CN109757023B - Printed circuit board and manufacturing method thereof - Google Patents

Printed circuit board and manufacturing method thereof Download PDFInfo

- Publication number

- CN109757023B CN109757023B CN201711091388.0A CN201711091388A CN109757023B CN 109757023 B CN109757023 B CN 109757023B CN 201711091388 A CN201711091388 A CN 201711091388A CN 109757023 B CN109757023 B CN 109757023B

- Authority

- CN

- China

- Prior art keywords

- wiring board

- printed wiring

- copper

- bending

- pcb

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title abstract description 15

- 238000005452 bending Methods 0.000 claims abstract description 58

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 39

- 229920001187 thermosetting polymer Polymers 0.000 claims abstract description 29

- 239000004744 fabric Substances 0.000 claims abstract description 19

- 239000011889 copper foil Substances 0.000 claims abstract description 16

- 239000011342 resin composition Substances 0.000 claims abstract description 16

- 239000000758 substrate Substances 0.000 claims abstract description 4

- 239000003822 epoxy resin Substances 0.000 claims description 33

- 229920000647 polyepoxide Polymers 0.000 claims description 33

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 claims description 27

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 claims description 27

- 239000000463 material Substances 0.000 claims description 26

- 229920005989 resin Polymers 0.000 claims description 26

- 239000011347 resin Substances 0.000 claims description 26

- 229910052802 copper Inorganic materials 0.000 claims description 24

- 239000010949 copper Substances 0.000 claims description 24

- 238000000034 method Methods 0.000 claims description 21

- 238000010438 heat treatment Methods 0.000 claims description 18

- 239000003795 chemical substances by application Substances 0.000 claims description 17

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 14

- 229920001400 block copolymer Polymers 0.000 claims description 13

- 229920001971 elastomer Polymers 0.000 claims description 12

- 239000005060 rubber Substances 0.000 claims description 12

- 239000005011 phenolic resin Substances 0.000 claims description 11

- RAXXELZNTBOGNW-UHFFFAOYSA-N imidazole Natural products C1=CNC=N1 RAXXELZNTBOGNW-UHFFFAOYSA-N 0.000 claims description 10

- 239000002105 nanoparticle Substances 0.000 claims description 10

- 229920001568 phenolic resin Polymers 0.000 claims description 10

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 claims description 9

- 239000002904 solvent Substances 0.000 claims description 9

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 claims description 8

- 239000011258 core-shell material Substances 0.000 claims description 8

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 claims description 8

- 229910052681 coesite Inorganic materials 0.000 claims description 7

- 229910052906 cristobalite Inorganic materials 0.000 claims description 7

- 239000000377 silicon dioxide Substances 0.000 claims description 7

- 229910052682 stishovite Inorganic materials 0.000 claims description 7

- 229910052905 tridymite Inorganic materials 0.000 claims description 7

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 claims description 6

- 239000004677 Nylon Substances 0.000 claims description 6

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 6

- -1 amine compound Chemical class 0.000 claims description 6

- JHIVVAPYMSGYDF-UHFFFAOYSA-N cyclohexanone Chemical compound O=C1CCCCC1 JHIVVAPYMSGYDF-UHFFFAOYSA-N 0.000 claims description 6

- 150000002148 esters Chemical class 0.000 claims description 6

- 239000003365 glass fiber Substances 0.000 claims description 6

- 229920001778 nylon Polymers 0.000 claims description 6

- 229920006287 phenoxy resin Polymers 0.000 claims description 6

- 239000013034 phenoxy resin Substances 0.000 claims description 6

- 238000000465 moulding Methods 0.000 claims description 5

- LLHKCFNBLRBOGN-UHFFFAOYSA-N propylene glycol methyl ether acetate Chemical compound COCC(C)OC(C)=O LLHKCFNBLRBOGN-UHFFFAOYSA-N 0.000 claims description 5

- XNWFRZJHXBZDAG-UHFFFAOYSA-N 2-METHOXYETHANOL Chemical compound COCCO XNWFRZJHXBZDAG-UHFFFAOYSA-N 0.000 claims description 3

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical class S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 claims description 3

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 claims description 3

- 229920002845 Poly(methacrylic acid) Polymers 0.000 claims description 3

- 150000008065 acid anhydrides Chemical class 0.000 claims description 3

- VTYYLEPIZMXCLO-UHFFFAOYSA-L calcium carbonate Substances [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 claims description 3

- 229910000019 calcium carbonate Inorganic materials 0.000 claims description 3

- 230000009477 glass transition Effects 0.000 claims description 3

- 238000012423 maintenance Methods 0.000 claims description 3

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N titanium dioxide Inorganic materials O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 claims description 3

- 239000008096 xylene Substances 0.000 claims description 3

- 239000003292 glue Substances 0.000 description 32

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 11

- ARXJGSRGQADJSQ-UHFFFAOYSA-N 1-methoxypropan-2-ol Chemical compound COCC(C)O ARXJGSRGQADJSQ-UHFFFAOYSA-N 0.000 description 10

- 238000012360 testing method Methods 0.000 description 10

- QGBSISYHAICWAH-UHFFFAOYSA-N dicyandiamide Chemical compound NC(N)=NC#N QGBSISYHAICWAH-UHFFFAOYSA-N 0.000 description 9

- 238000003825 pressing Methods 0.000 description 9

- 239000000126 substance Substances 0.000 description 9

- 239000003960 organic solvent Substances 0.000 description 8

- 238000002360 preparation method Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 7

- 230000003068 static effect Effects 0.000 description 7

- 150000001875 compounds Chemical class 0.000 description 6

- 230000035939 shock Effects 0.000 description 6

- 239000004593 Epoxy Substances 0.000 description 4

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 4

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 4

- 239000004843 novolac epoxy resin Substances 0.000 description 4

- 229920001721 polyimide Polymers 0.000 description 4

- 238000010998 test method Methods 0.000 description 4

- 239000004642 Polyimide Substances 0.000 description 3

- 230000009471 action Effects 0.000 description 3

- 230000001588 bifunctional effect Effects 0.000 description 3

- 230000000875 corresponding effect Effects 0.000 description 3

- 230000007547 defect Effects 0.000 description 3

- 238000005530 etching Methods 0.000 description 3

- 239000003063 flame retardant Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 150000002989 phenols Chemical class 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 2

- MQJKPEGWNLWLTK-UHFFFAOYSA-N Dapsone Chemical compound C1=CC(N)=CC=C1S(=O)(=O)C1=CC=C(N)C=C1 MQJKPEGWNLWLTK-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 125000000217 alkyl group Chemical group 0.000 description 2

- 150000001412 amines Chemical class 0.000 description 2

- WWNGFHNQODFIEX-UHFFFAOYSA-N buta-1,3-diene;methyl 2-methylprop-2-enoate;styrene Chemical compound C=CC=C.COC(=O)C(C)=C.C=CC1=CC=CC=C1 WWNGFHNQODFIEX-UHFFFAOYSA-N 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 125000003700 epoxy group Chemical group 0.000 description 2

- 239000011152 fibreglass Substances 0.000 description 2

- 150000004820 halides Chemical class 0.000 description 2

- 238000010030 laminating Methods 0.000 description 2

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 229920003986 novolac Polymers 0.000 description 2

- OUPZKGBUJRBPGC-UHFFFAOYSA-N 1,3,5-tris(oxiran-2-ylmethyl)-1,3,5-triazinane-2,4,6-trione Chemical compound O=C1N(CC2OC2)C(=O)N(CC2OC2)C(=O)N1CC1CO1 OUPZKGBUJRBPGC-UHFFFAOYSA-N 0.000 description 1

- HECLRDQVFMWTQS-RGOKHQFPSA-N 1755-01-7 Chemical compound C1[C@H]2[C@@H]3CC=C[C@@H]3[C@@H]1C=C2 HECLRDQVFMWTQS-RGOKHQFPSA-N 0.000 description 1

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 description 1

- VEORPZCZECFIRK-UHFFFAOYSA-N 3,3',5,5'-tetrabromobisphenol A Chemical compound C=1C(Br)=C(O)C(Br)=CC=1C(C)(C)C1=CC(Br)=C(O)C(Br)=C1 VEORPZCZECFIRK-UHFFFAOYSA-N 0.000 description 1

- VPWNQTHUCYMVMZ-UHFFFAOYSA-N 4,4'-sulfonyldiphenol Chemical compound C1=CC(O)=CC=C1S(=O)(=O)C1=CC=C(O)C=C1 VPWNQTHUCYMVMZ-UHFFFAOYSA-N 0.000 description 1

- YSWBFLWKAIRHEI-UHFFFAOYSA-N 4,5-dimethyl-1h-imidazole Chemical compound CC=1N=CNC=1C YSWBFLWKAIRHEI-UHFFFAOYSA-N 0.000 description 1

- JRLTTZUODKEYDH-UHFFFAOYSA-N 8-methylquinoline Chemical group C1=CN=C2C(C)=CC=CC2=C1 JRLTTZUODKEYDH-UHFFFAOYSA-N 0.000 description 1

- 241001521809 Acoma Species 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229930185605 Bisphenol Natural products 0.000 description 1

- 229920000877 Melamine resin Polymers 0.000 description 1

- 229920000459 Nitrile rubber Polymers 0.000 description 1

- 229910019142 PO4 Inorganic materials 0.000 description 1

- 244000137852 Petrea volubilis Species 0.000 description 1

- 241000519995 Stachys sylvatica Species 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- INKDAKMSOSCDGL-UHFFFAOYSA-N [O].OC1=CC=CC=C1 Chemical compound [O].OC1=CC=CC=C1 INKDAKMSOSCDGL-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 125000002723 alicyclic group Chemical group 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 150000003934 aromatic aldehydes Chemical class 0.000 description 1

- 150000001491 aromatic compounds Chemical class 0.000 description 1

- DWSWCPPGLRSPIT-UHFFFAOYSA-N benzo[c][2,1]benzoxaphosphinin-6-ium 6-oxide Chemical compound C1=CC=C2[P+](=O)OC3=CC=CC=C3C2=C1 DWSWCPPGLRSPIT-UHFFFAOYSA-N 0.000 description 1

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 1

- 239000004841 bisphenol A epoxy resin Substances 0.000 description 1

- 239000004842 bisphenol F epoxy resin Substances 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 229920006026 co-polymeric resin Polymers 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000013329 compounding Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 229930003836 cresol Natural products 0.000 description 1

- 239000004643 cyanate ester Substances 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000004088 foaming agent Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 238000007731 hot pressing Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 125000001624 naphthyl group Chemical group 0.000 description 1

- 150000002924 oxiranes Chemical class 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 1

- 239000010452 phosphate Substances 0.000 description 1

- 239000009719 polyimide resin Substances 0.000 description 1

- 229920005749 polyurethane resin Polymers 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 238000009864 tensile test Methods 0.000 description 1

- 238000004154 testing of material Methods 0.000 description 1

- 229920006305 unsaturated polyester Polymers 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/0277—Bendability or stretchability details

- H05K1/028—Bending or folding regions of flexible printed circuits

- H05K1/0281—Reinforcement details thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/244—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using glass fibres

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/0313—Organic insulating material

- H05K1/0353—Organic insulating material consisting of two or more materials, e.g. two or more polymers, polymer + filler, + reinforcement

- H05K1/0366—Organic insulating material consisting of two or more materials, e.g. two or more polymers, polymer + filler, + reinforcement reinforced, e.g. by fibres, fabrics

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Laminated Bodies (AREA)

Abstract

The invention provides a printed circuit board and a manufacturing method thereof. The printed circuit board comprises a bendable copper-clad plate as a substrate, wherein the copper-clad plate comprises a copper foil and a thermosetting resin composition impregnated base cloth adhered on the copper foil, the copper-clad plate has the elastic bending modulus of more than 10GPa, the peel strength between 60 and 200 ℃ is more than 1.0N/mm, and after the copper foil is removed, the copper-clad plate has the maximum stress value of more than 400MPa and the fracture strain value of more than 4 percent. The printed wiring board of the present invention can be formed into a printed wiring board having a bent structure by one-time or several-time press forming.

Description

Technical Field

The invention relates to the technical field of electronic products, in particular to a printed circuit board and a manufacturing method thereof.

Background

Along with development of electronic products in the direction of light, thin, short, small, multifunctional integration and daily shortage of battery endurance, the demand for three-dimensional installation of Printed Circuit Boards (PCBs) and electronic components is increasing, and currently, in order to realize three-dimensional installation, rigid-flexible PCB technical routes are mostly adopted. The traditional rigid-flexible PCB is characterized in that one PCB printed circuit board comprises one or more rigid zones and one or more flexible zones, the rigid PCB and the Flexible (FPCB) are sequentially laminated together, and the rigid PCB and the Flexible (FPCB) are electrically connected through metallized holes. The rigid-flex PCB not only can provide due support function of a rigid printed board, but also has the flexibility of a flexible board, can meet the requirement of three-dimensional assembly, and has more and more requirements in recent years. However, the rigid-flex PCB processing technology is complex and difficult, such as: the rigid PCB needs to be partially hollowed out and then is bonded with the FPCB through pressing, meanwhile, a non-glue-flowing bonding material is needed to be used between the partially hollowed rigid PCB and the flexible FPCB, and the material has a narrow laminated window and high pressing difficulty and is easy to have the defects of bubbles, white spots and the like; in addition, the Polyimide (PI) film of the Flexible Copper Clad Laminate (FCCL) has large surface inertness and low adhesion with hard boards and most of adhesive materials, while the rubber and acrylic resin system can be well adhered with the PI film, but the heat resistance, the dimensional stability and other properties are not good, so that the product reliability has hidden danger, the yield is low, and the cost is high.

Many soft and hard combined PCBs are used in the field of static bending, so-called static bending, that is, only one time of bending is needed during installation, or after one-time bending forming, the bending area does not need to swing, that is, the PCB is static during working and does not swing back and forth like a printer laser head; however, even in these static bending fields, the conventional rigid PCB cannot meet the bending forming and using requirements.

Therefore, in the field of electronic products such as a plurality of static bending installation PCBs and the like, the material is required to have the processing capacity of one-time impact forming, impact stress can be well borne in the impact forming process, cracking and layering are avoided, various three-dimensional bending or concave-convex shapes are punched for fixing, and the subsequent installation and use of the PCBs are facilitated.

Disclosure of Invention

The invention aims to provide a PCB mounted by static bending and a manufacturing method thereof.

The purpose of the invention can be realized by the following technical scheme.

One aspect of the present invention provides a printed wiring board comprising a statically bendable copper-clad laminate as a substrate, the copper-clad laminate comprising a copper foil and a thermosetting resin composition impregnated base fabric adhered to the copper foil, the copper-clad laminate having a flexural modulus of elasticity >10GPa (preferably >12GPa), a peel strength between 60-200 ℃ of greater than 1.0N/mm, and having a maximum stress value of greater than 400Mpa and a strain at break value of greater than 4% after removal of the copper foil.

In certain embodiments, the thermosetting resin composition comprises: a thermosetting resin; a curing agent; a toughening material; and a solvent, wherein the thermosetting resin is 100 parts by weight, the curing agent is 1-50 parts by weight, the toughening material is 20-60 parts by weight, and the solvent is 5-50 parts by weight.

In certain embodiments, the thermosetting resin comprises an epoxy resin, preferably a multifunctional epoxy resin; and/or the curing agent comprises at least one of phenolic resin, amine compound, acid anhydride, imidazole compound, sulfonium salt, dicyandiamide and active ester; and/or the toughening material comprises rubber (preferably rubber with a core-shell structure), phenoxy resin and polyethyleneButyral (PVB), nylon, nanoparticles (preferably SiO)2,TiO2Or CaCO3Nanoparticles), olefinic block copolymers (preferably block copolymers of polymethacrylic acid, butadiene and styrene); and/or, the solvent comprises at least one of Dimethylformamide (DMF), ethylene glycol methyl ether (MC), propylene glycol methyl ether (PM), propylene glycol methyl ether acetate (PMA), cyclohexanone, Methyl Ethyl Ketone (MEK), toluene, xylene.

In certain embodiments, the base fabric comprises a fiberglass cloth or a non-woven fabric.

In certain embodiments, the printed wiring board is a High Density Interconnect (HDI) printed wiring board.

Another aspect of the present invention provides a method for bending a printed wiring board, the method comprising: the printed circuit board is placed into a die for punch forming, and the die is designed to form a bending structure with a bending angle of 10-90 degrees and a bending radius of 1-25 mm.

In some embodiments, the printed wiring board is heated to a temperature of 60-200 ℃, preferably to a temperature of ± 50 ℃ of the glass transition temperature of the thermosetting resin composition in the copper clad laminate, prior to being placed in the mold.

In certain embodiments, the conditions of the stamping forming include:

1) stamping pressure: 100N-20000N;

2) press molding maintenance time: 2sec or more;

3) temperature of the die: normal temperature (20-35 ℃) or heating to below 100 ℃.

In some embodiments, the number of copper clad laminate layers in the printed wiring board subjected to punch forming is 4-14, and the thickness is 0.2 mm-1 mm.

Still another aspect of the present invention provides a High Density Interconnect (HDI) printed wiring board having a bending structure, wherein the HDI printed wiring board having a bending structure is manufactured by one or more times of press forming using the method of any one of claims 6 to 9, and has a bending angle of 10 to 90 ° and a bending radius of 1mm to 25mm, and preferably, the area of the printed wiring board to be bent has only a simple wiring and no via hole.

The invention may have at least one of the following advantages:

1. the copper-clad plate and the printed circuit board adopting the copper-clad plate can be plastically deformed in a certain temperature range under the action of mechanical force, and the shape generated by the original deformation can not be changed when the mechanical force is released and the normal temperature is recovered, so that the copper-clad plate can be fixedly formed, namely, the copper-clad plate has certain rigidity to bear the stress action, generate deformation without breakage, and have deformation strain.

2. The production process flow of the printed circuit board is simple, the manufacturing process of the printed circuit board with soft and hard combination is not needed, the efficiency is improved, and the cost is saved.

3. The printed circuit board has the processing capacity of bending and forming once or for a plurality of times, can better bear impact stress in the bending and forming process, does not crack or delaminate, can be punched into various three-dimensional bends or concave-convex shapes for fixing, is convenient for subsequent static bending and installation, and is particularly suitable for HDI printed circuit boards.

Drawings

Fig. 1 shows five types of stress-strain curves.

FIG. 2 shows a typical stress (F) -strain (L) curve of the CCL of the present invention obtained according to tensile strength and tensile modulus test method.

Fig. 3 shows a bending radius of the PCB formed by bending in embodiment 1 of the present application.

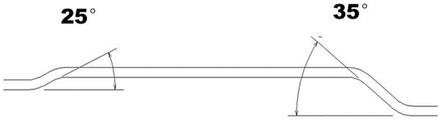

Fig. 4 shows a bending angle of the PCB bent and formed in embodiment 1 of the present application.

Detailed Description

The present invention surprisingly found that: the thermosetting resin composition containing toughening material is used for impregnating base cloth such as glass fiber cloth and the like to prepare a prepreg, the prepreg and a copper foil are laminated and compounded, and after complete curing, a copper-clad plate with rigid and tough (or hard and tough) characteristics can be obtained.

The stress-strain curve for a material with hard and tough characteristics is shown as curve 2 in fig. 1. In fig. 1, the material properties represented by the curves are as follows: 1. hard and brittle; 2. hard and tough; 3. hard and strong; 4. soft and tough; 5. soft and weak.

Based on the discovery, the invention provides a copper-clad plate capable of being bent and formed, a printed circuit board and a manufacturing method thereof. Various aspects of the invention are described in detail below.

Copper-clad plate

One aspect of the invention provides a bendable copper-clad plate, which comprises a copper foil and base cloth adhered to the copper foil and impregnated by the thermosetting resin composition.

Thermosetting resin composition

In the present invention, the thermosetting resin composition for impregnating the base fabric may comprise: a thermosetting resin; a curing agent; a toughening material; and a solvent.

In certain embodiments, the thermosetting resin may include epoxy resins, phenolic resins, polyimide resins, urea-formaldehyde resins, melamine resins, unsaturated polyesters, polyurethane resins, and the like, with epoxy resins being preferred.

Specific examples of the epoxy resin may include: bisphenol a epoxy resins, bisphenol F epoxy resins, bisphenol S epoxy resins, aralkyl epoxy resins, phenol novolac epoxy resins (phenol novolac epoxy resins), alkyl novolac epoxy resins (alkyl novolac epoxy resins), bisphenol epoxy resins, naphthalene epoxy resins, dicyclopentadiene epoxy resins, epoxides obtained by condensation of phenol compounds and aromatic aldehydes having a phenolic hydroxyl group, triglycidyl isocyanurate, alicyclic epoxy resins, and the like. These epoxy resins may be used alone or in combination of two or more kinds depending on the case.

Preferably, the epoxy resin is a polyfunctional epoxy resin containing two or more epoxy groups (preferably three or more epoxy groups) in one molecule. As such an epoxy resin, commercially available epoxy resins, for example, JER1003 (manufactured by Mitsubishi chemical corporation, 7 to 8 methyl groups, bifunctional, molecular weight 1300), EXA-4816 (manufactured by Diegon, molecular weight 824, majority methyl groups, bifunctional), YP50 (manufactured by Nichikomo Metal chemical corporation, molecular weight 60000 to 80000, majority methyl groups, bifunctional), DER593 (manufactured by Dow chemical corporation, polyfunctional epoxy resin), EPIKOTE 157 (manufactured by Resolution, polyfunctional epoxy resin), and the like can be used.

In certain embodiments, the curing agent in the thermosetting resin composition may be determined according to the kind of the thermosetting resin. For the epoxy resin, the curing agent may include at least one of a phenol resin, an amine-based compound, an acid anhydride, an imidazole-based compound, a sulfonium salt, dicyandiamide, and an active ester.

The active ester curing agent is obtained by reacting a phenolic compound, a difunctional carboxylic aromatic compound or an acid halide and a monohydroxy compound which are connected through an aliphatic cyclic hydrocarbon structure. The dosage of the difunctional carboxylic acid aromatic compound or the acid halide is 1mol, the dosage of the phenolic compound connected through the aliphatic cyclic hydrocarbon structure is 0.05-0.75 mol, and the dosage of the monohydroxy compound is 0.25-0.95 mol. The active ester curing agent may include an active ester of the formula:

wherein X in the formula is a benzene ring or a naphthalene ring, j is 0 or 1, k is 0 or 1, and n represents an average repeating unit of 0.25-1.25.

In certain embodiments, the curing agent is preferably a phenolic resin, an amine-based compound, an imidazole-based compound, and dicyandiamide. These curing agents may be used alone or in combination of two or more. Specific curing agents may include: phenolic resins (e.g., phenol novolac resins, cresol novolac resins, etc.); diamino Diphenyl Sulfone (DDS); dicyandiamide (DICY); dimethylimidazole (2-MI), and the like.

The curing agent is generally used in an amount of 1 to 50 parts by weight, for example, 1 to 40 parts by weight, or 1 to 30 parts by weight, relative to 100 parts by weight of the thermosetting resin. For epoxy resins, the amount of curing agent can be controlled such that the ratio of epoxy equivalents of the epoxy resin to hydroxyl equivalents of the phenolic resin is 1:1 to 0.95; or the equivalent ratio of epoxy resin to amino group is 1: 0.6 to 0.4.

In certain embodiments, the toughening material comprises at least one of rubber, phenoxy resin, polyvinyl butyral (PVB), nylon, nanoparticles, olefinic block copolymers. These toughening materials are selected according to compatibility with thermosetting resins such as epoxy resins, toughening effect (to achieve a corresponding stress strain requirement (described later)), and the like. Among them, the rubber is preferably a rubber having a core-shell structure, such as a methylmethacrylate-butadiene-styrene (MBS) core-shell type copolymer resin, a rubber-epoxy type core-shell resin, and the like, and representative thereof are commercially available including M-521, MX-395, and the like, from Bell-source Japan. The nanoparticles comprise SiO2,TiO2Or CaCO3Nanoparticles and the like, the particle diameter of which is generally 10 to 500 nm. Olefinic block copolymers are block copolymers formed by the copolymerization of different types of olefins, for example, block copolymers of polymethacrylic acid, butadiene and styrene.

The toughening materials may be used alone or in combination of two or more. For example, the nanoparticles can be used in combination with another toughening material (e.g., core shell rubber, phenoxy resin, PVB, nylon, olefinic block copolymer, or mixtures thereof) in a weight ratio of 1:10 to 2: 1.

For good toughening, the total amount of toughening materials used is generally from 20 to 60 parts by weight, for example, from 20 to 50 parts by weight, or from 30 to 60 parts by weight, per 100 parts by weight of the thermosetting resin.

In certain embodiments, the solvent may include at least one of Dimethylformamide (DMF), ethylene glycol methyl ether (MC), propylene glycol methyl ether (PM), propylene glycol methyl ether acetate (PMA), cyclohexanone, Methyl Ethyl Ketone (MEK), toluene, xylene. The solvent is generally used in an amount of 5 to 50 parts by weight, for example, 10 to 50 parts by weight, 20 to 50 parts by weight, etc., relative to 100 parts by weight of the thermosetting resin, to form a dope having a viscosity of 300-600 cPa.s.

In certain embodiments, the thermosetting resin composition may further contain fillers or auxiliaries and the like, such as flame retardants, leveling agents, colorants, dispersants, coupling agents, foaming agents and the like, within a range in which the effects of the present invention are not lost. Wherein the flame retardant can be one or more of organic flame retardant such as tetrabromobisphenol A, DOPO and phosphate.

-base cloth-

In certain embodiments, the base fabric comprises a fiberglass cloth or a non-woven fabric. The glass fiber cloth can be selected from 7628, 2116, 1080, 106, 1037, 1027, 1017 and other specifications.

-copper foil-

In some embodiments, the copper foil can be selected from 1OZ, 1/2OZ, 1/3OZ, and the like.

Copper clad laminate capable of being bent statically

The copper-clad plate capable of being statically bent can be plastically deformed within a certain temperature range under the action of mechanical force, and the shape generated by the original deformation cannot be changed when the mechanical force is released and the copper-clad plate is restored to the normal temperature, so that the copper-clad plate can be fixedly formed.

In certain embodiments, the copper clad laminate has a flexural modulus of elasticity >10GPa, a peel strength between 60-200 ℃ of greater than 1.0N/mm, and, after removal of the copper foil, a maximum stress value of greater than 400Mpa and a strain to failure value of greater than 4%.

The stress strain value is measured by the following tensile strength and tensile modulus test methods.

The method for testing the tensile strength and the tensile modulus of the material comprises the following steps:

A. test devices and/or materials

-material testing machine

A tensile compression tester according to ISO3384 standard, which can operate the tensile clamp at a stable speed. The error of the load measurement system does not exceed +/-1%.

An etching system capable of completely removing the metal-clad foil.

Vernier calipers (to the nearest 0.02mm) or micrometers (to the nearest 0.002mm)

-test sample

(1) Size and shape

The dimensions of the test specimen are 250mm × 25mm, the thickness of the test specimen is preferably 0.4mm, and the edge of the test specimen should be free from defects such as cracks, delamination and the like, otherwise, the test specimen is ground by sand paper or an equivalent tool (the edge is not formed into a round angle).

(2) Quantity and sampling

When the coefficient of variation is less than 5%, ten specimens, five pieces in the longitudinal direction and five pieces in the transverse direction (cut out on the whole sample plate or platelet) are used for each batch. When the dispersion coefficient is greater than 5%, the number of samples in each direction cannot be less than 10, and 10 valid samples are guaranteed.

(3) All the metal covering layer is etched and removed by an etching method.

B. Tensile test procedure

Measuring the dimensions of the sample

The width and thickness of the test specimen were measured and recorded, with the width being accurate to 0.02mm and the thickness being accurate to 0.002 mm.

-measuring

(1) And clamping the sample to make the center line of the sample consistent with the alignment center line of the upper clamp and the lower clamp.

(2) The distance between the upper clamp and the lower clamp is adjusted to be 125mm +/-0.5 mm.

(3) The loading speed was 12.5 mm/min.

(4) The tensile modulus calculation was set at a fraction between 0.05% and 0.25% strain.

(5) The test was performed and stress-strain curves were plotted.

(6) Specimens with significant internal defects should be discarded.

(7) The specimen should be rejected if the specimen breaks in the fixture or if the specimen breaks less than 10mm from the clamped position.

C. Computing

The tensile strength of each specimen was calculated as follows

In the formula:

τT: tensile strength, MPa

F: breaking or maximum load, N

b: width of specimen in mm

d: thickness of the sample in mm

The tensile modulus of elasticity of each specimen was calculated as follows

In the formula:

Et: tensile modulus of elasticity, MPa

σ ": tensile stress value measured at 0.25% epsilon ∈ strain, MPa

σ': tensile stress value measured at 0.05% ε strain, (. epsilon.'), MPa

-calculating the average tensile strength and the tensile modulus of elasticity in MPa.

Fig. 2 shows a typical stress-strain curve of the copper clad laminate obtained according to the tensile strength and tensile modulus test method described above. As shown in FIG. 2, the copper clad laminate of the present invention (after etching to remove the metal covering layer) has a maximum stress value of more than 400MPa and a fracture strain value of more than 4%.

Method for manufacturing copper clad laminate

In some embodiments, the copper-clad plate of the present invention can be made according to the following method:

preparation of prepregs

The base cloth is impregnated or coated with the thermosetting resin composition in the form of the glue of the present invention, and then heated at 100-200 ℃ for 1-10 minutes (e.g., 3-10 minutes) to obtain a prepreg (a semi-cured B-stage state). The resin content of the prepreg can be controlled to be between 40 and 70 wt%, and the resin fluidity of the prepreg can be controlled to be between 10 and 30%.

-manufacturing copper clad laminate

And laminating the cut prepreg on a copper foil, carrying out hot pressing at the heating rate of 1-3 ℃/min, keeping the pressure at the maximum of 300-500PSI, and keeping the temperature at the maximum of 180-200 ℃ for 30-120 minutes (such as 60-120 minutes) to obtain the copper-clad plate.

In certain embodiments, the copper clad laminate of the present invention can be stamped and formed in a die. Preferably, the temperature for stamping is selected within a range of ± 50 ℃, preferably ± 30 ℃ of the Tg value of the copper clad laminate (thermosetting resin composition).

Printed Circuit Board (PCB)

The invention also provides a bendable PCB which comprises the copper-clad plate as a substrate.

In certain embodiments, the PCB is a HDI-PCB (high density interconnect printed wiring board).

In some embodiments, the PCB is fabricated on the above copper clad laminate according to a conventional PCB fabrication process.

In some embodiments, the area of the PCB that needs to be bent is simply a circuit without vias.

Bending forming method of printed circuit board

Another aspect of the present invention provides a method for bending a printed wiring board, the method comprising: and putting the printed circuit board into a die, and performing punch forming to generate the required steps so as to be suitable for three-dimensional installation.

In certain embodiments, the die is pre-designed with different bend radii (2-50mm) and bend angles (10-90 °).

In certain embodiments, the printed wiring board is heated to a temperature of 60-200 ℃ prior to placement in the mold.

In some embodiments, the press molding temperature is + -50 deg.C (preferably + -30 deg.C) of the glass transition temperature of the thermosetting resin composition in the copper-clad laminate, and the setting time is 2sec or more.

In certain embodiments, the conditions of the stamping forming include:

1) stamping pressure: 100N-20000N;

2) press molding maintenance time: 2sec or more;

3) temperature of the die: normal temperature (20-35 ℃) or heating to below 100 ℃.

In certain embodiments, other clamp parameters may include: the mold clamping rate is 0 to 2000mm/min, and the upper limit of the mold clamping pressure value is 100 to 20000N.

In certain embodiments, the number of copper clad laminates in the printed wiring board subjected to stamping forming can be 4-14 layers, and the thickness can be 0.2 mm-1 mm.

In certain embodiments, one or more stamping presses may be performed to achieve various bending forms.

High Density Interconnect (HDI) printed wiring board with bend structure

Still another aspect of the present invention provides a High Density Interconnect (HDI) printed wiring board having a bending structure, which can be manufactured by the above bending method.

In certain embodiments, the HDI printed wiring board has a bend angle of 10 to 90 ° and a bend radius of 1mm to 25 mm.

In some embodiments, the HDI printed circuit board has only simple circuits and no via holes in the region where bending is required.

In certain embodiments, the HDI printed wiring board may be fabricated by one or several molding passes.

The technical solution of the present invention will be further described in detail with reference to the following specific examples. These examples are illustrative only and are not intended to limit the scope of the present invention.

Example 1:

1. glue solution preparation: 5 parts by weight of rubber (Japanese Brillouin M-521), 10 parts by weight of core-shell rubber (Japanese Brillouin MX-395) and 20 parts by weight of nano SiO2(winning bond Nanopol A710) as toughening material was mixed with 100 parts by weight of a multifunctional epoxy resin (DER 593 resin of DOW chemistry) and a phenolic resin (XZ 92741 resin of DOW chemistry) was added so that the epoxy equivalent to hydroxyl equivalent ratio was 1:1 and a proper amount of MEK organic solvent are prepared into glue solution, and the viscosity of the glue solution is controlled to be between 300-600 cPAS.

2. Manufacturing a prepreg: the glue is firstly used for dipping the glass fiber cloth (2116 glass fiber cloth) for gluing, and then the glass fiber cloth is put into an oven for heating and baking for 3 to 10 minutes at the temperature of 100-.

3. Manufacturing a copper-clad plate: selecting 1OZ copper foil, combining with the prepreg, placing into a laminating machine, heating at a rate of 1-3 ℃/min, pressing at a maximum pressure of 300-.

4. Manufacturing a PCB: the copper-clad plate is used for producing the PCB according to the traditional PCB manufacturing process, and the PCB is only provided with a simple circuit in an area which needs to be bent and formed locally.

5. Bending and forming the PCB: (1) firstly, heating the PCB to 60 ℃; (2) heating the PCB to stabilize the temperature, putting the PCB into a stamping machine, pressing the PCB for 5 seconds at 10000N pressure, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB are shown in fig. 3 and 4.

6. The PCB was tested for appearance, elastic modulus, thermal shock (288 ℃/10S), reflow (maximum stability 280 ℃), ion migration resistance (CAF) and other relevant properties, and the stress strain values were determined according to the tensile strength and tensile modulus test methods described in the specification.

Example 2:

copper clad laminates and PCBs were made in the same manner as in example 1, except for the following glue solution configuration.

Glue solution preparation: 20 parts by weight of phenol oxygen (53 BH35 of HEXION) and 10 parts by weight of core-shell rubber CSR (Japanese Brillouin MX-395) are selected as toughening materials, mixed with 100 parts by weight of multifunctional epoxy resin (EPIKOTE 157 resin of Resolution), added with 2.5 parts by weight of dicyandiamide and a proper amount of DMF organic solvent to prepare glue solution, and the viscosity of the glue solution is controlled between 300 and 600 cPAS.

Bending and forming the PCB: (1) firstly, heating the PCB to 120 ℃; (2) heating the PCB to stabilize the temperature, putting the PCB into a punching machine, pressing the PCB for 100 seconds at the pressure of 100N, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB were the same as those of example 1.

The appearance, modulus of elasticity, stress strain value, thermal shock, reflow, CAF, etc. were tested for the relevant properties as described in example 1.

Example 3:

copper clad laminates and PCBs were made in the same manner as in example 1, except for the following glue solution configuration.

Glue solution preparation: 20 parts of PVB (U.S. Konno B90) and 8 parts of nano SiO2(winning Nanopolo A710) and5 parts by weight of a block copolymer (Achima Nanostgth)) For toughening material, 100 weight parts of multifunctional epoxy resin (DER 593 resin from DOW chemical company) is mixed, 3 weight parts of dicyandiamide and a proper amount of DMF or PM organic solvent are added to prepare glue solution, and the viscosity of the glue solution is controlled between 300 cPAS and 600 cPAS.

Bending and forming the PCB: (1) firstly, heating the PCB to 200 ℃; (2) and heating the PCB to stabilize the temperature, putting the PCB into a die stamping machine, pressing the PCB for 2 seconds at 20000N pressure, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB were the same as those of example 1.

The appearance, modulus of elasticity, stress strain value, thermal shock, reflow, CAF, etc. were tested for the relevant properties as described in example 1.

Example 4:

copper clad laminates and PCBs were made in the same manner as in example 1, except for the following glue solution configuration.

Glue solution preparation: selecting 20 parts by weight of nylon (DuPont ST801A USA) and 8 parts by weight of nano SiO2(winning Nanopol A710), mixing with 100 weight parts of multifunctional epoxy resin (DOW chemical DER593 resin), adding phenolic resin (EPIKURE YLH129B65 of Resolution company) and a proper amount of MEK organic solvent according to the epoxy equivalent and hydroxyl equivalent of 1:1, preparing into glue solution, and controlling the viscosity of the glue solution between 300 and 600 cPAS.

Bending and forming the PCB: (1) firstly, heating the PCB to 100 ℃; (2) heating the PCB to stabilize the temperature, putting the PCB into a stamping machine, pressing the PCB for 10 seconds at 10000N pressure, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB were the same as those of example 1.

The appearance, modulus of elasticity, stress strain value, thermal shock, reflow, CAF, etc. were tested for the relevant properties as described in example 1.

Example 5:

copper clad laminates and PCBs were made in the same manner as in example 1, except for the following glue solution configuration.

Compounding of glue solutionPlacing: 25 parts by weight of a block copolymer (Acoma Nanostrength) is selected) And 8 parts by weight of nano SiO2(winning Nanopol A710) is taken as a toughening material, is mixed with 100 parts by weight of cyanate ester resin (HF-10 of Huiyou corporation), and is added with 20 parts by weight of phenolic resin (EPIKURE YLH129B65 of RESOLUTION corporation) and a proper amount of MEK organic solvent to prepare glue solution, and the viscosity of the glue solution is controlled between 300 and 600 cPAS.

Bending and forming the PCB: (1) firstly, heating the PCB to 200 ℃; (2) heating the PCB to stabilize the temperature, putting the PCB into a stamping machine, pressing the PCB for 20 seconds at 10000N pressure, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB were the same as those of example 1.

The appearance, modulus of elasticity, stress strain value, thermal shock, reflow, CAF, etc. were tested for the relevant properties as described in example 1.

Example 6:

copper clad laminates and PCBs were made in the same manner as in example 1, except for the following glue solution configuration.

Glue solution preparation: selecting 20 weight parts of phenoxy resin (Nissin iron chemical ERF-001), 10 weight parts of PVB (U.S. Konno B90) and 5 weight parts of nano SiO2(winning Nanopolo A710) as toughening material, mixing with 50 weight parts of PPO resin (such as MX90 from Sabour base) and 100 weight parts of epoxy resin (DOW chemical DER593 resin), adding 20 weight parts of phenolic resin (EPIKURE YLH129B65 from RESOLUTION), and appropriate amount of MEK organic solvent, and making into glue solution with viscosity controlled between 300 and 600 cPAS.

Bending and forming the PCB: (1) firstly, heating the PCB to 180 ℃; (2) heating the PCB to stabilize the temperature, putting the PCB into a stamping machine, pressing the PCB for 30 seconds at 10000N pressure, then opening the die, and taking out the PCB. The bending radius and bending angle of the resulting PCB were the same as those of example 1.

The appearance, modulus of elasticity, stress strain value, thermal shock, reflow, CAF, etc. were tested for the relevant properties as described in example 1.

Comparative example 1:

a PCB and a bending mold were fabricated in the same manner as example 1 except for the following glue solution configuration, and corresponding properties were tested.

Glue solution preparation: selecting 100 weight parts of multifunctional epoxy resin (DOW chemical DER593 resin), adding 2-3 weight parts of dicyandiamide and a proper amount of DMF organic solvent to prepare glue solution, and controlling the viscosity of the glue solution between 300 and 600 cPAS.

Comparative example 2:

a PCB and a bending mold were fabricated in the same manner as example 1 except for the following glue solution configuration, and corresponding properties were tested.

Glue solution preparation: 10 parts by weight of nitrile butadiene rubber (such as Japanese Brillouin M-521) and 100 parts by weight of multifunctional epoxy resin (DOW chemical DER593 resin) are mixed, 2-3 parts by weight of dicyandiamide and a proper amount of DMF organic solvent are added to prepare a glue solution, and the viscosity of the glue solution is controlled to be between 300-.

The test results are given in the following table:

while the present invention has been described with reference to the preferred embodiments, it will be understood by those skilled in the art that various changes and modifications may be made therein without departing from the spirit and scope of the invention as defined in the appended claims.

The present invention is illustrated in detail by the examples described above, but the present invention is not limited to the details described above, i.e., it is not intended that the present invention be implemented by relying on the details described above. It should be understood by those skilled in the art that any modification of the present invention, equivalent substitutions of the raw materials of the product of the present invention, addition of auxiliary components, selection of specific modes, etc., are within the scope and disclosure of the present invention.

Claims (13)

1. A printed circuit board is characterized in that the printed circuit board comprises a bendable copper clad laminate as a substrate, the copper clad laminate comprises a copper foil and a thermosetting resin composition impregnated base cloth adhered on the copper foil, the copper clad laminate has an elastic bending modulus of more than 10GPa, a peel strength of more than 1.0N/mm at 60-200 ℃, and has a maximum stress value of more than 400MPa and a fracture strain value of more than 4 percent after the copper foil is removed,

wherein the thermosetting resin composition comprises: a thermosetting resin; a curing agent; a toughening material; and a solvent, wherein the thermosetting resin is 100 parts by weight, the curing agent is 1-50 parts by weight, the toughening material is 20-60 parts by weight, and the solvent is 5-50 parts by weight,

wherein the thermosetting resin comprises an epoxy resin;

wherein the curing agent comprises at least one of phenolic resin, amine compound, acid anhydride, imidazole compound, sulfonium salt and active ester;

wherein the toughening material comprises the combination of nanoparticles and at least one of rubber, phenoxy resin, polyvinyl butyral, nylon and olefinic block copolymer with a core-shell structure;

wherein the nanoparticles are used in combination with at least one of rubber, phenoxy resin, polyvinyl butyral, nylon, olefinic block copolymers in a weight ratio of 1:10 to 2:1, and

wherein the base cloth comprises glass fiber cloth or non-woven cloth.

2. The printed wiring board of claim 1, wherein the epoxy resin is a multifunctional epoxy resin.

3. The printed wiring board of claim 1, wherein the nanoparticles comprise SiO2,TiO2Or CaCO3Nanoparticles.

4. The printed wiring board of claim 1, wherein the olefinic block copolymer comprises a block copolymer of polymethacrylic acid, butadiene, and styrene.

5. The printed wiring board of claim 1, wherein the solvent comprises at least one of dimethylformamide, ethylene glycol methyl ether, propylene glycol methyl ether acetate, cyclohexanone, methyl ethyl ketone, toluene, and xylene.

6. The printed wiring board of claim 1, wherein the printed wiring board is a high density interconnect printed wiring board.

7. A method for bending a printed wiring board, comprising: the printed wiring board according to any one of claims 1 to 6 is placed in a mold and press-formed, and the mold is designed to form a bent structure having a bending angle of 10 to 90 ° and a bending radius of 1mm to 25 mm.

8. The method of claim 7, wherein the printed wiring board is heated to a temperature of 60 to 200 ℃ before being placed in the mold.

9. The method of claim 7, wherein the printed wiring board is heated to a temperature within ± 50 ℃ of the glass transition temperature of the thermosetting resin composition in the copper clad laminate before being placed in the mold.

10. The method according to claim 8 or 9, wherein the conditions of the press forming include:

1) stamping pressure: 100 to 20000N;

2) press molding maintenance time: 2sec or more;

3) temperature of the die: 20-35 ℃ or heating to below 100 ℃.

11. The method according to claim 7, wherein the number of copper clad laminate layers in the printed circuit board subjected to punch forming is 4-14, and the thickness is 0.2-1 mm.

12. A high-density interconnected printed wiring board having a bent structure, characterized in that the high-density interconnected printed wiring board having a bent structure is manufactured by one-time or several-time press forming by the method of any one of claims 7 to 11, and has a bending angle of 10 to 90 ° and a bending radius of 1 to 25 mm.

13. The high-density interconnected printed wiring board with a bending structure as claimed in claim 12, wherein the area of the printed wiring board to be bent is only a simple wiring without via holes.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711091388.0A CN109757023B (en) | 2017-11-08 | 2017-11-08 | Printed circuit board and manufacturing method thereof |

| PCT/CN2017/117501 WO2019090918A1 (en) | 2017-11-08 | 2017-12-20 | Printed circuit board and manufacturing method therefor |

| KR1020207010583A KR102522754B1 (en) | 2017-11-08 | 2017-12-20 | Printed circuit board and its manufacturing method |

| TW107106258A TWI711354B (en) | 2017-11-08 | 2018-02-23 | Printed circuit board and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711091388.0A CN109757023B (en) | 2017-11-08 | 2017-11-08 | Printed circuit board and manufacturing method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109757023A CN109757023A (en) | 2019-05-14 |

| CN109757023B true CN109757023B (en) | 2022-04-26 |

Family

ID=66401468

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711091388.0A Active CN109757023B (en) | 2017-11-08 | 2017-11-08 | Printed circuit board and manufacturing method thereof |

Country Status (4)

| Country | Link |

|---|---|

| KR (1) | KR102522754B1 (en) |

| CN (1) | CN109757023B (en) |

| TW (1) | TWI711354B (en) |

| WO (1) | WO2019090918A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112662132B (en) * | 2020-12-22 | 2023-08-22 | 广东盈骅新材料科技有限公司 | Modified resin composition and preparation method and application thereof |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102304273A (en) * | 2011-04-03 | 2012-01-04 | 广东生益科技股份有限公司 | Thermosetting epoxy resin composition and epoxy fiberglass cloth-based copper clad laminate prepared from same |

| CN102585531A (en) * | 2011-12-14 | 2012-07-18 | 东北林业大学 | Lignin-epoxy resin composite material and preparation method thereof |

| CN103013045A (en) * | 2012-12-13 | 2013-04-03 | 东莞市海旭工艺制品有限公司 | Novel preparation method of epoxy tooling board |

| CN103459539A (en) * | 2011-02-15 | 2013-12-18 | 泽菲罗斯公司 | Improved structural adhesives |

| CN104010811A (en) * | 2012-01-17 | 2014-08-27 | Jx日矿日石金属株式会社 | Copper-polyimide laminate, three-dimensional molding body, and method for producing three-dimensional molding body |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4193381B2 (en) * | 2001-07-16 | 2008-12-10 | 日立電線株式会社 | Bending-resistant flexible flat cable and manufacturing method thereof |

| KR100523913B1 (en) * | 2003-09-16 | 2005-10-25 | 주식회사 엘지화학 | Composition for Resin Coated Copper and Method for Preparing a Resin Coated Copper Using the Same |

| WO2006112523A1 (en) * | 2005-04-19 | 2006-10-26 | Ube Industries, Ltd. | Polyimide film laminate |

| WO2006112478A1 (en) * | 2005-04-19 | 2006-10-26 | Denki Kagaku Kogyo Kabushiki Kaisha | Metal base circuit board, led, and led light source unit |

| JP5533657B2 (en) * | 2008-09-26 | 2014-06-25 | 住友ベークライト株式会社 | Laminate board, circuit board and semiconductor device |

| US8314487B2 (en) * | 2009-12-18 | 2012-11-20 | Infineon Technologies Ag | Flange for semiconductor die |

| JP2013203950A (en) * | 2012-03-29 | 2013-10-07 | Tamura Seisakusho Co Ltd | Thermosetting resin composition, resin film, copper-clad sheet and flexible printed wiring board |

| JP6225643B2 (en) * | 2013-10-31 | 2017-11-08 | 味の素株式会社 | Laminate production method |

| KR101987305B1 (en) * | 2013-11-19 | 2019-06-10 | 삼성전기주식회사 | Insulating resin composition for printed circuit board and products having the same |

| JP6269294B2 (en) * | 2014-04-24 | 2018-01-31 | 味の素株式会社 | Resin composition for insulating layer of printed wiring board |

| CN107206643B (en) * | 2014-09-23 | 2019-10-22 | 朗德万斯有限责任公司 | The method for forming circuit board |

| CN104725781B (en) * | 2015-03-11 | 2017-11-03 | 广东生益科技股份有限公司 | A kind of resin combination and use its prepreg and laminate |

| JP5969645B1 (en) * | 2015-03-16 | 2016-08-17 | 日本メクトロン株式会社 | Flexible printed wiring board |

-

2017

- 2017-11-08 CN CN201711091388.0A patent/CN109757023B/en active Active

- 2017-12-20 WO PCT/CN2017/117501 patent/WO2019090918A1/en active Application Filing

- 2017-12-20 KR KR1020207010583A patent/KR102522754B1/en active IP Right Grant

-

2018

- 2018-02-23 TW TW107106258A patent/TWI711354B/en active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103459539A (en) * | 2011-02-15 | 2013-12-18 | 泽菲罗斯公司 | Improved structural adhesives |

| CN102304273A (en) * | 2011-04-03 | 2012-01-04 | 广东生益科技股份有限公司 | Thermosetting epoxy resin composition and epoxy fiberglass cloth-based copper clad laminate prepared from same |

| CN102585531A (en) * | 2011-12-14 | 2012-07-18 | 东北林业大学 | Lignin-epoxy resin composite material and preparation method thereof |

| CN104010811A (en) * | 2012-01-17 | 2014-08-27 | Jx日矿日石金属株式会社 | Copper-polyimide laminate, three-dimensional molding body, and method for producing three-dimensional molding body |

| CN103013045A (en) * | 2012-12-13 | 2013-04-03 | 东莞市海旭工艺制品有限公司 | Novel preparation method of epoxy tooling board |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2019090918A1 (en) | 2019-05-16 |

| CN109757023A (en) | 2019-05-14 |

| KR20200053566A (en) | 2020-05-18 |

| TWI711354B (en) | 2020-11-21 |

| TW201919451A (en) | 2019-05-16 |

| KR102522754B1 (en) | 2023-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109749360B (en) | Thermosetting resin composition, copper-clad plate capable of being bent statically and printed circuit board prepared from thermosetting resin composition | |

| KR101141902B1 (en) | Epoxy resin composition, prepreg, laminate board, multilayer printed wiring board, semiconductor device, insulating resin sheet, and process for manufacturing multilayer printed wiring board | |

| KR101386373B1 (en) | Resin composition, insulating sheet with base, prepreg, multilayer printed wiring board and semiconductor device | |

| KR101184139B1 (en) | Resin composition, metal foil with resin, insulating sheet with base material and multilayer printed wiring board | |

| US10414916B2 (en) | Resin composition, article of manufacture made therefrom and method of making the same | |

| KR100920535B1 (en) | Resin composition, prepreg, laminated sheet and semiconductor package | |

| JP5090635B2 (en) | Resin composition, insulating sheet with substrate, and multilayer printed wiring board | |

| JPH11140281A (en) | Resin composition for copper-clad laminate, copper foil with resin, multilayer copper-clad laminate and multilayer printed circuit board | |

| JP3821728B2 (en) | Prepreg | |

| JP4132703B2 (en) | Prepreg for copper-clad laminate and copper-clad laminate using the same | |

| JP6620457B2 (en) | Resin composition | |

| JP4322463B2 (en) | Copper-clad laminate prepreg and copper-clad laminate | |

| CN109757023B (en) | Printed circuit board and manufacturing method thereof | |

| JP2003073543A (en) | Resin composition, prepreg and printed circuit board using the same | |

| JP2003213019A (en) | Prepreg and printed wiring board using the same | |

| CN109760385B (en) | Copper-clad plate capable of being bent statically, manufacturing method thereof and bending forming method | |

| JP2012019240A (en) | Resin composite, insulation sheet with substrate and multilayer printed wiring board | |

| JP2005209489A (en) | Insulation sheet | |

| JP5428212B2 (en) | Resin composition, prepreg and printed wiring board using the same | |

| JP4858359B2 (en) | Epoxy resin composition for prepreg, prepreg, laminate and printed wiring board using the same | |

| JP2003096296A (en) | Resin composition, prepreg and printed circuit board using the same | |

| JP2017019970A (en) | Resin composition | |

| JP3804812B2 (en) | Method for producing insulating varnish | |

| WO2013099771A1 (en) | Prepreg, circuit board and semiconductor device | |

| JP2011044459A (en) | Resin composition for electronic substrate, and electronic substrate using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |