screw 31 has all been seted up to corresponding position on 3 sides of collimating mirror base and rifle head body 1, then passes through the bolt spiro union in screw 31, and then installs the stable installation in rifle head body 1 of collimating mirror base 3.

The fixing plate 5 and the sleeve 6 are used for fixing the spray pipe 4, specifically, the fixing plate 5 is circumferentially fixed on the periphery of the front end face of the gun head body 1 at intervals, the side face of the fixing plate 5 close to the spray pipe 4 is attached to the peripheral face of the spray pipe 4, the front end of the side face of the fixing plate 5 far away from the spray pipe 4 is provided with a first inclined face 51 inclined towards the spray pipe 4, the sleeve 6 is sleeved on the periphery of the fixing plate 5 and is in threaded connection with the fixing plate 5, specifically, an external thread is arranged on the fixing plate 5 except the first inclined face 51, an internal thread is correspondingly arranged on the corresponding position of the inner wall of the sleeve 6, so that the sleeve 6 is in threaded connection with the periphery of the fixing plate 5, meanwhile, a second inclined face 61 matched with the sleeve 6 is arranged on the sleeve 6 corresponding to the first inclined face 51, when the sleeve 6 is loosened, then, the sleeve 6 is screwed until the second inclined surface 61 of the sleeve 6 is tightly attached to the first inclined surface 51, so that the fixing plate 5 clamps the nozzle 4, and further fixes the nozzle 4, in practice, the portion of the fixing plate 5 corresponding to the first inclined surface 51 is made of an elastic material.

The collimator comprises a stator 7 and a rotor 8, obviously, the stator 7 and the rotor 8 both belong to the components of a motor, the stator 7 and the rotor 8 are both arranged in the gun head body 1 and are positioned in front of a collimating mirror base 3, and actually, coils are arranged, and the rotor 8 can rotate relative to the stator 7 after being electrified; specifically, the rotor 8 includes an inner rotor 81 and an outer rotor 82, the inner rotor 81 and the outer rotor 82 are both hollow cylinders, and the outer rotor 82 is sleeved on the periphery of the inner rotor 81 and can rotate relative to the inner rotor 81;

Specifically, the outer rotor 82 can rotate relative to the inner rotor 81 through a first adjusting sleeve 91, a second adjusting sleeve 92 and an adjusting rod 9, the first adjusting sleeve 91 is installed on the periphery of the inner rotor 81, the second adjusting sleeve 92 is installed on the periphery of the outer rotor 82, the outer sides of the end portions of the first adjusting sleeve 91 and the second adjusting sleeve 92 are respectively provided with a bevel gear 93, the adjusting rod 9 is installed in the gun head body 1 and located between the first adjusting sleeve 91 and the second adjusting sleeve 92, the periphery of the end portion of the adjusting rod 9 is respectively meshed with the bevel gears 93 on the first adjusting sleeve 91 and the second adjusting sleeve 92, when the adjusting rod 9 rotates, the first adjusting sleeve 91 and the second adjusting sleeve 92 are further driven to rotate relative to each other, for example, the first adjusting sleeve 91 rotates clockwise the second adjusting sleeve 92 and rotates counterclockwise, so that the outer rotor 82 can be driven to rotate relative to the inner rotor 81, and further the first wedge mirror 21 and the second wedge mirror 22 rotate relative, to change the refraction angle of the optical path.

Furthermore, a plurality of positioning holes 94 are uniformly arranged on the first adjusting sleeve 91 at intervals along the circumferential direction, a spring 95 is fixed in the positioning hole 94, a ball 96 is fixed at the end of the spring 95, a groove 71 is correspondingly arranged on the second adjusting sleeve 92 at the position corresponding to the positioning hole 94, when the spring 95 is in a natural state, part of the end of the ball 96 is exposed outside the positioning hole 94 and can be clamped in the groove 71, when the first adjusting sleeve 91 rotates relative to the second adjusting sleeve 92, the spring 95 is compressed, when the positioning hole is opposite to another groove, the spring 95 returns to the natural state, and the ball 96 is clamped in the groove, so that the first adjusting sleeve 91 and the second adjusting sleeve 92 are mutually glued together, and the first wedge-shaped mirror 21 and the second wedge-shaped mirror 22 synchronously rotate at a high speed at the same time. In practice, positioning holes may be provided on the second adjusting sleeve 92 and corresponding grooves may be provided on the first adjusting sleeve 91, depending on the situation.

Still set up mounting hole 11 on rifle head body 1 inner wall, adjust the pole 9 and install in mounting hole 11, it is specific this regulation pole 9 be one end diameter big, the T shape structure that the other end diameter is little, and the tip that should adjust the pole 9 diameter can remove in mounting hole 11, adjust the little tip of pole 9 diameter and mesh with conical gear 93 when adjusting pole 9 and moving to and first adjusting collar 91 relative second adjusting collar 92 and contact, then rotate regulation pole 9 so can realize the rotation of first adjusting collar 91 relative second adjusting collar 92, further still adjust the little tip periphery of pole 9 diameter and still overlap and be equipped with return spring (not shown) in the pole, make under the effect of return spring and adjust pole 9 and reset.

Further, adjust 9 tip of pole and still be equipped with the constant head tank, it is concrete, can set up the constant head tank at the tip that adjusts 9 diameters, and this constant head tank is for can be regular hexagon, thereby stretch into the constant head tank through interior hexagonal spanner and rotate interior hexagonal spanner and make to adjust the pole 9 and rotate and then realize that first adjusting collar 91 rotates relative second adjusting collar 92, loosens interior hexagonal spanner, makes under the effect of answer spring and adjusts pole 9 and reset.

The cover plate 16 covers the gun head body 1, specifically, a clamping groove is further formed in the outer wall of the gun head body 1 corresponding to the mounting hole 11, the cover plate 16 is clamped in the clamping groove, a through hole 17 is formed in the cover plate 16 corresponding to the positioning groove, and the inner hexagonal wrench can extend into the positioning groove through the through hole 17, so that the rod 9 can be adjusted conveniently in a rotating mode.

Still include bearing 14, this bearing 14 cover is established at inner rotor 81 periphery, and inner rotor 81 passes through bearing 14 and rotates in rifle head body 1, still includes bearing frame 15, and its cover is established at inner rotor 81 periphery, and bearing 14 is installed on bearing frame 15.

The above description is only for the purpose of illustrating the preferred embodiments of the present invention and is not to be construed as limiting the invention, and any modifications, equivalents, improvements and the like that fall within the spirit and principle of the present invention are intended to be included therein.

Claims (10)

1. A spot-adjustable laser handheld gun head comprises: rifle head body (1) and collimating mirror (2), its characterized in that: the automatic pipette tip is characterized by further comprising a collimating lens base (3), the collimating lens (2) is installed on the collimating lens base (3), a through hole is formed in the pipette tip body (1), and the collimating lens base (3) is inserted into the pipette tip body (1) through the through hole.

2. The spot-tunable laser handheld gun head of claim 1, characterized in that: the novel gun head is characterized by further comprising bolts, wherein screw holes (31) are formed in the side face of the collimating mirror base (3) and corresponding positions on the gun head body (1), and the bolts are in threaded connection in the screw holes so that the collimating mirror base (3) is fixed in the gun head body (1).

3. The spot-tunable laser handheld gun head of claim 1, characterized in that: the spray gun is characterized by further comprising a spray pipe (4), wherein the spray pipe (4) is arranged inside the front end of the gun head body (1) and penetrates out of the gun head body (1), and the spray pipe (4) can move along the gun head body (1).

4. A spot-adjustable laser handheld gun head according to claim 2, characterized in that: still include fixed plate (5) and sleeve (6), fixed plate (5) interval circumference is fixed in rifle head body (1) preceding terminal surface periphery, fixed plate (5) are close to the side and spray tube (4) laminating mutually of spray tube (4), the side front end that spray tube (4) were kept away from in fixed plate (5) has towards spray tube (4) slope first inclined plane (51), sleeve (6) cover is established in fixed plate (5) periphery and with fixed plate (5) spiro union, correspond first inclined plane department on sleeve (6) and be equipped with second inclined plane (61) rather than the looks adaptation.

5. The spot-adjustable laser handheld gun head according to claim 4, characterized in that: the part of the fixing plate (5) corresponding to the first inclined surface (51) is made of elastic materials.

6. The spot-adjustable laser handheld gun head according to claim 4, characterized in that: still include stator (7), rotor (8), first wedge mirror (21) and second wedge mirror (22), stator (7), rotor (8) all are located rifle head body (1) and are located collimating mirror base (3) the place ahead, rotor (8) stator (2) relatively rotates, rotor (8) include inner rotor (81) and outer rotor (82), install in inner rotor (81) first wedge mirror (21), install in outer rotor (82) second wedge mirror (22), outer rotor (82) cover is established and is rotated in inner rotor (81) periphery and inner rotor (81) relatively.

7. The spot-adjustable laser handheld gun head according to claim 6, characterized in that: still include first adjusting collar (91), second adjusting collar (92) and adjust pole (9), install in inner rotor (81) periphery first adjusting collar (91), second adjusting collar (92) is installed in outer rotor (82) periphery, first adjusting collar (91), second adjusting collar (92) tip all are equipped with conical gear (93), adjust pole (9) and install in rifle head body (1) and be located between first adjusting collar (91), second adjusting collar (92), adjust pole (9) both sides respectively with conical gear (93) meshing, it rotates to drive outer rotor (72) inner rotor (71) relatively to adjust pole (9).

8. The spot-tunable laser handheld gun head of claim 7, wherein: a plurality of positioning holes (94) are formed in the first adjusting sleeve (91) along the circumferential direction, a spring (95) is fixed in each positioning hole (94), a ball (96) is fixed to the end portion of each spring (95), a groove is formed in the second adjusting sleeve (92) corresponding to each positioning hole (94), and the end portion of each ball (96) can be clamped in the groove.

9. The spot-tunable laser handheld gun head of claim 7, wherein: the gun head comprises a gun head body (1) and is characterized in that mounting holes (11) are formed in the inner wall of the gun head body (1), an adjusting rod (9) is located in the mounting holes (11) and can move along the mounting holes (11), and a return spring is sleeved on the periphery of the adjusting rod (9).

10. A spot-tunable laser handheld torch head according to claim 9, wherein: the end part of the adjusting rod (9) is also provided with a positioning groove.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010539714.5A CN111571014A (en) | 2020-06-15 | 2020-06-15 | Handheld rifle head of adjustable laser of facula |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010539714.5A CN111571014A (en) | 2020-06-15 | 2020-06-15 | Handheld rifle head of adjustable laser of facula |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111571014A true CN111571014A (en) | 2020-08-25 |

Family

ID=72110648

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010539714.5A Pending CN111571014A (en) | 2020-06-15 | 2020-06-15 | Handheld rifle head of adjustable laser of facula |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111571014A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112975116A (en) * | 2021-03-16 | 2021-06-18 | 深圳市慧之光激光器件有限公司 | Hand-held type gyration stirring welding ware |

| CN112975115A (en) * | 2021-03-16 | 2021-06-18 | 深圳市慧之光激光器件有限公司 | Hand-held type gyration stirring welding ware |

| CN113305425A (en) * | 2021-06-18 | 2021-08-27 | 深圳市镭康机械设备有限公司 | Handheld welding device |

| CN115255617A (en) * | 2022-09-13 | 2022-11-01 | 深圳欧斯普瑞智能科技有限公司 | Visual laser welding head capable of adjusting size of light spot |

-

2020

- 2020-06-15 CN CN202010539714.5A patent/CN111571014A/en active Pending

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112975116A (en) * | 2021-03-16 | 2021-06-18 | 深圳市慧之光激光器件有限公司 | Hand-held type gyration stirring welding ware |

| CN112975115A (en) * | 2021-03-16 | 2021-06-18 | 深圳市慧之光激光器件有限公司 | Hand-held type gyration stirring welding ware |

| CN113305425A (en) * | 2021-06-18 | 2021-08-27 | 深圳市镭康机械设备有限公司 | Handheld welding device |

| CN115255617A (en) * | 2022-09-13 | 2022-11-01 | 深圳欧斯普瑞智能科技有限公司 | Visual laser welding head capable of adjusting size of light spot |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111571014A (en) | Handheld rifle head of adjustable laser of facula | |

| CN108453097B (en) | Laser cleaning mechanism for inner wall of pipeline | |

| CN111682728B (en) | Laser motor with adjustable light spot | |

| DE3037981C2 (en) | ||

| FR2781707A1 (en) | EXCIMERATED LASER MACHINING PROCESS OF HOLES OR SHAPES WITH VARIABLE PROFILE | |

| CN103898297B (en) | A kind of blisk laser shock peening method | |

| CN110029345B (en) | Powder laser cladding device is sent in light | |

| US7038162B2 (en) | Hand-held laser welding wand filler media delivery systems and methods | |

| DE102011018648B3 (en) | Device for the thermal processing of a workpiece | |

| CN212495964U (en) | Handheld rifle head of adjustable laser of facula | |

| CA2343722A1 (en) | Robotically operated laser head | |

| CN114345837B (en) | Laser cleaning equipment | |

| CN110270762A (en) | The equipment that revolving parts inner wall is carved using laser processing mode | |

| WO2005053896A1 (en) | Device for working the surfaces of the internal surface of a cylinder using a laser beam | |

| RU2655402C2 (en) | Installation for laser treatment of product inner surface | |

| CN217739585U (en) | Multi-head thread focusing structure of lens | |

| CN107385436B (en) | Sealing structure of laser cladding device, spray head of laser cladding device and laser cladding device | |

| RU193933U1 (en) | Laser head for welding inner circumferential seams of products | |

| EP0168374B1 (en) | Method for marking a cylindrical metal object, such as a roll of a rolling mill | |

| DE102011117454B4 (en) | Laser processing device | |

| WO2021043108A1 (en) | Lens adjusting device and optical apparatus | |

| JPH06254680A (en) | Tip part processing device for wire welding torch | |

| CN211438579U (en) | Angle-adjustable laser head | |

| DE102006002931A1 (en) | Optical unit and method for laser remote welding | |

| KR20180131917A (en) | Laser processing module and laser processing apparatus having the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |