CN111468458A - Intelligent control method of high-pressure cleaning machine - Google Patents

Intelligent control method of high-pressure cleaning machine Download PDFInfo

- Publication number

- CN111468458A CN111468458A CN202010342601.6A CN202010342601A CN111468458A CN 111468458 A CN111468458 A CN 111468458A CN 202010342601 A CN202010342601 A CN 202010342601A CN 111468458 A CN111468458 A CN 111468458A

- Authority

- CN

- China

- Prior art keywords

- temperature

- pressure

- set temperature

- controller

- area

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B13/00—Accessories or details of general applicability for machines or apparatus for cleaning

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05D—SYSTEMS FOR CONTROLLING OR REGULATING NON-ELECTRIC VARIABLES

- G05D23/00—Control of temperature

- G05D23/19—Control of temperature characterised by the use of electric means

- G05D23/20—Control of temperature characterised by the use of electric means with sensing elements having variation of electric or magnetic properties with change of temperature

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Automation & Control Theory (AREA)

- Control Of Positive-Displacement Pumps (AREA)

Abstract

The invention provides an intelligent control method of a high-pressure cleaning machine, which comprises the following steps: s1, the cloud server calculates an enthalpy value h according to the area information of the equipment; s2, the cloud server determines the set temperature T according to the enthalpy value hsAnd the set temperature T is measuredsSending to a controller of the device; s3, the controller judges the current temperature T of the high-pressure liquiddAt a set temperature TsIf equal, go to step S4; if the temperature of the high-pressure liquid is higher than the preset temperature, the refrigeration system reduces the temperature of the high-pressure liquid and enters step S3; if the temperature of the high-pressure liquid is lower than the preset temperature, the refrigeration system raises the temperature of the high-pressure liquid and the step S3 is carried out; and S4, the controller controls the motor to drive the high-pressure pump to introduce the high-pressure liquid into the ejector for ejection. The intelligent control method of the high-pressure cleaning machine can utilize the cloud server to measure the meteorological parameters of the area where the equipment is locatedCalculating the enthalpy value h of the area where the equipment is located, and determining the set temperature T suitable for the equipment to work according to the enthalpy value hsThe controller of the device receiving the set temperature TsThe water temperature can be automatically regulated and controlled.

Description

Technical Field

The invention relates to the field of industrial descaling, in particular to an intelligent control method of a high-pressure cleaning machine.

Background

The prior high-pressure cleaning machine has wider use condition only in developed countries, and gradually enters the domestic market along with the development of economy. The traditional high-pressure cleaning machine generally drives a high-pressure pump through a power device to generate high-pressure water, and after the impact force of the water is larger than the adhesive force of dirt, the dirt can be peeled and washed away by the high-pressure water, so that the purpose of cleaning objects is achieved. However, the regions of China are widely distributed, and different regions correspond to different meteorological environments, so that different requirements are provided for the water temperature of the high-pressure cleaning machine, and the high-pressure cleaning machine in the prior art cannot realize free regulation and control of the water temperature. Therefore, it is necessary to invent an intelligent control method for a high pressure cleaning machine.

Disclosure of Invention

The technical problem to be solved by the invention is as follows: in order to solve the problem that the water temperature of the high-pressure cleaning machine in the prior art cannot be freely regulated and controlled, the invention provides an intelligent control method of the high-pressure cleaning machine to solve the problem.

The technical scheme adopted by the invention for solving the technical problems is as follows: an intelligent control method of a high-pressure cleaning machine comprises the following steps:

s1, the cloud server acquires meteorological parameters corresponding to the regional information according to the regional information of the equipment, and the cloud server calculates an enthalpy value h corresponding to the regional information according to the meteorological parameters;

s2, the cloud server identifies an enthalpy value area corresponding to the enthalpy value h in an enthalpy frequency diagram according to the enthalpy value h, and the cloud server obtains a set temperature T corresponding to the enthalpy value areasAnd the set temperature T is measuredsA controller for sending to the device, the controller being responsive to the set temperature TsAdjusting the use parameters of the equipment;

s3, judging the current temperature T of the high-pressure liquid by the controllerdWhether or not equal to the set temperature TsIf the current temperature T isdEqual to the set temperature TsStep S4 is entered;

if the current temperature T isdIs not equal to the set temperature TsThe controller determines the current temperature TdWhether or not it is higher than the set temperature Ts;

If the current temperature T isdGreater than a set temperature TsThe controller starts the refrigeration system to lower the temperature of the high-pressure liquid, and the step S3 is re-entered;

if the current temperature T isdLess than a set temperature TsThe controller starts the refrigeration system to raise the temperature of the high-pressure liquid, and the step S3 is re-entered;

and S4, the controller controls the motor to drive the high-pressure pump to introduce the high-pressure liquid into the ejector for ejection.

Preferably, in step S1, the mathematical model of enthalpy h is determined by the following formula:

h=1.01T+0.001d(2501+1.84T);

in the formula (I), the compound is shown in the specification,

t is the ambient temperature of the area where the equipment is located;

d is the moisture content of the area in which the equipment is located;

Pqthe partial pressure of water vapor which is the humid air of the area where the device is located;

Pq·bthe water vapor pressure of saturated humid air at the same temperature in the area where the equipment is located.

Preferably, in step S2, the controller adjusts the usage parameters of the plant using a PID control system, the mathematical model of the control parameters of the PID control system being determined by the following formula:

in the formula (I), the compound is shown in the specification,

e (t) is the temperature deviation;

kp is a proportionality coefficient;

TI is an integration time constant;

TD is a differential time constant;

Tcis a preset test temperature.

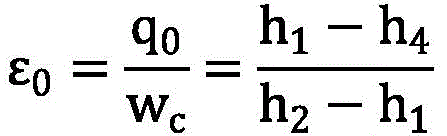

Preferably, in step S3, the controller varies the cooling coefficient0And coefficient of heatcControlling the refrigeration system, the refrigeration coefficient0And coefficient of heatingcIs determined by the following formula:

in the formula (I), the compound is shown in the specification,

q0the refrigerating capacity generated by the evaporator in the working process of the refrigerating coefficient;

qcheat generated by the condenser during operation of the refrigeration coefficient;

wcthe work consumed by the compressor during the operation of the refrigeration coefficient.

The intelligent control method of the high-pressure cleaning machine has the advantages that the cloud server can be used for calculating the enthalpy value h of the area where the equipment is located according to the meteorological parameters of the area where the equipment is located, and then the set temperature T suitable for the equipment to work is determined according to the enthalpy value hsThe controller of the device receiving the set temperature TsThe water temperature can be automatically regulated and controlled.

Drawings

The invention is further illustrated with reference to the following figures and examples.

Fig. 1 is a system configuration diagram of a high pressure cleaner according to an embodiment of the present invention.

FIG. 2 is a flow chart of a preferred embodiment of the intelligent control method of the high pressure washer of the present invention.

Fig. 3 is a system configuration diagram of a refrigeration system of an intelligent control method of a high pressure washer according to the present invention.

Fig. 4 is a pressure-enthalpy diagram of the refrigeration system of the intelligent control method of the high-pressure washer of the present invention.

Detailed Description

Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like or similar reference numerals refer to the same or similar elements or elements having the same or similar function throughout. The embodiments described below with reference to the accompanying drawings are illustrative only for the purpose of explaining the present invention, and are not to be construed as limiting the present invention.

In the description of the present invention, it is to be understood that the terms "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", "bottom", "inner", "outer", "axial", "radial", "circumferential", and the like, indicate orientations and positional relationships based on the orientations and positional relationships shown in the drawings, and are used merely for convenience of description and for simplicity of description, and do not indicate or imply that the device or element being referred to must have a particular orientation, be constructed and operated in a particular orientation, and therefore, should not be considered as limiting the present invention.

Furthermore, the terms "first," "second," and the like are used for descriptive purposes only and are not to be construed as indicating or implying relative importance. In the description of the present invention, it is to be noted that, unless otherwise explicitly specified or limited, the terms "connected" and "connected" are to be interpreted broadly, e.g., as being fixed or detachable or integrally connected; can be mechanically or electrically connected; may be directly connected or indirectly connected through an intermediate. The specific meanings of the above terms in the present invention can be understood in specific cases to those skilled in the art. In addition, in the description of the present invention, "a plurality" means two or more unless otherwise specified.

Any process or method descriptions in flow charts or otherwise described herein may be understood as representing modules, segments, or portions of code which include one or more executable instructions for implementing specific logical functions or steps of the process, and alternate implementations are included within the scope of the preferred embodiment of the present invention in which functions may be executed out of order from that shown or discussed, including substantially concurrently or in reverse order, depending on the functionality involved, as would be understood by those reasonably skilled in the art of the present invention.

The physical structure of the cloud server includes a CPU, a ROM, a RAM, a keyboard, a mouse, a display, a network interface, and a USB interface, the CPU is electrically connected to the ROM, the RAM, the keyboard, the mouse, the display, the network interface, and the USB interface, the ROM stores various data in a cloud database, various data in a content candidate library, a computer program for controlling the cloud server, various settings, initial values, and the like, and the RAM is used as a work area for loading various computer programs or a storage area for temporarily storing identification numbers.

As shown in fig. 1, the system structure of the high pressure washer includes: the refrigeration system comprises a hot water tank, a condenser, a compressor, an evaporator and a cold water tank. The controller can adjust the rotational speed and the power of motor, and the controller can also regulate and control refrigerating system's operating condition, and the motor can drive high-pressure pump work, and refrigerating system can change the temperature of the water in the high pressure cleaner according to operating condition's difference, and the high-pressure pump can be with water input to the ejector under the high pressure state spray.

Based on the above system, the invention provides an intelligent control method of a high-pressure cleaning machine, as shown in fig. 2 to 4, comprising the following steps:

s1, the cloud server acquires meteorological parameters corresponding to the regional information according to the regional information of the equipment; in this embodiment, the cloud server divides the country into seven areas, namely south China, north China, east China, southwest, northwest and northeast China, the area information is used for identifying the area where the equipment is located, the meteorological parameters comprise the ambient temperature and the relative humidity, the ambient temperature is measured by the temperature sensor, and the relative humidity is measured by the humidity sensor;

the cloud server calculates an enthalpy value h corresponding to the regional information according to the meteorological parameters, and a mathematical model of the enthalpy value h is determined by the following formula:

h=1.01T+0.001d(2501+1.84T);

in the formula (I), the compound is shown in the specification,

t is the ambient temperature of the area where the equipment is located;

d is the moisture content of the area in which the equipment is located;

Pqthe partial pressure of water vapor which is the humid air of the area where the device is located;

Pq·bthe water vapor pressure of saturated humid air at the same temperature in the area where the equipment is located;

C1=-5674.5359;

C2=6.3925247;

C3=-0.9677843×10-2;

C4=0.62215701×10-6;

C5=0.20747825×10-18;

C6=-0.9484024×10-12;

C7=4.1635019;

C8=-5800.2206;

C9=1.3914993;

C10=-0.048640239;

C11=0.41764768×10-4;

C12=-0.14452093×10-7;

C13=6.5459673;

s2, the cloud server identifies an enthalpy value area corresponding to the enthalpy value h in a pre-stored enthalpy frequency map according to the enthalpy value h;

the enthalpy values of all the regions are different when the regions are in different seasons, but the change of the enthalpy values has a range and a frequency, the enthalpy value of each region has a corresponding change region, and the cloud server can draw an enthalpy-frequency map according to the enthalpy value occurrence frequency;

the enthalpy-frequency diagram can be divided into a high-temperature area, a low-temperature area and a transition area, and the high-temperature area, the low-temperature area and the transition area are respectively corresponding to a set temperature TsThe cloud service can determine an enthalpy value area to which the enthalpy value h belongs according to the position of the enthalpy value h in the enthalpy frequency diagram, and further determine a set temperature T corresponding to the enthalpy value areas;

Cloud service acquiring set temperature TsThen the temperature T is setsA controller for sending to the device, the controller being responsive to the set temperature TsAdjusting the working state of the refrigerating system and the rotating speed and power of the motor;

in this embodiment, the controller adjusts the rotation speed and power of the motor by using a PID control system, and a mathematical model of control parameters of the PID control system is determined by the following formula:

in the formula (I), the compound is shown in the specification,

e (t) is the temperature deviation;

kp is a proportionality coefficient;

TI is an integration time constant;

TD is a differential time constant;

Tcis a preset test temperature;

s3, judging the current temperature T of the high-pressure liquid by the controllerdWhether or not equal to the set temperature TsIf the current temperature T isdEqual to the set temperature TsStep S4 is entered;

if the current temperature T isdIs not equal to the set temperature TsThe controller determines the current temperature TdWhether or not it is higher than the set temperature Ts;

If the current temperature T isdGreater than a set temperature TsThe controller starts the refrigeration system to lower the temperature of the high-pressure liquid, and the step S3 is re-entered;

if the current temperature T isdLess than a set temperature TsThe controller starts the refrigeration system to raise the temperature of the high-pressure liquid, and the step S3 is re-entered;

in this embodiment, the controller is based on the refrigeration factor0And coefficient of heatcControl of the refrigeration system, refrigeration coefficient0And coefficient of heatingcIs determined by the following formula:

in the formula (I), the compound is shown in the specification,

q0the refrigerating capacity generated by the evaporator in the working process of the refrigerating coefficient;

qcheat generated by the condenser during operation of the refrigeration coefficient;

wcthe work consumed by the compressor during the operation of the refrigeration coefficient.

In this embodiment, q0、qcAnd wcThe enthalpy-pressure diagram is determined by the pressure-enthalpy diagram of the refrigerating system, the abscissa of the pressure-enthalpy diagram is the enthalpy value, and the ordinate of the pressure-enthalpy diagram is the pressure value;

in the embodiment, the pressure variation range of high-pressure water in the refrigerating system is set to be P0-P1, two isobars are drawn in a pressure-enthalpy diagram, the pressure value of one isobar is set to be P0, and the pressure value of the other isobar is set to be P1;

in the pressure-enthalpy diagram, the intersection point of the isobar P0 and the dry saturated steam line is represented as point 1, and the enthalpy value at the point 1 is represented as h1;

Making an isentropic line through the point 1, intersecting the isentropic line with the isobaric line P1 at a point 2, and recording the enthalpy value at the point 2 as h2;

The intersection of isobar P1 and the dry saturated steam line is denoted as point 2;

the isobar P1 intersects the saturated liquid line at point 3, and the enthalpy at point 3 is denoted as h3;

Taking an isenthalpic line as the passing point 3, recording the intersection point of the isenthalpic line and the isobaric line P0 as a point 4, and recording the enthalpy value at the point 4 as h4;

And S4, the controller controls the motor to drive the high-pressure pump to introduce the high-pressure liquid into the ejector for ejection.

In the description herein, references to the description of the term "one embodiment," "some embodiments," "an example," "a specific example," or "some examples," etc., mean that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one embodiment or example of the invention. In this specification, a schematic representation of the term does not necessarily refer to the same embodiment or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments or examples.

In light of the foregoing description of the preferred embodiment of the present invention, many modifications and variations will be apparent to those skilled in the art without departing from the spirit and scope of the invention. The technical scope of the present invention is not limited to the content of the specification, and must be determined according to the scope of the claims.

Claims (4)

1. An intelligent control method of a high-pressure cleaning machine is characterized by comprising the following steps:

s1, the cloud server acquires meteorological parameters corresponding to the regional information according to the regional information of the equipment, and the cloud server calculates an enthalpy value h corresponding to the regional information according to the meteorological parameters;

s2, the cloud server identifies an enthalpy value area corresponding to the enthalpy value h in an enthalpy frequency diagram according to the enthalpy value h, and the cloud server obtains a set temperature T corresponding to the enthalpy value areasAnd the set temperature T is measuredsA controller for sending to the device, the controller being responsive to the set temperature TsAdjusting the use parameters of the equipment;

s3, judging the current temperature T of the high-pressure liquid by the controllerdWhether or not equal to the set temperature TsIf the current temperature T isdEqual to the set temperature TsStep S4 is entered;

if the current temperature T isdIs not equal to the set temperature TsThe controller determines the current temperature TdWhether or not it is higher than the set temperature Ts;

If the current temperature T isdGreater than a set temperature TsThe controller starts the refrigeration system to lower the temperature of the high-pressure liquid, and the step S3 is re-entered;

if the current temperature T isdLess than a set temperature TsThe controller starts the refrigeration system to raise the temperature of the high-pressure liquid, and the step S3 is re-entered;

and S4, the controller controls the motor to drive the high-pressure pump to introduce the high-pressure liquid into the ejector for ejection.

2. The intelligent control method of the high pressure washer according to claim 1, characterized in that:

in step S1, the mathematical model of enthalpy h is determined by the following formula:

h=1.01T+0.001d(2501+1.84T);

in the formula (I), the compound is shown in the specification,

t is the ambient temperature of the area where the equipment is located;

d is the moisture content of the area in which the equipment is located;

Pqthe partial pressure of water vapor which is the humid air of the area where the device is located;

Pq·bthe water vapor pressure of saturated humid air at the same temperature in the area where the equipment is located.

3. The intelligent control method of the high pressure washer according to claim 2, characterized in that:

in step S2, the controller adjusts the usage parameters of the plant using a PID control system whose mathematical model of the control parameters is determined by the following equation:

e(t)=Tc-Ts

in the formula (I), the compound is shown in the specification,

e (t) is the temperature deviation;

kp is a proportionality coefficient;

TI is an integration time constant;

TD is a differential time constant;

Tcis a preset test temperature.

4. The intelligent control method of the high pressure washer according to claim 3, characterized in that:

in step S3, the controller controls the cooling rate according to the cooling rate0And coefficient of heatcControlling the refrigeration system, the refrigeration coefficient0And coefficient of heatingcIs determined by the following formula:

in the formula (I), the compound is shown in the specification,

q0the refrigerating capacity generated by the evaporator in the working process of the refrigerating coefficient;

qcheat generated by the condenser during operation of the refrigeration coefficient;

wcthe work consumed by the compressor during the operation of the refrigeration coefficient.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010342601.6A CN111468458A (en) | 2020-04-26 | 2020-04-26 | Intelligent control method of high-pressure cleaning machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010342601.6A CN111468458A (en) | 2020-04-26 | 2020-04-26 | Intelligent control method of high-pressure cleaning machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111468458A true CN111468458A (en) | 2020-07-31 |

Family

ID=71762928

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010342601.6A Pending CN111468458A (en) | 2020-04-26 | 2020-04-26 | Intelligent control method of high-pressure cleaning machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111468458A (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2000045967A1 (en) * | 1999-02-05 | 2000-08-10 | Alfred Kärcher GmbH & Co. | High pressure cleaning device |

| JP2006159025A (en) * | 2004-12-03 | 2006-06-22 | Honda Motor Co Ltd | Controller for high-pressure cleaning machine |

| CN104117497A (en) * | 2013-04-25 | 2014-10-29 | 新昌县七星街道伟畅五金机械厂 | High-pressure cleaning machine with heating device |

| CN104833067A (en) * | 2015-04-30 | 2015-08-12 | 青岛海尔空调器有限总公司 | Method and device for controlling heat exchange temperature, collecting condensed water and cleaning air conditioner |

| CN106607371A (en) * | 2015-10-22 | 2017-05-03 | 西安品质信息科技有限公司 | Temperature self-adaption ultrasonic washing machine based on sensor |

| CN106766222A (en) * | 2016-12-26 | 2017-05-31 | 珠海格力电器股份有限公司 | Water supply temperature adjusting method and device of heat pump water heater |

| CN108006809A (en) * | 2017-11-30 | 2018-05-08 | 中国华电集团科学技术研究总院有限公司 | A kind of distributed busbar protection cooling heating intelligent control air navigation aid |

| US20190346222A1 (en) * | 2018-05-09 | 2019-11-14 | Saudi Arabian Oil Company | Air- cooled heat exchanger cleaning and temperature control apparatus and method |

| CN210397815U (en) * | 2019-03-13 | 2020-04-24 | 青岛创客机械设备制造有限公司 | Constant-temperature water washing device |

-

2020

- 2020-04-26 CN CN202010342601.6A patent/CN111468458A/en active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2000045967A1 (en) * | 1999-02-05 | 2000-08-10 | Alfred Kärcher GmbH & Co. | High pressure cleaning device |

| JP2006159025A (en) * | 2004-12-03 | 2006-06-22 | Honda Motor Co Ltd | Controller for high-pressure cleaning machine |

| CN104117497A (en) * | 2013-04-25 | 2014-10-29 | 新昌县七星街道伟畅五金机械厂 | High-pressure cleaning machine with heating device |

| CN104833067A (en) * | 2015-04-30 | 2015-08-12 | 青岛海尔空调器有限总公司 | Method and device for controlling heat exchange temperature, collecting condensed water and cleaning air conditioner |

| CN106607371A (en) * | 2015-10-22 | 2017-05-03 | 西安品质信息科技有限公司 | Temperature self-adaption ultrasonic washing machine based on sensor |

| CN106766222A (en) * | 2016-12-26 | 2017-05-31 | 珠海格力电器股份有限公司 | Water supply temperature adjusting method and device of heat pump water heater |

| CN108006809A (en) * | 2017-11-30 | 2018-05-08 | 中国华电集团科学技术研究总院有限公司 | A kind of distributed busbar protection cooling heating intelligent control air navigation aid |

| US20190346222A1 (en) * | 2018-05-09 | 2019-11-14 | Saudi Arabian Oil Company | Air- cooled heat exchanger cleaning and temperature control apparatus and method |

| CN210397815U (en) * | 2019-03-13 | 2020-04-24 | 青岛创客机械设备制造有限公司 | Constant-temperature water washing device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110360734B (en) | Air conditioner starting control method and device, storage medium and air conditioner | |

| CN105674496B (en) | A kind of air-conditioner defrosting method | |

| CN105333563B (en) | A kind of refrigeration control method, device and air conditioner | |

| CN104949270B (en) | Refrigeration control method, device and the air conditioner of air conditioner | |

| CN107143994A (en) | Air-conditioning condensation prevention control method and indoor apparatus of air conditioner | |

| CN106839340A (en) | A kind of air conditioner refrigerating measuring method, device and air-conditioner | |

| CN106839263B (en) | Air-conditioning and its control method | |

| CN101101239A (en) | Apparatus and method for testing air conditioner | |

| JP7328498B2 (en) | Information processing device, air conditioner, information processing method, air conditioning method, and program | |

| CN104776944A (en) | Air conditioner heat exchange amount detection method and device | |

| CN109916090A (en) | Heat pump water heater control method and heat pump water heater | |

| CN106016588A (en) | Air conditioner and air speed adjusting method and device thereof | |

| CN107676942A (en) | Control method, control system, computer-readable recording medium and mobile air conditioner | |

| CN107192084A (en) | The method of on-line checking air-conditioning heating Energy Efficiency Ratio and heating capacity | |

| CN113175735B (en) | Method for calculating capacity energy efficiency of air conditioner, computer storage medium and air conditioner | |

| CN112393320A (en) | Compressor rotation speed control method based on heat pump heating machine and heat pump heating machine | |

| CN106949611A (en) | A kind of air-conditioner managing device and the air-conditioner with the managing device | |

| CN111550910B (en) | Variable-frequency precision air conditioner and dehumidification control method and storage medium thereof | |

| CN112856748B (en) | Cold output control method and device, machine room air conditioner and storage medium | |

| CN107940675B (en) | Central air conditioning system, auxiliary machine starting self-diagnosis method and self-diagnosis device thereof | |

| CN111468458A (en) | Intelligent control method of high-pressure cleaning machine | |

| CN113944995A (en) | Control method of air conditioner, and computer-readable storage medium | |

| CN109556245A (en) | Humidification and water supplement control method and air conditioning unit | |

| CN109323381A (en) | Control method, device and the air conditioner with it of air conditioner | |

| CN107270423A (en) | A kind of control method and device of fan of outdoor unit of air conditioner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20200731 |

|

| WD01 | Invention patent application deemed withdrawn after publication |