CN110638691B - Paint mirror surface color-holding lip glaze and preparation method thereof - Google Patents

Paint mirror surface color-holding lip glaze and preparation method thereof Download PDFInfo

- Publication number

- CN110638691B CN110638691B CN201911112658.0A CN201911112658A CN110638691B CN 110638691 B CN110638691 B CN 110638691B CN 201911112658 A CN201911112658 A CN 201911112658A CN 110638691 B CN110638691 B CN 110638691B

- Authority

- CN

- China

- Prior art keywords

- color

- lip glaze

- paint

- oil

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/73—Polysaccharides

- A61K8/731—Cellulose; Quaternized cellulose derivatives

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/02—Cosmetics or similar toiletry preparations characterised by special physical form

- A61K8/04—Dispersions; Emulsions

- A61K8/06—Emulsions

- A61K8/062—Oil-in-water emulsions

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/19—Cosmetics or similar toiletry preparations characterised by the composition containing inorganic ingredients

- A61K8/25—Silicon; Compounds thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/19—Cosmetics or similar toiletry preparations characterised by the composition containing inorganic ingredients

- A61K8/29—Titanium; Compounds thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/33—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing oxygen

- A61K8/34—Alcohols

- A61K8/342—Alcohols having more than seven atoms in an unbroken chain

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/33—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing oxygen

- A61K8/34—Alcohols

- A61K8/345—Alcohols containing more than one hydroxy group

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/81—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- A61K8/8105—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers

- A61K8/8111—Homopolymers or copolymers of aliphatic olefines, e.g. polyethylene, polyisobutene; Compositions of derivatives of such polymers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/84—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds obtained by reactions otherwise than those involving only carbon-carbon unsaturated bonds

- A61K8/87—Polyurethanes

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/84—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds obtained by reactions otherwise than those involving only carbon-carbon unsaturated bonds

- A61K8/89—Polysiloxanes

- A61K8/891—Polysiloxanes saturated, e.g. dimethicone, phenyl trimethicone, C24-C28 methicone or stearyl dimethicone

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q1/00—Make-up preparations; Body powders; Preparations for removing make-up

- A61Q1/02—Preparations containing skin colorants, e.g. pigments

- A61Q1/04—Preparations containing skin colorants, e.g. pigments for lips

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Veterinary Medicine (AREA)

- Public Health (AREA)

- Animal Behavior & Ethology (AREA)

- Birds (AREA)

- Epidemiology (AREA)

- Chemical & Material Sciences (AREA)

- Emergency Medicine (AREA)

- Inorganic Chemistry (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Dispersion Chemistry (AREA)

- Cosmetics (AREA)

Abstract

The invention provides a paint gloss mirror surface color-holding lip glaze and a preparation method thereof. The paint light mirror surface color-holding lip glaze comprises the following components in percentage by weight: 20-80% of grease, 0.1-15% of oil-in-water emulsifier, 0.05-15% of colorant, 0.5-10% of oil phase film former, 0.5-20% of water phase film former and the balance of water. The paint gloss mirror surface color-holding lip glaze disclosed by the invention is an oil-in-water lip product, oil is an internal phase, and water is a continuous external phase, so that the greasy feeling of an ointment product is well solved. Meanwhile, the oil phase film forming agent and the grease are matched with each other, and the glossiness, the persistence and the moistening degree of the lip glaze are greatly improved under the synergistic action.

Description

Technical Field

The invention belongs to the field of cosmetics, and particularly relates to a paint-luster mirror surface color-holding lip glaze and a preparation method thereof.

Background

Lip color cosmetics are one of the fastest-growing categories of beauty treatment and personal care in recent years, and continue to grow at a high speed with the enhancement of the beauty consciousness of consumers and the gradual maturity of the beauty cosmetic market. With respect to lip color cosmetics, consumers prefer high gloss, moist, refreshing, long lasting moisturizing lip products. However, the existing long-acting durable products in the market are mostly matte and non-sticky products, and the products have the defects of poor moisture and moisture retention degree and easy drying; the moistening type product has the condition of poor freshness and persistence. The product which can achieve the combination of the two is few and few in the market.

CN104606093A discloses a water-in-oil emulsified lipstick, which contains the following components: water, octyldodecanol, pentaerythritol tetraisostearate, cyclopentadimethylsiloxane, ethylcellulose, ethanol, glycerol, polyglycerol-2-triisostearate, ethylene/propylene/styrene copolymer, butylene/ethylene/styrene copolymer, isododecane, polyglycerol-6 polyricinoleate, trimethylolpropane triisostearate, a colorant, disteardimonium hectorite, hydrogenated polyisobutene, polyglycerol-2 isostearate, rugosa, sodium chloride, phenoxyethanol and ethylhexylglycerol. The invention has higher gloss, saturated color and good makeup state for a long time, but the emulsified lipstick still has larger greasy feeling compared with oil-in-water and has less refreshing degree than the oil-in-water.

CN110302094A discloses a high-gloss non-stick lip glaze and a preparation method thereof, wherein the high-gloss non-stick lip glaze comprises the following components in percentage by weight: 0.1-10% of ethyl cellulose A, 0.1-10% of ethyl cellulose B and 0.1-30% of polydimethylsiloxane and polydimethylsiloxane/vinyl polydimethylsiloxane cross-linked polymer mixture, although a film with high glossiness and good waterproof effect can be formed on lips, the product has the defects of poor water-moistening and moisture-retaining degrees and easiness in drawing dry.

CN109330905A discloses a velvet matte lip glaze and a preparation method thereof, wherein the lip glaze comprises the following components in parts by weight: 27-40.5 parts of thickening agent, 0.1-1 part of humectant, 8.7-13.4 parts of colorant, 21-50 parts of softening agent, 0.1-0.3 part of antioxidant and 8-25 parts of skin feel regulator.

Therefore, there is a need to develop a product with good water retention, long-lasting moisture retention, long make-up time and high glossiness to meet the current consumer demands.

Disclosure of Invention

Aiming at the defects of the prior art, the invention aims to provide a paint-luster mirror surface color-retaining lip glaze and a preparation method thereof, wherein the lip glaze has higher glossiness, durability and moistening degree.

In order to achieve the purpose, the invention adopts the following technical scheme:

in a first aspect, the invention provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight: 20-80% of grease, 0.1-15% of oil-in-water emulsifier, 0.05-15% of colorant, 0.5-10% of oil phase film former, 0.5-20% of water phase film former and the balance of water.

In the present invention, the weight percentage of the fat or oil is 20 to 80%, and may be, for example, 20%, 22%, 24%, 26%, 28%, 30%, 32%, 34%, 36%, 38%, 40%, 42%, 44%, 46%, 48%, 50%, 52%, 54%, 56%, 58%, 60%, 62%, 64%, 66%, 68%, 70%, 72%, 74%, 76%, 78%, 80%.

In the present invention, the weight percentage of the oil-in-water emulsifier is 0.1-15%, for example, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9%, 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10%, 11%, 12%, 13%, 14%, 15%.

In the present invention, the colorant may be 0.05 to 15% by weight, for example, 0.05%, 0.1%, 0.5%, 1%, 2%, 3%, 4%, 5%, 6%, 8%, 9%, 10%, 11%, 12%, 13%, 14%, 15%.

In the present invention, the weight percentage of the oil phase film former is 0.5-10%, for example, 0.5%, 1%, 2%, 3%, 4%, 5%, 6%, 8%, 9%, 10%.

In the present invention, the weight percentage of the aqueous phase film forming agent is 0.5-20%, for example, 0.5%, 1%, 2%, 3%, 4%, 5%, 6%, 8%, 9%, 10%, 11%, 12%, 13%, 14%, 15%, 16%, 17%, 18%, 19%, 20%.

The paint gloss mirror surface color-retaining lip glaze is an oil-in-water lip product, an oil-in-water system is used, an O/W expression is adopted, oil is dispersed in water to form an emulsion system, the oil is used as an internal phase, the water is used as a continuous external phase, and the oil-in-water system has the advantages of simplicity in operation, fresh skin feel, better spreadability and the like, so that the greasy feel of an oil paste product is well solved. Meanwhile, the oil phase film forming agent and the grease are matched with each other, and the glossiness, the persistence and the moistening degree of the lip glaze are greatly improved under the synergistic action. The addition of the oil-in-water emulsifier can greatly reduce the tension of an oil/water interface and form an interface film on the interface by adsorption, thereby ensuring the stability of the emulsion. The gloss mirror surface color-retaining lip glaze provided by the invention has the glossiness and high color saturation of all-oil type and water-in-oil type lip glazes, and the water wettability of the lip glaze is higher than that of water-in-oil type lip glazes and all-oil type lip glazes. The emulsifier has charges when dispersed on the surface of the dispersoid, and can prevent the mutual agglomeration of oil drops so as to ensure the stability of the emulsion.

Preferably, the paint light mirror surface color-holding lip glaze comprises the following components in percentage by weight: 20-70% of grease, 0.1-10% of oil-in-water emulsifier, 1-15% of colorant, 1.5-10% of oil phase film former, 1.5-20% of water phase film former and the balance of water.

Preferably, the paint light mirror surface color-holding lip glaze comprises the following components in percentage by weight: 30-70% of grease, 0.1-8% of oil-in-water emulsifier, 2-15% of colorant, 2-10% of oil phase film former, 1.5-18% of water phase film former and the balance of water.

Preferably, the oil or fat comprises any one or a combination of at least two of squalane, octyldodecanol, caprylic/capric triglyceride, isononyl isononanoate, hydrogenated polyisobutene, pinosyl ester extract, diisostearyl malate, ethylhexyl palmitate, polydimethylsiloxane, polyglyceryl-2-triisostearate, pentaerythritol tetraisostearate, phenyl trimethicone or isododecane.

Preferably, the oil-in-water emulsifier comprises any one or a combination of at least two of sorbitan stearate, polysorbate-60, polysorbate-20, C20-22 alcohol (which may be, for example, C20 alcohol, C21 alcohol, C22 alcohol), C12-20 alkyl glucoside (which may be, for example, C12 alkyl glucoside, C14 alkyl glucoside, C16 alkyl glucoside, C18 alkyl glucoside, C20 alkyl glucoside), cetyl glucoside or coco glucoside.

Preferably, the colorant comprises any one of CI 17200, CI 75457, CI 45380, CI 15850, CI 45410, CI 42090, CI 15985, borosilicate, titanium dioxide or mica powder, or a combination of at least two thereof.

Preferably, the mass ratio of the oil phase film forming agent to the water phase film forming agent is (1-1.5):1, and can be 1:1, 1.1:1, 1.2:1, 1.3:1, 1.4:1, 1.5:1, for example.

Preferably, the oil phase film former comprises any one or a combination of at least two of ethyl cellulose, polybutene, dioleyl dilinoleate, ethylene/propylene/styrene copolymer (CAS No.: 66070-58-4), butene/ethylene/styrene copolymer (CAS No.: 68648-89-5), hydrogenated polycyclopentadiene or vinylpyridine/hexadecenoic acid copolymer (VP/hexadecene copolymer (CAS No.: 32440-50-9)), preferably any one or a combination of at least two of ethyl cellulose, polybutene or dioleyl dilinoleate.

Preferably, the aqueous phase film former comprises any one of or a combination of at least two of acrylic acid/ethylhexyl acrylate copolymer latex, polyurethane latex, styrene/acrylate/methacrylate copolymer latex, styrene/acrylate copolymer latex or polyvinyl acetate latex, preferably any one of or a combination of at least two of polyurethane copolymer latex or ethylhexyl acrylate copolymer latex.

Preferably, the paint light mirror color-retaining lip glaze further comprises a thickening agent.

Preferably, the weight percentage of the thickener in the paint light mirror color-retaining lip glaze is 1-5%, for example, 1%, 2%, 3%, 4%, 5%.

Preferably, the thickening agent comprises any one or a combination of at least two of cetostearyl alcohol, carbomer, aminomethyl propanol, guar gum, hydroxyethyl cellulose or distearyldimethylamine hectorite.

Preferably, the paint light mirror color-retaining lip glaze further comprises a humectant.

Preferably, the weight percentage of the humectant in the paint gloss mirror holding color lip glaze is 1-5%, for example, 1%, 2%, 3%, 4%, 5%.

Preferably, the humectant comprises any one or a combination of at least two of glycerol, propylene glycol, butylene glycol, dipropylene glycol or 1, 3-propanediol.

Preferably, the paint gloss mirror color-retaining lip glaze further comprises a preservative.

Preferably, the weight percentage of the preservative in the paint light mirror surface color-retaining lip glaze is 0.1-0.5%, for example, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%.

Preferably, the preservative comprises any one or a combination of at least two of phenoxyethanol, ethylhexyl glycerol, p-hydroxyacetophenone or glyceryl caprylate.

Preferably, the paint gloss mirror color-retaining lip glaze further comprises a cosolvent.

Preferably, the weight percentage of the cosolvent in the paint light mirror surface color-retaining lip glaze is 1-5%, and can be 1%, 2%, 3%, 4% and 5% for example.

Preferably, the cosolvent is edible alcohol.

Preferably, the paint light mirror color-retaining lip glaze further comprises an antioxidant.

Preferably, the antioxidant is present in the gloss mirror color lip enamel in an amount of 0.1 to 1% by weight, and may be, for example, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9%, 1%.

Preferably, the paint light mirror color-retaining lip glaze further comprises an aromatic.

Preferably, the weight percentage of the aromatic in the paint light mirror color-retaining lip glaze is 0.1-0.5%, for example, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%.

In a second aspect, the invention provides a preparation method of the gloss mirror surface color-retaining lip glaze according to the first aspect, and the preparation method specifically comprises the following steps:

(1) mixing a colorant with part of grease, grinding and dispersing to obtain color paste;

(2) stirring and dispersing the oil-in-water emulsifier, the oil phase film forming agent, the residual grease and the color paste obtained in the step (1) to obtain an oil phase mixed solution; stirring and dispersing the aqueous phase film forming agent and water to obtain an aqueous phase mixed solution;

(3) and (3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying to obtain the gloss mirror surface color-holding lip glaze.

Preferably, the preparation method specifically comprises the following steps:

(1) mixing a colorant with part of grease, grinding and dispersing to obtain color paste;

(2) stirring and dispersing an oil-in-water emulsifier, an oil phase film forming agent, residual grease and the color paste obtained in the step (1) to obtain an oil phase mixed solution; stirring and dispersing the aqueous phase film forming agent and water to obtain an aqueous phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying to obtain the gloss mirror surface color-holding lip glaze;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing and stirring, cooling, adding the rest components, mixing and stirring to obtain a finished product.

Preferably, the mass of the partial grease in the step (1) is 10-20% of the total mass of the grease, and for example, the mass may be 10%, 11%, 12%, 13%, 14%, 15%, 16%, 17%, 18%, 19%, 20%.

Preferably, the grinding of step (1) is carried out using a three-roll mill.

Preferably, the number of grinding times in step (1) is 2 to 5, and may be, for example, 2, 3, 4, or 5.

Preferably, the temperature for stirring and dispersing the oil-phase mixture obtained in the step (2) is 75 to 85 ℃, for example, 75 ℃, 76 ℃, 77 ℃, 78 ℃, 79 ℃, 80 ℃, 81 ℃, 82 ℃, 83 ℃, 84 ℃, 85 ℃.

Preferably, the stirring and dispersing time of the oil phase mixed solution obtained in step (2) is 5-10min, for example, 5min, 6min, 7min, 8min, 9min, 10 min.

Preferably, the temperature for stirring and dispersing the aqueous phase mixture obtained in the step (2) is 75 to 85 ℃, for example, 75 ℃, 76 ℃, 77 ℃, 78 ℃, 79 ℃, 80 ℃, 81 ℃, 82 ℃, 83 ℃, 84 ℃, 85 ℃.

Preferably, the time for stirring and dispersing the aqueous phase mixture obtained in step (2) is 5-10min, for example, 5min, 6min, 7min, 8min, 9min, and 10 min.

Preferably, the emulsification speed in step (3) is 2000-3000rpm, such as 2000rpm, 2100rpm, 2200rpm, 2300rpm, 2400rpm, 2500rpm, 2600rpm, 2700rpm, 2800rpm, 2900rpm, 3000 rpm.

Preferably, the emulsifying time in step (3) is 5-10min, such as 5min, 6min, 7min, 8min, 9min, 10 min.

Preferably, the temperature for mixing and stirring the thickener in the step (4) is 75-85 ℃, for example, 75 ℃, 76 ℃, 77 ℃, 78 ℃, 79 ℃, 80 ℃, 81 ℃, 82 ℃, 83 ℃, 84 ℃, 85 ℃.

Preferably, the time for mixing and stirring the thickener added in the step (4) is 5-10min, such as 5min, 6min, 7min, 8min, 9min, 10 min.

Preferably, the residual components in the step (4) are any one or a combination of at least two of a preservative, a cosolvent, an antioxidant or a essence.

Preferably, the temperature reduction in step (4) is to 30-50 deg.C, such as 30 deg.C, 32 deg.C, 34 deg.C, 36 deg.C, 38 deg.C, 40 deg.C, 42 deg.C, 44 deg.C, 46 deg.C, 48 deg.C, 50 deg.C.

Preferably, the preparation method specifically comprises the following steps:

(1) mixing a colorant with grease accounting for 10-20% of the total mass of the grease, and grinding and dispersing for 2-5 times by using a three-roll machine to obtain color paste;

(2) mixing the oil-in-water emulsifier, the oil phase film forming agent, the residual grease and the color paste obtained in the step (1), and stirring and dispersing at 75-85 ℃ for 5-10min to obtain oil phase mixed liquid; mixing the aqueous phase film forming agent, humectant and water, stirring and dispersing at 75-85 deg.C for 5-10min to obtain aqueous phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying at the speed of 2000-3000rpm for 5-10min to obtain the color-holding lip glaze of the paint finish surface;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing for 5-10min at 75-85 ℃, cooling to 30-50 ℃, adding the rest components, mixing and stirring for 5-10min to obtain a finished product.

Compared with the prior art, the invention has the following beneficial effects:

(1) the paint gloss mirror color-holding lip glaze is an oil-in-water lip product, oil is an internal phase, and water is a continuous external phase, so that the greasy feeling of the oil-paste products is well solved. Meanwhile, the oil phase film forming agent and the grease are matched with each other, and the glossiness, the persistence and the moistening degree of the lip glaze are greatly improved under the synergistic action.

(2) The paint gloss mirror surface color-holding lip glaze provided by the invention has the glossiness and high color saturation of all-oil type and water-in-oil type lip glazes, and the water wettability of the lip glaze is higher than that of water-in-oil type lip glazes and all-oil type lip glazes.

Drawings

FIG. 1A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 1.

FIG. 1B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 1.

FIG. 1C is a photograph of the lips 4h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 1.

FIG. 1D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 1.

FIG. 2A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color lip glaze prepared in example 2. FIG. 2B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 2. FIG. 2C is a photograph of the lips 4h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 2.

Fig. 2D is a photograph of the lips 6h of a volunteer applying the gloss mirror color-sustaining lip glaze prepared in example 2.

FIG. 3A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color lip glaze prepared in example 3. FIG. 3B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 3. Fig. 3C is a photograph of the lips 4h of a volunteer applying the gloss mirror color-sustaining lip glaze prepared in example 3.

FIG. 3D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in example 3.

FIG. 4A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 1. Fig. 4B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 1. FIG. 4C is a photograph of the lips 4h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 1.

Fig. 4D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 1.

FIG. 5A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 2. Fig. 5B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 2. Fig. 5C is a photograph of 4h of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 2.

Fig. 5D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 2.

FIG. 6A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 3. Fig. 6B is a photograph of the lips 2h of a volunteer applying the gloss mirror color-sustaining lip glaze prepared in comparative example 3. Fig. 6C is a photograph of 4h of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 3.

Fig. 6D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 3.

FIG. 7A is an initial photograph of the lips of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 4. FIG. 7B is a photograph of the lips 2h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 4. FIG. 7C is a photograph of the lips 4h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 4.

FIG. 7D is a photograph of the lips 6h of a volunteer who applied the paint finish mirror color-retaining lip glaze prepared in comparative example 4.

Detailed Description

The technical solution of the present invention is further explained by the following embodiments. It should be understood by those skilled in the art that the examples are only for the understanding of the present invention and should not be construed as the specific limitations of the present invention.

Example 1

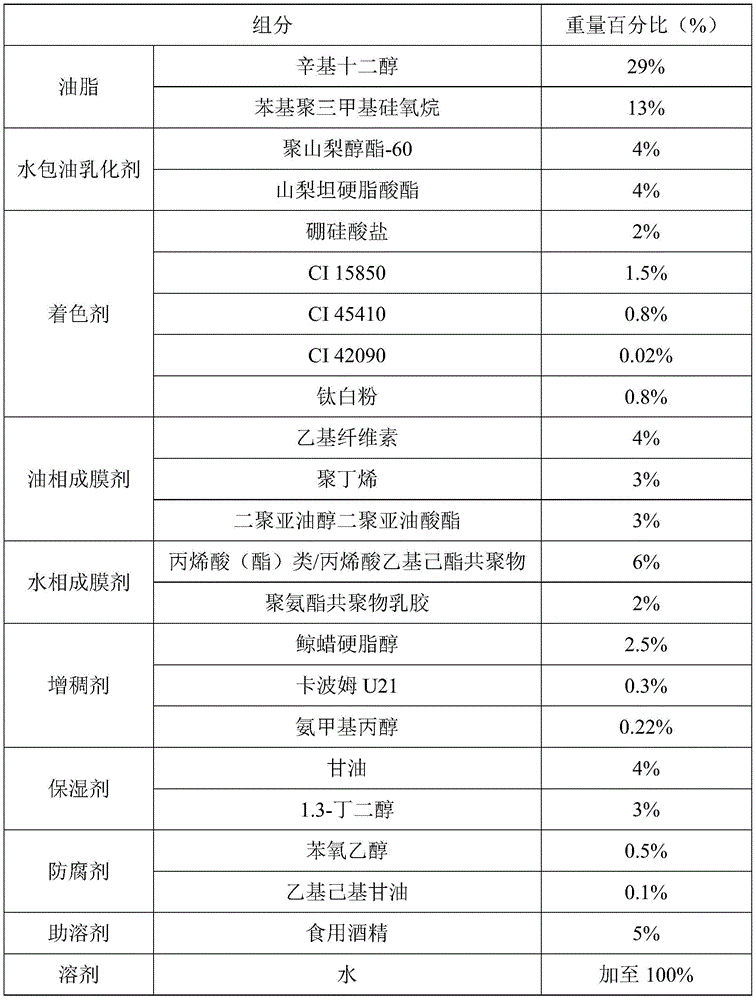

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror color-retaining lip glaze provided by the embodiment specifically comprises the following steps:

(1) mixing a colorant with 7% of octyl dodecanol, and grinding and dispersing for 3 times by using a three-roll machine to obtain color paste;

(2) mixing the oil-in-water emulsifier, the oil phase film forming agent, the residual grease and the color paste obtained in the step (1), and stirring and dispersing at 80 ℃ for 8min to obtain an oil phase mixed solution; mixing the water phase film forming agent, the humectant and water, and stirring and dispersing at 80 ℃ for 5min to obtain a water phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying at the speed of 2000rpm for 10min to obtain the paint gloss mirror surface color-holding lip glaze;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing for 10min at 75 ℃, cooling to 40 ℃, adding the rest components, mixing and stirring for 10min to obtain a finished product.

Example 2

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror color-retaining lip glaze provided by the embodiment specifically comprises the following steps:

(1) mixing a colorant with 7% of octyl dodecanol, and grinding and dispersing for 3 times by using a three-roll machine to obtain color paste;

(2) mixing the oil-in-water emulsifier, the oil phase film forming agent, the residual grease and the color paste obtained in the step (1), and stirring and dispersing at 75 ℃ for 10min to obtain an oil phase mixed solution; mixing the aqueous phase film forming agent, the humectant and water, and stirring and dispersing at 82 ℃ for 7min to obtain an aqueous phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying at the speed of 2000rpm for 10min to obtain the paint gloss mirror surface color-holding lip glaze;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing for 5min at 80 ℃, cooling to 35 ℃, adding the rest components, mixing and stirring for 10min to obtain a finished product.

Example 3

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror color-retaining lip glaze provided in this example is the same as that of example 1.

Example 4

The embodiment provides a paint mirror surface color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror surface color-retaining lip glaze provided in this example is the same as that in example 1.

Example 5

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror surface color-retaining lip glaze provided in this example is the same as that in example 1.

Example 6

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror color-retaining lip glaze provided in this example is the same as that of example 1.

Example 7

The embodiment provides a paint light mirror color-holding lip glaze, which comprises the following components in percentage by weight:

the preparation method of the paint light mirror color-retaining lip glaze provided in this example is the same as that of example 1.

Comparative example 1

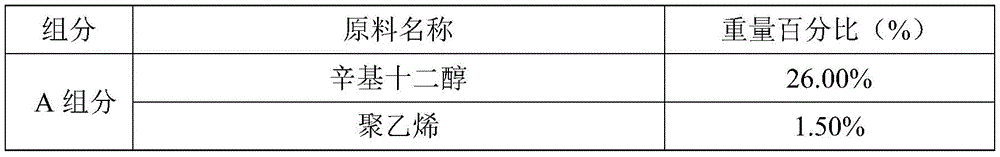

The comparative example provides an all-oil lip glaze, which comprises the following components in percentage by weight:

the preparation method of the lip glaze provided by the comparative example comprises the following steps:

(1) weighing the component A except the borosilicate, putting the rest raw materials into a clean emulsifying pot, heating to 80 ℃, starting stirring and homogenizing until no particles are dispersed completely;

(2) mixing the toner of the component B with octyl dodecanol, and grinding for three times by using a three-roll machine until the toner is completely and uniformly dispersed for later use;

(3) the dispersed component B is put into an emulsifying pot to be mixed and stirred uniformly with the component A, and borosilicate of the component A is added;

(4) cooling to 40 ℃, adding the component C, stirring uniformly, vacuumizing, stirring and discharging.

Comparative example 2

The comparative example provides a water-in-oil lip glaze, which comprises the following components in percentage by weight:

the preparation method of the lip glaze provided by the comparative example comprises the following steps:

(1) heating ethyl cellulose and octyl dodecanol of the component A to 70 ℃, and stirring to dissolve until the components are completely transparent and have no particles for later use;

(2) pre-mixing the raw materials of the component C and grinding the mixture for three times by a three-roll grinder until the mixture is completely and uniformly dispersed for later use;

(3) mixing the raw material of the component A and the prefabricated color paste of the component C, putting the mixture into an emulsifying pot, heating the mixture to 80 ℃, and uniformly stirring and dispersing the mixture to be used as an oil phase for later use;

(4) heating the raw material of the component B to 80 ℃, and dissolving and dispersing uniformly to obtain a water phase for later use;

(5) and slowly adding the component B into the oil phase at a constant speed under the stirring condition. After the addition is finished, emulsifying for 5min again at the homogenizing speed of 3000 rpm;

(6) cooling to 40 deg.C, adding the component D into an emulsifying pot, and stirring;

(7) vacuumizing, stirring and discharging.

Comparative example 3

This comparative example provides a lip glaze which differs from example 1 only in that: the lip glaze does not contain oil-phase film forming agents, and the content of other components and the preparation method are not changed.

Comparative example 4

This comparative example provides a lip glaze which differs from example 1 only in that: the lip glaze does not contain a water phase film forming agent, and the content of other components and the preparation method are not changed.

Comparative example 5

This comparative example provides a lip glaze which differs from example 1 only in that: the oil-in-water emulsifier is replaced by a water-in-oil emulsifier polyglycerol-2 dipolyhydroxystearate, the content of the polyglycerol-2 dipolyhydroxystearate is 2.8 percent, and the content of other components and the preparation method are not changed.

Comparative example 6

The comparative example provides a lip glaze comprising the following components in percentage by weight:

the lip glaze provided in this comparative example was prepared in the same manner as in example 1.

Comparative example 7

The comparative example provides a lip glaze comprising the following components in percentage by weight:

the lip glaze provided in this comparative example was prepared in the same manner as in example 1.

Test example 1

Experiment of oral acute toxicity in mice

According to the Hohne method, 70 healthy mice are selected and divided into 7 groups of 10 mice each, each group having half of male and female. Average body weight of female mice (19.4 + -1.6) g, male mice (18.5 + -1.5) g. Experimental samples the gloss mirror-surface color-retaining lip glaze prepared according to examples 1-7 of the present invention was administered orally at a dose of 21.5, 10.0, 4.64, 2.15g/(kg · bw) once, and after the test substance was administered orally, the animal was observed for a period of two weeks for the toxic reaction and death, and the test results of half of the lethal dose of mice are shown in table 1.

TABLE 1

The experimental result of the oral acute toxicity experiment of the mice shows that: all groups of mice have no abnormal reaction in an observation period, the growth condition is good, no death occurs, the final weight of female mice is (19.8 +/-1.6) g, the final weight of male mice is (18.6 +/-1.5) g, and LD50 is more than 31 g/(kg-bw); grading standard according to acute toxicity. The paint gloss mirror surface color-holding lip glaze prepared by the invention belongs to a non-toxic substance and can reach the edible level.

Test example 2

Durable effect test

70 healthy volunteer women are selected, aged 20-40 years are selected, no serious system disease, immunodeficiency or autoimmune disease exists, no allergy exists on cosmetics, no acute inflammation exists on the face, no hormone medicine or immunosuppressant is used, no other clinical test is carried out, no external preparation is applied, the groups are randomly divided into 14 groups, 5 people are in each group, the paint light mirror surface color-retaining lip glaze prepared in the above examples 1-7 and the lip glaze prepared in the comparative examples 1-7 are respectively applied to the lips and skins of the volunteers in the groups, and the effects of the lips and the skins of the volunteers are detected after 2 h. The lip moisture content (%) and the lip color change (the difference Δ L between the skin color tone after the lip glaze is used and before the lip mask is used, the larger Δ L indicates the more color tone of the lip with residual color, the better the gloss and the durability), were measured by a skin moisture meter, and the specific test results are shown in table 2:

TABLE 2

| Test sample | Lip moisture content (%) | Lip color change (DeltaL) |

| Example 1 | 60.2 | 2.2 |

| Example 2 | 56.9 | 2.1 |

| Example 3 | 58.3 | 2.1 |

| Example 4 | 57.2 | 2.2 |

| Example 5 | 56.8 | 2.2 |

| Example 6 | 55.6 | 2.1 |

| Example 7 | 55.2 | 2.1 |

| Comparative example 1 | 48.0 | 1.5 |

| Comparative example 2 | 49.1 | 1.6 |

| Comparative example 3 | 54.7 | 2.0 |

| Comparative example 4 | 48.2 | 1.6 |

| Comparative example 5 | 54.3 | 2.0 |

| Comparative example 6 | 54.7 | 2.0 |

| Comparative example 7 | 50.8 | 2.0 |

From the above test data, it can be known that the lip moisture content of the gloss mirror surface color-retaining lip glaze prepared in the embodiments 1 to 7 is above 55% after being coated for 2 hours, and the lip color change (Δ L) value is above 2.1, which fully indicates that the gloss mirror surface color-retaining lip glaze of the present invention is an oil-in-water lip product, oil is an internal phase, and water is a continuous external phase, thereby well solving the greasy feeling of the oil paste product. Meanwhile, the oil phase film forming agent and the grease are matched with each other, and the glossiness, the persistence and the moistening degree of the lip glaze are greatly improved under the synergistic effect.

Test example 3

Lip glaze human body experiment

Selecting 1 healthy volunteer without serious system diseases, immunodeficiency or autoimmune diseases, allergy to cosmetics, acute inflammation on the face, hormone drugs or immunosuppressants, other clinical tests and external preparations, coating the gloss mirror color-retaining lip glaze prepared in the examples 1 to 7 and the lip glaze prepared in the comparative examples 1 to 7 on the skin of the lips of the volunteer, and taking pictures of the lips of the volunteer at four time points of the beginning, 2h, 4h and 6h respectively, wherein the pictures of the lips of the volunteer are respectively pictures of the lips of the volunteer coated with the gloss mirror color-retaining lip glaze prepared in the example 1 at the four time points in fig. 1A to 1C; FIGS. 2A-2C are photographs of the lips of volunteers who applied the paint-finish mirror-hold lip glaze prepared in example 2 at the four time points described above, respectively; FIGS. 3A-3C are photographs of the lips of volunteers who applied the gloss mirror color-retaining lip glaze prepared in example 3 at the four time points described above, respectively; FIGS. 4A to 4C are photographs of the lips of volunteers who applied the lip glaze prepared in comparative example 1 at the above four time points, respectively; FIGS. 5A to 5C are photographs of the lips of volunteers applied with the lip glaze prepared in comparative example 2 at the above four time points, respectively; FIGS. 6A to 6C are photographs of the lips of the volunteer who applied the lip glaze prepared in comparative example 3 at the above four time points, respectively; fig. 7A to 7C are photographs of the lips of the volunteer who applied the lip glaze prepared in comparative example 4 at the above four time points, respectively.

As is apparent from the above photographs, the lip gloss, color saturation, water wettability and persistence of the volunteer coated with the paint-luster mirror surface color-retaining lip glaze are obviously improved. This is sufficient to show that the lip glaze of the present invention has the glossiness and high color saturation of the all-oil type and water-in-oil type lip glazes, and at the same time, has higher water-wettability than the water-in-oil type lip glazes and the all-oil type lip glazes.

Test example 4

Poll testing

Female volunteers 20-40 years old, 70 people in total, were selected by the opinion score method. The gloss mirror color-holding lip glaze prepared in the above examples 1 to 7 and the lip glaze prepared in the comparative examples 1 to 7 were applied to lips of volunteers, and evaluation items of the above gloss, color saturation and cleaness were evaluated in sensory evaluation on 5 grades, wherein 5 grades were excellent; 4 is excellent; 3, dividing into general parts; 2 is divided into a difference; 1 is very poor; and the volunteers are asked to score at four time points of 0h (initial just smearing), 2h, 4h and 6h respectively, the average value of the evaluators is taken, the evaluation items of the persistence are expressed in percentage form, the initial is 100%, the evaluation results of the glossiness, the color saturation and the freshness are shown in table 4, and the evaluation results of the persistence are shown in table 5:

TABLE 4

TABLE 5

As can be seen from the results of the civil investigation, the lip gloss, the color saturation, the water wettability and the persistence of the volunteer coated with the paint light mirror surface color-retaining lip glaze are obviously improved. This is sufficient to show that the lip glaze of the present invention has the glossiness and high color saturation of the all-oil type and water-in-oil type lip glazes, and at the same time, has higher water-wettability than the water-in-oil type lip glazes and the all-oil type lip glazes.

The applicant states that the invention is illustrated by the above examples to the paint-finishing mirror color-retaining lip glaze and the preparation method thereof, but the invention is not limited to the above examples, i.e. it does not mean that the invention must be implemented by means of the above examples. It will be apparent to those skilled in the art that any modification of the present invention, equivalent substitutions of selected materials and additions of auxiliary components, selection of specific modes and the like, which are within the scope and disclosure of the present invention, are contemplated by the present invention.

Claims (26)

1. The color-holding lip glaze for the glazed surface of the paint is characterized by comprising the following components in percentage by weight: 42-52.5% of grease, 2.3-8% of oil-in-water emulsifier, 0.05-15% of colorant, 7-10% of oil phase film forming agent, 3-8% of water phase film forming agent, 2.52-3.43% of thickening agent, 1-5% of humectant, 0.1-0.5% of preservative and the balance of water;

the mass ratio of the oil phase film-forming agent to the water phase film-forming agent is (1-1.5) to 1;

the oil phase film former comprises ethyl cellulose, polybutene and dioleyl dilinoleate;

the aqueous phase film forming agent comprises polyurethane copolymer latex and acrylic acid/ethylhexyl acrylate copolymer latex;

the grease comprises any one or the combination of at least two of octyl dodecanol, phenyl trimethicone, diisostearyl malate, isododecane, a pinosyl extract or polydimethylsiloxane;

the oil-in-water emulsifier comprises polysorbate-60 in combination with sorbitan stearate or cetearyl alcohol, coco glucoside in combination with polysorbate-20;

the thickening agent comprises any one or combination of at least two of cetearyl alcohol, carbomer or aminomethyl propanol.

2. The paint light mirror color lip gloss according to claim 1, wherein said colorant comprises any one or a combination of at least two of CI 17200, CI 75457, CI 45380, CI 15850, CI 45410, CI 42090, CI 15985, borosilicate, titanium dioxide, or mica powder.

3. The paint gloss mirror color lip glaze according to claim 1, wherein the humectant comprises any one or a combination of at least two of glycerin, propylene glycol, butylene glycol, or dipropylene glycol.

4. The paint gloss mirror color lip glaze according to claim 1, wherein the preservative comprises any one or a combination of at least two of phenoxyethanol, ethylhexyl glycerol, p-hydroxyacetophenone or glyceryl caprylate.

5. The paint mirror surface color-retaining lip glaze according to claim 1, characterized in that the paint mirror surface color-retaining lip glaze further comprises a cosolvent.

6. The paint mirror surface color-retaining lip glaze according to claim 5, wherein the weight percentage of the cosolvent in the paint mirror surface color-retaining lip glaze is 1-5%.

7. The paint mirror color-retaining lip glaze according to claim 5, wherein the cosolvent is edible alcohol.

8. The paint light mirror color lip glaze according to claim 1, wherein the paint light mirror color lip glaze further comprises an antioxidant.

9. The paint light mirror color lip glaze according to claim 8, wherein the antioxidant is 0.1-1% by weight of the paint light mirror color lip glaze.

10. The paint light mirror color lip glaze according to claim 1, wherein the paint light mirror color lip glaze further comprises an aromatic agent.

11. The paint gloss mirror surface color-retaining lip glaze according to claim 10, wherein the weight percentage of the aromatic in the paint gloss mirror surface color-retaining lip glaze is 0.1-0.5%.

12. The method for preparing the paint-light mirror surface color-retaining lip glaze according to any one of claims 1 to 11, characterized in that the preparation method specifically comprises the following steps:

(1) mixing a colorant with part of grease, grinding and dispersing to obtain color paste;

(2) stirring and dispersing an oil-in-water emulsifier, an oil phase film forming agent, residual grease and the color paste obtained in the step (1) to obtain an oil phase mixed solution; stirring and dispersing the aqueous phase film forming agent, the humectant and water to obtain an aqueous phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying to obtain the gloss mirror surface color-holding lip glaze;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing and stirring, cooling, adding the rest components, mixing and stirring to obtain a finished product.

13. The production method according to claim 12, wherein the mass of the partial fat in the step (1) is 10 to 20% of the total mass of the fat.

14. The method of claim 12, wherein the grinding of step (1) is carried out using a three-roll mill.

15. The method according to claim 12, wherein the number of grinding in step (1) is 2 to 5.

16. The method according to claim 12, wherein the temperature for stirring and dispersing the oil-phase mixture obtained in the step (2) is 75 to 85 ℃.

17. The method according to claim 12, wherein the time for stirring and dispersing the oil-phase mixture obtained in step (2) is 5 to 10 min.

18. The method according to claim 12, wherein the temperature for stirring and dispersing the aqueous mixture obtained in the step (2) is 75 to 85 ℃.

19. The method according to claim 12, wherein the time for stirring and dispersing the aqueous mixture obtained in the step (2) is 5 to 10 min.

20. The method as claimed in claim 12, wherein the emulsification rate in step (3) is 2000-3000 rpm.

21. The method according to claim 12, wherein the time for the emulsification in step (3) is 5-10 min.

22. The method according to claim 12, wherein the temperature for mixing and stirring the thickener added in the step (4) is 75 to 85 ℃.

23. The method according to claim 12, wherein the time for adding the thickener, mixing and stirring in the step (4) is 5 to 10 min.

24. The method according to claim 12, wherein the residual component in the step (4) is any one or a combination of at least two of a preservative, a cosolvent, an antioxidant or a perfume.

25. The method according to claim 12, wherein the temperature reduction in the step (4) is to be 30-50 ℃.

26. The method according to claim 12, comprising the steps of:

(1) mixing a colorant with grease accounting for 10-20% of the total mass of the grease, and grinding and dispersing for 2-5 times by using a three-roll machine to obtain color paste;

(2) mixing the oil-in-water emulsifier, the oil phase film forming agent, the residual grease and the color paste obtained in the step (1), and stirring and dispersing at 75-85 ℃ for 5-10min to obtain oil phase mixed liquid; mixing the aqueous phase film forming agent, humectant and water, stirring and dispersing at 75-85 deg.C for 5-10min to obtain aqueous phase mixed solution;

(3) mixing the oil phase mixed solution and the water phase mixed solution obtained in the step (2), and homogenizing and emulsifying at the speed of 2000-3000rpm for 5-10min to obtain the color-holding lip glaze of the paint finish surface;

(4) and (4) adding a thickening agent into the paint gloss mirror surface color-retaining lip glaze obtained in the step (3), mixing for 5-10min at 75-85 ℃, cooling to 30-50 ℃, adding the rest components, mixing and stirring for 5-10min to obtain a finished product.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911112658.0A CN110638691B (en) | 2019-11-14 | 2019-11-14 | Paint mirror surface color-holding lip glaze and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911112658.0A CN110638691B (en) | 2019-11-14 | 2019-11-14 | Paint mirror surface color-holding lip glaze and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110638691A CN110638691A (en) | 2020-01-03 |

| CN110638691B true CN110638691B (en) | 2022-07-08 |

Family

ID=68995963

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911112658.0A Active CN110638691B (en) | 2019-11-14 | 2019-11-14 | Paint mirror surface color-holding lip glaze and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110638691B (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111671673A (en) * | 2020-06-23 | 2020-09-18 | 泉后(广州)生物科技研究院有限公司 | Long-acting makeup holding powder base solution and preparation method thereof |

| CN111728899B (en) * | 2020-08-10 | 2023-01-17 | 丽鑫生技化妆品(上海)有限公司 | Three-layer lip glaze and preparation method thereof |

| CN112535647A (en) * | 2020-12-14 | 2021-03-23 | 广州艾蓓生物科技有限公司 | Degradable flash lip glaze and preparation method thereof |

| CN112641679A (en) * | 2020-12-29 | 2021-04-13 | 广州环亚化妆品科技有限公司 | Microcapsule and preparation method and application thereof |

| US20240099959A1 (en) * | 2021-03-05 | 2024-03-28 | Shiseido Company, Ltd. | Oil-in-water-type lip cosmetic |

| CN112656698A (en) * | 2021-03-15 | 2021-04-16 | 罗亚文 | Preparation process of anti-fading lipstick |

| CN113143777B (en) * | 2021-05-06 | 2022-07-26 | 美尚(广州)化妆品股份有限公司 | Oil-in-water lip cosmetic and preparation method thereof |

| CN114588080A (en) * | 2022-04-08 | 2022-06-07 | 广州卡洛莱化妆品有限公司 | Light and smooth lip glaze and preparation method thereof |

| CN114869807A (en) * | 2022-06-08 | 2022-08-09 | 上海臻臣化妆品有限公司 | All-natural water-containing lip glaze and preparation method thereof |

| CN115645309A (en) * | 2022-11-10 | 2023-01-31 | 广东雅丽诗科技有限公司 | Color-fixing lasting moisturizing velvet lip glaze and production process thereof |

| CN118477000A (en) * | 2024-03-04 | 2024-08-13 | 广州莱倩化妆品有限公司 | Mirror surface color-retaining lip glaze and preparation method thereof |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2871057A1 (en) * | 2004-06-08 | 2005-12-09 | Oreal | COSMETIC COMPOSITION CONTAINING AN ESTER AND A FILMOGENIC AGENT |

| CN104352359A (en) * | 2014-10-13 | 2015-02-18 | 万华化学集团股份有限公司 | Strippable facial mask substrate based on waterborne polyurethane dispersoid |

| CN105209010A (en) * | 2013-03-14 | 2015-12-30 | 雅芳产品公司 | Long-wearing glossy lipcolor |

| TW201711673A (en) * | 2015-06-26 | 2017-04-01 | 愛茉莉太平洋股份有限公司 | Lip cosmetic composition emulisified as water-in-oil type comprising a water-soluble polymer |

| FR3075630A1 (en) * | 2017-12-22 | 2019-06-28 | Lvmh Recherche | OIL-IN-WATER EMULSION FOR MAKE-UP AND LIP CARE |

| CN110200867A (en) * | 2019-06-12 | 2019-09-06 | 苏州绿叶日用品有限公司 | A kind of anti-wrinkle sleep mask and preparation method thereof |

| CN110302094A (en) * | 2019-07-16 | 2019-10-08 | 广州艾蓓生物科技有限公司 | A kind of non-sticky cup lip glaze of high glaze and preparation method thereof |

-

2019

- 2019-11-14 CN CN201911112658.0A patent/CN110638691B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2871057A1 (en) * | 2004-06-08 | 2005-12-09 | Oreal | COSMETIC COMPOSITION CONTAINING AN ESTER AND A FILMOGENIC AGENT |

| CN105209010A (en) * | 2013-03-14 | 2015-12-30 | 雅芳产品公司 | Long-wearing glossy lipcolor |

| CN104352359A (en) * | 2014-10-13 | 2015-02-18 | 万华化学集团股份有限公司 | Strippable facial mask substrate based on waterborne polyurethane dispersoid |

| TW201711673A (en) * | 2015-06-26 | 2017-04-01 | 愛茉莉太平洋股份有限公司 | Lip cosmetic composition emulisified as water-in-oil type comprising a water-soluble polymer |

| FR3075630A1 (en) * | 2017-12-22 | 2019-06-28 | Lvmh Recherche | OIL-IN-WATER EMULSION FOR MAKE-UP AND LIP CARE |

| CN110200867A (en) * | 2019-06-12 | 2019-09-06 | 苏州绿叶日用品有限公司 | A kind of anti-wrinkle sleep mask and preparation method thereof |

| CN110302094A (en) * | 2019-07-16 | 2019-10-08 | 广州艾蓓生物科技有限公司 | A kind of non-sticky cup lip glaze of high glaze and preparation method thereof |

Non-Patent Citations (1)

| Title |

|---|

| "完美日记沁色微光水唇釉H17";广州逸仙电子商务有限公司;《国产非特殊用途化妆品备案服务平台》;20190917;第1-3页 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110638691A (en) | 2020-01-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110638691B (en) | Paint mirror surface color-holding lip glaze and preparation method thereof | |

| CN108938439B (en) | Liquid crystal type emulsified composition and preparation method and application thereof | |

| EP1500385B1 (en) | Method of foam stabilization for foam cosmetic | |

| JP6082981B2 (en) | Oil-in-water emulsified solid cosmetic | |

| EP1787628B1 (en) | Oily cosmetic preparation | |

| CN110339146B (en) | Water-in-oil-in-water foundation liquid and preparation method thereof | |

| CN108348782B (en) | Cosmetic composition for imparting natural skin color and healthy appearance effects | |

| KR102715221B1 (en) | Make-up cosmetic composition comprising scoria powder | |

| KR101590803B1 (en) | Cosmetic composition for quick whitening or improving skin tone comprising calamine | |

| CN111920711B (en) | Gel composition and preparation method and application thereof | |

| KR20200102915A (en) | Oil-in-water emulsion for lip makeup and care | |

| JP2017048158A (en) | Makeup cosmetic | |

| JP7256624B2 (en) | Gel-form external preparation for skin or skin cosmetics | |

| KR101684415B1 (en) | Cosmetic composition of water-in-oil with liposome hexacarboxymethyl dipeptide-12 and menufacturing method thereof | |

| EP2100584A1 (en) | Foundation with UV filter combination | |

| CN115607472A (en) | Liquid foundation for dry skin and preparation method thereof | |

| JP4136965B2 (en) | Hair cosmetics | |

| CN110678162A (en) | Cosmetic composition exhibiting natural and healthy appearance | |

| JP3597520B2 (en) | External preparation for skin | |

| JP2003306410A (en) | Powder-containing water in oil type emulsion cosmetic | |

| CN107530252B (en) | Aqueous sunscreen cosmetic compositions free of surfactants | |

| JP2004123657A (en) | External preparation for skin | |

| JP2016193843A (en) | External composition | |

| JP6430789B2 (en) | Sunscreen cosmetics | |

| KR20160071744A (en) | Thermo-sensitive color cosmetic composition and the method of producing the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |