Drip irrigation formula water-saving irrigation device system

Technical Field

The invention relates to the field of water-saving agricultural irrigation, in particular to the field of drip irrigation modes.

Background

The growth of plants or crops needs water, and the traditional irrigation mode can not only not irrigate the plants or the crops well, can influence the growth of the plants or the crops for a long time, but also waste a lot of water resources, and reduces the utilization rate of the water. Therefore, the new irrigation mode is improved, and the utilization rate of the water can be improved. The general drip irrigation mode often causes water accumulation on the ground, and causes that plants or crops below a water dripping area are difficult to grow normally, so that the water accumulation is dispersed, and the water accumulation has important influence on the growth of the plants or the crops.

Disclosure of Invention

The purpose of the invention is as follows: in order to overcome the defects in the prior art, the invention provides a drip irrigation type water-saving irrigation device system which can realize the effects of positively influencing growth and saving water resources.

The technical scheme is as follows: in order to achieve the purpose, the technical scheme of the invention is as follows:

a drip irrigation type water-saving irrigation device system comprises a filtering layer structure and a drip irrigation structure; the water outlet end of the filter layer structure is communicated with one end provided with a drainage pipeline, and the other end of the drainage pipeline extends outwards in a winding manner to form an extension end; the side wall below the extension end of the drainage pipeline is connected with a plurality of drip irrigation structures, and the water inlet ends of the drip irrigation structures are communicated with the inside of the drainage pipeline; seedlings are planted below the water outlet end of the drip irrigation structure; and the drip irrigation structures are arranged at intervals along the extension track of the drainage pipeline.

Further, the filter layer structure comprises a filter knot structure and a backwashing device; the filter knot structure comprises a filter element structure and a shell structure; the whole shell structure is of a round cake type structure; the top of the shell structure is provided with a through hole structure; the filter element structure is arranged in the shell structure, and a gap is formed between the shell structure and the filter element structure; the whole filter element structure is spherical; a rotating block structure is fixedly arranged at the top of the filter element structure; the rotating block structure extends upwards to extend through the through hole structure, and is in rotating connection with the through hole structure; the upward extending end of the rotating block structure is fixedly provided with a cross-shaped rotating block structure; the cross-shaped rotating block structure is acted by external force, and the rotating block structure rotates, so that the filter element structure is driven to turn over in the shell structure; the water outlet end of the filtering knot structure is communicated with the backwashing device; and the backwashing device flushes water reversely to wash multiple surfaces of the filter element structure.

Further, a slag storage structure is fixedly arranged at the bottom of the shell structure; the whole slag storage structure is of an arc-shaped pipeline structure; one end of the slag storage structure is communicated with the interior of the shell structure; the other end of the slag storage structure extends downwards obliquely and is arranged above the ground; the slag storage structure is provided with a control valve.

Further, the filtering layer structure also comprises a slag particle filter screen structure; the filter knot structure is communicated with the backwashing device through the slag particle filter screen structure; the slag particle filter screen structure comprises a horn-shaped pipeline structure and a convex filter screen structure; the circumference of the trumpet-shaped pipeline structure is gradually reduced, and the filter knot structure faces the direction of the backwashing device; the convex filter screen structure is fixedly arranged in the horn-shaped pipeline structure; the convex filter screen structure is a filter screen plate type structure; the whole orientation of middle part of convex surface filter screen structure back flush unit forms protruding portion, just the central part of convex surface filter screen structure orientation back flush unit forms the concave recess portion.

Further, the filter element structure sequentially comprises a first adsorption layer structure, a filter paper layer structure, a ceramic filter element layer structure, a sponge layer structure, a molecular sieve layer structure and a second adsorption layer structure, a cavity is formed between adjacent filter layers, and the bottoms of the cavities are communicated; the bottom of the cavity is communicated with the feeding end of the slag storage structure.

Further, the drip irrigation structure comprises a condensation structure and an aeration structure; the whole condensation and dripping structure is of a gyro-type structure; the water inlet end of the condensation and dripping structure is communicated with the drainage pipeline; the condensation and dripping structure comprises a dissolving cavity structure and a dripping structure; the inflatable structure penetrates through the dissolving cavity structure and extends into the dripping structure to form a broken dripping structure.

Further, the dissolving cavity structure comprises a liquid separating disc structure, a rotating shaft structure and a solution box structure; the driving device at the bottom of the dissolving cavity structure is in driving connection with the rotating shaft structure; the rotating shaft structure extends upwards, and a plurality of bent and expanded stirring rod structures are fixedly arranged on the side wall of the rotating shaft structure; the extending end of the rotating shaft structure is provided with the liquid separating disc structure; the water inlet at the top of the dissolving cavity structure is arranged at a distance from the liquid separating disc structure; the liquid separating disc structure is provided with a hollow hole; the plurality of hollow holes are distributed at intervals around the rotating shaft structure; the inner wall of the solution box structure is provided with a groove; the edge of the liquid-separating disc structure is embedded into the groove; the driving device drives the rotating shaft structure to rotate, so that the liquid separating disc structure and the stirring rod structure are driven to rotate in the solution box structure.

Further, the inflation structure comprises a pneumatic pump; the pneumatic pump is arranged in the center of the liquid separating disc structure; the air inlet pipe of the pneumatic pump extends outwards and is communicated with the outside; the outward extending end of the air inlet pipe is rotationally connected with the liquid separating disc structure; an air outlet pipe of the pneumatic pump extends downwards to stretch into the water dripping structure, and penetrates through the rotating shaft structure; and the downward extending end of the air outlet pipe is rotatably connected with the rotating shaft structure.

Further, the bottom of the dissolving cavity structure is fixedly provided with the water dripping structure; the water dropping structure comprises a leakage-reducing groove and a water drop condensation structure; the leakage-slowing groove is of a circular ring structure; the slow leakage groove is communicated with the dissolving cavity structure through a leakage pipe; the plurality of water leakage pipes are annularly arranged and are externally provided with a plurality of rings; the water drop condensation structure is integrally of a bowl-shaped structure; the water drop condensation structure comprises a condensation ring structure and a fusion cavity; the integral molten polymer cavity is of an inverted bowl-shaped structure; the melt-aggregation cavity is communicated with the slow leakage groove through a fine condensation pipe; the multiple thin condensation pipes are annularly arranged and are externally provided with multiple rings; the coagulation ring structure is fixedly arranged on the inner wall of the bowl mouth of the coagulation chamber; the coagulation ring structure is a circular ring-shaped structure block; and a plurality of annular tooth openings are formed in the inner ring of the coagulation ring structure.

Further, an air outlet of the air outlet pipe extends to the middle of the fusion cavity, and forms the droplet breaking structure together with the fusion cavity and the coagulation ring structure; when the coagulation ring structure is coagulated into a water layer, the melt-coagulation cavity is in a sealed state; the gas is blown out by the gas filling structure, and the condensed water layer on the coagulation structure is broken.

Has the advantages that: the drip irrigation type water-saving irrigation device system can effectively save water resources and increase the grain yield in a drip irrigation mode; including but not limited to the following technologies:

1) the filter element structure is overturned under the action of external force, the backwashing device washes the filter element structure from multiple sides, and the washed slag particles leak out through the slag storage structure; the blockage of the drip irrigation structure caused by slag particles in the irrigation water can be effectively avoided;

2) the drop breaking structure can effectively inflate and explode water drops from the inside, so that the water is effectively dispersed, and the phenomenon that plants or crops below a dropping area are affected by dropping water for a long time to cause poor growth is avoided; not only saves water resources, but also has positive influence on the growth of plants.

Drawings

FIG. 1 is a system structure diagram of a drip irrigation type water-saving irrigation device;

FIG. 2 is a diagram showing the structure of a filter layer;

FIG. 3 is a cross-sectional view of a filter layer structure;

FIG. 4 is a cross-sectional view of a filter construction;

FIG. 5 is a cross-sectional view of the filter cartridge arrangement;

FIG. 6 is a sectional view of a slag particle filter screen structure;

FIG. 7 is a cross-sectional view of a drip irrigation structure;

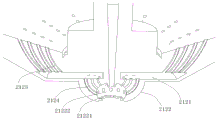

FIG. 8 is a sectional view of the structure of the dissolution chamber;

FIG. 9 is a cross-sectional view of a drip structure;

FIG. 10 is a cross-sectional view of a droplet breaking configuration;

fig. 11 is a sectional view of a condensation structure of water droplets.

Detailed Description

The present invention will be further described with reference to the accompanying drawings.

As shown in figures 1-11: a drip irrigation type water-saving irrigation device system comprises a filtering layer structure 1 and a drip irrigation structure 2; the water outlet end of the filter layer structure 1 is communicated with one end provided with a water drainage pipeline 3, and the other end of the water drainage pipeline 3 extends outwards in a winding manner to form an extension end; the side wall below the extending end of the drainage pipeline 3 is connected with the drip irrigation structures 2, and the water inlet ends of the drip irrigation structures 2 are communicated with the inside of the drainage pipeline 3; seedlings are planted below the water outlet end of the drip irrigation structure 2; the drip irrigation structures 2 are arranged at intervals along the extending track of the drainage pipeline 3. The irrigation water is filtered to remove slag particles in the irrigation water through the filter layer structure 1, so that the drip irrigation structure 2 is prevented from being blocked; then flows into the drip irrigation structure 2 through a drainage pipeline 3; finally, the drip irrigation structure 2 drips small water drops which are broken and dispersed to irrigate crops; design like this, earlier filter and irrigate through the mode of driping irrigation again, can not only the water economy resource, improve the utilization ratio of moisture, can also effectual increase grain output.

The filter layer structure 1 comprises a filter knot structure 11 and a backwashing device 12; the filter structure 11 comprises a filter element structure 111 and a shell structure 112; the shell structure 112 is of a round cake type structure as a whole; the top of the shell structure 112 is provided with a through hole structure 113; the filter element structure 111 is arranged in the shell structure 112, and a gap is formed between the shell structure 112 and the filter element structure 111, so that the filter element structure is convenient to turn over due to the gap; the filter element structure 111 is integrally spherical, so that the obstruction is reduced, and the overturning is convenient; the top of the filter element structure 111 is fixedly provided with a rotating block structure 114; the rotating block structure 114 extends upwards through the through hole structure 113, and the rotating block structure 114 is rotatably connected with the through hole structure 113; the upward extending end of the rotating block structure 114 is fixedly provided with a cross-shaped rotating block structure 115, so that the device is relatively suitable for hands and saves labor; the external force acts on the cross-shaped rotating block structure 115, and the rotating block structure 114 rotates, so as to drive the filter cartridge structure 111 to turn inside the shell structure 112; the water outlet end of the filtering knot structure 11 is communicated with the backwashing device 12; the backwashing device 12 flushes the filter element structure 111 in multiple sides by reverse flushing. The external force acts on the cross-shaped rotating block structure 115, and the rotating block structure 114 rotates along with the cross-shaped rotating block structure, so that the filter element structure 111 is driven to turn over on the inner circumference of the horizontal plane; then the back washing device 12 washes the filter element structure 111 to wash away slag particles on the filter element structure, so that blockage can be avoided; therefore, the cleaning device does not need to be disassembled for cleaning and can be automatically washed. Not only saves time but also saves labor.

A slag storage structure 116 is fixedly arranged at the bottom of the shell structure 112; the slag storage structure 116 is integrally of an arc-shaped pipeline structure, so that slag particles can conveniently slide along an arc-shaped surface; one end of the slag storage structure 116 is communicated with the inside of the shell structure 112; the other end of the slag storage structure 116 extends obliquely downwards and is arranged above the ground, and slag particles washed after filtration directly slide to the ground through the slag storage structure 116, so that the operation is convenient and easy, and the slag particles cannot pollute the ground; the slag storage structure 116 is provided with the control valve 117, the control valve 117 is opened periodically to clean slag particles, the slag particles are not required to be treated all the time, and the time can be effectively saved.

The filtering layer structure 1 further comprises a slag particle filtering net structure 13; the filter knot structure 11 is communicated with the backwashing device 12 through the slag particle filter screen structure 13; the slag particle filter screen structure 13 comprises a horn-shaped pipeline structure 131 and a convex filter screen structure 132; the circumference of the trumpet-shaped pipe structure 131 gradually decreases and is directed from the filter structure 11 to the backwashing device 12; the convex filter screen structure 132 is fixedly arranged inside the trumpet-shaped pipeline structure 131; the convex filter screen structure 132 is a filter screen plate type structure, and can effectively prevent slag particles which are not filtered by the filter element structure 111; whole orientation in middle part of convex surface filter screen structure 132 back washing unit 12 forms protruding portion 133, and the evagination has formed an cambered surface, can effectively avoid the sediment grain to adhere to on convex surface filter screen structure 132, just convex surface filter screen structure 132's central part orientation back washing unit 12 forms concave part 134, and when washing, water is from the position of concave part 134 to expanding around, washes to cleaner. The slag particle filter screen structure 13 is designed into a horn-shaped structure, and can form an inclined plane, so that the blocked slag particles can slide into the shell structure 112 and then enter the slag storage structure 116; the backwashing device 12 washes from the convex part 133 of the convex filtering net structure 132, so that the washing can be more thorough, and the mesh blockage of the convex filtering net structure 132 is avoided.

The filter element structure 111 sequentially comprises a first adsorption layer structure 1111, a filter paper layer structure 1112, a ceramic filter element layer structure 1113, a sponge layer structure 1114, a molecular sieve layer structure 1115 and a second adsorption layer structure 1116, a cavity 1117 is formed between adjacent filter layers, and the bottoms of the cavities 1117 are communicated; the bottom of the cavity 1117 is communicated with the feeding end of the slag storage structure 116, and the washed slag particles are gathered from the cavity 1117 to the communicated bottom of the cavity 1117 and then fall into the slag storage structure 116. Filter core structure 111 has set gradually multilayer filtration structure can more thoroughly better filtration fall the sediment grain of irrigation water to cause the jam to the device.

The drip irrigation structure 2 comprises a condensation structure 21 and an air inflation structure 22; the integral condensation and dripping structure 21 is of a gyro-type structure; the water inlet end of the condensation and drip structure 21 is communicated with the drainage pipeline 3, and water enters the drip irrigation structure 2; the condensation structure 21 comprises a dissolving cavity structure 211 and a water dropping structure 212; the air-filled structure 22 penetrates through the dissolution cavity structure 211 and into the water dripping structure 212 to form a droplet breaking structure 23. The inflatable structure 22 breaks open the water droplets formed by the drip structure 212 to prevent water from accumulating below the drip area and affecting the growth of the crops.

The dissolution cavity structure 211 comprises a liquid separation disc structure 2111, a rotating shaft structure 2113 and a solution box structure 2114; the driving device at the bottom of the dissolution cavity structure 211 is in driving connection with the rotating shaft structure 2113; the rotating shaft structure 2113 extends upwards, and a plurality of bent and expanded stirring rod structures 2112 are fixedly arranged on the side wall of the rotating shaft structure to stir water in the solution box structure 2114 so as to avoid generation of precipitates; the extension end of the rotating shaft structure 2113 is provided with the liquid separating disc structure 2111; a water inlet 2115 at the top of the dissolution cavity structure 211 is arranged at a distance from the liquid separation disc structure 2111; the liquid-separating disc structure 2111 is provided with a hollow hole 21111; the plurality of hollow holes 21111 are arranged around the rotating shaft structure 2113 at intervals; after entering, the water is dispersed from the hollow-out holes 21111, so that the impact force of the water is reduced; the inner wall of the solution box structure 2114 is provided with a groove 21141; the edge of the separating disc structure 2111 is embedded into the groove 21141; the driving device drives the rotating shaft structure 2113 to rotate, so as to drive the liquid separation disc structure 2111 and the stirring rod structure 2112 to rotate in the solution box structure 2114. By the design, the impact force of water entering can be effectively reduced, meanwhile, precipitation can be avoided, the service life of the device is prolonged, the device is prevented from being damaged, and the water dripping structure 212 is enabled to form a complete water dripping layer.

The inflatable structure 22 comprises a pneumatic pump; the air pressure pump is arranged in the center of the liquid separating disc structure 2111; an air inlet pipe 221 of the pneumatic pump extends outwards, is communicated with the outside and is filled with air; the outward extending end of the air inlet pipe 221 is rotatably connected with the liquid separating disc structure 2111, so that the air inlet pipe 221 is prevented from being damaged; an air outlet pipe 222 of the air pressure pump extends downwards to be inserted into the water dripping structure 212, and the air outlet pipe 222 penetrates through the rotating shaft structure 2113; the downwardly extending end of the outlet pipe 222 is rotatably connected to the rotating shaft structure 2113, so as to prevent the outlet pipe 222 from being damaged. The air pressure pump increases the pressure of the air entering from the air inlet pipe 221 and discharges the air from the air outlet pipe 222 to perform impact blasting on the water dropping layer formed in the water dropping structure 212, so that the water drops are broken; effectively avoiding the water dripping area from forming accumulated water to influence the growth of crops.

The bottom of the dissolving cavity structure 211 is fixedly provided with the water dripping structure 212; the drip structure 212 includes a slow drain groove 2121 and a drip condensation structure 2122; the slow leakage groove 2121 is of a circular ring structure; the slow leakage groove 2121 is communicated with the dissolving cavity structure 211 through a leakage pipe 2123; the plurality of water leakage pipes 2123 are annularly arranged and are externally provided with a plurality of rings; reducing the pressure of the water within the solution cartridge structure 2114 on the drip structure 212, facilitating the formation of a complete drip layer; the water drop condensation structure 2122 is integrally of a bowl-shaped structure; the water droplet condensing structure 2122 comprises a condensing ring structure 21221 and an converging cavity 21222; the melt aggregation cavity 21222 is integrally of an inverted bowl-shaped structure; the fusion cavity 21222 is communicated with the slow leakage groove 2121 through a fine condensation pipe 2124; the thin condensation pipes 2124 are annularly arranged and are externally provided with multiple rings; the coagulation ring structure 21221 is fixedly arranged on the inner wall of the bowl opening of the coagulation cavity 21222; the coagulation ring structure 21221 is a circular ring-shaped structure block; a plurality of annular tooth openings 21223 are formed in the inner ring of the coagulation ring structure 21221. The water in the solution box structure 2114 flows into the slow-leakage groove 2121 through the water leakage pipe 2123, then flows into the water drop condensation structure 2122 through the fine condensation pipe 2124, and then is converged at the tooth opening 21223 of the condensation structure 21221 to form a water drop layer; the gas discharged by the gas charging structure 22 breaks the water drop layer, disperses the water drop layer into a plurality of small water drops and finally waters the small water drops to crops; can effectively save water resources and reduce the influence of accumulated water on crops.

The air outlet of the air outlet pipe 222 extends to the middle of the fusion cavity 21222, and forms the droplet breaking structure 23 together with the fusion cavity 21222 and the coagulation ring structure 21221; when the coacervate structure 21221 is coacervated to form a water layer, the melt-aggregation cavity 21222 is in a sealed state; the gas is blown out from the gas filled structure 22, and the condensed water layer on the condensed ring structure 21221 is broken. By adopting the design, the drip irrigation mode is adopted for irrigation, so that the water resource is saved, meanwhile, the accumulated water below a dripping area is avoided, and the influence on the growth of plants or crops is reduced; can effectively increase the utilization rate of water and the yield of grains.

The foregoing is a preferred embodiment of the present invention, and it will be apparent to those skilled in the art that various modifications and enhancements can be made without departing from the principles of the invention, and such modifications and enhancements are also considered to be within the scope of the invention.