CN110605975B - Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method - Google Patents

Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method Download PDFInfo

- Publication number

- CN110605975B CN110605975B CN201910883199.XA CN201910883199A CN110605975B CN 110605975 B CN110605975 B CN 110605975B CN 201910883199 A CN201910883199 A CN 201910883199A CN 110605975 B CN110605975 B CN 110605975B

- Authority

- CN

- China

- Prior art keywords

- torque

- control

- motor

- driving

- power

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 39

- 229920006395 saturated elastomer Polymers 0.000 claims description 25

- 230000008569 process Effects 0.000 claims description 8

- 230000002265 prevention Effects 0.000 claims description 6

- 238000009825 accumulation Methods 0.000 claims description 5

- 238000005265 energy consumption Methods 0.000 claims description 3

- 230000000694 effects Effects 0.000 claims description 2

- 230000008859 change Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 238000013459 approach Methods 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- NTSBMKIZRSBFTA-AIDOXSFESA-N Digoxigenin bisdigitoxoside Chemical compound C1[C@H](O)[C@H](O)[C@@H](C)O[C@H]1O[C@@H]1[C@@H](C)O[C@@H](O[C@@H]2C[C@@H]3[C@]([C@@H]4[C@H]([C@]5(CC[C@@H]([C@@]5(C)[C@H](O)C4)C=4COC(=O)C=4)O)CC3)(C)CC2)C[C@@H]1O NTSBMKIZRSBFTA-AIDOXSFESA-N 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L15/00—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles

- B60L15/20—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles for control of the vehicle or its driving motor to achieve a desired performance, e.g. speed, torque, programmed variation of speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W50/00—Details of control systems for road vehicle drive control not related to the control of a particular sub-unit, e.g. process diagnostic or vehicle driver interfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/42—Drive Train control parameters related to electric machines

- B60L2240/423—Torque

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2710/00—Output or target parameters relating to a particular sub-units

- B60W2710/08—Electric propulsion units

- B60W2710/083—Torque

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/72—Electric energy management in electromobility

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Automation & Control Theory (AREA)

- Human Computer Interaction (AREA)

- Power Engineering (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

A multi-axis distributed electric drive vehicle torque distribution integrated controller and control method. Solving a target control force and a target control moment based on a sliding mode control theory according to the input of a driver, and realizing longitudinal vehicle speed tracking control and vehicle stability control; controlling the switching of the driving types according to a logic threshold value method, and then realizing the distribution of target control force and torque among all driving wheels based on an optimal control distribution theory; and the bottom layer controller performs slip rate control based on an anti-integral saturation PID method, performs torque coordination compensation control subsequently aiming at the performance loss caused by the slip rate control, judges whether the current compensation target is dynamic or stable according to the intention of a driver and the state of the vehicle, and adopts a corresponding torque coordination compensation strategy.

Description

Technical Field

The invention relates to automobile control, in particular to the field of multi-axis distributed electrically-driven vehicle torque distribution integration.

Technical Field

Hybrid electric transmission technology of special vehicles is an important driving form and technical route in the future. The motorization of the vehicle chassis brings a great revolution to the drive style: compared with the traditional driving mode of a centralized power source, the motorized chassis adopts an engine-generator set and a battery to provide energy, and drives wheels through motors arranged in a distributed mode. The configuration change brings new control freedom degree and improves control difficulty.

Heavy vehicles, which are generally designed for transporting very long, very heavy goods, require both good dynamic properties to meet fast maneuvering requirements and the ability of the vehicle to adapt to complex road conditions. When the vehicle is running at a relatively stable speed on a good road surface and the steering wheel angle is small, the demand for the stability control of the vehicle is small, and the vehicle has a demand for the improvement of energy efficiency. Therefore, improving energy efficiency, compensating for dynamic loss, and reducing wheel wear become issues that need to be addressed.

Disclosure of Invention

In order to solve the problems, the invention provides a multi-axis distributed electric drive vehicle torque distribution integrated controller and a control method, wherein the multi-axis distributed electric drive vehicle torque distribution integrated controller comprises an upper layer controller, a lower layer controller and a lower layer controller;

the upper layer controller calculates the generalized longitudinal resultant force fxcGeneralized lateral resultant force fycAnd a generalized yaw moment Mzc;

The generalized longitudinal resultant force F calculated by the lower layer controller and the upper layer controllerxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcAs an input variable, distributing and calculating the torque value of each driving motor by taking the lowest tire load rate as an optimal control target;

the lower layer controller calculates the required power of the driver according to the required torque of the driver and the current vehicle speed; acquiring a required power compensation amount according to the pedal variation; the driver demand power plus the demand power compensation amount is used as the total demand power; determining an output drive type according to the total required power;

and the bottom layer controller performs slip rate control on the vehicle based on the anti-integral saturation PID controller in combination with the current torque values of all the driving motors, and performs torque compensation on performance loss caused by the slip rate control.

Preferably, the upper layer motion controller calculates a generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcThe method specifically comprises the following steps:

by vehicle speed deviation Δ vxSetting a generalized longitudinal resultant force F for an input variablexcTo control the actual longitudinal vehicle speed vx(ii) a The vehicle speed deviation DeltavxIs a target vehicle speed vxdWith actual longitudinal velocity vx(ii) a The target vehicle speed vxdRestraining by using the conditions of sideslip prevention and rollover prevention;

setting a generalized yaw moment F by using the yaw rate deviation Delta omega as an input variableycThe sliding mode control equation of (1) to control the actual yaw rate; the yaw angular velocity deviation Δ ω isDesired yaw angular velocity ωzdFrom the actual yaw rate omegazA difference of (d); the ideal yaw rate ωzdConstraining by using the road surface adhesion condition;

setting generalized lateral force M by taking centroid slip angle deviation delta beta as input variablezcThe sliding mode control equation of (1) to control the actual centroid slip angle; the centroid slip angle deviation delta beta is an ideal centroid slip angle betadDifference from the actual centroid slip angle β; according to the input rotation angle of the driver and the target speed vxdAnd calculating the ideal centroid slip angle beta when the vehicle runs stablydAnd ideal yaw rate ωzd。

Preferably, said determining the output drive pattern is in particular: dividing the total required power into a plurality of adjacent power intervals, wherein each power interval corresponds to one driving type, and switching the driving types according to the position of the power interval in which the total required power is positioned, wherein the higher the total required power is, the more driving types with more driving wheels are adopted.

Preferably, the slip ratio control is specifically: taking the current wheel slip rate, the current torque value of each driving motor and the current external characteristic torque of each driving motor as input, carrying out hysteresis switching according to the slip rate, and stopping integral accumulation in the corresponding direction when the controller is saturated; the output control torque is used as a torque command of the motor and is also used as an upper limit of lower-layer control distribution of the next period.

Preferably, the performing of the torque compensation control specifically includes: when the steering wheel angle and the vehicle speed are both smaller than corresponding threshold values, adopting dynamic torque coordination control; and when the steering wheel angle and the vehicle speed are both larger than corresponding threshold values, adopting stability torque coordination control.

Preferably, the dynamic torque coordination control process is to make full use of the driving torque of the non-slipping wheels to compensate the torque lost by slipping, and specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the wheels on the same side are saturated;

when the wheels on the same side are saturated, compensating by torque on different sides until all the wheels are saturated;

the stability torque coordination control basically reduces the undesired yaw moment by increasing the torque of the wheels on the own side or reducing the torque of the wheels on the different side, and specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the capacity of the wheels on the same side is saturated;

when the capacity of the wheels on the same side is saturated, reducing the torque of the motor on the different side until the yaw moment meets the requirement;

the above-mentioned medium saturation means the longitudinal driving friction force F of the ground to which the wheel is subjectedxwijThe maximum friction force between the tyre and the ground is achieved, and the longitudinal driving friction force F of the ground on the wheel is received even if the driving force is increasedxwijStill remain unchanged.

The invention discloses a multi-axis distributed electric drive vehicle torque distribution integrated control method, which comprises the following steps of

Calculating a generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment Mzc;

With said generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcAs an input variable, distributing and calculating the torque value of each driving motor by taking the lowest tire load rate as an optimal control target;

calculating the driver required power according to the driver required torque and the current vehicle speed; acquiring a required power compensation amount according to the pedal variation; the driver demand power plus the demand power compensation amount is used as the total demand power; determining an output drive type according to the total required power;

and carrying out slip rate control on the vehicle based on the anti-integral saturation PID controller, and simultaneously carrying out torque compensation on performance loss caused by the slip rate control.

Preferably, a generalized longitudinal resultant force F is calculatedxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcThe method specifically comprises the following steps:

by vehicle speed deviation Δ vxSetting a generalized longitudinal resultant force F for an input variablexcTo control the actual longitudinal vehicle speed vx(ii) a The vehicle speed deviation DeltavxIs a target vehicle speed vxdWith actual longitudinal velocity vx(ii) a The target vehicle speed vxdRestraining by using conditions of preventing sideslip and rollover

Setting generalized yaw moment M by using yaw angular velocity deviation delta omega as input variablezcThe sliding mode control equation of (1) to control the actual yaw rate; the yaw rate deviation Delta omega is an ideal yaw rate omegazdFrom the actual yaw rate omegazA difference of (d); the ideal yaw rate ωzdConstraining by using the road surface adhesion condition; setting generalized lateral force F by taking centroid slip angle deviation delta beta as input variableycThe sliding mode control equation of (1) to control the actual centroid slip angle; the centroid slip angle deviation delta beta is an ideal centroid slip angle betadDifference from the actual centroid slip angle β; according to the input rotation angle of the driver and the target speed vxdAnd calculating the ideal centroid slip angle beta when the vehicle runs stablydAnd ideal yaw rate ωzd。

Preferably, said determining the output drive pattern is in particular: dividing the total required power into a plurality of adjacent power intervals, wherein each power interval corresponds to one driving type, and switching the driving types according to the position of the power interval in which the total required power is positioned, wherein the higher the total required power is, the more driving types with more driving wheels are adopted.

Preferably, the slip ratio control is specifically: taking the current wheel slip rate, the current torque value of each driving motor and the current external characteristic torque of each driving motor as input, carrying out hysteresis switching according to the slip rate, and stopping integral accumulation in the corresponding direction when the controller is saturated; the output control torque is used as a torque command of the motor and is also used as an upper limit of lower-layer control distribution of the next period.

Preferably, the performing of the torque compensation control specifically includes: when the steering wheel angle and the vehicle speed are both smaller than corresponding threshold values, adopting dynamic torque coordination control; when the steering wheel angle and the vehicle speed are both larger than corresponding threshold values, adopting stability torque coordination control;

preferably, the dynamic torque coordination control process is to make full use of the driving torque of the non-slipping wheels to compensate the torque lost by slipping, and specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the wheels on the same side are saturated;

when the wheels on the same side are saturated, compensating by torque on different sides until all the wheels are saturated;

the stability torque coordination control basically reduces the undesired yaw moment by increasing the torque of the wheels on the own side or reducing the torque of the wheels on the different side, and specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the capacity of the wheels on the same side is saturated;

when the capacity of the wheels on the same side is saturated, reducing the torque of the motor on the different side until the yaw moment meets the requirement;

the above-mentioned medium saturation means the longitudinal driving friction force F of the ground to which the wheel is subjectedxwijThe maximum friction force between the tyre and the ground is achieved, and the longitudinal driving friction force F of the ground on the wheel is received even if the driving force is increasedxwijStill remain unchanged.

The invention at least comprises the following beneficial effects:

1. the upper layer controller tracks an ideal motion state, calculates a target control force and moment according to the reference motion state, and can realize longitudinal speed tracking control and vehicle stability control; the non-linear characteristic of the vehicle can be solved based on a sliding mode control method, and the anti-interference performance of the controller is improved;

2. the driving type switching control can improve the total efficiency of the driving motor and achieve the aim of energy saving;

3. the performance function considering the road driving force margin and the performance function considering the tire slip energy loss are set based on the optimal control distribution method, so that the tire force reserve can be improved and the tire wear can be reduced on the basis of tracking the intention of a driver;

4. the bottom-layer slip rate controller can perform torque coordination compensation control aiming at the performance loss caused by slip rate control, and can switch between a dynamic-oriented torque coordination compensation strategy and a stability-oriented torque coordination compensation strategy, so that the current torque compensation requirement is better met.

Additional advantages, objects, and features of the invention will be set forth in part in the description which follows and in part will become apparent to those having ordinary skill in the art upon examination of the following or may be learned from practice of the invention.

Drawings

FIG. 1 is a flow chart of a multi-axle distributed electric drive vehicle torque distribution integrated control method of the present invention;

FIG. 2 is a flow chart of the drive type switching control for the multi-axle distributed electrically driven vehicle according to the present invention;

FIG. 3 is a force analysis diagram of a multi-axle distributed electrically driven vehicle according to the present invention;

FIG. 4 is a schematic diagram of a dynamic torque coordination control process in the method provided by the present invention;

fig. 5 is a schematic diagram of a stability torque coordination control process in the method provided by the invention.

Detailed Description

In order to understand the technical content of the present invention, the following detailed description is made with reference to the accompanying drawings:

fig. 1 shows a flow chart of a torque distribution integrated control method for a multi-axis distributed electrically-driven vehicle according to the present invention, which takes a five-axis distributed driven vehicle as an example, and comprises the following specific steps:

the upper layer controller analyzes the target speed according to the opening degree of an accelerator pedal and calculates an ideal mass center slip angle beta through a vehicle two-degree-of-freedom reference model according to the steering wheel rotation angledAnd ideal yaw rate ωzdThen using the centroid slip angle deviation delta beta and the yaw angular speed deviation delta omegazVehicle speed deviation Δ vxCalculating generalized longitudinal direction based on sliding mode control as input variableThe method comprises the following specific steps of combining force, generalized lateral combining force and generalized yaw moment:

step 1), collecting the input rotation angle delta of the driver by a sensordAnd the opening degree alpha of the driver's pedalxd;

Step 2), according to the opening degree alpha of the pedal of the driverxdAnalyzing the target vehicle speed vxd;

Target vehicle speed vxdThe calculation process of (2) is as follows:

vxd=kαxd

k is a proportionality coefficient and represents that the target vehicle speed is in direct proportion to the opening;

simultaneous target vehicle speed vxdThe constraint conditions of preventing sideslip and rollover are also met:

wherein μ is a road surface adhesion coefficient, L1The length from the wheel center of the 1 st axle wheel to the mass center of the vehicle, H is the height of the mass center, B is the wheel tread, SslipA sideslip safety factor is manually selected; soverSafety factor of rollover, delta, for manual selection1The wheel rotation angle of the 1 st axle.

Step 3) obtaining the actual yaw velocity omega of the vehicle according to the sensor or the state observerzActual centroid slip angle beta and actual longitudinal vehicle speed vx;

Step 4), according to the input rotation angle delta of the driverdAnd a target vehicle speed vxdCalculating the ideal mass center slip angle beta of the vehicle during stable running through a two-degree-of-freedom vehicle modeldAnd ideal yaw rate ωzd;

The linear two-degree-of-freedom vehicle model of the n-axis distributed driving vehicle is established as follows:

wherein m is the total vehicle mass, LiIs as followsThe length from the wheel center of the i-axis wheel to the mass center of the vehicle is n-axis and CiYaw stiffness of the i-th axis, vxIs the actual longitudinal velocity, vyTo actual lateral velocity, IzIs the moment of inertia, delta, of the vehicle about the z-axisiThe wheel rotation angle of the ith axis.

While the ideal yaw angular velocity ωzdThe constraint condition of road surface adhesion and the final ideal yaw angular velocity omega should be metzdComprises the following steps:

wherein L iseAnd K are the equivalent wheelbase and the stability factor respectively;

sgn is a sign function, and its expression is as follows:

step 5), using the centroid slip angle deviation delta beta and the yaw angular speed deviation delta omegazVehicle speed deviation Δ vxCalculating generalized longitudinal resultant force F based on sliding mode control respectively as input variablexcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcAn upper-layer motion controller is formed, so that longitudinal vehicle speed tracking control and vehicle stability control are realized;

centroid slip angle deviation delta beta, yaw angular velocity deviation delta omega and vehicle speed deviation delta vxThe calculation process is as follows:

Δβ=βd-β

Δωz=ωzd-ωz

Δvx=vxd-vx

based on the three-degree-of-freedom motion differential equation of the vehicle body, a control system of the upper-layer motion controller is established:

wherein, deltaijThe rotation angle value of the jth wheel of the ith axle is shown, wherein j-1 represents the left wheel of the ith axle, and j-2 represents the right wheel of the ith axle; fywijIs a driving lateral force generated by a driving motor of each wheel; wherein i represents the ith axle in which the wheel is located, j equals 1 to represent the ith axle left wheel, and j equals 2 to represent the ith axle right wheel; xix、ξyAnd xizError terms caused by external interference, model errors and measurement precision; fRIs the running resistance of the vehicle.

Taking a generalized longitudinal resultant force FxcTo effect longitudinal vehicle speed tracking control, and hence vehicle speed deviation Δ vxFor the input variables, an exponential approximation law with a saturation function is set, and the switching function is designed as follows:

wherein,is v isxThe switching coefficient is a function of the switching coefficient,is v isxSliding mode switching gain.

The sliding mode control equation of the generalized longitudinal resultant force is as follows:

taking generalized yaw moment MzcTo control the actual yaw rate. Setting an exponential approximation law with a saturation function by taking the yaw rate deviation delta omega as an input variable, and designing a switching function as follows:

wherein,is omegazThe switching coefficient is a function of the switching coefficient,is omegazSliding mode switching gain.

The sliding mode control equation of the generalized yaw moment is as follows:

taking generalized lateral force FycTo control the actual centroid slip angle. Setting an exponential approximation law with a saturation function by taking the deviation delta beta of the centroid side deflection angle as an input variable, and designing a switching function as follows:

wherein epsilonβIs a beta switching coefficient, kβIs a beta sliding mode switching gain.

The sliding mode control equation of the generalized lateral force is as follows:

and tracking control is respectively carried out on the actual yaw velocity and the actual mass center slip angle by the generalized yaw moment and the generalized lateral force, and finally the stability control of the vehicle is realized.

The lower controller realizes the drive pattern switching and the torque distribution at the same time. Firstly, calculating the required power of a driver according to the required torque of the driver and the current speed, and acquiring the compensation amount of the required power according to the variable amount of a pedal; the driver demand power plus the demand power compensation amount is used as the total demand power; and judging the output driving type according to the total required power and the power threshold. And then based on an optimal control distribution theory, under the multiple constraints of the motor and the tire force, the lowest tire load rate is taken as a performance target, and the reasonable distribution of the torque is realized.

The specific steps of the driving pattern switching strategy shown in the driving pattern switching control flow chart of the multi-axis distributed driving vehicle shown in fig. 2 are as follows:

step 1), according to the opening degree alpha of the pedal of the driverpedalAnalyzing driver demand torque TdesiretAs shown below;

Tdesire=αpedal×(10×Tmotor)

wherein, TmotorIs the peak torque of the hub motor;

step 2), according to the driver demand torque TdesireCalculating the power required by the driver according to the current vehicle speedPdesire;

And 3), obtaining a required power compensation quantity delta P by looking up a table according to the pedal variation, preferably, obtaining the relation between the pedal variation and the required power compensation quantity by the following method:

firstly, solving a control sequence of a drive type by adopting an off-line dynamic programming method to serve as a global optimal solution, and then analyzing and fitting the global optimal solution to obtain the relation between the pedal variation and the required power compensation.

The method comprises the following steps of:

step a), defining a state variable as x as a driving type; preferably, where x ═ 1 corresponds to a 10 × 10 drive pattern, x ═ 2 corresponds to a 10 × 8 drive pattern, and x ═ 3 corresponds to a 10 × 6 drive pattern.

Defining a control variable u representing a holding or switching operation between the drive types; u has different feasible ranges according to the state of the previous stage, and all possible values are { -2, -1,0,1,2 }.

Step 3.2) designing a target function:

defining a performance function J1To reduce the energy consumption, promote the overall efficiency of motor:

wherein, Ptot,τAnd ητRespectively calculating the total power and the total motor efficiency offline at the time of tau, wherein the total power and the total motor efficiency satisfy the following relations:

η=∑(Tij·nij)/∑[(Tij·nij)/(ηij)]

wherein, PijThe power of a jth motor of an ith shaft; t isijTorque of the jth motor of the ith shaft; n is nijIs the ith axis of the jthThe rotation speed of the motor; etaijIs the two-dimensional efficiency characteristic of the ith motor of the ith axis.

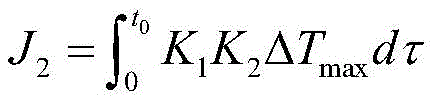

Defining a penalty function J2To reduce unnecessary handovers:

wherein, K1For the switching identification, 1 is taken when switching occurs, otherwise 0 is taken; k2The first penalty factor is artificially set and is used for evaluating the influence of switching; delta TmaxThe torque variation quantity of the wheel with the largest torque variation in all wheels before and after switching is used for measuring the impact degree of switching.

Defining a penalty function J3To take into account the peak characteristics of each motor:

wherein, K3When the motor is an overload mark, 1 is selected when the motor is overloaded, and otherwise, 0 is selected; k4Is a second penalty factor set by human; preal/PtypicalThe ratio of the actual motor power to the rated motor power is used for evaluating the overload degree.

Simultaneously, each motor torque should satisfy the total required torque of the vehicle:

∑Tij,t=Treq,t t∈[0,t0]

step b), solving the global optimal solution of the drive type control sequence and the vehicle state information through an offline dynamic programming algorithm;

and then, analyzing and fitting the global optimal solution of the drive type control sequence to obtain the relation between the pedal variation and the required power compensation.

Step 4), according to the power P required by the driverdesireAnd a required power compensation amount Δ P, calculating a total required power P as follows:

P=Pdesire+△P

step 5), the total required power P and a set power threshold value P are compared1、P2(P1<P2) Carrying out comparison and judgment;

when the total required power P is less than the power threshold value P1When the driving mode is 10x 4;

when the total required power P is larger than the power threshold value P1Less than a power threshold value P2When the driving mode is 10x 6;

when the total required power P is larger than the power threshold value P2A 10x10 drive pattern was used.

The specific method of torque distribution is as follows:

the generalized longitudinal resultant force, the generalized lateral resultant force and the generalized yaw moment calculated by the upper-layer motion controller are used as input variables, the optimal control target with the lowest tire load rate is used, and the torque values of all the driving motors are calculated based on the optimal control distribution, so that a lower-layer torque distribution controller is formed;

as shown in FIG. 3, the resultant generalized longitudinal force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcLongitudinal force F generated by the drive motor of each wheelxwijThe relationship between them is as follows:

the invention distributes the generalized force and the moment to each electric wheel based on an optimal control distribution theory.

The lower control problem is expressed as:

B·u=v

umin≤u≤umax

wherein, B is a system coefficient matrix:

wherein, deltaijThe rotation angle value of the jth wheel of the ith shaft is obtained; l isiThe length from the wheel center of the ith axle wheel to the mass center of the vehicle; dBIs the track width.

u is the tire longitudinal force:

u=[Fxw11 Fxw12 Fxw21 Fxw22 Fxw31 Fxw32 Fxw41 Fxw42 Fxw51 Fxw52]T

v is the control target:

v=[Fxc Fyc Mzc]T

where u is limited by the electric wheel output torque and rate of change and road surface conditions. For motor output torque limitation, at any time tkIt should satisfy:

Twijmin(tk)≤Twij(tk)≤Twijmax(tk)

in particular, for a failed motor, given a known fault condition, no torque should be distributed to the motor, and T is takenwijmin=Twijmax=0。

For an actual motor and an actual controller, in order to avoid the situation that the impact instability is caused by too fast torque change, the change rate of the motor torque is limited, and for the motor after the time delta T, the following requirements are met:

Designing a performance function with the lowest tire load rate and integrating the performance function with an approximation error function to obtain the following target function:

wherein gamma is a coordination factor, the weights of the approximation error function and the performance function can be adjusted by changing the value of the factor, when gamma is large, the above formula is equivalent to solving the approximation error function preferentially, and then solving the performance function;

Wufor a diagonal weighting matrix of the performance function, the expression is as follows:

in the formula, cijC is taken for weighting the longitudinal force of each electric wheel, and because each electric motor of the vehicle is the same for convenient maintenanceij=1;

WvTo approximate the diagonal weighting matrix of the error function, the expression is as follows:

Wv=diag[WvFxc WvFyc WvMzc]

in the formula, WvFxc WvFyc WvMzcRespectively, the weight coefficients for the corresponding generalized forces.

The above is a convex quadratic programming problem, and an active set method can be adopted to obtain an optimal solution of the torque value of each driving motor.

The bottom layer controller controls the slip rate of the vehicle based on the anti-integral saturation PID controller, meanwhile performs torque compensation control on performance loss caused by the slip control, judges whether the current compensation target is dynamic or stable according to the intention of a driver and the vehicle state, and adopts a corresponding torque coordination compensation strategy.

Selecting a 'threshold weakening method' to control the slip rate, taking the current wheel slip rate, the current torque value of each driving motor and the current external characteristic torque of each driving motor as input, switching hysteresis loops according to the magnitude of the slip rate, and stopping integral accumulation in the corresponding direction when the controller is saturated; the output control torque is used as a torque command of the motor and is also used as an upper limit of lower-layer control distribution of the next period.

And (3) torque compensation target judgment:

when the steering wheel angle and the vehicle speed are both smaller than corresponding threshold values, a dynamic torque coordination method is adopted; when the steering wheel angle and the vehicle speed are both larger than corresponding threshold values, a stability torque coordination method is adopted:

wherein δ is a steering wheel angle, v is a vehicle speed;andrespectively, are set threshold values. The aim of dynamic coordination is to meet the longitudinal driving requirement as far as possible under the conditions that the vehicle has a small turning angle and low vehicle speed and is not easy to destabilize, and the generated additional moment is used as a secondary requirement. The stability coordination aims at meeting the requirement of the yaw moment as much as possible and losing part of longitudinal dynamic property under the condition of easy instability such as large vehicle turning angle or high vehicle speed.

When performing the coordination compensation, the following constraints need to be satisfied or partially satisfied:

1) longitudinal force demand constraint, i.e. the longitudinal force of all wheels approaches the driver longitudinal force demand:

wherein n is the total number of axles; j is 1Represents the i-th axle left wheel; j-2 denotes the i-th axle right wheel; fxwijIs the longitudinal force of the wheel; deltaijIs a wheel corner; fxreqThe driver longitudinal force demand.

2) Yaw moment demand constraint, i.e. the yaw moment generated by the longitudinal force approaches the driver demand:

wherein M iszreqThe total yaw moment is required; fxwi2The longitudinal force of the wheel on the right side of the ith shaft is shown; deltai2Is the corner of the wheel on the right side of the ith shaft; fxwi1The longitudinal force of the left wheel of the ith shaft is shown; deltai1The rotation angle of the left wheel of the ith shaft; and B is a wheel track.

3) The motor driving capacity is limited, and the motor torque of normal work does not exceed the maximum torque:

|Tij|≤|Tmax|

wherein, TijThe motor torque on the j side of the ith shaft; t ismaxThe maximum torque of the motor.

FIG. 4 shows a flow chart of the dynamic torque coordination method of the multi-axle distributed vehicle according to the present invention.

The principle of the dynamic torque coordination control is to make full use of the driving torque of the non-slipping wheels to compensate for the torque lost from slipping. Firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the wheels on the same side are saturated; and after the wheels on the same side are saturated, compensating by using torque on different sides until all the wheels are saturated.

FIG. 5 shows a flow chart of the multi-axis distributed vehicle stability torque coordination method of the present invention.

The principle of the stability torque coordination control is to reduce the undesired yaw moment by increasing the torque of the wheels on the present side or reducing the torque of the wheels on the different side.

Firstly, carrying out moment compensation on the same side, and firstly, evenly distributing the moment compensation to each wheel to improve the tire margin until the capacity of the wheels on the same side is saturated; and after the wheels on the same side are saturated, reducing the moment of the motor on the different side until the yaw moment meets the requirement. Meanwhile, the working mode of the motor also has rated power and peak power, and under the peak power, the motor has stronger driving capability, but the motor cannot work in the mode for a long time, otherwise, the temperature is easily overhigh, and the failure rate is increased.

In summary, the above description is only a preferred embodiment of the present invention, and is not intended to limit the scope of the present invention. Any modification, equivalent replacement, or improvement made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (8)

1. A multi-axis distributed electrically-driven vehicle torque distribution integrated controller, characterized by:

comprises an upper layer controller, a lower layer controller and a bottom layer controller;

the upper layer controller calculates a generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcThe method specifically comprises the following steps:

by vehicle speed deviation Δ vxSetting a generalized longitudinal resultant force F for an input variablexcTo control the actual longitudinal vehicle speed vx(ii) a The vehicle speed deviation DeltavxIs a target vehicle speed vxdWith actual longitudinal velocity vxA difference of (d); the target vehicle speed vxdRestraining by using the conditions of sideslip prevention and rollover prevention;

setting generalized yaw moment M by using yaw angular velocity deviation delta omega as input variablezcThe sliding mode control equation of (1) to control the actual yaw rate; the yaw rate deviation Delta omega is an ideal yaw rate omegazdFrom the actual yaw rate omegazA difference of (d); the ideal yaw rate ωzdConstraining by using the road surface adhesion condition;

setting generalized lateral resultant force F by taking mass center lateral deviation angle deviation delta beta as an input variableycThe sliding mode control equation of (1) to control the actual centroid slip angle; the centroid slip angle deviation delta beta is an ideal centroid slip angle betadAnd the actual qualityThe difference in the slip angle β; according to the input rotation angle of the driver and the target speed vxdAnd calculating the ideal centroid slip angle beta when the vehicle runs stablydAnd ideal yaw rate ωzd;

The generalized longitudinal resultant force F calculated by the lower layer controller and the upper layer controllerxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcAs an input variable, distributing and calculating the torque value of each driving motor by taking the lowest tire load rate as an optimal control target;

the lower layer controller calculates the required power of the driver according to the required torque of the driver and the current vehicle speed;

the driver demand power plus the demand power compensation amount is used as the total demand power; determining an output drive type according to the total required power;

the bottom layer controller performs slip rate control on the vehicle based on the anti-integral saturation PID controller in combination with the current torque values of all the driving motors, and performs torque compensation on performance loss caused by the slip rate control;

acquiring a required power compensation amount according to the pedal variation, comprising the following steps:

step a), defining a state variable x as a driving type and defining a control variable u representing a holding or switching action among the driving types;

defining a performance function J1To reduce the energy consumption, promote the overall efficiency of motor:

wherein, Ptot,τAnd ητRespectively calculating the total power and the total motor efficiency offline at the time of tau, wherein the total power and the total motor efficiency satisfy the following relations:

η=∑(Tij·nij)/∑[(Tij·nij)/(ηij)]

wherein, PijThe power of a jth motor of an ith shaft; t isijTorque of the jth motor of the ith shaft; n isijThe rotating speed of the jth motor of the ith shaft is set; etaijThe two-dimensional efficiency characteristic of the jth motor of the ith shaft is obtained;

defining a penalty function J2To reduce unnecessary handovers:

wherein, K1For the switching identification, 1 is taken when switching occurs, otherwise 0 is taken; k2The first penalty factor is artificially set and is used for evaluating the influence of switching; delta TmaxThe torque variation quantity of the wheel with the largest torque variation in all wheels before and after switching is used for measuring the impact degree of switching;

defining a penalty function J3To take into account the peak characteristics of each motor:

wherein, K3When the motor is an overload mark, 1 is selected when the motor is overloaded, and otherwise, 0 is selected; k4Is a second penalty factor set by human; preal/PtypicalThe ratio of the actual motor power to the rated motor power is used for evaluating the overload degree;

meanwhile, the torque of each motor should meet the total required torque of the vehicle;

step b), solving the global optimal solution of the drive type control sequence and the vehicle state information through an offline dynamic programming algorithm;

and c) analyzing and fitting the global optimal solution of the drive type control sequence to obtain the relation between the pedal variation and the required power compensation.

2. The controller according to claim 1, wherein: the determining the output drive type is specifically: dividing the total required power into a plurality of adjacent power intervals, wherein each power interval corresponds to one driving type, and switching the driving types according to the position of the power interval in which the total required power is positioned, wherein the higher the total required power is, the more driving types with more driving wheels are adopted.

3. The controller according to claim 1, wherein: the slip ratio control is specifically as follows: taking the current wheel slip rate, the current torque value of each driving motor and the current external characteristic torque of each driving motor as input, carrying out hysteresis switching according to the slip rate, and stopping integral accumulation in the corresponding direction when the controller is saturated; the output control torque is used as a torque command of the driving motor and is also used as an upper limit of lower-layer control distribution of the next period.

4. The controller according to claim 1, wherein: the torque compensation specifically includes: when the steering wheel angle and the vehicle speed are both smaller than corresponding threshold values, adopting dynamic torque coordination control; and when the steering wheel angle and the vehicle speed are both larger than corresponding threshold values, adopting stability torque coordination control.

5. The controller of claim 4, wherein:

the dynamic torque coordination control basically fully utilizes the driving torque of non-slip wheels to compensate the torque lost by slip, and the process specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the wheels on the same side are saturated;

when the wheels on the same side are saturated, compensating by torque on different sides until all the wheels are saturated;

the stability torque coordination control principle is to reduce the undesired yaw moment by increasing the torque of the wheels on the own side or reducing the torque of the wheels on the different side, and the process specifically comprises the following steps:

firstly, carrying out moment compensation on the same side, and averagely distributing the moment of slip control loss to each wheel in order to improve the tire margin until the capacity of the wheels on the same side is saturated;

when the capacity of the wheels on the same side is saturated, reducing the torque of the motor on the different side until the yaw moment meets the requirement;

the above-mentioned medium saturation means the longitudinal driving friction force F of the ground to which the wheel is subjectedxwijThe maximum friction force between the tyre and the ground is achieved, and the longitudinal driving friction force F of the ground on the wheel is received even if the driving force is increasedxwijStill remain unchanged.

6. A multi-shaft distributed electric drive vehicle torque distribution integrated control method is characterized in that:

calculating a generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcThe method specifically comprises the following steps:

by vehicle speed deviation Δ vxSetting a generalized longitudinal resultant force F for an input variablexcTo control the actual longitudinal vehicle speed vx(ii) a The vehicle speed deviation DeltavxIs a target vehicle speed vxdWith actual longitudinal velocity vxA difference of (d); the target vehicle speed vxdRestraining by using the conditions of sideslip prevention and rollover prevention;

setting generalized yaw moment M by using yaw angular velocity deviation delta omega as input variablezcThe sliding mode control equation of (1) to control the actual yaw rate; the yaw rate deviation Delta omega is an ideal yaw rate omegazdFrom the actual yaw rate omegazA difference of (d); the ideal yaw rate ωzdConstraining by using the road surface adhesion condition;

setting generalized lateral resultant force F by taking mass center lateral deviation angle deviation delta beta as an input variableycThe sliding mode control equation of (1) to control the actual centroid slip angle; the centroid slip angle deviation delta beta is an ideal centroid slip angle betadDifference from the actual centroid slip angle β; according to the input rotation angle of the driver and the target speed vxdAnd calculating the ideal centroid slip angle beta when the vehicle runs stablydAnd ideal yaw rate ωzd;

With said generalized longitudinal resultant force FxcGeneralized lateral resultant force FycAnd a generalized yaw moment MzcAs an input variable, distributing and calculating the torque value of each driving motor by taking the lowest tire load rate as an optimal control target;

calculating the driver required power according to the driver required torque and the current vehicle speed;

the driver demand power plus the demand power compensation amount is used as the total demand power; determining an output drive type according to the total required power;

slip rate control of a vehicle based on an anti-integral saturation PID controller, while torque compensation of performance losses caused by slip rate control

Acquiring a required power compensation amount according to the pedal variation, comprising the following steps:

step a), defining a state variable x as a driving type and defining a control variable u representing a holding or switching action among the driving types;

defining a performance function J1To reduce the energy consumption, promote the overall efficiency of motor:

wherein, Ptot,τAnd ητRespectively calculating the total power and the total motor efficiency offline at the time of tau, wherein the total power and the total motor efficiency satisfy the following relations:

η=∑(Tij·nij)/∑[(Tij·nij)/(ηij)]

wherein, PijThe power of a jth motor of an ith shaft; t isijTorque of the jth motor of the ith shaft; n isijThe rotating speed of the jth motor of the ith shaft is set; etaijTwo-dimensional effect for ith motor of ith axisRate characteristics;

defining a penalty function J2To reduce unnecessary handovers:

wherein, K1For the switching identification, 1 is taken when switching occurs, otherwise 0 is taken; k2The first penalty factor is artificially set and is used for evaluating the influence of switching; delta TmaxThe torque variation quantity of the wheel with the largest torque variation in all wheels before and after switching is used for measuring the impact degree of switching;

defining a penalty function J3To take into account the peak characteristics of each motor:

wherein, K3When the motor is an overload mark, 1 is selected when the motor is overloaded, and otherwise, 0 is selected; k4Is a second penalty factor set by human; preal/PtypicalThe ratio of the actual motor power to the rated motor power is used for evaluating the overload degree;

meanwhile, the torque of each motor should meet the total required torque of the vehicle;

step b), solving the global optimal solution of the drive type control sequence and the vehicle state information through an offline dynamic programming algorithm;

and c) analyzing and fitting the global optimal solution of the drive type control sequence to obtain the relation between the pedal variation and the required power compensation.

7. The control method according to claim 6, characterized in that: the determining the output drive type is specifically: dividing the total required power into a plurality of adjacent power intervals, wherein each power interval corresponds to one driving type, and switching the driving types according to the position of the power interval in which the total required power is positioned, wherein the higher the total required power is, the more driving types with more driving wheels are adopted.

8. The control method according to claim 6, characterized in that: the slip ratio control is specifically as follows: taking the current wheel slip rate, the current torque value of each driving motor and the current external characteristic torque of each driving motor as input, carrying out hysteresis switching according to the slip rate, and stopping integral accumulation in the corresponding direction when the controller is saturated; the output control torque is used as a torque command of the driving motor and is also used as an upper limit of lower-layer control distribution of the next period.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910883199.XA CN110605975B (en) | 2019-09-18 | 2019-09-18 | Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910883199.XA CN110605975B (en) | 2019-09-18 | 2019-09-18 | Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110605975A CN110605975A (en) | 2019-12-24 |

| CN110605975B true CN110605975B (en) | 2021-03-23 |

Family

ID=68892404

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910883199.XA Active CN110605975B (en) | 2019-09-18 | 2019-09-18 | Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110605975B (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111731267B (en) * | 2020-06-02 | 2021-08-06 | 南京航空航天大学 | Distributed electric vehicle stability control system and method equipped with non-inflatable elastic wheels |

| CN111746305B (en) * | 2020-07-10 | 2021-07-06 | 江西科技学院 | Energy-saving control method and system for wire-controlled four-wheel drive hub motor electric automobile |

| CN113246749B (en) * | 2021-07-14 | 2021-11-05 | 北京理工大学 | Multi-wheel/multi-shaft independent driving electric automobile multi-target dynamics control method |

| CN113753054B (en) * | 2021-09-23 | 2023-01-20 | 扬州亚星客车股份有限公司 | Vehicle line control chassis control method and device, electronic equipment and medium |

| CN114919421B (en) * | 2022-05-10 | 2024-08-20 | 武汉理工大学 | Hierarchical driving control device and method for hub motor vehicle under off-road working condition |

| CN115320594B (en) * | 2022-07-11 | 2024-09-24 | 东风汽车集团股份有限公司 | Wheel anti-slip control method, whole vehicle controller and vehicle |

| CN115447566B (en) * | 2022-08-10 | 2024-06-28 | 佛山仙湖实验室 | Yaw stability control method, device and medium for distributed electrically driven vehicle |

| CN118850042A (en) * | 2023-04-28 | 2024-10-29 | 比亚迪股份有限公司 | Vehicle control method and device and vehicle |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105253141A (en) * | 2015-09-09 | 2016-01-20 | 北京理工大学 | Wheel longitudinal force regulation-based vehicle handling stability control method |

| CN106183892A (en) * | 2016-10-09 | 2016-12-07 | 重庆理工大学 | The experimental model of electric wheel drive vehicle and driving stability control method |

| CN106696760A (en) * | 2017-01-19 | 2017-05-24 | 北京理工大学 | Power distribution method for hub-motor-driven vehicle |

| CN108674254A (en) * | 2018-05-11 | 2018-10-19 | 吉林大学 | A kind of multiaxis driving electric vehicle wheel torque distribution method based on driving energy on-line optimization |

| CN109606133A (en) * | 2019-01-16 | 2019-04-12 | 浙江科技学院 | Distributed-driving electric automobile torque vector control method based on bilayer control |

| CN110203075A (en) * | 2019-05-31 | 2019-09-06 | 武汉理工大学 | A kind of four-wheel hub motor Vehicular system power matching method |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6335852B2 (en) * | 2015-08-05 | 2018-05-30 | 本田技研工業株式会社 | Control device for hybrid vehicle |

| CN109204310B (en) * | 2017-06-29 | 2020-05-26 | 上海汽车集团股份有限公司 | Vehicle power control method and device |

-

2019

- 2019-09-18 CN CN201910883199.XA patent/CN110605975B/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105253141A (en) * | 2015-09-09 | 2016-01-20 | 北京理工大学 | Wheel longitudinal force regulation-based vehicle handling stability control method |

| CN106183892A (en) * | 2016-10-09 | 2016-12-07 | 重庆理工大学 | The experimental model of electric wheel drive vehicle and driving stability control method |

| CN106696760A (en) * | 2017-01-19 | 2017-05-24 | 北京理工大学 | Power distribution method for hub-motor-driven vehicle |

| CN108674254A (en) * | 2018-05-11 | 2018-10-19 | 吉林大学 | A kind of multiaxis driving electric vehicle wheel torque distribution method based on driving energy on-line optimization |

| CN109606133A (en) * | 2019-01-16 | 2019-04-12 | 浙江科技学院 | Distributed-driving electric automobile torque vector control method based on bilayer control |

| CN110203075A (en) * | 2019-05-31 | 2019-09-06 | 武汉理工大学 | A kind of four-wheel hub motor Vehicular system power matching method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110605975A (en) | 2019-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110605975B (en) | Multi-shaft distributed electric drive vehicle torque distribution integrated controller and control method | |

| CN110605973B (en) | Control method for operation stability of multi-axis distributed electrically-driven vehicle based on layered structure | |

| CN109263716B (en) | Control method for driving vehicle to steer by four-hub motor | |

| CN108422901B (en) | A kind of In-wheel-motor driving wheel of vehicle torque Multipurpose Optimal Method optimal based on vehicle comprehensive performance | |

| Zhai et al. | Electronic stability control based on motor driving and braking torque distribution for a four in-wheel motor drive electric vehicle | |

| Goodarzi et al. | Design of a VDC system for all-wheel independent drive vehicles | |

| CN110422053B (en) | Energy-saving control method for four-wheel hub motor driven electric automobile | |

| CN108437978B (en) | Four wheel hub electricity drive vehicle running surface automatic identification and stability integrated control method | |

| CN108674254B (en) | A kind of multiaxis driving electric vehicle wheel torque distribution method based on driving energy on-line optimization | |

| CN111391822B (en) | Automobile transverse and longitudinal stability cooperative control method under limit working condition | |

| CN110481338A (en) | A kind of hub motor vehicle disablement control method and entire car controller | |

| CN112373459B (en) | Method for controlling upper-layer motion state of four-hub motor-driven vehicle | |

| CN108177692A (en) | A kind of differential power-assisted steering of electric wheel drive vehicle and stability control method for coordinating | |

| CN113221257B (en) | Vehicle transverse and longitudinal stability control method under extreme working condition considering control area | |

| CN106828504A (en) | A kind of four-wheel drive system and its control method for automobile | |

| CN113978263A (en) | Electric automobile stability control method with driving wheel skid resistance and torque optimization fusion | |

| CN112622875B (en) | Lower-layer torque distribution control method for four-hub motor driven vehicle | |

| CN105109477A (en) | Torque distributing method for in-wheel-motor driven vehicles | |

| CN109017446B (en) | Expected path vehicle longitudinal speed tracking control method and device | |

| CN115723590B (en) | Energy-saving torque vector control method for hub motor driven automobile | |

| CN113147413B (en) | Method, device and system for recovering energy of in-wheel motor differential steering vehicle | |

| Wu et al. | Distribution method of automotive torque for hub motor considering energy consumption optimization | |

| CN112373293A (en) | Fault processing method for distributed driving system of hub motor | |

| CN115848162B (en) | Control method for six-wheel independent electrically-driven unmanned vehicle differential steering | |

| CN114919421B (en) | Hierarchical driving control device and method for hub motor vehicle under off-road working condition |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |