CN110658543A - High-speed railway track geometric parameter detection method based on non-contact measurement - Google Patents

High-speed railway track geometric parameter detection method based on non-contact measurement Download PDFInfo

- Publication number

- CN110658543A CN110658543A CN201810700229.4A CN201810700229A CN110658543A CN 110658543 A CN110658543 A CN 110658543A CN 201810700229 A CN201810700229 A CN 201810700229A CN 110658543 A CN110658543 A CN 110658543A

- Authority

- CN

- China

- Prior art keywords

- track

- measurement

- coordinates

- fitting

- inertial

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01S—RADIO DIRECTION-FINDING; RADIO NAVIGATION; DETERMINING DISTANCE OR VELOCITY BY USE OF RADIO WAVES; LOCATING OR PRESENCE-DETECTING BY USE OF THE REFLECTION OR RERADIATION OF RADIO WAVES; ANALOGOUS ARRANGEMENTS USING OTHER WAVES

- G01S19/00—Satellite radio beacon positioning systems; Determining position, velocity or attitude using signals transmitted by such systems

- G01S19/38—Determining a navigation solution using signals transmitted by a satellite radio beacon positioning system

- G01S19/39—Determining a navigation solution using signals transmitted by a satellite radio beacon positioning system the satellite radio beacon positioning system transmitting time-stamped messages, e.g. GPS [Global Positioning System], GLONASS [Global Orbiting Navigation Satellite System] or GALILEO

- G01S19/42—Determining position

- G01S19/45—Determining position by combining measurements of signals from the satellite radio beacon positioning system with a supplementary measurement

- G01S19/47—Determining position by combining measurements of signals from the satellite radio beacon positioning system with a supplementary measurement the supplementary measurement being an inertial measurement, e.g. tightly coupled inertial

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01S—RADIO DIRECTION-FINDING; RADIO NAVIGATION; DETERMINING DISTANCE OR VELOCITY BY USE OF RADIO WAVES; LOCATING OR PRESENCE-DETECTING BY USE OF THE REFLECTION OR RERADIATION OF RADIO WAVES; ANALOGOUS ARRANGEMENTS USING OTHER WAVES

- G01S17/00—Systems using the reflection or reradiation of electromagnetic waves other than radio waves, e.g. lidar systems

- G01S17/02—Systems using the reflection of electromagnetic waves other than radio waves

- G01S17/06—Systems determining position data of a target

- G01S17/42—Simultaneous measurement of distance and other co-ordinates

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01S—RADIO DIRECTION-FINDING; RADIO NAVIGATION; DETERMINING DISTANCE OR VELOCITY BY USE OF RADIO WAVES; LOCATING OR PRESENCE-DETECTING BY USE OF THE REFLECTION OR RERADIATION OF RADIO WAVES; ANALOGOUS ARRANGEMENTS USING OTHER WAVES

- G01S19/00—Satellite radio beacon positioning systems; Determining position, velocity or attitude using signals transmitted by such systems

- G01S19/38—Determining a navigation solution using signals transmitted by a satellite radio beacon positioning system

- G01S19/39—Determining a navigation solution using signals transmitted by a satellite radio beacon positioning system the satellite radio beacon positioning system transmitting time-stamped messages, e.g. GPS [Global Positioning System], GLONASS [Global Orbiting Navigation Satellite System] or GALILEO

- G01S19/42—Determining position

- G01S19/50—Determining position whereby the position solution is constrained to lie upon a particular curve or surface, e.g. for locomotives on railway tracks

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Engineering & Computer Science (AREA)

- Radar, Positioning & Navigation (AREA)

- Remote Sensing (AREA)

- Physics & Mathematics (AREA)

- Computer Networks & Wireless Communication (AREA)

- General Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Navigation (AREA)

Abstract

The invention belongs to a precision detection technology, in particular to a high-speed railway track geometric parameter detection method based on non-contact measurement.

Description

Technical Field

The invention belongs to a precision detection technology, and particularly relates to a high-speed railway track geometric parameter detection method based on non-contact measurement.

Background

In order to ensure the operation safety of rail transit, in recent years, the rail precision detection technology is rapidly developed, and a large amount of manpower and material resources are invested in a plurality of countries to develop and update various rail detection methods so as to meet the requirements of high speed and heavy load of the current railway. The vehicle-mounted dynamic detection mode has small influence on normal operation, high efficiency and high speed, truly reflects the infrastructure state under the train operation condition, and becomes one of the main detection means of the safety state of the railway and urban rail traffic infrastructure.

The detection of the geometrical parameter state of the track mainly comprises the detection items of track gauge, track direction, height and the like, wherein the track gauge refers to the distance between track gauge points at 16mm positions below the working surfaces of the left and right strands of steel rails with the same cross section. The commonly used track gauge measuring methods mainly include contact measurement and non-contact measurement. The contact type track gauge measuring method is characterized in that the track gauge is measured by utilizing a linear displacement sensor, the sensor is ensured to be constantly contacted with a track gauge point of a track to be measured through a mechanical structure in the detection process, the measuring efficiency is low, and the method is not suitable for high-speed measurement. The common non-contact track gauge measuring method is to utilize a camera mechanism to continuously shoot the inner section of the track gauge, reproduce the inner side curve of the track by an image reconstruction method and calculate the track gauge value. The measuring method has high measuring accuracy and is not influenced by the detection speed, but the method is easily interfered by light, has strict requirements on the use environment and is limited in the use range. The method for detecting the track direction and height of the track mainly comprises a chord measuring method, an inertia reference method and the like, wherein the chord measuring method is that a chord line is really established on the track by adopting a manual wire pulling method, and the smoothness of the track direction and height (track direction) is evaluated by measuring the relative displacement of the track top surface (track distance point) and the chord line. The length of the chord measuring method is closely related to the length of the detection chord, when the track smoothness of various wavelengths needs to be analyzed, the detection device needs to be replaced for re-measurement, or conversion of small pushing is carried out according to the current detection result, the former increases the workload of detection personnel, the working efficiency is low, and the latter has larger errors. The inertial reference method is based on the strapdown inertial navigation technology, acceleration information of a carrier in three axial directions is measured by an accelerometer, angular rate information of the carrier in the three axial directions is measured by a gyroscope, an inertial reference datum is established through the acceleration and the angular rate information, and the relative position of a track relative to the datum is measured by a displacement sensor or an image sensor, so that the relative position of a steel rail in an inertial coordinate system is obtained.

At present, the railway track detection method of most countries in the world is changed from a chord measuring method to an inertia reference method, and particularly in the field of high-speed railway detection, each country is engaged in developing an advanced track detection method which is based on an inertia technology, and has the advantages of strong comprehensiveness, high precision, high speed, high intelligence and high reliability. For example, a T10 type rail inspection vehicle developed by Ensco corporation in America adopts an inertia reference measurement principle and a non-contact measurement method, and can measure geometric parameters of a rail, a steel rail section, wave abrasion and other parameters. The Italy Archimedes comprehensive detection train also adopts a non-contact measurement scheme based on an inertia reference method, and can detect 119 different parameters including track geometric parameters, steel rail sections, steel rail wave abrasion, contact network and current receiving states, communication and signals, acceleration of a train body and an axle box and wheel-rail acting force. The French MVG comprehensive detection train has the detection speed designed to be 320km/h, and the detection parameters comprise track geometric parameters, steel rail sections, steel rail surfaces, communication signals, digital images of line environments, fasteners, sleepers, ballast and other infrastructure states. The GJ-3 type, GJ-4 type and GJ-5 type rail detection vehicles in China all adopt rail detection methods based on the inertial technology, but have strict requirements on the running speed of the detection vehicles, and taking the GJ-5 type rail detection vehicle as an example, the highest measurement speed per hour is only 180 km/h. From the technical development at home and abroad, the non-contact measurement based on the inertial technology is a commonly adopted mode in a high-speed environment, mainly comprising the steps of continuously updating a posture matrix through gyroscope angular rate information, converting acceleration information into a geographic coordinate system, continuously integrating the converted acceleration signal twice, obtaining a spatial motion track of an inertial measurement unit, reproducing track inner side curved surface calculation through image reconstruction and other methods, and obtaining track geometric parameters such as track gauge, smoothness and the like. However, the method has strict requirements on the running speed of the rail detection vehicle, and the measurement requirement of the smoothness of the long wave of more than 150 meters on the high-speed rail is difficult to meet. The invention provides a track geometric parameter detection method based on inertia/laser measurement, which has no strict requirement on the running speed of a train, can be applied to the normally operated train and can meet the measurement requirements of wave smoothness of 150 meters, 300 meters and the like.

Disclosure of Invention

The invention aims to provide a method for detecting geometric parameters of a high-speed railway track based on non-contact measurement.

The technical scheme of the invention is as follows:

a high-speed railway track geometric parameter detection method based on non-contact measurement comprises the following steps:

step 1) inertial/satellite combined navigation calculation to obtain position, speed and attitude information of an inertial measurement unit

Step 2) laser measurement data processing

2.1) time-aligning the inertial measurement data with the laser measurement data;

2.2) judging the effectiveness of the coordinates of the track characteristic points measured at different measuring moments;

2.3) calculating to obtain the three-dimensional position coordinates of the effective track characteristic points

Step 3) fitting calculation of track position coordinates

3.1) calculating the displacement S of each measuring point relative to the initial point according to the coordinates of the characteristic points of the track

S=S+ΔS

In the formula (I), the compound is shown in the specification,three-dimensional coordinates of characteristic points of the track at two adjacent moments, wherein delta S isThe displacement variation between two adjacent points;

3.2) piecewise coordinate fitting

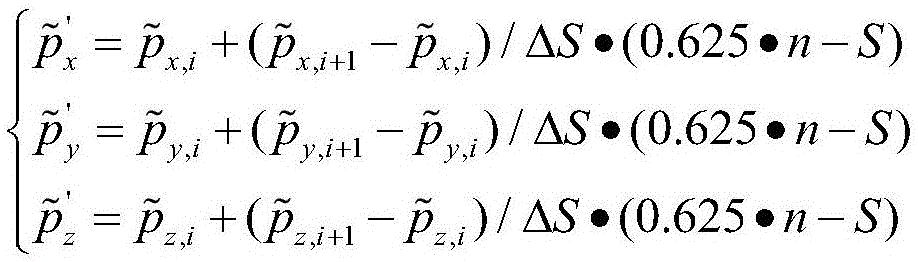

Performing piecewise coordinate fitting with a fixed length of 0.625m, and obtaining the fitted track position coordinate if S > 0.625m

In the formula (I), the compound is shown in the specification,n is the fitting frequency at intervals of 0.625m for the three-dimensional coordinates of the track characteristic points obtained by fitting;

step 4) obtaining three-dimensional coordinates of track characteristic points by fittingAnd determining three-dimensional displacement information of the track characteristic point at any position relative to the starting point in the measurement process.

The step 1) is specifically as follows:

1.1) determining the equation of state

w is the system noise and A is the system state matrix

1.2) determining the measurement equation

The Kalman filtering measurement equation is

Z=HX+v

In the formula, Z represents Kalman filtering observed quantity, H represents a system observation matrix, and v is system measurement noise;

observed quantity is Represents the navigation coordinate system speed obtained by inertial navigation solution,A navigation coordinate system velocity component representing a differential satellite positioning output;

the observation matrix H is

1.3) carrying out Kalman filtering estimation, and estimating a position error, a speed error and an attitude error of the inertial navigation system;

1.4) carrying out error correction on the obtained state estimation value to obtain the position, speed and attitude information of the inertial measurement unit.

The step 2.2) is to judge the effectiveness of the coordinates of the characteristic points of the track measured at different measuring moments, and specifically comprises the following steps:

the coordinates of the track characteristic points measured by the laser at different moments are set as (x)i,yi,zi)、(xi+1,yi+1,zi+1)、(xi+2,yi+2,zi+2)

If xi+1-xi| is > ζ and | xi+2-xiIf | < ζ, then xi+1For abnormal coordinate values, x needs to be realignedi+1Fitting is performed, xi+1=(xi+xi+2)/2;

If yi+1-yiZeta > and yi+2-yiζ is less than | then yi+1For abnormal coordinate values, y needs to be realignedi+1Fitting is performed, yi+1=(yi+yi+2)/2;

If zi+1-ziZeta > and | zi+2-ziZeta < ζ, then zi+1For abnormal coordinate values, z needs to be realignedi+1Fitting is performed, zi+1=(zi+zi+2)/2;

Wherein ζ is a constant value of 0.1 to 0.5.

The step 2.3) is specifically as follows:

setting the relative coordinates of the orbit feature points obtained by laser measurement after effectiveness judgment as (x, y, z), and obtaining the position (p) according to the inertia/satellite combinationx,py,pz) And the three-dimensional position coordinates of the track characteristic points can be obtained by calculation

In the formula, LbA lever arm between the laser range finder and the inertial measurement unit, obtained by calibration before testing, CαFor the transformation matrix of the laser measurement coordinate system to the carrier coordinate system,and converting the inertial navigation system carrier coordinate system to a navigation coordinate system.

The invention has the following remarkable effects:

the method takes the inertial measurement as a reference, and utilizes the position and attitude information of an inertial measurement unit and the track characteristic point coordinate information obtained by laser measurement to obtain the smoothness of the left and right steel rails and the track distance value between the left and right steel rails. The method comprises the steps of firstly, carrying out combined navigation resolving through an inertial navigation system and a high-precision differential satellite positioning system to obtain the spatial position and attitude information of an inertial measurement unit, and obtaining the position and attitude information of the laser range finder because the installation relation of the laser range finder and the inertial measurement unit can be obtained through calibration. And combining the coordinate values of the characteristic points of the left and right rails measured by the laser range finder to obtain the position coordinates of the left and right rails, and realizing high-precision and continuous measurement of the geometric parameters of the rails by referring to the track gauge and smoothness calculation method specified in TB/T3147-2012.

Detailed Description

The present invention will be described in further detail with reference to specific examples.

Step 1 inertial/satellite integrated navigation computation

1.1) determining the equation of state

Firstly, the position, the speed and the attitude information of an inertial measurement unit are obtained by utilizing high-precision differential satellite positioning (DGPS) information and adopting a combined navigation method based on Kalman filtering. The SINS/DGPS combined navigation state variables comprise: speed error delta V of north, sky and eastN、δVU、δVEAttitude error phi in north, sky and east directionsN、φU、φEError in north, sky, and east positionsDelta h, delta lambda, gyro drift of carrier system in each axial directionAnd accelerometer zero offset

Determining system state variables

Determining an equation of state

In the formula, w is system noise, A is a system state matrix, and values of elements in the system state matrix can be obtained by referring to an error equation of the strapdown inertial navigation system according to state variables.

1.2) determining the measurement equation

The Kalman filter measurement equation has the form:

Z=HX+v

in the formula, Z represents Kalman filtering observed quantity, H represents a system observation matrix, and v represents system measurement noise.

The SINS/DGPS combined navigation Kalman filtering adopts a speed matching mode, and the difference value of the speed obtained by inertial navigation resolving and the speed measured by differential satellite positioning is used as the observed quantity of a Kalman filter. Namely, observed quantity:

in the formula (I), the compound is shown in the specification,represents the navigation coordinate system speed obtained by inertial navigation solution,A navigation coordinate system velocity component representing the differential satellite positioning output.

According to the observed quantity, a corresponding measurement matrix H can be obtained

1.3) Filter calculation

Selecting an initial state estimation value X according to a combined navigation system state equation and a measurement equation0Initial estimation mean square error matrix P0Initial variance matrix Q of system noise0And measuring the noise variance matrix RkBy referring to a Kalman filtering calculation formula, accurate estimation of each error can be realized, and details are not repeated in the mature prior art.

1.4) error correction

And correcting the position error, the speed error and the attitude error of the inertial navigation system by using the state estimation value obtained by Kalman filtering calculation to obtain the position, the speed and the attitude information of the inertial measurement unit.

Step 2 laser measurement data processing

2.1) time synchronization

And according to the time stamps of the inertial measurement data and the laser measurement data, carrying out time alignment on the measurement data of the inertial measurement data and the laser measurement data.

2.2) abnormal data culling

The coordinates of the track characteristic points measured by the laser at different time points are assumed to be (x)i,yi,zi)、(xi+1,yi+1,zi+1)、(xi+2,yi+2,zi+2) The validity of the measurement coordinates at each time needs to be judged.

Taking x coordinate as an example, if | xi+1-xi| is > ζ and | xi+2-xiIf | < ζ, then xi+1For abnormal coordinate values, x needs to be realignedi+1Fitting is performed, xi+1=(xi+xi+2)/2Zeta is a constant value of 0.1 to 0.5.

By adopting the same method, the validity judgment of the y coordinate and the z coordinate is needed.

If yi+1-yiZeta > and yi+2-yiζ is less than | then yi+1For abnormal coordinate values, y needs to be realignedi+1Fitting is performed, yi+1=(yi+yi+2) Zeta is a constant value of 0.1 to 0.5.

If zi+1-ziZeta > and | zi+2-ziZeta < ζ, then zi+1For abnormal coordinate values, z needs to be realignedi+1Fitting is performed, zi+1=(zi+zi+2) Zeta is a constant value of 0.1 to 0.5.

2.3) spatial coordinate transformation

Setting the relative coordinates of the orbit feature points obtained by laser measurement after effectiveness judgment as (x, y, z), and obtaining the position (p) according to the inertia/satellite combinationx,py,pz) And the three-dimensional position coordinates of the track characteristic points can be obtained by calculation

In the formula, LbFor laser rangefinders and inertiasThe lever arm between the sexual measurement units, obtained by calibration before the test, CαIs obtained by calibrating a conversion matrix from a laser measurement coordinate system to a carrier coordinate system before test,and converting the inertial navigation system carrier coordinate system to a navigation coordinate system.

Step 3, calculating the coordinate fitting of the track position

Because the high-speed railway has high running speed, coordinate fitting calculation needs to be carried out among all sampling points.

3.1) calculating the displacement S of each measuring point relative to the initial point according to the coordinates of the characteristic points of the track

S=S+ΔS

In the formula (I), the compound is shown in the specification,the three-dimensional coordinates of the characteristic points of the track at two adjacent moments are shown, and delta S is the displacement variation between the two adjacent points.

3.2) piecewise coordinate fitting

Performing piecewise coordinate fitting with a fixed length of 0.625m, and obtaining the fitted track position coordinate if S > 0.625m

In the formula (I), the compound is shown in the specification,for the three-dimensional coordinates of the orbit feature points obtained by fitting, n is the number of fitting times at intervals of 0.625 m.

Step 4 track geometric parameter calculation

Obtaining three-dimensional coordinates of track characteristic points according to fittingThe three-dimensional displacement information of the track characteristic point at any position relative to the starting point in the measuring process can be obtained through calculation, the required geometric parameters can be obtained by referring to the track distance and the smoothness calculation method specified in TB/T3147-2012, and the high-precision and continuous measurement of the track geometric parameters is realized.

Claims (4)

1. A high-speed railway track geometric parameter detection method based on non-contact measurement is characterized by comprising the following steps:

step 1) inertial/satellite combined navigation calculation to obtain position, speed and attitude information of an inertial measurement unit

Step 2) laser measurement data processing

2.1) time-aligning the inertial measurement data with the laser measurement data;

2.2) judging the effectiveness of the coordinates of the track characteristic points measured at different measuring moments;

2.3) calculating to obtain the three-dimensional position coordinates of the effective track characteristic points

Step 3) fitting calculation of track position coordinates

3.1) calculating the displacement S of each measuring point relative to the initial point according to the coordinates of the characteristic points of the track

S=S+ΔS

In the formula (I), the compound is shown in the specification,three-dimensional coordinates of characteristic points of the track at two adjacent moments are obtained, and delta S is the displacement variation between the two adjacent points;

3.2) piecewise coordinate fitting

Performing piecewise coordinate fitting with a fixed length of 0.625m, and obtaining the fitted track position coordinate if S > 0.625m

In the formula (I), the compound is shown in the specification,n is the fitting frequency at intervals of 0.625m for the three-dimensional coordinates of the track characteristic points obtained by fitting;

2. The method for detecting the geometric parameters of the high-speed railway track based on the non-contact measurement as claimed in claim 1, wherein the step 1) is specifically as follows:

1.1) determining the equation of state

State variable X ═ δ VN δVU δVE φN φU φE δL δh δλ ▽x ▽y ▽z εx εy εz]T

w is the system noise and A is the system state matrix

1.2) determining the measurement equation

The Kalman filtering measurement equation is

Z=HX+v

In the formula, Z represents Kalman filtering observed quantity, H represents a system observation matrix, and v is system measurement noise;

observed quantity is Represents the navigation coordinate system speed obtained by inertial navigation solution,A navigation coordinate system velocity component representing a differential satellite positioning output;

the observation matrix H is

1.3) carrying out Kalman filtering estimation, and estimating a position error, a speed error and an attitude error of the inertial navigation system;

1.4) carrying out error correction on the obtained state estimation value to obtain the position, speed and attitude information of the inertial measurement unit.

3. The method for detecting the geometric parameters of the high-speed railway track based on the non-contact measurement as claimed in claim 1, wherein the step 2.2) is to judge the validity of the coordinates of the track feature points measured at different measurement moments, specifically:

the coordinates of the track characteristic points measured by the laser at different moments are set as (x)i,yi,zi)、(xi+1,yi+1,zi+1)、(xi+2,yi+2,zi+2)

If xi+1-xi| is > ζ and | xi+2-xiIf | < ζ, then xi+1For abnormal coordinate values, x needs to be realignedi+1Fitting is performed, xi+1=(xi+xi+2)/2;

If yi+1-yiZeta > and yi+2-yiζ is less than | then yi+1For abnormal coordinate values, y needs to be realignedi+1Fitting is performed, yi+1=(yi+yi+2)/2;

If zi+1-ziZeta > and | zi+2-ziZeta < ζ, then zi+1For abnormal coordinate values, z needs to be realignedi+1To carry outFitting, zi+1=(zi+zi+2)/2;

Wherein ζ is a constant value of 0.1 to 0.5.

4. The method for detecting the geometric parameters of the high-speed railway track based on the non-contact measurement as claimed in claim 1, wherein the step 2.3) is specifically as follows:

setting the relative coordinates of the orbit feature points obtained by laser measurement after effectiveness judgment as (x, y, z), and obtaining the position (p) according to the inertia/satellite combinationx,py,pz) And the three-dimensional position coordinates of the track characteristic points can be obtained by calculation

In the formula, LbA lever arm between the laser range finder and the inertial measurement unit, obtained by calibration before testing, CαFor the transformation matrix of the laser measurement coordinate system to the carrier coordinate system,and converting the inertial navigation system carrier coordinate system to a navigation coordinate system.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810700229.4A CN110658543B (en) | 2018-06-29 | 2018-06-29 | High-speed railway track geometric parameter detection method based on non-contact measurement |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810700229.4A CN110658543B (en) | 2018-06-29 | 2018-06-29 | High-speed railway track geometric parameter detection method based on non-contact measurement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110658543A true CN110658543A (en) | 2020-01-07 |

| CN110658543B CN110658543B (en) | 2023-07-14 |

Family

ID=69026893

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810700229.4A Active CN110658543B (en) | 2018-06-29 | 2018-06-29 | High-speed railway track geometric parameter detection method based on non-contact measurement |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110658543B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111895996A (en) * | 2020-08-09 | 2020-11-06 | 宁波一直轨道科技有限公司 | High-speed track detection system and method |

| CN114136275A (en) * | 2021-10-29 | 2022-03-04 | 北京自动化控制设备研究所 | Track line state detection device and roadbed settlement detection method |

| CN114162170A (en) * | 2021-10-29 | 2022-03-11 | 北京自动化控制设备研究所 | Track measuring system and measuring method |

| CN114162169A (en) * | 2021-10-28 | 2022-03-11 | 北京自动化控制设备研究所 | Inertial and laser scanner combined online calibration method |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20100068595A (en) * | 2008-12-15 | 2010-06-24 | 한국철도기술연구원 | System for measuring cross-level irregularity of track using inertial sensor, and method thereof |

| CN102252627A (en) * | 2011-04-12 | 2011-11-23 | 中国航空工业第六一八研究所 | Gauge detection device and detection method for high-speed railway track |

| CN103207403A (en) * | 2013-01-15 | 2013-07-17 | 萨伏威(西安)导航技术有限公司 | Satellite navigation and inertial measurement combined orbit measuring system and method |

| CN104634298A (en) * | 2015-02-13 | 2015-05-20 | 中铁第一勘察设计院集团有限公司 | Existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data |

| CN107782335A (en) * | 2016-08-31 | 2018-03-09 | 北京自动化控制设备研究所 | A kind of contactless line detection system inertial navigation and laser range finder self-calibrating method |

-

2018

- 2018-06-29 CN CN201810700229.4A patent/CN110658543B/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20100068595A (en) * | 2008-12-15 | 2010-06-24 | 한국철도기술연구원 | System for measuring cross-level irregularity of track using inertial sensor, and method thereof |

| CN102252627A (en) * | 2011-04-12 | 2011-11-23 | 中国航空工业第六一八研究所 | Gauge detection device and detection method for high-speed railway track |

| CN103207403A (en) * | 2013-01-15 | 2013-07-17 | 萨伏威(西安)导航技术有限公司 | Satellite navigation and inertial measurement combined orbit measuring system and method |

| CN104634298A (en) * | 2015-02-13 | 2015-05-20 | 中铁第一勘察设计院集团有限公司 | Existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data |

| CN107782335A (en) * | 2016-08-31 | 2018-03-09 | 北京自动化控制设备研究所 | A kind of contactless line detection system inertial navigation and laser range finder self-calibrating method |

Non-Patent Citations (1)

| Title |

|---|

| 郭玉胜 等: "惯性/卫星/里程计多信息融合方法及在铁路测绘中的应用", 《中国惯性技术学报》, vol. 25, no. 3, 30 June 2017 (2017-06-30), pages 334 - 337 * |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111895996A (en) * | 2020-08-09 | 2020-11-06 | 宁波一直轨道科技有限公司 | High-speed track detection system and method |

| CN114162169A (en) * | 2021-10-28 | 2022-03-11 | 北京自动化控制设备研究所 | Inertial and laser scanner combined online calibration method |

| CN114136275A (en) * | 2021-10-29 | 2022-03-04 | 北京自动化控制设备研究所 | Track line state detection device and roadbed settlement detection method |

| CN114162170A (en) * | 2021-10-29 | 2022-03-11 | 北京自动化控制设备研究所 | Track measuring system and measuring method |

| CN114162170B (en) * | 2021-10-29 | 2023-09-12 | 北京自动化控制设备研究所 | Track measurement system and measurement method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110658543B (en) | 2023-07-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103343498B (en) | Track irregularity detecting system and method based on INS/GNSS | |

| CN110658543B (en) | High-speed railway track geometric parameter detection method based on non-contact measurement | |

| CN107402006B (en) | Based on the matched train precision positioning method of track geometry characteristic information and system | |

| CN108842544B (en) | A kind of high-speed railway rail static parameter detection system and method using optical fiber inertial navigation | |

| CN110657788B (en) | Dynamic detection method for smoothness of crane track | |

| CN101625235B (en) | Orbit radius curve measurement system based on a plurality of split inertial references | |

| Zhou et al. | Kinematic measurement of the railway track centerline position by GNSS/INS/odometer integration | |

| CN107782335B (en) | Non-contact type line detection system inertial navigation and laser range finder self-calibration method | |

| CN106405592B (en) | Vehicle-mounted Beidou carrier phase cycle slips detection and restorative procedure and system | |

| CN110700029B (en) | Track ride comfort testing method and system | |

| CN115597535B (en) | High-speed magnetic levitation track irregularity detection system and method based on inertial navigation | |

| CN112628524B (en) | High-precision positioning method for small-diameter pipeline robot based on turning angle | |

| CN108195374A (en) | For the integrated navigation system of track automatic measurement vehicle and integrated navigation calculation method | |

| CN114046789A (en) | Rail detection method based on collaborative measurement of rail inspection trolley navigation IMU | |

| CN110631573B (en) | Multi-information fusion method for inertia/mileometer/total station | |

| CN114719884A (en) | Attitude measurement precision evaluation method and application of inertial navigation system | |

| CN113758483A (en) | Self-adaptive FKF map matching method and system | |

| CN104047212A (en) | Automatic track settlement measuring device and method based on angle measurement | |

| CN111721250B (en) | Real-time detection device and detection method for smoothness of railway track | |

| CN111895996B (en) | High-speed track detection system and method | |

| CN114162170B (en) | Track measurement system and measurement method | |

| CN212300369U (en) | High-speed track detection system | |

| CN114136275A (en) | Track line state detection device and roadbed settlement detection method | |

| CN114353835B (en) | Dynamic calibration system and method for inertial track measuring instrument and application of dynamic calibration system | |

| CN114674345B (en) | Inertial navigation/camera/laser velocimeter online joint calibration method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |