CN108075622B - Power converter gate drive control method, device, controller and converter - Google Patents

Power converter gate drive control method, device, controller and converter Download PDFInfo

- Publication number

- CN108075622B CN108075622B CN201711435054.0A CN201711435054A CN108075622B CN 108075622 B CN108075622 B CN 108075622B CN 201711435054 A CN201711435054 A CN 201711435054A CN 108075622 B CN108075622 B CN 108075622B

- Authority

- CN

- China

- Prior art keywords

- voltage

- gate

- output current

- current

- output

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 54

- 238000012545 processing Methods 0.000 claims description 37

- 230000015654 memory Effects 0.000 claims description 32

- 230000001276 controlling effect Effects 0.000 claims description 31

- 238000005070 sampling Methods 0.000 claims description 10

- 238000003860 storage Methods 0.000 claims description 9

- 230000001105 regulatory effect Effects 0.000 claims description 7

- 238000010586 diagram Methods 0.000 description 14

- 238000004891 communication Methods 0.000 description 8

- 238000004590 computer program Methods 0.000 description 7

- 230000006870 function Effects 0.000 description 4

- 238000012886 linear function Methods 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 230000005669 field effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/08—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/08—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters

- H02M1/088—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters for the simultaneous control of series or parallel connected semiconductor devices

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/0048—Circuits or arrangements for reducing losses

- H02M1/0054—Transistor switching losses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B70/00—Technologies for an efficient end-user side electric power management and consumption

- Y02B70/10—Technologies improving the efficiency by using switched-mode power supplies [SMPS], i.e. efficient power electronics conversion e.g. power factor correction or reduction of losses in power supplies or efficient standby modes

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Inverter Devices (AREA)

- Power Conversion In General (AREA)

Abstract

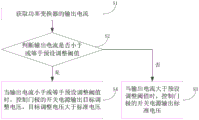

The invention provides a method, a device, a controller and a converter for controlling gate drive of a power converter, wherein the control method comprises the following steps: acquiring the output current of a power converter; judging whether the output current is less than or equal to a preset adjusting threshold value; when the output current is larger than a preset adjusting threshold value, the switching power supply of the gate pole is controlled to output a standard voltage; and when the output current is less than or equal to the preset adjustment threshold, the switching power supply for controlling the gate pole outputs a target adjustment voltage, and the target adjustment voltage is greater than the standard voltage. The method ensures that the gate driving voltage in the medium and small power stage is greater than that in the high power stage, improves the gate driving voltage in the medium and small power stage and further reduces the loss of the power converter.

Description

Technical Field

The invention relates to the technical field of distribution automation, in particular to a gate drive control method, a gate drive control device, a gate drive controller and a gate drive converter of a power converter.

Background

Power converters are used to convert a power supply from one form or amplitude to another, and are typically made up of one or more switches, such as Insulated Gate Bipolar Transistors (IGBTs) with gates to which a drive voltage is applied, the losses of the power converter being closely related to the Gate voltage, the higher the Gate voltage the smaller the turn-on voltage drop and the smaller the losses of the power converter. Fig. 1 is a typical transfer characteristic curve of an IGBT, and it can be known from the curve in fig. 1 that the higher the gate voltage is, the smaller the conduction-tube voltage drop is, and the conduction loss is the product of the conduction-tube voltage drop and the current, so the conduction loss is also smaller.

In the prior art, the loss of the power converter is usually reduced by adopting a method of increasing the gate driving voltage, but the gate voltage is too high, and when the power converter is put into use due to stray influence of a line or an active clamping circuit and the like, the gate voltage is continuously raised when the power converter is turned off under a large-current working condition, so that the risk of damage is caused. In the actual wind power field, due to regional differences, for example, the northwest region has rich wind power resources but low power consumption, and the south china has large power consumption but poor wind power resources, these factors often cause the fans in the wind power field to be in a low wind stage or a state that the electricity limit of owners is not enough, so that the power converter applied to the wind power field is in a low power stage. All of the above factors result in non-optimal power converter losses.

Disclosure of Invention

Therefore, the invention provides a method, a device, a controller and a converter for controlling gate drive of a power converter, so as to further reduce conduction loss of the power converter.

Therefore, the embodiment of the invention provides the following technical scheme:

in a first aspect of the present invention, a method for controlling gate drive of a power converter is provided, comprising the steps of: acquiring the output current of a power converter; judging whether the output current is less than or equal to a preset adjusting threshold value; when the output current is larger than the preset adjusting threshold, the switching power supply of the gate pole is controlled to output standard voltage; and when the output current is less than or equal to the preset adjustment threshold, controlling the switching power supply of the gate pole to output a target adjustment voltage, wherein the target adjustment voltage is greater than the standard voltage. The output current is divided into different areas, and the different areas correspond to different output voltages of the switching power supply, so that the power converter is prevented from being damaged under the current high-power working condition, and the safety of the power converter under the high-current working condition is improved; the gate driving voltage of the power converter under the working condition of medium and small power is improved, and the loss of the power converter is further reduced.

As an optional implementation manner of the first aspect, after the step of outputting the target regulation voltage by the switching power supply controlling the gate when the output current is less than or equal to the preset regulation threshold, the method further includes: acquiring the actual output voltage of the switching power supply; judging whether the actual output voltage is equal to the target adjusting voltage or not; and when the actual output voltage is not equal to the target adjusting voltage, controlling the switching power supply to adjust the output voltage to the target adjusting voltage. The output of the switching power supply is regulated through closed-loop feedback, and the actual output voltage of the switching power supply is further ensured to be consistent with the target regulation voltage.

As another alternative implementation manner of the first aspect, the switching power supply for controlling the gate outputs the target regulation voltage when the output current is less than or equal to the preset regulation threshold, including: pre-establishing a corresponding relation between output current and gate driving voltage, wherein the smaller the output current is, the higher the corresponding gate driving voltage is; and acquiring the current output current, and setting the gate driving voltage corresponding to the current output current as a target adjusting voltage according to a preset corresponding relation. The smaller the output current is, the larger the target adjusting voltage is, so that the loss of the power converter can be reduced in a small-power section with low current, and the conversion efficiency is improved.

As another optional implementation manner of the first aspect, the corresponding relationship is a corresponding relationship between a preset range segment of the output current and a preset gate driving voltage; or the output current and the gate drive voltage are in a linear relation or a curve relation. The purpose of further reducing the loss is achieved by subdividing the output current of the medium and small power sections into different range sections, and corresponding each range section to different gate driving voltages. The linear relation or the curve relation enables the relation between the output current and the gate driving voltage to be more visual and the operation to be more convenient.

As another optional implementation manner of the first aspect, the obtaining the current output current, and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to a preset corresponding relationship includes: judging whether the output current is greater than or equal to a first threshold value; when the output current is greater than or equal to the first threshold value, the target adjustment voltage is a first gate voltage. The medium and small power sections are subdivided into different working conditions, and corresponding target gate voltage values are set for each working condition respectively, so that loss is further optimized, and the purpose of reducing loss is achieved.

As another optional implementation manner of the first aspect, the obtaining the current output current, and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to a preset corresponding relationship, further includes: when the output current is smaller than the first threshold, judging whether the output current is larger than or equal to a second threshold; when the output current is larger than or equal to a second threshold value, the target adjustment voltage is a second gate voltage, and the second gate voltage is larger than the first gate voltage. The medium and small power sections are subdivided into different working conditions, and corresponding target gate voltage values are set for each working condition respectively, so that loss is further optimized, and the purpose of reducing loss is achieved.

As another optional implementation manner of the first aspect, the obtaining the current output current, and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to a preset corresponding relationship, further includes: when the output current is smaller than the second threshold value, the target adjustment voltage is a third gate voltage, and the third gate voltage is larger than the second gate voltage. The medium and small power sections are subdivided into different working conditions, and corresponding target gate voltage values are set for each working condition respectively, so that loss is further optimized, and the purpose of reducing loss is achieved.

As another optional implementation manner of the first aspect, the preset adjustment threshold is 50% of a rated current value of the power converter; and/or the first threshold value is 30% of the rated current value; and/or the second threshold value is 15% of the rated current value. The data processing amount is set to be moderate and is close to the practical application.

In an alternative embodiment of the first aspect, the first gate voltage is 16V; and/or the second gate voltage is 17V; and/or the third gate voltage is 18V; and/or the standard voltage is 15V. This arrangement is closer to practical use and can meet the overall performance of the power converter.

In a second aspect of the present invention, a gate drive control apparatus for a power converter is provided, comprising: the first acquisition module is used for acquiring the output current of the power converter; the first judgment module is used for judging whether the output current is less than or equal to a preset adjustment threshold value or not; the first processing module is used for controlling the switching power supply of the gate pole to output standard voltage when the output current is larger than the preset adjusting threshold; and the second processing module is used for controlling the switching power supply of the gate pole to output a target adjusting voltage when the output current is less than or equal to the preset adjusting threshold, wherein the target adjusting voltage is greater than the standard voltage.

As an optional implementation manner of the second aspect, the gate drive control device of the power converter further includes: the second acquisition module is used for acquiring the actual output voltage of the switching power supply; the second judgment module is used for judging whether the actual output voltage is equal to the target adjustment voltage or not; and the third processing module is used for controlling the switching power supply to adjust the output voltage to the target adjustment voltage when the actual output voltage is not equal to the target adjustment voltage.

As another optional implementation of the second aspect, the second processing module comprises: the first processing unit is used for establishing a corresponding relation between output current and gate driving voltage in advance, and the gate driving voltage corresponding to the smaller the output current is, the higher the output current is; and the second processing unit is used for acquiring the current output current and setting the gate driving voltage corresponding to the current output current as a target adjustment voltage according to a preset corresponding relation.

As another optional implementation manner of the second aspect, the corresponding relationship is a corresponding relationship between a preset range section of the output current and a preset gate driving voltage.

As another optional implementation of the second aspect, the second processing unit comprises:

the first judging subunit is used for judging whether the output current is greater than or equal to a first threshold value; the first processing subunit is used for setting the target adjusting voltage as a first gate voltage when the output current is greater than or equal to the first threshold value; and/or

A second judgment subunit, configured to, when the output current is smaller than the first threshold, judge whether the output current is greater than or equal to a second threshold; the second processing subunit is used for determining the target adjustment voltage as a second gate voltage when the output current is greater than or equal to a second threshold value, wherein the second gate voltage is greater than the first gate voltage; and/or

And the third processing subunit is configured to, when the output current is smaller than the second threshold, set the target adjustment voltage to a third gate voltage, where the third gate voltage is greater than the second gate voltage.

In a third aspect of the present invention, there is provided a gate drive controller comprising: the present invention also provides a method for controlling a gate drive of a power converter, comprising the steps of, by a processor, performing a control operation on a gate drive of the power converter, and communicating with the processor, wherein the control operation is performed by the processor.

In a fourth aspect of the present invention, a computer-readable storage medium is provided, where computer instructions are stored, and the computer instructions are configured to cause the computer to execute the method for controlling gate drive of a power converter according to the first aspect of the present invention or any optional implementation manner thereof.

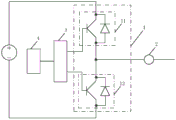

In a fifth aspect of the present invention, there is provided a converter, comprising: a power converter; the current detector is connected with the power converter and is used for collecting the output current of the power converter; the switching power supply is connected with the gate pole of the power converter and provides driving voltage for the gate pole of the power converter; the input end of the gate driving controller is connected with the current detector, and the output end of the gate driving controller is connected with the control end of the switching power supply; the gate drive controller comprises at least one processor and a memory communicatively connected to the at least one processor, wherein the memory stores instructions executable by the at least one processor, and the instructions are executed by the at least one processor to cause the at least one processor to perform the method for controlling gate drive of a power converter according to the first aspect of the present invention or any optional embodiment thereof. The loss of the converter is reduced by adopting a gate drive control method for reducing the loss.

As an optional implementation manner of the fifth aspect, the gate driver further includes a voltage sampling unit, disposed at an output end of the switching power supply, for detecting an output voltage value of the switching power supply and feeding the output voltage value back to the gate driver controller. The output of the switching power supply is regulated through closed-loop feedback, the actual output voltage of the switching power supply is further ensured to be consistent with the target regulation voltage, and the loss of the converter is further reduced.

The technical scheme in the embodiment of the invention has the following advantages:

1. the invention provides a gate drive control method of a power converter, which comprises the following steps: acquiring the output current of a power converter; judging whether the output current is less than or equal to a preset adjusting threshold value; when the output current is larger than the preset adjusting threshold, the switching power supply of the gate pole is controlled to output standard voltage; and when the output current is less than or equal to the preset adjustment threshold, controlling the switching power supply of the gate pole to output a target adjustment voltage, wherein the target adjustment voltage is greater than the standard voltage. The method enables the power converter to be respectively provided with different gate driving voltages in a high-power stage and a middle-low power stage, the gate driving voltage in the high-power stage is set to be a standard voltage, so that the damage of the power converter in the process of outputting large current can be avoided, the safety of the power converter in the process of outputting large current is improved, the gate driving voltage in the middle-low power stage is set to be larger than the standard voltage, and the loss of the power converter is further reduced by improving the gate voltage on the premise of meeting the safety.

2. On the basis of the above embodiment, the gate driving control method of the power converter further includes the following steps: acquiring the actual output voltage of the switching power supply; judging whether the actual output voltage is equal to the target adjusting voltage or not; and when the actual output voltage is not equal to the target adjusting voltage, controlling the switching power supply to adjust the output voltage to the target adjusting voltage. The output of the switching power supply is regulated through closed-loop feedback, so that the actual output voltage of the switching power supply is further ensured to be consistent with the target regulation voltage, and the control accuracy is improved.

3. The invention provides a current transformer, comprising: a power converter; the current detector is connected with the power converter and used for collecting the output current of the power converter; the switching power supply is connected with the gate pole of the power converter and provides driving voltage for the gate pole of the power converter; and the input end of the gate driving controller is connected with the current detector, and the output end of the gate driving controller is connected with the control end of the switching power supply. The loss of the converter is reduced by adopting the gate drive controller provided by the invention.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, and it is obvious that the drawings in the following description are some embodiments of the present invention, and other drawings can be obtained by those skilled in the art without creative efforts.

Fig. 1 is a typical transfer characteristic curve of an IGBT;

FIG. 2 is a flowchart showing a specific example of a gate drive control method of a power converter according to embodiment 1 of the present invention;

fig. 3 is a flowchart showing a specific example of the step of outputting the target regulation voltage by the switching power supply for controlling the gate when the output current is less than or equal to the preset regulation threshold in the gate drive control method of the power converter according to embodiment 1 of the present invention;

fig. 4 is a diagram illustrating a method for controlling gate driving of a power converter according to embodiment 1 of the present invention, in which a current output current is obtained, and a gate driving voltage corresponding to the current output current is set according to a preset corresponding relationship

A flow chart of one specific example of the step of setting the voltage to the target;

FIG. 5 is a flowchart showing a specific example of a method for controlling gate drive of a power converter according to embodiment 2 of the present invention;

FIG. 6 is a flowchart showing another specific example of a gate drive control method of a power converter according to embodiment 2 of the present invention;

FIG. 7 is a schematic structural diagram of a gate drive control apparatus of a power converter according to embodiment 3 of the present invention;

FIG. 8 is a schematic diagram showing another structure of a gate drive control apparatus of a power converter according to embodiment 3 of the present invention;

fig. 9 is a schematic structural diagram of a gate drive controller according to embodiment 4 of the present invention;

fig. 10 is a structural view of a specific example of the inverter in embodiment 5 of the present invention;

fig. 11 is a structural view of another specific example of the inverter in embodiment 5 of the present invention;

fig. 12 is a structural view of another specific example of the inverter in embodiment 5 of the present invention;

fig. 13 is a schematic diagram illustrating an operation of the inverter in embodiment 5 of the present invention.

Reference numerals:

1-a power converter; 11-a first switch; 12-a second switch; 2-a current detector; 3-a switching power supply; a 4-gate drive controller; 41-analog digital sampler; 42-a digital CPU; 5-a voltage sampling unit.

Detailed Description

The technical solutions of the present invention will be described clearly and completely with reference to the accompanying drawings, and it should be understood that the described embodiments are some, but not all embodiments of the present invention. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer", etc., indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplicity of description, but do not indicate or imply that the device or element being referred to must have a particular orientation, be constructed and operated in a particular orientation, and thus, should not be construed as limiting the present invention. Furthermore, the terms "first," "second," and "third" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

In the description of the present invention, it should be noted that, unless otherwise explicitly specified or limited, the terms "mounted," "connected," and "connected" are to be construed broadly, e.g., as meaning either a fixed connection, a removable connection, or an integral connection; can be mechanically or electrically connected; the two elements may be directly connected or indirectly connected through an intermediate medium, or may be communicated with each other inside the two elements, or may be wirelessly connected or wired connected. The specific meanings of the above terms in the present invention can be understood in specific cases to those skilled in the art.

In addition, the technical features involved in the different embodiments of the present invention described below may be combined with each other as long as they do not conflict with each other.

Example 1

The embodiment of the invention provides a gate drive control method of a power converter, which is used in a drive controller of a gate switch power supply of the power converter to control the gate voltage of the power converter such as an IGBT (insulated gate bipolar transistor) so as to further reduce conduction loss, and the flow chart of the method is shown in figure 2, and comprises the following steps:

s1: an output current of the power converter is obtained.

In this embodiment, the switches in the power converter are composed of Insulated Gate Bipolar Transistors (IGBTs), but in other embodiments, the switches may also be Metal Oxide Semiconductor Field Effect Transistors (MOSFETs), MOS-gated thyristors, bipolar junction transistors, or other suitable power devices, and the like, as needed. The output current of the power converter may be detected by providing a current detector at the output of the power converter, which is fed back to the drive controller.

S2: and judging whether the output current is less than or equal to a preset adjusting threshold value.

In this embodiment, the preset adjustment threshold is 50% of the rated current value of the power converter, and in other embodiments, the preset adjustment threshold may also be set to 60% or 40% of the rated current value, and the like, as needed, and may be set reasonably as needed. When the output current is greater than the preset adjustment threshold, executing step S3; when the output current is less than or equal to the preset adjustment threshold, step S4 is performed.

S3: and when the output current is larger than the preset adjusting threshold, the switching power supply of the control gate outputs the standard voltage.

Since the gate driving of the IGBT usually needs 15-20V, in order to ensure the safety of the IGBT device during use, a stable 15V is generally selected as the gate driving voltage of the IGBT when driving is designed, and therefore, in this embodiment, the standard voltage is set to 15V, and of course, in other embodiments, the standard voltage may also be set to other values, such as 16V or 14V, and may be reasonably set as needed. In the scheme, when the output current is larger than the preset threshold value, the standard voltage is output, so that the risk that the gate voltage is continuously raised and damaged when the power converter is turned off under the condition of large current working condition is avoided, and the safety of the IGBT under the large current working condition is ensured.

S4: and when the output current is less than or equal to the preset adjustment threshold, the switching power supply for controlling the gate pole outputs a target adjustment voltage, and the target adjustment voltage is greater than the standard voltage.

The higher the gate voltage of the IGBT is, the lower the voltage drop of the conduction tube is under the same current, so that when the output current is less than or equal to the preset adjusting voltage, the target adjusting voltage is increased, the loss of the power converter can be reduced in a medium-small power section, and the conversion efficiency is improved. Because the gate voltage can not be raised too high when the power converter is switched off under the working condition of medium and small power, the conduction loss can be further reduced under the working condition of medium and small power current. The target adjustment voltage may be set to a fixed voltage such as 16V, 17V, 18V, 19V, 20V, or may be set to a voltage value adjusted according to the magnitude of the output current, and since the smaller the output current is, the lower the gate voltage raised when the power converter is turned off is, the smaller the gate voltage is, and therefore, the target adjustment voltage may be set to be increased as the output current is decreased, but needs to be smaller than the maximum value of the gate voltage.

According to the gate drive control method of the power converter in the embodiment, when the power converter is under a high-power working condition, namely the output current of the power converter is greater than the preset threshold value, the standard voltage is output, so that damage caused by the increase of the gate voltage when the power converter is turned off under the condition of large current is avoided, and the safety of the power converter under the condition of large current is ensured; when the power converter is under the working condition of medium and small power, namely the output current of the power converter is less than or equal to the preset threshold value, the target adjustment voltage is output, the target adjustment voltage is greater than the standard voltage, and because the output current is small, the raised gate voltage when the power converter is switched off is also small, the conduction loss is further reduced on the premise of ensuring the safety of the power converter, and the efficiency is improved.

As a specific implementation manner, the step S4, as shown in fig. 3, includes:

s41: the corresponding relation between the output current and the gate driving voltage is established in advance, and the smaller the output current is, the higher the corresponding gate driving voltage is.

In the embodiment, according to the relationship between the output current and the rated current, the output current is divided into 3 interval ranges, namely 0% -15% of rated current, 15% -30% of rated current and 30% -50% of rated current of IGBT output current; of course, in other embodiments, the output current range may be reasonably divided according to actual needs.

S42: and acquiring the current output current, and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to the preset corresponding relation.

As a specific implementation, when the output current is less than 50% of the rated current, the step S42 is further divided into a plurality of data segments to set the target adjustment voltage respectively, as shown in fig. 4, and the process includes:

s421: it is determined whether the output current is greater than or equal to a first threshold.

In the present embodiment, the first threshold value is 30% of the rated current value. Step S422 is performed when the output current is less than 50% but greater than or equal to 30% of the rated current, otherwise step S423 is performed.

S422: when the output current is larger than or equal to the first threshold value, the target adjusting voltage is the first gate voltage.

In this embodiment, the first gate voltage is 16V, but in other embodiments, the first gate voltage may be other values larger than the standard voltage (set to 15V), such as 17V, etc., and may be set as needed.

S423: and when the output current is smaller than the first threshold value, judging whether the output current is larger than or equal to a second threshold value.

In the present embodiment, the second threshold value is 15% of the rated current value. Step S424 is performed when the output current is less than 30% but greater than or equal to 15% of the rated current, otherwise step S425 is performed.

S424: when the output current is larger than or equal to the second threshold value, the target adjusting voltage is a second gate voltage, and the second gate voltage is larger than the first gate voltage.

In this embodiment, the second gate voltage is 17V, but in other embodiments, the second gate voltage may also be another value greater than the first gate voltage (set to 16V), such as 16.5V, and may be set reasonably as needed.

S425: when the output current is smaller than the second threshold value, the target adjusting voltage is a third gate voltage, and the third gate voltage is larger than the second gate voltage.

In this embodiment, the third gate voltage is 18V, but in other embodiments, the third gate voltage may also be other values greater than the second gate voltage (set to 17V), such as 19V, and the like, and may be set as needed.

According to the embodiment, the working condition of the medium and small power is further divided into a plurality of range sections, different range sections correspond to different target adjustment voltages, the smaller the output current is, the larger the target adjustment voltage is, the more accurate the target adjustment voltage can be controlled, so that the conduction loss is smaller under the condition of the medium and small power with small output current, and the output current has a better optimization effect in the whole range.

As other alternative implementations: in step S4, when the output current is less than or equal to the preset adjustment threshold, the switching power supply controlling the gate outputs the target adjustment voltage, and may be further configured to control the gate driving voltage to continuously increase according to the decrease of the output current.

As a specific embodiment, the corresponding relationship between the target adjustment voltage and the output current may be a continuous linear relationship, when the output current is less than or equal to the preset adjustment threshold, the target adjustment voltage and the output current are in a linear relationship, and linear control is simpler and more convenient through a functional relation of the target adjustment voltage and the output current, such as a simple linear function with a positive proportion y of kx or a more complex linear function in a linear function, and the relationship between the target adjustment voltage and the output current is more intuitive.

As another specific embodiment, the corresponding relationship between the target adjustment voltage and the output current may be a continuous non-linear relationship, i.e., a curve relationship. The curve relation can be an accumulation of a plurality of linear relations, for example, by a method of linear interpolation for a plurality of times, the curve relation can be divided into a plurality of sections, for example, into a plurality of y ═ kx; more complex curves, such as quadratic or cubic relationships, are also possible. The nonlinearity is closer to the actual application working condition of the power converter, the control mode is more reasonable, and the control accuracy is higher.

When the output current is less than or equal to the preset adjustment threshold, the corresponding relation between the target adjustment voltage and the output current can be continuous or discontinuous; the device can be linear or nonlinear, and can be reasonably arranged according to needs.

Example 2

In practical applications, there is usually a certain deviation between the actual output voltage of the gate switching power supply and the target regulated voltage, and in order to further ensure that the actual output voltage is consistent with the target regulated voltage, on the basis of steps S1-S4 in embodiment 1, the gate driving control method of the power converter in this embodiment further includes the following steps, as shown in fig. 5, of:

s5: and acquiring the actual output voltage of the switching power supply.

The voltage sampling unit is used for sampling the gate electrode driving voltage in real time to obtain the actual output voltage of the switching power supply, the deviation between the actual output voltage and the target adjustment voltage is obtained according to the collected actual output voltage of the switching power supply, and the switching power supply is adjusted through the deviation so that the driving voltage finally reaching the gate electrode is equal to the target adjustment voltage.

S6: and judging whether the actual output voltage is equal to the target adjusting voltage or not. When the actual output voltage is not equal to the target adjustment voltage, step S7 is performed; when the actual output voltage is equal to the target adjustment voltage, step S8 is performed.

S7: and when the actual output voltage is not equal to the target adjusting voltage, controlling the switching power supply to adjust the output voltage to the target adjusting voltage. In the embodiment, the switching power supply adopts a conventional flyback topology structure, adopts closed-loop PWM control, and enables the actual output voltage of the switching power supply to be equal to the target regulation voltage by regulating the duty ratio; of course, in other embodiments, the actual output voltage may be adjusted by other feedback control methods, and may be set reasonably as needed.

S8: when the actual output voltage is equal to the target adjustment voltage, the switching power supply is controlled to be free from adjusting the output voltage, the actual output voltage is consistent with the target adjustment voltage, the switching power supply continues to keep the target adjustment voltage output, and the switching power supply is free from adjusting.

Specifically, the gate driving control method of the power converter may also be implemented according to the flow shown in fig. 6, and the embodiment of the present invention provides only a specific example, and is not limited thereto.

According to the gate drive control method of the power converter, the actual output voltage of the switching power supply is collected in real time, closed-loop regulation is performed on the switching power supply when the actual output voltage is inconsistent with the target regulation voltage, the actual output voltage of the switching power supply is optimized, the loss of the power converter is further reduced, and the efficiency is improved.

Example 3

In this embodiment, a gate driving control apparatus of a power converter is provided, and a schematic structural diagram is shown in fig. 7, including:

a first obtaining module 31, configured to obtain an output current of the power converter; the specific implementation manner is the same as S1 in embodiment 1 or embodiment 2, and is not described herein again.

A first determining module 32, configured to determine whether the output current is less than or equal to a preset adjustment threshold; the specific implementation manner is the same as S2 in embodiment 1 or embodiment 2, and is not described herein again.

The first processing module 33 is configured to control the gate of the switching power supply to output a standard voltage when the output current is greater than a preset adjustment threshold; the specific implementation manner is the same as S3 in embodiment 1 or embodiment 2, and is not described herein again.

The second processing module 34 is configured to control the gate switching power supply to output a target adjustment voltage when the output current is less than or equal to a preset adjustment threshold, where the target adjustment voltage is greater than a standard voltage; the specific implementation manner is the same as S4 in embodiment 1 or embodiment 2, and is not described herein again.

As a specific implementation manner, the second processing module 34 includes:

the first processing unit 341 is configured to pre-establish a correspondence between the output current and the gate driving voltage, where the smaller the output current is, the higher the corresponding gate driving voltage is; the specific implementation manner is the same as S41 in embodiment 1 or embodiment 2, and is not described herein again.

The second processing unit 342 is configured to obtain a current output current, and set a gate driving voltage corresponding to the current output current as a target adjustment voltage according to a preset correspondence; the specific implementation manner is the same as S42 in embodiment 1 or embodiment 2, and is not described herein again.

As a specific implementation manner, the second processing unit 342 includes:

a first determining subunit 3421, configured to determine whether the output current is greater than or equal to a first threshold; the specific implementation manner is the same as S421 in embodiment 1 or embodiment 2, and is not described herein again.

A first processing subunit 3422, configured to, when the output current is greater than or equal to a first threshold, set the target adjustment voltage to a first gate voltage; the specific implementation manner is the same as S422 in embodiment 1 or embodiment 2, and is not described herein again.

A second judging subunit 3423, configured to, when the output current is smaller than the first threshold, judge whether the output current is greater than or equal to a second threshold; the specific implementation manner is the same as S423 in embodiment 1 or embodiment 2, and is not described herein again.

A second processing subunit 3424, configured to, when the output current is greater than or equal to a second threshold, set the target adjustment voltage to a second gate voltage, where the second gate voltage is greater than the first gate voltage; the specific implementation manner is the same as S424 in embodiment 1 or embodiment 2, and is not described herein again.

A third processing subunit 3425, configured to, when the output current is smaller than the second threshold, set the target adjustment voltage to a third gate voltage, where the third gate voltage is greater than the second gate voltage; the specific implementation manner is the same as S425 in embodiment 1 or embodiment 2, and is not described herein again.

The gate driving control device of the power converter in the embodiment collects the magnitude of the alternating current output by the power converter in real time, divides the alternating current into different working conditions according to the magnitude of the alternating current, subdivides the working conditions in a medium-small power section, and sets corresponding target gate voltage values respectively, so that the gate driving voltage in the medium-small power section is greater than the gate driving voltage in a high-power section. When the power converter is under a high-power working condition, the damage caused by the rising of the gate voltage when the power converter is turned off can be avoided, and the safety of the power converter under a high-current working condition is ensured; when the power converter is under the working condition of medium and small power, because the output current is small, the raised gate voltage is small when the power converter is switched off, the conduction loss is further reduced on the premise of ensuring the safety of the power converter, and the efficiency is improved.

In practical applications, there is usually a certain deviation between the actual output voltage of the gate switching power supply and the target regulation voltage, and in order to further ensure that the actual output voltage is consistent with the target regulation voltage, on the basis of the above embodiment, as shown in fig. 8, the gate driving control device of the power converter in this embodiment further includes:

a second obtaining module 35, configured to obtain an actual output voltage of the switching power supply; the specific implementation manner is the same as S5 in embodiment 2, and is not described herein again.

A second determining module 36, configured to determine whether the actual output voltage is equal to the target adjustment voltage; the specific implementation manner is the same as S6 in embodiment 2, and is not described herein again.

A third processing module 37, configured to control the switching power supply to adjust the output voltage to the target adjustment voltage when the actual output voltage is not equal to the target adjustment voltage; the specific implementation manner is the same as S7 in embodiment 2, and is not described herein again.

The gate drive control device of the power converter collects the actual output voltage of the switching power supply in real time, and performs closed-loop regulation on the switching power supply when the actual output voltage is inconsistent with the target regulation voltage, so that the input voltage of the power converter is optimized, the loss of the power converter is further reduced, and the efficiency is improved.

Example 4

In the present embodiment, a gate driving controller is provided, as shown in fig. 9, including: at least one processor 901, such as a CPU (Central Processing Unit), at least one communication interface 903, memory 904, at least one communication bus 902. Wherein a communication bus 902 is used to enable connective communication between these components. The communication interface 903 may include a Display (Display) and a Keyboard (Keyboard), and the optional communication interface 903 may also include a standard wired interface and a standard wireless interface. The Memory 904 may be a RAM (random Access Memory) or a non-volatile Memory (non-volatile Memory), such as at least one disk Memory. The memory 904 may optionally be at least one storage device located remotely from the processor 901. Wherein the processor 901 may be combined with the gate drive control apparatus of the power converter described in fig. 7 and 8, the memory 904 stores a set of program codes, and the processor 901 calls the program codes stored in the memory 904 for executing a gate drive control method of the power converter, i.e. for executing the gate drive control method of the power converter in the embodiment of fig. 2-6.

The communication bus 902 may be a Peripheral Component Interconnect (PCI) bus or an Extended Industry Standard Architecture (EISA) bus. The communication bus 902 may be divided into an address bus, a data bus, a control bus, etc. For ease of illustration, only one thick line is shown in FIG. 9, but this does not indicate only one bus or one type of bus.

The memory 904 may include a volatile memory (RAM), such as a random-access memory (RAM); the memory may also include a non-volatile memory (english: non-volatile memory), such as a flash memory (english: flash memory), a hard disk (english: hard disk drive, abbreviation: HDD), or a solid-state drive (english: SSD); the memory 904 may also comprise a combination of the above-described types of memory.

The processor 901 may be a Central Processing Unit (CPU), a Network Processor (NP), or a combination of CPU and NP.

The processor 901 may further include a hardware chip. The hardware chip may be an application-specific integrated circuit (ASIC), a Programmable Logic Device (PLD), or a combination thereof. The aforementioned PLD may be a Complex Programmable Logic Device (CPLD), a field-programmable gate array (FPGA), a General Array Logic (GAL), or any combination thereof.

Optionally, the memory 904 is also used to store program instructions. Processor 901 can invoke program instructions to implement a method for gate drive control of a power converter as shown in the embodiments of fig. 2-6 of the present application.

Embodiments of the present invention also provide a computer-readable storage medium having computer-executable instructions stored thereon, where the computer-executable instructions are capable of executing the method for controlling gate drive of a power converter in any of the above-mentioned method embodiments. The storage medium may be a magnetic Disk, an optical Disk, a Read-only Memory (ROM), a Random Access Memory (RAM), a flash Memory (FlashMemory), a Hard Disk (Hard Disk Drive, abbreviated as HDD) or a Solid State Drive (SSD), etc.; the storage medium may also comprise a combination of memories of the kind described above.

As will be appreciated by one skilled in the art, embodiments of the present invention may be provided as a method, system, or computer program product. Accordingly, the present invention may take the form of an entirely hardware embodiment, an entirely software embodiment or an embodiment combining software and hardware aspects. Furthermore, the present invention may take the form of a computer program product embodied on one or more computer-usable storage media (including, but not limited to, disk storage, CD-ROM, optical storage, and the like) having computer-usable program code embodied therein.

The present invention is described with reference to flowchart illustrations and/or block diagrams of methods, apparatus (systems), and computer program products according to embodiments of the invention. It will be understood that each flow and/or block of the flow diagrams and/or block diagrams, and combinations of flows and/or blocks in the flow diagrams and/or block diagrams, can be implemented by computer program instructions. These computer program instructions may be provided to a processor of a general purpose computer, special purpose computer, embedded processor, or other programmable data processing apparatus to produce a machine, such that the instructions, which execute via the processor of the computer or other programmable data processing apparatus, create means for implementing the functions specified in the flowchart flow or flows and/or block diagram block or blocks.

These computer program instructions may also be stored in a computer-readable memory that can direct a computer or other programmable data processing apparatus to function in a particular manner, such that the instructions stored in the computer-readable memory produce an article of manufacture including instruction means which implement the function specified in the flowchart flow or flows and/or block diagram block or blocks.

These computer program instructions may also be loaded onto a computer or other programmable data processing apparatus to cause a series of operational steps to be performed on the computer or other programmable apparatus to produce a computer implemented process such that the instructions which execute on the computer or other programmable apparatus provide steps for implementing the functions specified in the flowchart flow or flows and/or block diagram block or blocks.

Example 5

In this embodiment, a current transformer is provided, as shown in fig. 10, including:

the power converter 1, in this embodiment, the power converter 1 includes the first switch 11 and the second switch 12, but of course, in other embodiments, the power converter 1 may also include one switch or three or more switches, which may be appropriately set as needed.

And the current detector 2 is connected with the power converter 1 and is used for collecting the output current of the power converter 1. In this embodiment, the current detector 2 is a current hall sensor, and of course, in other embodiments, the current detector 2 may also be other current detection devices, such as a sampling resistor, and may be set reasonably as required.

And the switching power supply 3 is connected with the gate pole of the power converter 1 and provides driving voltage for the gate pole of the power converter 1.

A gate driving controller 4, the input end of which is connected with the current detector 2 and the output end of which is connected with the control end of the switching power supply 3; the gate drive controller 4 includes at least one processor, and a memory communicatively coupled to the at least one processor, wherein the memory stores instructions executable by the at least one processor, and the instructions are executable by the at least one processor to cause the at least one processor to perform the method for controlling the gate drive of a power converter according to any one of embodiment 1 or embodiment 2 of the present invention. In this embodiment, as shown in fig. 11, the gate driving controller 4 includes an analog-digital sampler 41 and a digital CPU42, but in other embodiments, the gate driving controller 4 may also be an analog CPU, and the like, and may be set as needed.

According to the converter, different gate driving voltages are respectively set in a high-power stage and a medium-low power stage, the gate driving voltage in the high-power stage is set to be a standard voltage, and the gate driving voltage in the medium-low power stage is set to be greater than the standard voltage.

In order to further ensure that the actual output voltage of the switching power supply 3 is consistent with the target adjustment voltage, and further improve the control accuracy, on the basis of the above embodiment, as shown in fig. 12, the converter further includes a voltage sampling unit 5, which is arranged at the output end of the switching power supply 3, and is used for detecting the output voltage value of the switching power supply 3 and feeding the output voltage value back to the gate drive controller 4. The voltage sampling unit 5 can be a sampling resistor or a voltage collector and the like, and can be reasonably arranged according to needs.

The operating principle of the converter is described by taking an IGBT-based power converter as an example. The working principle of the converter is shown in fig. 13, the gate drive controller detects the output alternating current of the IGBT, and dynamically adjusts the gate drive voltage of the IGBT according to the magnitude of the alternating current. A programmable CPU is arranged in the gate drive controller, the magnitude of the alternating current output by the IGBT is collected in real time, the magnitude of the power output of the IGBT for supplying power to the gate of the IGBT by the sampling driver is simultaneously sampled, and the CPU controls the output of the switching power supply in a closed-loop mode according to the two feedback quantities and dynamically adjusts and outputs the voltage of the drive gate. The switching power supply adopts a conventional flyback topology structure and adopts closed-loop PWM control, the output voltage is fed back to the CPU, and the duty ratio is adjusted, so that the output target voltage value is adjusted. The method comprises the steps of collecting the magnitude of alternating current output by the IGBT in real time, dividing the magnitude into a plurality of working conditions according to the magnitude of the alternating current, subdividing the magnitude into a plurality of working conditions in a middle-small power section below 50%, respectively setting corresponding target gate voltage values, and carrying out real-time closed-loop regulation to achieve the purpose of reducing the magnitude of IGBT turn-on voltage VCE (collector-emitter voltage Vce, the voltage is lower when the voltage is turned on, generally about 2V, and the voltage is very high when the voltage is turned off and is equal to the voltage of a direct current bus, and more than 1000V) in the middle-small power section, thereby reducing. When the driving voltage is actually adjusted, the corresponding judgment threshold value and the output voltage can be changed according to different characteristics of the IGBT and the like, and the setting is flexible. By adjusting the gate voltage, the conduction voltage drop can be dynamically adjusted, so that the conduction loss in a medium-small power section is reduced, and the efficiency of the whole system is improved.

It should be understood that the above examples are only for clarity of illustration and are not intended to limit the embodiments. Other variations and modifications will be apparent to persons skilled in the art in light of the above description. And are neither required nor exhaustive of all embodiments. And obvious variations or modifications therefrom are within the scope of the invention.

Claims (16)

1. A method for controlling gate drive of a power converter, comprising the steps of:

acquiring the output current of a power converter;

judging whether the output current is less than or equal to a preset adjusting threshold value;

when the output current is larger than the preset adjusting threshold, the switching power supply of the gate pole is controlled to output standard voltage;

when the output current is smaller than or equal to the preset adjusting threshold, the switching power supply of the control gate outputs a target adjusting voltage, and the target adjusting voltage is larger than the standard voltage;

when the output current is less than or equal to the preset adjustment threshold, the switching power supply for controlling the gate outputs a target adjustment voltage, including:

pre-establishing a corresponding relation between output current and gate driving voltage, wherein the smaller the output current is, the higher the corresponding gate driving voltage is;

and acquiring the current output current, and setting the gate driving voltage corresponding to the current output current as a target adjusting voltage according to a preset corresponding relation.

2. The method of claim 1, wherein the step of controlling the gate of the switching power supply to output the target regulated voltage when the output current is less than or equal to the preset regulation threshold further comprises:

acquiring the actual output voltage of the switching power supply;

judging whether the actual output voltage is equal to the target adjusting voltage or not;

and when the actual output voltage is not equal to the target adjusting voltage, controlling the switching power supply to adjust the output voltage to the target adjusting voltage.

3. The method of claim 1, wherein the correspondence relationship is a correspondence relationship between a preset range of the output current and a preset gate driving voltage; or

The output current and the gate drive voltage are in a linear relationship or a curvilinear relationship.

4. The method of claim 3, wherein the obtaining the current output current and setting the gate driving voltage corresponding to the current output current to the target adjustment voltage according to the predetermined correspondence comprises:

judging whether the output current is greater than or equal to a first threshold value;

when the output current is greater than or equal to the first threshold value, the target adjustment voltage is a first gate voltage.

5. The method of claim 4, wherein the obtaining the current output current and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to the predetermined correspondence relationship further comprises:

when the output current is smaller than the first threshold, judging whether the output current is larger than or equal to a second threshold;

when the output current is larger than or equal to a second threshold value, the target adjustment voltage is a second gate voltage, and the second gate voltage is larger than the first gate voltage.

6. The method of claim 5, wherein the obtaining the current output current and setting the gate driving voltage corresponding to the current output current as the target adjustment voltage according to the predetermined correspondence relationship further comprises:

when the output current is smaller than the second threshold value, the target adjustment voltage is a third gate voltage, and the third gate voltage is larger than the second gate voltage.

7. The method of claim 6, wherein the predetermined adjustment threshold is 50% of a rated current of the power converter; and/or

The first threshold value is 30% of the rated current value; and/or

The second threshold value is 15% of the rated current value.

8. The method of claim 6 or 7, wherein the first gate voltage is 16V; and/or

The second gate voltage is 17V; and/or

The third gate voltage is 18V; and/or

The standard voltage is 15V.

9. A gate drive control apparatus for a power converter, comprising:

the first acquisition module is used for acquiring the output current of the power converter;

the first judgment module is used for judging whether the output current is less than or equal to a preset adjustment threshold value or not;

the first processing module is used for controlling the switching power supply of the gate pole to output standard voltage when the output current is larger than the preset adjusting threshold;

the second processing module is used for controlling the switching power supply of the gate pole to output a target adjusting voltage when the output current is less than or equal to the preset adjusting threshold, and the target adjusting voltage is greater than a standard voltage;

the second processing module comprises:

the first processing unit is used for establishing a corresponding relation between output current and gate driving voltage in advance, and the gate driving voltage corresponding to the smaller the output current is, the higher the output current is;

and the second processing unit is used for acquiring the current output current and setting the gate driving voltage corresponding to the current output current as a target adjustment voltage according to a preset corresponding relation.

10. The power converter gate drive control device of claim 9, further comprising:

the second acquisition module is used for acquiring the actual output voltage of the switching power supply;

the second judgment module is used for judging whether the actual output voltage is equal to the target adjustment voltage or not;

and the third processing module is used for controlling the switching power supply to adjust the output voltage to the target adjustment voltage when the actual output voltage is not equal to the target adjustment voltage.

11. The gate drive control device of a power converter according to claim 9, wherein the corresponding relationship is a corresponding relationship between a preset range of the output current and a preset gate drive voltage.

12. The gate drive control device of a power converter of claim 11, wherein the second processing unit comprises:

the first judging subunit is used for judging whether the output current is greater than or equal to a first threshold value;

the first processing subunit is used for setting the target adjusting voltage as a first gate voltage when the output current is greater than or equal to the first threshold value; and/or

A second judgment subunit, configured to, when the output current is smaller than the first threshold, judge whether the output current is greater than or equal to a second threshold;

the second processing subunit is used for determining the target adjustment voltage as a second gate voltage when the output current is greater than or equal to a second threshold value, wherein the second gate voltage is greater than the first gate voltage; and/or

And the third processing subunit is configured to, when the output current is smaller than the second threshold, set the target adjustment voltage to a third gate voltage, where the third gate voltage is greater than the second gate voltage.

13. A gate drive controller comprising: at least one processor, and a memory communicatively coupled to the at least one processor, wherein the memory stores instructions executable by the at least one processor, wherein the instructions are executable by the at least one processor to cause the at least one processor to perform the method of controlling a gate drive of a power converter as claimed in any one of claims 1 to 8.

14. A computer-readable storage medium storing computer instructions for causing a computer to perform the method for controlling gate drive of a power converter according to any one of claims 1-8.

15. A current transformer, comprising:

a power converter;

the current detector is connected with the power converter and is used for collecting the output current of the power converter;

the switching power supply is connected with the gate pole of the power converter and provides driving voltage for the gate pole of the power converter;

the input end of the gate driving controller is connected with the current detector, and the output end of the gate driving controller is connected with the control end of the switching power supply; the gate drive controller comprises at least one processor and a memory communicatively coupled to the at least one processor, wherein the memory stores instructions executable by the at least one processor, the instructions being executable by the at least one processor to cause the at least one processor to perform the method of gate drive control of a power converter according to any of claims 1-8.

16. The converter according to claim 15, further comprising a voltage sampling unit disposed at an output terminal of the switching power supply for detecting an output voltage value of the switching power supply and feeding the output voltage value back to the gate driving controller.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711435054.0A CN108075622B (en) | 2017-12-26 | 2017-12-26 | Power converter gate drive control method, device, controller and converter |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711435054.0A CN108075622B (en) | 2017-12-26 | 2017-12-26 | Power converter gate drive control method, device, controller and converter |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108075622A CN108075622A (en) | 2018-05-25 |

| CN108075622B true CN108075622B (en) | 2020-05-15 |

Family

ID=62155251

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711435054.0A Active CN108075622B (en) | 2017-12-26 | 2017-12-26 | Power converter gate drive control method, device, controller and converter |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108075622B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111781790B (en) * | 2019-04-04 | 2022-12-23 | 中强光电股份有限公司 | Electronic device and laser unit protection method |

| EP4075652B1 (en) * | 2021-04-14 | 2024-07-31 | Hitachi Energy Ltd | Inverter circuit for an electrical ac motor, electrical drive and method for controlling an electrical drive |

| CN116865536B (en) * | 2023-09-05 | 2023-12-15 | 深圳市力生美半导体股份有限公司 | Rate control method, rate control system, and computer-readable storage medium |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101459383A (en) * | 2007-12-14 | 2009-06-17 | 雅达电子国际有限公司 | Switching power converter with reduced switching losses |

| CN101692596A (en) * | 2008-11-20 | 2010-04-07 | 杭州矽力杰半导体技术有限公司 | Control circuit and control method of synchronous rectifier |

| CN101882864A (en) * | 2010-06-25 | 2010-11-10 | 杭州矽力杰半导体技术有限公司 | Electrifying startup circuit and electrifying startup method thereof |

| CN102577060A (en) * | 2009-08-05 | 2012-07-11 | 苹果公司 | Controlling power loss in a switched-capacitor power converter |

| CN102694470A (en) * | 2011-03-22 | 2012-09-26 | 株式会社东芝 | Switching circuit and DC-to-DC converter |

| CN102739044A (en) * | 2012-06-29 | 2012-10-17 | 圣邦微电子(北京)股份有限公司 | DC/DC (direct current) boost converter and LED (light emitting diode) driver |

| CN204216774U (en) * | 2013-11-24 | 2015-03-18 | 半导体元件工业有限责任公司 | Load detecting circuit |

| CN104600984A (en) * | 2013-10-31 | 2015-05-06 | 天钰科技股份有限公司 | Switch power supply voltage regulator |

| CN105939124A (en) * | 2015-03-06 | 2016-09-14 | 联发科技股份有限公司 | Dynamic reduction of synchronous rectifier power losses |

| CN206379873U (en) * | 2016-12-22 | 2017-08-04 | 比亚迪股份有限公司 | The gate driving circuit and switching power unit of Switching Power Supply |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4333802B1 (en) * | 2008-03-18 | 2009-09-16 | トヨタ自動車株式会社 | Inverter drive |

-

2017

- 2017-12-26 CN CN201711435054.0A patent/CN108075622B/en active Active

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101459383A (en) * | 2007-12-14 | 2009-06-17 | 雅达电子国际有限公司 | Switching power converter with reduced switching losses |

| CN101692596A (en) * | 2008-11-20 | 2010-04-07 | 杭州矽力杰半导体技术有限公司 | Control circuit and control method of synchronous rectifier |

| CN102577060A (en) * | 2009-08-05 | 2012-07-11 | 苹果公司 | Controlling power loss in a switched-capacitor power converter |

| CN101882864A (en) * | 2010-06-25 | 2010-11-10 | 杭州矽力杰半导体技术有限公司 | Electrifying startup circuit and electrifying startup method thereof |

| CN102694470A (en) * | 2011-03-22 | 2012-09-26 | 株式会社东芝 | Switching circuit and DC-to-DC converter |

| CN102739044A (en) * | 2012-06-29 | 2012-10-17 | 圣邦微电子(北京)股份有限公司 | DC/DC (direct current) boost converter and LED (light emitting diode) driver |

| CN104600984A (en) * | 2013-10-31 | 2015-05-06 | 天钰科技股份有限公司 | Switch power supply voltage regulator |

| CN204216774U (en) * | 2013-11-24 | 2015-03-18 | 半导体元件工业有限责任公司 | Load detecting circuit |

| CN105939124A (en) * | 2015-03-06 | 2016-09-14 | 联发科技股份有限公司 | Dynamic reduction of synchronous rectifier power losses |

| CN206379873U (en) * | 2016-12-22 | 2017-08-04 | 比亚迪股份有限公司 | The gate driving circuit and switching power unit of Switching Power Supply |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108075622A (en) | 2018-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108075622B (en) | Power converter gate drive control method, device, controller and converter | |

| US7741884B2 (en) | Load drive circuit | |

| US10084383B2 (en) | Booster device and converter device | |

| EP3474449B1 (en) | Drive device | |

| US8854109B2 (en) | Method for controlling two electrically series-connected reverse conductive IGBTs of a half bridge | |

| CN103424679A (en) | Apparatus for testing thyristor valve | |

| US10090761B2 (en) | Power conversion apparatus | |

| EP4164111A1 (en) | Inverter and inverter apparatus | |

| CN105960758A (en) | Rectifier circuit with self-clamping transistor | |

| CN102904329A (en) | Power supply management circuit | |

| US20150145491A1 (en) | Power converter | |

| US7075271B2 (en) | Power controlling apparatus with power converting circuit | |

| CN104578811A (en) | Matrix converter | |

| CN208369467U (en) | totem PFC circuit and air conditioner | |

| CN104600992B (en) | DC-DC conversion circuit | |

| CN108631565A (en) | Two-stage type Switching Power Supply | |

| CN203562950U (en) | Output time-delay circuit | |

| CN211957318U (en) | Integrated full-digital contactless electromagnet control device | |

| CN212935767U (en) | Power switching control circuit | |

| CN210327025U (en) | Direct current micro-grid system | |

| CN211321234U (en) | H-bridge rapid linear adjustment driving circuit in probe power supply | |

| CN102594099A (en) | Grid drive circuit of intelligent power module | |

| CN212367243U (en) | Electronic switch device capable of realizing double control or multiple control | |

| CN110676908A (en) | Intelligent power supply circuit, DSP processing method and system | |

| US10038224B2 (en) | Power supply device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |