CN111236565B - Self-adhesive inner wall hanging plate assembly adopting combined installation mode - Google Patents

Self-adhesive inner wall hanging plate assembly adopting combined installation mode Download PDFInfo

- Publication number

- CN111236565B CN111236565B CN202010239251.0A CN202010239251A CN111236565B CN 111236565 B CN111236565 B CN 111236565B CN 202010239251 A CN202010239251 A CN 202010239251A CN 111236565 B CN111236565 B CN 111236565B

- Authority

- CN

- China

- Prior art keywords

- plate

- glue

- bonding

- groove

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F13/00—Coverings or linings, e.g. for walls or ceilings

- E04F13/07—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor

- E04F13/08—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements

- E04F13/0866—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements composed of several layers, e.g. sandwich panels or layered panels

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F13/00—Coverings or linings, e.g. for walls or ceilings

- E04F13/07—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor

- E04F13/08—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements

- E04F13/0801—Separate fastening elements

- E04F13/0832—Separate fastening elements without load-supporting elongated furring elements between wall and covering elements

- E04F13/0833—Separate fastening elements without load-supporting elongated furring elements between wall and covering elements not adjustable

- E04F13/0835—Separate fastening elements without load-supporting elongated furring elements between wall and covering elements not adjustable the fastening elements extending into the back side of the covering elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F13/00—Coverings or linings, e.g. for walls or ceilings

- E04F13/07—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor

- E04F13/08—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements

- E04F13/0885—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements specially adapted for being adhesively fixed to the wall; Fastening means therefor; Fixing by means of plastics materials hardening after application

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Finishing Walls (AREA)

- Supports Or Holders For Household Use (AREA)

Abstract

The invention belongs to the technical field of interior wall decorative plates, and particularly relates to a self-adhesive interior wall hanging plate assembly adopting a combined installation mode. The invention achieves the mounting effect of the inner wall decorative plate which is hung and bonded by arranging the mounting groove, the limiting plate, the hanging plate unit, the supporting plate unit and the glue unit on the inner wall decorative plate, and the bonding structure of the inner wall decorative plate has small and uniform glue consumption and is just matched with the combined mounting structure. The invention has the advantages that the two combined mounting methods of hanging and bonding the inner wall decorative plate have high structural strength, small pressure intensity at the screw joint, strong pertinence of the glue bonding position at the hanging position and high relative bonding strength, and the use of the pre-bonding layer and the main bonding agent can be further matched with the combined mounting structure.

Description

Technical Field

The invention belongs to the technical field of interior wall decorative plates, and particularly relates to a self-adhesive interior wall hanging plate assembly adopting a combined installation mode.

Background

Interior wall decorative board, according to the difference of mounting means, can divide into interior wall link plate and interior wall paste board on a large scale, wherein the former adopts the mode installation that articulates, it exempts from gluey advantage to have the environmental protection, but also there is poor stability after the installation, easy both sides are rocked, and articulate the screw department pressure-bearing at position too big, the problem that the decorative board splits easily in this department, the direct mode that adopts glue to paste of the latter goes on, then whole decorative board back needs relatively more glue, because of economic environmental protection's consideration, then it is unsatisfactory again, so the urgent need in market is with gluey volume few, and the installation, support firm novel decorative board.

The patent publication number is CN 209874336U, and the china utility model patent that bulletin day is 2019.12.31 discloses a wallboard pendant of pasting formula, connect limit and third including first connection limit, second and be connected the limit, first connection limit with the vertical setting in third connection limit, the limit level setting is connected to the second, the front end on limit is connected to the second with the rear surface middle part on first connection limit is connected, the rear end on second connection limit with the upper end on third connection limit is connected, the front surface on first connection limit evenly is equipped with a plurality of T type pieces.

But the wallboard pendant in this utility model patent has and rocks easily after the wallboard installation, and the problem that the screw support position is pressed strongly, splits easily.

The patent publication No. CN106830804A, Chinese patent application publication No. 2017.06.13, discloses a cement wallboard, which is made of a cement mixture and auxiliary materials, wherein the cement mixture comprises portland cement powder, river sand, pottery clay and the like, and the auxiliary materials comprise a naphthalene sulfonate water reducing agent, polymeric polyol, polymeric alcohol amine and the like.

However, the cement wallboard in the patent of the invention has the problems of poor pasting use effect and insufficient pasting mode for environmental protection.

The invention discloses a method for sticking face bricks during prefabricating concrete floors and wallboards, which is disclosed in Chinese patent publication No. CN 105437354A and published as 2016.03.30, and comprises the steps of manufacturing a bottom die of the precast concrete floor or wallboard, paving a single-sided adhesive plastic film on the bottom die of the precast concrete floor or wallboard, placing a positioning grid and face bricks of the face bricks and pouring hot paraffin liquid on the bottom die of the precast concrete floor or wallboard with the single-sided adhesive plastic film, placing side dies of the precast concrete floor or wallboard, binding reinforcing steel bar materials of the precast concrete floor or wallboard, and pouring concrete of the precast concrete floor or wallboard.

But the wallboard in the patent of the invention has the problem of great difficulty in pasting and using operations.

Disclosure of Invention

The invention aims to provide a self-adhesive inner wall hanging plate assembly adopting a combined installation mode, which can achieve the installation effect of hanging and bonding the combined inner wall decorating plate by arranging an installation groove, a limiting plate, a hanging plate unit, a supporting plate unit and a glue unit on the inner wall decorating plate, and the self bonding structure of the inner wall decorating plate has small and uniform glue consumption and is just matched with the combined installation structure. The invention has the advantages that the two combined mounting methods of hanging and bonding the inner wall decorative plate have high structural strength, small pressure intensity at the screw joint, strong pertinence of the glue bonding position at the hanging position and high relative bonding strength, and the use of the pre-bonding layer and the main bonding agent can be further matched with the combined mounting structure.

The technical scheme adopted by the invention for solving the problems is as follows: the utility model provides an adopt self-adhesion interior wall link plate subassembly of built-up mounting mode, includes interior wall decorative board, interior wall decorative board includes by front inoxidizing coating, decorative layer, foaming core plate layer, tie coat and the hole sheet layer in advance to the back, be equipped with the array trompil that is used for loading main binder on the hole sheet layer.

The further preferred technical scheme is as follows: the back of the inner wall decorative plate is provided with a separation groove for disconnecting the pre-bonding layer and the hole plate layer until the pre-bonding layer and the hole plate layer are exposed, and the mounting groove is arranged in the area of the separation groove on the foaming core plate layer.

The further preferred technical scheme is as follows: the hanging plate unit is arranged on the mounting groove and used for increasing the supporting area, and the glue unit is arranged on the mounting groove and used for bonding two ends of the hanging plate unit in a releasing mode after the hanging plate unit is punctured.

The further preferred technical scheme is as follows: the hanging plate unit comprises inserting plates used for being inserted into the inner sides of the paired limiting plates, fastening screws penetrating through the inserting plates and used for being arranged on the wall in a threaded mode, and screw countersunk holes which are arranged on the inserting plates and used for the glue unit to bond and fix the inserting plates and the fastening screws on the inner side surfaces of the mounting grooves in a countersunk head mounting mode.

The further preferred technical scheme is as follows: the supporting plate unit comprises top plates arranged between the two paired limiting plates, annular supporting plates arranged on the outer side faces of the inserting plates and arranged with the bolt countersunk holes in a concentric circle position relation and fastened by fastening bolts in threaded connection with arc-shaped thread faces below, and arc-shaped grooves arranged at the lower ends of the top plates and used for clamping and butting the annular supporting plates.

The further preferred technical scheme is as follows: glue unit includes that the four sides corresponds the bonding to be fixed the three medial surface of mounting groove, in addition the limiting plate with the seal membrane on the medial surface that the roof parallel and level is constituteed sets up insert board up end, inside and outside both sides face, in addition glue guiding gutter on the annular face above the annular supporting plate, and set up the seal membrane with bonding glue between the top surface in the mounting groove.

The further preferred technical scheme is as follows: the upper end of the inserting plate is a bending surface used for piercing the sealing membrane, the fastening screw is a straight screw which is used for introducing the bonding glue into the screw countersunk head hole in a butt joint glue guide groove mode, and a straight groove of the straight screw is vertically aligned with the glue guide groove.

The further preferred technical scheme is as follows: the glue unit further comprises an auxiliary flow guide groove which is arranged on the bending surface and used for guiding glue into the glue flow guide groove.

The further preferred technical scheme is as follows: the glue unit further comprises an arc-shaped groove which is arranged on the end face of the annular supporting plate, the upper end notch of the arc-shaped groove is in butt joint with the glue guide groove and used for storing glue, and the width of the arc-shaped groove on the lower side is smaller than that of the arc-shaped groove on the upper side.

The further preferred technical scheme is as follows: the glue unit also comprises an arc cavity channel which is formed outwards from the inner side surface of the arc-shaped groove, is communicated with the outer plane of the groove and is used for introducing air into the bonding glue.

The invention achieves the mounting effect of the inner wall decorative plate which is hung and bonded by arranging the mounting groove, the limiting plate, the hanging plate unit, the supporting plate unit and the glue unit on the inner wall decorative plate, and the bonding structure of the inner wall decorative plate has small and uniform glue consumption and is just matched with the combined mounting structure. The invention has the advantages that the two combined mounting methods of hanging and bonding the inner wall decorative plate have high structural strength, small pressure intensity at the screw joint, strong pertinence of the glue bonding position at the hanging position and high relative bonding strength, and the use of the pre-bonding layer and the main bonding agent can be further matched with the combined mounting structure.

Drawings

Fig. 1 is a schematic view showing a structure of an interior wall decorative panel according to the present invention.

Fig. 2 is a schematic view showing the position of the spacing groove in the present invention.

Fig. 3 is a schematic view of the hanging, bonding, assembling and mounting structure of the interior wall decorative panel of the present invention.

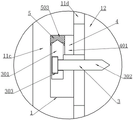

Fig. 4 is a schematic view of the position structure of the spring jack-up unit in the invention.

Fig. 5 is a schematic structural diagram of the position of the arc-shaped groove in the invention.

Fig. 6 is a schematic view of the mounting structure of the straight screw on the screw countersunk hole in the invention.

Fig. 7 is a schematic view of a storage structure of the adhesive glue of the present invention.

FIG. 8 is a schematic view of a position structure of the arc-shaped channel of the present invention.

Detailed Description

The following description is only a preferred embodiment of the present invention and is not intended to limit the scope of the present invention.

Example (b): as shown in accompanying figures 1, 2, 3, 4, 5, 6, 7 and 8, a self-adhesive interior wall hanging plate assembly adopting a combined installation mode comprises an interior wall decorating plate 11 and further comprises a mounting groove 1 arranged on the back surface of the interior wall decorating plate 11, a limiting plate 2 arranged on the mounting groove 1, a hanging plate unit 3 arranged on a wall body 12 in a screwed mode and used for limiting and fixing the outside through the limiting plate 2, a supporting plate unit 4 arranged on the mounting groove 1 and the hanging plate unit 3 and used for increasing the supporting area, and a glue unit 5 arranged on the mounting groove 1 and used for bonding two ends of a releasing mode after the hanging plate unit 3 is punctured.

In this embodiment, the hanging plate unit 3 is firstly installed on the wall 12, and then the interior wall decoration plate 11 is moved, so that the hanging plate unit 3 enters from the installation groove 1 and slides into the limiting plate 2 to complete the limiting installation action, and at this time, the first heavy hanging action of the interior wall decoration plate 11 is completed.

The second step bonding action, then through link plate unit 3 punctures glue unit 5, glue unit 5's glue flows to two places, and the first department is link plate unit 3 with between 1 medial surface of mounting groove for it is fixed to bond, can also be used for bonding simultaneously and fix link plate unit 3 self, the second department is backup pad unit 4 with region between wall body 12 is used for bonding fixedly on the wall body 12 backup pad unit 4 guarantees that the second heavy bonding effect has many fixed advantages.

On the other hand, the introduction of the supporting plate unit 4 mainly increases the supporting area of the interior wall decorative plate 11 on the screw of the hanging plate unit 3, the supporting area is large, the pressure is small, and the interior wall decorative plate 11 is not easy to break at the screw.

The interior wall decorative board 11 comprises a protective layer 11a, a decorative layer 11b, a foaming core board layer 11c, a pre-bonding layer 11d and a hole board layer 11e from the front surface to the back surface, wherein the hole board layer 11e is provided with array holes for filling main bonding agents.

In this embodiment, inoxidizing coating 11a is current plastic film, decorative layer 11b is current colored membrane, foaming core layer 11c is current polyethylene or polyvinyl chloride foaming board, and the mutual bonding of three or direct coextrusion shaping, and the material of tack coat 11d is for the current omnipotent glue as supplementary glue in advance, has the bonding and takes effect fast but the life-span is short, characteristics that intensity is low, supplementary glue is in array trompil department can coat, also can vacate not scribble, and the kind of main binder is current special floor glue, has to take effect slowly but bonding strength is big, longe-lived characteristics, with can guarantee after the cooperation of supplementary glue interior wall decorative board 11's effective bonding installation.

In the embodiment, the supporting plate unit 4 is supported on and bonded to the wall 12, and it is necessary to ensure that the main adhesive can be bonded to the wall 12 after being coated, so that a double-bonding fixing manner is provided in addition to a combined mounting manner of hanging and bonding.

The back of the interior wall decorative plate 11 is provided with a spacing groove 11f which cuts off the pre-bonding layer 11d and the hole plate layer 11e until the foaming core plate layer 11c is exposed, and the mounting groove 1 is arranged on the foaming core plate layer 11c and is positioned in the area of the spacing groove 11 f.

In this embodiment, the spacing grooves 11f are used to expose the foam core layer 11c, so as to ensure that the mounting groove 1 is effectively opened, and on the other hand, the mounting groove 1 is directly opened from the hole plate layer 11e inward to open the hole plate layer 11e and the pre-bonding layer 11d, so that the support plate unit 4 can be bonded to the wall 12 together with the main bonding agent.

The hanging plate unit 3 comprises an insertion plate 301 inserted into the inner sides of the pair of limiting plates 2, a fastening screw 302 passing through the insertion plate 301 and screwed on the wall 12, and a screw countersunk hole 303 arranged on the insertion plate 301 and used for bonding and fixing the insertion plate 301 and the fastening screw 302 on the inner side surface of the mounting groove 1 by the glue unit 5 in a manner of countersunk mounting the fastening screw 302.

In this embodiment, the fastening screw 302 is used to screw the insertion plate 301, and then is screwed and fixed on the wall 12, and the screw countersunk hole 303 is provided, so that the whole side surface of the insertion plate 301 can be completely bonded on the inner side surface of the mounting groove 1 by glue, thereby ensuring that the screwing action in the hanging structure is not easy to return, and finally achieving the double strengthening effect of hanging and bonding combination.

The two limit plates 2 are respectively arranged at two sides of the mounting groove 1 and are spaced apart from each other, so as to limit and fix the insertion plate 301 and leave a clamping space for the fastening screw 302.

The supporting plate unit 4 includes a top plate 401 disposed between the two paired limiting plates 2, an annular supporting plate 402 disposed on the outer side surface of the inserting plate 301 and disposed in a concentric position relation with the screw countersunk hole 303 and fastened by the fastening screw 302 in a screwed manner on the lower arc-shaped thread surface, and an arc-shaped groove 403 disposed at the lower end of the top plate 401 and used for engaging and abutting against the annular supporting plate 402.

In this embodiment, if the annular support plate 402 is not provided, the top plate 401 directly presses on the fastening screw 302, which has the problems of small pressing surface area and large pressure intensity, so the annular support plate 402 can firstly directly protect the top plate 401 to prevent the top plate 401 from cracking.

In addition, the end face of the annular supporting plate 402 is fixedly connected with the insert plate 301, i.e. integrally formed, and the lower annular face is threaded and therefore is screwed with the fastening screw 302, so that the actual supporting area of the annular supporting plate 402 on the fastening screw 302 is larger, the pressure is smaller, and the top plate 401 and even the whole interior wall decoration plate 11 are less prone to fracture.

In this embodiment, the bonding glue 503 has two drops, the first is to flow into the inner auxiliary guiding groove 504, pass through the inner glue guiding groove 502, and finally flow into the screw countersunk hole 303 to flow onto the inner side surface of the insertion plate 301, so as to bond and fix the fastening screw 302 and the entire insertion plate 301.

The second place is that the adhesive glue 503 sequentially flows out of the auxiliary diversion trench 504, the glue diversion trench 502 on the insertion plate 301 and the glue diversion trench 502 on the annular support plate 402, and finally flows to the contact side surface of the annular support plate 402 and the wall body 12, so that the annular support plate 402 and the wall body 12 are not only supported, but also have the second-layer adhesive effect, and finally, the combined installation strength of hanging and bonding is ensured to be large enough.

The glue unit 5 further comprises an arc-shaped groove 505 which is arranged on the end face of the annular support plate 402, the upper end notch of the arc-shaped groove is in butt joint with the glue flow guide groove 502 and used for storing glue, and the width of the arc-shaped groove 505 on the lower side is smaller than that of the arc-shaped groove 505 on the upper side.

In this embodiment, if the end surface of the annular supporting plate 402 directly flows down the bonding glue 503 for bonding and fixing, the bonding area is not large enough and the amount of the bonding glue 503 which can be accommodated is not enough, so that the arc-shaped groove 505 is introduced for uniformly and massively accommodating the bonding glue 503 to improve the bonding strength, in addition, the arc-shaped groove 505 on the lower side can preferentially obtain the bonding glue 503 compared with the arc-shaped groove 505 on the upper side, and the amount of the flowing-down glue is relatively large, so that the glue distribution amounts on the upper side and the lower side of the end surface of the annular supporting plate 402 are balanced in a relatively narrow grooving manner, and the final uniform bonding strength is ensured.

The glue unit 5 further comprises an arc-shaped cavity 506 which is opened outwards from the inner side surface of the arc-shaped groove 505, is communicated with the outer plane of the groove, and is used for introducing air into the bonding glue 503.

In this embodiment, the solidification speed of the bonding glue 503 on the auxiliary guiding grooves 504 and the glue guiding grooves 502 is required to be reduced to prevent the bonding glue 503 from flowing to a corresponding place, and at the arc-shaped groove 505, which is a flowing end point of the bonding glue 503, the bonding glue 503 needs to be solidified relatively quickly to bond the wall 12, and at this time, the arc-shaped cavity 506 ensures that more air can be passively "blown" above the bonding glue 503, and the air is "blown" by the relatively quick air convection generated by the flowing of the bonding glue 503 to accelerate solidification and accelerate the bonding effect.

Finally, the interior wall decorative panel 11 in this embodiment may be replaced by a floor, and at this time, the hanging panel unit 3 is also engaged with the limiting plate 2 and also abuts against the supporting plate unit 4, but after the glue unit 5 is punctured, part of the bonding glue 503 may accidentally leak due to its own weight, i.e., the bonding glue 503 does not pass through the glue guiding groove 502 and the auxiliary guiding groove 504, which also exists when the interior wall decorative panel 11 is vertically installed, but leaks to different degrees, and the effect of the hanging and bonding combination mode is not affected as a whole.

The embodiments of the present invention have been described in detail with reference to the accompanying drawings, but the present invention is not limited to the above embodiments, and various modifications can be made within the knowledge of those skilled in the art without departing from the gist of the present invention. These are non-inventive modifications, which are intended to be protected by patent laws within the scope of the claims appended hereto.

Claims (6)

1. The utility model provides an adopt self-adhesion interior wall link plate subassembly of aggregate erection mode, includes interior wall decorative board (11), its characterized in that: the interior wall decorative plate (11) comprises a protective layer (11 a), a decorative layer (11 b), a foaming core plate layer (11 c), a pre-bonding layer (11 d) and a hole plate layer (11 e) from the front surface to the back surface, wherein the hole plate layer (11 e) is provided with array holes for filling a main bonding agent;

the back of the inner wall decorative plate (11) is provided with a spacing groove (11 f) which cuts off the pre-bonding layer (11 d) and the hole plate layer (11 e) until the foaming core plate layer (11 c) is exposed, and an installation groove (1) is arranged in the area, located in the spacing groove (11 f), on the foaming core plate layer (11 c);

the hanging plate is characterized by further comprising a limiting plate (2) arranged on the mounting groove (1), a hanging plate unit (3) which is arranged on a wall body (12) in a threaded manner and is limited and fixed at the outer side by the limiting plate (2), a supporting plate unit (4) which is arranged on the mounting groove (1) and the hanging plate unit (3) and is used for increasing the supporting area, and a glue unit (5) which is arranged on the mounting groove (1) and is used for bonding the hanging plate unit (3) at two ends in a release mode after the hanging plate unit (3) is punctured;

the hanging plate unit (3) comprises an insertion plate (301) inserted into the inner sides of the paired limiting plates (2), a fastening screw (302) penetrating through the insertion plate (301) and used for being in threaded connection with the wall body (12), and a screw countersunk hole (303) arranged on the insertion plate (301), the fastening screw (302) is arranged in the screw countersunk hole (303) in a countersunk installation mode, and the glue unit (5) is used for bonding and fixing the insertion plate (301) and the fastening screw (302) on the inner side surface of the installation groove (1);

backup pad unit (4) including set up in two in pairs roof (401) in the middle of limiting plate (2), set up insert on board (301) lateral surface and with screw counter bore (303) are concentric circles position relation setting and by fastening screw (302) carry out spiro union fastening's annular support board (402) on the arc helicoid of below, and set up and be in roof (401) lower extreme is used for the block to dock arc wall (403) of annular support board (402).

2. The self-adhesive interior wall panel assembly of claim 1 in a modular installation, wherein: glue unit (5) are fixed including the four sides correspondence bonding mounting groove (1) three medial surface, in addition limiting plate (2) with seal membrane (501) on the medial surface that roof (401) parallel and level is constituteed set up insert board (301) up end, inside and outside both sides face, in addition glue guiding gutter (502) on the annular surface above annular supporting plate (402), and set up seal membrane (501) with bonding glue (503) between the top surface in mounting groove (1).

3. The self-adhesive interior wall panel assembly of claim 2 in a modular installation, wherein: the upper end of the insertion plate (301) is provided with a bending surface (304) for puncturing the sealing membrane (501), the fastening screw (302) is a straight screw which is used for introducing the bonding glue (503) into the screw countersunk hole (303) in a mode of butting the glue guide groove (502), and a straight groove of the straight screw is vertically aligned with the glue guide groove (502).

4. A modular self-adhesive interior wall panel assembly according to claim 3 wherein: the glue unit (5) further comprises an auxiliary flow guide groove (504) which is arranged on the bending surface (304) and used for guiding glue into the glue flow guide groove (502).

5. The self-adhesive interior wall panel assembly of claim 4 in a modular installation, wherein: the glue unit (5) further comprises an arc-shaped groove (505) which is arranged on the end face of the annular supporting plate (402), the notch of the upper end of the arc-shaped groove is butted with the glue flow guide groove (502) and used for storing glue, and the width of the arc-shaped groove (505) on the lower side is smaller than that of the arc-shaped groove (505) on the upper side.

6. The self-adhesive interior wall panel assembly of claim 5 in a modular installation, wherein: the glue unit (5) further comprises an arc-shaped cavity (506) which is opened outwards from the inner side surface of the arc-shaped groove (505), is communicated with the outer plane of the groove and is used for introducing air into the bonding glue (503).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010239251.0A CN111236565B (en) | 2020-03-30 | 2020-03-30 | Self-adhesive inner wall hanging plate assembly adopting combined installation mode |

| PCT/CN2020/084272 WO2021196261A1 (en) | 2020-03-30 | 2020-04-10 | Self-attaching interior wall hanging board assembly employing combination assembly |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010239251.0A CN111236565B (en) | 2020-03-30 | 2020-03-30 | Self-adhesive inner wall hanging plate assembly adopting combined installation mode |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111236565A CN111236565A (en) | 2020-06-05 |

| CN111236565B true CN111236565B (en) | 2020-08-21 |

Family

ID=70877223

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010239251.0A Active CN111236565B (en) | 2020-03-30 | 2020-03-30 | Self-adhesive inner wall hanging plate assembly adopting combined installation mode |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN111236565B (en) |

| WO (1) | WO2021196261A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112878521B (en) * | 2021-01-20 | 2022-09-02 | 深圳华创建筑装饰股份有限公司 | Novel acoustic celotex board for green building |

| CN112975770B (en) * | 2021-03-31 | 2022-08-23 | 长光卫星技术股份有限公司 | A gasbag press mold bonding frock for polishing of numerical control intelligence |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002146997A (en) * | 2000-11-16 | 2002-05-22 | Inax Corp | Structure for executing plate-shaped building material |

| CN1756880A (en) * | 2003-03-07 | 2006-04-05 | 卡因德尔地板材料有限责任公司 | Covering panel |

| CN201531106U (en) * | 2009-10-23 | 2010-07-21 | 中国建筑科学研究院 | Floor slab sound insulation tie plate |

| CN103243890A (en) * | 2013-05-15 | 2013-08-14 | 王云飞 | Hanging and buckling assembly of heat-insulating decorating plate and installation process of buckle assembly |

| CN209443693U (en) * | 2018-11-29 | 2019-09-27 | 武汉市盘龙明达建筑有限公司 | A kind of inner corner trim work of nature stone mounting structure |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09228603A (en) * | 1996-02-21 | 1997-09-02 | Otsuka Oomi Togyo Kk | Installing structure of decorative sheet |

| CN203049970U (en) * | 2013-01-18 | 2013-07-10 | 山西峰岩新型建材股份有限公司 | Backer board |

| CN203373932U (en) * | 2013-08-08 | 2014-01-01 | 茅金声 | Novel fireproof thermal insulating wall and novel fireproof thermal insulating wallboard |

| CN206722278U (en) * | 2017-05-22 | 2017-12-08 | 汝州市环宇建材有限公司 | A kind of reinforcing thermal insulation external wall panel of convenient installation |

| CN210067309U (en) * | 2018-12-14 | 2020-02-14 | 武汉职业技术学院 | Combined assembled building decorative plate |

-

2020

- 2020-03-30 CN CN202010239251.0A patent/CN111236565B/en active Active

- 2020-04-10 WO PCT/CN2020/084272 patent/WO2021196261A1/en active Application Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002146997A (en) * | 2000-11-16 | 2002-05-22 | Inax Corp | Structure for executing plate-shaped building material |

| CN1756880A (en) * | 2003-03-07 | 2006-04-05 | 卡因德尔地板材料有限责任公司 | Covering panel |

| CN201531106U (en) * | 2009-10-23 | 2010-07-21 | 中国建筑科学研究院 | Floor slab sound insulation tie plate |

| CN103243890A (en) * | 2013-05-15 | 2013-08-14 | 王云飞 | Hanging and buckling assembly of heat-insulating decorating plate and installation process of buckle assembly |

| CN209443693U (en) * | 2018-11-29 | 2019-09-27 | 武汉市盘龙明达建筑有限公司 | A kind of inner corner trim work of nature stone mounting structure |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111236565A (en) | 2020-06-05 |

| WO2021196261A1 (en) | 2021-10-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111236565B (en) | Self-adhesive inner wall hanging plate assembly adopting combined installation mode | |

| CN104594535B (en) | Combination carrying construction unit curtain wall | |

| CN111270793B (en) | Integrated heat-preservation double-sided superposed wallboard and construction method | |

| CN202578718U (en) | Locating system for embedded part at construction joint between tunnel invert and secondary lining | |

| CN113293882A (en) | Assembled building structure convenient to butt joint and grout | |

| CN207760890U (en) | Basement outer wall post-cast strip closed structure | |

| CN113802760A (en) | Heat preservation is decorated and is maintained integration wallboard and wall structure | |

| CN218437756U (en) | Assembly type linear composite wallboard self-tapping nail cluster and post-cast strip combined connection structure | |

| CN203654652U (en) | Waterproof thermal insulating decoration board for external wall | |

| WO2009009955A1 (en) | A manufacturing process to connect a branch wind pipe with a main wind pipe and an article therefrom | |

| CN212582919U (en) | Self preservation temperature wallboard of convenient concatenation | |

| CN112523459A (en) | Indoor floor decoration method | |

| CN218623098U (en) | Modularization buckle formula ceramic tile dry process subassembly | |

| CN213979554U (en) | Sealed light composite wallboard | |

| CN206562680U (en) | A kind of exterior sheathing cast-in-place concrete heat-preservation structural system | |

| CN112627396A (en) | Detachable partition wall structure | |

| CN111809863A (en) | Pouring mold for bamboo texture decorative surface concrete wall | |

| CN114482442B (en) | Modular decorative wallboard | |

| CN220688420U (en) | Water supply and drainage pipeline protection equipment | |

| CN212957400U (en) | High strength stone material decorative board convenient to butt joint | |

| CN221850588U (en) | Superimposed sheet mould that can splice | |

| CN217299576U (en) | Building decorative panel structure with truncated cone just by holding frame direction | |

| CN219863644U (en) | Solid waste-based cementing material foaming cement wallboard containing FRP | |

| CN217680196U (en) | Waterproof structure suitable for integral bathroom wallboard | |

| CN221481289U (en) | Assembled binding off skirting line component |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |