CN110549240B - End point detection method and chemical mechanical polishing device - Google Patents

End point detection method and chemical mechanical polishing device Download PDFInfo

- Publication number

- CN110549240B CN110549240B CN201910881051.2A CN201910881051A CN110549240B CN 110549240 B CN110549240 B CN 110549240B CN 201910881051 A CN201910881051 A CN 201910881051A CN 110549240 B CN110549240 B CN 110549240B

- Authority

- CN

- China

- Prior art keywords

- polishing

- time series

- substrate

- detection method

- point

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005498 polishing Methods 0.000 title claims abstract description 144

- 238000001514 detection method Methods 0.000 title claims abstract description 43

- 239000000126 substance Substances 0.000 title claims abstract description 24

- 239000000758 substrate Substances 0.000 claims abstract description 65

- 230000008859 change Effects 0.000 claims abstract description 21

- 238000012544 monitoring process Methods 0.000 claims abstract description 17

- 230000003287 optical effect Effects 0.000 claims description 19

- 238000004590 computer program Methods 0.000 claims description 16

- 238000003860 storage Methods 0.000 claims description 9

- 239000004065 semiconductor Substances 0.000 claims description 6

- 238000003825 pressing Methods 0.000 claims description 3

- 238000000034 method Methods 0.000 abstract description 17

- 239000000463 material Substances 0.000 description 39

- 238000005259 measurement Methods 0.000 description 12

- 230000008569 process Effects 0.000 description 11

- 239000007788 liquid Substances 0.000 description 8

- 238000007517 polishing process Methods 0.000 description 6

- 239000002245 particle Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 230000033001 locomotion Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 238000007689 inspection Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 238000002310 reflectometry Methods 0.000 description 2

- 238000012876 topography Methods 0.000 description 2

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000004422 calculation algorithm Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000013480 data collection Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000011344 liquid material Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 229910052755 nonmetal Inorganic materials 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 239000013077 target material Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/34—Accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B47/00—Drives or gearings; Equipment therefor

- B24B47/10—Drives or gearings; Equipment therefor for rotating or reciprocating working-spindles carrying grinding wheels or workpieces

- B24B47/12—Drives or gearings; Equipment therefor for rotating or reciprocating working-spindles carrying grinding wheels or workpieces by mechanical gearing or electric power

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B57/00—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents

- B24B57/02—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents for feeding of fluid, sprayed, pulverised, or liquefied grinding, polishing or lapping agents

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Abstract

The invention provides an end point detection method and a chemical mechanical polishing device, wherein the method comprises the following steps: acquiring a measured value acquired by a polishing monitoring module; forming a time series data line for representing the change of the film layer on the surface of the substrate along with the time by using the measured values; acquiring inflection points of the time series data lines by adopting a Laplace criterion; and determining a polishing end point according to the time when the inflection point appears. The invention improves the accuracy of the end point detection.

Description

Technical Field

The invention belongs to the technical field of chemical mechanical polishing, and particularly relates to an end point detection method and a chemical mechanical polishing device.

Background

Chemical Mechanical Planarization (CMP) is a global surface Planarization technique used in semiconductor manufacturing processes to reduce the effects of substrate thickness variations and surface topography. Since CMP can precisely and uniformly planarize a substrate to a desired thickness and flatness, it has become one of the most widely used surface planarization techniques in semiconductor manufacturing.

The CMP process is realized by the following steps: the carrier head holds the substrate and rotates at a certain speed and horizontally reciprocates, a certain downward pressure is applied to press the substrate on a rotating polishing pad, polishing solution consisting of submicron or nanometer abrasive particles and chemical solution flows between the substrate and the polishing pad, the polishing solution is uniformly distributed under the action of transmission and rotating centrifugal force of the polishing pad to form a layer of liquid film between the substrate and the polishing pad, chemical components in the liquid chemically react with the substrate to convert insoluble substances into easily soluble substances, then the chemical reactants are removed from the surface of the substrate through micro-mechanical friction of the abrasive particles and dissolved in the flowing liquid to be taken away, namely surface materials are removed in the alternate process of chemical film forming and mechanical film removing to realize surface planarization treatment, and the aim of global planarization is fulfilled.

In the CMP process, the yield is low due to over-polishing due to excessive material removal or under-polishing due to insufficient material removal, so that the removal amount of the material needs to be strictly controlled to avoid the occurrence of the conditions of over-polishing or under-polishing of the substrate. In a practical production process, endpoint detection is often used to gauge whether the CMP process has polished the material to the desired thickness.

However, in the prior art, due to the complex polishing process and the multiple related actuating mechanisms, the polishing end point is not accurately judged, so that misjudgment is caused, and the final polishing effect is influenced.

Disclosure of Invention

In view of the above, embodiments of the present invention provide an end point detection method and a chemical mechanical polishing apparatus, which are intended to solve at least one of the technical problems in the prior art.

A first aspect of embodiments of the present invention provides an end-point detection method comprising, during polishing of a semiconductor substrate:

acquiring a measured value acquired by a polishing monitoring module;

forming a time series data line for representing the change of the film layer on the surface of the substrate along with the time by using the measured values;

acquiring inflection points of the time series data lines by adopting a Laplace criterion;

and determining a polishing end point according to the time when the inflection point appears.

A second aspect of an embodiment of the present invention provides a chemical mechanical polishing apparatus, including:

a polishing pad covered with a polishing pad for polishing a substrate;

a carrier head for holding and pressing a substrate against the polishing pad;

the polishing monitoring module is used for detecting the surface film layer of the substrate to obtain a measured value;

and the control module is used for acquiring the measured value acquired by the polishing monitoring module, forming a time series data line for representing the change of the film layer on the surface of the substrate along with time by using the measured value, acquiring the inflection point of the time series data line by adopting a Lauda criterion, and determining the polishing end point according to the time when the inflection point appears.

A third aspect of embodiments of the present invention provides a control module, comprising a memory, a processor and a computer program stored in the memory and executable on the processor, wherein the processor implements the steps of the endpoint detection method as described above when executing the computer program.

A fourth aspect of embodiments of the present invention provides a computer-readable storage medium having stored thereon a computer program which, when executed by a processor, carries out the steps of the endpoint detection method as described above.

Compared with the prior art, the embodiment of the invention has the following beneficial effects: according to the polishing end point detection method and device, the time sequence is obtained according to the measured value acquired by the polishing monitoring module, and then the inflection point of the curve is judged by adopting the Lauda criterion so as to determine the polishing end point, so that the accuracy of end point detection is improved.

Drawings

The advantages of the invention will become clearer and more readily appreciated from the detailed description given with reference to the following drawings, which are given by way of illustration only and do not limit the scope of protection of the invention, wherein:

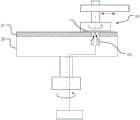

FIG. 1 is a schematic diagram of a chemical mechanical polishing apparatus according to an embodiment of the present invention;

FIG. 2 is a schematic illustration of a polishing process provided by one embodiment of the present invention;

FIG. 3 is a schematic cross-sectional view of a chemical mechanical polishing apparatus according to an embodiment of the present invention;

FIG. 4 is a schematic flow chart of an endpoint detection method according to an embodiment of the present invention;

FIG. 5 is a data line provided in accordance with an embodiment of the present invention;

fig. 6 is a time series provided by an embodiment of the present invention.

Detailed Description

The technical solution of the present invention will be described in detail with reference to the following embodiments and accompanying drawings. The embodiments described herein are specific embodiments of the present invention for the purpose of illustrating the concepts of the invention; the description is intended to be illustrative and exemplary and should not be taken to limit the scope of the invention. In addition to the embodiments described herein, those skilled in the art will be able to employ other technical solutions which are obvious based on the disclosure of the claims and the specification thereof, and these technical solutions include technical solutions which make any obvious replacement or modification of the embodiments described herein.

In order to explain the technical means of the present invention, the following description will be given by way of specific examples.

As shown in fig. 1, the main constituent components of the chemical mechanical polishing apparatus are a carrier head 10 for holding and rotating a substrate w, a polishing disk 20 covered with a polishing pad 21, a dresser 30 for dressing the polishing pad 21, and a liquid supply portion 40 for supplying a polishing liquid.

In the chemical mechanical polishing process, the carrier head 10 presses the substrate w against the polishing pad 21 covered by the surface of the polishing disk 20, and the carrier head 10 performs a rotating motion and a reciprocating motion along the radial direction of the polishing disk 20 so that the surface of the substrate w contacting with the polishing pad 21 is gradually removed, and simultaneously the polishing disk 20 rotates, and the liquid supply part 40 sprays the polishing liquid onto the surface of the polishing pad 21. The substrate w is rubbed against the polishing pad 21 by the relative movement of the carrier head 10 and the polishing platen 20 under the chemical action of the polishing liquid to perform polishing. During polishing, the dresser 30 serves to dress and activate the topography of the polishing pad 21. The use of the dresser 30 can remove foreign particles remaining on the surface of the polishing pad 21, such as abrasive particles in the polishing liquid and waste materials detached from the surface of the substrate w, and can also planarize the surface deformation of the polishing pad 21 due to polishing.

During the chemical mechanical polishing, the substrate is pressed against the polishing pad 11 by the carrier head 20 and reciprocates with the carrier head 20 in a radial direction along the polishing pad 10, and at the same time, the carrier head 20 rotates in synchronization with the polishing pad 10, so that the surface of the substrate contacting the polishing pad 11 is gradually removed.

As shown in fig. 2, before polishing, the substrate surface film layer is the first material layer m1, and as the first material layer m1 is gradually polished to expose the second material layer m2, when the substrate is polished to a predetermined target material or target position, it is considered that the polishing endpoint is reached and the polishing is stopped.

< example 1>

As an embodiment of the present invention, the polishing monitoring module is an optical detection device to perform polishing endpoint detection by using an optical detection method, and the optical detection method tracks the process progress by detecting the change of the reflected light from the surface of the substrate, thereby determining the endpoint of the polishing process.

As shown in fig. 3, the optical detection device 50 is disposed below the disk surface of the polishing disk 20 and rotates following the polishing disk 20 to realize online measurement while polishing. A light-transmissive window is provided on the polishing pad 21. The laser line emitted from the optical detection device 50 is irradiated to the surface of the substrate w on the polishing pad 21 through the window and receives the reflected light of the substrate w to determine the material change of the surface of the substrate w from the reflected light.

The optical inspection device 50 employs a non-contact measurement method, and can measure the film material change during the polishing process without damaging the film on the substrate surface. The optical detection device 50 determines the material change of the substrate surface film layer by detecting the intensity of the reflected light by using the difference of the reflectivity of different materials to light.

Taking metal and non-metal materials as an example, because different materials have different reflectivities for the laser emitted by the optical detection device 50, when the interface between the two materials is ground during polishing, the material of the polished surface of the substrate changes, so that the optical measurement value detected by the optical detection device 50 also changes obviously.

Illustratively, as shown in fig. 2, the optical measurement value measured by the optical detection device 50 is a certain value when the first material layer of the substrate surface is polished. When the first material layer is removed to expose the second material layer, the polished surface of the substrate changes from the first material to the second material, and the optical measurements measured by the optical inspection device 50 also change.

Therefore, the polishing state can be monitored based on the measurement value of the optical detection device 50 to judge the polishing end point. Based on this, the present embodiment proposes an end point detection method, as shown in fig. 4, which performs the following steps during polishing of a semiconductor substrate:

step S1, obtaining the measured value collected by the polishing monitoring module;

in this embodiment, step S1 is to obtain the optical measurement value collected by the optical detection device 50.

Step S2, forming a time series data line for representing the change of the substrate surface film layer along with the time by using the measured values;

as shown in fig. 5, an example of a time-series data line is shown. The time series data line can be composed of measured values acquired according to time sequence, and can also be composed of a time series of measured value mean values in a certain area.

Taking fig. 5 as an example, the first material layer of the substrate surface film starts to be removed at the stage t0 to t1, the material of the substrate surface film starts to be changed at the stage t1 to t2, the second material layer is exposed, and the first material layer is completely removed at the stage after t 2.

Step S3, obtaining inflection points of the time series data lines by adopting a Lauda criterion;

it can be understood that, when the material of the film layer on the surface of the substrate is unchanged, the measured values and the random errors thereof are subject to normal distribution, therefore, a group of time series is inspected by using the Laudea criterion, the standard deviation is obtained by calculation processing, a measurement error interval is determined according to the probability of 3 times of the standard deviation, the measurement errors of the measured values adjacent to the time series are inspected, if the measurement error interval is larger than the measurement error interval, the measurement errors are considered to be coarse errors, and the change of the film layer material at the moment is judged.

And step S4, determining a polishing end point according to the time when the inflection point appears.

Specifically, as shown in fig. 5, when it is detected that the time-series data line reaches the second inflection point, it is determined as the polishing end point.

According to the polishing end point detection method and device, the time sequence is obtained according to the measured value acquired by the polishing monitoring module, and then the inflection point of the curve is judged by adopting the Lauda criterion so as to determine the polishing end point, so that the accuracy of end point detection is improved.

In one embodiment, step S3 includes:

step S31, selecting time series samples from the time series data lines;

step S32, calculating an error interval according to the time series samples by adopting a Laudea criterion;

and step S33, determining an inflection point according to the error interval.

In one embodiment, step S32 includes:

1) calculating the standard deviation and the mean value of the time series samples;

2) and taking the standard deviation with the difference value not more than a preset multiple from the mean value as the error interval.

In one embodiment, step S33 includes:

1) calculating whether data points adjacent to the time series samples are located within the error interval;

2) when the data point is outside the error interval, the data point is taken as an inflection point.

The specific calculation process comprises the following steps:

selecting time series sample as [ X ]m,Xm+1,……Xn-1,Xn]Wherein the size of the sample can be preset.

Judgment and time series sample [ Xm,Xm+1,……Xn-1,Xn]Adjacent data points XjWhether or not in the error intervalWherein j is m-1 or j is n + 1.

Due to gross errors in the measured values when the material of the film layer changes, i.e.As shown by the slope line in fig. 6, so when X isjIn the intervalIn the outer case, the data points marked by the triangle frame in fig. 6 are the inflection points.

It is understood that the time series samples may be selected from the time series data lines in a time sequential manner, sliding continuously in a recursive manner. In other words, during data acquisition, a set of data is selected as a time series of samples [ X ]m,Xm+1,……Xn-1,Xn]And determining the value X at both ends of the group of dataj(j ═ m-1 or j ═ n +1) in the intervalThen, the data collection is continued along with the time sequence to select the next new group of data as a new time series sample [ Xm+i,Xm+i+1,……Xn+i-1,Xn+i]And i is a natural number, and judging whether an inflection point appears according to the new time series sample. .

In this embodiment, the error interval is determined by the standard deviation and the mean. Specifically, the error interval may be determined by a standard deviation of 3 times.

The present embodiment takes data points located outside the error interval as inflection points. When it is detected that the measured value is greater than a preset multiple of the standard deviation of the previous sample, determining the moment at which the measured value appears as the inflection point.

< example 2>

As another possible embodiment of the present invention, the polishing monitoring module is a friction force detecting device.

As shown in FIG. 2, when the first material layer m1 of the substrate surface is polished, the coefficient of friction between the polishing surface of the substrate and the polishing pad is μ based on the material property of the layer1. When the first material layer m1 is polished to expose the second material layer m2, the polishing surface of the substrate changes from the first material to the second material, and the coefficient of friction between the polishing surface of the substrate and the polishing pad changes, denoted as μ2。

Because the friction coefficients of different materials under the same polishing condition are different, the material of the polished surface of the substrate changes when the interface of the two layers of materials is ground in the polishing process, so that the friction force between the polishing pad and the polished surface of the substrate also changes obviously.

Therefore, the polishing end point can be obtained by detecting the change of the frictional force by the frictional force detecting means.

During the chemical mechanical polishing, when the polishing is performed to different medium surfaces of the substrate, the friction coefficient between the polishing surface of the substrate and the polishing pad changes, and when the rotation speeds of the polishing disk and the carrier head and the polishing downforce exerted by the carrier head on the substrate are not changed, the friction force between the polishing surface of the substrate and the polishing pad changes obviously, so that the operating parameters of the polishing disk also change correspondingly. The operating parameter may be a load rate, a load power, a torque, and/or a motor current of a first motor for driving the polishing disc to rotate.

When the polishing of the substrate reaches the end point and one layer of material on the surface of the substrate is polished to expose the next layer of material, the polishing material changes to change the friction coefficient between the polishing surface of the substrate and the polishing pad, and accordingly the change of the friction force causes the change of the operation parameters of the polishing disk, so that the change of the load rate, the load power, the torque or the motor current of the driving motor of the polishing disk related to the friction force in the CMP process can be detected by the friction force detection device to judge when the polishing end point is reached.

Based on this, the present embodiment proposes to determine the polishing end point by detecting the frictional force between the polishing pad and the substrate using a frictional force detection device or detecting the load factor, load power, torque, and/or motor current of the first motor for driving the polishing pad to rotate.

The process is carried out during polishing of the semiconductor substrate by performing the following steps:

step S1, obtaining the measured value collected by the polishing monitoring module;

in this embodiment, step S1 is to obtain the measured value collected by the friction force detection device.

Step S2, forming a time series data line for representing the change of the substrate surface film layer along with the time by using the measured values;

since the measurement varies with the friction, a step curve like that in fig. 5 can be obtained.

Step S3, obtaining inflection points of the time series data lines by adopting a Lauda criterion;

and step S4, determining a polishing end point according to the time when the inflection point appears.

As can be seen by those skilled in the art, the specific principle of detecting the endpoint by using the friction force detection device is basically the same as the endpoint detection method described in embodiment 1, except that the specific values of the measured values are different, and the process of obtaining the endpoint by using the inflection point of the curve change is the same, and is not described herein again.

In addition, as an implementation manner, after delaying a preset time when the polishing endpoint is detected, the chemical mechanical polishing apparatus is controlled to stop polishing, that is, to perform over-polishing for a certain period of time, so that a better polishing effect can be achieved. Specifically, after the end point is captured, the polishing is carried out for a proper time, and the polishing is finished after the polishing is stopped.

It should be understood that, the sequence numbers of the steps in the foregoing embodiments do not imply an execution sequence, and the execution sequence of each process should be determined by its function and inherent logic, and should not constitute any limitation to the implementation process of the embodiments of the present invention.

An embodiment of the present invention further provides a chemical mechanical polishing apparatus, including:

a polishing pad 20 covered with a polishing pad for polishing a substrate;

a carrier head 10 for holding and pressing a substrate against the polishing pad;

the polishing monitoring module is used for detecting the surface film layer of the substrate to obtain a measured value;

and the control module is used for acquiring the measured value acquired by the polishing monitoring module, forming a time series data line for representing the change of the film layer on the surface of the substrate along with time by using the measured value, acquiring the inflection point of the time series data line by adopting a Lauda criterion, and determining the polishing end point according to the time when the inflection point appears.

An embodiment of the present invention further provides a control module, including: a processor, a memory, and a computer program stored in the memory and executable on the processor. The processor, when executing the computer program, performs the steps in the embodiments as described in the above-mentioned method embodiments, e.g. steps S1 to S4 shown in fig. 4.

The control module refers to a terminal with data processing capability, and includes but is not limited to a computer, a workstation, a server, and even some Smart phones, palm computers, tablet computers, Personal Digital Assistants (PDAs), Smart televisions (Smart TVs), and the like with excellent performance.

The Processor may be a Central Processing Unit (CPU), other general purpose Processor, a Digital Signal Processor (DSP), an Application Specific Integrated Circuit (ASIC), an off-the-shelf Programmable Gate Array (FPGA) or other Programmable logic device, discrete Gate or transistor logic, discrete hardware components, etc.

The memory may be an internal storage unit of the control module, such as a hard disk or a memory of the control module. The memory may also be an external storage device of the control module, such as a plug-in hard disk, a Smart Media Card (SMC), a Secure Digital (SD) Card, a Flash memory Card (Flash Card), and the like, provided on the control module. Further, the memory may also include both an internal storage unit of the control module and an external storage device. The memory is used for storing the computer program and other programs and data required by the control module. The memory may also be used to temporarily store data that has been output or is to be output.

Embodiments of the present invention further provide a computer-readable storage medium, which stores a computer program, and when the computer program is executed by a processor, the computer program implements steps in the embodiments described in the above method embodiments, such as steps S1 to S4 shown in fig. 4.

The computer program may be stored in a computer readable storage medium, which when executed by a processor, may implement the steps of the various method embodiments described above. Wherein the computer program comprises computer program code, which may be in the form of source code, object code, an executable file or some intermediate form, etc. The computer-readable medium may include: any entity or device capable of carrying the computer program code, recording medium, usb disk, removable hard disk, magnetic disk, optical disk, computer Memory, Read-Only Memory (ROM), Random Access Memory (RAM), electrical carrier wave signals, telecommunications signals, software distribution medium, and the like.

In the above embodiments, the description of each embodiment has a respective emphasis, and the embodiments may be combined arbitrarily, and a new embodiment formed by combining the embodiments is also within the scope of the present application. For parts which are not described or illustrated in a certain embodiment, reference may be made to the description of other embodiments.

Those of ordinary skill in the art will appreciate that the various illustrative elements and algorithm steps described in connection with the embodiments disclosed herein may be implemented as electronic hardware or combinations of computer software and electronic hardware. Whether such functionality is implemented as hardware or software depends upon the particular application and design constraints imposed on the implementation. Skilled artisans may implement the described functionality in varying ways for each particular application, but such implementation decisions should not be interpreted as causing a departure from the scope of the present invention.

The above-mentioned embodiments are only used for illustrating the technical solutions of the present invention, and not for limiting the same; although the present invention has been described in detail with reference to the foregoing embodiments, it will be understood by those of ordinary skill in the art that: the technical solutions described in the foregoing embodiments may still be modified, or some technical features may be equivalently replaced; such modifications and substitutions do not substantially depart from the spirit and scope of the embodiments of the present invention, and are intended to be included within the scope of the present invention.

Claims (9)

1. An end-point detection method, characterized in that during polishing of a semiconductor substrate:

acquiring a measured value acquired by a polishing monitoring module;

forming a time series data line for representing the change of the film layer on the surface of the substrate along with the time by using the measured values;

acquiring inflection points of the time series data lines by adopting a Laplace criterion, which specifically comprises the following steps: selecting a time series sample from the time series data line, calculating an error interval according to the time series sample by adopting a Lauda criterion, calculating whether a data point adjacent to the time series sample is positioned in the error interval, and taking the data point as an inflection point when the data point is positioned outside the error interval;

and determining a polishing end point according to the time when the inflection point appears.

2. The endpoint detection method of claim 1, wherein the calculating the error interval comprises:

calculating the standard deviation and the mean value of the time series samples;

and taking the standard deviation with the difference value not more than a preset multiple from the mean value as the error interval.

3. The endpoint detection method of claim 2, wherein the error interval is determined according to a standard deviation of 3 times.

5. The end-point detection method of claim 1, wherein the polishing monitoring module comprises an optical detection device.

6. The end-point detection method of claim 1, wherein the polishing monitoring module comprises a friction force detection device.

7. A chemical mechanical polishing apparatus, comprising:

a polishing pad covered with a polishing pad for polishing a substrate;

a carrier head for holding and pressing a substrate against the polishing pad;

the polishing monitoring module is used for detecting the surface film layer of the substrate to obtain a measured value;

the control module is used for acquiring a measured value acquired by the polishing monitoring module, forming a time series data line for representing the change of a substrate surface film layer along with time by using the measured value, acquiring an inflection point of the time series data line by adopting a Lauda criterion, and determining a polishing end point according to the time of the inflection point;

wherein the obtaining of the inflection point by using the Lauda criterion comprises: selecting a time series sample from the time series data line, calculating an error interval according to the time series sample by adopting a Lauda criterion, calculating whether a data point adjacent to the time series sample is positioned in the error interval, and taking the data point as an inflection point when the data point is positioned outside the error interval.

8. A control module comprising a memory, a processor and a computer program stored in the memory and executable on the processor, the processor implementing the steps of the endpoint detection method as claimed in any one of claims 1 to 6 when executing the computer program.

9. A computer-readable storage medium, characterized in that the computer-readable storage medium stores a computer program which, when being executed by a processor, carries out the steps of the endpoint detection method according to any one of claims 1 to 6.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910881051.2A CN110549240B (en) | 2019-09-18 | 2019-09-18 | End point detection method and chemical mechanical polishing device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910881051.2A CN110549240B (en) | 2019-09-18 | 2019-09-18 | End point detection method and chemical mechanical polishing device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110549240A CN110549240A (en) | 2019-12-10 |

| CN110549240B true CN110549240B (en) | 2020-12-29 |

Family

ID=68740694

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910881051.2A Active CN110549240B (en) | 2019-09-18 | 2019-09-18 | End point detection method and chemical mechanical polishing device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110549240B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112247826B (en) * | 2020-09-03 | 2022-03-22 | 北京烁科精微电子装备有限公司 | Grinding fluid flow control method, device and equipment and readable storage medium |

| CN112911483B (en) * | 2021-01-22 | 2022-08-09 | 苏州华兴源创科技股份有限公司 | Interception method, device and storage medium for effective data starting point of feedback signal |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11285968A (en) * | 1998-04-01 | 1999-10-19 | Nikon Corp | Polishing device and method |

| JP2005294365A (en) * | 2004-03-31 | 2005-10-20 | Matsushita Electric Ind Co Ltd | Method and device for polishing end detection and semiconductor device |

| JP2009004442A (en) * | 2007-06-19 | 2009-01-08 | Renesas Technology Corp | Polishing method for semiconductor wafer |

| CN101511539A (en) * | 2006-09-12 | 2009-08-19 | 株式会社荏原制作所 | Polishing apparatus and polishing method |

| CN101530983A (en) * | 2002-10-17 | 2009-09-16 | 株式会社荏原制作所 | Polishing state monitoring apparatus and polishing apparatus and method |

| CN102909649A (en) * | 2011-08-05 | 2013-02-06 | 中芯国际集成电路制造(上海)有限公司 | Chemical and mechanical polishing equipment, chemical and mechanical polishing finishing point detection device and chemical and mechanical polishing finishing point detection method |

| CN103978421A (en) * | 2013-02-07 | 2014-08-13 | 中芯国际集成电路制造(上海)有限公司 | Device and method for detecting chemical mechanical polishing end point |

| CN104907921A (en) * | 2010-03-02 | 2015-09-16 | 株式会社荏原制作所 | Polishing monitoring method, polishing method, polishing monitoring apparatus and polishing apparatus |

| CN106463378A (en) * | 2014-04-30 | 2017-02-22 | 应用材料公司 | Serial feature tracking for endpoint detection |

| CN106926110A (en) * | 2017-04-14 | 2017-07-07 | 天津华海清科机电科技有限公司 | Chemically mechanical polishing end point determination device |

| CN107234495A (en) * | 2017-07-24 | 2017-10-10 | 黄亦翔 | Set up the method for average material removal rate forecast model and the method for predicted velocity |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008044786A1 (en) * | 2006-10-06 | 2008-04-17 | Ebara Corporation | Machining end point detecting method, grinding method, and grinder |

| JP2012124419A (en) * | 2010-12-10 | 2012-06-28 | Toshiba Corp | Processing end point detection method and processing end point detection apparatus |

| JP6775354B2 (en) * | 2015-10-16 | 2020-10-28 | 株式会社荏原製作所 | Polishing equipment and polishing method |

| US11133231B2 (en) * | 2017-11-20 | 2021-09-28 | Taiwan Semiconductor Manufacturing Company Ltd. | CMP apparatus and method for estimating film thickness |

-

2019

- 2019-09-18 CN CN201910881051.2A patent/CN110549240B/en active Active

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11285968A (en) * | 1998-04-01 | 1999-10-19 | Nikon Corp | Polishing device and method |

| CN101530983A (en) * | 2002-10-17 | 2009-09-16 | 株式会社荏原制作所 | Polishing state monitoring apparatus and polishing apparatus and method |

| JP2005294365A (en) * | 2004-03-31 | 2005-10-20 | Matsushita Electric Ind Co Ltd | Method and device for polishing end detection and semiconductor device |

| CN101511539A (en) * | 2006-09-12 | 2009-08-19 | 株式会社荏原制作所 | Polishing apparatus and polishing method |

| JP2009004442A (en) * | 2007-06-19 | 2009-01-08 | Renesas Technology Corp | Polishing method for semiconductor wafer |

| CN104907921A (en) * | 2010-03-02 | 2015-09-16 | 株式会社荏原制作所 | Polishing monitoring method, polishing method, polishing monitoring apparatus and polishing apparatus |

| CN102909649A (en) * | 2011-08-05 | 2013-02-06 | 中芯国际集成电路制造(上海)有限公司 | Chemical and mechanical polishing equipment, chemical and mechanical polishing finishing point detection device and chemical and mechanical polishing finishing point detection method |

| CN103978421A (en) * | 2013-02-07 | 2014-08-13 | 中芯国际集成电路制造(上海)有限公司 | Device and method for detecting chemical mechanical polishing end point |

| CN106463378A (en) * | 2014-04-30 | 2017-02-22 | 应用材料公司 | Serial feature tracking for endpoint detection |

| CN106926110A (en) * | 2017-04-14 | 2017-07-07 | 天津华海清科机电科技有限公司 | Chemically mechanical polishing end point determination device |

| CN107234495A (en) * | 2017-07-24 | 2017-10-10 | 黄亦翔 | Set up the method for average material removal rate forecast model and the method for predicted velocity |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110549240A (en) | 2019-12-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5542802B2 (en) | Endpoint detection in chemical mechanical polishing using multiple spectra | |

| JP5774059B2 (en) | Determination of polishing end point using spectrum | |

| KR101326903B1 (en) | Apparatus and methods for real-time error detection in cmp processing | |

| US8992286B2 (en) | Weighted regression of thickness maps from spectral data | |

| CN110394728B (en) | End point detection method and system and chemical mechanical polishing device | |

| US20100114532A1 (en) | Weighted spectrographic monitoring of a substrate during processing | |

| CN110549240B (en) | End point detection method and chemical mechanical polishing device | |

| TWI654678B (en) | Serial feature tracking for endpoint detection | |

| US7768659B2 (en) | Determining copper concentration in spectra | |

| US20070077671A1 (en) | In-situ substrate imaging | |

| CN113681457B (en) | Film thickness measuring method and chemical mechanical polishing equipment | |

| TW201632311A (en) | Polishing-amount simulation method for buffing process, and buffing device | |

| CN109262445A (en) | A kind of online end-point detection method of chemical-mechanical planarization based on spectrum | |

| US6432728B1 (en) | Method for integration optimization by chemical mechanical planarization end-pointing technique | |

| US10643853B2 (en) | Wafer thinning apparatus having feedback control and method of using | |

| TW202235213A (en) | Polishing method, polishing monitoring method and polishing monitoring apparatus for workpiece | |

| US20140024293A1 (en) | Control Of Overpolishing Of Multiple Substrates On the Same Platen In Chemical Mechanical Polishing | |

| CN110509178B (en) | Chemical mechanical polishing method and device for semiconductor substrate | |

| US6293847B1 (en) | Apparatus for chemical mechanical polishing endpoint detection using a hydrogen sensor | |

| CN116423378A (en) | Metal film thickness on-line measurement compensation method, film thickness sensor and equipment | |

| US20220219282A1 (en) | Method and apparatus with polishing pad conditioning simulation | |

| US20140030956A1 (en) | Control of polishing of multiple substrates on the same platen in chemical mechanical polishing | |

| US20080138988A1 (en) | Detection of clearance of polysilicon residue | |

| TWI806898B (en) | Chattering correction for accurate sensor position determination on wafer | |

| CN116276619B (en) | Data compensation method and chemical mechanical polishing equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| CB02 | Change of applicant information | ||

| CB02 | Change of applicant information |

Address after: 100084 Haidian District Tsinghua Yuan Beijing No. 1 Applicant after: TSINGHUA University Applicant after: Huahaiqingke Co., Ltd Address before: 100084 Haidian District Tsinghua Yuan Beijing No. 1 Applicant before: TSINGHUA University |

|

| GR01 | Patent grant | ||

| GR01 | Patent grant |