CN110978298B - Processing machine and processing technology for building curtain wall dry-hanging decorative face stone - Google Patents

Processing machine and processing technology for building curtain wall dry-hanging decorative face stone Download PDFInfo

- Publication number

- CN110978298B CN110978298B CN201911331620.2A CN201911331620A CN110978298B CN 110978298 B CN110978298 B CN 110978298B CN 201911331620 A CN201911331620 A CN 201911331620A CN 110978298 B CN110978298 B CN 110978298B

- Authority

- CN

- China

- Prior art keywords

- sliding

- plate

- rod

- stone

- block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004575 stone Substances 0.000 title claims abstract description 78

- 238000005516 engineering process Methods 0.000 title abstract description 11

- 238000009434 installation Methods 0.000 claims abstract description 21

- 230000007246 mechanism Effects 0.000 claims description 38

- 238000007664 blowing Methods 0.000 claims description 24

- 239000000463 material Substances 0.000 claims description 20

- 238000003466 welding Methods 0.000 claims description 15

- 238000003860 storage Methods 0.000 claims description 11

- 230000000630 rising effect Effects 0.000 claims description 6

- 238000000034 method Methods 0.000 abstract description 7

- 239000002699 waste material Substances 0.000 abstract description 6

- 238000005520 cutting process Methods 0.000 abstract description 5

- 239000000428 dust Substances 0.000 abstract description 5

- 230000008569 process Effects 0.000 abstract description 5

- 238000005336 cracking Methods 0.000 abstract description 4

- 238000010276 construction Methods 0.000 abstract description 3

- 238000001914 filtration Methods 0.000 description 5

- 230000001174 ascending effect Effects 0.000 description 3

- 238000005034 decoration Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

- B28D1/22—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by cutting, e.g. incising

- B28D1/225—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by cutting, e.g. incising for scoring or breaking, e.g. tiles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D7/00—Accessories specially adapted for use with machines or devices of the preceding groups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D7/00—Accessories specially adapted for use with machines or devices of the preceding groups

- B28D7/02—Accessories specially adapted for use with machines or devices of the preceding groups for removing or laying dust, e.g. by spraying liquids; for cooling work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D7/00—Accessories specially adapted for use with machines or devices of the preceding groups

- B28D7/04—Accessories specially adapted for use with machines or devices of the preceding groups for supporting or holding work or conveying or discharging work

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

Abstract

The invention relates to a processing machine and a processing technology for building curtain wall dry-hanging decorative stone, which comprise an installation frame, a slotting kit and a fixing kit, wherein the slotting kit and the fixing kit are sequentially arranged in the installation frame from top to bottom, and the processing machine can solve the following problems in the actual slotting process of the existing dry-hanging stone: a: when the grooving operation is carried out on the surface of the stone at present, the grooving operation is directly carried out on the stone by using a grooving cutter, wherein the blade is extremely easy to be clamped by stone dust splashed in the grooving operation, so that the blade is broken, the phenomenon of delaying the construction period is caused, and the waste is caused; b: when the grooving operation is carried out on the surface of the stone at present, the phenomenon of stone surface cracking is caused due to the irregularity during the stress transfer during the cutting, thereby causing the cost waste.

Description

Technical Field

The invention relates to the technical field of building curtain wall decoration, in particular to a processing machine and a processing technology for dry-hanging decorative face stone of a building curtain wall.

Background

With the rapid growth of economy in China and the gradual improvement of the national living standard, the wall decoration process is carried out by long-term use of a stone dry-hanging method for installation, and the facing stone is directly hung on the wall by a metal hanger, so that when the wall stone is dry-hung, grooving treatment is often required to be carried out on the stone to serve as a hanging point for installation, but the existing stone grooving machine still has certain defects when the grooving operation is carried out on the surface of the stone.

The existing dry-hanging stone often has the following problems in the actual grooving process: a: when the grooving operation is carried out on the surface of the stone at present, the grooving operation is directly carried out on the stone by using a grooving cutter, wherein the blade is extremely easy to be clamped by stone dust splashed in the grooving operation, so that the blade is broken, the phenomenon of delaying the construction period is caused, and the waste is caused; b: when the grooving operation is carried out on the surface of the stone at present, the phenomenon of stone surface cracking is caused due to the irregularity during the stress transfer during the cutting, thereby causing the cost waste.

In order to make up the defects of the prior art, the invention provides a processing machine and a processing technology for building curtain wall dry-hanging decorative face stone.

Disclosure of Invention

The technical scheme adopted by the invention to solve the technical problem is as follows: the utility model provides a building curtain hangs veneer stone material processing machinery futilely, includes mounting bracket, fluting external member and fixed external member, the mounting bracket is inside from last fluting external member and the fixed external member of down having set gradually, wherein:

the slotting kit includes pneumatic cylinder A, the sliding plate, the mount pad, pneumatic cylinder B, the slotting machine, the glide post, slotting mechanism and slotting shovel, pneumatic cylinder A installs on the mounting bracket outer wall, install the sliding plate on pneumatic cylinder A's the output shaft, be provided with spout A on the sliding plate, be provided with the mount pad through the welded mode on the sliding plate, install pneumatic cylinder B on the mount pad, install the slotting machine on pneumatic cylinder B's the output shaft, be provided with the glide post that uses of mutually supporting with spout A through the welded mode on the slotting machine, the inside slotting mechanism that is provided with of slotting machine, the slotting shovel is installed through welded mode symmetry on the terminal surface under the slotting machine.

Fixed external member includes motor A, presss from both sides tight external member, mounting panel, fixed establishment and direction slat, and motor A passes through the motor cabinet to be installed on the mounting bracket inner wall, is provided with on motor A's the output shaft and presss from both sides tight external member, presss from both sides tight external member below and is provided with the mounting panel, is provided with spout B on the mounting panel, and the inside fixed establishment that is provided with of mounting panel, both sides are provided with the direction slat through welded mode symmetry about the mounting panel, and the direction slat opposite side is installed on the mounting bracket inner wall through the welded mode, is provided.

As a preferred technical scheme of the invention, the grooving mechanism comprises a motor B, a rotating shaft rod, a line scribing cutter, a blowing mechanism and a hammering roller, wherein the motor B is arranged on the outer wall of the grooving frame through a motor base, the rotating shaft rod is arranged on an output shaft of the motor B, one end of the rotating shaft rod is arranged on the inner wall of the grooving frame in a bearing connection mode, the line scribing cutter is symmetrically arranged on the rotating shaft rod, the blowing mechanism is uniformly arranged inside the line scribing cutter along the circumferential direction of the line scribing cutter, the hammering roller is arranged between the line scribing cutters, and the hammering roller is fixedly arranged on the rotating shaft rod.

As a preferred technical scheme of the invention, an annular through groove is arranged in the scribing cutter, and a freely moving spherical ball is arranged in the annular through groove.

According to a preferable technical scheme, the blowing mechanism comprises a rebound top column, a fan-shaped air bag, a blowing pipe and a filtering head cover, the rebound top column is installed on the inner wall of the scribing cutter in a sliding connection mode, the fan-shaped air bag is arranged at the upper end of the rebound top column, the bottom end of the rebound top column is located inside the fan-shaped air bag, the blowing pipe is evenly arranged on the surface of the fan-shaped air bag, and the filtering head cover is installed on the blowing pipe.

As a preferred technical scheme of the invention, the clamping kit comprises a rotating plate, a traction column, a traction plate, a sliding column, a sliding block, a connecting rod, a clamping plate and a clamping mechanism, wherein the rotating plate is installed on an output shaft of a motor A in a welding mode, the traction column is symmetrically arranged on the rotating plate, the traction plate is installed on the traction column, the sliding column which is matched with the sliding chute C for use is installed on the traction plate, the sliding block is arranged on the sliding column, the connecting rod is arranged on the left end face of the sliding block in a welding mode, the clamping plate is installed on the connecting rod, and the clamping mechanism is arranged inside the clamping plate.

As a preferred technical scheme of the invention, the clamping mechanism comprises a trigger push rod, an ascending ejector rod, a T-shaped air bag, a driving push rod, a driving block, a descending slide rod, an air storage bag, a connector and an expansion air bag, wherein the trigger push rod is installed on the inner wall of the clamping plate in a sliding connection mode, the triggering push rod abuts against the ascending ejector rod, the T-shaped air bag is arranged at the upper end of the ascending ejector rod, the driving push rod is arranged at the right end inside the T-shaped air bag, the driving block abuts against the driving block at the lower end of the driving push rod, the driving block is installed on the inner wall of the clamping plate in a spring connection mode, the descending slide rod is installed on the driving block, the air storage bag is arranged on the lower end.

As a preferred technical scheme of the invention, the fixing mechanism comprises a trigger block, a spiral push rod, a rotating base plate, a sliding rod, an installation block, a connecting frame, a fixed block, a sliding block and a fixed plate, wherein the trigger block is installed on the inner wall of the installation plate in a spring sliding connection mode, the spiral rod is installed on the lower end face of the trigger block, the rotating base plate is arranged on the spiral rod in a threaded connection mode, the sliding rod is arranged on the lower end face of the rotating base plate and is installed on the inner wall of the installation plate in a sliding connection mode, the installation block is symmetrically installed on the upper end face of the rotating base plate in a welding mode, the connecting frame is arranged on the installation block, the fixed block which is matched with the sliding groove B for use is installed on the connecting frame, the sliding block is installed on the fixed block.

In addition, the invention also provides a processing technology of the building curtain wall dry-hanging decorative face stone, the processing technology is mainly completed by matching the processing machinery of the building curtain wall dry-hanging decorative face stone, and the processing technology specifically comprises the following steps:

s1, feeding: placing the stone to be grooved on the mounting plate 32 in a manual feeding mode;

s2, stone clamping: motor A begins work, it begins to rotate to drive the back rotor plate, and then drive and pull the post, traction plate and sliding post move along spout C, thereby drive the gliding piece and remove, and then drive the grip block and remove to the stone material surface after, the stone material promotes and triggers the push rod to move to inside, drive the upward motion of lift ejector pin, extrude the inside air of T type gasbag, drive push rod and move right, drive the drive block and move down, thereby drive down slide bar downstream, extrude the inside air of gas storage bag, transmit the air to the inflation gasbag along the connector, make its inflation, thereby reach the purpose of fastening the stone material.

S3, stone wrapping: when the stone material was placed on the installation version, drive and trigger the piece downstream, and then drive the screw push rod downstream, drive and rotate the backing plate and rotate to drive the fixed block through the link and move to inside along spout B, and then drive sliding block and fixed plate and move to the stone material surface, thereby reach the purpose of the tight stone material of package.

S4, stone grooving: pneumatic cylinder A begins work, drives the gliding board and the frame downstream of slotting, and pneumatic cylinder B begins work simultaneously and drives the frame of slotting and remove along spout A, and motor B drives the pivot pole and rotates when removing, drives the rule sword simultaneously and hammers the compression roller and rotate, and back slotting shovel shovels away the stone material at the removal in-process to reach the grooved purpose of stone material.

S5, repeating the steps from S1 to S4, and continuously performing grooving operation on the surface of the stone.

Compared with the prior art, the invention has the following advantages:

1. the invention can solve the following problems in the actual grooving process of the existing dry-hanging stone: a: when the grooving operation is carried out on the surface of the stone at present, the grooving operation is directly carried out on the stone by using a grooving cutter, wherein the blade is extremely easy to be clamped by stone dust splashed in the grooving operation, so that the blade is broken, the phenomenon of delaying the construction period is caused, and the waste is caused; b: when the grooving operation is carried out on the surface of the stone at present, the phenomenon of stone surface cracking is caused due to the irregularity during the stress transfer during the cutting, thereby causing the cost waste.

2. The blowing mechanism is designed, the motor B works to drive the scribing cutter to rotate, the spherical balls inside the scribing cutter roll along the annular through groove, when the cutting edge is lifted, the balls extrude the rebounding ejection column to move downwards to store air inside the fan-shaped air bag, and the air is discharged to the outside along the blowing pipe, so that the purpose of blowing is achieved, when the balls leave, the rebounding ejection column rebounds to drive the fan-shaped air bag to absorb air on the outer wall, the filtering head cover starts to work at the same time to block dust, the phenomenon that the blowing pipe is blocked is prevented, the phenomenon that the blade is broken due to the material carrying phenomenon caused by the rotation of the gear is prevented, and the production efficiency is greatly improved.

3. According to the invention, a clamping sleeve is designed, the motor A starts to work to drive the rear rotating plate to rotate, so that the traction column, the traction plate and the sliding column are driven to move along the sliding groove C, the sliding block is driven to move, the clamping plate is driven to move to the surface of the stone, the stone pushes the trigger push rod to move inwards, the lifting ejector rod is driven to move upwards, air in the T-shaped air bag is extruded, the drive push rod is driven to move rightwards, the drive block is driven to move downwards, the downward sliding rod is driven to move downwards, air in the air storage bag is extruded, the air is transmitted into the expansion air bag along the connector to expand the expansion air bag, the purpose of tightly wrapping the stone is achieved, and then when stress is dispersed, media except the air are transmitted, so that the phenomenon of stone cracking is avoided.

Drawings

The invention is further illustrated with reference to the following figures and examples.

FIG. 1 is a schematic structural view of the present invention;

FIG. 2 is a schematic structural view of the grooving kit of the present invention;

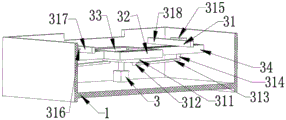

FIG. 3 is a schematic structural view of the fixing kit of the present invention;

FIG. 4 is a schematic structural view of the notching mechanism of the present invention;

FIG. 5 is a schematic cross-sectional view A-A of FIG. 4 of the present invention;

FIG. 6 is an enlarged schematic view of area A of FIG. 5 of the present invention;

FIG. 7 is a schematic structural view of the clamping mechanism of the present invention;

FIG. 8 is an enlarged schematic view of area B of FIG. 7 in accordance with the present invention;

FIG. 9 is a schematic structural view of the securing mechanism of the present invention;

Detailed Description

In order to make the technical means, the creation features, the achievement purposes and the effects of the invention easy to understand, the invention is further explained with reference to fig. 1 to 9.

The utility model provides a building curtain hangs veneer stone material processing machinery futilely, includes mounting bracket 1, fluting external member 2 and fixed external member 3, 1 inside from last fluting external member 2 and the fixed external member 3 of down having set gradually of mounting bracket, wherein:

the slotting kit 2 comprises a hydraulic cylinder A, a sliding plate 21, a mounting seat 22, a hydraulic cylinder B, a slotting bracket 23, a sliding column 24, a slotting mechanism 25 and a slotting shovel 26, wherein the hydraulic cylinder A is mounted on the outer wall of the mounting frame 1, the sliding plate 21 is mounted on an output shaft of the hydraulic cylinder A, the sliding plate 21 is provided with the sliding slot A, the mounting seat 22 is arranged on the sliding plate 21 in a welding mode, the hydraulic cylinder B is mounted on the mounting seat 22, the slotting bracket 23 is mounted on an output shaft of the hydraulic cylinder B, the slotting bracket 23 is provided with the sliding column 24 which is matched with the sliding slot A for use in a welding mode, the slotting mechanism 25 is arranged inside the slotting bracket 23, the slotting shovel 26 is symmetrically mounted on the lower end face of the slotting bracket 23 in a welding mode, during specific work, the hydraulic cylinder A starts to work to drive the sliding plate 21 and the slotting bracket 23 to move downwards, and simultaneously the hydraulic cylinder B starts to work to drive the slotting, and the grooving mechanism 25 starts to work to groove the surface of the stone while moving.

The grooving mechanism 25 comprises a motor B, a rotating shaft rod 251, a line scribing cutter 252, a blowing mechanism 253 and a hammering roller 254, the motor B is installed on the outer wall of the grooving frame 23 through a motor base, the rotating shaft rod 251 is installed on an output shaft of the motor B, one end of the rotating shaft rod 251 is installed on the inner wall of the grooving frame 23 in a bearing connection mode, the line scribing cutter 252 is symmetrically installed on the rotating shaft rod 251, the blowing mechanism 253 is evenly arranged inside the line scribing cutter 252 along the circumferential direction of the line scribing cutter, the hammering roller 254 is arranged between the line scribing cutters 252, the hammering roller 254 is fixedly installed on the rotating shaft rod 251, in specific work, the motor B drives the rotating shaft rod 251 to rotate, the line scribing cutter 252 and the hammering roller 254 are driven to rotate, and therefore the purposes of scribing and reducing the strength of stones needing to be shoveled are achieved.

An annular through groove is formed in the scribing cutter 252, and a freely moving spherical ball is arranged in the annular through groove.

The material blowing mechanism 253 comprises a rebound top column 2531, a fan-shaped air bag 2532, a blowing pipe 2533 and a filtering head cover 2534, the rebound top column 2531 is installed on the inner wall of the scribing cutter 252 in a sliding connection mode, the fan-shaped air bag 2532 is arranged at the upper end of the rebound top column 2531, the bottom end of the rebound top column 2531 is positioned inside the fan-shaped air bag 2532, the blowing pipe 2533 is evenly arranged on the surface of the fan-shaped air bag 2532, the filtering head cover 2534 is installed on the blowing pipe 2533, when the material blowing mechanism works in detail, a motor B drives the scribing cutter 252 to rotate with the fan-shaped air bag, spherical balls inside the scribing cutter 252 roll along an annular through groove, when a cutting edge is lifted up, the balls extrude the rebound top column 2531 to move downwards, the air inside the fan-shaped air bag 2532 is sampled, the air is discharged to the outside along the blowing pipe 2533, the purpose of material blowing is achieved, when the balls leave, the rebound top column 2531 rebounds to, the dust is blocked, thereby preventing the phenomenon that the blowpipe 2533 is blocked.

Fixed external member 3 includes motor A, press from both sides tight external member 31, mounting panel 32, fixed establishment 33 and direction slat 34, motor A passes through the motor cabinet and installs on 1 inner wall of mounting bracket, be provided with on motor A's the output shaft and press from both sides tight external member 31, it is provided with mounting panel 32 to press from both sides tight external member 31 below, be provided with spout B on the mounting panel 32, the inside fixed establishment 33 that is provided with of mounting panel 32, both sides are provided with direction slat 34 through welded mode symmetry about mounting panel 32, it installs on 1 inner wall of mounting bracket through welded mode to lead the opposite side of slat 34, be provided with spout C on the direction slat 34, concrete during operation, motor A begins to work, it draws along direction slat 34 to drive tight external member 31, and put into the mounting panel 32 with the stone material on, fixed establishment 33 begins to.

The clamping kit 31 comprises a rotating plate 311, a traction column 312, a traction plate 313, a sliding column 314, a sliding block 315, a connecting rod 316, a clamping plate 317 and a clamping mechanism 318, wherein the rotating plate 311 is installed on an output shaft of the motor A in a welding manner, the traction column 312 is symmetrically arranged on the rotating plate 311, the traction plate 313 is installed on the traction column 312, the sliding column 314 matched with the chute C for use is installed on the traction plate 313, the sliding block 315 is arranged on the sliding column 314, the connecting rod 316 is arranged on the left end face of the sliding block 315 in a welding manner, the clamping plate 317 is installed on the connecting rod 316, the clamping mechanism 318 is arranged inside the clamping plate 317, when the clamping mechanism works specifically, the motor A starts to work to drive the rear rotating plate 311 to start rotating, and then the traction column 313, the traction plate 313 and the sliding column 314 are driven to move along the chute C, so as to drive the sliding block 315 to move, and further drive the clamping plate, the clamping mechanism 318 is operated to secure the stone.

The clamping mechanism 318 comprises a triggering push rod 3181, a rising push rod 3182, a T-shaped air bag 3183, a driving push rod 3184, a driving block 3185, a descending slide rod 3186, an air storage bag 3187, a connector 3188 and an expansion air bag 3189, the triggering push rod 3181 is installed on the inner wall of the clamping plate 317 in a sliding connection mode, the triggering push rod 3181 abuts against the rising push rod 3182, the T-shaped air bag 3183 is arranged at the upper end of the rising push rod 3182, the driving push rod 3184 is arranged at the right end inside the T-shaped air bag 3183, the driving block 3185 abuts against the driving block 3185 at the lower end of the driving push rod 3184, the driving block 3185 is installed on the inner wall of the clamping plate 317 in a spring connection mode, the descending slide rod 3186 is installed on the driving block 3185, the air storage bag 3187 is arranged on the lower end face of the descending slide rod 3186, the connector 3188 is uniformly arranged on the air storage bag 3188, the expansion air bag 3189 is, the lifting top rod 3182 is driven to move upwards to extrude the air in the T-shaped air bag 3183, the driving push rod 3184 is driven to move rightwards to drive the driving block 3185 to move downwards, so that the descending slide rod 3186 is driven to move downwards to extrude the air in the air storage bag 3187, the air is transferred to the expansion air bag 3189 along the connector 3188 to expand, and the aim of fastening the stone is achieved.

The fixing mechanism 33 comprises a trigger block 331, a screw push rod 332, a rotating base plate 333, a sliding rod 334, a mounting block 335, a connecting frame 336, a fixing block 337, a sliding block 338 and a fixing plate 339, the trigger block 331 is mounted on the inner wall of the mounting plate 32 in a spring sliding connection manner, the screw rod is mounted on the lower end surface of the trigger block 331, the rotating base plate 333 is arranged on the screw rod in a threaded connection manner, the sliding rod 334 is arranged on the lower end surface of the rotating base plate 333, the sliding rod 334 is mounted on the inner wall of the mounting plate 32 in a sliding connection manner, the mounting blocks 335 are symmetrically mounted on the upper end surface of the rotating base plate 333 in a welding manner, the connecting frame 336 is arranged on the mounting block 335, the fixing block 337 matched with the sliding groove B for use is mounted on the connecting frame 336, the sliding block 338 is mounted on the fixing block 337, the, when the stone is placed on the installation plate 32, the trigger block 331 is driven to move downwards, the spiral push rod 332 is driven to move downwards, the rotary backing plate 333 is driven to rotate, the connecting frame 336 drives the fixing block 337 to move inwards along the sliding groove B, and the sliding block 338 and the fixing plate 339 are driven to move to the surface of the stone, so that the purpose of fixing the stone is achieved.

In addition, the invention also provides a processing technology of the building curtain wall dry-hanging decorative face stone, the processing technology is mainly completed by matching the processing machinery of the building curtain wall dry-hanging decorative face stone, and the processing technology specifically comprises the following steps:

s1, feeding: placing the stone to be grooved on the mounting plate 32 in a manual feeding mode;

s2, stone clamping: the motor a starts to work to drive the rear rotating plate 311 to rotate, and further drive the traction column 313, the traction plate 313 and the sliding column 314 to move along the sliding groove C, so as to drive the sliding block 315 to move, and further drive the clamping plate 317 to move to the surface of the stone, the stone pushes the trigger push rod 3181 to move inwards, and drives the lifting ejector rod 3182 to move upwards, so as to extrude the air inside the T-shaped air bag 3183, drive the drive push rod 3184 to move rightwards, and drive the drive block 3185 to move downwards, so as to drive the downlink slide rod 3186 to move downwards, and extrude the air inside the air storage bag 3187, and the air is transferred to the expansion air bag 3189 along the connector 3188, so that the expansion air bag is expanded, and the purpose of.

S3, stone wrapping: when the stone material was placed on installation board 32, drive trigger block 331 downstream, and then drive screw rod 332 downstream, drive and rotate backing plate 333 and rotate to drive fixed block 337 along spout B to inside motion through link 336, and then drive sliding block 338 and fixed plate 339 move to the stone material surface, thereby reach the purpose of the tight stone material of package.

S4, stone grooving: the hydraulic cylinder A starts to work to drive the sliding plate 21 and the slotting bracket 23 to move downwards, meanwhile, the hydraulic cylinder B starts to work to drive the slotting bracket 23 to move along the sliding chute A, the motor B drives the rotating shaft rod 251 to rotate while moving, meanwhile, the line scribing knife 252 and the hammering roller 254 are driven to rotate, and the rear slotting shovel 26 shovels away the stone in the moving process, so that the aim of slotting the stone is achieved.

S5, repeating the steps from S1 to S4, and continuously performing grooving operation on the surface of the stone.

The foregoing illustrates and describes the principles, general features, and advantages of the present invention. It will be understood by those skilled in the art that the present invention is not limited to the embodiments described above, which are given by way of illustration of the principles of the present invention, and that various changes and modifications may be made without departing from the spirit and scope of the invention as defined by the appended claims. The scope of the invention is defined by the appended claims and equivalents thereof.

Claims (6)

1. The utility model provides a building curtain hangs veneer stone material processing machinery futilely, includes mounting bracket (1), fluting external member (2) and fixed external member (3), its characterized in that: installation frame (1) is inside from last to down having set gradually fluting external member (2) and fixed external member (3), wherein:

the slotting kit (2) comprises a hydraulic cylinder A, a sliding plate (21), a mounting seat (22), a hydraulic cylinder B, a slotting bracket (23), a sliding column (24), a slotting mechanism (25) and a slotting shovel (26), the hydraulic cylinder A is installed on the outer wall of the installation frame (1), a sliding plate (21) is installed on an output shaft of the hydraulic cylinder A, a sliding groove A is arranged on the sliding plate (21), an installation seat (22) is arranged on the sliding plate (21) in a welding mode, a hydraulic cylinder B is installed on the installation seat (22), a slotting frame (23) is installed on an output shaft of the hydraulic cylinder B, a sliding column (24) which is matched with the sliding groove A for use is arranged on the slotting frame (23) in a welding mode, a slotting mechanism (25) is arranged inside the slotting frame (23), and slotting shovels (26) are symmetrically installed on the lower end face of the slotting frame (23) in a welding mode;

the grooving mechanism (25) comprises a motor B, a rotating shaft rod (251), a scribing cutter (252), a blowing mechanism (253) and a hammering roller (254), the motor B is mounted on the outer wall of the grooving frame (23) through a motor base, the rotating shaft rod (251) is mounted on an output shaft of the motor B, one end of the rotating shaft rod (251) is mounted on the inner wall of the grooving frame (23) in a bearing connection mode, the scribing cutter (252) is symmetrically mounted on the rotating shaft rod (251), the blowing mechanism (253) is uniformly arranged inside the scribing cutter (252) along the circumferential direction of the scribing cutter, the hammering roller (254) is arranged between the scribing cutters (252), and the hammering roller (254) is fixedly mounted on the rotating shaft rod (251);

fixed external member (3) includes motor A, press from both sides tight external member (31), mounting panel (32), fixed establishment (33) and direction slat (34), motor A passes through the motor cabinet and installs on mounting bracket (1) inner wall, be provided with on motor A's the output shaft and press from both sides tight external member (31), it is provided with mounting panel (32) to press from both sides tight external member (31) below, be provided with spout B on mounting panel (32), inside fixed establishment (33) that is provided with of mounting panel (32), both sides are provided with direction slat (34) through welded mode symmetry about mounting panel (32), direction slat (34) opposite side is installed on mounting bracket (1) inner wall through the welded mode, be provided with spout C on direction slat (34).

2. The processing machine for dry-hanging decorative stone of building curtain walls as claimed in claim 1, characterized in that: an annular through groove is formed in the scribing cutter (252), and a ball-shaped ball capable of moving freely is arranged in the annular through groove.

3. The processing machine for dry-hanging decorative stone of building curtain walls as claimed in claim 1, characterized in that: blow material mechanism (253) including resilience fore-set (2531), fan-type gasbag (2532), blowing pipe (2533) and filter hood (2534), resilience fore-set (2531) are installed on rule sword (252) inner wall through sliding connection's mode, resilience fore-set (2531) upper end is provided with fan-type gasbag (2532), resilience fore-set (2531) bottom is located inside fan-type gasbag (2532), fan-type gasbag (2532) evenly are provided with blowing pipe (2533) on the surface, install filter hood (2534) on blowing pipe (2533).

4. The processing machine for dry-hanging decorative stone of building curtain walls as claimed in claim 1, characterized in that: the clamping set piece (31) comprises a rotating plate (311), a traction column (312), a traction plate (313), a sliding column (314), a sliding block (315), a connecting rod (316), a clamping plate (317) and a clamping mechanism (318), wherein the rotating plate (311) is installed on an output shaft of the motor A in a welding mode, the traction column (312) is symmetrically arranged on the rotating plate (311), the traction plate (313) is installed on the traction column (312), the sliding column (314) matched with the sliding groove C for use is installed on the traction plate (313), the sliding block (315) is arranged on the sliding column (314), the connecting rod (316) is arranged on the left end face of the sliding block (315) in a welding mode, the clamping plate (317) is installed on the connecting rod (316), and the clamping mechanism (318) is arranged inside the clamping plate (317).

5. The processing machine for dry-hanging decorative stone of building curtain walls as claimed in claim 4, characterized in that: the clamping mechanism (318) comprises a trigger push rod (3181), a rising ejector rod (3182), a T-shaped air bag (3183), a drive push rod (3184), a drive block (3185), a descending slide rod (3186), an air storage bag (3187), a connector (3188) and an expansion air bag (3189), the trigger push rod (3181) is arranged on the inner wall of a clamping plate (317) in a sliding connection mode, the rising ejector rod (3182) abuts against the trigger push rod (3181), the T-shaped air bag (3183) is arranged at the upper end of the rising ejector rod (3182), the drive push rod (3184) is arranged at the right end inside the T-shaped air bag (3183), the drive block (3185) abuts against the drive block (3185), the drive block (3185) is arranged on the inner wall of the clamping plate (317) in a spring connection mode, the descending slide rod (3186) is arranged on the drive block (3185), the air storage bag (3187) is arranged on the lower end face of the descending slide rod (3186), and the, the connector (3188) is provided with an inflatable air bag (3189).

6. The processing machine for dry-hanging decorative stone of building curtain walls as claimed in claim 1, characterized in that: the fixing mechanism (33) comprises a trigger block (331), a spiral push rod (332), a rotating base plate (333), a sliding rod (334), an installation block (335), a connecting frame (336), a fixing block (337), a sliding block (338) and a fixing plate (339), the trigger block (331) is installed on the inner wall of the installation plate (32) in a spring sliding connection mode, the spiral rod is installed on the lower end face of the trigger block (331), the rotating base plate (333) is arranged on the spiral rod in a threaded connection mode, the sliding rod (334) is arranged on the lower end face of the rotating base plate (333), the sliding rod (334) is installed on the inner wall of the installation plate (32) in a sliding connection mode, the installation blocks (335) are symmetrically installed on the upper end face of the rotating base plate (333) in a welding mode, the connecting frame (336) is arranged on the installation blocks (335), the connecting frame (336) is provided with the fixing block, the fixed block (337) is provided with a sliding block (338), the sliding block (338) is provided with a fixed plate (339), and the surface of the fixed plate (339) is uniformly provided with rectangular teeth.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911331620.2A CN110978298B (en) | 2019-12-21 | 2019-12-21 | Processing machine and processing technology for building curtain wall dry-hanging decorative face stone |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911331620.2A CN110978298B (en) | 2019-12-21 | 2019-12-21 | Processing machine and processing technology for building curtain wall dry-hanging decorative face stone |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110978298A CN110978298A (en) | 2020-04-10 |

| CN110978298B true CN110978298B (en) | 2021-05-11 |

Family

ID=70074538

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911331620.2A Expired - Fee Related CN110978298B (en) | 2019-12-21 | 2019-12-21 | Processing machine and processing technology for building curtain wall dry-hanging decorative face stone |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110978298B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112140368B (en) * | 2020-09-26 | 2022-04-19 | 济南展风花岗石机械构件有限公司 | Marble processing is with beating fluting device |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5758634A (en) * | 1997-03-26 | 1998-06-02 | Ellison, Jr.; Russell P. | Concrete shearing method |

| JP2001079828A (en) * | 1999-09-17 | 2001-03-27 | Yoshitaka Sakamoto | Tile cutting machine |

| TW200932420A (en) * | 2008-01-29 | 2009-08-01 | Ying Sun | Cutting tool exchange mechanism for universal cutting machine (I) |

| CN205735576U (en) * | 2016-05-18 | 2016-11-30 | 长葛市珏石矿业设备制造有限公司 | A kind of horizontal stone groover |

| CN107617880A (en) * | 2017-11-03 | 2018-01-23 | 李佳清 | A kind of channel-section steel fluting bending sub-assembly processing unit (plant) |

| CN109129952A (en) * | 2018-09-07 | 2019-01-04 | 曹荣翠 | A kind of building outer wall decorative material dry-hang stone processing work platform |

| CN209648200U (en) * | 2019-04-09 | 2019-11-19 | 梅州市梅县区雄辉实业有限公司 | A kind of heavy type casting processing clamping device |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5777849B2 (en) * | 2009-05-29 | 2015-09-09 | 三星ダイヤモンド工業株式会社 | Break device and break method |

| CN104044216A (en) * | 2014-06-18 | 2014-09-17 | 泉州市佳能机械制造有限公司 | Cylindrical stone profiling machine |

| CN206765111U (en) * | 2017-04-22 | 2017-12-19 | 刘莉 | A kind of building curtain wall fluting operated implement |

-

2019

- 2019-12-21 CN CN201911331620.2A patent/CN110978298B/en not_active Expired - Fee Related

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5758634A (en) * | 1997-03-26 | 1998-06-02 | Ellison, Jr.; Russell P. | Concrete shearing method |

| JP2001079828A (en) * | 1999-09-17 | 2001-03-27 | Yoshitaka Sakamoto | Tile cutting machine |

| TW200932420A (en) * | 2008-01-29 | 2009-08-01 | Ying Sun | Cutting tool exchange mechanism for universal cutting machine (I) |

| CN205735576U (en) * | 2016-05-18 | 2016-11-30 | 长葛市珏石矿业设备制造有限公司 | A kind of horizontal stone groover |

| CN107617880A (en) * | 2017-11-03 | 2018-01-23 | 李佳清 | A kind of channel-section steel fluting bending sub-assembly processing unit (plant) |

| CN109129952A (en) * | 2018-09-07 | 2019-01-04 | 曹荣翠 | A kind of building outer wall decorative material dry-hang stone processing work platform |

| CN209648200U (en) * | 2019-04-09 | 2019-11-19 | 梅州市梅县区雄辉实业有限公司 | A kind of heavy type casting processing clamping device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110978298A (en) | 2020-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107639726B (en) | Production process of environment-friendly autoclaved aerated concrete block | |

| CN111421649B (en) | Post-processing machinery for manufacturing prefabricated beam column steel formwork die of fabricated building | |

| CN113680942A (en) | Workpiece forging and pressing production equipment | |

| CN110978298B (en) | Processing machine and processing technology for building curtain wall dry-hanging decorative face stone | |

| CN111300204A (en) | Building materials grinding device | |

| CN215750054U (en) | Convertible stone material two-sided engraving device | |

| CN209614319U (en) | A kind of automatic punch | |

| CN112266160B (en) | Processing device for tempered glass convenient to cut | |

| CN206718116U (en) | A kind of ceramic bottle production blank remedying device | |

| CN104015113B (en) | Spiral pipe die polishing machine | |

| CN211250605U (en) | Ceramic manufacture process scrapes limit device | |

| CN209466291U (en) | A kind of glass fibre reinforced plastics rockbolts automatic angle cutting machine | |

| CN210100399U (en) | Interval-adjustable cutting device for split brick processing | |

| CN112705657A (en) | Equipment for heat treatment of oppositely-rotating excavating cutting teeth by adopting automation | |

| CN113814640A (en) | Intelligent metal plate welding positioning device | |

| CN209774868U (en) | Rock wool board magnetism pressurization forming device | |

| CN206794775U (en) | A kind of numerically controlled lathe automatic material taking mechanism | |

| CN219337150U (en) | Blank forging processing burr processing mechanism | |

| CN214000033U (en) | Novel gang saw is used in stone material processing | |

| CN221085841U (en) | Tantalum doped lithium lanthanum zirconium oxygen ball milling equipment | |

| CN114102877B (en) | Marble plate cutting and sorting equipment | |

| CN111761699B (en) | Angle device is clapped with a section of thick bamboo made of baked clay for building engineering | |

| CN221697415U (en) | Ceramic tile perforating device for construction | |

| CN221021580U (en) | Ceramic processing is with multi-functional carousel device | |

| CN221247338U (en) | High-precision laser welding machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20210422 Address after: 102600 No.8 Qirong Road, Changziying Town, Daxing District, Beijing Applicant after: BEIJING TIANCHENG YINGLIANG STONE Co.,Ltd. Address before: 230041 Graduate School of China University of science and technology, No. 96, Jinzhai Road, Baohe District, Hefei City, Anhui Province Applicant before: Xu Cuiling |

|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20210511 |