CN108155276B - Photoelectric device and manufacturing method thereof - Google Patents

Photoelectric device and manufacturing method thereof Download PDFInfo

- Publication number

- CN108155276B CN108155276B CN201711424036.2A CN201711424036A CN108155276B CN 108155276 B CN108155276 B CN 108155276B CN 201711424036 A CN201711424036 A CN 201711424036A CN 108155276 B CN108155276 B CN 108155276B

- Authority

- CN

- China

- Prior art keywords

- quantum dot

- dot structure

- substrate

- upper electrode

- optoelectronic device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 34

- 239000002096 quantum dot Substances 0.000 claims abstract description 151

- 238000000034 method Methods 0.000 claims abstract description 69

- 230000008569 process Effects 0.000 claims abstract description 48

- 239000003446 ligand Substances 0.000 claims abstract description 30

- 239000000463 material Substances 0.000 claims abstract description 17

- 239000000126 substance Substances 0.000 claims abstract description 17

- 239000000758 substrate Substances 0.000 claims description 48

- 239000010410 layer Substances 0.000 claims description 39

- 230000005693 optoelectronics Effects 0.000 claims description 35

- 238000005498 polishing Methods 0.000 claims description 13

- 239000011241 protective layer Substances 0.000 claims description 13

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 9

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 claims description 8

- 229910052581 Si3N4 Inorganic materials 0.000 claims description 6

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 claims description 6

- 239000003990 capacitor Substances 0.000 claims description 5

- 239000011248 coating agent Substances 0.000 claims description 4

- 238000000576 coating method Methods 0.000 claims description 4

- 239000000377 silicon dioxide Substances 0.000 claims description 4

- 235000012239 silicon dioxide Nutrition 0.000 claims description 4

- DHBXNPKRAUYBTH-UHFFFAOYSA-N 1,1-ethanedithiol Chemical compound CC(S)S DHBXNPKRAUYBTH-UHFFFAOYSA-N 0.000 claims description 3

- 238000000151 deposition Methods 0.000 claims description 3

- 238000001755 magnetron sputter deposition Methods 0.000 claims description 3

- 238000001259 photo etching Methods 0.000 claims description 3

- 238000000227 grinding Methods 0.000 abstract description 3

- 230000015572 biosynthetic process Effects 0.000 description 7

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 6

- 229910052710 silicon Inorganic materials 0.000 description 6

- 239000010703 silicon Substances 0.000 description 6

- 238000003384 imaging method Methods 0.000 description 4

- 238000000059 patterning Methods 0.000 description 4

- 238000000206 photolithography Methods 0.000 description 4

- 239000004065 semiconductor Substances 0.000 description 4

- 238000011282 treatment Methods 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000035945 sensitivity Effects 0.000 description 3

- 238000000231 atomic layer deposition Methods 0.000 description 2

- 230000000295 complement effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 238000004528 spin coating Methods 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- VYMPLPIFKRHAAC-UHFFFAOYSA-N 1,2-ethanedithiol Chemical compound SCCS VYMPLPIFKRHAAC-UHFFFAOYSA-N 0.000 description 1

- ODINCKMPIJJUCX-UHFFFAOYSA-N Calcium oxide Chemical compound [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 description 1

- UHYPYGJEEGLRJD-UHFFFAOYSA-N cadmium(2+);selenium(2-) Chemical compound [Se-2].[Cd+2] UHYPYGJEEGLRJD-UHFFFAOYSA-N 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 229940056932 lead sulfide Drugs 0.000 description 1

- 229910052981 lead sulfide Inorganic materials 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000004297 night vision Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 229920002120 photoresistant polymer Polymers 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L33/00—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L33/02—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof characterised by the semiconductor bodies

- H01L33/04—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof characterised by the semiconductor bodies with a quantum effect structure or superlattice, e.g. tunnel junction

- H01L33/06—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof characterised by the semiconductor bodies with a quantum effect structure or superlattice, e.g. tunnel junction within the light emitting region, e.g. quantum confinement structure or tunnel barrier

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L33/00—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L33/005—Processes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L33/00—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L33/44—Semiconductor devices having potential barriers specially adapted for light emission; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof characterised by the coatings, e.g. passivation layer or anti-reflective coating

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Light Receiving Elements (AREA)

Abstract

The invention provides a photoelectric device and a manufacturing method thereof. In the photoelectric device and the manufacturing method thereof provided by the invention, device combinations with different wave bands can be formed through the first quantum dot structure and the second quantum dot structure, and the performance of the first/second quantum dot structure is improved through a ligand exchange process; the quantum dot structure is patterned by adopting twice chemical mechanical grinding in the manufacturing method, so that the process compatibility of the photoelectric device can be improved, the possibility of crosstalk is reduced, and the method is suitable for quantum dot materials, thereby reducing the production cost.

Description

Technical Field

The invention relates to the field of semiconductor manufacturing, in particular to a photoelectric device and a manufacturing method thereof.

Background

Photoelectric detectors can convert optical image information into electric signals, and photoelectric devices in the photoelectric detectors are key devices in products such as image sensors, spectrometers, infrared night vision and the like. Common photodetectors are CCD (charge coupled device) and photodiode devices in compound semiconductor or silicon technology, and common CMOS (complementary metal oxide semiconductor) image sensors employ silicon photodiodes.

At present, a photoelectric detector can be made of quantum dot (quantum dot) materials, the detection wavelength of the photoelectric detector can be adjusted along with the size of the quantum dot, and meanwhile, the photoelectric detector has high responsivity. At present, a visible light and near infrared image sensor is developed on the basis of a photoelectric detector of quantum dots, and compared with a traditional CMOS image sensor and the like, the photoelectric detector of the quantum dots has the advantages of high sensitivity, small crosstalk, high filling rate, high shutter speed and the like.

In the application of the quantum dot photoelectric detector, the photoelectric detector of each quantum dot can be combined with a signal processing unit such as a signal device to form a pixel unit, and in order to avoid crosstalk between pixels, the quantum dot film of each pixel point needs to be isolated, so that the quantum dot film needs to be subjected to graphical processing. Meanwhile, the signal processing unit can be manufactured by adopting a CMOS (complementary metal oxide semiconductor) process, and then a forming process of a photoelectric device structure of the quantum dot is carried out, wherein the forming process comprises a patterning process of a quantum dot film and the like. For quantum dot photodetectors, two different types of quantum dots are often required, or different processing techniques are required for the same type of quantum dot to achieve the desired performance. Thus, imaging may require separate imaging and processing of two different quantum dot regions. Therefore, a process integration method capable of supporting multiple quantum dot film formation and patterning is needed.

Therefore, how to provide an optoelectronic device and a method for manufacturing the same is a technical problem to be solved by those skilled in the art.

Disclosure of Invention

The invention aims to provide a photoelectric device and a manufacturing method thereof, and provides the photoelectric device.

In order to solve the above technical problem, the present invention provides a method for manufacturing a photovoltaic device, comprising:

providing a substrate, forming a first groove in the substrate, forming a first quantum dot structure in the first groove, and performing a ligand exchange process on the first quantum dot structure;

carrying out first chemical mechanical polishing on the substrate;

forming a capping layer on the substrate;

forming a second groove in the substrate, forming a second quantum dot structure in the second groove, and performing a ligand exchange process on the second quantum dot structure;

carrying out second chemical mechanical polishing to expose the first quantum dot structure;

forming a first upper electrode on the first quantum dot structure and a second upper electrode on the second quantum dot structure.

Optionally, in the method for manufacturing an optoelectronic device, the ligand exchange process includes: and (3) adopting a ligand exchange solution to carry out surface coating, keeping the time for 1-10 min, and removing the residual solution.

Optionally, in the method for fabricating an optoelectronic device, the ligand exchange solution includes a perovskite solution or a dithioglycol solution.

Optionally, in the manufacturing method of the photoelectric device, the material of the covering layer includes silicon dioxide, and the thickness of the covering layer is 50nm to 200 nm.

Optionally, in the manufacturing method of the optoelectronic device, the substrate includes a protective layer on a surface, the material of the protective layer includes silicon nitride, and the thickness of the protective layer is 50nm to 200 nm.

Optionally, in the method for manufacturing an optoelectronic device, the forming the first upper electrode and the forming the second upper electrode include: depositing an indium tin oxide layer by adopting a magnetron sputtering method, wherein the thickness of the indium tin oxide layer is 100 nm-500 nm, and then forming the indium tin oxide layer by photoetching.

The invention also provides a photoelectric device, which comprises a first quantum dot structure, a second quantum dot structure, a first upper electrode and a second upper electrode, wherein the first quantum dot structure and the second quantum dot structure are formed by adopting a ligand exchange process, the first quantum dot structure and the second quantum dot structure are both positioned in a substrate, the first upper electrode and the second upper electrode are both arranged on the substrate, the first upper electrode is connected with the first quantum dot structure, and the second upper electrode is connected with the second quantum dot structure.

Optionally, in the optoelectronic device, a first lower electrode and a second lower electrode are disposed in the substrate, the first lower electrode is connected to the first quantum dot structure, and the second lower electrode is connected to the second quantum dot structure.

Optionally, in the optoelectronic device, the first lower electrode, the second lower electrode, the first upper electrode and the second upper electrode are respectively connected to a signal device, and the signal device includes a transistor and/or a capacitor.

Optionally, in the optoelectronic device, the wavelength of light responded by the first quantum dot structure includes 400nm to 760nm, and the wavelength of light responded by the second quantum dot structure includes 900nm to 1700 nm.

In summary, in the optoelectronic device and the manufacturing method thereof provided by the present invention, device combinations of different wavebands can be formed by the first quantum dot structure and the second quantum dot structure, and the performance of the first/second quantum dot structure is improved by the ligand exchange process; the quantum dot structure is patterned by adopting twice chemical mechanical grinding in the manufacturing method, so that the process compatibility of the photoelectric device can be improved, the possibility of crosstalk is reduced, and the method is suitable for quantum dot materials, thereby reducing the production cost.

Drawings

FIG. 1 is a flow chart of a method of fabricating an optoelectronic device according to an embodiment of the present invention;

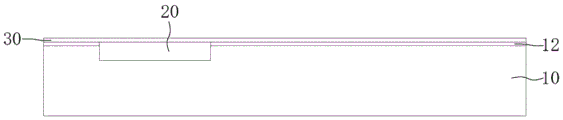

FIGS. 2-6 are cross-sectional views of an optoelectronic device at various steps in a method of fabricating an optoelectronic device according to an embodiment of the present invention;

FIG. 7 is a cross-sectional view of a photovoltaic device according to an embodiment of the present invention;

the quantum dot structure comprises a substrate 10, a first groove 11, a protective layer 12, a second groove 13, a first quantum dot structure 20, a first upper electrode 21, a first lower electrode 22, a covering layer 30, a second quantum dot structure 40, a second upper electrode 41, a second lower electrode 42 and a signal device 50.

Detailed Description

To make the objects, features and advantages of the present invention comprehensible, reference is made to the accompanying drawings. It should be understood that the structures, ratios, sizes, and the like shown in the drawings and described in the specification are only used for matching with the disclosure of the specification, so as to be understood and read by those skilled in the art, and are not used to limit the conditions under which the present invention can be implemented, so that the present invention has no technical significance, and any structural modification, ratio relationship change, or size adjustment should still fall within the scope of the present invention without affecting the efficacy and the achievable purpose of the present invention.

As shown in fig. 1, the present invention provides a method for manufacturing an optoelectronic device, the method for manufacturing an optoelectronic device comprising:

step S10, providing a substrate, forming a first groove in the substrate, forming a first quantum dot structure in the first groove, and performing a ligand exchange process on the first quantum dot structure;

step S20, performing a first Chemical Mechanical Polishing (CMP) on the substrate;

step S30, forming a covering layer on the substrate;

step S40, forming a second groove in the substrate, forming a second quantum dot structure in the second groove, and performing a ligand exchange process on the second quantum dot structure;

step S50, performing a second chemical mechanical polishing to expose the first quantum dot structure;

step S60, forming a first upper electrode on the first quantum dot structure, and forming a second upper electrode on the second quantum dot structure.

The features of the method for fabricating an optoelectronic device according to the present invention will be described in more detail with reference to fig. 2 to 6.

First, as shown in fig. 2, according to step S10, a substrate 10 is provided, a first groove 11 is formed in the substrate 10, the substrate may be a silicon substrate, a groove may be formed in the substrate by a photolithography process, a first quantum dot structure 20 is formed in the first groove 11, the first quantum dot structure 20 may be coated in the first groove 11 by a quantum dot solution, the quantum dot film may be formed by spin coating, spray coating, etc. of the quantum dot solution, and molding by drying, etc., the quantum dot film with a suitable thickness may be formed after the multi-step spin coating/spray coating and film hardening, the thickness may be 100nm to 500nm, and then a ligand exchange process is performed on the first quantum dot structure 20, so that the ligand in the quantum dot solution may be replaced by other ligands, and the photoresponse sensitivity of the quantum dot structure may be improved. For example, for applications of quantum dot structures such as optoelectronic devices to visible light, the quantum dot solution may be a lead sulfide solution or a cadmium selenide solution.

With continued reference to fig. 2, in order to achieve the protection effect, the substrate further includes a protection layer 12 located on the surface, the material of the protection layer 12 includes silicon nitride, the thickness of the protection layer 12 is 50nm to 200nm, so as to prevent the substrate from being damaged by other process steps, and when the first groove 11 is formed, the protection layer 12 at the groove needs to be etched away, so that other areas are protected.

In this embodiment, the ligand exchange process comprises: and (3) adopting ligand exchange solution to carry out surface coating, namely coating the surface of the formed quantum dot structure, and removing the residual solution after the retention time is 1-10 min, namely removing the residual solution after ligand exchange.

Optionally, the ligand exchange solution comprises a perovskite (ABO3) solution or a ethanedithiol (C2H6S2) solution, and the main chemical composition of the perovskite solution comprises calcium oxide (CaO) and titanium oxide (TiO2), for example, the sensitivity of the PbS quantum dot structure in visible light can be improved by using the perovskite solution as ligand exchange, and if the quantum dot film formation is for short-wave infrared application, the ethanedithiol can be used as ligand exchange to improve the continuous response performance of the PbS quantum dot structure in short-wave infrared.

Then, according to step S20, corresponding to the processing on the surface of the substrate 10 after the first quantum dot structure 20 is formed, the first chemical mechanical polishing is performed on the substrate 10, the quantum dot solution and the ligand exchange solution remaining on the surface of the substrate 10 can be removed by the first chemical mechanical polishing, and the first quantum dot structure 20 formed in the first groove 11 is not affected, so that the effect on other devices such as the quantum dot structure in the substrate is reduced compared with other processes, and in a specific embodiment, the first chemical mechanical polishing can be performed until the protection layer 12 made of silicon nitride is formed.

Next, as shown in fig. 3, according to step S30, a covering layer 30 is formed on the substrate, the covering layer 30 covers the first quantum dot structure 20 in the substrate 10, and after the covering treatment of the first quantum dot structure 20, the influence of the subsequent process is prevented.

Optionally, the material of the covering Layer 30 includes silicon dioxide, the thickness of the covering Layer 30 is 50nm to 200nm, and an Atomic Layer Deposition (ALD) process may be used to form a silicon dioxide Layer on the surface of the substrate 10, so as to serve as a protective substrate and a first quantum dot structure, thereby performing a subsequent process.

Then, as shown in fig. 4, according to step S40, a second groove 13 is formed in the substrate 10, similarly to the first groove 11, a second quantum dot structure 40 is formed in the second groove 13, and a ligand exchange process is performed on the second quantum dot structure 40, the thickness ranges of the first quantum dot structure 20 and the second quantum dot structure 40 are both 100nm to 500nm, the second groove 13 is another groove disposed outside the first groove 11, the relative positional relationship between the first groove 11 and the second groove 13 is not limited, and the specific positional relationship, the size, the shape, and the like can be determined by the formed pixel array. The protective layer 12 and the capping layer 30 at the recess need to be etched away when forming the second recess 13. Two different photosensitive units can be obtained through the first quantum dot structure 20 and the second quantum dot structure 40 which are formed respectively, and meanwhile, different processing modes of the two photosensitive units can be realized, the requirements of various different products and process conditions are met, and meanwhile, mutual influence is avoided.

Next, as shown in fig. 5, according to step S50, a second chemical mechanical polishing is performed to expose the first quantum dot structure 20, that is, the covering layer 30 is removed by the second chemical mechanical polishing to expose the first quantum dot structure 20, and the remaining quantum dot solution and the ligand exchange solution on the surface of the substrate are also removed, so as to reduce the influence on other devices such as the first/second quantum dot structures in the substrate 10 compared with other processes. In a specific embodiment, the chemical mechanical polishing can also polish away the protective layer 12 of silicon nitride to expose the silicon substrate.

Finally, as shown in fig. 6, according to step S60, a first upper electrode 21 is formed on the first quantum dot structure 20, and a second upper electrode 41 is formed on the second quantum dot structure 40, so that the electrical connection relationship of the optoelectronic device can be realized.

In the present embodiment, forming the first upper electrode 21 and forming the second upper electrode 41 include: an Indium Tin Oxide (ITO) layer is deposited by adopting a magnetron sputtering method, the thickness of the ITO layer is 100 nm-500 nm, and the ITO layer is formed by photoetching. That is, the first upper electrode 21 and the second upper electrode 41 are made of transparent indium tin oxide, and can be formed at the same time, and then the first upper electrode 21 and the second upper electrode 41 are formed on the first quantum dot structure 20 and the second quantum dot structure 40, respectively, by a photolithography process.

In combination with the manufacturing method of the above-mentioned optoelectronic device, as shown in fig. 7, the optoelectronic device further provides an optoelectronic device, where the optoelectronic device includes a first quantum dot structure 20, a second quantum dot structure 40, a first upper electrode 21 and a second upper electrode 41, the first quantum dot structure 20 and the second quantum dot structure 40 are both formed by a ligand exchange process, the first quantum dot structure 20 and the second quantum dot structure 40 are both located in a substrate 10, the first upper electrode 21 and the second upper electrode 41 are both disposed on the substrate 10, the first upper electrode 21 is connected to the first quantum dot structure 20, and the second upper electrode 41 is connected to the second quantum dot structure 40.

Continuing to refer to fig. 7, a first lower electrode 22 and a second lower electrode 42 are disposed in the substrate 10, the first lower electrode 22 is connected to the first quantum dot structure 20, the second lower electrode 42 is connected to the second quantum dot structure 40, the first lower electrode 22 and the second lower electrode 42 can be formed in the substrate 10 by a CMOS front-end manufacturing process, a through hole and a multilayer interconnection line can be formed by a metal interconnection manner of a through hole required for device interconnection, by processes such as photolithography, etching, deposition, and the like, and isolation between metal interconnection lines can be achieved by a dielectric layer. The lower electrode of the optoelectronic device and the via connection line, which can also be connected to the first/second upper electrode of the optoelectronic device, can be formed using CMOS processes. The dielectric layer around the through hole connecting line can be a silicon oxide dielectric layer material, and a layer of silicon nitride and the like can be deposited on the dielectric layer, and the thickness can be 50 nm-200 nm. In a specific embodiment, the second chemical mechanical polishing may expose the via connecting line connecting the first upper electrode and the second upper electrode, so as to achieve the electrical connection.

Optionally, the first lower electrode 22, the second lower electrode 42, the first upper electrode 21 and the second upper electrode 41 are respectively connected to a signal device 50, the signal device 50 includes a transistor and/or a capacitor, the transistor can be switched by starting a switching control signal, the capacitor can be used for storing or reading an electrical signal, and thus, the first quantum dot structure 20 and the second quantum dot structure 40 can be both connected to a signal processing unit. Wherein, the materials for realizing the through hole connecting line for connecting the first/second lower electrodes and the first/second upper electrodes comprise copper and titanium nitride.

In this embodiment, the first quantum dot structure 20 may respond with a wavelength of light including 400nm to 760nm, that is, may cover a visible light band, and the second quantum dot structure 40 may respond with a wavelength of light including 900nm to 1700nm, that is, may cover a short-wave infrared band.

The above steps can be repeated to form and pattern the quantum dot structure of each application waveband in the array of the photoelectric device as required, and the photoelectric devices can be made of materials different from the quantum dot film or the same material but need different process treatments, so the film forming and patterning are carried out by adopting the above steps.

In order to realize optimal photoelectric response, an array can be formed by integrating photoelectric devices of various quantum dots, and the photoelectric devices respond to R (red light), G (green light), B (blue light), S (short wave infrared) and other quantum dots. For example, an image sensor formed by a photoelectric device adopting full quantum dots can cover a visible light band and a short wave infrared band, each pixel point can comprise four photosensitive units which are respectively R/G/B/S, R/G/B responds to visible light (400 nm-760 nm), wherein the R unit senses red light, the G unit senses green light, the B unit senses blue light, and the S unit senses the short wave infrared unit (900 nm-1.7 um). The structures of all quantum dot photoelectric devices can be similar and can be formed by an upper electrode, a lower electrode and a middle quantum dot structure, the upper electrode and the lower electrode can be made of the same metal material, different quantum dot photoelectric devices can need different quantum dot materials to form films, or different treatment processes are needed after the same quantum dot material is formed into the films so as to improve the performances of respective application wave bands, and when the quantum dot films are patterned, the quantum dot films of different photoelectric devices can be respectively patterned.

Since the photoresist in the photolithography process may contaminate the quantum dot film to affect its performance, and in addition, if the top layer via process is performed after the quantum dot film is formed, the silicon wafer needs to be returned to the CMOS process line, and actually, since the material used for the quantum dot film is not allowed to be used in the existing CMOS process line at present, the silicon wafer cannot be returned to the related process. This makes it necessary to add additional equipment to the production line for processing the quantum dot film to make the top layer via. Therefore, the manufacturing method of the photoelectric device provided by the application improves the compatibility with the CMOS process, and the CMOS process refers to a plurality of process modes including transistor formation, capacitor formation, through hole formation, metal connecting line formation, dielectric layer formation and the like, mainly can realize read-write circuits required by various applications, and realizes related processes of electrical connection of the circuits and the photoelectric device. In addition, the photoelectric device provided by the application can still adopt a CMOS photodiode for a visible light waveband.

For a full quantum dot image sensor applied in a wide photosensitive range (such as multiple wave bands covering visible light + short wave infrared), the required performance can be achieved through two different quantum dots or different processing technologies required by the same quantum dot. Thus, the imaging can be respectively carried out on two different quantum dot regions by imaging and process treatment, and the process integration method of forming and patterning the quantum dots for multiple times can be supported.

In summary, in the optoelectronic device and the manufacturing method thereof provided by the present invention, device combinations of different wavebands can be formed by the first quantum dot structure and the second quantum dot structure, and the performance of the first/second quantum dot structure is improved by the ligand exchange process; the quantum dot structure is patterned by adopting twice chemical mechanical grinding in the manufacturing method, so that the process compatibility of the photoelectric device can be improved, the possibility of crosstalk is reduced, and the method is suitable for quantum dot materials, thereby reducing the production cost.

The above description is only for the purpose of describing the preferred embodiments of the present invention, and is not intended to limit the scope of the present invention, and any variations and modifications made by those skilled in the art based on the above disclosure are within the scope of the appended claims.

Claims (10)

1. A method for fabricating an optoelectronic device, the method comprising:

providing a substrate, wherein a protective layer is formed on the substrate, a first groove is formed in the substrate, a first quantum dot structure is formed in the first groove, and a ligand exchange process is carried out on the first quantum dot structure;

carrying out first chemical mechanical polishing on the substrate, and stopping on the protective layer;

forming a cover layer on the protective layer, wherein the cover layer covers the first quantum dot structure;

forming a second groove in the substrate, forming a second quantum dot structure in the second groove, and performing a ligand exchange process on the second quantum dot structure;

carrying out second chemical mechanical polishing to remove the covering layer and expose the first quantum dot structure;

forming a first upper electrode on the first quantum dot structure and a second upper electrode on the second quantum dot structure.

2. A method of fabricating optoelectronic devices according to claim 1, wherein the ligand exchange process comprises: and (3) adopting a ligand exchange solution to carry out surface coating, keeping the time for 1-10 min, and removing the residual solution.

3. A method of fabricating an optoelectronic device according to claim 2, wherein the ligand exchange solution comprises a perovskite solution or a ethanedithiol solution.

4. A method of fabricating an optoelectronic device according to any one of claims 1 to 3, wherein the material of the cap layer comprises silicon dioxide, and the thickness of the cap layer is in the range of 50nm to 200 nm.

5. The method for manufacturing an optoelectronic device according to any one of claims 1 to 3, wherein the substrate comprises a protective layer on the surface, the material of the protective layer comprises silicon nitride, and the thickness of the protective layer is 50nm to 200 nm.

6. A method of fabricating an optoelectronic device according to any of claims 1 to 3, wherein forming the first upper electrode and forming the second upper electrode comprises: depositing an indium tin oxide layer by adopting a magnetron sputtering method, wherein the thickness of the indium tin oxide layer is 100 nm-500 nm, and then forming the indium tin oxide layer by photoetching.

7. An optoelectronic device, wherein the optoelectronic device comprises:

the structure comprises a first quantum dot structure and a second quantum dot structure, wherein the first quantum dot structure and the second quantum dot structure are formed by adopting a ligand exchange process, the first quantum dot structure and the second quantum dot structure are respectively positioned in a first groove and a second groove in a substrate, and the upper surface of the substrate is a protective layer;

the first upper electrode and the second upper electrode are both arranged on the substrate, the first upper electrode is connected with the first quantum dot structure, and the second upper electrode is connected with the second quantum dot structure.

8. The optoelectronic device according to claim 7, wherein a first lower electrode and a second lower electrode are disposed in the substrate, the first lower electrode is connected to the first quantum dot structure, and the second lower electrode is connected to the second quantum dot structure.

9. The optoelectronic device according to claim 8, wherein the first lower electrode, the second lower electrode, the first upper electrode and the second upper electrode are each connected to a signal device comprising a transistor and/or a capacitor.

10. The optoelectronic device according to any one of claims 7 to 9, wherein the first quantum dot structure responds to a light wavelength comprising 400nm to 760nm and the second quantum dot structure responds to a light wavelength comprising 900nm to 1700 nm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711424036.2A CN108155276B (en) | 2017-12-25 | 2017-12-25 | Photoelectric device and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711424036.2A CN108155276B (en) | 2017-12-25 | 2017-12-25 | Photoelectric device and manufacturing method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108155276A CN108155276A (en) | 2018-06-12 |

| CN108155276B true CN108155276B (en) | 2020-05-22 |

Family

ID=62462133

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711424036.2A Active CN108155276B (en) | 2017-12-25 | 2017-12-25 | Photoelectric device and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108155276B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022000480A1 (en) * | 2020-07-03 | 2022-01-06 | 深圳市思坦科技有限公司 | Display module manufacturing method and display screen |

| CN117148688A (en) * | 2023-11-01 | 2023-12-01 | 长春理工大学 | Method for processing quantum dots for direct lithography and dual-channel imaging chip |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATE551723T1 (en) * | 2005-08-25 | 2012-04-15 | Edward Sargent | QUANTUM DOT OPTICAL DEVICES WITH INCREASED GAIN AND SENSITIVITY |

| EP3039724A4 (en) * | 2013-08-29 | 2017-06-21 | University of Florida Research Foundation, Inc. | Air stable infrared photodetectors from solution-processed inorganic semiconductors |

| KR20150072888A (en) * | 2013-12-20 | 2015-06-30 | 한국과학기술연구원 | Quantum dot sensitized metal oxide phototransistor and manufacturing process thereof |

| CN105405857B (en) * | 2015-10-29 | 2018-08-10 | 上海集成电路研发中心有限公司 | Silicon substrate and the fully integrated imaging sensor of quantum dot and preparation method |

| CN106197687B (en) * | 2016-07-19 | 2019-03-05 | 中国科学院重庆绿色智能技术研究院 | A kind of micro-metering bolometer based on graphene quantum dot |

-

2017

- 2017-12-25 CN CN201711424036.2A patent/CN108155276B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN108155276A (en) | 2018-06-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12080738B2 (en) | Image sensor having stacked metal oxide films as fixed charge film | |

| TWI682553B (en) | Semiconductor image sensor devices and methods for forming image sensors | |

| US7875947B2 (en) | Filter, color filter array, method of manufacturing the color filter array, and image sensor | |

| CN103227178B (en) | For improvement of the method and apparatus of the reflectance optical grid of imageing sensor | |

| US9123609B2 (en) | Solid-state imaging device, manufacturing method of solid-state imaging device and electronic apparatus | |

| CN107818995B (en) | Method of manufacturing image sensor | |

| WO2007055141A1 (en) | Solid-state imager having antireflection film, display, and its manufacturing method | |

| CN110349992B (en) | Image sensor, method of manufacturing the same, and image forming apparatus including the same | |

| US7423307B2 (en) | CMOS image sensor and method for fabricating the same | |

| US11843013B2 (en) | Polarizers for image sensor devices | |

| KR100731128B1 (en) | Method for manufacturing cmos image sensor | |

| CN108155276B (en) | Photoelectric device and manufacturing method thereof | |

| US7633105B2 (en) | CMOS image sensor and method of manufacture | |

| US11557620B2 (en) | Metal grid structure integrated with deep trench isolation structure | |

| KR100769126B1 (en) | Method for Fabricating CMOS Image Sensor | |

| US10304891B2 (en) | Backside metal grid and metal pad simplification | |

| US10504964B2 (en) | Image sensors and methods for manufacturing the same | |

| CN106783902A (en) | Image sensor architecture and preparation method thereof | |

| KR100917817B1 (en) | Method for fabricating of CMOS Image sensor | |

| US20230197746A1 (en) | Image sensor | |

| KR100897814B1 (en) | Semiconductor device and method of fabricating the same | |

| KR100958628B1 (en) | Method of fabricating CMOS image sensor | |

| KR100913326B1 (en) | Image sensor and method for fabricating the same | |

| KR20090050863A (en) | Image sensor and method for manufacturing the image sensor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |