CN110669437A - Rosin modified resin, preparation method thereof and UV offset printing ink - Google Patents

Rosin modified resin, preparation method thereof and UV offset printing ink Download PDFInfo

- Publication number

- CN110669437A CN110669437A CN201911005031.5A CN201911005031A CN110669437A CN 110669437 A CN110669437 A CN 110669437A CN 201911005031 A CN201911005031 A CN 201911005031A CN 110669437 A CN110669437 A CN 110669437A

- Authority

- CN

- China

- Prior art keywords

- modified resin

- rosin modified

- acid

- rosin

- ink

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000011347 resin Substances 0.000 title claims abstract description 95

- 229920005989 resin Polymers 0.000 title claims abstract description 95

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 title claims abstract description 82

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 title claims abstract description 82

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 title claims abstract description 82

- 238000007645 offset printing Methods 0.000 title abstract description 30

- 238000002360 preparation method Methods 0.000 title abstract description 11

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 19

- 239000000463 material Substances 0.000 claims abstract description 18

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims abstract description 17

- 239000013522 chelant Substances 0.000 claims abstract description 16

- 239000002994 raw material Substances 0.000 claims abstract description 12

- 238000006243 chemical reaction Methods 0.000 claims description 21

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 13

- 150000007519 polyprotic acids Polymers 0.000 claims description 12

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 11

- 239000000194 fatty acid Substances 0.000 claims description 11

- 229930195729 fatty acid Natural products 0.000 claims description 11

- 150000004665 fatty acids Chemical class 0.000 claims description 11

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 claims description 9

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 claims description 9

- 238000010438 heat treatment Methods 0.000 claims description 9

- 239000000178 monomer Substances 0.000 claims description 9

- DAKWPKUUDNSNPN-UHFFFAOYSA-N Trimethylolpropane triacrylate Chemical compound C=CC(=O)OCC(CC)(COC(=O)C=C)COC(=O)C=C DAKWPKUUDNSNPN-UHFFFAOYSA-N 0.000 claims description 8

- 239000003963 antioxidant agent Substances 0.000 claims description 8

- 230000003078 antioxidant effect Effects 0.000 claims description 8

- 239000003054 catalyst Substances 0.000 claims description 8

- -1 3, 5-di-tert-butyl-4-hydroxyphenyl Chemical group 0.000 claims description 7

- 229920005862 polyol Polymers 0.000 claims description 7

- 150000003077 polyols Chemical class 0.000 claims description 7

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 claims description 7

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 claims description 6

- 150000008064 anhydrides Chemical class 0.000 claims description 6

- JZODKRWQWUWGCD-UHFFFAOYSA-N 2,5-di-tert-butylbenzene-1,4-diol Chemical compound CC(C)(C)C1=CC(O)=C(C(C)(C)C)C=C1O JZODKRWQWUWGCD-UHFFFAOYSA-N 0.000 claims description 5

- 235000010354 butylated hydroxytoluene Nutrition 0.000 claims description 5

- VOZRXNHHFUQHIL-UHFFFAOYSA-N glycidyl methacrylate Chemical compound CC(=C)C(=O)OCC1CO1 VOZRXNHHFUQHIL-UHFFFAOYSA-N 0.000 claims description 5

- 238000000034 method Methods 0.000 claims description 5

- CUXYLFPMQMFGPL-UHFFFAOYSA-N (9Z,11E,13E)-9,11,13-Octadecatrienoic acid Natural products CCCCC=CC=CC=CCCCCCCCC(O)=O CUXYLFPMQMFGPL-UHFFFAOYSA-N 0.000 claims description 4

- SPSPIUSUWPLVKD-UHFFFAOYSA-N 2,3-dibutyl-6-methylphenol Chemical compound CCCCC1=CC=C(C)C(O)=C1CCCC SPSPIUSUWPLVKD-UHFFFAOYSA-N 0.000 claims description 4

- AFVFQIVMOAPDHO-UHFFFAOYSA-N Methanesulfonic acid Chemical compound CS(O)(=O)=O AFVFQIVMOAPDHO-UHFFFAOYSA-N 0.000 claims description 4

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 4

- CUXYLFPMQMFGPL-SUTYWZMXSA-N all-trans-octadeca-9,11,13-trienoic acid Chemical compound CCCC\C=C\C=C\C=C\CCCCCCCC(O)=O CUXYLFPMQMFGPL-SUTYWZMXSA-N 0.000 claims description 4

- FPCJKVGGYOAWIZ-UHFFFAOYSA-N butan-1-ol;titanium Chemical compound [Ti].CCCCO.CCCCO.CCCCO.CCCCO FPCJKVGGYOAWIZ-UHFFFAOYSA-N 0.000 claims description 4

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 claims description 4

- 239000011976 maleic acid Substances 0.000 claims description 4

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 claims description 4

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 claims description 4

- 238000004321 preservation Methods 0.000 claims description 4

- JOXIMZWYDAKGHI-UHFFFAOYSA-N toluene-4-sulfonic acid Chemical compound CC1=CC=C(S(O)(=O)=O)C=C1 JOXIMZWYDAKGHI-UHFFFAOYSA-N 0.000 claims description 4

- OYHQOLUKZRVURQ-NTGFUMLPSA-N (9Z,12Z)-9,10,12,13-tetratritiooctadeca-9,12-dienoic acid Chemical compound C(CCCCCCC\C(=C(/C\C(=C(/CCCCC)\[3H])\[3H])\[3H])\[3H])(=O)O OYHQOLUKZRVURQ-NTGFUMLPSA-N 0.000 claims description 3

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 claims description 3

- GTELLNMUWNJXMQ-UHFFFAOYSA-N 2-ethyl-2-(hydroxymethyl)propane-1,3-diol;prop-2-enoic acid Chemical class OC(=O)C=C.OC(=O)C=C.OC(=O)C=C.CCC(CO)(CO)CO GTELLNMUWNJXMQ-UHFFFAOYSA-N 0.000 claims description 3

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 claims description 3

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 claims description 3

- 235000010469 Glycine max Nutrition 0.000 claims description 3

- 244000068988 Glycine max Species 0.000 claims description 3

- 239000005642 Oleic acid Substances 0.000 claims description 3

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 claims description 3

- 235000021355 Stearic acid Nutrition 0.000 claims description 3

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 claims description 3

- 150000008065 acid anhydrides Chemical class 0.000 claims description 3

- 239000001530 fumaric acid Substances 0.000 claims description 3

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 claims description 3

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical group O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 claims description 3

- QIQXTHQIDYTFRH-UHFFFAOYSA-N octadecanoic acid Chemical compound CCCCCCCCCCCCCCCCCC(O)=O QIQXTHQIDYTFRH-UHFFFAOYSA-N 0.000 claims description 3

- OQCDKBAXFALNLD-UHFFFAOYSA-N octadecanoic acid Natural products CCCCCCCC(C)CCCCCCCCC(O)=O OQCDKBAXFALNLD-UHFFFAOYSA-N 0.000 claims description 3

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid Chemical compound CCCCCCCC\C=C/CCCCCCCC(O)=O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 claims description 3

- 239000008117 stearic acid Substances 0.000 claims description 3

- 239000003784 tall oil Substances 0.000 claims description 3

- XBDQKXXYIPTUBI-UHFFFAOYSA-M Propionate Chemical compound CCC([O-])=O XBDQKXXYIPTUBI-UHFFFAOYSA-M 0.000 claims 1

- 229940098779 methanesulfonic acid Drugs 0.000 claims 1

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 claims 1

- OJMIONKXNSYLSR-UHFFFAOYSA-N phosphorous acid Chemical compound OP(O)O OJMIONKXNSYLSR-UHFFFAOYSA-N 0.000 claims 1

- 210000000988 bone and bone Anatomy 0.000 abstract description 2

- 239000000976 ink Substances 0.000 description 71

- 238000004945 emulsification Methods 0.000 description 9

- XCJYREBRNVKWGJ-UHFFFAOYSA-N copper(II) phthalocyanine Chemical compound [Cu+2].C12=CC=CC=C2C(N=C2[N-]C(C3=CC=CC=C32)=N2)=NC1=NC([C]1C=CC=CC1=1)=NC=1N=C1[C]3C=CC=CC3=C2[N-]1 XCJYREBRNVKWGJ-UHFFFAOYSA-N 0.000 description 8

- 239000002253 acid Substances 0.000 description 7

- 238000012360 testing method Methods 0.000 description 7

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 6

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 6

- 238000001723 curing Methods 0.000 description 6

- 229910052709 silver Inorganic materials 0.000 description 6

- 239000004332 silver Substances 0.000 description 6

- FPAFDBFIGPHWGO-UHFFFAOYSA-N dioxosilane;oxomagnesium;hydrate Chemical group O.[Mg]=O.[Mg]=O.[Mg]=O.O=[Si]=O.O=[Si]=O.O=[Si]=O.O=[Si]=O FPAFDBFIGPHWGO-UHFFFAOYSA-N 0.000 description 5

- 239000003595 mist Substances 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 239000000049 pigment Substances 0.000 description 5

- 230000007547 defect Effects 0.000 description 4

- WPMYUUITDBHVQZ-UHFFFAOYSA-N 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoic acid Chemical compound CC(C)(C)C1=CC(CCC(O)=O)=CC(C(C)(C)C)=C1O WPMYUUITDBHVQZ-UHFFFAOYSA-N 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 239000013067 intermediate product Substances 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 238000007639 printing Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 150000005846 sugar alcohols Polymers 0.000 description 3

- 230000008719 thickening Effects 0.000 description 3

- 239000004408 titanium dioxide Substances 0.000 description 3

- MGMXGCZJYUCMGY-UHFFFAOYSA-N tris(4-nonylphenyl) phosphite Chemical compound C1=CC(CCCCCCCCC)=CC=C1OP(OC=1C=CC(CCCCCCCCC)=CC=1)OC1=CC=C(CCCCCCCCC)C=C1 MGMXGCZJYUCMGY-UHFFFAOYSA-N 0.000 description 3

- OSNILPMOSNGHLC-UHFFFAOYSA-N 1-[4-methoxy-3-(piperidin-1-ylmethyl)phenyl]ethanone Chemical compound COC1=CC=C(C(C)=O)C=C1CN1CCCCC1 OSNILPMOSNGHLC-UHFFFAOYSA-N 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 239000006229 carbon black Substances 0.000 description 2

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 2

- 239000003086 colorant Substances 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 239000002270 dispersing agent Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- 239000003999 initiator Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 231100000252 nontoxic Toxicity 0.000 description 2

- 230000003000 nontoxic effect Effects 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 238000005070 sampling Methods 0.000 description 2

- 239000012974 tin catalyst Substances 0.000 description 2

- ODIGIKRIUKFKHP-UHFFFAOYSA-N (n-propan-2-yloxycarbonylanilino) acetate Chemical compound CC(C)OC(=O)N(OC(C)=O)C1=CC=CC=C1 ODIGIKRIUKFKHP-UHFFFAOYSA-N 0.000 description 1

- YXGOYRIWPLGGKN-UHFFFAOYSA-N 2,3-ditert-butylbenzene-1,4-diol Chemical compound CC(C)(C)C1=C(O)C=CC(O)=C1C(C)(C)C YXGOYRIWPLGGKN-UHFFFAOYSA-N 0.000 description 1

- 230000003712 anti-aging effect Effects 0.000 description 1

- KKBWAGPOKIAPAW-UHFFFAOYSA-N butoxyalumane Chemical compound CCCCO[AlH2] KKBWAGPOKIAPAW-UHFFFAOYSA-N 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 1

- 125000002915 carbonyl group Chemical group [*:2]C([*:1])=O 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- BMAJFOMUMXCOIA-UHFFFAOYSA-M di(butan-2-yloxy)alumanyl 3-oxobutanoate Chemical compound [Al+3].CCC(C)[O-].CCC(C)[O-].CC(=O)CC([O-])=O BMAJFOMUMXCOIA-UHFFFAOYSA-M 0.000 description 1

- 239000003085 diluting agent Substances 0.000 description 1

- 230000001804 emulsifying effect Effects 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- 238000011056 performance test Methods 0.000 description 1

- 150000008301 phosphite esters Chemical class 0.000 description 1

- 238000000016 photochemical curing Methods 0.000 description 1

- 229920001225 polyester resin Polymers 0.000 description 1

- 239000004645 polyester resin Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000012797 qualification Methods 0.000 description 1

- 238000003847 radiation curing Methods 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 125000004213 tert-butoxy group Chemical group [H]C([H])([H])C(O*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 239000003440 toxic substance Substances 0.000 description 1

- 238000009489 vacuum treatment Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09F—NATURAL RESINS; FRENCH POLISH; DRYING-OILS; OIL DRYING AGENTS, i.e. SICCATIVES; TURPENTINE

- C09F1/00—Obtaining purification, or chemical modification of natural resins, e.g. oleo-resins

- C09F1/04—Chemical modification, e.g. esterification

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D11/00—Inks

- C09D11/02—Printing inks

- C09D11/08—Printing inks based on natural resins

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Wood Science & Technology (AREA)

- Inks, Pencil-Leads, Or Crayons (AREA)

Abstract

The invention discloses rosin modified resin, a preparation method thereof and UV offset printing ink. The rosin modified resin is prepared from the following raw materials in parts by weight: 100 parts of rosin modified resin base material; 2-5 parts of aluminum chelate. Compared with other types of resin, the rosin modified resin has the characteristics of high viscosity and low viscosity, so that good body bones are provided for the UV offset printing ink.

Description

Technical Field

The invention relates to the field of photocuring materials, in particular to rosin modified resin, a preparation method thereof and UV offset printing ink.

Background

The offset resin is a binder applied to preparing offset ink, and the proportion of the binder in an ink formula is the largest, so that various properties of the ink are determined. Polyester acrylate resin, modified epoxy resin and some inert resins are available in the market at present and can be used as main resin for ink. However, these types of resins have corresponding defects, wherein the polyester acrylate resin has the problems of general reactivity and serious ink flying, and the modified epoxy resin has the problems of serious influence on ink balance due to emulsification and the like. Therefore, the existing offset printing resin has corresponding defects, and the preparation of the ink with better performance is limited.

Accordingly, the prior art is yet to be improved and developed.

Disclosure of Invention

In view of the defects of the prior art, the invention aims to provide a rosin modified resin, a preparation method thereof and a UV offset printing ink, and aims to solve the corresponding defects of the prior offset printing resin and limit the performance of the UV offset printing ink.

The rosin modified resin is prepared from the following raw materials in parts by weight:

100 parts of rosin modified resin base material;

2-5 parts of aluminum chelate.

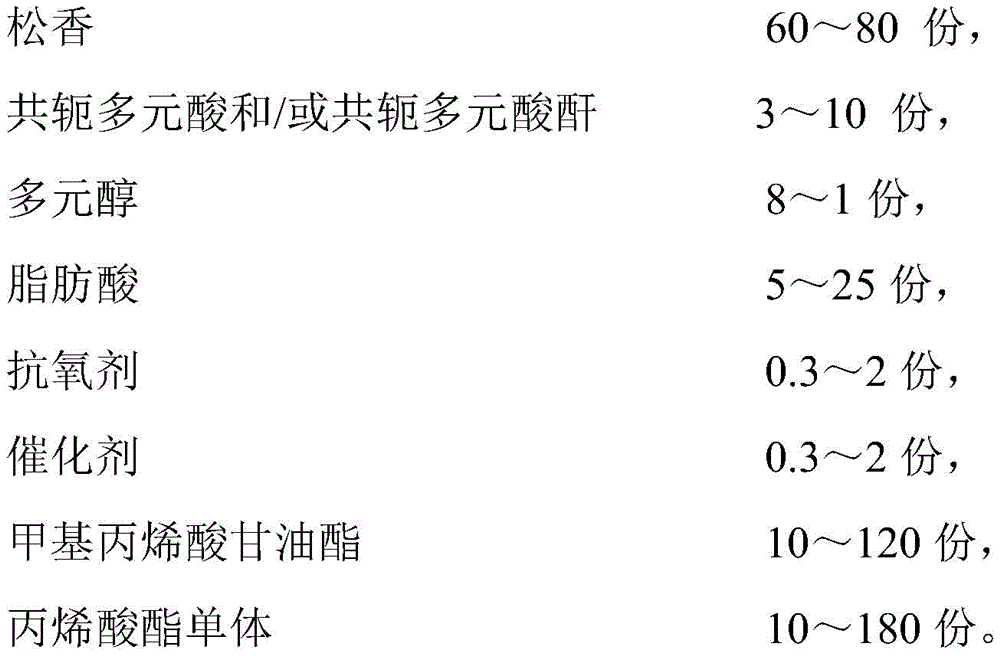

The rosin modified resin comprises a rosin modified resin base material and is prepared from the following raw materials in parts by weight:

the rosin modified resin is characterized in that the conjugated polybasic acid is one or more of maleic acid and fumaric acid, and the conjugated polybasic anhydride is maleic anhydride.

The rosin modified resin is prepared by mixing the rosin modified resin and the polyol, wherein the polyol is one or more of neopentyl glycol, ethylene glycol, glycerol, trimethylolpropane and pentaerythritol.

The rosin modified resin is characterized in that the fatty acid is one or more of eleostearic acid, linoleic acid, soybean oleic acid, stearic acid and tall oil fatty acid.

The rosin modified resin is characterized in that the antioxidant is one or more of di-tert-butyl hydroquinone, tetra [ beta- (3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] pentaerythritol ester, dibutyl hydroxy toluene and trinonyl phenyl phosphite ester.

The rosin modified resin is prepared by mixing a rosin modified resin and a catalyst, wherein the catalyst is one or more of an organic tin catalyst, butyl titanate, p-methyl benzene sulfonic acid and methyl sulfonic acid.

The rosin modified resin is characterized in that the acrylate monomer is one or more of trimethylolpropane triacrylate, ethoxylated trimethylolpropane triacrylate and glycerinated acrylate.

A method for producing the rosin-modified resin described above, comprising the steps of:

putting the molten rosin into a reaction kettle, and heating to 140-200 ℃;

adding conjugated polybasic acid and/or conjugated polybasic anhydride, polyol, fatty acid, antioxidant and catalyst, preserving heat for 20-40 minutes, and then heating to 250-290 ℃ for heat preservation;

adding an acrylate monomer and glycidyl methacrylate for reaction;

adding aluminum chelate to obtain the rosin modified resin.

A UV offset ink comprising the rosin-modified resin as described above.

Has the advantages that: the rosin modified resin can be used as a main resin of UV offset printing ink. Compared with other types of resin, the rosin modified resin has the characteristics of high viscosity and low viscosity, so that good body bones are provided for the UV offset printing ink.

Detailed Description

The invention provides rosin modified resin, a preparation method thereof and UV offset printing ink, and the invention is further described in detail below in order to make the purpose, technical scheme and effect of the invention clearer and more clear. It should be understood that the specific embodiments described herein are merely illustrative of the invention and are not intended to limit the invention.

The rosin modified resin is prepared from the following raw materials in parts by weight:

100 parts of rosin modified resin base material;

2-5 parts of aluminum chelate.

The rosin modified resin base material is a resin base material containing rosin or modified rosin. The rosin is carboxyl-containing rosin with a molecular formula of C19H29COOH. The aluminum chelate compound of the present invention is an organic aluminum type chelate compound such as aluminum oxide acylate, aluminum alkoxide and the like, and specifically the aluminum chelate compound can be di-sec-butoxy aluminum acetoacetate, di-iso-butoxy aluminum acetoacetate, n-butoxy aluminum, tert-butoxy aluminumOr the aluminum chelate complex may be directly a commercially available organic aluminum type complex X-110. The invention forms a thickening structure by the reaction of the aluminum chelate and carboxyl or hydroxyl in the rosin modified resin base material, so that the rosin modified resin has the characteristics of high viscosity and low viscosity.

The rosin modified resin can be used as a main resin of UV offset printing ink. Compared with other types of resin, the rosin modified resin has the characteristics of high viscosity and low viscosity, so that a good body skeleton is provided for the UV offset printing ink, and the UV offset printing ink has the comprehensive properties of good printing transferability, high gloss, low ink flying, low emulsification (good ink-water balance), excellent adhesion and the like.

In the rosin modified resin, the rosin modified resin base material comprises the following raw materials in parts by weight:

rosin, conjugated polybasic acid and/or conjugated polybasic anhydride, polyol, fatty acid and the like in the rosin modified resin base material can react with the aluminum chelate to form a thickening structure, so that the prepared rosin modified resin has more remarkable characteristics of high viscosity and low viscosity.

The structural formulas of the conjugated polybasic acid and the conjugated polybasic acid anhydride are molecular structures containing at least one carbonyl group connected to two ends of a carbon-carbon double bond. Specifically, the conjugate polybasic acid is one or more of maleic acid and fumaric acid, and the conjugate polybasic anhydride is maleic anhydride.

The polyhydric alcohol can be dihydric alcohol, trihydric alcohol and the like, and specifically, the polyhydric alcohol is one or more of neopentyl glycol, ethylene glycol, glycerol, trimethylolpropane and pentaerythritol.

The fatty acid is one or more of eleostearic acid, linoleic acid, soybean oleic acid, stearic acid and tall oil fatty acid.

The antioxidant is one or more of di-tert-butyl hydroquinone, tetra [ beta- (3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] pentaerythritol ester, dibutyl hydroxy toluene and trinonyl phenyl phosphite ester. The ditert-butylhydroquinone, DTBHQ for short, belongs to a non-toxic substance, and does not influence the physicochemical property of the resin; the tetra [ beta- (3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] pentaerythritol ester, which is 1010 for short, is white crystalline powder, has stable chemical properties, is not colored, is not polluted, is nontoxic, and is an excellent antioxidant; dibutyl hydroxy toluene, BHT for short, has high stability and strong oxidation resistance; the trisnonylphenyl phosphite ester is TNPP for short, and is a non-polluting heat-resistant antioxidant anti-aging agent.

The catalyst is one or more of organic tin catalyst, butyl titanate, p-methyl benzene sulfonic acid and methyl sulfonic acid.

The acrylate monomer can be monofunctional acrylate or multifunctional acrylate, and specifically, the acrylate monomer is one or more of trimethylolpropane triacrylate, ethoxylated trimethylolpropane triacrylate (EM 2380 for short) and glycerinated acrylate (OTA-480 for short).

Further, the present invention provides a method for preparing the rosin modified resin, comprising the steps of:

A. putting the molten rosin into a reaction kettle, and heating to 140-200 ℃;

B. adding conjugated polybasic acid and/or conjugated polybasic anhydride, polyol, fatty acid, antioxidant and catalyst, preserving heat for 20-40 minutes, and then heating to 250-290 ℃ for heat preservation;

C. adding an acrylate monomer and glycidyl methacrylate for reaction;

D. adding aluminum chelate to obtain the rosin modified resin.

The reaction kettle is a reaction vessel for preparing the rosin modified resin, and other reaction vessels similar to the reaction kettle can be adopted by the technical personnel in the field. The invention adopts a step-by-step reaction method, namely, firstly, reacting rosin with conjugate polybasic acid and/or conjugate polybasic acid anhydride, polyalcohol and fatty acid to form a polymer with a certain molecular weight, then adding an acrylate monomer and glycidyl methacrylate for reaction to achieve the purpose of regulating and controlling the composition of the polymer in the rosin modified resin, obtaining the rosin modified resin with good comprehensive performance, and finally adding a certain amount of aluminum chelate to obtain the rosin modified resin with proper viscosity.

In the preparation method of the rosin modified resin, before the step C, the acid value of a product in the reaction kettle is detected, and when the acid value of the first intermediate product in the reaction kettle is 40-60mgKOH/g, the step C can be carried out. Before the step D, detecting the acid value of the second intermediate product in the reaction kettle, and performing the subsequent step D when the acid value of the product in the reaction kettle is less than or equal to 5 mgKOH/g. The invention determines whether the corresponding step is finished or not by controlling the acid value of the intermediate product in the reaction process.

Further, the invention also provides a UV offset printing ink, which comprises the rosin modified resin. The UV offset printing ink adopts the rosin modified resin as a main resin. The UV offset printing ink disclosed by the invention has the comprehensive properties of good printing transferability, high gloss, low ink flying, low emulsification (good ink balance), excellent adhesion and the like.

Specifically, the UV offset printing ink is prepared from the following raw material components in parts by weight:

the main resin is the rosin modified resin; the active diluent is trimethylolpropane triacrylate (TMPTA), and the viscosity of the formula is adjusted; the initiator is a UV initiator, such as a ketone photoinitiator, and specifically can be one or more of 907 (commercially available), ITX (commercially available) and TPO (commercially available); the filler is talcum powder used as a filler of the UV offset printing ink, and the talcum powder is 8000 meshes of talcum powder; the pigment is one or more of pigment red, titanium dioxide, benzidine yellow, phthalocyanine blue and carbon black.

Further, the present invention also provides a method for preparing the UV offset ink as described above, comprising:

uniformly mixing the components according to a UV offset printing ink formula to obtain ink paste;

and grinding the mixed ink paste on a three-roller machine for 4-5 times, and detecting the fineness of the ink paste by using a fineness plate to be less than 10 micrometers to obtain the UV offset printing ink.

The technical solution of the present invention will be described below by specific examples.

Example 1

Preparation of rosin modified resin

1. The formula of the rosin modified resin base material comprises the following raw materials:

the preparation method of the rosin modified resin comprises the following steps:

putting rosin in a molten state into a reaction kettle, and heating to 170 ℃;

<2> adding raw materials of maleic acid, neopentyl glycol, eleostearic acid, DTBHQ and butyl titanate;

after the temperature is kept for 30 minutes, the temperature is increased to 260 ℃ for heat preservation;

<4> the acid value was measured by sampling and was 51mgKOH/g, and after passing, the temperature was lowered after 1 hour of vacuum treatment.

And (5) adding trimethylolpropane triacrylate, dropwise adding glycidyl methacrylate, and keeping the temperature at 120 ℃ for reaction until the acid value is less than or equal to 5mgKOH/g to obtain the rosin modified resin base material.

2. The formula of the rosin modified resin comprises the following raw materials:

100g of rosin modified resin base material,

commercially available aluminum chelate X-1105 g.

According to the formula, rosin modified resin is used for enabling a rosin modified resin base material to react with a commercially available aluminum chelate X-110 to form a thickening structure, and the method comprises the following steps:

putting the rosin modified resin base material into a reaction kettle, and heating to 130 ℃;

dripping the aluminum chelate solution at the temperature of 120 ℃ under the stirring condition;

heating to 150 ℃, and keeping the temperature for 1 h;

and <2> cooling after sampling and determining qualification.

Secondly, UV offset printing ink is prepared, and the formula composition of the UV offset printing ink is shown in table 1.

TABLE 1 UV offset ink composition raw materials

| Ink formulation | Red colour | Yellow colour | Blue color | White colour | Black color |

| Main body resin (g) | 50 | 52 | 50 | 35 | 52 |

| TMPTA(g) | 18 | 18 | 18 | 10 | 18 |

| 907/ITX/TPO(g) | 4/2/1 | 6/1/0 | 6/1/0 | 2/1/2 | 8/1/0 |

| 8000 mesh talcum powder (g) | 5 | 5 | 5 | 5 | 5 |

| Pigment Red (57:1) L5B01(g) | 20 | \ | \ | \ | \ |

| Titanium dioxide RDIS (g) | \ | \ | \ | 45 | \ |

| Carbon black MA-11(g) | \ | \ | \ | \ | 12 |

| BiphenylamineYellow 1138(g) | \ | 16 | \ | \ | \ |

| 15DT7072 phthalocyanine blue (g) | \ | \ | 18 | \ | \ |

| 24000 dispersing agent (g) | 1 | 1 | 1 | 1 | 1 |

| Total amount (g) | 101 | 101 | 101 | 101 | 97 |

Note: in Table 1, "\" indicates that the corresponding component content is 0.

The main resins in table 1 are rosin modified resin, modified epoxy resin HE 3219 (commercially available), and polyester resin HT7379 (commercially available) prepared in this example, and the monomer TMPTA is changxing EM 231; the 8000-mesh talcum powder is used for filling ink; the pigment red (57:1) is Crainen L5B 01; the titanium dioxide is Finland RDI-S provided by Heshi wall chemical industry; benzidine yellow 1138 provides Yuhong pigment; 15DT7072 phthalocyanine blue Fulitt organic phthalocyanine blue provided by Kjeldahl chemical; the dispersing agent is Luborun 24000, and improves the wetting and dispersing effects of the resin.

The preparation method of the UV offset printing ink for each color comprises the following specific steps:

the components were mixed uniformly according to the formulation shown in table 1;

and grinding the mixed ink paste for 5 times on a three-roller machine, and detecting the fineness of the ink paste by using a fineness plate to be less than 10um to obtain the UV offset printing ink.

Thirdly, evaluating the prepared UV offset printing ink

Substrate material: coated paper, PVC, PET, silver card paper.

The ultraviolet radiation curing conditions are as follows:

lamp tube type: a high-pressure mercury lamp;

lamp tube output power: more than or equal to 30 KW;

energy of the lamp tube: 100 to 1000J/cm2。

Equipment: offset printing color developing instrument, ink emulsifying instrument, viscosity instrument, 60-degree inclined glass plate and Rayleigh viscosity instrument.

Construction viscosity: 8 to 12.

Coating thickness: 3 to 5 μm.

Performance testing of the UV offset inks of various colors prepared in this example

The UV offset inks of the respective colors prepared in this example were tested for ink fluidity, gloss, emulsion rate, viscosity Poise, adhesion property, and curing property by a conventional test method in the art, and the test results are shown in tables 2, 3, 4, 5, and 6.

In the embodiment, the ink flying performance is measured by using the adhesion instrument to operate, the ink layer is split, when ink drops fly off the ink roller and enter the air, the ink sticking condition of the white paper on the beam of the ink adhesion instrument is observed, specifically, after the ink adhesion instrument is started for one minute, a piece of white paper is placed on the beam, the white paper is taken down after the beam continues rotating for 1 minute, whether the white paper has ink or not is observed, and the ink flying degree is judged according to the amount of the ink stuck on the white paper.

TABLE 2 white UV offset ink test results

| Example-white color | Rosin modified resin | HE3219 | HT7379 |

| Fluidity/cm | 40 | 30 | 35 |

| Gloss of | 75 | 66 | 60 |

| Degree of emulsification/%) | 23 | 35 | 34 |

| Viscosity of | 9 | 14 | 13 |

| Viscosity Poise | 950 | 983 | 901 |

| Silver card paper-attachment | 5B | 5B- | 5B |

| PVC adhesion | 5B- | 0B | 5B- |

| PET-attachment | 4B | 0B | 3B |

| Curing | 4 | 5 | 3 |

| Ink mist | 5 | 4 | 3 |

TABLE 3 yellow UV offset ink test results

| Example yellow color | Rosin modified resin | HE3219 | HT7379 |

| Fluidity/cm | 35 | 15 | 20 |

| Gloss of | 70 | 61 | 55 |

| Degree of emulsification/%) | 25 | 34 | 35 |

| Viscosity of | 8 | 13 | 12 |

| Viscosity Poise | 890 | 912 | 900 |

| Silver card paper-attachment | 5B | 5B | 5B |

| PVC adhesion | 5B- | 0B | 5B- |

| PET-attachment | 5B- | 0B | 4B |

| Curing | 4- | 4 | 3 |

| Ink mist | 5 | 3 | 3- |

TABLE 4 test results for Red UV offset ink

| Example Red color | Rosin modified resin | HE3219 | HT7379 |

| Fluidity/cm | 36 | 20 | 27 |

| Gloss of | 80 | 71 | 72 |

| Degree of emulsification/%) | 26 | 33 | 36 |

| Viscosity of | 10 | 15 | 14 |

| Viscosity Poise | 953 | 971 | 964 |

| Silver card paper-attachment | 5B | 5B | 5B |

| PVC adhesion | 5B- | 0B | 5B- |

| PET-attachment | 5B- | 0B | 4B |

| Curing | 4 | 4+ | 4- |

| Ink mist | 5 | 3 | 3- |

TABLE 5 Red UV offset ink test results

| Example blue color | Rosin modified resin | HE3219 | HT7379 |

| Fluidity/cm | 30 | 13 | 15 |

| Gloss of | 66 | 54 | 57 |

| Degree of emulsification/%) | 27.5 | 34.3 | 35.7 |

| Viscosity of | 8.2 | 12.6 | 13.4 |

| Viscosity Poise | 933 | 951 | 938 |

| Silver card paper-attachment | 5B | 5B | 5B |

| PVC adhesion | 5B- | 0B | 5B- |

| PET-attachment | 5B- | 0B | 4B |

| Curing | 4- | 4 | 3 |

| Ink mist | 5- | 3- | 2 |

TABLE 6 test results for black UV offset ink

| example-Black color | Rosin modified resin | HE3219 | HT7379 |

| Fluidity/cm | 32 | 21 | 22 |

| Gloss of | 68 | 61 | 58 |

| Degree of emulsification/%) | 24.6 | 32.9 | 34.4 |

| Viscosity of | 9.3 | 12.5 | 12.7 |

| Viscosity Poise | 911 | 923 | 920 |

| Silver card paper-attachment | 5B | 5B- | 5B |

| PVC adhesion | 4B | 0B | 3B |

| PET-attachment | 3B | 0B | 2B |

| Curing | 3 | 4 | 2 |

| Ink mist | 4 | 2 | 2- |

Note: the cured and ink-flying scores in tables 2 to 6 were 1 to 5, and the larger the score, the better the corresponding performance.

Compared with other types of resin, the rosin modified resin prepared by the invention has the characteristics of high viscosity and low viscosity through ink performance test, and is a good UV offset printing ink skeleton. The UV offset printing ink skeleton prepared by the invention has the comprehensive properties of good printing transferability, high gloss, low ink flying, low emulsification (good ink balance), excellent adhesion and the like.

It is to be understood that the invention is not limited to the examples described above, but that modifications and variations may be effected thereto by those of ordinary skill in the art in light of the foregoing description, and that all such modifications and variations are intended to be within the scope of the invention as defined by the appended claims.

Claims (10)

1. The rosin modified resin is characterized by being prepared from the following raw materials in parts by weight:

100 parts of rosin modified resin base material;

2-5 parts of aluminum chelate.

3. the rosin modified resin according to claim 2, wherein the conjugated polybasic acid is one or more of maleic acid and fumaric acid, and the conjugated polybasic acid anhydride is maleic anhydride.

4. The rosin modified resin according to claim 2, wherein the polyol is one or more of neopentyl glycol, ethylene glycol, glycerol, trimethylolpropane, and pentaerythritol.

5. The rosin modified resin of claim 2, wherein the fatty acid is one or more of eleostearic acid, linoleic acid, soya oleic acid, stearic acid, tall oil fatty acid.

6. The rosin modified resin of claim 2, wherein the antioxidant is one or more of di-tert-butylhydroquinone, pentaerythritol tetrakis [ β - (3, 5-di-tert-butyl-4-hydroxyphenyl) propionate ], dibutylhydroxytoluene, and trisnonylphenyl phosphite.

7. The rosin modified resin according to claim 2, wherein the catalyst is one or more of an organotin catalyst, butyl titanate, p-toluenesulfonic acid, and methanesulfonic acid.

8. The rosin modified resin according to claim 2, wherein the acrylate monomer is one or more selected from trimethylolpropane triacrylate, ethoxylated trimethylolpropane triacrylate, and glycerated acrylate.

9. A method of preparing the rosin-modified resin according to claim 2, comprising the steps of:

putting the molten rosin into a reaction kettle, and heating to 140-200 ℃;

adding conjugated polybasic acid and/or conjugated polybasic anhydride, polyol, fatty acid, antioxidant and catalyst, preserving heat for 20-40 minutes, and then heating to 250-290 ℃ for heat preservation;

adding an acrylate monomer and glycidyl methacrylate for reaction;

adding aluminum chelate to obtain the rosin modified resin.

10. A UV offset ink comprising the rosin-modified resin according to any one of claims 1 to 8.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911005031.5A CN110669437A (en) | 2019-10-22 | 2019-10-22 | Rosin modified resin, preparation method thereof and UV offset printing ink |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911005031.5A CN110669437A (en) | 2019-10-22 | 2019-10-22 | Rosin modified resin, preparation method thereof and UV offset printing ink |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110669437A true CN110669437A (en) | 2020-01-10 |

Family

ID=69083573

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911005031.5A Pending CN110669437A (en) | 2019-10-22 | 2019-10-22 | Rosin modified resin, preparation method thereof and UV offset printing ink |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110669437A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111647303A (en) * | 2020-06-30 | 2020-09-11 | 湖南科茂林化有限公司 | Phenolic-free rosin ester resin for offset printing ink and preparation method thereof |

| CN113416492A (en) * | 2021-07-13 | 2021-09-21 | 桂林兴松林化有限责任公司 | Production process of rosin modified resin for hot melt adhesive production |

| CN115029068A (en) * | 2022-06-20 | 2022-09-09 | 广东科茂林产化工股份有限公司 | Rosin-based ultraviolet curing resin, application, printing ink and preparation method thereof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070232786A1 (en) * | 2001-01-05 | 2007-10-04 | Sun Chemical Corporation | Acrylated maleic-modified rosin ester and method of preparation |

| CN105838141A (en) * | 2016-06-06 | 2016-08-10 | 上海飞亚油墨有限公司 | Rosin and fatty acid modified polyacrylate resin for UV (ultraviolet) offset ink and preparation method of rosin and fatty acid modified polyacrylate resin |

| CN108219676A (en) * | 2016-12-22 | 2018-06-29 | 谭海剑 | A kind of special modified rosin resin, preparation method and its application |

-

2019

- 2019-10-22 CN CN201911005031.5A patent/CN110669437A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070232786A1 (en) * | 2001-01-05 | 2007-10-04 | Sun Chemical Corporation | Acrylated maleic-modified rosin ester and method of preparation |

| CN105838141A (en) * | 2016-06-06 | 2016-08-10 | 上海飞亚油墨有限公司 | Rosin and fatty acid modified polyacrylate resin for UV (ultraviolet) offset ink and preparation method of rosin and fatty acid modified polyacrylate resin |

| CN108219676A (en) * | 2016-12-22 | 2018-06-29 | 谭海剑 | A kind of special modified rosin resin, preparation method and its application |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111647303A (en) * | 2020-06-30 | 2020-09-11 | 湖南科茂林化有限公司 | Phenolic-free rosin ester resin for offset printing ink and preparation method thereof |

| CN113416492A (en) * | 2021-07-13 | 2021-09-21 | 桂林兴松林化有限责任公司 | Production process of rosin modified resin for hot melt adhesive production |

| CN115029068A (en) * | 2022-06-20 | 2022-09-09 | 广东科茂林产化工股份有限公司 | Rosin-based ultraviolet curing resin, application, printing ink and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108219676B (en) | Special modified rosin resin, preparation method and application thereof | |

| CN110669437A (en) | Rosin modified resin, preparation method thereof and UV offset printing ink | |

| US6166100A (en) | Cationically polymerizable pigmented composition | |

| CN102645845B (en) | Photosensitive polymer combination, colour filter and display device using the photosensitive polymer combination | |

| CN103045015B (en) | Anti-anodic oxidation ink of liquid photosensitive imaging and developing with alkali and preparation method thereof | |

| JP5848837B1 (en) | Laminating ink composition for flexible packaging | |

| EP2041230A1 (en) | A printing ink | |

| CN109071785A (en) | Modified rosin resin and its manufacturing method, curable with actinic energy ray planographic ink varnish, curable with actinic energy ray planographic ink and printed article | |

| CN112250850B (en) | Environment-friendly alkyd resin and preparation method and application thereof | |

| CN106980230A (en) | Photosensitive polymer combination, colour filter and display device using the photosensitive polymer combination | |

| CN106046335A (en) | Photocured rosin-based polyester resin for UV offset ink and preparation method of photocured rosin-based polyester resin | |

| CN108641475A (en) | A kind of one-component acrylated polyester two-piece can ink and preparation method thereof | |

| US4368316A (en) | Process for the preparation of high-solids rosin-modified polyesters | |

| CN111363411B (en) | Rubber ink composition, preparation method and application method | |

| JP5108430B2 (en) | Ink composition | |

| JP2014516368A (en) | Radiation curable composition | |

| CN116769349B (en) | Phenoxy copolymer-containing doped anti-welding ink, and preparation method and application thereof | |

| CN115135730B (en) | Active energy ray-curable lithographic printing ink and printed matter | |

| US4252727A (en) | Esters of an adduct of diolefinic polymer and unsaturated dicarboxylic compound | |

| JP2018150469A (en) | Method for producing rosin-modified resin, and active energy ray-curable lithographic printing ink | |

| CN111548709B (en) | Coiled material transfer powder coating and preparation method thereof | |

| JP6933288B1 (en) | Varnish for active energy ray-curable ink, active energy ray-curable ink, and printed matter | |

| CN115477922B (en) | UV cold-stamping adhesive using improved rosin resin and preparation method thereof | |

| KR101050998B1 (en) | Vehicle resin for off-set ink and the manufacturing method thereof | |

| CN114958078B (en) | High-viscosity low-viscosity pure vegetable oil ink and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20200110 |