CN110631270B - Hot dry rock geothermal exploitation and utilization method and system - Google Patents

Hot dry rock geothermal exploitation and utilization method and system Download PDFInfo

- Publication number

- CN110631270B CN110631270B CN201910901845.0A CN201910901845A CN110631270B CN 110631270 B CN110631270 B CN 110631270B CN 201910901845 A CN201910901845 A CN 201910901845A CN 110631270 B CN110631270 B CN 110631270B

- Authority

- CN

- China

- Prior art keywords

- heat exchange

- heat

- bacteria

- pipe

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000011435 rock Substances 0.000 title claims abstract description 221

- 238000000034 method Methods 0.000 title claims abstract description 103

- 239000007788 liquid Substances 0.000 claims abstract description 235

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 186

- 238000009826 distribution Methods 0.000 claims abstract description 125

- 238000012544 monitoring process Methods 0.000 claims abstract description 105

- 238000005553 drilling Methods 0.000 claims abstract description 19

- 241000894006 Bacteria Species 0.000 claims description 215

- 239000012530 fluid Substances 0.000 claims description 107

- 230000001580 bacterial effect Effects 0.000 claims description 57

- 238000013528 artificial neural network Methods 0.000 claims description 48

- 230000035605 chemotaxis Effects 0.000 claims description 44

- 238000010438 heat treatment Methods 0.000 claims description 42

- 238000005338 heat storage Methods 0.000 claims description 40

- 230000005540 biological transmission Effects 0.000 claims description 38

- 230000008569 process Effects 0.000 claims description 37

- 239000011232 storage material Substances 0.000 claims description 34

- 230000008859 change Effects 0.000 claims description 33

- 239000010410 layer Substances 0.000 claims description 33

- 238000004806 packaging method and process Methods 0.000 claims description 33

- 230000010076 replication Effects 0.000 claims description 30

- 238000002347 injection Methods 0.000 claims description 27

- 239000007924 injection Substances 0.000 claims description 27

- 239000012071 phase Substances 0.000 claims description 24

- 239000004568 cement Substances 0.000 claims description 20

- 238000005457 optimization Methods 0.000 claims description 18

- 230000009191 jumping Effects 0.000 claims description 15

- 239000011229 interlayer Substances 0.000 claims description 14

- 235000006508 Nelumbo nucifera Nutrition 0.000 claims description 13

- 240000002853 Nelumbo nucifera Species 0.000 claims description 13

- 230000002431 foraging effect Effects 0.000 claims description 12

- 230000006870 function Effects 0.000 claims description 9

- 239000004576 sand Substances 0.000 claims description 9

- 230000001276 controlling effect Effects 0.000 claims description 8

- 239000003795 chemical substances by application Substances 0.000 claims description 6

- 239000013013 elastic material Substances 0.000 claims description 6

- 230000036541 health Effects 0.000 claims description 6

- 238000009413 insulation Methods 0.000 claims description 6

- 230000005012 migration Effects 0.000 claims description 6

- 238000013508 migration Methods 0.000 claims description 6

- 238000012163 sequencing technique Methods 0.000 claims description 6

- 239000007790 solid phase Substances 0.000 claims description 6

- 239000008400 supply water Substances 0.000 claims description 6

- 230000010415 tropism Effects 0.000 claims description 6

- 239000011148 porous material Substances 0.000 claims description 5

- 238000004321 preservation Methods 0.000 claims description 5

- 239000000243 solution Substances 0.000 claims description 5

- 238000001514 detection method Methods 0.000 claims description 4

- 238000005065 mining Methods 0.000 claims description 4

- 238000005086 pumping Methods 0.000 claims description 4

- 230000005484 gravity Effects 0.000 claims description 3

- 230000033001 locomotion Effects 0.000 claims description 3

- 238000002360 preparation method Methods 0.000 claims description 3

- 238000005070 sampling Methods 0.000 claims description 3

- 230000003068 static effect Effects 0.000 claims description 3

- 230000005489 elastic deformation Effects 0.000 claims description 2

- 230000001537 neural effect Effects 0.000 claims description 2

- 230000001105 regulatory effect Effects 0.000 claims description 2

- 230000008901 benefit Effects 0.000 abstract description 4

- 238000013461 design Methods 0.000 abstract description 4

- 230000000694 effects Effects 0.000 abstract description 3

- 238000004134 energy conservation Methods 0.000 abstract description 2

- 238000005516 engineering process Methods 0.000 description 10

- 238000011161 development Methods 0.000 description 9

- 230000002829 reductive effect Effects 0.000 description 7

- 238000000605 extraction Methods 0.000 description 6

- 238000002844 melting Methods 0.000 description 5

- 230000008018 melting Effects 0.000 description 5

- 238000010276 construction Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000012782 phase change material Substances 0.000 description 4

- 230000005855 radiation Effects 0.000 description 3

- 238000011160 research Methods 0.000 description 3

- 238000004378 air conditioning Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 125000004122 cyclic group Chemical group 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000003399 chemotactic effect Effects 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 230000002860 competitive effect Effects 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000005538 encapsulation Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000009349 indirect transmission Effects 0.000 description 1

- 239000012774 insulation material Substances 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000009347 mechanical transmission Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000009877 rendering Methods 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24T—GEOTHERMAL COLLECTORS; GEOTHERMAL SYSTEMS

- F24T10/00—Geothermal collectors

- F24T10/10—Geothermal collectors with circulation of working fluids through underground channels, the working fluids not coming into direct contact with the ground

- F24T10/13—Geothermal collectors with circulation of working fluids through underground channels, the working fluids not coming into direct contact with the ground using tube assemblies suitable for insertion into boreholes in the ground, e.g. geothermal probes

- F24T10/17—Geothermal collectors with circulation of working fluids through underground channels, the working fluids not coming into direct contact with the ground using tube assemblies suitable for insertion into boreholes in the ground, e.g. geothermal probes using tubes closed at one end, i.e. return-type tubes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24T—GEOTHERMAL COLLECTORS; GEOTHERMAL SYSTEMS

- F24T10/00—Geothermal collectors

- F24T10/40—Geothermal collectors operated without external energy sources, e.g. using thermosiphonic circulation or heat pipes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24T—GEOTHERMAL COLLECTORS; GEOTHERMAL SYSTEMS

- F24T50/00—Geothermal systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D20/00—Heat storage plants or apparatus in general; Regenerative heat-exchange apparatus not covered by groups F28D17/00 or F28D19/00

- F28D20/02—Heat storage plants or apparatus in general; Regenerative heat-exchange apparatus not covered by groups F28D17/00 or F28D19/00 using latent heat

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24T—GEOTHERMAL COLLECTORS; GEOTHERMAL SYSTEMS

- F24T10/00—Geothermal collectors

- F24T2010/50—Component parts, details or accessories

- F24T2010/56—Control arrangements

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/10—Geothermal energy

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/14—Thermal energy storage

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E70/00—Other energy conversion or management systems reducing GHG emissions

- Y02E70/30—Systems combining energy storage with energy generation of non-fossil origin

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Road Paving Structures (AREA)

Abstract

The invention discloses a method and a system for exploiting and utilizing geothermal heat of hot dry rock, wherein the method comprises the following steps: firstly, detecting geothermal energy and drilling a well; secondly, fixing the supporting plate; thirdly, preparing an underground rock stratum heat exchange tube; fourthly, connecting the liquid distribution box with the underground rock stratum heat exchange tube; fifthly, the underground rock stratum heat exchange pipe goes down the well; sixthly, putting the heat source side water supply main pipe and the heat source side water return main pipe into a well; seventhly, connecting a heat source side pipeline with a primary heat supply network pipeline; eighthly, connecting the primary heat supply network pipeline and the secondary heat supply network pipeline; ninth, the connection of the secondary heat supply network pipeline and the load side pipeline; tenth, connecting the data acquisition and monitoring circuit of the heat source side pipeline; eleven, connecting a data acquisition and monitoring circuit of a side pipeline of the ground heat exchange system; and twelfth, operating the underground heat exchange system. The method has the advantages of simple steps, novel design, convenience, energy conservation, capability of realizing efficient geothermal exploitation and utilization, capability of achieving a good energy-saving effect, strong practicability and high popularization and application values.

Description

Technical Field

The invention belongs to the field of geothermal resource exploitation and clean energy utilization, and particularly relates to a method and a system for exploiting and utilizing geothermal energy of dry hot rocks.

Background

The economic construction of China is rapidly developed, and the demand on energy is rapidly increased. The coal reserves in China are relatively rich, but a large amount of pollution is generated in the process of mining and utilizing, so that the ecological environment is seriously influenced, and meanwhile, the petroleum resources in China are deficient and the external dependence degree is high, so that the potential risk is brought to the national energy safety. The development and utilization of clean renewable energy sources are important measures for changing the energy development mode and adjusting the energy structure.

Geothermal resources, as a very competitive clean renewable energy source, have become a new topic of active experimental research in the world due to their renewable, pollution-free and abundant reserves.

The geothermal energy is divided into shallow geothermal energy, hydrothermal geothermal resources and dry hot rock geothermal resources according to the buried depth. The ground source heat pump heat supply technology utilizing shallow geothermal energy has developed in China for nearly 20 years, but the ground source heat pump heat supply technology still faces various problems and limitations in popularization and application, and the dry hot rock heat supply technology with great development potential is in a preliminary development stage. At present, a plurality of technical problems exist in the development of the dry and hot rock, no mature theoretical technology can be used for reference at abroad, a multidisciplinary joint attack is urgently needed, and the key technology in the development of the dry and hot rock is deeply researched. Including fracturing and artificial storage techniques, heat exchange and heat energy extraction techniques. The fracturing and manual storage project mainly researches the directions of crack and extension control, later-stage temperature change characteristic and crack network change prediction, vertical crack fracturing design, crack distribution monitoring and the like. Three technical requirements of heat extraction and heat system service life, fluid extraction temperature and efficiency guarantee, energy consumption reduction and cyclic loss need to be met, but the problems of low artificial underground heat storage geothermal extraction efficiency and high heat exchange fluid loss rate exist in the existing hot dry rock geothermal mining technology, technical indexes such as heat extraction and heat system service life, fluid extraction temperature and efficiency, energy consumption and cyclic loss are not met, and a large amount of tests and investigation work still needs to be carried out.

In 5 months of 2015, designing a deep dry hot rock resource exploration well with the depth of 4000 meters to drill in a clear spring forest farm in Zhangzhou city of Fujian, which is the first deep dry hot rock resource exploration well in China implemented by the geological survey bureau in China. In 9 months of 2017, exploration personnel drill a high-temperature dry and hot rock mass at 236 ℃ in 3705 meters deep in the Qinghai-Harmony basin, which is the dry and hot rock mass which is drilled and buried shallowest and has the highest temperature for the first time in China, and the major breakthrough of China in dry and hot rock exploration is realized. In 2018, in 5 months, the first dry hot rock parameter well in the east of China is well drilled. The research meeting of dry hot rock selection, exploration and development academy held by multiple units such as China geological university and national geothermal energy center, reveals that after 66 days of drilling, the first dry hot rock parameter well in the east of China is drilled in northeast China completely, and the drill well drills the dry hot rock with the temperature of more than 185 ℃ in the depth of 4387 meters, which indicates that the dry hot rock exists in the east of China coastal, and has milestone significance for the development and utilization of the dry hot rock geothermal energy of China.

The traditional central heating mode in northern China adopts hot water or steam generated by a central heat source as a heating medium, and supplies heat to production, heating and living heat users in a town or a larger area through a heat supply network. The centralized heating in cities and towns is characterized by large investment, large boiler, large chimney and large centralized mode of large pipe network. The method has the advantages of causing a series of problems of huge construction investment, low energy-saving and emission-reducing level, overlong pipe network, serious loss, inflexible heat supply regulation, standard and many-cause toll and the like. At present, the drilling technology of the dry hot rock is broken through, but the uncontrollable property of the underground heat storage construction technology is high. The heat exchange fluid leakage in the artificial heat reservoir is serious on one hand, and the seepage channel resistance of the heat exchange fluid in the artificial heat reservoir is large on the other hand.

Aiming at the problems, a method and a system for taking hot dry rock are provided by combining the current technical development situation. The artificial heat storage is constructed by utilizing a drilling well, heat is efficiently taken from a dry heat rock stratum through an underground rock stratum heat exchange tube, and stable and reliable heat supply all the year round is realized by combining a novel overground heat exchange system.

Disclosure of Invention

The invention aims to solve the technical problem of providing a hot dry rock geothermal exploitation method aiming at the defects in the prior art, which is a hot dry rock geothermal exploitation method for utilizing an artificial drilling technology to extract heat through heat exchange fluid in an underground rock heat exchange pipe; the traditional centralized heating technology in China has a series of problems of large construction investment, low energy-saving level, long pipe network, serious loss, inflexible heating regulation, many standard and many defects in charge and the like, and provides a dry hot rock geothermal utilization method for realizing novel distributed heating. The hot dry rock geothermal exploitation method and the hot dry rock geothermal utilization method are combined to comprehensively obtain the hot dry rock geothermal exploitation method.

In order to solve the technical problem, the technical scheme adopted by the invention is as follows: the geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps:

firstly, carrying out geothermal energy detection, drilling a main well, drilling an annular groove hole at the bottom of the main well, and drilling a plurality of auxiliary wells uniformly arranged around the main well at the bottom of the main well;

hoisting and fixing a support plate for fixedly supporting the well mouths of the multiple auxiliary wells into an annular groove hole at the bottom of the main well;

step three, preparing an underground rock stratum heat exchange tube;

step four, connecting the liquid distribution box and the underground rock stratum heat exchange tube;

step five, simultaneously putting a plurality of groups of underground rock stratum heat exchange tubes into the main well, ensuring that the sections of the corresponding positions of the underground rock stratum heat exchange tubes are positioned at the same horizontal plane position through a horizontal detector, and ensuring that the sections of the corresponding positions of the underground rock stratum heat exchange tubes smoothly pass through the supporting plates to enter the auxiliary wells; when the underground rock stratum heat exchange tube advances to the tail end of the auxiliary well, the liquid distribution box accurately falls on the set position on the supporting plate, and the liquid distribution box is lowered into the well and fixed;

sixthly, putting the heat source side water supply main pipe and the heat source side water return main pipe into the main well and reaching the position of the liquid distribution box;

connecting a heat source side water supply main pipe and a heat source side water return main pipe with a heat source side interface of the lotus root removing tank, and connecting a primary heat supply network water supply pipe and a primary heat supply network water return pipe with a heat supply network side interface of the lotus root removing tank;

step eight, connecting a secondary heat supply network water supply pipe on a reserved interface of the primary heat supply network water supply pipe, connecting a secondary heat supply network water return pipe on a reserved interface of the primary heat supply network water return pipe, and connecting the secondary heat supply network water supply pipe and the secondary heat supply network water return pipe with a heat exchange station heat supply network side interface;

step nine, connecting a load side water supply pipe and a load side water return pipe with a load side interface of the heat exchange station;

tenth, connecting the heat source side pipeline data acquisition and monitoring circuit;

eleven, connecting the data acquisition and monitoring circuit of the pipeline at the side of the overground heat exchange system;

step twelve, the cold heat exchange fluid enters the main well from the heat source side water supply main pipe and enters the underground rock heat exchange pipe through the liquid distribution box, the cold heat exchange fluid absorbs the heat of the underground rock after passing through the underground heat exchange system, the temperature is raised to become the heat exchange fluid, and the heat exchange fluid enters the heat source side water return main pipe from the underground rock heat exchange pipe and the liquid distribution box; the heat exchange fluid enters a pipeline at the side of the ground heat exchange system from the lotus root removing tank, and finally heat energy is used by a terminal user; cold heat exchange fluid enters the underground rock stratum heat exchange tube from the liquid distribution box to carry out primary heating; when the heat exchange fluid heated by the first stage reaches the tail end of the heat exchange tube of the underground rock stratum, the heat exchange fluid reversely flows towards the direction of the liquid distribution box, exchanges heat in the heat exchange tube of the underground rock stratum and carries out second stage heating; and in the running process of the underground heat exchange system, the underground data acquisition and monitoring system is used for monitoring and controlling related parameters of the underground heat exchange system.

The geothermal exploitation and utilization method for the hot dry rock is characterized in that a heat-preservation cement sleeve is arranged in the main well, a heat-conducting cement sleeve is arranged in the auxiliary well, a heat-conducting agent is coated in a gap between the heat-conducting cement sleeve and the hot dry rock, an infrared irradiation instrument is arranged in an annular groove hole in the bottom of the main well, the supporting plate comprises an L-L end plate and an M-M end plate, an X-shaped ribbed plate is arranged on the L-L end plate, the M-M end plate is a movable end plate, an infrared signal receiver used for receiving infrared signals emitted by the infrared irradiation instrument is arranged on the M-M end plate, a guide plate made of elastic materials is arranged at the lower part of the M-M end plate, and reserved holes for allowing underground rock heat exchange tubes to penetrate through are symmetrically arranged on the L-L end plate and the M-M end plate.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: the number of the guide plates is two, and the guide plates are respectively a 45-degree guide plate and a 135-degree guide plate;

and fifthly, in the process that the underground rock stratum heat exchange tube enters each auxiliary well, adjusting the speed of the underground rock stratum heat exchange tube going into the well according to the stress deformation characteristics of the 45-degree guide plate and the 135-degree guide plate, so that the 45-degree guide plate and the 135-degree guide plate generate elastic deformation at an angle of 45 degrees.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: the underground rock stratum heat exchange tube comprises a concentric sleeve, a heat exchange packaging sleeve and a monitoring disc, the tail end of the concentric sleeve is sealed, a high-temperature phase change heat storage material is filled in a concentric sleeve interlayer, the heat exchange packaging sleeve is fixed in an inner cavity of the concentric sleeve, a liquid injection tube and a liquid return cavity which are symmetrically arranged are arranged on the heat exchange packaging sleeve, a low-temperature phase change heat storage material is filled in the heat exchange packaging sleeve interlayer, and a data line wire collecting tube which is symmetrically arranged is arranged on the heat exchange packaging sleeve.

The three concrete processes for preparing the underground rock stratum heat exchange tube are as follows:

301, filling a solid-phase high-temperature phase change heat storage material in the concentric sleeve interlayer;

302, fastening a heat exchange packaging sleeve in an inner cavity of the concentric sleeve;

step 303, filling a solid-phase low-temperature phase change heat storage material into the interlayer of the heat exchange packaging sleeve;

step 304, fixing a monitoring disc at the tail end of the underground rock stratum heat exchange tube;

305, mounting a temperature sensor, a vacuum degree sensor and a flow velocity sensor at corresponding positions of a monitoring disc;

step 306, connecting the temperature sensor data line, the vacuum degree sensor data line and the flow velocity sensor data line with the temperature sensor, the vacuum degree sensor and the flow velocity sensor through reserved pore passages of the monitoring disc respectively, and then summarizing the data lines into a data line collecting pipe in the heat exchange packaging sleeve;

307, determining the lengths of underground rock stratum heat exchange tubes in a plurality of auxiliary wells according to the measured lengths of the auxiliary wells drilled;

308, repeating the steps 301 to 307 until the preparation of the underground rock stratum heat exchange tube is completed.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: the liquid distribution box comprises a shell, an A-A end plate, a C-C end plate, an E-E end plate and a G-G end plate, wherein a liquid collection cavity is formed by a closed region enclosed by the A-A end plate, the C-C end plate and the shell, a signal line cavity is formed by a closed region enclosed by the C-C end plate, the E-E end plate, the G-G end plate and the shell, a liquid distribution cavity is formed by a closed region enclosed by the E-A end plate, the A-A end plate is provided with a plurality of groups of symmetrically distributed liquid distribution holes, liquid return holes and data line wire collection holes, the C-C end plate is provided with liquid return collection holes and a plurality of groups of symmetrically distributed liquid distribution holes and data line wire collection holes, the E-E end plate is provided with liquid return collection holes and a plurality of groups of symmetrically distributed liquid distribution holes, and the G-G end plate is provided with a group of symmetrically distributed liquid return collection holes and liquid return collection holes, the liquid distribution pipe is connected with the liquid distribution hole on the E-E end plate through the liquid distribution hole on the A-A end plate, the liquid return collecting pipe is connected with the liquid return collecting hole on the G-G end plate through the liquid return collecting hole on the C-C end plate, the bottom of the A-A end plate is provided with an X-shaped slotted hole, a vacuum pumping valve and a vacuum degree sensor are arranged in a signal line cavity of the liquid distribution box, and a temperature sensor and a flow velocity sensor are arranged in the liquid return collecting pipe and the liquid injection collecting pipe of the liquid distribution box;

when the liquid distribution box and the underground rock stratum heat exchange tube are connected in the fourth step, the liquid distribution hole, the liquid return hole and the data line collecting hole in the A-A end plate of the liquid distribution box are respectively connected with the liquid injection tube, the liquid return cavity and the data line collecting tube in the heat exchange packaging sleeve;

when the liquid distribution box accurately falls on the set position on the supporting plate in the step five, the X-shaped rib plate on the L-L end plate is matched with the X-shaped slotted hole at the bottom of the A-A end plate;

putting the heat source side water supply main pipe and the heat source side water return main pipe into the main well and reaching the position of the liquid distribution box, namely the position of the G-G end plate of the liquid distribution box, and respectively connecting the heat source side water supply main pipe and the heat source side water return main pipe with a liquid injection header and a liquid return header on the G-G end plate of the liquid distribution box;

when the cold heat exchange fluid enters the underground rock stratum heat exchange tube through the liquid distribution box in the twelfth step, the cold heat exchange fluid firstly enters the liquid distribution cavity through the liquid injection collecting holes in the G-G end plate of the liquid distribution box; the cold heat exchange fluid enters the liquid separating pipe from the liquid separating holes symmetrically distributed on the E-E end plate and enters the liquid injecting pipe in the underground rock stratum heat exchange pipe through the liquid separating holes symmetrically distributed on the A-A end plate;

the specific process that the heat exchange fluid enters the heat source side water return main pipe from the underground rock stratum heat exchange pipe and the liquid distribution box in the step twelve is as follows: the heat exchange fluid enters the liquid collecting cavity from liquid returning cavities symmetrically distributed in the underground rock stratum heat exchange tube through liquid returning holes in the G-G end plate; the heat exchange fluid enters the liquid return header from the liquid return collecting holes on the C-C end plate and enters the heat source side water return header pipe through the liquid return collecting holes on the G-G end plate;

and a step twelve, the cold heat exchange fluid enters the underground rock stratum heat exchange tube from the liquid distribution box, and the specific process of primary heating is as follows: the cold heat-exchange fluid enters each liquid injection pipe in a plurality of groups of underground rock stratum heat exchange pipes from liquid separation holes symmetrically distributed on an A-A end plate of the liquid distribution box and flows towards the tail end of each group of underground rock stratum heat exchange pipes along the liquid injection pipes, and the cold heat-exchange fluid absorbs heat of the heat-exchange fluid in the liquid cavity in the liquid injection pipes to carry out primary heating;

and step twelve, when the heat exchange fluid after primary heating reaches the tail end of the heat exchange tube of the underground rock stratum, reversely flows towards the liquid distribution box, exchanges heat in the heat exchange tube of the underground rock stratum, and the specific process of secondary heating is as follows: the heat exchange fluid heated in the first stage reversely flows into each liquid return cavity and flows towards the liquid distribution box along the liquid return cavities, the inner wall of the concentric sleeve exchanges heat with the high-temperature phase-change heat storage material, the high-temperature phase-change heat storage material exchanges heat with the dry heat rock stratum through the outer wall of the concentric sleeve, the heat exchange fluid indirectly obtains heat from the dry heat rock, and meanwhile the heat exchange fluid heated in the first stage exchanges heat with the low-temperature phase-change heat storage material in the liquid return cavities; when the heat exchange fluid reaches the A-A end plate of the liquid distribution box, the heat exchange fluid flows into the liquid return holes symmetrically distributed on the A-A end plate.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: the underground data acquisition and monitoring system comprises a temperature sensor, a vacuum degree sensor, a flow velocity sensor, a temperature sensor data line, a vacuum degree sensor data line, a flow velocity sensor data line, a data line collecting pipe, a signal line cavity, a data transmission line, a monitoring disc, a data acquisition module, a data monitoring module and a computer;

the specific process of performing the connection of the heat source side pipeline data acquisition and the monitoring circuit in the step ten is as follows:

step 1001, installing the temperature sensor, the vacuum degree sensor and the flow velocity sensor at corresponding positions of a monitoring disc;

step 1002, connecting a temperature sensor data line, a vacuum degree sensor data line and a flow velocity sensor data line with the temperature sensor, the vacuum degree sensor and the flow velocity sensor through reserved pore passages of a monitoring disc respectively, and then summarizing the data lines into a data line collecting pipe in the heat exchange packaging sleeve;

step 1003, the data line collecting pipes are communicated with a signal line cavity through data line collecting holes in an A-A end plate of the liquid distribution box, data transmission lines in a plurality of groups of underground rock layer heat exchange tubes are collected into groups in the signal line cavity, and the data line collecting pipes are connected to a data acquisition module and a data monitoring module on the ground through the data line collecting pipes respectively arranged in a heat source side water supply main pipe heat insulation layer and a heat source side water return main pipe heat insulation layer;

step 1004, the data acquisition module and the data monitoring module are connected to a computer through a data transmission line;

in the running process of the underground heat exchange system in the twelfth step, the specific process that the underground data acquisition and monitoring system is used for monitoring and controlling the related parameters of the underground heat exchange system is as follows: the flow velocity sensor, the temperature sensor and the vacuum degree sensor are arranged on the monitoring disc, and the flow velocity, the temperature and the vacuum degree of the heat exchange fluid are measured at intervals of a certain time; the data transmission line transmits the measured signal to the data acquisition module and the data monitoring module; the data acquisition module and the data monitoring module are used for connecting and displaying the flow velocity signal of the heat exchange fluid at each measuring point, the temperature signal of the heat exchange fluid at each measuring point and the vacuum cavity vacuum degree signal at each measuring point on a computer so as to monitor and control related parameters of the underground heat exchange system.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: the overground heat exchange system side pipeline comprises a primary heat supply network water supply pipe, a primary heat supply network water return pipe, a primary heat supply network bypass pipe, a secondary heat supply network water supply pipe, a secondary heat supply network water return pipe, a load side water supply pipe and a load side water return pipe;

the side pipeline data acquisition and monitoring system of the overground heat exchange system comprises: the system comprises a heat source circulating pump, a primary heat supply network circulating pump, a secondary heat supply network circulating pump, a differential pressure sensor, a temperature difference sensor, a control actuator, a data transmission line, a pressure sensor data line, a temperature sensor data line, a variable frequency regulator, a data acquisition module, a data monitoring module and a computer;

step eleven, the specific process of performing the connection of the overground heat exchange system side pipeline data acquisition and monitoring circuit is as follows:

1101, additionally arranging a variable frequency regulator on the circulating water pump, wherein the variable frequency regulator is connected to a control actuator through a data transmission line;

step 1102, a temperature sensor is arranged on a water supply pipe of a system where the circulating water pump is located, one end of a data line of the temperature sensor is connected to the temperature sensor, and the other end of the data line of the temperature sensor is connected to a control actuator;

step 1103, mounting a temperature sensor on a water return pipe of a system where the circulating water pump is located, wherein one end of a data line of the temperature sensor is connected to the temperature sensor, and the other end of the data line of the temperature sensor is connected to a control actuator;

1104, repeating 1101, 1102 and 1103, and sequentially connecting a heat source circulating pump, a primary heat supply network circulating pump and a secondary heat supply network circulating pump to the data acquisition and monitoring system;

step 1105, installing a flow switch on the primary heat supply network bypass pipe, wherein the flow switch is connected with the control actuator through a data transmission line;

step 1106, installing a pressure sensor on a primary heat supply network water supply pipe, wherein one end of a pressure sensor data line is connected to the pressure sensor, and the other end of the pressure sensor data line is connected to a control actuator;

step 1107, a pressure sensor is arranged on a primary heat supply network water return pipe, one end of a pressure sensor data line is connected to the pressure sensor, and the other end of the pressure sensor data line is connected to a control actuator;

step 1108, connecting the control actuators to a data acquisition module and a data monitoring module respectively through data transmission lines;

and step 1109, connecting the data acquisition module and the data monitoring module with a computer through a data transmission line.

The geothermal exploitation and utilization method of the hot dry rock is characterized by comprising the following steps: in the data acquisition and monitoring system for the side pipeline of the overground heat exchange system, the heat source circulating pump, the primary heat supply network circulating pump and the secondary heat supply network circulating pump run in a variable flow mode, a return water supply temperature difference control mode is adopted in the variable flow regulation mode, the return water supply temperature difference of the circulating pipeline where the water pump is located is constant, the rotating speed is adjusted according to the change of the temperature difference, an optimized fuzzy neural network PID control method is adopted in the control method, and the specific process is as follows:

the method comprises the following steps that firstly, a controller periodically samples the temperature difference of supply water and return water;

step two, the controller is according to the formulaThe temperature difference of the supply water and the return water obtained by sampling the ith timeTemperature difference between the water supply and the return waterMaking a difference to obtain a deviation ei;

Step two, the controller is according to the formulaFor deviation eiDerivative to obtain a deviation eiRate of change over time t

step four, the controller will eiAnddividing fuzzy subsets, determining the number of nodes of a fuzzy layer in a fuzzy neural network, wherein a Gaussian function is adopted as a membership function;

step five, the controller determines the number of nodes of a fuzzy rule layer in the fuzzy neural network;

step six, the controller resolves the ambiguity of the de-ambiguity layer in the fuzzy neural network by adopting a gravity center method to form a node which is used as a node of a PID input layer in the PID neural network;

step seven, the controller enables KP、KI、KDAs in PID neural networksThree nodes of the PID layer adopt an improved bacterial foraging optimization algorithm to optimize the weight of the PID neural network, so that the K of the static parameterP、KI、KDConverting into a dynamic adjustment form;

the specific process of optimizing the weight of the PID neural network by adopting the improved bacterial foraging optimization algorithm is as follows:

step 701, initializing bacterial foraging optimization algorithm parameters: the bacterial foraging optimization algorithm parameters comprise a search working dimension p of the weight of the total number S, PID of bacteria corresponding to the weight of the PID neural network in the bacterial flora, and chemotaxis times N of the weight of the PID neural networkcMaximum step number N of weight unidirectional motion of PID neural network in chemotaxis processSAnd the copy number N of the weight of the PID neural networkreAnd the learning times N of the weight of the PID neural networkedMaximum chemotaxis step length C of weight of PID neural networkmaxAnd minimum chemotaxis step length C of weight of PID neural networkmin;

Step 702, initializing the flora position: by means of random initialization and according to the formula X ═ Xmin+rand×(Xmax-Xmin) Initializing 2S points in p-dimensional space as initialization positions of bacteria, wherein S bacteria are randomly selected as flora X1The remaining S bacteria are used as flora X2;XminFor minimum value of the optimization interval, XmaxFor the maximum value of the optimization interval, X is the initialization position of the bacteria, and rand is uniformly distributed in [0,1 ]]A random number of intervals;

step 703, updating the fitness value: according to the formulaCalculating the fitness value of each bacterium; wherein d isattractDepth of attraction between bacteria, wattractWidth of attraction between bacteria, hrepellantHeight of repulsion between bacteria, wrepella ntThe width of the repulsive force between bacteria, P (i, j, k, l) is the j-th tropism operation and the k-th replication operation of the bacteria iThe location after the first migration operation, P (1: S, J, k, l) is a random location in the neighborhood of the current individual P (i, J, k, l), JCC(i, j, k, l) is the fitness value of the bacterium i after the jth tropism operation, the kth replication operation and the l migration operation;

step 704, setting parameters of the circulation variables: wherein the chemotaxis cycle number j is 1 to NcThe number of reproduction cycles k is 1 to NreLearning cycle times l is 1-Ned;

Step 705, entering a chemotaxis cycle to perform chemotaxis operation, wherein the specific method comprises the following steps:

against bacterial flora X2Chemotaxis of each bacterium was performed according to the following chemotaxis operation of step Q21 to step Q211:

step Q21, reassigning the bacteria i to i +1, judging whether the scale of the bacteria i is smaller than the scale S of the bacteria, executing the step Q22 when the scale of the bacteria i is smaller than the scale S of the bacteria, and executing the step Q212 when the scale of the bacteria i is not smaller than the scale S of the bacteria;

step Q22, calculating the fitness value of the bacterium i;

step Q23, bacteria i are turned one unit step in the randomly generated direction;

step Q24, initializing j to 1;

step Q25, calculating the fitness value of the bacteria i at the new position;

step Q26, judge if j is less than the maximum step number NcWhen less than, executing the step Q2, and when not less than, jumping to execute the step Q21;

step Q2, reassigning j to j + 1;

step Q28, determining whether the fitness value of bacterium i at the new position has changed, and if so, executing step Q29, and if not, making j equal to NSAnd jumps to execute step Q26;

step Q29, updating the fitness value of the bacterium i;

step Q210, the bacterial population continues to swim in the overturning direction;

step Q211, jumping to execute step Q25, and continuing to circulate until the value of i in step Q21 is equal to S;

step Q212, the chemotaxis operation is finished;

against bacterial flora X1Chemotaxis of each bacterium was performed according to the following chemotaxis operation of step Q11 to step Q112:

step Q11, reassigning the bacteria i to i +1, judging whether the scale of the bacteria i is smaller than the bacterial colony scale S, executing a step Q12 when the scale of the bacteria i is smaller than the bacterial colony scale S, and executing a step Q112 when the scale of the bacteria i is not smaller than the bacterial colony scale S;

step Q12, calculating the fitness value of the bacterium i;

step Q13, according to the formulaCalculating a bacterial flora density function factor D (i), calculating a chemotaxis step length C (i) according to a formula C (i) ═ A.D (i) + B, and turning the bacterium i in a randomly generated direction C (i), wherein L is the maximum length in a diagonal of a search space, X (m, i) is a position coordinate value of the bacterium i in the mth dimension of the search space,the average position coordinate value of all bacteria in the current search space in the mth dimension of the search space is obtained;

step Q14, initializing j to 1;

step Q15, calculating the fitness value of the bacteria i at the new position;

step Q16, judge if j is less than the maximum step number NcWhen less than, executing the step Q1, and when not less than, jumping to execute the step Q11;

step Q1, reassigning j to j + 1;

step Q18, determining whether the fitness value of bacterium i at the new position has changed, and if so, executing step Q19, and if not, making j equal to NSAnd jumps to execute step Q16;

step Q19, updating the fitness value of the bacterium i;

step Q110, the bacterial population continues to swim in the overturning direction;

step Q111, jumping to execute step Q15, and continuing to circulate until the value of i in step Q11 is equal to S;

step Q112, the chemotaxis operation is finished;

step 706, entering a replication cycle, and performing replication operation, wherein the method specifically comprises the following steps:

against bacterial flora X1Each bacterium was replicated according to the following replication operations of step F11 to step F16:

step F11, reassigning the bacteria i to i +1, judging whether the scale of the bacteria i is smaller than the scale S of the bacteria, executing the step F12 when the scale of the bacteria i is smaller than the scale S of the bacteria, and executing the step F16 when the scale of the bacteria i is not smaller than the scale S of the bacteria;

step F12, calculating the sum of the fitness of all positions passed by the bacteria in the last replication operation cycle, and defining the sum as a health value;

step F13, sequencing the bacteria according to the quality of the health value;

f14, jumping to execute the step F11;

step F15, eliminating the poor healthBacteria, the restEach bacterium divides a new individual which is completely the same as the bacterium itself;

step F16, the copying operation is finished;

against bacterial flora X2Each bacterium was replicated according to the following replication operations of step F21 to step F24:

step F21, calculating the fitness values of all bacteria, sequencing the bacteria in a sequence from small to large, and selecting the currently optimal bacteria as elite bacteria;

step F22, carrying out treatment on the currently best half of bacteria according to the formula X'2(i)=X2(i) + N (0,1) is mutated to generateThe new bacteria and the original bacteria form a new daughter bacterial flora X'2(ii) a Wherein N (0,1) is a Gaussian distribution with a mean value of 0 and a mean square error of 1;

step F23, performing cross operation on the worst half of the bacteria according to golden section ratio and the bacteria sorted in the first 61.8 percent and the elite bacteria selected in the step F21 to generateThe new bacteria and the original bacteria form a new daughter bacterial group X2;

Step F24, obtaining from daughter bacterial flora X'2Fungus group X2Selecting the first S bacteria with the best fitness value to replace the original bacteria group X2;

Step 707, entering a learning cycle to perform a learning operation, specifically comprising: bacterial group X1With the bacterium group X2The bacteria in (1) are sequenced, and the flora X is1The first 61.8% of the bacteria were selected to be 0.382S bacteria and group X according to roulette' S method2The second 38.2% of the bacteria are exchanged, and the exchanged 0.382S bacteria form a new flora X2;

Step 708, judging whether the cycle times of the chemotaxis cycle, the replication cycle and the learning cycle reach a set value, when the cycle times of the chemotaxis cycle, the replication cycle and the learning cycle reach the set value, finishing the cycle, comparing the optimal bacteria found in the two floras through a fitness value, selecting the best bacteria as a global optimal solution, and outputting the result, otherwise, continuously and circularly executing the steps 705-708 until the cycle times of the chemotaxis cycle, the replication cycle and the learning cycle reach the set value;

step eight, outputting the control voltage U after optimizing the heat source circulating pump, the primary heat supply network circulating pump and the secondary heat supply network circulating pump by an output layer in the PID neural network*And driving the heat source circulating pump, the primary heat supply network circulating pump and the secondary heat supply network circulating pump.

The invention also discloses a system for exploiting and utilizing the geothermal energy of the hot dry rock, which has the advantages of reasonable system, simple steps, novel design, convenience, energy conservation, high efficiency of exploiting and utilizing the geothermal energy, good energy-saving effect, strong practicability and high popularization and application values, and is characterized in that: the system comprises a hot dry rock geothermal exploitation system and a hot dry rock geothermal utilization system, wherein the hot dry rock geothermal exploitation system comprises a fluid transmission and distribution system, an underground heat exchange system and an underground monitoring and control system, and the fluid transmission and distribution system comprises a heat source side water supply main pipe, a heat source side water return main pipe, a heat source circulating pump, a main well and a liquid distribution box; the underground heat exchange system comprises a supporting plate, an underground rock stratum heat exchange tube and a plurality of auxiliary wells; the underground monitoring control system comprises a temperature sensor, a vacuum degree sensor, a flow velocity sensor, a temperature sensor data line, a vacuum degree sensor data line, a flow velocity sensor data line, a data transmission line, a monitoring disc, a vacuumizing valve, an underground rock stratum heat exchange tube, a signal line cavity, a liquid distribution box, a data line collecting hole, a data line collecting tube, a data acquisition module, a data monitoring module and a computer.

The system is characterized in that a heat-preservation cement sleeve is arranged in the main well, a heat-conducting cement sleeve is arranged in the auxiliary well, a heat-conducting cement sleeve is arranged in a gap between the heat-conducting cement sleeve and the dry hot rock stratum, a heat-conducting agent is coated in the gap between the heat-conducting cement sleeve and the dry hot rock stratum, the support plate comprises L-L end plates and an M-M end plate, X-shaped ribbed plates are arranged on the L-L end plate, the M-M end plate is a movable end plate, guide plates made of elastic materials are arranged at the lower part of the M-M end plate, preformed holes for allowing heat exchange tubes of the underground rock stratum to penetrate through are symmetrically arranged on the L-L end plate and the M-M end plate, the guide plates are two 45-degree guide plates and 135-degree guide plates respectively, the heat exchange tubes of the underground rock stratum comprise concentric sleeves, heat exchange packaging sleeves and a monitoring disc, the tail ends of the concentric sleeves are sealed, high-temperature-phase-change heat storage material is filled in the concentric sleeve interlayer, the concentric sleeve is fixed in the concentric sleeve, the concentric sleeve is fixed in the inner cavity of the concentric sleeve, a heat exchange packaging sleeve is provided with a heat-storage liquid collection system, a high-temperature-phase-change heat-storage liquid collection system, a temperature-by-temperature.

Compared with the prior art, the invention has the following advantages:

1. according to the method for exploiting and utilizing the geothermal heat of the hot dry rock, a plurality of auxiliary wells share one main well, so that the number of well drilling is reduced, the compactness of a heat source side system is improved, and the underground space is saved;

2. according to the method for exploiting and utilizing the geothermal heat of the dry hot rock, the underground rock stratum heat exchange tubes are only paved in the geothermal energy enrichment area, so that the system is good in economy;

3. according to the method for exploiting and utilizing the geothermal heat of the dry hot rock, the underground rock stratum heat exchange tube is made of the composite phase change heat storage material and can supply constant-temperature hot water;

4. the method for exploiting and utilizing the geothermal energy of the hot dry rock realizes a distributed heat supply mode, breaks through the situation that a service object in the traditional centralized heat supply mode is only a heating user, and can meet the requirements of production and living users;

5. the method for exploiting and utilizing the geothermal heat of the hot dry rock breaks through the situation that the traditional centralized heating mode is only applied to the north, and the heat users in any geographical position can be realized in principle;

6. according to the method for exploiting and utilizing the geothermal energy of the hot dry rock, the heat exchange efficiency of an underground heat exchange system can be obviously improved through the secondary heating structure of the underground rock heat exchange tube, the geothermal energy is efficiently extracted, and the system operation efficiency is high;

7. according to the system for exploiting and utilizing the geothermal heat of the dry hot rock, disclosed by the invention, the heat exchange fluid flows in a closed circulation manner among the heat source side pipeline, the primary heat supply network side pipeline and the secondary heat supply network side pipeline, so that the water resource can be effectively saved, and the energy loss caused by leakage can be reduced;

8. the system for exploiting and utilizing the geothermal heat of the hot dry rock adopts the improved distributed two-stage pump indirect transmission and distribution system, and realizes the coordinated operation of the overground heat exchange system, the underground heat exchange system and the fluid transmission and distribution system.

In conclusion, the system is reasonable, the method steps are simple, the design is novel, the energy is saved conveniently, the high-efficiency geothermal exploitation and utilization can be realized, the good energy-saving effect can be achieved, the practicability is high, and the popularization and application values are high.

The technical solution of the present invention is further described in detail by the accompanying drawings and embodiments.

Drawings

FIG. 1 is a schematic structural view of a geothermal exploitation system of hot dry rock according to the present invention;

FIG. 2 is a schematic diagram of the underground heat exchange system of the present invention;

FIG. 3.1 is a front view of the liquid distribution box;

fig. 3.2 is a top view of fig. 3.1;

FIG. 3.3 is a cross-sectional view A-A of FIG. 3.1;

FIG. 3.4 is a cross-sectional view B-B of FIG. 3.1;

FIG. 3.5 is a cross-sectional view C-C of FIG. 3.1;

FIG. 3.6 is a cross-sectional view taken along line D-D of FIG. 3.1;

FIG. 3.7 is a cross-sectional view E-E of FIG. 3.1;

FIG. 3.8 is a cross-sectional view F-F of FIG. 3.1;

FIG. 3.9 is a sectional view taken along line G-G of FIG. 3.1;

FIG. 3.10 is a cross-sectional view taken at H-H of FIG. 3.2;

FIG. 3.11 is a cross-sectional view taken along line I-I of FIG. 3.2;

FIG. 3.12 is an isometric view of FIG. 3.1;

FIG. 3.13 is a bottom view of FIG. 3.1;

FIG. 3.14 is a sectional view taken along line J-J of FIG. 3.1;

FIG. 4.1 is a front view of the support plate;

fig. 4.2 is a left side view of fig. 4.1;

FIG. 4.3 is a cross-sectional view taken along line K-K of FIG. 4.1;

FIG. 4.4 is a cross-sectional view of L-L of FIG. 4.1;

FIG. 4.5 is a cross-sectional view M-M of FIG. 4.1;

fig. 4.6 is an isometric view of fig. 4.1;

FIG. 5.1 is a left side view of a horizontal subterranean formation heat exchange tube;

FIG. 5.2 is a cross-sectional view of the N-N (monitoring disk) of FIG. 5.1;

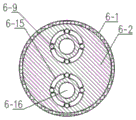

FIG. 5.3 is a cross-sectional view of the O-O of FIG. 5.1;

FIG. 5.4 is an isometric view of the monitoring disk;

FIG. 5.5 is a partial rendering of FIG. 5.4;

fig. 5.6 is the layout of fig. 5.4;

figure 5.7 is a longitudinal cross-sectional view of the end of the secondary well.

Detailed Description

As shown in fig. 1 to 5.7, the method for geothermal mining and utilizing dry hot rock of the present embodiment includes the following steps:

firstly, carrying out geothermal energy detection, drilling a main well 5-1, drilling an annular groove hole at the bottom of the main well 5-1, and drilling a plurality of auxiliary wells uniformly arranged around the main well 5-1 at the bottom of the main well 5-1;

in specific implementation, geothermal energy detection equipment is adopted to detect the underground heat storage and distribution, the topographic and geological characteristics are integrated, and the position and the depth of a main drilling well 5-1 are selected appropriately, wherein the depth of the main drilling well 5-1 is 1500-2000 m;

secondly, hoisting and fixing a support plate 3 for fixedly supporting the well mouths of the multiple auxiliary wells into an annular groove hole at the bottom of the main well 5-1;

in specific implementation, according to the geological structure, the structural characteristics and the heat flow density distribution of a deep dry-hot rock stratum 4-11, a plurality of auxiliary wells are drilled by controlling the drilling direction, the drilling depth and other parameters, and the auxiliary wells are sequentially named as an I auxiliary well 5-2, an II auxiliary well 5-3, ┄ and an N auxiliary well; well heads of the auxiliary well I5-2, the auxiliary wells II 5-3 and ┄ and the auxiliary well N are uniformly arranged at the bottom of the main well 5-1 through a supporting plate 3;

in the embodiment, the number of the auxiliary wells 5-2 is two, namely the auxiliary well I5-2 and the auxiliary well II 5-3, and the auxiliary well I5-2 and the auxiliary well II 5-3 are uniformly arranged at the bottom of the main well 5-1 through the supporting plate 3;

a plurality of auxiliary wells share one main well 5-1, so that the number of drilled wells is reduced, the compactness of a heat source side system is improved, and the underground space is saved;

step three, preparing an underground rock stratum heat exchange tube 4;

step four, connecting the liquid distribution box 6 with the underground rock stratum heat exchange tube 4;

step five, simultaneously putting a plurality of groups of underground rock stratum heat exchange tubes 4 into the main well 5-1, ensuring that the sections of the corresponding positions of the underground rock stratum heat exchange tubes 4 are positioned at the same horizontal plane position through a horizontal detector, and ensuring that the sections of the corresponding positions of the underground rock stratum heat exchange tubes 4 smoothly pass through the supporting plates 3 and enter each auxiliary well; when the underground rock stratum heat exchange tube 4 advances to the tail end of the auxiliary well, the liquid distribution box 6 accurately falls on the set position on the supporting plate 3, and the well descending and the fixing of the liquid distribution box 6 are completed;

sixthly, putting the heat source side water supply main pipe 1-6 and the heat source side water return main pipe 1-7 into the main well 5-1 and reaching the position of the liquid distribution box 6;

in specific implementation, the heat source side water supply main pipe 1-6 and the heat source side water return main pipe 1-7 are made of steel pipelines which are externally coated with heat insulation materials;

seventhly, connecting a heat source side water supply main pipe 1-6 and a heat source side water return main pipe 1-7 with a heat source side interface of the lotus root removing tank 2-5, and connecting a primary heat supply network water supply pipe 1-1 and a primary heat supply network water return pipe 1-2 with a heat supply network side interface of the lotus root removing tank 2-5;

the connection between a heat source side pipeline and a primary heat supply network pipeline is realized, the heat source side pipeline comprises heat source side water supply main pipes 1-6, heat source side water return main pipes 1-7 and an underground rock stratum heat exchange pipe 4, and the primary heat supply network pipeline comprises primary heat supply network water supply pipes 1-1, primary heat supply network water return pipes 1-2 and primary heat supply network bypass pipes 1-3;

the primary heat supply network water supply pipe 1-1 and the primary heat supply network water return pipe 1-2 are connected with the heat source side water supply main pipe 1-6 and the heat source side water return main pipe 1-7 through the lotus root removing tank 2-5;

a primary heat supply network circulating pump 2-2 is arranged on the primary heat supply network water return pipe 1-2, and a heat source circulating pump 2-1 is arranged on the heat source side water return main pipe 1-7;

step eight, connecting a secondary heat supply network water supply pipe 1-4 to a reserved interface of a primary heat supply network water supply pipe 1-1, connecting a secondary heat supply network water return pipe 1-5 to a reserved interface of a primary heat supply network water return pipe 1-2, and connecting the secondary heat supply network water supply pipe 1-4 and the secondary heat supply network water return pipe 1-5 with a heat exchange station 2-4 heat supply network side interface;

the connection between a primary heat supply network pipeline and a secondary heat supply network pipeline is realized, and the secondary heat supply network pipeline comprises a secondary heat supply network water supply pipe 1-4 and a secondary heat supply network water return pipe 1-5;

a plurality of secondary heat supply network systems are connected in parallel to the primary heat supply network water supply pipe 1-1, so that the heat supply requirements of different users can be met; a secondary heat supply network circulating pump 2-3 is arranged on the secondary heat supply network water supply pipe 1-4;

step nine, connecting a load side water supply pipe 1-8 and a load side water return pipe 1-9 with a load side interface of the heat exchange station 2-4;

the connection between a secondary heat supply network pipeline and a load side pipeline is realized, and the load side pipeline comprises a load side water supply pipe 1-8 and a load side water return pipe 1-9;

in specific implementation, a proper end system form is selected according to the requirements of users, and the end system form comprises a low-temperature floor radiation heating system, a radiator heating system, an air-conditioning hot air heating system, a domestic hot water system and an all-air system;

the heat exchange stations 2 to 4 adopt novel plate heat exchangers, cold and hot channels of the novel plate heat exchangers are of asymmetric structures, the geometric sizes of large and small flow side channels are different, and the distance between the plates can be adjusted through bolts;

tenth, connecting the heat source side pipeline data acquisition and monitoring circuit;

eleven, connecting the data acquisition and monitoring circuit of the pipeline at the side of the overground heat exchange system;

step twelve, cold heat exchange fluid enters a main well 5-1 from a heat source side water supply header 1-6 and enters an underground rock heat exchange tube 4 through a liquid distribution box 6, the cold heat exchange fluid absorbs heat of the underground rock after passing through an underground heat exchange system, the temperature is increased to become heat exchange fluid, and the heat exchange fluid enters a heat source side water return header 1-7 from the underground rock heat exchange tube 4 and the liquid distribution box 6; the heat exchange fluid enters a side pipeline of the ground heat exchange system from the lotus root removing tank 2-5, and finally the heat energy is used by a terminal user; cold heat exchange fluid enters the underground rock stratum heat exchange tube 4 from the fluid distribution box 6 to be heated for the first stage; when the heat exchange fluid heated by the first stage reaches the tail end of the underground rock stratum heat exchange tube 4, the heat exchange fluid reversely flows towards the liquid distribution box 6 and exchanges heat in the underground rock stratum heat exchange tube 4; and in the running process of the underground heat exchange system, the underground data acquisition and monitoring system is used for monitoring and controlling related parameters of the underground heat exchange system.

In this embodiment, a heat-insulating cement casing is arranged in the main well 5-1, a heat-conducting cement casing is arranged in the auxiliary well 5-2, and a heat-conducting agent is coated in a gap between the heat-conducting cement casing and the dry-hot rock stratum 4-11.

In the embodiment, the supporting plate 3 comprises L-L end plates 3-1 and M-M end plates 3-2, X-shaped ribbed plates 3-3 are arranged on the L-L end plates 3-1, the M-M end plates 3-2 are movable end plates and are in an unstretched state, guide plates made of elastic materials are arranged at the lower parts of the M-M end plates 3-2, and reserved holes 3-6 for allowing the underground rock stratum heat exchange tubes 4 to penetrate through are symmetrically arranged on the L-L end plates 3-1 and the M-M end plates 3-2.

In the specific implementation, the number of the reserved holes 3-6 on each supporting plate 3 is two, the M-M end plate 3-2 is matched with a prefabricated annular slotted hole at the bottom of the main well 5-1, the azimuth level of the supporting plate 3 can be ensured, and the maximum uniform supporting area can be obtained, the azimuth level of the supporting plate 3 and the X-shaped rib plate 3-3 on the L-L end plate 3-1 are favorable for smoothly lowering the pipe;

in the embodiment, the number of the guide plates is two, and the guide plates are respectively a 45-degree guide plate 3-4 and a 135-degree guide plate 3-5;

and in the fifth step, in the process that the underground rock stratum heat exchange tube 4 enters each auxiliary well, the underground rock stratum heat exchange tube 4 is adjusted in the well descending speed according to the stress deformation characteristics of the 45-degree guide plates 3-4 and the 135-degree guide plates 3-5, so that the 45-degree guide plates 3-4 and the 135-degree guide plates 3-5 are elastically deformed at an angle of 45 degrees, and the underground rock stratum heat exchange tube 4 is ensured to smoothly advance in the auxiliary well.

The elastic guide plate of the M-M end plate 3-2 is horizontal when bearing no force, the guide plate is continuously extruded in the process of putting the underground rock stratum heat exchange tube 4 into the auxiliary well, the guide plate is deformed by 45 degrees by controlling the tube putting speed, counter force is applied to the underground rock stratum heat exchange tube 4, and the underground rock stratum heat exchange tube 4 is guaranteed to smoothly advance in the auxiliary well.

In this embodiment, an infrared irradiator is installed in an annular groove hole at the bottom of the main well 5-1, and an infrared signal receiver for receiving an infrared signal emitted by the infrared irradiator is installed on the M-M end plate 3-2.

In specific implementation, after the infrared signal receiver receives an infrared signal transmitted by the infrared irradiator, the infrared signal receiver sends an instruction to the mechanical transmission device, so that the M-M end plate 3-2 extends into the annular groove hole at the bottom of the main well 5-1.

In the embodiment, the underground rock stratum heat exchange tube 4 comprises a concentric sleeve 4-1, a heat exchange packaging sleeve 4-3 and a monitoring disc 4-14, the tail end of the concentric sleeve 4-1 is sealed, a high-temperature phase change heat storage material 4-2 is filled in an interlayer of the concentric sleeve 4-1, the heat exchange packaging sleeve 4-3 is fixed in an inner cavity of the concentric sleeve 4-1, a liquid injection tube 4-5 and a liquid return cavity 4-6 which are symmetrically arranged are arranged on the heat exchange packaging sleeve 4-3, a low-temperature phase change heat storage material 4-4 is filled in an interlayer of the heat exchange packaging sleeve 4-3, and a data line collecting tube 4-7 which is symmetrically arranged is arranged on the heat exchange packaging sleeve 4-3.

The concrete process for preparing the underground rock stratum heat exchange tube 4 in the third step is as follows:

301, filling a solid-phase high-temperature phase change heat storage material 4-2 in an interlayer of the concentric sleeve 4-1;

302, fastening a heat exchange packaging sleeve 4-3 in an inner cavity of a concentric sleeve 4-1;

step 303, filling a solid-phase low-temperature phase change heat storage material 4-4 in an interlayer of the heat exchange packaging sleeve 4-3;

step 304, fixing a monitoring disc 4-14 at the tail end of the underground rock stratum heat exchange tube 4;

305, mounting a temperature sensor 4-8, a vacuum degree sensor 4-9 and a flow velocity sensor 4-10 to corresponding positions of a monitoring disc 4-14;

step 306, respectively connecting a data line of a temperature sensor 4-8, a data line of a vacuum degree sensor 4-9 and a data line of a flow velocity sensor 4-10 with the temperature sensor 4-8, the vacuum degree sensor 4-9 and the flow velocity sensor 4-10 through reserved pore passages of a monitoring disc 4-14, and then summarizing the data lines into a data line collecting pipe 4-7 in a heat exchange packaging sleeve 4-3;

307, determining the lengths of the underground rock stratum heat exchange tubes 4 in the multiple auxiliary wells 5-2 according to the actually measured lengths of the drilled auxiliary wells;

308, repeating the steps 301 to 307 until the preparation of the underground rock stratum heat exchange tube 4 is completed.

The underground rock stratum heat exchange tube 4 comprises a high-temperature phase change heat storage material 4-2 and a low-temperature phase change heat storage material 4-4, the high-temperature phase change heat storage material 4-2 is filled in an interlayer of the concentric sleeve 4-1, and the low-temperature phase change heat storage material 4-4 is filled in the heat exchange packaging sleeve 4-3; the phase change material with high phase change temperature is arranged close to one side of the outer wall of the underground rock stratum heat exchange tube 4, the phase change material with low phase change temperature is arranged close to one side of the inner cavity of the underground rock stratum heat exchange tube 4, and the phase change material with different melting point temperatures is in composite configuration, so that the melting-solidification circulation operation is realized.

The underground rock stratum heat exchange tube 4 is internally provided with a high-temperature phase-change heat storage material 4-2 and a low-temperature phase-change heat storage material 4-4, and the temperature of a heat exchange fluid in the underground rock stratum heat exchange tube 4 is between the melting point of the high-temperature phase-change heat storage material 4-2 and the melting point of the low-temperature phase-change heat storage material 4-4, so that constant-temperature hot water can be supplied all year round basically, the requirements of users on different seasons and various lives in different time periods are met, and the.