CN107942479B - Optical imaging lens assembly and image pickup equipment - Google Patents

Optical imaging lens assembly and image pickup equipment Download PDFInfo

- Publication number

- CN107942479B CN107942479B CN201711283176.2A CN201711283176A CN107942479B CN 107942479 B CN107942479 B CN 107942479B CN 201711283176 A CN201711283176 A CN 201711283176A CN 107942479 B CN107942479 B CN 107942479B

- Authority

- CN

- China

- Prior art keywords

- lens

- optical imaging

- optical

- optical axis

- image

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/001—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras

- G02B13/0015—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design

- G02B13/002—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface

- G02B13/0045—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface having five or more lenses

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/06—Panoramic objectives; So-called "sky lenses" including panoramic objectives having reflecting surfaces

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/18—Optical objectives specially designed for the purposes specified below with lenses having one or more non-spherical faces, e.g. for reducing geometrical aberration

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Lenses (AREA)

Abstract

The invention discloses an optical imaging lens group, which comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens which are sequentially arranged from an object side to an image side along an optical axis; the first lens element with negative refractive power has a concave image-side surface; the second lens element with positive refractive power has a convex image-side surface; the third lens element with positive refractive power has a convex object-side surface and a convex image-side surface; the fourth lens element with refractive power; the fifth lens element with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region thereof and a convex region away from the optical axis. The optical imaging lens group can meet the imaging of a large field angle, effectively reduce the total length of the lens group and achieve light weight, thinness and miniaturization by optimally configuring the focal lengths of the second lens and the third lens and the surface shape of the fifth lens and optimally configuring the air intervals among the lenses. The invention also discloses an image pickup device comprising the optical imaging lens group.

Description

Technical Field

The invention relates to the technical field of optical lenses, in particular to an optical imaging lens group. The invention also relates to an image pickup apparatus.

Background

With the development of electronic science and technology, portable mobile electronic devices, such as smart phones, tablet computers, automobile data recorders, motion cameras and the like, are rapidly popularized, and meanwhile, optical imaging lenses applied to the portable mobile electronic devices are developed vigorously.

While mobile portable electronic equipment brings great convenience to life of people, people have higher and higher requirements on the mobile electronic equipment, and continuously pursue more convenient and better use experience, so that the optical imaging lens used by the mobile portable electronic equipment is required to be lighter, thinner and more miniaturized; on the other hand, in some applications, the optical imaging lens is required to have a larger field angle, such as a self-portrait, a game machine, a panoramic camera, and the like, and the large field angle can make a shot scene wider and a field of view larger. With the above, the market demand for an optical imaging lens with a small size, a light weight, a small thickness, and a large field angle is rapidly increasing, and the optical imaging lens is particularly applied to the fields of mobile phones, vehicle-mounted lenses, and the like.

The traditional light and thin wide-angle optical imaging lens mainly adopts a four-piece lens structure, but the four-piece lens structure has limitations in the aspects of refractive power distribution, aberration astigmatism correction, sensitivity distribution and the like, and cannot further meet the imaging requirements of higher specifications. The total length of the lens is increased along with the increase of the number of the lenses, and the total length of the lens cannot be effectively suppressed.

Disclosure of Invention

The invention aims to provide an optical imaging lens group, which can meet the requirement of imaging with a large field angle and can effectively reduce the total length of the lens group so as to achieve lightness, thinness and miniaturization.

In order to achieve the purpose, the invention provides the following technical scheme:

an optical imaging lens group includes a first lens, a second lens, a third lens, a fourth lens, and a fifth lens arranged in order from an object side to an image side along an optical axis;

the first lens element with negative refractive power has a concave image-side surface;

the second lens element with positive refractive power has a convex image-side surface;

the third lens element with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element with refractive power;

the fifth lens element with refractive power has a convex object-side surface without inflection point, a concave image-side surface at a paraxial region, and a convex region away from the optical axis;

and satisfies the following conditions:

0.8<f3/f2<2;

0<AG12-∑AG25<0.26;

0.1<SAG51-SAG52<0.4;

wherein f is3Denotes the focal length of the third lens, f2Denotes the focal length, AG, of the second lens12Represents an air space on the optical axis between the first lens and the second lens, Σ AG25Denotes a sum of air intervals on the optical axis between the respective adjacent lenses of the second lens to the fifth lens, SAG51(iv) a distance, SAG, representing a projection point on the optical axis of a maximum optical effective diameter position of the object-side surface of the fifth lens from an intersection point of the object-side surface of the fifth lens and the optical axis52And the distance from the intersection point of the image side surface of the fifth lens and the optical axis to the projection point of the maximum optical effective diameter position of the image side surface of the fifth lens on the optical axis is represented.

Optionally, the following condition is also satisfied: 0 < | (R)31+R32)/(R31-R32) < 2, wherein R31Represents a radius of curvature, R, of the object-side surface of the third lens32Represents a radius of curvature of the image-side surface of the third lens.

Optionally, the following condition is also satisfied: 0 < | R32|-|R41< 2.4, wherein R41Represents a radius of curvature of the object-side surface of the fourth lens.

Optionally, the following condition is also satisfied: r is more than 1.211/R12< 3 wherein R11Denotes a radius of curvature, R, of the object-side surface of the first lens12Represents a radius of curvature of the image-side surface of the first lens.

Optionally, the following condition is also satisfied: v2-V1>30,V3-V4> 30, wherein V1Expressing the Abbe number, V, of the first lens2Expressing the Abbe number, V, of the second lens3Expressing the Abbe number, V, of the third lens4Representing the abbe number of the fourth lens.

Optionally, the following condition is also satisfied: 1.4 < CA51/CA11< 2 wherein CA51Denotes a maximum optical effective diameter, CA, of the object side surface of the fifth lens11Represents the maximum optical effective diameter of the object side surface of the first lens.

Optionally, the following condition is also satisfied: 10 < f5/CT5< 50, wherein f5Denotes the focal length, CT, of the fifth lens5Represents the thickness of the fifth lens on the optical axis.

Optionally, the following condition is also satisfied: 0.2 < BFL/f < 0.7, wherein BFL represents the optical back focal length of the optical imaging lens group, and f represents the focal length of the optical imaging lens group.

Optionally, the following condition is also satisfied: 2 < ∑ CT/∑ AG < 4, where Σ CT represents a sum of thicknesses of the respective lenses of the first lens to the fifth lens on the optical axis, and Σ AG represents a sum of air spaces between the respective adjacent lenses of the first lens to the fifth lens on the optical axis.

Optionally, the following condition is also satisfied: 2 < f3/CT3< 4, wherein CT3Represents the thickness of the third lens on the optical axis.

Optionally, the following condition is also satisfied: 4 < (CT)3+CT4+CT5)/(AG34+AG45) < 8, wherein, CT3Representing the thickness of said third lens on the optical axis, CT4Represents the thickness of the fourth lens on the optical axis, CT5Represents the thickness, AG, of the fifth lens on the optical axis34Represents an air space between the third lens and the fourth lens on the optical axis, AG45An air space on an optical axis between the fourth lens and the fifth lens is indicated.

Optionally, the following condition is also satisfied: l f1|>|f2|,|f1|>|f3|,|f1|>|f4L, wherein f1Denotes the focal length of the first lens, f4Denotes a focal length of the fourth lens.

Optionally, the following condition is also satisfied: f is more than 0.625/EFL<0.8,f25Represents a combined focal length of the second lens to the fifth lens.

An image pickup device comprises an electronic photosensitive element and the optical imaging lens group, wherein the electronic photosensitive element is arranged on an imaging surface of the optical imaging lens group.

In view of the above technical solutions, the optical imaging lens assembly provided by the present invention is a five-piece lens structure, and includes a first lens, a second lens, a third lens, a fourth lens, and a fifth lens, which are sequentially disposed from an object side to an image side along an optical axis, where an object side light passes through the lenses in sequence to form an image on an image plane located at the image side of the fifth lens. According to the optical imaging lens group, each lens adopts a reasonable surface structure and refractive power collocation, so that the whole lens group has better light convergence capacity; the fifth lens has a specific shape by optimally configuring the focal lengths of the second lens and the third lens and optimally configuring the surface shape of the fifth lens, so that aberration and astigmatism are reasonably corrected; in addition, the air space between the lenses is optimally configured, so that the total length of the optical lens group can be effectively reduced, and the optical lens group is light, thin and small. Therefore, the optical imaging lens group can effectively reduce the total length of the lens group while meeting the requirement of imaging with a large field angle, and achieves light weight, thinness and miniaturization.

The image pickup device provided by the invention can achieve the beneficial effects.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to the drawings without creative efforts.

Fig. 1 is a schematic diagram of an optical imaging lens assembly according to a first embodiment of the present disclosure;

FIG. 2 is a distortion curvature of an optical imaging lens assembly according to a first embodiment of the present invention;

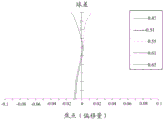

FIG. 3 is a spherical aberration diagram of an optical imaging lens assembly according to a first embodiment of the present invention;

FIG. 4 is a diagram illustrating an optical imaging lens assembly according to a second embodiment of the present invention;

FIG. 5 is a distortion field diagram of an optical imaging lens assembly according to a second embodiment of the present invention;

FIG. 6 is a spherical aberration diagram of an optical imaging lens assembly according to a second embodiment of the present invention;

FIG. 7 is a diagram illustrating an optical imaging lens assembly according to a third embodiment of the present invention;

FIG. 8 is a distortion curvature diagram of an optical imaging lens assembly according to a third embodiment of the present invention;

FIG. 9 is a spherical aberration diagram of an optical imaging lens assembly according to a third embodiment of the present invention;

FIG. 10 is a diagram illustrating an optical imaging lens assembly according to a fourth embodiment of the present invention;

FIG. 11 is a distortion curvature diagram of an optical imaging lens assembly according to a fourth embodiment of the present invention;

FIG. 12 is a spherical aberration chart of an optical imaging lens assembly according to a fourth embodiment of the present invention;

FIG. 13 is a diagram illustrating an optical imaging lens assembly according to a fifth embodiment of the present invention;

FIG. 14 is a distortion field diagram of an optical imaging lens assembly according to a fifth embodiment of the present invention;

FIG. 15 is a spherical aberration diagram of an optical imaging lens assembly according to a fifth embodiment of the present invention;

FIG. 16 is a diagram illustrating an optical imaging lens assembly according to a sixth embodiment of the present invention;

FIG. 17 is a distortion curvature of an optical imaging lens group according to a sixth embodiment of the present invention;

FIG. 18 is a spherical aberration diagram of an optical imaging lens group according to a sixth embodiment of the present invention;

FIG. 19 is a diagram illustrating an optical imaging lens assembly according to a seventh embodiment of the present invention;

FIG. 20 is a distortion field diagram of an optical imaging lens assembly according to a seventh embodiment of the present invention;

FIG. 21 is a spherical aberration chart of an optical imaging lens assembly according to a seventh embodiment of the present invention;

FIG. 22 is a diagram illustrating an optical imaging lens assembly according to an eighth embodiment of the present invention;

FIG. 23 is a distortion curvature diagram of an optical imaging lens assembly according to an eighth embodiment of the present invention;

FIG. 24 is a spherical aberration diagram of an optical imaging lens assembly according to an eighth embodiment of the present invention.

Detailed Description

In order to make those skilled in the art better understand the technical solution of the present invention, the technical solution in the embodiment of the present invention will be clearly and completely described below with reference to the drawings in the embodiment of the present invention, and it is obvious that the described embodiment is only a part of the embodiment of the present invention, and not all embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

An embodiment of the present invention provides an optical imaging lens assembly, including a first lens, a second lens, a third lens, a fourth lens, and a fifth lens arranged in order from an object side to an image side along an optical axis;

the first lens element with negative refractive power has a concave image-side surface;

the second lens element with positive refractive power has a convex image-side surface;

the third lens element with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element with refractive power;

the fifth lens element with refractive power has a convex object-side surface without inflection point, a concave image-side surface at a paraxial region, and a convex region away from the optical axis;

and satisfies the following conditions:

0.8<f3/f2<2;

0<AG12-∑AG25<0.26;

0.1<SAG51-SAG52<0.4;

wherein f is3Denotes the focal length of the third lens, f2Denotes the focal length, AG, of the second lens12Presentation instrumentAn air space on an optical axis between the first lens and the second lens, Σ AG25Denotes a sum of air intervals on the optical axis between the respective adjacent lenses of the second lens to the fifth lens, SAG51(iv) a distance, SAG, representing a projection point on the optical axis of a maximum optical effective diameter position of the object-side surface of the fifth lens from an intersection point of the object-side surface of the fifth lens and the optical axis52And the distance from the intersection point of the image side surface of the fifth lens and the optical axis to the projection point of the maximum optical effective diameter position of the image side surface of the fifth lens on the optical axis is represented.

In the optical imaging lens assembly of this embodiment, an object-side light beam sequentially passes through the first lens element, the second lens element, the third lens element, the fourth lens element and the fifth lens element to be imaged on an image plane located at an image side of the fifth lens element. Each lens adopts a reasonable surface structure and refractive power collocation, so that the whole lens group has better light convergence capability. The fifth lens has a specific shape by optimally configuring the focal lengths of the second lens and the third lens and optimally configuring the surface shape of the fifth lens, so that aberration and astigmatism are reasonably corrected, and the imaging quality is ensured.

In addition, through the optimal configuration of the air space between the lenses, the air space between the lenses satisfies the following conditions: 0 < AG12-∑AG25Less than 0.26, and can effectively suppress the total length of the optical lens group, thereby achieving lightness, thinness and miniaturization.

Therefore, the optical imaging lens assembly of the present embodiment can satisfy the requirement of imaging with a large field angle, and at the same time, can effectively reduce the total length of the lens assembly, thereby achieving the purposes of light weight, thinness and miniaturization.

Preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: 0 < | (R)31+R32)/(R31-R32) < 2, wherein R31Represents a radius of curvature, R, of the object-side surface of the third lens32Represents a radius of curvature of the image-side surface of the third lens. By effectively adjusting the curvatures of the object side surface and the image side surface of the third lens, light can be better converged.

The following conditions are further satisfied: 0 < | R32|-|R41< 2.4, wherein R32Represents a radius of curvature, R, of an image-side surface of the third lens41Represents a radius of curvature of the object-side surface of the fourth lens. By further adjusting the curvatures of the surfaces of the third lens and the fourth lens in a matching manner, light rays can be better converged.

Preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: r is more than 1.211/R12< 3 wherein R11Denotes a radius of curvature, R, of the object-side surface of the first lens12Represents a radius of curvature of the image-side surface of the first lens. By reasonably arranging the curvatures of the surfaces of the first lens, the field angle of the lens group is favorably expanded.

In one embodiment, the present optical imaging lens group further satisfies the following condition: v2-V1>30,V3-V4> 30, wherein V1Expressing the Abbe number, V, of the first lens2Expressing the Abbe number, V, of the second lens3Expressing the Abbe number, V, of the third lens4Representing the abbe number of the fourth lens.

More specifically, the optical imaging lens group further satisfies the following conditions: 1.4 < CA51/CA11< 2 wherein CA51Denotes a maximum optical effective diameter, CA, of the object side surface of the fifth lens11Represents the maximum optical effective diameter of the object side surface of the first lens. By adjusting the maximum optical effective diameter of the first lens and the last lens, the reasonable image height increase is facilitated.

Preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: 10 < f5/CT5< 50, wherein f5Denotes the focal length, CT, of the fifth lens5Represents the thickness of the fifth lens on the optical axis. So as to further optimize the refractive power and the lens thickness of the fifth lens element.

The optical imaging lens group of the present embodiment further satisfies the following conditions: 0.2 < BFL/f < 0.7, wherein BFL represents the optical back focal length of the optical imaging lens group, and f represents the focal length of the optical imaging lens group. By controlling the back focal length of the optical lens group and the proportion of the focal length of the optical lens group, the whole structure of the lens group is compact, and the lens group is lighter, thinner and miniaturized.

Preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: 2 < ∑ CT/∑ AG < 4, where Σ CT represents a sum of thicknesses of the respective lenses of the first lens to the fifth lens on the optical axis, and Σ AG represents a sum of air spaces between the respective adjacent lenses of the first lens to the fifth lens on the optical axis. The overall structure of the lens group is compact by optimally adjusting the ratio of the thickness of the whole lens group to the sum of the air intervals among the lenses, and the lens group is lighter, thinner and more miniaturized.

Preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: 2 < f3/CT3< 4, wherein CT3Represents the thickness of the third lens on the optical axis. The focal length and the lens thickness of the third lens are optimized through adjustment.

Further preferably, the optical imaging lens group of the present embodiment further satisfies the following conditions: 4 < (CT)3+CT4+CT5)/(AG34+AG45) < 8, wherein, CT3Representing the thickness of said third lens on the optical axis, CT4Represents the thickness of the fourth lens on the optical axis, CT5Represents the thickness, AG, of the fifth lens on the optical axis34Represents an air space between the third lens and the fourth lens on the optical axis, AG45An air space on an optical axis between the fourth lens and the fifth lens is indicated. The proportion of the thickness of each lens close to the image space in the optical lens group and the air space between the lenses is adjusted, so that the optical lens group is beneficial to the whole structure compactness.

The optical imaging lens group of the present embodiment further satisfies the following conditions: l f1|>|f2|,|f1|>|f3|,|f1|>|f4L, wherein f1Denotes the focal length of the first lens, f4Denotes a focal length of the fourth lens.

In particular also satisfyThe following conditions were used: f is more than 0.625/EFL<0.8,f25Represents a combined focal length of the second lens to the fifth lens.

The optical imaging lens group of the present invention will be described in detail below with specific examples.

First embodiment

Referring to fig. 1, a schematic diagram of an optical imaging lens assembly according to a first embodiment of the invention is shown. As can be seen from the figure, the optical imaging lens group includes a first lens 11, a second lens 12, a third lens 13, a fourth lens 14, and a fifth lens 15 arranged in order from the object side to the image side along the optical axis;

the first lens element 11 with negative refractive power has a concave image-side surface;

the second lens element 12 with positive refractive power has a convex image-side surface;

the third lens element 13 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 14 with refractive power;

the fifth lens element 15 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 10 between a first lens 11 and a second lens 12. An infrared filter 16 is arranged between the fifth lens 15 and the imaging surface, and infrared band light entering the optical lens group is filtered by the infrared filter 16, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 1-1, the focal length f is 1.864mm, the aperture value Fno is 2.32, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length in the table is mm, and the surfaces 0-14 sequentially represent the surfaces from the object side to the image side, wherein the surfaces 1-11 sequentially represent the object side surface of the first lens, the image side surface of the first lens, the aperture, the object side surface of the second lens, the image side surface of the second lens, the object side surface of the third lens, the image side surface of the third lens, the object side surface of the fourth lens, the image side surface of the fourth lens, the object side surface of the fifth lens and the image side surface of the fifth lens. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 1-1

Each lens in the optical imaging lens group adopts aspheric surface design, and the curve equation of the aspheric surface is expressed as follows:

wherein z represents a point on the aspheric surface at a distance r from the optical axis and a relative distance from a vertex tangent to the aspheric surface on the optical axis, c represents a radius of curvature, r represents a distance from the aspheric surface to the optical axis, k represents a conic coefficient, and Ai represents an i-th order aspheric coefficient.

The aspherical surface coefficients of the lenses of this embodiment are specifically shown in tables 1 to 2, and a2 to a16 represent aspherical surface coefficients of orders 2 to 16, respectively, on the lens surface.

Tables 1 to 2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in fig. 2 and fig. 3, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm. The test wavelength in the test graph in each of the following examples is the same as that in the present example.

Second embodiment

Fig. 4 is a schematic view of an optical imaging lens assembly according to a second embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 21, a second lens 22, a third lens 23, a fourth lens 24, and a fifth lens 25 arranged in order from the object side to the image side along the optical axis;

the first lens element 21 with negative refractive power has a concave image-side surface;

the second lens element 22 with positive refractive power has a convex image-side surface;

the third lens element 23 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 24 with refractive power;

the fifth lens element 25 with refractive power has a convex object-side surface without inflection point, a concave image-side surface at a paraxial region, and a convex surface at a region away from the optical axis.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 20 between a first lens 21 and a second lens 22. An infrared filter 26 is arranged between the fifth lens 25 and the imaging surface, and infrared band light entering the optical lens group is filtered by the infrared filter 26, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 2-1, the focal length f is 1.995mm, the aperture value Fno is 2.42, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length in the table is mm, and the surfaces 0-14 sequentially represent the surfaces from the object side to the image side, wherein the surfaces 1-11 sequentially represent the object side surface of the first lens, the image side surface of the first lens, the aperture, the object side surface of the second lens, the image side surface of the second lens, the object side surface of the third lens, the image side surface of the third lens, the object side surface of the fourth lens, the image side surface of the fourth lens, the object side surface of the fifth lens and the image side surface of the fifth lens. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the center thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 2-1

The aspheric coefficients of the lenses of this embodiment are shown in table 2-2, and a2-a16 represent aspheric coefficients of orders 2-16 of the lens surface, respectively.

Tables 2 to 2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in FIG. 5 and FIG. 6, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Third embodiment

Fig. 7 is a schematic view of an optical imaging lens assembly according to a third embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 31, a second lens 32, a third lens 33, a fourth lens 34, and a fifth lens 35, which are arranged in order from the object side to the image side along the optical axis;

the first lens element 31 with negative refractive power has a concave image-side surface;

the second lens element 32 with positive refractive power has a convex image-side surface;

the third lens element 33 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 34 with refractive power;

the fifth lens element 35 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 30 between a first lens 31 and a second lens 32. An infrared filter 36 is arranged between the fifth lens 35 and the imaging surface, and infrared band light entering the optical lens group is filtered through the infrared filter 36, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 3-1, wherein the focal length f is 1.832mm, the aperture value Fno is 2.37, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 3-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 3-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 3-2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in FIG. 8 and FIG. 9, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Fourth embodiment

Fig. 10 is a schematic view of an optical imaging lens assembly according to a fourth embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 41, a second lens 42, a third lens 43, a fourth lens 44, and a fifth lens 45 arranged in order from the object side to the image side along the optical axis;

the first lens element 41 with negative refractive power has a concave image-side surface;

the second lens element 42 with positive refractive power has a convex image-side surface;

the third lens element 43 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 44 with refractive power;

the fifth lens element 45 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 40 between a first lens 41 and a second lens 42. An infrared filter 46 is arranged between the fifth lens 45 and the imaging surface, and infrared band light entering the optical lens group is filtered by the infrared filter 46, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 4-1, the focal length f is 1.807mm, the aperture value Fno is 2.35, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 4-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 4-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 4-2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in FIG. 11 and FIG. 12, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Fifth embodiment

Fig. 13 is a schematic view of an optical imaging lens assembly according to a fifth embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 51, a second lens 52, a third lens 53, a fourth lens 54, and a fifth lens 55 arranged in order from the object side to the image side along the optical axis;

the first lens element 51 with negative refractive power has a concave image-side surface;

the second lens element 52 with positive refractive power has a convex image-side surface;

the third lens element 53 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 54 with refractive power;

the fifth lens element 55 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 50 between a first lens 51 and a second lens 52. An infrared filter 56 is arranged between the fifth lens 55 and the imaging surface, and infrared band light entering the optical lens group is filtered by the infrared filter 56, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 5-1, the focal length f is 1.878mm, the aperture value Fno is 2.39, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 5-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 5-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 5-2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in FIG. 14 and FIG. 15, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Sixth embodiment

Fig. 16 is a schematic view of an optical imaging lens assembly according to a sixth embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 61, a second lens 62, a third lens 63, a fourth lens 64, and a fifth lens 65 arranged in order from the object side to the image side along the optical axis;

the first lens element 61 with negative refractive power has a concave image-side surface;

the second lens element 62 with positive refractive power has a convex image-side surface;

the third lens element 63 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 64 with refractive power;

the fifth lens element 65 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex region away from the optical axis.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 60 between a first lens 61 and a second lens 62. An infrared filter 66 is arranged between the fifth lens 65 and the imaging surface, and infrared band light entering the optical lens group is filtered by the infrared filter 66, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters shown in table 6-1, the focal length f is 1.859mm, the aperture value Fno is 2.37, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 6-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 6-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 6-2

Fig. 17 and 18 show the distortion field curve and the spherical aberration curve obtained by testing the optical lens assembly of this embodiment, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Seventh embodiment

Fig. 19 is a schematic view of an optical imaging lens assembly according to a seventh embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 71, a second lens 72, a third lens 73, a fourth lens 74, and a fifth lens 75, which are arranged in order from the object side to the image side along the optical axis;

the first lens element 71 with negative refractive power has a concave image-side surface;

the second lens element 72 with positive refractive power has a convex image-side surface;

the third lens element 73 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 74 with refractive power;

the fifth lens element 75 with refractive power has a convex object-side surface without inflection point, a concave image-side surface at a paraxial region, and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 70 between a first lens 71 and a second lens 72. An infrared filter 76 is disposed between the fifth lens element 75 and the imaging surface, and infrared band light entering the optical lens assembly is filtered by the infrared filter 76, so as to prevent infrared light from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters of each lens as shown in table 7-1, the focal length f is 1.884mm, the aperture value Fno is 2.37, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 7-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 7-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 7-2

The distortion field curve and the spherical aberration curve of the optical lens set design of this embodiment are shown in FIG. 20 and FIG. 21, respectively, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

Eighth embodiment

Fig. 22 is a schematic view of an optical imaging lens assembly according to an eighth embodiment of the present invention. As can be seen from the figure, the optical imaging lens group includes a first lens 81, a second lens 82, a third lens 83, a fourth lens 84, and a fifth lens 85, which are arranged in order from the object side to the image side along the optical axis;

the first lens element 81 with negative refractive power has a concave image-side surface;

the second lens element 82 with positive refractive power has a convex image-side surface;

the third lens element 83 with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element 84 with refractive power;

the fifth lens element 85 with refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region and a convex surface at a paraxial region.

The values of the conditional expressions in the present embodiment are shown in the following table:

the optical imaging lens group of the present embodiment is provided with a diaphragm 80 between a first lens 81 and a second lens 82. An infrared filter 86 is disposed between the fifth lens 85 and the imaging surface, and infrared band light entering the optical lens assembly is filtered by the infrared filter 86, so that the infrared light is prevented from irradiating the photosensitive chip to generate noise. The optional filter is made of glass and does not affect the focal length.

The optical imaging lens assembly of this embodiment has the structural parameters of each lens as shown in table 8-1, the focal length f is 1.890mm, the aperture f is 2.38, and the half field angle HFOV is 60 degrees. The unit of curvature radius, thickness and focal length is mm, and surfaces 0-14 represent the surfaces from the object side to the image side in that order. In the table below, in the thickness column, the numerical value in the first column corresponding to the same lens is the central thickness of the lens, and the numerical value in the second column is the air space between the lens and the next optical element; the numerical value in the column corresponding to the aperture is the air space between the aperture and the next lens; the value in the first column corresponding to the infrared filter is the thickness of the infrared filter, and the value in the second column is the air interval between the infrared filter and the imaging plane.

TABLE 8-1

The aspherical surface coefficients of the lenses of this embodiment are shown in Table 8-2, and A2-A16 show aspherical surface coefficients of 2 nd to 16 th orders, respectively.

TABLE 8-2

Fig. 23 and 24 show the distortion field curve and the spherical aberration curve obtained by testing the optical lens assembly of this embodiment, wherein the test wavelength of the distortion field curve is 0.555 μm, and the test wavelength of the spherical aberration curve is 0.470 μm, 0.510 μm, 0.555 μm, 0.610 μm and 0.650 μm.

In the optical imaging lens assembly provided by each embodiment of the invention, each lens adopts a reasonable surface shape structure and refractive power collocation, so that the whole lens assembly has better light converging capability, and the total length of the lens assembly can be effectively reduced to achieve lightness and thinness while meeting the requirement of a large field angle.

The optical lens group has the advantage of a large aperture, the large aperture ensures sufficient light input, the light sensitivity can be effectively improved, and better imaging quality is ensured.

In addition, the five-piece aspheric lens structure is adopted, and the appropriate surface type and higher-order aspheric coefficients are adopted, so that various aberrations such as field curvature, astigmatism, chromatic aberration of magnification and the like can be effectively corrected. Meanwhile, the method has the advantages of better thickness ratio and sensitivity, improved process yield and reduced production cost.

The plastic material is adopted, the characteristic that the plastic material has precise mould pressing is utilized, the batch production is realized, the processing cost of the optical element can be greatly reduced, the cost of the optical system is further greatly reduced, and the large-scale popularization is facilitated.

Correspondingly, the embodiment of the invention also provides image pickup equipment, which comprises an electronic photosensitive element and the optical imaging lens group, wherein the electronic photosensitive element is arranged on an imaging surface of the optical imaging lens group. The image pickup device adopts the optical imaging lens group, meets the requirement of imaging with a large field angle, can effectively reduce the total length of the lens group, and achieves light weight, thinness and miniaturization.

The optical imaging lens assembly and the image pickup apparatus provided by the present invention are described in detail above. The principles and embodiments of the present invention are explained herein using specific examples, which are presented only to assist in understanding the method and its core concepts. It should be noted that, for those skilled in the art, it is possible to make various improvements and modifications to the present invention without departing from the principle of the present invention, and those improvements and modifications also fall within the scope of the claims of the present invention.

Claims (14)

1. An optical imaging lens group is characterized by comprising five lenses, wherein the five lenses comprise a first lens, a second lens, a third lens, a fourth lens and a fifth lens which are sequentially arranged from an object side to an image side along an optical axis;

the first lens element with negative refractive power has a concave image-side surface;

the second lens element with positive refractive power has a convex image-side surface;

the third lens element with positive refractive power has a convex object-side surface and a convex image-side surface;

the fourth lens element with negative refractive power;

the fifth lens element with positive refractive power has a convex object-side surface without inflection point, and a concave image-side surface at a paraxial region thereof and a convex region away from the optical axis;

and satisfies the following conditions:

0.8<f3/f2<2;

0<AG12-∑AG25<0.26;

0.1<SAG51-SAG52<0.4;

wherein f is3Denotes the focal length of the third lens, f2Denotes the focal length, AG, of the second lens12Represents an air space on the optical axis between the first lens and the second lens, Σ AG25Denotes a sum of air intervals on the optical axis between the respective adjacent lenses of the second lens to the fifth lens, SAG51(iv) a distance, SAG, representing a projection point on the optical axis of a maximum optical effective diameter position of the object-side surface of the fifth lens from an intersection point of the object-side surface of the fifth lens and the optical axis52And the distance from the intersection point of the image side surface of the fifth lens and the optical axis to the projection point of the maximum optical effective diameter position of the image side surface of the fifth lens on the optical axis is represented.

2. An optical imaging lens group according to claim 1, further satisfying the following condition: 0 < | (R)31+R32)/(R31-R32) < 2, wherein R31Represents a radius of curvature, R, of the object-side surface of the third lens32Represents a radius of curvature of the image-side surface of the third lens.

3. An optical imaging lens group according to claim 2, further satisfying the following condition: 0 < | R32|-|R41< 2.4, wherein R32Represents a radius of curvature, R, of an image-side surface of the third lens41Represents a radius of curvature of the object-side surface of the fourth lens.

4. An optical imaging lens group according to claim 1, further satisfying the following condition: r is more than 1.211/R12< 3 wherein R11Denotes a radius of curvature, R, of the object-side surface of the first lens12A radius of curvature representing a surface on the image side of the first lens。

5. An optical imaging lens group according to claim 1, further satisfying the following condition: v2-V1>30,V3-V4> 30, wherein V1Expressing the Abbe number, V, of the first lens2Expressing the Abbe number, V, of the second lens3Expressing the Abbe number, V, of the third lens4Representing the abbe number of the fourth lens.

6. An optical imaging lens group according to claim 5, further satisfying the following condition: 1.4 < CA51/CA11< 2 wherein CA51Denotes a maximum optical effective diameter, CA, of the object side surface of the fifth lens11Represents the maximum optical effective diameter of the object side surface of the first lens.

7. An optical imaging lens group according to claim 1, further satisfying the following condition: 10 < f5/CT5< 50, wherein f5Denotes the focal length, CT, of the fifth lens5Represents the thickness of the fifth lens on the optical axis.

8. An optical imaging lens group according to claim 1, further satisfying the following condition: 0.2 < BFL/f < 0.7, wherein BFL represents the optical back focal length of the optical imaging lens group, and f represents the focal length of the optical imaging lens group.

9. An optical imaging lens group according to claim 1, further satisfying the following condition: 2 < ∑ CT/∑ AG < 4, where Σ CT represents a sum of thicknesses of the respective lenses of the first lens to the fifth lens on the optical axis, and Σ AG represents a sum of air spaces between the respective adjacent lenses of the first lens to the fifth lens on the optical axis.

10. According to the claimsThe optical imaging lens group according to claim 9, further satisfying the following conditions: 2 < f3/CT3< 4, wherein CT3Represents the thickness of the third lens on the optical axis.

11. An optical imaging lens group according to claim 1, further satisfying the following condition: 4 < (CT)3+CT4+CT5)/(AG34+AG45) < 8, wherein, CT3Representing the thickness of said third lens on the optical axis, CT4Represents the thickness of the fourth lens on the optical axis, CT5Represents the thickness, AG, of the fifth lens on the optical axis34Represents an air space between the third lens and the fourth lens on the optical axis, AG45An air space on an optical axis between the fourth lens and the fifth lens is indicated.

12. An optical imaging lens group according to claim 1, further satisfying the following condition: l f1|>|f2|,|f1|>|f3|,|f1|>|f4L, wherein f1Denotes the focal length of the first lens, f4Denotes a focal length of the fourth lens.

13. The optical imaging lens group of claim 12, further satisfying the condition: f is more than 0.625/EFL<0.8,f25Denotes a combined focal length of the second lens to the fifth lens, and EFL denotes an optical front focal length of the optical imaging lens group.

14. An image pickup apparatus comprising an electron-sensitive element and the optical imaging lens group according to any one of claims 1 to 13, wherein the electron-sensitive element is disposed on an imaging surface of the optical imaging lens group.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711283176.2A CN107942479B (en) | 2017-12-07 | 2017-12-07 | Optical imaging lens assembly and image pickup equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711283176.2A CN107942479B (en) | 2017-12-07 | 2017-12-07 | Optical imaging lens assembly and image pickup equipment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107942479A CN107942479A (en) | 2018-04-20 |

| CN107942479B true CN107942479B (en) | 2021-02-05 |

Family

ID=61945140

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711283176.2A Active CN107942479B (en) | 2017-12-07 | 2017-12-07 | Optical imaging lens assembly and image pickup equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN107942479B (en) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI461728B (en) * | 2011-09-02 | 2014-11-21 | Largan Precision Co Ltd | Lens assembly for image taking |

| CN103123413B (en) * | 2013-01-30 | 2015-05-06 | 歌崧光学精密工业有限公司 | Wide-angle lens |

| CN103631000B (en) * | 2013-07-10 | 2016-12-28 | 玉晶光电(厦门)有限公司 | Portable electronic devices and its optical imaging lens |

| CN105988192B (en) * | 2015-05-08 | 2018-09-18 | 浙江舜宇光学有限公司 | Wide-angle image camera lens |

-

2017

- 2017-12-07 CN CN201711283176.2A patent/CN107942479B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN107942479A (en) | 2018-04-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109061838B (en) | Optical imaging lens and electronic equipment | |

| CN110764234B (en) | Optical lens and imaging apparatus | |

| CN107861218B (en) | Optical imaging lens and camera equipment | |

| CN107783259B (en) | Optical imaging lens and camera module | |

| CN112987258B (en) | Optical system, image capturing module and electronic equipment | |

| CN109100855B (en) | Optical imaging lens group and electronic equipment | |

| CN110187473B (en) | Five-piece type wide-angle lens and electronic equipment | |

| CN109270665B (en) | Optical imaging lens and electronic device | |

| CN108802969B (en) | Optical imaging lens group | |

| CN109765678B (en) | Camera lens and electronic equipment | |

| CN113805310A (en) | Optical system, image capturing module and electronic equipment | |

| CN113138458A (en) | Optical system, image capturing module and electronic equipment | |

| CN113484983B (en) | Optical system, lens module and electronic equipment | |

| CN113433656B (en) | Imaging system, lens module and electronic equipment | |

| CN113391430A (en) | Optical system, lens module and electronic equipment | |

| CN113219628A (en) | Optical system, image capturing module and electronic equipment | |

| CN211061764U (en) | Image pickup lens assembly | |

| CN211014809U (en) | Optical imaging system | |

| CN111781711A (en) | Image pickup lens assembly | |

| CN113391429B (en) | Optical system, camera module and electronic equipment | |

| CN107966786B (en) | Wide-view-angle optical imaging lens system | |

| CN212543902U (en) | Optical lens, camera module and electronic equipment | |

| CN113625425A (en) | Optical lens, camera module and electronic equipment | |

| CN210488107U (en) | Five-piece type telephoto lens and electronic device | |

| CN113189748A (en) | Optical system, image capturing module and electronic equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |