CN111207244B - Steam boiler pipeline installation construction method - Google Patents

Steam boiler pipeline installation construction method Download PDFInfo

- Publication number

- CN111207244B CN111207244B CN202010113198.XA CN202010113198A CN111207244B CN 111207244 B CN111207244 B CN 111207244B CN 202010113198 A CN202010113198 A CN 202010113198A CN 111207244 B CN111207244 B CN 111207244B

- Authority

- CN

- China

- Prior art keywords

- plate

- pipeline

- steam boiler

- spring

- installation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L1/00—Laying or reclaiming pipes; Repairing or joining pipes on or under water

- F16L1/024—Laying or reclaiming pipes on land, e.g. above the ground

- F16L1/0243—Laying or reclaiming pipes on land, e.g. above the ground above ground

- F16L1/0246—Laying or reclaiming pipes on land, e.g. above the ground above ground at a certain height off the ground

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K31/00—Processes relevant to this subclass, specially adapted for particular articles or purposes, but not covered by only one of the preceding main groups

- B23K31/02—Processes relevant to this subclass, specially adapted for particular articles or purposes, but not covered by only one of the preceding main groups relating to soldering or welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K37/00—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups

- B23K37/04—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups for holding or positioning work

- B23K37/053—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups for holding or positioning work aligning cylindrical work; Clamping devices therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L1/00—Laying or reclaiming pipes; Repairing or joining pipes on or under water

- F16L1/024—Laying or reclaiming pipes on land, e.g. above the ground

- F16L1/06—Accessories therefor, e.g. anchors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L1/00—Laying or reclaiming pipes; Repairing or joining pipes on or under water

- F16L1/024—Laying or reclaiming pipes on land, e.g. above the ground

- F16L1/06—Accessories therefor, e.g. anchors

- F16L1/09—Accessories therefor, e.g. anchors for bringing two tubular members closer to each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/04—Tubular or hollow articles

- B23K2101/06—Tubes

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Manufacturing Of Tubular Articles Or Embedded Moulded Articles (AREA)

Abstract

The invention relates to a steam boiler pipeline installation construction method, which comprises a bottom plate, a lifting device, a clamping device, a buffer device and a bearing device, wherein the lifting device is arranged at the upper end of the bottom plate, the lower end of the lifting device is connected with the bottom plate, the clamping device is arranged in the middle of the lifting device, the clamping device is connected with the lifting device through thread fit, and the buffer device is arranged below the clamping device. The invention can solve the problems that the existing equipment can not clamp and fix the pipeline during pipeline installation when the pipeline of the steam boiler is installed, can not keep the pipeline horizontal, and is easy to generate the phenomenon of pipeline deviation during pipeline installation, thereby increasing the difficulty of pipeline installation, reducing the success rate of installation, simultaneously, realizing the function of continuous feeding, and needing manual work to sequentially convey the pipeline to the installation position, thereby increasing manpower and material resources, increasing working steps, reducing the efficiency of pipeline installation and the like.

Description

Technical Field

The invention relates to the technical field of pipeline installation, in particular to a steam boiler pipeline installation construction method.

Background

The steam boiler refers to boiler equipment for producing steam, belongs to special equipment, and is designed, produced, delivered and installed by being inspected by national technical supervision departments, a user can operate the boiler only by obtaining a boiler use certificate, the steam boiler can be divided into an electric steam boiler, an oil steam boiler, a gas steam boiler and the like according to fuels, and the steam boiler is mainly divided into two structures of a vertical double-return stroke structure and a horizontal three-return stroke structure.

At present, when the existing steam boiler pipe is installed, the following defects generally exist: 1. the existing equipment can not clamp and fix the pipeline during pipeline installation, can not keep the pipeline horizontal, and easily causes the pipeline offset phenomenon during pipeline installation, thereby increasing the pipeline installation difficulty and reducing the installation success rate; 2. the function of continuous feeding can not be realized when the existing equipment is used for installing the pipeline, and the pipeline needs to be manually transported to an installation position in sequence, so that manpower and material resources are increased, working steps are increased, and the efficiency of pipeline installation is reduced.

Disclosure of Invention

Technical problem to be solved

The invention can solve the problems that the existing equipment can not clamp and fix the pipeline during pipeline installation when the pipeline of the steam boiler is installed, can not keep the pipeline horizontal, and is easy to generate the phenomenon of pipeline deviation during pipeline installation, thereby increasing the difficulty of pipeline installation, reducing the success rate of installation, simultaneously, realizing the function of continuous feeding, and needing manual work to sequentially convey the pipeline to the installation position, thereby increasing manpower and material resources, increasing working steps, reducing the efficiency of pipeline installation and the like.

(II) technical scheme

In order to achieve the purpose, the invention adopts the following technical scheme that a steam boiler pipeline installation construction method uses a steam boiler pipeline installation device, the steam boiler pipeline installation device comprises a bottom plate, a lifting device, a clamping device, a buffering device and a bearing device, and the specific method for installing the steam boiler pipeline by adopting the steam boiler pipeline installation device is as follows:

s1, selecting a pipeline: selecting corresponding pipelines according to the type of the steam boiler in a manual mode, cleaning the surfaces of the pipelines and removing stains on the surfaces of the pipelines;

s2, placing a pipeline: manually placing the pipelines cleaned in the step S1 in a bearing device, and orderly arranging the pipelines by the bearing device;

s3, feeding treatment: the pipeline in the bearing device falls into the clamping device, the clamping device clamps and fixes the pipeline, and the pipeline is conveyed to a pipeline installation position through the lifting device;

s4, mounting a pipeline: manually welding and installing the pipeline at the pipeline installation position in the step S3;

s5, processing the connection part: and manually cleaning welding slag and residues at the welding position, and detecting whether welding repair is complete or not to avoid the phenomenon of welding missing.

The lifting device is installed at the upper end of the bottom plate, the lower end of the lifting device is connected with the bottom plate, the clamping device is arranged in the middle of the lifting device and connected with the lifting device through matching of threads, the buffer device is arranged below the clamping device and installed on the bottom plate, and the bearing device is arranged on the right side of the buffer device and installed on the bottom plate.

The clamping device comprises an upper lifting plate, a connecting plate, a lower arc plate, an upper arc plate, a limiting branched chain, a clamping mechanism, a limiting seat, an electric push rod and a jacking rod, wherein the upper lifting plate is connected with the lifting device in a sliding fit manner, the right end of the upper lifting plate is provided with the connecting plate, the lower end of the connecting plate is provided with a reinforcing rib, the upper end of the connecting plate is symmetrically provided with the lower arc plate through a base, the lower arc plate is connected with the upper arc plate through a pin shaft, the two upper arc plates are connected through a connecting rod, the upper arc plate is provided with a buckle, the lower arc plate is internally and slidably connected with the clamping mechanism, the left side of the lower arc plate is provided with the limiting seat, the limiting seat is arranged on the upper lifting plate, a circular groove is arranged in the upper lifting plate, the bottom end in the circular groove is provided with the electric push rod, the jacking rod is arranged at the, the connecting plate extrudees the device of putting to holding, thereby the realization falls into the function of arc inboard down with the pipeline, later, manual start electric putter, electric putter passes through the jacking pole with last arc board and arc board joint down, thereby the realization is to the pipeline function of fixing, and adopt two arc boards down can make the pipeline keep the level when the installation, avoid appearing the phenomenon of slope, and finally, after the piping erection finishes, elevating gear drives the connecting plate downstream, thereby realize automatic feeding's function.

The bearing and placing device comprises a support rod, a bearing and placing frame, a blanking plate, a lower pressing plate, a telescopic rod, a telescopic spring, a transition wheel, a baffle plate and a reset spring, wherein the support rod is uniformly arranged at the upper end of the bottom plate, the bearing and placing frame is arranged at the upper end of the support rod, an arc-shaped through hole with a rectangular cross section is arranged in the bearing and placing frame, the blanking plate is arranged at the left end of the arc-shaped through hole and is in sliding connection with the bearing and placing frame, the lower end of the blanking plate is connected with the lower pressing plate through a connecting rod, the telescopic rod is arranged at the right side of the blanking plate and is arranged on the lower pressing plate, the telescopic rod is arranged on the lower pressing plate, the telescopic spring is arranged on the outer surface of the telescopic rod and is arranged on the lower pressing plate, the transition wheel is arranged above the telescopic spring, the transition wheel is arranged in, reset spring installs in holding puts the frame, concrete during operation, at first, place the pipeline in holding puts the frame through artificial mode, later, the connecting plate pushes down and moves blanking plate downstream through holding down the board, thereby open the arc through-hole, realize the function of blanking, and, when blanking plate descends, it rises to separate the baffle through the drive of wire rope, block other pipelines, thereby avoid appearing the too much phenomenon of blanking, and at last, the connecting plate rises the back, reset spring resets blanking plate and separate the baffle, thereby be convenient for next time material loading.

Preferably, the lifting device comprises a lifting column, a threaded rod, a first helical gear, a linkage rod, a driving motor and a second helical gear, the lifting column is symmetrically installed at the upper end of the bottom plate, a rectangular groove is formed in the lifting column, a rectangular through hole is formed in the side wall of the inner end of the rectangular groove, the threaded rod is connected to the interior of the rectangular groove through a bearing, the first helical gear is installed at the lower end of the threaded rod and is located in the bottom plate, the linkage rod is connected to the inner side insection of the first helical gear, the driving motor is arranged between the two linkage rods and is installed on the bottom plate through a motor base, the second helical gear is installed on an output shaft of the driving motor and is connected with the insection of the linkage rod, and during specific work, firstly, the driving motor is manually started, the driving motor drives the threaded rod to rotate through the linkage, and finally, after the pipeline is installed, the driving motor drives the clamping device to descend through the threaded rod, so that the continuous feeding function is realized.

Preferably, buffer include down the traveller, go up traveller and buffer spring, the downslide post install on the bottom plate, the inside sliding connection of downslide post has the traveller, upward the traveller lower extreme is provided with buffer spring, buffer spring installs on the bottom plate, during specific work, when clamping device descends, go up the traveller and play the effect of buffering to clamping device through buffer spring.

Preferably, spacing branch include gag lever post, limiting plate and spacing spring, last arc board on the symmetry be provided with the gag lever post, gag lever post and last arc board sliding connection, the limiting plate is installed to gag lever post inner, the gag lever post surface is provided with spacing spring, spacing spring installs on the limiting plate, during concrete work, when carrying out the centre gripping to the pipeline, the limiting plate is fixed the pipeline through spacing spring, avoids the pipeline to appear sliding when the installation.

Preferably, chucking mechanism include chucking pole and chucking spring, lower arc board outer end sliding connection have the chucking pole, chucking pole and buckle joint, chucking pole surface is provided with the chucking spring, the chucking spring is installed under on the arc board, concrete during operation, when last arc board with down the arc board joint, the buckle extrudees the chucking pole, afterwards, the chucking spring resets the chucking pole to realize the function of chucking, after the piping erection, the manual work is pulled out the chucking pole, arc board and last arc board part under will manually.

Preferably, the rolling wheels are symmetrically arranged at the lower end of the bottom plate, and when the pipeline installation device works, the rolling wheels can achieve the function of moving to the next installation position after the pipeline installation is completed.

Preferably, the two ends of the linkage rod are symmetrically provided with the bevel gears, and when the linkage rod works specifically, the two bevel gears are respectively matched with the first bevel gear and the second bevel gear to realize a transmission function.

(III) advantageous effects

1. According to the steam boiler pipeline installation construction method provided by the invention, the adopted clamping device can provide a supporting force during pipeline installation, and can clamp and fix the pipeline, so that the phenomena of sliding and rotating during pipeline installation are avoided, and meanwhile, the clamping device can keep the pipeline horizontal during installation, so that the phenomenon that the installation difficulty is increased due to the fact that the joints of the pipeline are not uniform during installation is avoided, the success rate of pipeline installation is improved, and the waste of materials is avoided;

2. according to the steam boiler pipeline installation construction method provided by the invention, the adopted bearing device can realize the function of sequential feeding, the phenomenon of excessive feeding or clamping at one time is avoided, the bearing device and the clamping device are matched to realize the function of automatic feeding, the working steps are reduced, and the working efficiency is improved;

3. the steam boiler pipeline installation construction method provided by the invention can drive other pipelines to move to the next installation position after the pipeline installation is finished, and reduces the manual work for sequentially transporting the pipelines to the installation positions, thereby reducing the manpower and material resources and improving the pipeline installation efficiency.

Drawings

The invention is further illustrated with reference to the following figures and examples.

FIG. 1 is a process flow diagram of the present invention;

FIG. 2 is a front view of the present invention;

FIG. 3 is a left side view of the present invention;

FIG. 4 is a cross-sectional view A-A of FIG. 2 in accordance with the present invention;

FIG. 5 is a cross-sectional view of B-B of FIG. 3 in accordance with the present invention;

FIG. 6 is a cross-sectional view of C-C of FIG. 3 in accordance with the present invention;

FIG. 7 is an enlarged view of the invention taken in the direction of N in FIG. 5;

FIG. 8 is an enlarged view taken in the direction X of FIG. 5 in accordance with the present invention;

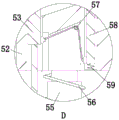

fig. 9 is an enlarged view of the invention taken along direction D in fig. 6.

Detailed Description

The embodiments of the invention will be described in detail below with reference to the drawings, but the invention can be implemented in many different ways as defined and covered by the claims.

As shown in fig. 1 to 9, a steam boiler pipe installation method using a steam boiler pipe installation apparatus including a bottom plate 1, a lifting device 2, a clamping device 3, a buffer device 4 and a receiving device 5, the steam boiler pipe installation apparatus is specifically installed on a steam boiler pipe by the following method:

s1, selecting a pipeline: selecting corresponding pipelines according to the type of the steam boiler in a manual mode, cleaning the surfaces of the pipelines and removing stains on the surfaces of the pipelines;

s2, placing a pipeline: manually placing the pipelines cleaned in the step S1 in a bearing device 5, and orderly arranging the pipelines by the bearing device 5;

s3, feeding treatment: the pipeline in the bearing device 5 falls into the clamping device 3, the clamping device 3 clamps and fixes the pipeline, and the pipeline is conveyed to a pipeline installation position through the lifting device 2;

s4, mounting a pipeline: manually welding and installing the pipeline at the pipeline installation position in the step S3;

s5, processing the connection part: and manually cleaning welding slag and residues at the welding position, and detecting whether welding repair is complete or not to avoid the phenomenon of welding missing.

The rolling wheels are symmetrically arranged at the lower end of the bottom plate 1, and when the pipeline installation device works, the rolling wheels can achieve the function of moving to the next installation position after the pipeline installation is completed.

The lifting device 2 comprises a lifting column 21, a threaded rod 22, a first helical gear 23, a linkage rod 24, a driving motor 25 and a second helical gear 26, the lifting column 21 is symmetrically installed at the upper end of the bottom plate 1, a rectangular groove is formed in the lifting column 21, a rectangular through hole is formed in the side wall of the inner end of the rectangular groove, the threaded rod 22 is connected in the rectangular groove through a bearing, the first helical gear 23 is installed at the lower end of the threaded rod 22, the first helical gear 23 is located in the bottom plate 1, the linkage rod 24 is connected with the inner side insection of the first helical gear 23, the driving motor 25 is arranged between the two linkage rods 24, the driving motor 25 is installed on the bottom plate 1 through a motor base, the second helical gear 26 is installed on the output shaft of the driving motor 25, the second helical gear 26 is connected with the insection of the linkage rods 24, during specific work, firstly, the driving motor 25 is manually, thereby drive clamping device 3 and carry out the downstream, later, after clamping device 3 material loading, driving motor 25 drives clamping device 3 through threaded rod 22 and rises, and finally, after the piping erection, driving motor 25 drives clamping device 3 through threaded rod 22 and descends to realize the function of continuous material loading.

The two ends of the linkage rod 24 are symmetrically provided with the bevel gears, and when the linkage rod works specifically, the two bevel gears are respectively matched with the first bevel gear 23 and the second bevel gear 26 to realize a transmission function.

The clamping device 3 comprises an ascending plate 31, a connecting plate 32, a lower arc plate 33, an upper arc plate 34, a limiting branched chain 35, a clamping mechanism 36, a limiting seat 37, an electric push rod 38 and a jacking rod 39, wherein the ascending plate 31 is connected with the lifting device 2 in a sliding fit mode, the connecting plate 32 is installed at the right end of the ascending plate 31, reinforcing ribs are arranged at the lower end of the connecting plate 32, the lower arc plate 33 is symmetrically installed at the upper end of the connecting plate 32 through a base, the lower arc plate 33 is connected with the upper arc plate 34 through a pin shaft, the two upper arc plates 34 are connected through a connecting rod, a buckle is arranged on the upper arc plate 34, the clamping mechanism 36 is slidably connected inside the lower arc plate 33, the limiting seat 37 is arranged at the left side of the lower arc plate 33, the limiting seat 37 is installed on the ascending plate 31, a circular groove is arranged inside the ascending plate 31, the electric push rod 38 is installed, the gyro wheel is installed to jacking pole 39 upper end, concrete during operation, at first, elevating gear 2 drives connecting plate 32 downstream through upwelling board 31, connecting plate 32 extrudes holding device 5, thereby realize falling into the function in arc board 33 down with the pipeline, afterwards, manual start electric putter 38, electric putter 38 will go up arc board 34 and arc board 33 joint down through jacking pole 39, thereby realize carrying out the function fixed to the pipeline, and adopt two arc boards 33 down to make the pipeline when the installation keep the level, avoid appearing the phenomenon of slope, finally, after pipeline installation finishes, elevating gear 2 drives connecting plate 32 downstream, thereby realize automatic feeding's function.

Spacing branched chain 35 include gag lever post 351, limiting plate 352 and spacing spring 353, last arc 34 on the symmetry be provided with gag lever post 351, gag lever post 351 and last arc 34 sliding connection, limiting plate 352 is installed to gag lever post 351 the inner, gag lever post 351 surface is provided with spacing spring 353, spacing spring 353 installs on limiting plate 352, during specific work, when carrying out the centre gripping to the pipeline, limiting plate 352 fixes the pipeline through spacing spring 353, avoids the pipeline to appear sliding when the installation.

The bearing device 5 comprises a support rod 51, a bearing frame 52, a blanking plate 53, a lower press plate 54, an expansion link 55, a telescopic spring 56, a transition wheel 57, a baffle plate 58 and a return spring 59, wherein the support rod 51 is uniformly arranged at the upper end of the bottom plate 1, the bearing frame 52 is arranged at the upper end of the support rod 51, an arc-shaped through hole with a rectangular section is arranged in the bearing frame 52, the blanking plate 53 is arranged at the left end of the arc-shaped through hole, the blanking plate 53 is in sliding connection with the bearing frame 52, the lower end of the blanking plate 53 is connected with the lower press plate 54 through a connecting rod, the expansion link 55 is arranged at the right side of the blanking plate 53, the expansion link 55 is arranged on the lower press plate 54, the outer surface of the expansion link 55 is provided with the telescopic spring 56, the telescopic spring 56 is arranged on the lower press plate 54, the transition wheel 57 is arranged above the telescopic spring 56, the steel wire rope is connected with a separation baffle plate 58 through a transition wheel 57, the separation baffle plate 58 is in sliding connection with the bearing frame 52, a reset spring 59 is arranged at the lower end of the separation baffle plate 58, the reset spring 59 is installed in the bearing frame 52, during specific work, firstly, a pipeline is placed in the bearing frame 52 in a manual mode, then, the connecting plate 32 is pressed downwards to drive the blanking plate 53 to move downwards through the lower pressing plate 54, the arc-shaped through hole is opened, the blanking function is achieved, in addition, the blanking plate 53 is driven to ascend through the steel wire rope, other pipelines are blocked, the phenomenon that blanking is too much is avoided, finally, after the connecting plate 32 ascends, the blanking plate 53 and the separation baffle plate 58 are reset through the reset spring 59, and therefore next feeding is facilitated.

During installation: the first step is as follows: manually placing the pipeline in the arc-shaped through hole in the bearing frame 52;

the second step is that: firstly, manually starting a driving motor 25, driving the connecting plate 32 to move downwards by the driving motor 25 through a threaded rod 22, driving a blanking plate 53 to descend by the connecting plate 32 through a lower pressing plate 54 so as to carry out loading, then manually starting an electric push rod 38, clamping an upper arc plate 34 and a lower arc plate 33 by the electric push rod 38 through a jacking rod 39, and finally, driving the connecting plate 32 to ascend by the driving motor 25 so as to manually install a pipeline;

the third step: after the second step is finished, pushing the equipment to the next installation position, and repeating the second step;

the fourth step: after the pipeline is completely installed, the driving motor 25 is manually turned off, and the pipeline installation is finished.

The above description is only a preferred embodiment of the present invention and is not intended to limit the present invention, and various modifications and changes may be made by those skilled in the art. Any modification, equivalent replacement, or improvement made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (7)

1. A steam boiler pipeline installation construction method uses a steam boiler pipeline installation device which comprises a bottom plate (1), a lifting device (2), a clamping device (3), a buffering device (4) and a bearing device (5), and is characterized in that: the specific method for installing the steam boiler pipeline by adopting the steam boiler pipeline installation device is as follows:

s1, selecting a pipeline: selecting corresponding pipelines according to the type of the steam boiler in a manual mode, cleaning the surfaces of the pipelines and removing stains on the surfaces of the pipelines;

s2, placing a pipeline: manually placing the pipelines cleaned in the step S1 in a bearing device (5), and orderly arranging the steel pipes by the bearing device (5);

s3, feeding treatment: the pipeline in the bearing device (5) falls into the clamping device (3), the clamping device (3) clamps and fixes the pipeline, and the pipeline is conveyed to a pipeline installation position through the lifting device (2);

s4, mounting a pipeline: manually welding and installing the pipeline at the pipeline installation position in the step S3;

s5, processing the connection part: manually cleaning welding slag and residues at the welding position, and detecting whether welding repair is complete or not so as to avoid welding missing;

the lifting device (2) is installed at the upper end of the bottom plate (1), the lower end of the lifting device (2) is connected with the bottom plate (1), the clamping device (3) is arranged in the middle of the lifting device (2), the clamping device (3) is connected with the lifting device (2) through matching of threads, the buffer device (4) is arranged below the clamping device (3), the buffer device (4) is installed on the bottom plate (1), the bearing and placing device (5) is arranged on the right side of the buffer device (4), and the bearing and placing device (5) is installed on the bottom plate (1);

the clamping device (3) comprises an ascending plate (31), a connecting plate (32), a lower arc plate (33), an upper arc plate (34), a limiting branched chain (35), a clamping mechanism (36), a limiting seat (37), an electric push rod (38) and a jacking rod (39), wherein the ascending plate (31) is connected with the lifting device (2) in a sliding fit mode, the connecting plate (32) is installed at the right end of the ascending plate (31), a reinforcing rib is arranged at the lower end of the connecting plate (32), the lower arc plate (33) is symmetrically installed at the upper end of the connecting plate (32) through a base, the lower arc plate (33) is connected with the upper arc plate (34) through a pin shaft, the two upper arc plates (34) are connected through a connecting rod, a buckle is arranged on the upper arc plate (34), the clamping mechanism (36) is slidably connected inside the lower arc plate (33), the limiting seat (37) is arranged on the left side of the lower arc plate (33), and the limiting seat (37), a circular groove is formed in the inner part of the lifting plate (31), an electric push rod (38) is installed at the bottom end of the inner part of the circular groove, a lifting rod (39) is installed at the top end of the electric push rod (38), and a roller is installed at the upper end of the lifting rod (39);

the bearing and placing device (5) comprises a supporting rod (51), a bearing frame (52), a blanking plate (53), a lower pressing plate (54), an expansion link (55), an expansion spring (56), a transition wheel (57), a baffle plate (58) and a reset spring (59), wherein the supporting rod (51) is uniformly arranged at the upper end of the bottom plate (1), the bearing frame (52) is arranged at the upper end of the supporting rod (51), an arc-shaped through hole with a rectangular cross section is arranged in the bearing frame (52), the blanking plate (53) is arranged at the left end of the arc-shaped through hole, the blanking plate (53) is in sliding connection with the bearing frame (52), the lower end of the blanking plate (53) is connected with the lower pressing plate (54) through a connecting rod, the expansion link (55) is arranged at the right side of the blanking plate (53), the expansion link (55) is arranged on the lower pressing plate (54), the expansion spring (56) is arranged on the outer surface of the expansion link (, a transition wheel (57) is arranged above the telescopic spring (56), the transition wheel (57) is installed in the bearing frame (52), the lower end of the blanking plate (53) is connected with a steel wire rope, the steel wire rope is connected with a baffle plate (58) through the transition wheel (57), the baffle plate (58) is in sliding connection with the bearing frame (52), a return spring (59) is arranged at the lower end of the baffle plate (58), and the return spring (59) is installed in the bearing frame (52).

2. A steam boiler tube installation and construction method according to claim 1, wherein: the lifting device (2) comprises a lifting column (21), a threaded rod (22), a first helical gear (23), a linkage rod (24), a driving motor (25) and a second helical gear (26), the lifting column (21) is symmetrically installed at the upper end of the base plate (1), a rectangular groove is formed in the lifting column (21), a rectangular through hole is formed in the side wall of the inner end of the rectangular groove, a threaded rod (22) is connected to the inside of the rectangular groove through a bearing, a first helical gear (23) is installed at the lower end of the threaded rod (22), the first helical gear (23) is located inside the base plate (1), a linkage rod (24) is connected to the inner side tooth pattern of the first helical gear (23), a driving motor (25) is arranged between the two linkage rods (24), the driving motor (25) is installed on the base plate (1) through a motor base, a second helical gear (26) is installed on the output shaft of the driving motor (25), and the second helical gear (26) is connected with.

3. A steam boiler tube installation and construction method according to claim 1, wherein: buffer (4) including traveller (41), last traveller (42) and buffer spring (43) down, traveller (41) install on bottom plate (1), traveller (41) inside sliding connection has last traveller (42) down, goes up traveller (42) lower extreme and is provided with buffer spring (43), buffer spring (43) are installed on bottom plate (1).

4. A steam boiler tube installation and construction method according to claim 1, wherein: spacing branched chain (35) include gag lever post (351), limiting plate (352) and spacing spring (353), last arc board (34) on the symmetry be provided with gag lever post (351), gag lever post (351) and last arc board (34) sliding connection, limiting plate (352) are installed to gag lever post (351) the inner, gag lever post (351) surface is provided with spacing spring (353), spacing spring (353) are installed on limiting plate (352).

5. A steam boiler tube installation and construction method according to claim 1, wherein: chucking mechanism (36) including chucking pole (361) and chucking spring (362), lower arc board (33) outer end sliding connection have chucking pole (361), chucking pole (361) and buckle joint, chucking pole (361) surface is provided with chucking spring (362), chucking spring (362) are installed under on arc board (33).

6. A steam boiler tube installation and construction method according to claim 1, wherein: the lower end of the bottom plate (1) is symmetrically provided with rolling wheels.

7. A steam boiler tube installation and construction method according to claim 2, wherein: and helical gears are symmetrically arranged at two ends of the linkage rod (24).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010113198.XA CN111207244B (en) | 2020-02-24 | 2020-02-24 | Steam boiler pipeline installation construction method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010113198.XA CN111207244B (en) | 2020-02-24 | 2020-02-24 | Steam boiler pipeline installation construction method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111207244A CN111207244A (en) | 2020-05-29 |

| CN111207244B true CN111207244B (en) | 2021-06-29 |

Family

ID=70789020

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010113198.XA Active CN111207244B (en) | 2020-02-24 | 2020-02-24 | Steam boiler pipeline installation construction method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111207244B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112059551B (en) * | 2020-09-05 | 2021-03-09 | 北方国际合作股份有限公司 | Method for manufacturing and processing coal economizer of thermal power generation boiler |

| CN113231785B (en) * | 2021-05-31 | 2023-02-10 | 龙泉市恒丰汽车空调配件有限公司 | Automatic processing equipment for liquid storage drying bottle |

| CN115255750B (en) * | 2022-09-28 | 2022-12-13 | 济南盛世阳光机械零部件有限公司 | Welding equipment and welding method for embedded part of balancing weight |

| CN117823716B (en) * | 2024-03-06 | 2024-05-14 | 福建三元安装有限公司 | Steam boiler pipeline installation construction method |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9517024D0 (en) * | 1995-08-19 | 1995-10-25 | Subsea Offshore Ltd | Method of and apparatus for repairing a pipeline |

| DE202009004500U1 (en) * | 2009-04-03 | 2010-08-19 | Sbb Stahl Stahl- Und Anlagenbau Gmbh | Auxiliary device for a workplace |

| US20140346702A1 (en) * | 2012-06-01 | 2014-11-27 | Altex Technologies Corporation | Method and apparatus for material densification |

| CN103986108B (en) * | 2014-04-03 | 2017-01-25 | 杭州吉宝传动设备有限公司 | Ocean engineering thermal insulation movable fully-enclosed cable bridge and erection method thereof |

| US20200018424A1 (en) * | 2018-07-10 | 2020-01-16 | Comalander Fabrication and Services, LLC | Pipe Support System, And Method Of Use |

| CN208587600U (en) * | 2018-08-01 | 2019-03-08 | 天津国化集团有限公司 | A kind of fixation device for natural gas line |

| CN109604890B (en) * | 2019-01-29 | 2021-04-23 | 瑞安市金易得机电有限公司 | Adjustable pipe installation, welding, assembly and moving in-place device |

| CN109973717B (en) * | 2019-05-20 | 2020-09-04 | 金湖县农副产品营销协会 | Running water conveying pipeline laying device |

-

2020

- 2020-02-24 CN CN202010113198.XA patent/CN111207244B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN111207244A (en) | 2020-05-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111207244B (en) | Steam boiler pipeline installation construction method | |

| CN110344490B (en) | Municipal road sewer pipeline construction equipment and method | |

| CN110919225B (en) | Welding manufacturing and processing technology for hot-dip galvanized steel | |

| CN111604636B (en) | Chemical plant pipeline laying connecting device and connecting method thereof | |

| CN110849748A (en) | PVC pipe quality detection equipment | |

| CN111532971A (en) | Environment-friendly glass fiber reinforced plastic septic tank installation and construction system and installation and construction process | |

| CN114991139A (en) | Positioning auxiliary support of basement anti-floating anchor rod | |

| CN110116359B (en) | Pre-buried exposing reinforcing bar rust cleaning device of building engineering of adaptable different diameters | |

| CN207903835U (en) | Pipeline apparatus for automatically lifting | |

| CN117451734A (en) | Concrete bridge bottom surface crack detection device and application method thereof | |

| CN217108486U (en) | Concrete rainwater pipeline installation device capable of being rapidly disassembled | |

| CN212608977U (en) | Combined lifting appliance for mounting solar panel | |

| CN111495787A (en) | Composite carbon fiber rod detection device and detection method thereof | |

| CN206653879U (en) | Tyre bead breaker | |

| CN216479277U (en) | Support frame is used in concrete drain pipe installation | |

| CN219324687U (en) | Reducing screen pipe shaping processingequipment | |

| CN216447260U (en) | Self-locking vertical net joint | |

| CN219566467U (en) | Inclined rail type steel pipe conveying device | |

| CN221875638U (en) | Hoisting type cement pipe quality detection equipment | |

| CN117754227B (en) | Pipeline welding auxiliary device for petrochemical industry | |

| CN214360158U (en) | Device is laid with well lid of being convenient for remove to road facilities construction | |

| CN218426690U (en) | Material pipe loading attachment | |

| CN221247182U (en) | Seamless steel tube cutting table with dust collection device | |

| CN218285429U (en) | Civil engineering pipe fitting rack | |

| CN216511358U (en) | Steel pipe tower flange group is to machine and is had suspension mobile device of anti-drop structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20210602 Address after: 297-2908, block B, Wanda office building, Fengze District, Quanzhou City, Fujian Province, 362000 Applicant after: Fujian Sanyuan installation Co.,Ltd. Address before: 314001 Jiaxing Shuangli pipe fittings Co., Ltd., Guangyi Road, Nanhu District, Jiaxing City, Zhejiang Province Applicant before: Pan Xuejun |

|

| GR01 | Patent grant | ||

| GR01 | Patent grant |