CN111198501A - Method for determining fuel equivalent factor by RBF neural network - Google Patents

Method for determining fuel equivalent factor by RBF neural network Download PDFInfo

- Publication number

- CN111198501A CN111198501A CN202010039719.1A CN202010039719A CN111198501A CN 111198501 A CN111198501 A CN 111198501A CN 202010039719 A CN202010039719 A CN 202010039719A CN 111198501 A CN111198501 A CN 111198501A

- Authority

- CN

- China

- Prior art keywords

- neural network

- fuel

- rbf neural

- average

- equivalent factor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 62

- 238000013528 artificial neural network Methods 0.000 title claims abstract description 44

- 238000000034 method Methods 0.000 title claims abstract description 23

- 230000006870 function Effects 0.000 claims description 24

- 210000002569 neuron Anatomy 0.000 claims description 5

- 238000011478 gradient descent method Methods 0.000 claims description 4

- 230000004913 activation Effects 0.000 claims description 3

- 238000013507 mapping Methods 0.000 claims description 2

- 238000013178 mathematical model Methods 0.000 claims 1

- 230000001133 acceleration Effects 0.000 abstract description 3

- 238000005457 optimization Methods 0.000 abstract description 3

- 238000007726 management method Methods 0.000 description 6

- 238000007670 refining Methods 0.000 description 5

- 230000008859 change Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000007781 pre-processing Methods 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 238000003064 k means clustering Methods 0.000 description 1

- 238000010606 normalization Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B13/00—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion

- G05B13/02—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric

- G05B13/04—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric involving the use of models or simulators

- G05B13/042—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric involving the use of models or simulators in which a parameter or coefficient is automatically adjusted to optimise the performance

Landscapes

- Engineering & Computer Science (AREA)

- Software Systems (AREA)

- Artificial Intelligence (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Evolutionary Computation (AREA)

- Medical Informatics (AREA)

- Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

- Combined Controls Of Internal Combustion Engines (AREA)

- Hybrid Electric Vehicles (AREA)

Abstract

The invention discloses a method for calculating fuel equivalent factors by an RBF neural network. When the Pontryagin minimum value principle is applied to energy management of a hybrid electric vehicle, a Hamiltonian based on fuel economy can be constructed according to a whole vehicle power model, and a covariate can be regarded as a fuel equivalent factor for converting instantaneous electric quantity consumption into instantaneous fuel consumption. Aiming at the problem that the optimal fuel equivalent factor is difficult to determine so that the fuel economy of the whole vehicle reaches the global optimal value, the RBF neural network is adopted to optimize the fuel equivalent factor. And taking the average speed, the average acceleration, the average deceleration and the average impact degree as input layers of the neural network, and taking the fuel equivalent factor as output. Compared with the method for determining the fuel equivalent factor only through the type of the working condition of the vehicle, the method can obtain a better equivalent factor; compared with a method for calculating the fuel equivalent factor through an intelligent optimization algorithm, the method provided by the invention has the advantages of smaller calculated amount and stronger real-time property.

Description

Technical Field

The invention relates to the field of automobiles, optimizes a hybrid electric vehicle energy management method based on the Pontryagin minimum value principle, and particularly relates to a method for calculating a fuel equivalent factor through a Radial Basis Function (RBF) neural network.

Background

Before a new energy automobile replaces a traditional fuel automobile, a hybrid electric automobile as a transition automobile type exists for a long time, and an energy management strategy of the hybrid electric automobile is a key for solving the problems of fuel economy, exhaust emission and the like. Aiming at the nonlinear time-varying system such as a hybrid electric vehicle, an energy management strategy can be designed by applying the Pontryagin minimum value principle. According to a dynamic model of the whole vehicle, a Hamiltonian can be constructed, wherein the covariates can be regarded as fuel equivalent factors for converting instantaneous electric quantity consumption into instantaneous fuel consumption.

The energy management method based on the Pontryagin minimum value is a global optimization algorithm, meanwhile, the energy management can be converted into an instantaneous problem through a Hamiltonian, the key is a fuel equivalent factor, and the optimal fuel equivalent factor can ensure the best fuel economy of the whole vehicle. The method of determining the fuel equivalent factor only according to the type of the working condition of the vehicle or the driving style of the driver ignores the influence of other vehicle condition information on the fuel equivalent factor, and is difficult to obtain the optimal fuel equivalent factor. The method for searching the optimal fuel equivalent factor through the intelligent optimization algorithm has large calculation amount and poor real-time performance.

Disclosure of Invention

In order to solve the technical problems in the prior art, the invention provides a method for determining a fuel equivalent factor by an RBF neural network so as to quickly obtain the nearly optimal fuel equivalent factor and improve the fuel economy of the whole vehicle.

The technical scheme for solving the problems is as follows:

1) and (5) preprocessing the working condition data (offline). Extracting a plurality of 600s working condition segments from the existing driving record working condition library, calculating the optimal power distribution of each working condition segment by a Hamiltonian, and determining the fuel equivalent factor lambda by an enumeration method. And calculating the average speed of each working condition segmentAverage accelerationAverage decelerationAnd average impact strength

2) The RBF neural network is trained (offline). At an average speedAverage accelerationAverage decelerationAnd average impact strengthAnd (3) taking the optimal fuel equivalent factor lambda as an output for inputting layer parameters, and training the RBF neural network by a gradient descent method.

3) The fuel equivalence factor is calculated (on-line). Extracting the latest 120s of working conditions from the recorded running working conditions of the vehicle, and calculating the average speedAverage accelerationAverage decelerationAnd average impact strengthAnd then calculating the fuel equivalent factor through the trained RBF neural network.

In the step 1, the impact degree is the magnitude of the acceleration change rate

Where v (t) is the current running speed.

In the step 1, the Hamiltonian is

Wherein, x (t) is a state variable of the system, which is referred to as a battery SOC state; u (T) is a control variable of the system, here motor torque Tm。The instantaneous oil consumption of the engine is lambda (t) & f (x (t), u (t), and t), the equivalent oil consumption of the motor is t,λ (t) is a fuel equivalent factor. When the Hamiltonian is minimal, there is an optimal power distribution of the engine and the electric machine. The fuel equivalent factor which enables the fuel economy of the whole vehicle to reach the best is the optimal equivalent factor.

In the step 2, the RBF neural network comprises an input layer, a hidden layer and an output layer. Taking Gaussian radial basis function as activation function of hidden layer

Wherein, ciIs the radial basis function center, σ is the radial basis function width, and x is the input layer parameter; the output layer is a linear combination of hidden layer neuron outputs with different weights

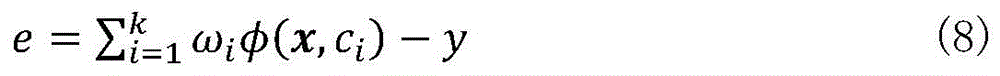

Wherein, ω isiY is the output value of the output layer.

In the step 2, each coefficient of the neural network is adjusted by a gradient descent method. The output mean square error is taken as an objective function, and because the single-output RBF neural network is constructed by the method, the method comprises the following steps:

where e is the output error, y is the actual value,is the value output by the RBF neural network. In order to minimize the objective function, the individual parameters are adjusted in the direction of the negative gradient, there are

ωi←ωi+Δωi,ci←ci+Δci,σi←σi+Δσ

Where, ← is the assignment symbol, and η is the learning rate.

In the step 3, after the training of the RBF neural network is completed, each coefficient omega is obtainedi、ci、σiIs already a definite value, at which time the speed will be averagedAverage accelerationAverage decelerationAnd average impact strengthSubstituting to obtain the fuel equivalent factor.

Compared with the existing method for determining the fuel equivalent factor, the method has the following advantages: the influence of each item of vehicle condition information on the fuel equivalent factor is fully considered, the mapping relation between the basic vehicle condition information and the optimal fuel equivalent factor is established through the RBF neural network, and the fuel equivalent factor close to the optimal can be quickly obtained in a real-time environment.

Drawings

Fig. 1 is a diagram of an RBF neural network architecture.

Fig. 2 is a flow chart of energy management for a PMP-based hybrid vehicle.

Detailed Description

The invention is further described below with reference to the accompanying drawings.

Fig. 1 is a block diagram of an RBF neural network. As shown in FIG. 2, the characteristic parameters are extracted from the driving record, the fuel equivalent factor is calculated by an RBF neural network, and the power distribution of the engine and the motor is calculated by a Hamilton function in combination with the required power.

The invention discloses a method for determining fuel equivalent factors by an RBF neural network, which comprises the following steps:

step 1: and (5) preprocessing the working condition data (offline). Extracting 600s driving segments from the existing working condition library, and calculating the average speed of the driving segmentsAverage accelerationAverage decelerationAnd average impact strengthThe impact degree is the magnitude of the change rate of the acceleration, and is shown in formula 1:

the optimal power distribution is determined by the Hamilton function, so that the fuel equivalent factor with the optimal fuel economy of the whole vehicle is the optimal fuel equivalent factor of the working condition, and the optimal fuel equivalent factor can be determined by a stepping method. The Hamiltonian is shown in equation 2:

wherein, x (t) is a state variable of the system, which is referred to as a battery SOC state; u (T) is a control variable of the system, here motor torque Tm。The instantaneous oil consumption of the engine is lambda (t) & f (x (t), u (t), and t), the equivalent oil consumption of the motor is t,λ (t) is a fuel equivalent factor. When the Hamiltonian is minimum, there is an optimal power allocation.

Step 2: the RBF neural network is trained (offline). The RBF neural network comprises an input layer, a hidden layer and an output layer, and a Gaussian radial basis function is used as an activation function of the hidden layer, as shown in formula 3:

wherein, ciDetermining the initial radial basis function centers of the hidden layer neurons by K-means clustering, wherein the radial basis function centers are sigma, the radial basis function widths are sigma, the input layer parameters are x, and the number of the hidden layer neurons is 7; output layer is a linear with different weights for hidden layer neuron outputA combination, as shown in formula 4:

the output of the gaussian radial basis function is highly correlated with the euclidean distance, and in order to avoid that high-order parameters have a decisive influence on the output of the gaussian radial basis function, normalization processing needs to be performed on the parameters of the input layer to make them in the same order of magnitude. Meanwhile, in order to reflect the difference of the influence degree of each input layer parameter on the output, the normalized parameters may be weighted, as shown in equation 5.

a1+a2+a3+a41 (6) wherein a1、a2、a3、a4Is the weight coefficient, and is the assignment symbol.

And adjusting each coefficient of the neural network by a gradient descent method. The output mean square error is taken as an objective function, the output layer only has one parameter and is a fuel equivalent factor, so the RBF neural network constructed by the invention is a single-output neural network. Equation 7 is the objective function, and equation 8 is the error expression.

Where e is the output error, y is the actual value,is the value output by the RBF neural network. In order to minimize the objective function, the individual parameters are adjusted in the direction of the negative gradient, there are

ωi←ωi+Δωi,ci←ci+Δci,σi←σi+Δσ (9)

And the step of either refining the RBF neural network or refining the RBF neural network, wherein the step of either refining the RBF neural network or refining the RBF neural network is used as the key, and the step of refining the RBF neural network is used as the key.

And step 3: the equivalence factor is calculated (on-line). Extracting the latest 120s of vehicle condition information from the driving record, and calculating the average speedAverage accelerationAverage decelerationAnd average impact strengthSubstituting the calculated equivalent fuel factors into the trained RBF neural network to obtain the equivalent fuel factors required by the next stroke, calculating the optimal power distribution by combining the Hamiltonian, and updating the equivalent fuel factors every 3 seconds.

Claims (5)

1. A method for determining a fuel equivalent factor by an RBF neural network is characterized by comprising the following steps:

in an off-line environment, effective driving segments are selected from an existing working condition library, the optimal fuel equivalent factors of the driving segments are calculated, and an RBF neural network is constructed to fit the mapping relation between the basic information of the vehicle condition and the optimal fuel equivalent factors;

and after the RBF neural network training is finished, extracting corresponding characteristic parameters from the driving record to calculate the fuel equivalent factor in a real-time online environment.

2. A method for determining fuel equivalence factors by an RBF neural network as claimed in claim 1, wherein, under off-line conditions, effective 600s operating condition segments are selected from an existing operating condition library and their average speeds are calculated respectivelyAverage accelerationAverage decelerationAnd average impact strengthThe degree of impact is defined as

According to the extreme value principle of Pontryagin, a Hamiltonian is constructed according to a mathematical model of the hybrid electric vehicle

When the Hamiltonian has the minimum value, the whole vehicle has the optimal power distribution, when the fuel equivalent factor lambda takes the optimal value, the whole vehicle has the optimal fuel economy, and the optimal equivalent factors of all working condition segments are determined by a stepping method.

3. An RBF neural network as claimed in claim 1 for determining fuel equivalence factorsMethod, characterized by constructing RBF neural network fitting basic vehicle condition information (average speed)Average accelerationAverage decelerationAverage degree of impact) And an optimal equivalence factor λ; the RBF neural network is divided into three layers, including an input layer, a hidden layer and an output layer, wherein the hidden layer takes a Gaussian radial basis function as an activation function:

wherein, ciIs the radial basis function center, σ is the radial basis function width, and x is the input layer parameter; the output layer is a linear combination of hidden layer neuron outputs with different weights

Wherein, ω isiY is the output value of the output layer.

4. A method for determining fuel equivalence factors by an RBF neural network as claimed in claim 1, wherein the parameters of the input layer are normalized and then weighted

a1+a2+a3+a4=1

Wherein, a1、a2、a3、a4Is the weight coefficient, and is the assignment symbol. Training RBF neural network by gradient descent method to minimize output mean square error as objective function

ωi←ωi+Δωi,ci←ci+Δci,σi←σi+Δσ

Where, ← is the assignment symbol, and η is the learning rate.

5. A method for determining fuel equivalence factors by an RBF neural network as claimed in claim 1, wherein after training of the RBF neural network is completed, basic vehicle condition information including average speed is extracted from the last 120s driving record under real-time on-line conditionAverage accelerationAverage decelerationAverage degree of impactSubstituting into RBF neural network to calculate fuel equivalent factor every 3 secondsAnd updating the primary fuel equivalent factor.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010039719.1A CN111198501B (en) | 2020-01-14 | 2020-01-14 | Method for determining fuel equivalent factor by RBF neural network |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010039719.1A CN111198501B (en) | 2020-01-14 | 2020-01-14 | Method for determining fuel equivalent factor by RBF neural network |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111198501A true CN111198501A (en) | 2020-05-26 |

| CN111198501B CN111198501B (en) | 2022-05-13 |

Family

ID=70746496

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010039719.1A Active CN111198501B (en) | 2020-01-14 | 2020-01-14 | Method for determining fuel equivalent factor by RBF neural network |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111198501B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111923897A (en) * | 2020-09-29 | 2020-11-13 | 北京航空航天大学 | Intelligent energy management method for plug-in hybrid electric vehicle |

| CN112193232A (en) * | 2020-09-23 | 2021-01-08 | 江苏大学 | Self-adaptive energy management system and method for hybrid electric vehicle |

| CN116118709A (en) * | 2023-03-14 | 2023-05-16 | 合众新能源汽车股份有限公司 | Energy management method and system for hybrid electric vehicle |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103914985A (en) * | 2014-04-25 | 2014-07-09 | 大连理工大学 | Method for predicting future speed trajectory of hybrid power bus |

| CN105527110A (en) * | 2015-12-03 | 2016-04-27 | 东软集团股份有限公司 | Evaluation method and device of automotive fuel economy |

| US20170146362A1 (en) * | 2015-11-19 | 2017-05-25 | GM Global Technology Operations LLC | Method and apparatus for fuel consumption prediction and cost estimation via crowd-sensing in vehicle navigation system |

| CN107688343A (en) * | 2017-08-01 | 2018-02-13 | 北京理工大学 | A kind of energy control method of motor vehicle driven by mixed power |

| CN109131350A (en) * | 2018-08-23 | 2019-01-04 | 北京理工大学 | A kind of hybrid vehicle energy management method and system |

| CN109143867A (en) * | 2018-09-26 | 2019-01-04 | 上海海事大学 | A kind of energy management method of the hybrid power ship based on ANN Control |

| CN110194172A (en) * | 2019-06-28 | 2019-09-03 | 重庆大学 | Based on enhanced neural network plug-in hybrid passenger car energy management method |

-

2020

- 2020-01-14 CN CN202010039719.1A patent/CN111198501B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103914985A (en) * | 2014-04-25 | 2014-07-09 | 大连理工大学 | Method for predicting future speed trajectory of hybrid power bus |

| US20170146362A1 (en) * | 2015-11-19 | 2017-05-25 | GM Global Technology Operations LLC | Method and apparatus for fuel consumption prediction and cost estimation via crowd-sensing in vehicle navigation system |

| CN105527110A (en) * | 2015-12-03 | 2016-04-27 | 东软集团股份有限公司 | Evaluation method and device of automotive fuel economy |

| CN107688343A (en) * | 2017-08-01 | 2018-02-13 | 北京理工大学 | A kind of energy control method of motor vehicle driven by mixed power |

| CN109131350A (en) * | 2018-08-23 | 2019-01-04 | 北京理工大学 | A kind of hybrid vehicle energy management method and system |

| CN109143867A (en) * | 2018-09-26 | 2019-01-04 | 上海海事大学 | A kind of energy management method of the hybrid power ship based on ANN Control |

| CN110194172A (en) * | 2019-06-28 | 2019-09-03 | 重庆大学 | Based on enhanced neural network plug-in hybrid passenger car energy management method |

Non-Patent Citations (4)

| Title |

|---|

| FENG TIANHENG等: "A Supervisory Control Strategy for Plug-In Hybrid Electric Vehicles Based on Energy Demand Prediction and Route Preview", 《 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY》 * |

| NINGYUAN GUO等: "A Novel Velocity Forecast Method for Improving Predictive Energy Management of Plug-In Hybrid Electric Vehicles", 《2017 IEEE VEHICLE POWER AND PROPULSION CONFERENCE (VPPC)》 * |

| 武振: "基于神经网络和PMP的混合动力汽车能量管理策略研究", 《中国优秀博硕士学位论文全文数据库(硕士) 工程科技Ⅱ辑》 * |

| 王庆年等: "插电式混合动力汽车动力传动系参数优化", 《吉林大学学报(工学版)》 * |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112193232A (en) * | 2020-09-23 | 2021-01-08 | 江苏大学 | Self-adaptive energy management system and method for hybrid electric vehicle |

| CN112193232B (en) * | 2020-09-23 | 2021-10-12 | 江苏大学 | Self-adaptive energy management system and method for hybrid electric vehicle |

| CN111923897A (en) * | 2020-09-29 | 2020-11-13 | 北京航空航天大学 | Intelligent energy management method for plug-in hybrid electric vehicle |

| CN116118709A (en) * | 2023-03-14 | 2023-05-16 | 合众新能源汽车股份有限公司 | Energy management method and system for hybrid electric vehicle |

| CN116118709B (en) * | 2023-03-14 | 2024-01-16 | 合众新能源汽车股份有限公司 | Energy management method and system for hybrid electric vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111198501B (en) | 2022-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111198501B (en) | Method for determining fuel equivalent factor by RBF neural network | |

| CN107688343B (en) | Energy control method of hybrid power vehicle | |

| CN111038485B (en) | Hybrid electric vehicle control method and system based on driving style recognition | |

| WO2021103625A1 (en) | Short-term vehicle speed condition real-time prediction method based on interaction between vehicle ahead and current vehicle | |

| CN113153521B (en) | System and method for predicting vehicle engine torque by using artificial neural network | |

| CN110775065B (en) | Hybrid electric vehicle battery life prediction method based on working condition recognition | |

| Wu et al. | Fuzzy energy management strategy for a hybrid electric vehicle based on driving cycle recognition | |

| CN110962837B (en) | Plug-in hybrid electric vehicle energy management method considering driving style | |

| CN112668799A (en) | Intelligent energy management method and storage medium for PHEV (Power electric vehicle) based on big driving data | |

| CN111047085B (en) | Hybrid vehicle working condition prediction method based on meta-learning | |

| CN111775925B (en) | Working mode decision method and device for power split hybrid electric vehicle | |

| CN110929920A (en) | Hybrid power train energy management method based on working condition identification | |

| CN112046489B (en) | Driving style identification algorithm based on factor analysis and machine learning | |

| CN112026744B (en) | Series-parallel hybrid power system energy management method based on DQN variants | |

| CN115492928B (en) | Economical efficiency, dynamic performance and safety comprehensive optimal gear shifting rule optimization method | |

| CN112298155B (en) | Method for predicting energy consumption of hybrid power truck based on variable time domain model | |

| CN111923897A (en) | Intelligent energy management method for plug-in hybrid electric vehicle | |

| Montazeri-Gh et al. | Driving condition recognition for genetic-fuzzy HEV control | |

| CN117465301A (en) | Fuel cell automobile real-time energy management method based on data driving | |

| CN110077389B (en) | Energy management method for plug-in hybrid electric vehicle | |

| CN114969982A (en) | Fuel cell automobile deep reinforcement learning energy management method based on strategy migration | |

| CN107527093B (en) | Wind turbine generator running state diagnosis method and device | |

| Nguyen et al. | Optimal Energy Management Strategy based on Driving Pattern Recognition for a Dual-Motor Dual-Source Electric Vehicle | |

| CN113997925B (en) | Energy management method for plug-in hybrid power system | |

| Ji et al. | Driving Condition Recognition Combined With Stochastic Prediction and Machine Learning and Its Application in Energy Management of Medium Fuel Cell Trucks |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |