CN108227324B - Test key and test method for broken line repair and broken line repair method - Google Patents

Test key and test method for broken line repair and broken line repair method Download PDFInfo

- Publication number

- CN108227324B CN108227324B CN201810036209.1A CN201810036209A CN108227324B CN 108227324 B CN108227324 B CN 108227324B CN 201810036209 A CN201810036209 A CN 201810036209A CN 108227324 B CN108227324 B CN 108227324B

- Authority

- CN

- China

- Prior art keywords

- test

- test point

- point

- metal

- photoresist

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000012360 testing method Methods 0.000 title claims abstract description 206

- 238000010998 test method Methods 0.000 title claims abstract description 22

- 238000000034 method Methods 0.000 title claims abstract description 21

- 239000002184 metal Substances 0.000 claims abstract description 123

- 229920002120 photoresistant polymer Polymers 0.000 claims abstract description 59

- 239000000758 substrate Substances 0.000 description 29

- 238000010586 diagram Methods 0.000 description 13

- 238000002161 passivation Methods 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000003086 colorant Substances 0.000 description 3

- 238000009413 insulation Methods 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 229910052681 coesite Inorganic materials 0.000 description 1

- 229910052906 cristobalite Inorganic materials 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 229910052682 stishovite Inorganic materials 0.000 description 1

- 229910052905 tridymite Inorganic materials 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/136—Liquid crystal cells structurally associated with a semi-conducting layer or substrate, e.g. cells forming part of an integrated circuit

- G02F1/1362—Active matrix addressed cells

- G02F1/136259—Repairing; Defects

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/136—Liquid crystal cells structurally associated with a semi-conducting layer or substrate, e.g. cells forming part of an integrated circuit

- G02F1/1362—Active matrix addressed cells

- G02F1/136222—Colour filters incorporated in the active matrix substrate

Landscapes

- Physics & Mathematics (AREA)

- Nonlinear Science (AREA)

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Mathematical Physics (AREA)

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Liquid Crystal (AREA)

- Testing Or Measuring Of Semiconductors Or The Like (AREA)

Abstract

The invention provides a test key for repairing broken lines, a test method and a broken line repairing method. The test key includes: the metal layer comprises a first test point and a second test point which are electrically disconnected; a color filter layer on the metal layer and including a color photoresist; the additional metal layer is positioned below the metal layer and comprises a third test point; an upper insulating layer between the metal layer and the color filter layer; and the lower insulating layer is positioned between the metal layer and the additional metal layer.

Description

Technical Field

The invention relates to the field of display manufacturing, in particular to a test key and a test method for repairing broken lines of an array substrate of a display and a broken line repairing method.

Background

The display may implement a desired image by displaying light of different colors (e.g., three primary colors of red, green, and blue). The color filter may pass only light of a specific color. For example, a red filter may pass substantially only red light, a green filter may pass substantially only green light, and a blue filter may pass substantially only blue light. Accordingly, the color filter may be applied to the field of displays to display desired colors.

The color filter may be formed on an array substrate, that is, a color filter on array (COA). Compared with a non-COA array substrate, the COA array substrate is added with a colorful photoresist film on the array substrate in the actual production process. According to the sequence and structure of the manufacturing process, when the electrical testing machine tests that the metal circuit is broken, the broken line repair is needed. In the process of metal connection, the color photoresist needs to be removed, and then metal growth is carried out. Therefore, it is necessary to perform a resistance test and a photoresist removal test. In an actual production process, the impedance test can be performed by using a test key. However, in the existing production line, the test key is a pure metal structure, which is mainly used for testing the non-COA array substrate. In the COA array substrate, the panel active area is actually covered with the color photoresist.

Disclosure of Invention

In order to perform a wire break repair on an array substrate (e.g., a COA array substrate), the invention provides a test key and a test method for the wire break repair, and a wire break repair method.

According to an aspect of the present invention, there is provided a test key for repairing a broken line, the test key may include: the metal layer comprises a first test point and a second test point which are electrically disconnected; a color filter layer on the metal layer and including a color photoresist; the additional metal layer is positioned below the metal layer and comprises a third test point; an upper insulating layer between the metal layer and the color filter layer; and the lower insulating layer is positioned between the metal layer and the additional metal layer.

According to another aspect of the present invention, there is provided a test method for broken line repair, which may include: removing part of the color photoresist of the color filter layer of the test key; growing a metal wire at the part where the color light resistor is removed, wherein the grown metal wire is used for electrically connecting the first test point and the second test point; measuring the resistance between the first test point and the second test point, thereby determining whether the first test point and the second test point are successfully electrically connected through the grown metal wire; and carrying out short circuit test and current test between the first test point and the third test point or between the second test point and the third test point so as to determine whether the photoresist is successfully removed.

According to an exemplary embodiment, when the resistance between the first test point and the second test point is measured to be less than 600 ohms, it may be determined that the electrical connection between the first test point and the second test point through the grown metal line is successful.

According to an exemplary embodiment, when a short circuit between the first test point and the third test point or a short circuit between the second test point and the third test point is measured in a short circuit test, it may be determined that the upper and lower insulating layers are broken down due to excessively high photoresist removal energy, and thus it may be determined that the photoresist removal is unsuccessful.

According to an exemplary embodiment, the current between the first test point and the third test point is less than 10 when measured in the current test-6AOr the current between the second test point and the third test point is less than 10-6AThen, it can be determined that the photoresist residue is caused by the excessively low photoresist removal energy, so thatAnd determining that the photoresist removal is unsuccessful.

According to an exemplary embodiment, the grown metal line may be formed in a bracket shape at the same side of the first test point and the second test point.

According to an exemplary embodiment, when the first test point and the second test point are not electrically connected or the photo-resist removal is not successful through the grown metal line, the test may be performed again using the same test key, wherein the newly grown metal line may be in a bracket shape and may be surrounded by or surround the previously grown metal line.

According to an exemplary embodiment, when the electrical connection of the first test point and the second test point through the grown metal line is unsuccessful or the photoresist removal is unsuccessful, the test may be performed again using another test key.

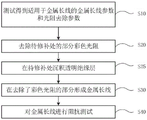

According to another aspect of the present invention, there is provided a broken wire repairing method including: executing the test method; when the first test point and the second test point are unsuccessfully electrically connected or the light resistance is unsuccessfully removed through the grown metal wire, adjusting the metal long wire parameter or the light resistance removal parameter, and repeatedly executing the test method until the first test point and the second test point are successfully electrically connected and the light resistance is successfully removed through the grown metal wire; and forming the metal connecting line pair broken line repairing by using the successful photoresist removing parameters and the metal long line parameters.

According to an exemplary embodiment, the broken line repairing method may further include: and carrying out impedance test on the metal connecting wire.

The test key and the test method can test the photoresistance removing condition, thereby obtaining proper photoresistance removing parameters and avoiding the influence of overhigh or overlow photoresistance removing energy on broken line repairing. The broken wire repairing method can better prevent the grown metal wire from being short-circuited with the inherent circuit or having photoresistance residue.

Drawings

The above and other objects and features of the present invention will become more apparent from the following description taken in conjunction with the accompanying drawings, in which:

FIG. 1 shows a schematic diagram of testing a metal long wire using a test key in the prior art;

FIG. 2 is a schematic diagram showing a comparison between the structures of a non-COA array substrate and a COA array substrate;

FIG. 3 is a schematic diagram of a COA array substrate with broken metal lines;

FIG. 4 shows a test key according to the prior art;

FIG. 5 illustrates a test key according to an exemplary embodiment of the present invention;

FIG. 6 shows a flow diagram of a method of testing a metal long line according to an exemplary embodiment of the present invention;

fig. 7 shows a flow chart of a method of broken line repair according to an exemplary embodiment of the present invention.

Detailed Description

Hereinafter, the present invention will be described more fully with reference to the accompanying drawings. Those skilled in the art will appreciate that the described embodiments may be modified in various different ways, without departing from the spirit or scope of the disclosure. Descriptions of prior art and common general knowledge not relevant to the inventive concept will be omitted so as to not unnecessarily obscure the inventive concept.

Fig. 1 shows a schematic diagram of testing a metal long wire using a test key in the prior art. Referring to fig. 1, a connecting line connects two test points of a test key in a bracket shape "]". The connection line may be connected to two test points by vias. The method is mainly used for testing the non-COA array substrate. However, the COA array substrate further includes a color filter layer including a color photoresist, compared to a non-COA array substrate.

Fig. 2 is a schematic diagram showing a comparison between the structures of a non-COA array substrate and a COA array substrate.

Fig. 2 (a) shows a schematic structural view of a non-COA array substrate manufactured by an Al process. The structure of the non-COA array substrate mainly comprises a metal layer M2. In addition, the structure of the non-COA array substrate further includes an insulating layer (passivation layer) PV on the metal layer M2 and a transparent electrode ITO on the insulating layer PV.

Fig. 2 (b) shows a schematic structural view of a COA array substrate manufactured by a Cu + COA process. Compared with a non-COA array substrate, the structure of the COA array substrate includes a color filter layer C/F in addition to the metal layer M2. In addition, the structure of the COA array substrate further includes a first insulation layer (passivation layer) PV1 between the metal layer M2 and the color filter layer C/F, a second insulation layer (passivation layer) PV2 on the color filter layer C/F, and a transparent electrode ITO on the second insulation layer PV 2.

It can be seen that the COA array substrate further includes a color filter layer C/F including a color photoresist. The color photoresist may be red, blue, and green, but exemplary embodiments are not limited thereto. The color photoresist is not conducive to connecting broken wires using connecting wires. On the one hand, the higher temperature for forming the connecting wire can carbonize the color photoresist, which leads to easy detachment of the connecting wire. On the other hand, the growth characteristics of the connecting lines on the color resist are also poor.

Fig. 3 is a schematic diagram of a COA array substrate in which a metal line is broken. Referring to fig. 3, when a metal line break is detected, a color filter layer C/F exists in the COA array substrate. Therefore, the color filter layer C/F needs to be removed first when the metal wire is grown. The test key according to the prior art is a pure metal structure and cannot test the removal condition of the color photoresist. The test key according to the prior art is explained in detail below with reference to fig. 4.

Fig. 4 shows a test key 900 according to the prior art. Fig. 4 (a) shows a schematic diagram of a film structure of the test key 900, fig. 4 (b) shows a schematic diagram of a film structure of the test key 900 after a metal line is grown, and fig. 4 (c) shows a schematic diagram of a test line of the test key 900.

Referring to fig. 4, the test key 900 includes only the metal layer M2. Metal layer M2 includes two electrically disconnected test points P1 and P2. After growing the metal lines for the test key 900, P1 and P2 are connected by a connection line 150. The resistance between P1 and P2 was measured and when the resistance was less than 600 ohms, it was defined as a long line success.

For the COA array substrate, the color photoresist is removed first, and then the metal lines are grown. For example, a laser may be used to remove the color resist. However, if the removal energy is too low, there will be color photoresist residue; if the removal energy is too high, the passivation film may be broken down, resulting in a short circuit. Therefore, the COA array substrate needs to be tested for resistance of the metal long line as well as for resistance removal. However, the test key 900 cannot test for a photo resist removal condition.

Fig. 5 shows a test key 100 according to an exemplary embodiment of the present invention. Fig. 5 (a) shows a schematic diagram of a film structure of the test key 100, fig. 5 (b) shows a schematic diagram of a film structure of the test key 100 after metal lines are grown, and fig. 5 (c) shows a schematic diagram of a test line of the test key 100.

Referring to (a) of fig. 5, the test key 100 may include a metal layer M2, an additional metal layer 110 positioned under the metal layer M2, and a color filter layer 140 positioned on the metal layer M2. In addition, the test key 100 may further include a lower insulating layer (passivation layer) 120 interposed between the metal layer M2 and the additional metal layer 110 and an upper insulating layer (passivation layer) 130 interposed between the metal layer M2 and the color filter layer 140. Metal layer M2 includes two electrically disconnected test points P1 and P2, and additional metal layer 110 includes or serves as test point P3.

In the test of growing metal lines using the test key 100, a portion of the color photoresist of the color filter layer 140 needs to be removed first. For example, a color photoresist such as a dogleg shape or a bracket shape "]" may be removed at one side of the test points P1 and P2, and the removed area may have an overlapping portion with the test points P1 and P2, but the exemplary embodiment is not limited thereto. Thereafter, the connection line 150 is formed at the portion where the color resists are removed. The connection line 150 may be formed through a mask by using a chemical vapor deposition method. The connection line 150 may be electrically connected to the test points P1 and P2 through vias, respectively, but the exemplary embodiment is not limited thereto. In addition, referring to (b) of fig. 5, although it is illustrated that the color filter layer 140 and the upper insulating layer 130 are completely removed and the lower insulating layer 120 is not affected, it is not necessarily so in reality. For example, in a desired long line region, the color filter layer 140 may not be completely removed, the upper insulating layer 130 may not be completely removed, and the lower insulating layer 120 may be partially or completely removed. One purpose of test key 100 is to test for removal.

Referring to (c) of fig. 5, the test points P1 and P2 of the metal layer M2 and the test point P3 of the additional metal layer 110 form a capacitance via a metal long line. The short circuit test and the current test may be performed using the test points P1 and P2 of the metal layer M2 and the test point P3 of the additional metal layer 110.

In the short test, if a short is detected between the test point P1 or P2 and the test point P3, it indicates that the photoresist removal energy is too large and the insulating layers 120 and 130 have been broken down. In this case, it is necessary to perform the subsequent photoresist removal with a lower photoresist removal energy. For example, when removing a resist by laser, the power of the laser can be reduced, and the operation time can be shortened.

In the current test, if the current between the test point P1 or P2 and the test point P3 is measured using a conventional test voltage to be very small, for example, less than 10-6A indicates that there is a photoresist residue, i.e., the photoresist removal energy is insufficient, resulting in an excessive capacitive reactance between the test point P1 or P2 and the test point P3. In this case, it is necessary to perform the subsequent photoresist removal using a higher photoresist removal energy. For example, when removing a resist by laser, the power of the laser can be increased, and the operation time can be prolonged.

If there is neither a short circuit between the test points P1 and P2 and the test point P3, but there is sufficient current, the photoresist stripping energy is considered suitable for photoresist stripping, and the corresponding parameters can be used to photoresist strip the region to be repaired.

In addition, test point P1 or P2 of test key 100 can be used to determine whether a metal trace is successful. If the resistance R between P1 and P212<600 ohms, the metal long line is considered to be successful, and the metal long line can be performed on the area to be actually repaired by using corresponding parameters.

Fig. 6 shows a flowchart of a method of testing a metal long line using the test key 100 according to an exemplary embodiment of the present invention.

In step S100, a portion of the color photoresist of the color filter layer 140 of the test key 100 is removed for subsequent formation of the metal connection line 150.

In step S110, the connection line 150 is formed at the portion where the color resists are removed. The connection line 150 may be electrically connected to the test points P1 and P2 through vias, respectively, but the exemplary embodiment is not limited thereto.

In step S120, it is tested whether the metal long wire connection is successful. If the resistance R between the test points P1 and P212<600 ohms, the metal long line is considered to be successfully connected, and the metal long line can be performed on the area to be actually repaired by using corresponding parameters. Otherwise, the resistance is too large or is not connected, and the metal long line parameters need to be adjusted for further testing.

In step S130, whether the photoresist removal is successful is tested. If the short circuit or the current is not found to be too small in the short circuit test and the current test, the photoresist is considered to be successfully removed, and the photoresist can be removed from the actual region to be repaired by using corresponding parameters. Otherwise, photoresist residue or breakdown of the insulating layer 120/130 requires further testing by adjusting the photoresist strip parameters. The short circuit test and the current test may be performed separately, but the exemplary embodiments are not limited thereto, and for example, the short circuit test and the current test may be implemented using the same I-V curve.

The order of step S120 and step S130 may be interchanged. After the steps S120 and S130 are completed, one test for the metal long wire is completed. If it is found in steps S120 and S130 that the metal long line parameter or the photoresist removal parameter needs to be adjusted, steps S100-S130 may be repeated after the corresponding adjustment is performed until the test result indicates that both the metal long line parameter and the photoresist removal parameter are suitable for the metal long line. Subsequent tests may be performed using different test keys 100, but example embodiments are not limited thereto and subsequent tests may also be performed using the same test key 100. For example, the later formed metal connection line may be connected to the test points P1 and P2 through different via holes than the previous metal connection line, respectively. For example, the metal connection line formed later may be longer than the metal connection line of the bracket "]" formed earlier and form a metal connection line of the bracket "]" surrounding the metal connection line formed earlier, or the metal connection line formed later may be shorter than the metal connection line of the bracket "]" formed earlier and form a metal connection line of the bracket "]" surrounded by the metal connection line formed earlier.

Fig. 7 shows a flowchart of a broken line repairing method according to an exemplary embodiment of the present invention.

In step S10, the test key 100 is used to test the metal long line parameters and the photoresist stripping parameters suitable for the metal long line. The test method is described with reference to fig. 6 and the corresponding description.

Then, in step S20, the obtained photoresist removing parameters are used to remove part of the color photoresist of the color filter layer to be repaired for forming the metal connection line.

Thereafter, in step S30, a metal connection line is formed at the portion where the color resists are removed. The metal connection lines may be electrically connected with the two disconnection points through vias, respectively, but the exemplary embodiments are not limited thereto.

In addition, the method may further include a step S40 of performing an impedance test on the metal connection line after the step S30.

In addition, the method may further include a step S25 of depositing a transparent insulating layer at a portion to be repaired between the steps S20 and S30. The transparent insulating layer may be SiO2. The transparent insulating layer can prevent the lower insulating layer (passivation layer) at the position to be repaired from being broken down due to the overlarge photoresist removing energy, so that the short circuit between the long-line metal and the inherent circuit is prevented. Since the photoresist removal parameter suitable for the metal long line is obtained using step S10, a breakdown phenomenon generally does not occur to cause a short circuit, and thus step S25 may not be generally performed, but the exemplary embodiment is not limited thereto. Alternatively, step S25 may be performed.

It will be apparent to those skilled in the art that various modifications and variations can be made in the present invention without departing from the spirit or scope of the invention. Thus, it is intended that the present invention cover the modifications and variations of this invention provided they come within the scope of the appended claims and their equivalents.

Claims (10)

1. A test key for broken line repair, the test key comprising:

the metal layer comprises a first test point and a second test point which are electrically disconnected; in the testing process, the first testing point and the second testing point are electrically connected through a grown metal wire;

a color filter layer on the metal layer and including a color photoresist;

the additional metal layer is positioned below the metal layer and comprises a third test point; in the test process, the first test point, the second test point and the third test point form capacitance through metal long lines, so as to carry out short circuit test and current test between the first test point and the third test point or between the second test point and the third test point;

an upper insulating layer between the metal layer and the color filter layer; and

and the lower insulating layer is positioned between the metal layer and the additional metal layer.

2. A test method for broken line repair, the test method comprising:

removing a portion of the color photoresist of the color filter layer of a test key, wherein the test key is the test key of claim 1;

growing a metal wire at the part where the color light resistor is removed, wherein the grown metal wire is used for electrically connecting the first test point and the second test point;

measuring the resistance between the first test point and the second test point, thereby determining whether the first test point and the second test point are successfully electrically connected through the grown metal wire; and

and carrying out short circuit test and current test between the first test point and the third test point or between the second test point and the third test point so as to determine whether the photoresist is successfully removed.

3. The test method of claim 2, wherein:

and when the resistance between the first test point and the second test point is measured to be less than 600 ohms, determining that the first test point and the second test point are successfully electrically connected through the grown metal wire.

4. The test method of claim 2, wherein:

and when the short circuit between the first test point and the third test point or the short circuit between the second test point and the third test point is detected in the short circuit test, determining that the upper and lower insulating layers are broken down due to overhigh photoresist removing energy, thereby determining that the photoresist is not successfully removed.

5. The test method of claim 2, wherein:

when the current between the first test point and the third test point is less than 10-6A or the current between the second test point and the third test point is less than 10-6And A, determining that the photoresist is residual due to too low photoresist removal energy, thereby determining that the photoresist is not successfully removed.

6. The test method of claim 2, wherein:

the grown metal line is formed in a bracket shape on the same side of the first test point and the second test point.

7. The test method of claim 6, wherein:

and when the first test point and the second test point are not connected electrically or the photoresist removal is not successful through the grown metal wire, performing the test again by using the same test key, wherein the newly grown metal wire is in a bracket shape and is surrounded by or surrounds the previously grown metal wire.

8. The test method of claim 2, wherein:

when the first test point and the second test point are not electrically connected or the light resistance is not successfully removed through the grown metal wire, the test is performed again by using another test key.

9. A broken wire repairing method comprises the following steps:

performing the test method of one of claims 2 to 8;

when the first test point and the second test point are not electrically connected or the light resistance removal is not successful through the grown metal wire, adjusting the metal long wire parameter or the light resistance removal parameter, and repeatedly executing the test method of any one of claims 2 to 8 until the first test point and the second test point are electrically connected successfully and the light resistance removal is successful through the grown metal wire;

and forming the metal connecting line pair broken line repairing by using the successful photoresist removing parameters and the metal long line parameters.

10. The broken wire repairing method according to claim 9, further comprising:

and carrying out impedance test on the metal connecting wire.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810036209.1A CN108227324B (en) | 2018-01-15 | 2018-01-15 | Test key and test method for broken line repair and broken line repair method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810036209.1A CN108227324B (en) | 2018-01-15 | 2018-01-15 | Test key and test method for broken line repair and broken line repair method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108227324A CN108227324A (en) | 2018-06-29 |

| CN108227324B true CN108227324B (en) | 2020-12-04 |

Family

ID=62642088

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810036209.1A Active CN108227324B (en) | 2018-01-15 | 2018-01-15 | Test key and test method for broken line repair and broken line repair method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108227324B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8049523B2 (en) | 2007-12-05 | 2011-11-01 | Solaredge Technologies Ltd. | Current sensing on a MOSFET |

| GB2498365A (en) | 2012-01-11 | 2013-07-17 | Solaredge Technologies Ltd | Photovoltaic module |

| CN109491163A (en) * | 2018-12-12 | 2019-03-19 | 惠科股份有限公司 | Array substrate repairing process, array substrate and display panel |

| CN110033725B (en) * | 2019-04-23 | 2022-05-31 | 深圳市华星光电半导体显示技术有限公司 | Resistance measuring method and resistance measuring device for disconnection repairing line |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0780720A1 (en) * | 1995-12-22 | 1997-06-25 | General Electric Company | Method for repairing low noise metal lines in thin film imagers |

| CN101216643A (en) * | 2007-12-26 | 2008-07-09 | 昆山龙腾光电有限公司 | LCD device array substrate, its mending method and LCD device |

| CN104090435A (en) * | 2014-06-24 | 2014-10-08 | 合肥鑫晟光电科技有限公司 | Display panel and repairing method thereof |

| CN104765170A (en) * | 2015-04-17 | 2015-07-08 | 深圳市华星光电技术有限公司 | Long-line repair method of COA array substrate |

| CN105785678A (en) * | 2016-05-12 | 2016-07-20 | 深圳市华星光电技术有限公司 | Broken wire repairing method of TFT (Thin Film Transistor) substrate |

| CN106896601A (en) * | 2017-02-27 | 2017-06-27 | 深圳市华星光电技术有限公司 | Array base palte method for repairing disconnected lines |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100752547B1 (en) * | 2000-12-29 | 2007-08-29 | 엘지.필립스 엘시디 주식회사 | Identity Mark and method for the same in Array Panel for Liquid Crystal Display Device |

| KR101182570B1 (en) * | 2005-06-30 | 2012-09-12 | 엘지디스플레이 주식회사 | Method of repairing short defect and method of fabricating liquid crystal display |

-

2018

- 2018-01-15 CN CN201810036209.1A patent/CN108227324B/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0780720A1 (en) * | 1995-12-22 | 1997-06-25 | General Electric Company | Method for repairing low noise metal lines in thin film imagers |

| CN101216643A (en) * | 2007-12-26 | 2008-07-09 | 昆山龙腾光电有限公司 | LCD device array substrate, its mending method and LCD device |

| CN104090435A (en) * | 2014-06-24 | 2014-10-08 | 合肥鑫晟光电科技有限公司 | Display panel and repairing method thereof |

| CN104765170A (en) * | 2015-04-17 | 2015-07-08 | 深圳市华星光电技术有限公司 | Long-line repair method of COA array substrate |

| CN105785678A (en) * | 2016-05-12 | 2016-07-20 | 深圳市华星光电技术有限公司 | Broken wire repairing method of TFT (Thin Film Transistor) substrate |

| CN106896601A (en) * | 2017-02-27 | 2017-06-27 | 深圳市华星光电技术有限公司 | Array base palte method for repairing disconnected lines |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108227324A (en) | 2018-06-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108227324B (en) | Test key and test method for broken line repair and broken line repair method | |

| CN103345093B (en) | Pixel cell, array base palte and manufacture, restorative procedure and display device | |

| CN102540524B (en) | Prevent the method for electrostatic breakdown, the manufacture method of array base palte and display backboard | |

| CN106711028B (en) | Method and device for repairing transistor | |

| CN106876436B (en) | Array substrate and repairing method thereof | |

| CN104851404A (en) | Array substrate and restoration method, test method and manufacture method thereof, and display apparatus | |

| CN103311220A (en) | Circuit repair structure and method | |

| CN104143519A (en) | Product through hole etching defect detection method | |

| CN104007571B (en) | Array base plate and manufacture method thereof | |

| CN108646476A (en) | A kind of broken wire repair method of liquid crystal display panel | |

| CN109061914B (en) | Manufacturing method of display substrate, display substrate and display device | |

| CN105489596A (en) | Array substrate and fabrication method | |

| CN102798999A (en) | Array substrate cross curve repairing method, array substrate and liquid crystal display | |

| CN104485337B (en) | The preparation method of thin-film transistor array base-plate and thin-film transistor array base-plate | |

| CN105425492B (en) | Array substrate and preparation method thereof | |

| CN108957804A (en) | A kind of array substrate and its method for maintaining, display panel and display device | |

| CN104090393B (en) | A kind of liquid crystal cell electric transistor method of testing | |

| CN111916464A (en) | Array substrate, preparation method thereof and display panel | |

| CN101562152B (en) | manufacturing method of active element array substrate | |

| CN106054416A (en) | Liquid crystal display thin film transistor structure | |

| CN109817577A (en) | A kind of array substrate and a kind of preparation method of organic light-emitting display device | |

| CN101226932B (en) | Pixel structure and manufacturing method thereof | |

| JP3295025B2 (en) | Manufacturing method of liquid crystal display device | |

| CN114807840A (en) | Preparation method of gallium arsenide-based LED chip transparent conducting layer test point | |

| CN105742293A (en) | Array substrate and manufacturing method therefor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder |

Address after: 9-2 Tangming Avenue, Guangming New District, Shenzhen City, Guangdong Province Patentee after: TCL China Star Optoelectronics Technology Co.,Ltd. Address before: 9-2 Tangming Avenue, Guangming New District, Shenzhen City, Guangdong Province Patentee before: Shenzhen China Star Optoelectronics Technology Co.,Ltd. |