CN110911652B - Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof - Google Patents

Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof Download PDFInfo

- Publication number

- CN110911652B CN110911652B CN201811083905.4A CN201811083905A CN110911652B CN 110911652 B CN110911652 B CN 110911652B CN 201811083905 A CN201811083905 A CN 201811083905A CN 110911652 B CN110911652 B CN 110911652B

- Authority

- CN

- China

- Prior art keywords

- mno

- alpha

- solution

- manganese

- nano

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/362—Composites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/36—Accumulators not provided for in groups H01M10/05-H01M10/34

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/48—Selection of substances as active materials, active masses, active liquids of inorganic oxides or hydroxides

- H01M4/50—Selection of substances as active materials, active masses, active liquids of inorganic oxides or hydroxides of manganese

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Nanotechnology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Composite Materials (AREA)

- Inorganic Chemistry (AREA)

- Materials Engineering (AREA)

- Inorganic Compounds Of Heavy Metals (AREA)

- Battery Electrode And Active Subsutance (AREA)

Abstract

The invention relates to nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof, and nano spherical alpha-MnO 2 /Bi 2 O 3 The material is composed of alpha-MnO 2 Main phase and Bi 2 O 3 A second phase composition of said Bi 2 O 3 The content of the second phase is 0.5 to 10wt.%.

Description

Technical Field

The invention belongs to the technical field of zinc batteries, and particularly relates to nano spherical alpha-MnO 2 /Bi 2 O 3 A preparation method of the material and application of the material in a positive electrode of a zinc ion battery.

Background

Manganese dioxide has structural diversity and unique physical and chemical properties, is rich in reserves, low in price and environment-friendly, and is widely applied to catalysts, adsorbents, ceramics, battery electrode materials and the like as an important functional material. Especially, in order to meet the increasing demand of people on energy, manganese dioxide is widely used in alkaline zinc-manganese batteries, lithium ion batteries, supercapacitors and the like as a pollution-free green energy material.

Currently, rechargeable aqueous zinc/MnO 2 The battery adopts a metal zinc cathode and a manganese dioxide anode, and the theoretical specific capacity based on the manganese dioxide material can reach 308mAh g -1 . The battery can normally operate in a neutral or weakly acidic environment, and compared with an alkaline zinc-manganese battery, the electrochemical stability of the battery can be remarkably improved. The main structure of manganese dioxide includes α type, β type, γ type, δ type, and the like. alpha-MnO in comparison with other crystalline forms 2 The zinc ion membrane has unique 1 x 1 and 2 x 2 type three-dimensional tunnel structures, is easy for the de-intercalation reaction of zinc ions, and has excellent electrochemical stability. And nano alpha-MnO 2 Has extremely large specific surface area and excellent electrochemical activity along with alpha-MnO 2 The particle size of the material is reduced, the smoothness of the particle surface is reduced, abundant rugged atomic steps are formed, the contact area of electrochemical reaction is increased, and a special microstructure can provide a superior ion and electron transmission channel (CN 102275903B), so that the material has excellent electrochemical performance and cycle stability in a water system zinc battery, and has a great application prospect. Meanwhile, the bismuth oxide doped manganese dioxide electrode material can obviously improve the cycle stability of the electrode (Li, X.; li, Z.; xia, T.; dong, H.; song, Y.; wang, L.journal)of Physics and Chemistry of Solids 2012,73, (10), 1229-1234). Currently, the preparation of nano-alpha-MnO 2 The main methods of (1) are as follows: sol-gel method, low-temperature solid-phase synthesis method, electrodeposition method, microemulsion method, chemical precipitation method, hydrothermal method, template method, etc. Nano alpha-MnO with good crystallization performance is prepared by a hydrothermal method through Pan (H.L.; shao, Y.Y.; yan, P.F.; cheng, Y.W.; han, K.S.; nie, Z.M.; wang, C.M.; yang, J.H.; li, X.L.; bhattacharya, P.; mueller, K.T.; liu J.Nature Energy 2016,1, (5), 16039.), and the like 2 The material is applied to a water-based zinc ion battery to obtain higher rate performance, but the preparation method is more complicated, needs to be carried out in a high-temperature and high-pressure reaction kettle, and is difficult to prepare in batch. Sandip Saha (Saha, S.; pal, A.separation and Purification Technology 2014,134, 26-36.) et al prepared alpha-MnO with potassium permanganate and manganese acetate under coprecipitation conditions 2 The material is adopted in the experimental process, however, according to the proportion that manganese acetate and potassium permanganate are 3 to 2, the reaction is easy to be incomplete, so that high-valence manganese elements exist in the product, meanwhile, acetic acid is contained in reaction byproducts, so that the acidity in the reaction solution is enhanced, the stability of manganese dioxide is influenced, the finally prepared manganese dioxide is uneven in particle size distribution and serious in agglomeration, the electrochemical stability of the product is reduced, and the practical application of the manganese dioxide material is influenced.

The research results show that the preparation method of the cathode material with lower requirements on preparation conditions, simple and feasible process and stable electrochemical performance is found, and the cathode material is used for water system zinc/MnO 2 The practical application of the battery produces great promotion effect.

Disclosure of Invention

The present invention is directed to overcoming the disadvantages and drawbacks of the prior art and providing an alpha-MnO having good crystallization properties, stable electrochemical properties and uniform particle size 2 /Bi 2 O 3 The material and the preparation condition have lower requirements, the process is simple and feasible, and the electrochemical performance is stable 2 /Bi 2 O 3 A preparation method of the material and application of the material in an aqueous zinc ion battery.

In one aspect, the present invention provides a nano-spherical alpha-MnO 2 /Bi 2 O 3 Material characterized in that said nanospherical α -MnO is 2 /Bi 2 O 3 The material is composed of alpha-MnO 2 Main phase and Bi 2 O 3 A second phase composition of said Bi 2 O 3 The content of the second phase is 0.5 to 10wt.%.

alpha-MnO of the invention 2 /Bi 2 O 3 The material, manganese dioxide and bismuth oxide reach nano-grade dispersion and compounding, and the contact performance is good. alpha-MnO 2 /Bi 2 O 3 The material is in a nano-sphere shape, and has the advantages of high specific surface area, multiple electrochemical active sites and the like. Bi 2 O 3 The content of the second phase is 0.5-10 wt.%, and the cycle stability of the material can be effectively improved by compounding a proper amount of bismuth oxide (the reversible cycle number of the assembled zinc ion full battery can be improved from 40 circles to more than 500 circles). Nano spherical alpha-MnO 2 /Bi 2 O 3 The material has good crystallization property (the XRD peak shape is strong and sharp, and is well matched with a standard PDF card), and the particle size is uniform.

Preferably, the nano-spherical alpha-MnO 2 /Bi 2 O 3 The particle size of the material is 5-500 nm.

On the other hand, the invention also provides a method for preparing the nano spherical alpha-MnO 2 /Bi 2 O 3 The preparation method of the material is characterized by comprising the following steps:

mixing a solution A obtained by mixing potassium permanganate, a foaming agent and a first solvent with a solution B obtained by mixing a manganese salt, a bismuth salt and a second solvent, then adding an alkaline regulator, regulating the pH value of the mixed solution to 7-11, and carrying out coprecipitation reaction to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 Precursor powder; and placing the precursor powder at 300-600 ℃ for heat treatment to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 A material.

The invention utilizes a normal temperature liquid phase coprecipitation methodPreparation of alpha-MnO with good crystallization property 2 /Bi 2 O 3 The preparation method of the material comprises the steps of mixing a solution A containing potassium permanganate and a foaming agent with a solution B containing manganese salt and bismuth salt, then adding an alkaline regulator, carrying out coprecipitation reaction to obtain a precipitate product, and then carrying out heat treatment to prepare the nano spherical alpha-MnO with good crystallization performance 2 /Bi 2 O 3 A material. The coprecipitation reaction can be normally carried out at room temperature, the requirements on equipment parameters and functions are low, and the process is simple. The alpha-MnO can be further enhanced by heat treatment 2 /Bi 2 O 3 The crystalline properties of the material. The hydroxyl ionized by water in the reaction process participates in the reaction and is consumed, and hydrogen ions are accumulated in the solution, so that the pH value of the solution is lowered, the added foaming agent can promote the solution to generate carbon dioxide bubbles while reacting, the dispersion performance of the product is improved, the agglomeration of the product can be effectively avoided, and the nanocrystallization of product particles is promoted. The pH of the solution is then adjusted to 7-11 to facilitate precipitation of the bismuth salt. The manganese dioxide and the bismuth oxide are dispersed and compounded in a nano-scale manner, the contact performance is good, and the cycle stability of the material can be effectively improved by compounding the bismuth oxide. Prepared nano spherical alpha-MnO 2 /Bi 2 O 3 The material has good crystallization property and uniform grain diameter. The method has the advantages of low cost, high yield, low energy consumption, environmental protection, excellent material electrochemical performance, easy popularization and the like, has wide application prospect in the field of anode materials of water-system zinc-ion batteries, and is expected to be applied to water-system zinc/MnO 2 The practical application of the battery produces great promotion effect.

The foaming agent may be sodium carbonate and/or potassium carbonate. In the method of the present invention, the foaming agent can also function as a pH regulator, hydrogen ions are accumulated in the solution due to the fact that hydroxyl ionized by water during the reaction participates in the reaction and is consumed, so that the pH of the solution becomes low, and the added foaming agent contains carbonate and can be combined with the hydrogen ions in the solution to be separated from the reaction system, so that the acidity of the reaction solution is inhibited from being enhanced.

The manganese salt can be a low-valence manganese salt, and is preferably at least one of manganese sulfate, manganese nitrate and manganese chloride.

The bismuth salt may be bismuth citrate and/or bismuth acetate. Bismuth salts as Bi 2 O 3 Is a source of alpha-MnO 2 /Bi 2 O 3 In situ synthesis of the material provides a precursor.

The alkaline regulator can be sodium hydroxide and/or ammonia water.

The amount of the substance of the foaming agent may be 1 to 1.5 times the amount of the substance of the potassium permanganate.

The ratio of the amounts of the potassium permanganate and the manganese salt species may be 1:1 to 1:4, preferably less than 2:3 and in the range of 2:4 or less, more preferably 2: 3.01-2.

The amount of the substance of the bismuth salt is 0.1 to 20 percent of the amount of the substance of the manganese salt.

The ratio of the amounts of the bismuth salt and the substance of the basic regulator may be 1:2 to 1:6.

the first solvent and/or the second solvent may be at least one of water and ethanol.

The time of the heat treatment can be 2 to 24 hours.

The solution A can be added into the solution B in a dropping mode, and the dropping speed of the solution A can be 50-300 drops/min. The solution B can be dispersed and stirred at room temperature, and the solution A is added into the solution B at the same time to carry out coprecipitation reaction. The dispersion stirring may be at least one of ultrasonic dispersion, mechanical stirring, and emulsion dispersion. By controlling the dispersion stirring and the dropping acceleration, the dispersion of the solution A in the solution B can be further effectively promoted, and the agglomeration of the product is reduced.

The time for the coprecipitation reaction may be 2 to 24 hours. The solution can be filtered, washed and dried after the reaction to obtain alpha-MnO 2 /Bi 2 O 3 And (3) precursor powder. The filtration and washing can be performed by one or a combination of filter pressing and suction filtration. The temperature of drying may be 60-115 ℃.

In yet another aspect, the invention provides a zinc ion battery, the positive electrode of which comprises the aforementioned nano-spherical α -MnO 2 /Bi 2 O 3 A material. Mixing the nano spherical alpha-MnO 2 /Bi 2 O 3 When the material is applied to a zinc ion battery (an aqueous zinc ion battery), the electrochemical performance is excellent (the reversible cycle number of the assembled zinc ion full battery can be increased from 40 circles to more than 500 circles).

Drawings

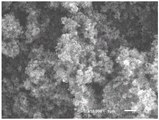

FIG. 1a is a nano-spherical α -MnO prepared in example 1 2 /Bi 2 O 3 SEM picture of precursor powder;

FIG. 1b is a nano-spherical α -MnO prepared in example 1 2 /Bi 2 O 3 XRD pattern of precursor powder;

FIG. 2a is a nano-spherical α -MnO prepared in example 1 2 /Bi 2 O 3 SEM pictures of the material;

FIG. 2b is a diagram of nano-spherical α -MnO prepared in example 1 2 /Bi 2 O 3 XRD pattern of the material;

FIG. 3 is a nano-spherical α -MnO of example 1 2 /Bi 2 O 3 The material is used as a positive electrode material, metal zinc is used as a negative electrode material, and a voltage-specific capacity curve diagram of the assembled full battery at 0.5C multiplying power is shown;

FIG. 4 is a nano-spherical α -MnO of example 1 2 /Bi 2 O 3 A circulation-specific capacity comparison diagram of a zinc battery assembled by a material anode and a commercial electrolytic manganese dioxide anode respectively under 2C multiplying power;

FIG. 5 is a nano-spherical α -MnO of example 1 2 /Bi 2 O 3 The multiplying power performance curve of the material anode assembled zinc battery;

FIG. 6 is a nano-spherical α -MnO of example 1 2 /Bi 2 O 3 The material is used as a positive electrode material, the metal zinc is used as a negative electrode material, and a cycle life diagram of the assembled full cell under the multiplying power of 3C is shown;

FIG. 7 is a nano-spherical α -MnO prepared in example 2 2 /Bi 2 O 3 SEM pictures of the material;

FIG. 8 is a nano-spherical α -MnO prepared in example 3 2 /Bi 2 O 3 SEM image of material.

Detailed Description

The present invention is further described below in conjunction with the following examples and the accompanying drawings, it being understood that the following examples are intended to illustrate the present invention only and are not intended to limit the present invention.

The invention relates to nano spherical alpha-MnO with good crystallization performance 2 /Bi 2 O 3 A material and a preparation method thereof belong to the field of zinc ion batteries. The nano spherical alpha-MnO 2 /Bi 2 O 3 The material is composed of alpha-MnO 2 Main phase (or called nano spherical alpha-MnO) 2 Component (c) and Bi 2 O 3 Second phase (or called "Bi 2 O 3 Material component), said Bi 2 O 3 The content of the second phase is 0.5-10 wt.%, and the nano spherical alpha-MnO is 2 /Bi 2 O 3 The particle size of the material is 5-500 nm. Preparation of alpha-MnO 2 /Bi 2 O 3 When the material is prepared, the solution A containing potassium permanganate and foaming agent and the solution B containing low-valence manganese salt and bismuth salt are uniformly mixed in a certain mode under mild conditions, and the alpha-MnO is prepared by a liquid-phase coprecipitation reaction method 2 /Bi 2 O 3 Precursor powder of the material, and the crystallization performance of the material is improved through heat treatment. The method has the characteristics of simple and easily-controlled reaction, convenience in operation, low cost, environmental friendliness, easiness in industrial production and the like, is applied to the water system zinc ion battery, has the advantages of high specific capacity, excellent rate capability, good cycle stability and the like, and has a great application prospect.

Hereinafter, preparation of α -MnO in the present invention will be exemplified 2 /Bi 2 O 3 A method of making a material.

First, a manganese source solution (i.e., solution A) and a bismuth source solution (i.e., solution B) were prepared. Specifically, the solution a may be formed by mixing and uniformly dispersing potassium permanganate, a foaming agent, and a first solvent. The foaming agent can be any one of sodium carbonate and potassium carbonate or a mixture of the sodium carbonate and the potassium carbonate. In the method of the present invention, the foaming agent can also function as a pH adjuster, and can suppress the increase in acidity of the reaction solution. The first solvent may be water, ethanol, or the like. The amount of the foaming agent can be 1-1.5 times of that of potassium permanganate, so that the increase of the acidity of the solution can be effectively inhibited, and other pollution sources are prevented from being introduced. The ratio of potassium permanganate to first solvent can be between 0.1g/mL and 5g/mL.

The solution B can be formed by mixing and uniformly dispersing a manganese salt, a bismuth salt, and a second solvent. The bismuth salt can be any one of bismuth citrate and bismuth acetate or a mixture of the bismuth citrate and the bismuth acetate. Because the manganese source needs to be subjected to a neutralization reaction with high-valence manganese in the potassium permanganate, and the low-valence manganese source has low cost and stable performance, the manganese source is preferably a low-valence manganese source. The manganese source may be any one of manganese sulfate, manganese nitrate, manganese chloride, or a mixture thereof, for example. The amount of the substance of the bismuth salt may be 0.1 to 20%, preferably 0.1 to 5% of the amount of the substance of the manganese salt. The second solvent may be water, ethanol, or the like. The ratio of the manganese salt to the second solvent can be from 0.1g/mL to 5g/mL.

And then mixing the solution A with the solution B, adding an alkaline regulator, adjusting the pH value of the solution to 7-11, and carrying out coprecipitation reaction. Solution A can be added to solution B by dropping at a rate of 50-300 drops/min, preferably 50-150 drops/min. By controlling the dropping speed, the dispersion of the solution A in the solution B can be effectively promoted, and the agglomeration of products is reduced. The solution B can be dispersed and stirred at room temperature, the solution A is added into the solution B, and then alkaline regulator is added to adjust the pH value of the solution to 7-11, and the coprecipitation reaction is carried out. The dispersion stirring may be carried out by one or a combination of ultrasonic dispersion (which may be carried out by an ultrasonic dispersing machine), mechanical stirring (which may be carried out by a mechanical stirrer), and emulsion dispersion (which may be carried out by an emulsion dispersing machine). Through dispersion and stirring, the dispersion of the solution A in the solution B can be effectively promoted, and the agglomeration of products is reduced. The alkaline modifier may be sodium hydroxide and/or ammonia. The ratio of the amount of the bismuth salt to the amount of the substance of the basic regulator may be 1:2 to 1:6.

the ratio of the amounts of potassium permanganate to manganese salt species may be 1:1 to 1:4, preferably less than 2:3 and in the range of 2:4 or less. From the chemical reaction equation, the ratio of the amounts of potassium permanganate to manganese salt species under fully reacted conditions is 2: and 3, the trace excess of the low-valence manganese salt can enable potassium permanganate to completely react, so that the residual potassium permanganate is prevented from participating in side reaction, and the excessive residual of the manganese salt is also avoided, so that the mass ratio of the potassium permanganate to the manganese salt is more preferably 2: 3.01-2.

The time for the coprecipitation reaction may be 2 to 24 hours. Specifically, after the completion of the dropwise addition, the mixed solution may be left to stand for 2 to 24 hours. The coprecipitation reaction can be normally carried out at room temperature, the requirements on equipment parameters and functions are low, and the process is simple. Because hydrogen ions are generated in the reaction process, the added foaming agent can promote the solution to generate carbon dioxide bubbles while reacting, the dispersion performance of the product is improved, the agglomeration of the product can be further effectively avoided, and the nanocrystallization of product particles is promoted.

The solution can be filtered, washed and dried after the reaction to obtain alpha-MnO 2 /Bi 2 O 3 And (3) precursor powder. The filtration and washing can be performed by one or a combination of filter pressing and suction filtration. The drying temperature can be 60-115 ℃, and the drying time can be 5-24 h.

And then, the precursor powder is placed at a certain temperature for heat treatment. Specifically, the temperature of the heat treatment may be 300 to 600 ℃, preferably 350 to 450 ℃. The time of the heat treatment can be 2 to 24 hours. The alpha-MnO can be further enhanced by heat treatment 2 /Bi 2 O 3 The crystalline properties of the material.

Thus, alpha-MnO having excellent crystallization properties can be obtained 2 /Bi 2 O 3 A material. alpha-MnO 2 /Bi 2 O 3 The material is in a nano spherical shape, and has the advantages of high specific surface area, multiple electrochemical active sites and the like. alpha-MnO 2 /Bi 2 O 3 Material alpha-MnO 2 /Bi 2 O 3 In the material, bi 2 O 3 The content of the bismuth oxide is 0.5-10 wt.%, and the cycle stability of the material can be effectively improved by compounding a proper amount of bismuth oxide (the reversible cycle frequency of the assembled zinc ion full cell can be improved to more than 500 cycles from 40 cycles). Nano spherical alpha-MnO 2 /Bi 2 O 3 The particle size of the material may be 5 to 500nm. The manganese dioxide and the bismuth oxide are dispersed and compounded in a nano-scale manner, the contact performance is good, and the cycle stability of the material can be effectively improved by compounding the bismuth oxide. Prepared nano spherical alpha-MnO 2 /Bi 2 O 3 The material has good crystallization property (the XRD peak shape is strong and sharp, and is well matched with a standard PDF card), and the particle size is uniform. The method has the characteristics of simple and easily-controlled reaction, convenient operation, low cost, environmental protection, easy industrial production and the like, and has excellent electrochemical performance when being applied to the water system zinc ion battery.

Nano spherical alpha-MnO 2 /Bi 2 O 3 The material can be used as a battery cathode material. For example, nano-spherical alpha-MnO 2 /Bi 2 O 3 The material can be used for the positive electrode of a zinc ion battery. For example, the above-mentioned nano-spherical α -MnO is added 2 /Bi 2 O 3 When the material is applied to a zinc ion battery (a water-based zinc ion battery), the material has excellent electrochemical performance, and the charge-discharge specific capacity of the material can reach 230mAh g under the multiplying power condition of 0.5C -1 Above, the circulation capacity can be kept at 180mAh g after 55 cycles under the 2C multiplying power -1 Above, the battery has good stability, and the specific capacity is still maintained at 120mAh g when the charging and discharging cycle is more than 500 circles -1 Above, and the coulombic efficiency can be kept close to 100%.

Using alpha-MnO 2 /Bi 2 O 3 The material for manufacturing the battery positive electrode can comprise: the prepared nano spherical alpha-MnO 2 /Bi 2 O 3 Mixing the materials, acetylene black and polyvinylidene fluoride (PVDF) according to the proportion of (60-80) to (5-20) to (5-15), adding proper amount (the mass can be nano spherical alpha-MnO) 2 /Bi 2 O 3 20 to 50 times the material) solvent (e.g., methyl pyrrolidone; NMP), mixing uniformly, and then coating the uniformly mixed slurry on a substrate (such as stainless steel) to obtain a positive electrodeAnd (3) slicing. The coating may be by casting. The positive pole piece can also be cut into a certain size to be used as the positive pole, the metal zinc is used as the negative pole, the zinc sulfate solution with the concentration of 0.5-2M is used as the electrolyte, and the zinc battery is assembled.

The invention has the beneficial effects that:

the coprecipitation reaction can be normally carried out at room temperature, the requirements on equipment parameters and functions are low, and the process is simple; the dispersion stirring and dripping speed are controlled, so that the dispersion of the solution A in the solution B is effectively promoted, and the product agglomeration is reduced; because hydrogen ions are generated in the reaction process, the added foaming agent can promote the solution to generate carbon dioxide bubbles while reacting, improve the dispersion property of the product, effectively avoid the agglomeration of the product and promote the nanocrystallization of the product particles; the manganese dioxide and the bismuth oxide are dispersed and compounded in a nano-scale manner, the contact performance is good, and the composite bismuth oxide can effectively improve the cycling stability of the material; prepared nano spherical alpha-MnO 2 /Bi 2 O 3 The material has good crystallization property and uniform grain diameter; the invention has the advantages of low cost, high yield, low energy consumption, environmental protection, excellent material electrochemical performance, easy popularization and the like, and has wide application prospect in the field of anode materials of the water system zinc ion battery.

The present invention will be described in further detail with reference to examples. It is also to be understood that the following examples are illustrative of the present invention and are not to be construed as limiting the scope of the invention, and that insubstantial modifications and adaptations of the invention by those skilled in the art based on the foregoing description are intended to be included within the scope of the invention. The specific process parameters and the like of the following examples are also merely one example of suitable ranges, i.e., those skilled in the art can select the appropriate ranges through the description herein, and are not limited to the specific values exemplified below.

Example 1:

(1) Weighing 0.4mol of potassium permanganate and 0.4mol of sodium carbonate, dissolving in 2L of deionized water, and uniformly dispersing to obtain a solution A; 0.61mol of manganese chloride and 0.05mol of bismuth citrate are weighed out and dissolved in 2L of deionized water, and the solution is marked as solution B after uniform dispersion. And dispersing the solution B by using an emulsifying dispersion machine, simultaneously dripping the solution A into the solution B, controlling the dripping speed to be 100 drops/minute, and then adding 0.1mol of ammonia water to adjust the pH value to be alkaline. And after the reaction is completed, standing the reacted mixed solution for 24 hours, carrying out suction filtration and washing on the precipitate, and collecting the obtained precipitate product.

(2) Drying the precipitation product obtained in the step (1) in an oven at 110 ℃ for 10 hours to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 The attached drawings 1a and 1b of the precursor powder of the material are an SEM image and an XRD image of the microstructure of the precursor powder respectively, and the images show that the material has good dispersion performance, is in a nano-sphere shape, has uniform particle size and weaker XRD peak shape, and shows that the crystallization performance needs to be improved through heat treatment.

(3) Nano spherical alpha-MnO obtained in the step (2) 2 /Bi 2 O 3 The precursor powder of the material is placed in a muffle furnace, the temperature is raised to 400 ℃, and the temperature is kept for 5 hours, thus obtaining the nano spherical alpha-MnO with good crystallization property 2 /Bi 2 O 3 The accompanying figures 2a and 2b show SEM image and XRD image of microstructure, respectively, and it can be seen that the product after heat treatment still maintains good dispersibility, has less agglomeration, particle size of about 200nm, XRD shows that manganese dioxide is alpha-type, and sharp peak shape and higher peak strength show nano spherical alpha-MnO 2 /Bi 2 O 3 The material has excellent crystallization property.

In order to further research the performance of the material when the material is used as the anode material of the water-system zinc ion battery, the prepared nano spherical alpha-MnO is 2 /Bi 2 O 3 The material, acetylene black and polyvinylidene fluoride (PVDF) are mixed according to the proportion of 7. And (3) cutting the positive pole piece into a certain size to be used as a positive pole, taking metal zinc as a negative pole, and taking zinc sulfate solution with the concentration of 2M as electrolyte to assemble the zinc battery. FIG. 3 is a voltage-specific capacity curve diagram of a battery assembled into a full battery, and it can be seen from the graph that the charge-discharge specific capacity of the material can be measured under the condition of 0.5C rateUp to 230mAh g -1 . FIG. 4 shows the nano-spherical alpha-MnO 2 /Bi 2 O 3 The circulation capacity diagram of the zinc battery assembled by the material anode and the commercial electrolytic manganese dioxide anode respectively under the 2C multiplying power shows that the initial specific capacity of the commercial electrolytic manganese dioxide anode is only about 110mAh g -1 And after 55 cycles of circulation, the capacity is quickly attenuated to 55mAh g -1 And the nano spherical alpha-MnO 2 /Bi 2 O 3 The capacity of the anode of the material can be kept at 180mAh g -1 The above, and excellent charge/discharge stability. FIG. 5 is the nano-spherical alpha-MnO 2 /Bi 2 O 3 The rate performance curve of the material anode assembled zinc battery shows that the material has excellent rate performance, and the specific capacity can still be kept at 85mAh g under the condition of 10C high rate -1 Left and right, and the reversibility is better. FIG. 6 is a graph showing the long cycle life at 3C rate after the battery is assembled into a full cell, and it can be seen that the battery stability is good, and the specific capacity is still maintained at 120mAh g after 500 cycles of charge-discharge cycle -1 Above, and the coulombic efficiency remains close to 100%.

Example 2:

(1) Weighing 0.35mol of potassium permanganate and 0.5mol of potassium carbonate, dissolving in 2L of deionized water, and uniformly dispersing to obtain a solution A; 0.52mol of manganese nitrate and 0.05mol of bismuth citrate are weighed out separately and dissolved in 2L of deionized water, and the solution is recorded as solution B after uniform dispersion. And dispersing the solution B by using ultrasonic stirring dispersion, simultaneously dripping the solution A into the solution B, controlling the dripping speed to be 80 drops/min, and then adding 0.05mol of sodium hydroxide to adjust the pH value to be alkaline. And after the reaction is completed, standing the reacted mixed solution for 24 hours, carrying out suction filtration and washing on the precipitate, and collecting the obtained precipitate product.

(2) Drying the precipitation product obtained in the step (1) in an oven at 100 ℃ for 10 hours to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 Precursor powder of the material.

(3) The nano spherical alpha-MnO obtained in the step (2) 2 /Bi 2 O 3 Placing the material precursor powder in a muffle furnace, heating to 380 ℃, and preserving heat for 5 hours to obtain the crystallization propertyGood nano-spherical alpha-MnO 2 /Bi 2 O 3 FIG. 7 shows a SEM image of the material.

The material is applied to the anode material of a zinc battery, and the specific capacity of the material can reach 205mAh g -1 And has excellent rate capability and cycle stability.

Example 3:

(1) Weighing 0.6mol of potassium permanganate and 0.8mol of potassium carbonate, dissolving in 2.5L of deionized water, and uniformly dispersing to obtain a solution A; in addition, 0.9mol of manganese sulfate and 0.1mol of bismuth acetate are weighed and dissolved in 2.5L of deionized water, and the solution B is marked after uniform dispersion. The solution B was dispersed by mechanical stirring dispersion while dropping the solution A into the solution B at a rate of 50 drops/min, followed by addition of 0.15mol of sodium hydroxide to adjust the pH to alkaline. And after the reaction is completed, standing the reacted mixed solution for 24 hours, carrying out suction filtration and washing on the precipitate, and collecting the obtained precipitate product.

(2) Drying the precipitation product obtained in the step (1) in a drying oven at 105 ℃ for 10 hours to obtain the nano spherical alpha-MnO 2 /Bi 2 O 3 Precursor powder of the material.

(3) Nano spherical alpha-MnO obtained in the step (2) 2 /Bi 2 O 3 The precursor powder of the material is placed in a muffle furnace, the temperature is raised to 430 ℃, and the temperature is preserved for 5 hours, thus obtaining the nano spherical alpha-MnO with good crystallization property 2 /Bi 2 O 3 FIG. 8 shows a SEM image of the material.

The material is applied to the anode material of a zinc battery, and the specific capacity of the material can reach 198mAh g -1 And has excellent rate performance and cycle stability.

Example 4:

(1) Weighing 1mol of potassium permanganate and 1mol of potassium carbonate, dissolving in 4L of deionized water, and uniformly dispersing to obtain a solution A; in addition, 4mol of manganese sulfate and 0.8mol of bismuth acetate are weighed and dissolved in 4L of deionized water, and the solution B is recorded as a solution B after uniform dispersion. And dispersing the solution B by using mechanical stirring dispersion, simultaneously dripping the solution A into the solution B, controlling the dripping speed to be 150 drops/minute, and then adding 0.32mol of ammonia water to adjust the pH value to be alkaline. And after the reaction is completed, standing the mixed solution after the reaction for 24 hours, carrying out suction filtration and washing on the precipitate, and collecting the obtained precipitate product.

(2) Drying the precipitation product obtained in the step (1) in an oven at 70 ℃ for 10 hours to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 Precursor powder of the material.

(3) The nano spherical alpha-MnO obtained in the step (2) 2 /Bi 2 O 3 The precursor powder of the material is placed in a muffle furnace, the temperature is raised to 380 ℃, and the temperature is kept for 5 hours, thus obtaining the nano spherical alpha-MnO with good crystallization property 2 /Bi 2 O 3 A material.

The material is applied to the anode material of a zinc battery, and the specific capacity of the material can reach 240mAh g -1 And has excellent rate performance and cycle stability.

Claims (10)

1. Nano spherical alpha-MnO 2 /Bi 2 O 3 The preparation method of the material is characterized by comprising the following steps:

mixing a solution A obtained by mixing potassium permanganate, a foaming agent and a first solvent with a solution B obtained by mixing manganese salt, bismuth salt and a second solvent, then adding an alkaline regulator, regulating the pH value of the mixed solution to 7-11, and carrying out coprecipitation reaction to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 Precursor powder; the first solvent and/or the second solvent is/are at least one of water and ethanol;

and placing the precursor powder at 300-600 ℃ for heat treatment to obtain nano spherical alpha-MnO 2 /Bi 2 O 3 A material;

the nano spherical alpha-MnO 2 /Bi 2 O 3 The material is composed of alpha-MnO 2 Main phase and Bi 2 O 3 A second phase of said Bi 2 O 3 The content of the second phase is 0.5-10 wt.%.

2. The method of claim 1, wherein the foaming agent is sodium carbonate and/or potassium carbonate.

3. The method according to claim 1, wherein the manganese salt is a low-valent manganese salt and is at least one of manganese sulfate, manganese nitrate and manganese chloride.

4. The method according to claim 1, wherein the bismuth salt is bismuth citrate and/or bismuth acetate.

5. The method according to claim 1, wherein the alkaline modifier is sodium hydroxide and/or aqueous ammonia.

6. The preparation method according to claim 1, characterized in that the amount of the substance of the foaming agent is 1 to 1.5 times the amount of the substance of the potassium permanganate;

the mass ratio of the potassium permanganate to the manganese salt is 1:1 to 1:4;

the amount of the substance of the bismuth salt is 0.1 to 20 percent of the amount of the substance of the manganese salt;

the ratio of the amount of the bismuth salt to the amount of the substance of the basic regulator is 1:2 to 1:6.

7. the method according to claim 1, wherein the heat treatment is carried out for 2 to 24 hours.

8. The nanosphere-shaped α -MnO of any of claims 1 to 7 2 /Bi 2 O 3 Nano spherical alpha-MnO obtained by material preparation method 2 /Bi 2 O 3 A material.

9. The nanosphere-shaped α -MnO of claim 8 2 /Bi 2 O 3 Material, characterized in that said nano-spherical alpha-MnO is 2 /Bi 2 O 3 The particle size of the material is 5-500 nm.

10. A zinc ion battery, wherein a positive electrode of the zinc ion battery comprises the nano spherical α -MnO of claim 8 or 9 2 /Bi 2 O 3 A material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811083905.4A CN110911652B (en) | 2018-09-17 | 2018-09-17 | Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811083905.4A CN110911652B (en) | 2018-09-17 | 2018-09-17 | Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110911652A CN110911652A (en) | 2020-03-24 |

| CN110911652B true CN110911652B (en) | 2021-03-02 |

Family

ID=69812638

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811083905.4A Active CN110911652B (en) | 2018-09-17 | 2018-09-17 | Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110911652B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115566150A (en) * | 2021-07-01 | 2023-01-03 | 陈璞 | Neutral or weakly acidic system water system zinc ion battery positive electrode material and preparation method and application thereof |

| CN113694083B (en) * | 2021-09-30 | 2022-09-27 | 安徽医科大学 | Bismuth oxide/manganese oxide composite nanospheres, preparation method thereof and application thereof in psoriasis treatment |

| CN116137321A (en) * | 2021-11-18 | 2023-05-19 | 瑞海泊(常州)能源科技有限公司 | Positive electrode material, preparation method and application thereof |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101059786B1 (en) * | 2008-04-11 | 2011-08-26 | 주식회사 단석산업 | Manufacturing Method of Manganese Oxide Nanoparticles with Ultra High Capacity Electrode Characteristics |

| CN103972518A (en) * | 2013-02-05 | 2014-08-06 | 中国科学院大连化学物理研究所 | Manganese dioxide/carbon nanocomposite, and preparation method and application thereof |

| CN104941631A (en) * | 2015-07-22 | 2015-09-30 | 重庆工商大学 | Preparation method of nano-alpha-MnO2 catalyst, nano-alpha-MnO2 catalyst and application of nano-alpha-MnO2 catalyst |

| CN107281999A (en) * | 2017-05-26 | 2017-10-24 | 北京工业大学 | A kind of ferriferous oxide/manganese dioxide nano-composite material and preparation method and application |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107004860B (en) * | 2014-10-13 | 2020-11-06 | 纽约城市大学研究基金会 | Mixed material cathode for secondary alkaline batteries |

-

2018

- 2018-09-17 CN CN201811083905.4A patent/CN110911652B/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101059786B1 (en) * | 2008-04-11 | 2011-08-26 | 주식회사 단석산업 | Manufacturing Method of Manganese Oxide Nanoparticles with Ultra High Capacity Electrode Characteristics |

| CN103972518A (en) * | 2013-02-05 | 2014-08-06 | 中国科学院大连化学物理研究所 | Manganese dioxide/carbon nanocomposite, and preparation method and application thereof |

| CN104941631A (en) * | 2015-07-22 | 2015-09-30 | 重庆工商大学 | Preparation method of nano-alpha-MnO2 catalyst, nano-alpha-MnO2 catalyst and application of nano-alpha-MnO2 catalyst |

| CN107281999A (en) * | 2017-05-26 | 2017-10-24 | 北京工业大学 | A kind of ferriferous oxide/manganese dioxide nano-composite material and preparation method and application |

Non-Patent Citations (3)

| Title |

|---|

| Chaiti Ray et al..Redox mediated synthesis of hierarchical Bi2O3/MnO2 nanoflowers: a non-enzymatic hydrogen peroxide electrochemical sensor.《Dalton Transactions》.2016,第4780-4790页. * |

| Improved performance of Bi2O3-doped MnO2 cathode on rechargeability in LiOH aqueous cell;Manickam Minakshi;《Journal Of Solid State Electrochemistry》;20080827;第1209-1214页 * |

| Redox mediated synthesis of hierarchical Bi2O3/MnO2 nanoflowers: a non-enzymatic hydrogen peroxide electrochemical sensor;Chaiti Ray et al.;《Dalton Transactions》;20160128;第4780-4790页 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110911652A (en) | 2020-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109686938B (en) | Magnesium ion doped gradient nickel cobalt lithium manganate positive electrode material and preparation method thereof | |

| CN111785960B (en) | Vanadium pentoxide/rGO coated nickel cobalt lithium manganate positive electrode material and preparation method thereof | |

| CN102386381B (en) | Preparation method of nano positive material for lithium ion battery | |

| CN102386391B (en) | Method for preparing ternary complex anode material (LiNixCoyMn1-x-yO2) | |

| CN108767216B (en) | Lithium ion battery anode material with variable slope and full concentration gradient and synthesis method thereof | |

| CN109244390B (en) | Phosphorus-doped lithium-rich manganese-based positive electrode material for lithium ion battery and preparation method thereof | |

| CN107364901B (en) | A kind of high-voltage spinel nickel lithium manganate cathode material and preparation method thereof | |

| CN102244236A (en) | Method for preparing lithium-enriched cathodic material of lithium ion battery | |

| WO2015039490A1 (en) | Lithium-rich anode material and preparation method thereof | |

| CN106784726B (en) | Lithium vanadyl phosphate modified lithium-rich manganese-based layered lithium ion battery cathode material and preparation method thereof | |

| CN110233261B (en) | Preparation method of single crystal ternary lithium battery positive electrode material and lithium ion battery | |

| CN110911652B (en) | Nano spherical alpha-MnO 2 /Bi 2 O 3 Material, preparation method and application thereof | |

| CN107394178B (en) | Cobalt carbonate/graphene composite material for sodium-ion battery cathode and preparation method and application thereof | |

| CN101704681B (en) | Method for preparing lithium titanate with spinel structure | |

| CN111384366B (en) | alpha-MnO 2 Carbon/carbon composite electrode material and preparation method and application thereof | |

| CN111785942A (en) | Water-based zinc ion battery positive electrode material and preparation method and application thereof | |

| CN105576236A (en) | Lithium ion battery 442 ternary anode modified material and preparing method thereof | |

| CN108777293B (en) | Nano composite material and preparation method and application thereof | |

| CN103956456A (en) | Halogen anion doped lithium-rich positive electrode material as well as preparation method and application of positive electrode material | |

| CN113206242A (en) | Nickel-cobalt-manganese-aluminum quaternary precursor, positive electrode material and preparation method | |

| CN112694104A (en) | Prussian blue analogue, preparation method thereof, negative electrode material and application | |

| CN112194195A (en) | Preparation method of NCA (negative polarity anodic oxidation) cathode material doped, coated and modified by one-step method | |

| CN111933914A (en) | Vanadium pentoxide and rGO co-coated gradient ternary cathode material and preparation method thereof | |

| CN108807971B (en) | Lithium-rich manganese-based positive electrode material of lithium ion battery and preparation method thereof | |

| CN103236532B (en) | Preparation method for lithium ion battery positive electrode material with 4.5 V voltage platform |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |