CN109304219B - Catalyst for preparing low-carbon olefin from synthesis gas - Google Patents

Catalyst for preparing low-carbon olefin from synthesis gas Download PDFInfo

- Publication number

- CN109304219B CN109304219B CN201710628255.6A CN201710628255A CN109304219B CN 109304219 B CN109304219 B CN 109304219B CN 201710628255 A CN201710628255 A CN 201710628255A CN 109304219 B CN109304219 B CN 109304219B

- Authority

- CN

- China

- Prior art keywords

- catalyst

- parts

- oxide

- synthesis gas

- molecular sieve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/40—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively

- B01J29/48—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively containing arsenic, antimony, bismuth, vanadium, niobium tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/40—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively

- B01J29/42—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively containing iron group metals, noble metals or copper

- B01J29/46—Iron group metals or copper

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C1/00—Preparation of hydrocarbons from one or more compounds, none of them being a hydrocarbon

- C07C1/02—Preparation of hydrocarbons from one or more compounds, none of them being a hydrocarbon from oxides of a carbon

- C07C1/04—Preparation of hydrocarbons from one or more compounds, none of them being a hydrocarbon from oxides of a carbon from carbon monoxide with hydrogen

- C07C1/0425—Catalysts; their physical properties

- C07C1/043—Catalysts; their physical properties characterised by the composition

- C07C1/0435—Catalysts; their physical properties characterised by the composition containing a metal of group 8 or a compound thereof

- C07C1/044—Catalysts; their physical properties characterised by the composition containing a metal of group 8 or a compound thereof containing iron

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/10—After treatment, characterised by the effect to be obtained

- B01J2229/18—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself

- B01J2229/186—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself not in framework positions

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

- Y02P20/52—Improvements relating to the production of bulk chemicals using catalysts, e.g. selective catalysts

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Catalysts (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Abstract

The invention relates to a catalyst for preparing low-carbon olefin from synthesis gas, which mainly solves the problems of low CO conversion rate and low-carbon olefin selectivity in the reaction of preparing low-carbon olefin from synthesis gas in the prior art. The invention relates to a catalyst for preparing low-carbon olefin by using synthesis gas, which comprises the following components in parts by weight: a) 20-50 parts of iron element or oxide thereof; b) 5-30 parts of at least one element selected from VIIB group or oxide thereof; c) 5-30 parts of at least one element selected from IVB group or oxide thereof; d) 5-15 parts of at least one element selected from group IA elements or oxides thereof; e) 10-65 parts of the catalyst comprises a technical scheme selected from ZSM-5 type molecular sieves, so that the problem is well solved, and the catalyst can be used for industrial production of directly synthesizing low-carbon olefin from synthesis gas.

Description

Technical Field

The invention relates to a catalyst for preparing low-carbon olefin from synthesis gas.

Background

The lower olefin is an olefin having 4 or less carbon atoms. The low-carbon olefin represented by ethylene and propylene is a very important basic organic chemical raw material, and the market of the low-carbon olefin is short in supply and demand for a long time along with the rapid growth of the economy of China. At present, the production of low-carbon olefin mainly adopts a petrochemical route of light hydrocarbon (ethane, naphtha and light diesel oil) cracking, and due to the gradual shortage of global petroleum resources and the long-term high-order running of the price of crude oil, the development of the tubular cracking furnace process which only depends on the light hydrocarbon as the raw material in the low-carbon olefin industry encounters larger and larger raw material problems, and the production process and the raw material of the low-carbon olefin need to be diversified. The one-step method for directly preparing the low-carbon olefin from the synthesis gas is a process for directly preparing the low-carbon olefin with the carbon atom number less than or equal to 4 by the Fischer-Tropsch synthesis reaction of carbon monoxide and hydrogen under the action of the catalyst, and the process does not need to further prepare the olefin from the synthesis gas through methanol or dimethyl ether like an indirect process, thereby simplifying the process flow and greatly reducing the investment. At present, the shortage of petroleum resources in China, higher and higher external dependence and the soaring international oil price, the process for preparing olefin by selecting synthesis gas can broaden the raw material sources, and the synthesis gas can be produced by taking crude oil, natural gas, coal and renewable materials as raw materials, so that a substitute scheme can be provided for the technical aspect of steam cracking based on high-cost raw materials such as naphtha. The abundant coal resources and the relatively low coal price in China provide good market opportunities for developing processes for refining coal and preparing low-carbon olefins by using synthesis gas. In the vicinity of the rich oil-gas field of natural gas in China, if the natural gas is low in price, the method is also an excellent opportunity for preparing low-carbon olefin by using the synthesis gas. If the abundant coal and natural gas resources in China can be utilized, the synthesis gas (the mixed gas of carbon monoxide and hydrogen) is prepared by gas making, and the development of the petroleum alternative energy technology for preparing low-carbon olefin from the synthesis gas is bound to have great significance for solving the energy problem in China.

The technology for directly synthesizing the low-carbon olefin from the synthesis gas originates from the traditional Fischer-Tropsch synthesis reaction, the carbon number distribution of the traditional Fischer-Tropsch synthesis product conforms to ASF distribution, and each hydrocarbon has the maximum theoretical selectivity, such as C2-C4The maximum selectivity of the fraction is 57%, the gasoline fraction (C)5-C11) The selectivity of (a) is at most 48%. The greater the value of the chain growth probability α, the greater the selectivity of the product heavy hydrocarbons. Once the alpha value is determined, the selectivity of the overall synthesis product is determined, and the chain growth probability alpha value depends on the catalyst composition, particle size, reaction conditions, and the like. In recent years, it has been found that the product distribution deviates from the ideal ASF distribution due to secondary reactions of olefins caused by re-adsorption of olefins on the catalyst. The Fischer-Tropsch synthesis is a strong exothermic reaction, and a large amount of reaction heat promotes the carbon deposition reaction of the catalyst to generate methane and low-carbon alkane more easily, so that the selectivity of the low-carbon alkene is greatly reduced; secondly, complex kinetic factors also give selective synthesis of low carbonOlefins cause disadvantages; the ASF distribution of the Fischer-Tropsch synthesis product limits the selectivity of synthesizing low-carbon olefin. The catalyst for preparing the low-carbon olefin from the Fischer-Tropsch synthesis gas is mainly an iron catalyst, and can be used for carrying out physical and chemical modification on the Fischer-Tropsch synthesis catalyst in order to improve the selectivity of directly preparing the low-carbon olefin from the synthesis gas, for example, the proper pore channel structure of a molecular sieve is utilized, so that the low-carbon olefin can be conveniently diffused away from a metal active center in time, and the secondary reaction of the low-carbon olefin is inhibited; the metal ion dispersibility is improved, and the olefin selectivity is better; the selectivity of the low-carbon olefin can also be improved by changing the interaction between the metal and the carrier; proper transition metal is added, so that the bond energy of the active component and carbon can be enhanced, the generation of methane is inhibited, and the selectivity of low-carbon olefin is improved; the electron promoting assistant is added to promote the increase of CO chemical adsorption heat, the increase of adsorption quantity and the decrease of hydrogen adsorption quantity, so that the selectivity of the low-carbon olefin is increased; eliminating the acid center of the catalyst can inhibit the secondary reaction of the low-carbon olefin and improve the selectivity of the low-carbon olefin. The performance of the catalyst can be obviously improved by the carrier effect of the catalyst carrier and the addition of certain transition metal additives and alkali metal additives, and a novel Fischer-Tropsch synthesis catalyst with non-ASF distribution of products and high activity and high selectivity for preparing low-carbon olefin is developed.

The synthesis of low-carbon olefin directly from synthesis gas has become one of the research hotspots for developing Fischer-Tropsch synthesis catalysts. In patent CN1083415A published by institute of chemical and physical sciences in the chinese academy of sciences, an iron-manganese catalyst system supported by an alkali metal oxide of group IIA such as MgO or a high-silicon zeolite molecular sieve (or a phospho-aluminum zeolite) is used, and strong base K or Cs ions are used as an auxiliary agent, so that high activity (90% of CO conversion) and high selectivity (66% of low-carbon olefin selectivity) can be obtained at a reaction temperature of 300-400 ℃ under a reaction pressure of 1.0-5.0 MPa for preparing low-carbon olefin from synthesis gas. However, the preparation process of the catalyst is complex, and particularly, the preparation and forming process of the carrier zeolite molecular sieve has high cost and is not beneficial to industrial production. In the patent application No. 01144691.9 filed by Beijing university of chemical industry, the Fe is prepared by combining laser pyrolysis with solid phase reaction combined technology3The Fe-based nano catalyst mainly containing C is applied to preparing low-carbon olefin from synthesis gas and obtains good catalytic effect due to the fact that laser pyrolysis is neededThe technology and the preparation process are relatively complex, and the raw materials adopt Fe (CO)5The catalyst cost is high, and industrialization is difficult. In patent ZL03109585.2 filed by Beijing university of chemical industry, a vacuum impregnation method is adopted to prepare a Fe/activated carbon catalyst taking manganese, copper, zinc, silicon, potassium and the like as additives for the reaction of preparing low-carbon olefin from synthesis gas, and under the condition of no circulation of raw material gas, the conversion rate of CO is 96 percent, and the selectivity of the low-carbon olefin in hydrocarbon is 68 percent. The iron salt and the auxiliary agent manganese salt used for preparing the catalyst are relatively expensive and relatively difficult to dissolve, and simultaneously, the ethanol is used as a solvent, so that the raw material cost and the operation cost in the catalyst preparation process are inevitably increased. In order to further reduce the cost of the catalyst, in the patent application No. 200710063301.9, the catalyst is prepared by using common medicines and reagents, iron salt is used as ferric nitrate, manganese salt is used as manganese nitrate, potassium salt is used as potassium carbonate, activated carbon is coconut shell carbon, the catalyst needs to be roasted at high temperature and passivated under the protection of flowing nitrogen, special equipment is needed, the preparation process is complex, and the cost is high. And the catalyst has lower CO conversion rate and lower selectivity of the low-carbon olefin in the reaction of preparing the low-carbon olefin from the synthesis gas.

Disclosure of Invention

One of the technical problems to be solved by the invention is to solve the problems of low CO conversion rate and low-carbon olefin selectivity in the technology of preparing low-carbon olefin from synthesis gas in the prior art, and provide a novel catalyst for preparing low-carbon olefin from synthesis gas, wherein the catalyst has the advantages of high CO conversion rate and high low-carbon olefin selectivity.

The second technical problem to be solved by the present invention is a method for preparing a catalyst corresponding to the catalyst described in one of the above technical problems.

The third technical problem to be solved by the present invention is to use the catalyst described in one of the above technical problems.

In order to solve one of the above technical problems, the technical scheme adopted by the invention is as follows:

the catalyst for preparing the low-carbon olefin by the synthesis gas comprises the following components in parts by weight:

a) 20-50 parts of iron element or oxide thereof;

b) 5-30 parts of at least one element selected from VIIB group or oxide thereof;

c) 5-30 parts of at least one element selected from IVB group or oxide thereof;

d) 5-15 parts of at least one element selected from group IA elements or oxides thereof;

e) 10-65 comprises a ZSM-5 type molecular sieve.

In the above technical solution, the iron oxide is preferably iron sesquioxide.

In the technical scheme, the preferable proportion of the iron oxide is 20-40 parts.

In the technical scheme, the content of the component b) is preferably 10-25 parts.

In the above technical scheme, the component b) preferably further comprises group IIB elements or oxides thereof.

In the above technical solution, the VIIB group element preferably includes Mn or an oxide thereof.

In the above technical solution, the group IIB element preferably includes Zn or an oxide thereof.

In the above technical scheme, the component b) preferably comprises both Mn (or its oxide) and Zn (or its oxide), and in this case, the Mn (or its oxide) and Zn (or its oxide) have a synergistic effect in improving the CO conversion rate and the selectivity of low-carbon olefins in the product.

The ratio of Mn to Zn is not particularly limited, manganese or an oxide thereof is MnO, and Zn or an oxide thereof is ZnO, and the weight ratio of manganese (or an oxide thereof) to zinc (or zinc oxide) may be, but is not limited to, 0.51 to 5, and more specific non-limiting weight ratios may be 0.61, 0.71, 0.81, 0.91, 1.01, 1.11, 1.21, 1.51, 1.61, 1.71, 1.81, 2.01, 2.11, 2.21, 2.51, 3.01, 3.51, 4.01, 4.51, and the like.

In the technical scheme, the content of the component c) is preferably 10-25 parts. The group IVB element in component c) is preferably zirconium and the oxide of the group IVB element is preferably an oxide of zirconium, such as but not limited to zirconium dioxide.

In the technical scheme, the content of the component d) is preferably 10-25 parts.

The technical proposal is thatIn d), the IA element in d) is preferably at least one of Na and K, more preferably both Na and K, and the oxide of Na is selected from Na2The oxide of O, K is preferably K2And O, wherein Na (or oxide thereof) and K (or oxide thereof) have a synergistic effect on improving the CO conversion rate and the selectivity of the low-carbon olefin.

The ratio of Na to K is not particularly limited, and Na or its oxide is Na2O and K or an oxide thereof in K2In terms of O, the weight ratio of Na (or an oxide thereof) to K (or an oxide thereof) may be, but not limited to, 0.11 to 3, and more specific non-limiting weight ratios may be 0.11, 0.21, 0.31, 0.41, 0.51, 0.61, 0.71, 0.81, 0.91, 1.01, 1.21, 1.51, 1.71, 1.91, 2.01, 2.51, and the like.

In the technical scheme, the catalyst contains ZSM-5 type molecular sieve with SiO/Si ratio2/Al2O3Is 50 to 500. For example, but not limiting of, the silicon to aluminum ratio may be 100, 150, 200, 250, 300, 350, 400, 450, and so forth. For same proportion, the embodiment of the invention partially adopts SiO2/Al2O3A 300 ZSM-5 type molecular sieve.

In the above technical scheme, the ZSM-5 type molecular sieve is preferably a ZSM-5 molecular sieve modified by using at least one element including IIA element or an oxide thereof as a modifier.

In the technical scheme, the modified ZSM-5 molecular sieve preferably contains 1-15% of a modifier by weight.

In the above technical scheme, the IIA element preferably comprises at least one of Mg and Sr, the oxide of Mg is preferably MgO, and the oxide of Sr is preferably SrO. At this time, Mg (or oxide thereof) and Sr (or oxide thereof) have a synergistic effect in improving the CO conversion rate and the selectivity of the lower olefins.

In the above-mentioned embodiment, the mutual ratio of Mg and Sr is not particularly limited, and Mg or an oxide thereof is MgO, and Sr or an oxide thereof is SrO, and the weight ratio of Mg (or an oxide thereof) to Sr (or an oxide thereof) may be, but not limited to, 0.11 to 3, and more specifically, non-limiting weight ratios may be 0.11, 0.21, 0.31, 0.41, 0.51, 0.61, 0.71, 0.81, 0.91, 1.01, 1.21, 1.51, 1.71, 1.91, 2.01, 2.51, and the like.

To solve the second technical problem, the technical solution of the present invention is as follows:

the preparation method of the catalyst for preparing low-carbon olefin by using the synthesis gas, which is described in any one of the technical schemes of the technical problems, comprises the following steps:

(1) mixing oxides corresponding to the components a), b) and c), carbonates corresponding to the component d) and a binder to obtain a powdery material A;

(2) adding water into the material A, and kneading to obtain a material B;

(3) extruding the material B into strips, forming and drying to obtain a material C;

(4) and sintering the material C at a high temperature, cooling, crushing and screening to obtain a required molten state mixture D.

(5) And mixing the molten mixture D and a ZSM-5 type molecular sieve to obtain the required catalyst.

In the above technical scheme, the binder and the amount used in step (1) are not particularly limited, and may be reasonably selected by those skilled in the art. For example, but not limited to, the binder may be hydroxypropyl methylcellulose powder, hydroxyethyl methylcellulose powder, carboxymethyl cellulose, starch, dextrin, polyethylene glycol, polyvinyl alcohol, and the like; the binder is used in an amount such as, but not limited to, 3 to 6% of the total weight of components a), b), c) and d).

In the above technical solution, the amount of water used in step (2) is not particularly limited, and is preferably such that the kneading and extruding degree can be achieved, and for this reason, a person skilled in the art can reasonably select and does not need to pay creative labor, for example, but not limited to, the amount of water used in step (2) is preferably 5 to 15% of the total weight of all components a), b), c) and d) in step (1).

In the above-mentioned technical means, the process conditions for drying in the step (3) are not particularly limited, and the final degree of drying is not particularly limited. For example, but not limited to, the drying temperature is 100-150 ℃, and the drying time is more than 6 hours (e.g., 8 hours, 12 hours, 18 hours, 24 hours, etc.).

In the technical scheme, the preferable range of the high-temperature sintering temperature in the step (4) is 1300-1700 ℃. Such as but not limited to 1350 deg.C, 1400 deg.C, 1450 deg.C, 1500 deg.C, 1550 deg.C, 1600 deg.C, 1650 deg.C, etc.

In the technical scheme, the high-temperature sintering time in the step (4) is preferably 4-10 hours. Such as but not limited to 5 hours, 6 hours, 7 hours, 8 hours, 9 hours, and the like.

In the technical scheme, the mixing mode of the step (5) has no special requirement, and all the technical effects can be obtained. However, those skilled in the art know that the effect of further crushing and sieving is particularly good when the mixture is formed by tabletting after being milled in a ball mill.

When the ZSM-5 type molecular sieve adopts the ZSM-5 molecular sieve modified by taking at least one element in IIA elements or the oxide thereof as a modifier, the modified ZSM-5 molecular sieve is prepared by adopting a method comprising the following steps:

(i) dissolving IIA element salt in water to prepare a solution E;

(ii) mixing the solution E with a ZSM-5 molecular sieve to obtain a mixture F;

(iii) and drying and roasting the mixture F to obtain the required modified ZSM-5 molecular sieve G.

In the above embodiments, the salt of IIA element may be, by way of non-limiting example, a nitrate, a carboxylate (such as, but not limited to, acetate, carbonate, bicarbonate), and the like.

In the above technical scheme, ZSM-5 hydrogen type molecular sieve is preferably used in the step (ii).

In the above technical solution, the mixing manner in the step (ii) is not particularly required, but the mixing effect is particularly good under vacuum. For example, but not limited to, the solution is impregnated with the corresponding solid component under a vacuum of 1 to 80 kPa.

In the above technical scheme, the preferable range of the roasting temperature in the step (iii) is 400 to 600 ℃, and the preferable range of the roasting time is 2.0 to 6.0 hours.

To solve the third technical problem, the technical scheme of the invention is as follows:

one of the technical problems is that the catalyst is used for preparing C from synthesis gas2~C4To olefins according to (1).

The technical key of the invention is the selection of the catalyst, and the technical conditions of the specific application can be reasonably selected by a person skilled in the art without creative labor. For example, the specific application conditions may be:

the method for preparing the low-carbon olefin by the synthesis gas comprises the step of generating C-containing carbon by the contact reaction of the synthesis gas serving as a raw material and the catalyst in any one of the technical schemes of the technical problems2~C4The olefin of (1).

In the above technical scheme, H in the synthesis gas2The molar ratio of CO to CO is preferably 1 to 3.

In the technical scheme, the reaction temperature is preferably 250-400 ℃.

In the technical scheme, the reaction pressure is preferably 1.0-3.0 MPa.

In the technical scheme, the volume space velocity of the raw material gas is preferably 500-5000 h-1。

As known to those skilled in the art, the catalyst of the present invention is used in the preparation of C from synthesis gas2~C4Before the reaction of the olefin(s) in (b), it is preferable to carry out an on-line reduction treatment step, and the specific reduction conditions can be reasonably selected by those skilled in the art without any inventive step, such as but not limited to the following:

the reduction temperature is 400-500 ℃;

the reducing agent is H2And/or CO;

the pressure of reduction is normal pressure to 2MPa (measured by gauge pressure);

the volume space velocity of the reducing agent is 1500-6000 hr-1;

The reduction time is 6-24 hours.

For convenience of comparison, the reduction conditions in the examples of the present invention are:

the reduction conditions for the above examples were:

the temperature is 450 DEG C

Pressure and atmosphere

Catalyst loading 3ml

Volumetric space velocity of reducing agent4500 hr-1

Reducing gas H2

The reduction time is 12 hours

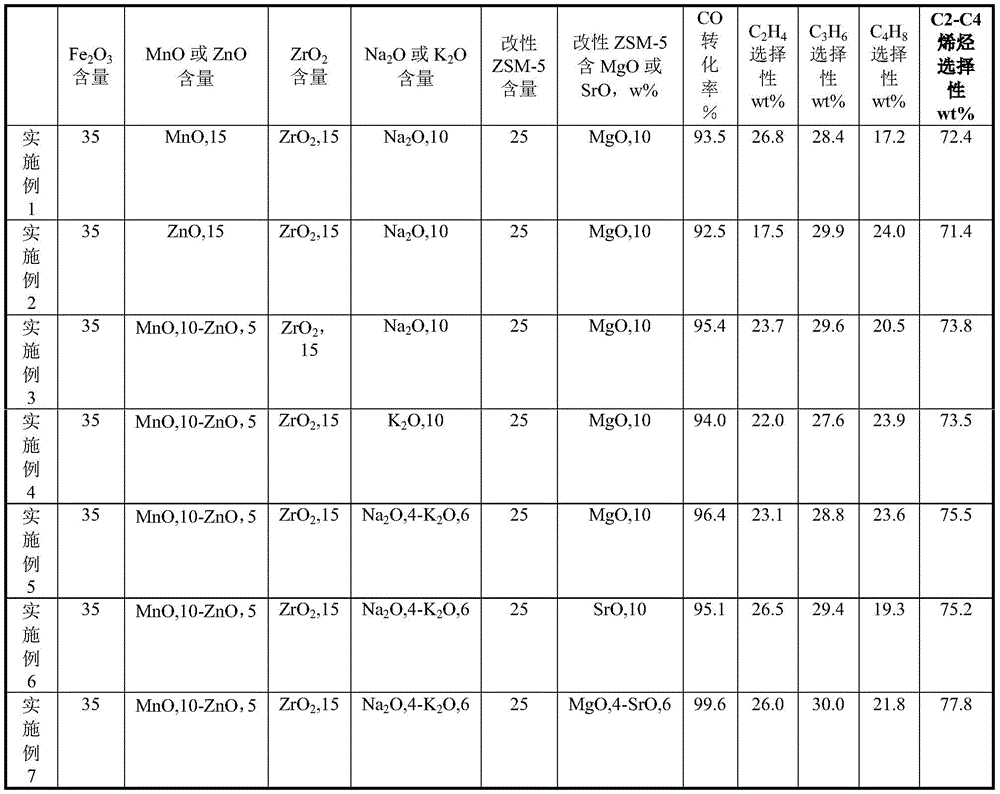

By adopting the catalyst, the CO conversion rate can reach 99.6 percent, which is improved by 3.6 percent compared with the prior art; the selectivity of the low-carbon olefin in hydrocarbon can reach 77.8%, which is improved by 9.8% compared with the prior art, and a better technical effect is achieved.

Detailed Description

[ example 1 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 10 g of MgO, and dissolving the magnesium nitrate hexahydrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 15.0 parts by weight of manganese oxide (MnO) and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 10 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Grinding and mixing the four raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the four raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of molten mixture D and 25G of modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting and molding, crushing the sieve and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,15%MnO,15%ZrO2,10%Na2O, 25% modified ZSM-5 (containing MgO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

[ example 2 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 10 g of MgO, and dissolving the magnesium nitrate hexahydrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 15.0 parts by weight of zinc oxide (ZnO), 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 10 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Grinding and mixing the four raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the four raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B;feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,15%ZnO,15%ZrO2,10%Na2O, 25% modified ZSM-5 (containing MgO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

[ example 3 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 10 g of MgO, and dissolving the magnesium nitrate hexahydrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 10.0 parts by weight of manganese oxide (MnO), 5.0 parts by weight of zinc oxide (ZnO), and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 10 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Grinding and mixing five raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the five raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,10%MnO,5%ZnO,15%ZrO2,10%Na2O, 25% modified ZSM-5 (containing MgO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

From example 3 in comparison with examples 1 and 2, it can be seen that Mn (or its oxide) and Zn (or its oxide) have a synergistic effect in increasing CO conversion and low olefin selectivity in the product.

[ example 4 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 10 g of MgO, and dissolving the magnesium nitrate hexahydrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 10.0 parts by weight of manganese oxide (MnO), 5.0 parts by weight of zinc oxide (ZnO), and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 10 parts by weight of K2Potassium carbonate (K) of O2CO3) Grinding and mixing five raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the five raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,10%MnO,5%ZnO,15%ZrO2,10%K2O, 25% modified ZSM-5 (containing MgO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

[ example 5 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 10 g of MgO, and dissolving the magnesium nitrate hexahydrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 10.0 parts by weight of manganese oxide (MnO), 5.0 parts by weight of zinc oxide (ZnO), and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 4 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Equivalent to 6 parts by weight of K2Potassium carbonate (K) of O2CO3) Grinding and mixing six raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the six raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine, making into strips with the diameter of 5mm, cutting into columns with the length of 20mm, and naturally dryingThen, the mixture is sent into drying equipment and dried for 8 hours at the temperature of 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,10%MnO,5%ZnO,15%ZrO2,4%Na2O,6%K2O, 25% modified ZSM-5 (containing MgO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

From example 5 in comparison with examples 3 and 4, it is seen that Na (or its oxide) and K (or its oxide) have a synergistic effect in increasing CO conversion and selectivity to lower olefins.

[ example 6 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing strontium nitrate equivalent to 10 g of SrO, and dissolving the strontium nitrate in 60 g of deionized water to prepare a solution E; under the condition of vacuum degree of 80kPa, dipping the solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 10.0 parts by weight of manganese oxide (MnO), 5.0 parts by weight of zinc oxide (ZnO), and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 4 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Equivalent to 6 parts by weight of K2Potassium carbonate (K) of O2CO3) Grinding and mixing six raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the six raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The prepared catalyst comprises the following components in percentage by weight: 35% Fe2O3,10%MnO,5%ZnO,15%ZrO2,4%Na2O,6%K2O, 25% modified ZSM-5 (containing SrO 10%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw materialsRatio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

[ example 7 ]

1. Preparation of modified ZSM-5 molecular sieve

Weighing magnesium nitrate hexahydrate equivalent to 4 g of MgO and strontium nitrate equivalent to 6 g of SrO, and dissolving the magnesium nitrate hexahydrate equivalent to 4 g of MgO and the strontium nitrate equivalent to 6 g of SrO in 60 g of deionized water to prepare a mixed solution E; under the condition of vacuum degree of 80kPa, dipping the mixed solution E on 90 g of ZSM-5 hydrogen type molecular sieve with the silica-alumina ratio of 300 to obtain a mixture F; and drying the mixture F at 110 ℃, and then roasting at 500 ℃ for 4 hours to obtain the modified ZSM-5 molecular sieve G.

2. Preparation of the catalyst

35.0 parts by weight of iron (Fe) oxide2O3) 10.0 parts by weight of manganese oxide (MnO), 5.0 parts by weight of zinc oxide (ZnO), and 15.0 parts by weight of zirconium oxide (ZrO)2) Corresponding to 4 parts by weight of Na2Sodium carbonate (Na) of O2CO3) Equivalent to 6 parts by weight of K2Potassium carbonate (K) of O2CO3) Grinding and mixing six raw materials and hydroxypropyl methyl cellulose powder accounting for 4 percent of the total weight of the six raw materials in a ball mill for 4 hours to obtain a material A; adding deionized water accounting for 7 percent of the total weight of the four raw materials into the milled and mixed material A, and kneading the mixture to be soft to obtain a material B; feeding the kneaded material B into a strip extruding machine to prepare a strip with the diameter of 5mm, cutting the strip into a column shape with the length of 20mm, naturally airing the strip, feeding the strip into drying equipment, and drying the strip for 8 hours at 110 ℃ to obtain a material C; and (3) feeding the dried material C into a high-temperature furnace, calcining for 5.0 hours at 1500 ℃, cooling and crushing, and taking particles passing through a 120-mesh standard sieve to obtain a molten state mixture D.

Mixing 75G of the molten mixture D and 25G of the modified ZSM-5 molecular sieve G, grinding and mixing in a ball mill, tabletting for molding, crushing and sieving to obtain 40-80 mesh particles to obtain the catalyst.

The obtained catalyst comprises the following components in percentage by weightDividing into: 35% Fe2O3,10%MnO,5%ZnO,15%ZrO2,4%Na2O,6%K2O, 25% modified ZSM-5 (containing MgO 4%, SrO 6%).

3. Catalyst evaluation

The evaluation conditions of the catalyst were:

the reaction conditions are as follows:

phi 8 mm fixed bed reactor

The reaction temperature is 320 DEG C

The reaction pressure is 1.2MPa

Catalyst loading 3ml

Catalyst loading 1500 hours-1

Raw material ratio (mol) H2/CO=1.5/1。

For convenience of comparison, the composition of the catalyst of the present invention and the evaluation results are shown in Table 1.

From the comparison between example 7 and examples 5 and 6, it is clear that Mg (or its oxide) and Sr (or its oxide) have a synergistic effect in increasing CO conversion and selectivity to lower olefins.

TABLE 1

Claims (8)

1. The catalyst for preparing the low-carbon olefin by the synthesis gas comprises the following components in parts by weight:

a) 20-50 parts of iron element or oxide thereof;

b) 5-30 parts of at least one element selected from VIIB group or oxide thereof;

c) 5-30 parts of at least one element selected from IVB group or oxide thereof;

d) 5-15 parts of at least one element selected from group IA elements or oxides thereof;

e) 10-65 parts of a molecular sieve selected from ZSM-5 type molecular sieves;

the ZSM-5 type molecular sieve is a ZSM-5 molecular sieve modified by taking IIA element or oxide thereof as a modifier, and the modified ZSM-5 molecular sieve contains 1-15% of the modifier by weight;

the IIA element is selected from Mg and Sr; the weight ratio of Mg to Sr is 0.11-2.01.

2. The catalyst for producing light olefins according to claim 1, wherein the iron oxide is ferric oxide.

3. The catalyst for preparing low-carbon olefin from synthesis gas according to claim 1, wherein the content of the component b) is 10-25 parts.

4. The catalyst for preparing low-carbon olefin from synthesis gas according to claim 1, wherein the content of the component c) is 10-25 parts.

5. The catalyst for preparing light olefins from synthesis gas according to claim 1, wherein the catalyst contains ZSM-5 type molecular sieve having a silica-alumina ratio of SiO2/Al2O3Is 50 to 500.

6. The preparation method of the catalyst for preparing low-carbon olefin from synthesis gas according to any one of claims 1 to 5, comprising the following steps:

(1) mixing oxides corresponding to the components a), b) and c), carbonate corresponding to the component d) and a binder to obtain a powdery material A;

(2) adding water into the material A, and kneading to obtain a material B;

(3) extruding the material B into strips, forming and drying to obtain a material C;

(4) sintering the material C at a high temperature, cooling, crushing and screening to obtain a required molten state mixture D;

(5) mixing the molten mixture D and a ZSM-5 type molecular sieve to obtain a required catalyst;

the temperature of the high-temperature sintering in the step (4) is 1200-1800 ℃.

7. The method for preparing the catalyst for preparing the light olefins from the synthesis gas according to claim 6, wherein the high-temperature sintering time is 4-10 hours.

8. The catalyst of any one of claims 1 to 5, used in the synthesis of C2~C4To olefins according to (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710628255.6A CN109304219B (en) | 2017-07-28 | 2017-07-28 | Catalyst for preparing low-carbon olefin from synthesis gas |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710628255.6A CN109304219B (en) | 2017-07-28 | 2017-07-28 | Catalyst for preparing low-carbon olefin from synthesis gas |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109304219A CN109304219A (en) | 2019-02-05 |

| CN109304219B true CN109304219B (en) | 2021-06-18 |

Family

ID=65202560

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201710628255.6A Active CN109304219B (en) | 2017-07-28 | 2017-07-28 | Catalyst for preparing low-carbon olefin from synthesis gas |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109304219B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109304220B (en) * | 2017-07-28 | 2021-10-01 | 中国石油化工股份有限公司 | Catalyst for preparing low-carbon olefin from synthetic gas |

| CN112619691B (en) * | 2019-10-09 | 2022-08-12 | 中国石油化工股份有限公司 | Catalyst for directly producing low-carbon olefin by Fischer-Tropsch synthesis and preparation method and application thereof |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1083415A (en) * | 1992-09-03 | 1994-03-09 | 中国科学院大连化学物理研究所 | Iron manganese catalyst for preparation of low carbon olefines by synthetic gas and building-up reactions |

| CN1537674A (en) * | 2003-04-15 | 2004-10-20 | 北京化工大学 | Iron/active carbon catalyst used for preparing ethylene, propylene, butylene from synthetic gas |

| CN103230810A (en) * | 2013-04-25 | 2013-08-07 | 武汉凯迪工程技术研究总院有限公司 | Fischer-Tropsch synthetic catalyst for preparing low-carbon olefin by utilizing synthetic gas, modified molecular sieve carrier and preparation method |

| CN104148106A (en) * | 2013-05-16 | 2014-11-19 | 中国石油化工股份有限公司 | Catalyst for producing low-carbon olefin by using synthesis gas and preparation method of catalyst |

| CN104549342A (en) * | 2013-10-28 | 2015-04-29 | 中国石油化工股份有限公司 | Iron catalyst for preparing light olefins by use of synthesis gas and preparation method of iron catalyst |

| CN105582936A (en) * | 2014-10-24 | 2016-05-18 | 中国石油化工股份有限公司 | Catalyst used for preparing light olefin with sintered synthetic gas, and preparation method thereof |

-

2017

- 2017-07-28 CN CN201710628255.6A patent/CN109304219B/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1083415A (en) * | 1992-09-03 | 1994-03-09 | 中国科学院大连化学物理研究所 | Iron manganese catalyst for preparation of low carbon olefines by synthetic gas and building-up reactions |

| CN1537674A (en) * | 2003-04-15 | 2004-10-20 | 北京化工大学 | Iron/active carbon catalyst used for preparing ethylene, propylene, butylene from synthetic gas |

| CN103230810A (en) * | 2013-04-25 | 2013-08-07 | 武汉凯迪工程技术研究总院有限公司 | Fischer-Tropsch synthetic catalyst for preparing low-carbon olefin by utilizing synthetic gas, modified molecular sieve carrier and preparation method |

| CN104148106A (en) * | 2013-05-16 | 2014-11-19 | 中国石油化工股份有限公司 | Catalyst for producing low-carbon olefin by using synthesis gas and preparation method of catalyst |

| CN104549342A (en) * | 2013-10-28 | 2015-04-29 | 中国石油化工股份有限公司 | Iron catalyst for preparing light olefins by use of synthesis gas and preparation method of iron catalyst |

| CN105582936A (en) * | 2014-10-24 | 2016-05-18 | 中国石油化工股份有限公司 | Catalyst used for preparing light olefin with sintered synthetic gas, and preparation method thereof |

Non-Patent Citations (1)

| Title |

|---|

| Zr助剂对铁基催化剂F-T合成性能的影响;张皓荐等;《天然气化工》;20121231;第37卷(第2期);第12-16页 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109304219A (en) | 2019-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104148106B (en) | Synthesis gas produces catalyst of low-carbon alkene and preparation method thereof | |

| CN107913718B (en) | Iron-based catalyst for directly synthesizing low-carbon olefin by synthesis gas | |

| CN109304219B (en) | Catalyst for preparing low-carbon olefin from synthesis gas | |

| CN109304218B (en) | Catalyst for producing low carbon olefin from synthetic gas | |

| CN105435801B (en) | Load typed iron catalyst and its preparation method and application | |

| CN109304216B (en) | Catalyst for producing low-carbon olefin by synthesis gas one-step method | |

| CN109304220B (en) | Catalyst for preparing low-carbon olefin from synthetic gas | |

| CN105582936B (en) | Slug type preparation of low carbon olefines by synthetic gas catalyst and preparation method thereof | |

| CN109304215B (en) | Catalyst for preparing low-carbon olefin by synthesis gas one-step method | |

| CN109305870B (en) | Method for preparing low-carbon olefin by synthesis gas one-step method | |

| CN109305871B (en) | Method for producing low-carbon olefin by synthesis gas one-step method | |

| CN109304217B (en) | Catalyst for producing low-carbon olefin by using synthesis gas | |

| CN111068740B (en) | Catalyst for producing low-carbon olefin by Fischer-Tropsch synthesis and application thereof | |

| CN109647492B (en) | Catalyst for directly producing low-carbon olefin by synthesis gas | |

| CN111068762B (en) | Catalyst for producing low-carbon olefin by Fischer-Tropsch synthesis and application thereof | |

| CN109651028B (en) | Method for producing low-carbon olefin by fixed bed | |

| CN109651029B (en) | Catalyst for producing low-carbon olefin by fixed bed | |

| CN111068765B (en) | Catalyst for preparing low-carbon olefin by Fischer-Tropsch synthesis and application thereof | |

| CN111068766B (en) | Catalyst for preparing low-carbon olefin by Fischer-Tropsch synthesis and application thereof | |

| CN109647416B (en) | Catalyst for preparing low-carbon olefin by fixed bed | |

| CN109651033B (en) | Method for preparing low-carbon olefin by fixed bed | |

| CN109647491B (en) | Catalyst for directly preparing low-carbon olefin from synthesis gas | |

| CN109651030B (en) | Method for directly preparing low-carbon olefin from synthesis gas | |

| CN111068742B (en) | Catalyst for synthesizing low-carbon olefin by one-step method and application thereof | |

| CN111068741B (en) | Catalyst for synthesizing low-carbon olefin by one-step method and application thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |