CN107706479B - Turnover online device and method for waste lead-acid batteries - Google Patents

Turnover online device and method for waste lead-acid batteries Download PDFInfo

- Publication number

- CN107706479B CN107706479B CN201711054523.4A CN201711054523A CN107706479B CN 107706479 B CN107706479 B CN 107706479B CN 201711054523 A CN201711054523 A CN 201711054523A CN 107706479 B CN107706479 B CN 107706479B

- Authority

- CN

- China

- Prior art keywords

- battery

- overturning

- clamping mechanism

- power

- turnover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/54—Reclaiming serviceable parts of waste accumulators

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/84—Recycling of batteries or fuel cells

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Processing Of Solid Wastes (AREA)

- Secondary Cells (AREA)

Abstract

The invention discloses a waste lead-acid battery overturning and wire-feeding device, which is used for overturning and feeding cut waste lead-acid batteries and is characterized by mainly comprising the following steps: the device comprises a turnover frame, a battery clamping mechanism, a turnover power mechanism and a pushing mechanism; the battery clamping mechanism, the turnover power mechanism and the pushing mechanism are arranged below the turnover frame, and the battery clamping mechanism is connected with the turnover power mechanism and realizes turnover under the action of the turnover power mechanism; the battery clamping mechanism is positioned below the pushing mechanism in the initial state, and when the overturning power mechanism overturns to the horizontal height corresponding to the pushing mechanism, the pushing mechanism acts to push out the waste lead-acid batteries clamped in the battery clamping mechanism. The problem of battery jar online and upset has been effectually solved, realizes mechanical automation production, avoids the acid pickle in the battery jar to cause harm to environment and workman's health.

Description

Technical Field

The invention relates to the technical field of waste material recovery treatment, in particular to a novel device for overturning and feeding a waste lead storage battery.

Background

The traditional lead-acid battery tank recovery and regeneration industry at home and abroad mainly adopts a recovery mode of mixing before separating, and can obtain useful resources such as lead-antimony alloy, plastic, lead plaster, separator paper, lead-calcium alloy, sulfuric acid and the like through a series of procedures, but the traditional recovery mode has some problems. The recovery mode is that firstly, a method of centralized crushing by a crusher is used for carrying out recovery pretreatment on the battery tank, after all parts of the battery tank crushed by high-power crushing equipment are mixed together, the plastic tank body part contains fragments of simple substances of lead and lead compounds, and impurities such as copper, iron and the like are mixed in the lead, so that the subsequent recovery difficulty and cost are increased, the purity of the recovery product is influenced, and the problems of low recovery rate, high recovery difficulty, high recovery cost and the like exist in the whole recovery process are caused; on the one hand, the acid liquid flowing out in the crushing process is extremely easy to be brought into other subsequent equipment to cause damage to the equipment, and on the other hand, a large part of the acid liquid flowing out and acid mist formed in the crushing process can leak into the surrounding environment to pollute the environment and harm the health of human bodies, and the acid liquid is a waste of resources; the use of high-power crushing equipment increases the energy demand in the recovery process, which is not beneficial to saving the cost and implementing the national policy of energy conservation and emission reduction.

Compared with the coarser recycling mode, the method of cutting and then separating the upper cover and the polar plate of the battery tank at the earlier stage is more advanced, but the method is manually separated or transferred to other equipment for separation after cutting. For the manual separation mode, the efficiency is low, and heavy metals and sulfuric acid liquid in the cut waste lead-acid battery tank have great harm to the body of workers; for the mode of transferring to other equipment for processing, the process of processing is increased due to unreasonable transferring process, the efficiency is reduced, and the cost is increased.

Disclosure of Invention

The invention aims to solve the technical problem of developing a device for overturning and feeding the cut waste lead-acid battery, namely, the waste lead-acid battery with the cut upper cover is overturned by 180 degrees and then is conveyed to a vibration separation integrated machine for high-efficiency separation; the separation process is environment-friendly and efficient and has low cost.

In order to solve the technical problems, the invention adopts the following technical scheme:

the utility model provides a old and useless lead acid battery upset device of going up for overturn and go up line to old and useless lead acid battery after cutting, its characterized in that mainly includes: the device comprises a turnover frame, a battery clamping mechanism, a turnover power mechanism and a pushing mechanism; the battery clamping mechanism, the turnover power mechanism and the pushing mechanism are arranged below the turnover frame, and the battery clamping mechanism is connected with the turnover power mechanism and realizes turnover under the action of the turnover power mechanism; the battery clamping mechanism is positioned below the pushing mechanism in the initial state, and when the overturning power mechanism overturns to the horizontal height corresponding to the pushing mechanism, the pushing mechanism acts to push out the waste lead-acid batteries clamped in the battery clamping mechanism.

Further, the front end of the waste lead-acid battery overturning and wire feeding device is in linear butt joint with a roller conveyor belt, the cut battery is conveyed into the battery clamping mechanism through the roller conveyor belt, and an acid liquid collecting device is arranged on a running track below the battery clamping mechanism and used for collecting the dumped sulfuric acid liquid in the overturning process of the battery; the battery overturning and feeding device is in butt joint with the vibration separation integrated machine, and when the notch of the battery clamping mechanism is in butt joint with the notch of the vibration groove of the vibration separation integrated machine, the pushing mechanism acts to push the battery groove of the battery clamping mechanism after pouring liquid into the vibration separation integrated machine for subsequent separation vibration.

Further, the pushing mechanism comprises an air cylinder and a suspension plate, the lateral section of the suspension plate is L-shaped, the vertical end of the L-shape is fixed below the overturning frame, the horizontal end of the L-shape extends out of the space below the overturning frame in a suspending way, the air cylinder is horizontally fixed on the horizontal end of the L-shape of the suspension plate, a push plate is arranged at the end head of a piston rod of the air cylinder, and the push plate is vertically arranged perpendicular to the horizontal end of the L-shape; when the battery clamping mechanism is turned over from the lower part, one end of the battery clamping mechanism corresponds to the pushing plate, and the other end of the battery clamping mechanism corresponds to the vibration separation integrated machine, so that the air cylinder can push out the battery in the battery clamping mechanism into the vibration separation integrated machine through the pushing plate.

Further, the battery clamping mechanism comprises a transition groove shell, a transition roller, a rectangular tooth clamping plate, a clamping cylinder and an extension arm: the transition groove shell is provided with a horizontal upper cover and two vertical parallel opposite side walls, and a rectangular clamping cavity is formed by the transition groove shell and a transition roller arranged on the bottom surface of the transition groove shell; the clamping cylinder is fixed at the bottom of the transition groove shell and pushes the rectangular tooth clamping plate to move upwards to clamp the cut battery in the clamping cavity; the extending arm extends out from one side surface of the transition groove shell in the outward inclined downward direction and keeps a set angle with the vertical direction; in the initial clamping position, the transition roller is in linear butt joint with the roller conveyor belt, and when the battery clamping mechanism just turns over 180 degrees, the transition groove shell is in butt joint with a vibration groove notch and a push plate in the vibration separation integrated machine.

Further, the rectangular tooth clamping plate comprises a plurality of rectangular teeth which are arranged in parallel at intervals, and the rectangular teeth are fixed on the clamping cylinder through the bottom plate; the rectangular tooth clamping plate is fixed on the clamping cylinder, is placed below the transition roller in the transition groove shell, and is arranged to clamp or retract the cut battery back to the initial state in the gap of the transition roller along with the action of the clamping cylinder.

Further, the turnover power mechanism comprises a combination of a double rocker part and a crank block part:

the double-rocker mechanism comprises a turnover frame, a power rod, a rocker and a battery clamping mechanism, wherein the upper end of the rocker is hinged on the turnover frame, the lower end of the rocker is hinged on one side of a transition groove shell of the battery clamping mechanism, which is not provided with an extension arm, the whole battery clamping mechanism is positioned at a connecting rod position, and the lower part of the extension arm of the battery clamping mechanism is hinged with the power rod through a hinge shaft of the extension arm; when the power rod rotates by 80 degrees anticlockwise, the battery clamping mechanism turns over by 180 degrees, and the transition groove shell just is in butt joint with a vibration groove opening in the vibration separation integrated machine;

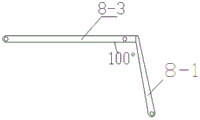

the crank slide block part comprises a power cylinder as a slide block module and a power rod; the power rod 8 is a V-shaped crank, and two branches of the V-shaped crank are a main push rod and a push arm; the two branches of the V-shaped crank are arranged in unequal length and form a V-shaped included angle larger than 90 degrees, the two branches of the V-shaped crank are connected through an auxiliary push rod, the main push rod is vertically arranged with the auxiliary push rod, and the push arm is vertically arranged with the auxiliary push rod; the power rod is hinged on the overturning frame through one of the two branches, namely the pushing arm, the tail end of the branch is hinged with the battery clamping mechanism, and the other branch of the V-shaped crank, namely the tail end of the main pushing rod is hinged with the free end of the power cylinder; the power cylinder is hinged on the overturning frame through a cylinder fixed hinged support.

Further, two pushing arms are arranged in parallel at intervals.

Further, the power rod is hinged on the lower suspension fixing arm through one of the two branches, namely the pushing arm, and the lower suspension fixing arm is suspended and fixed on the overturning frame.

In the technical scheme, corresponding bearings are arranged between the power cylinder and the power rod, between the power rod and the connecting rod, between the connecting rod and the rocker, and between the rocker and the base support part so as to reduce friction between rotating parts.

The method for overturning and feeding the waste lead-acid battery by adopting the overturning and feeding device of the invention is characterized by comprising the following specific steps:

firstly, a battery groove enters a transition groove shell after being accelerated by a roller conveyor belt and then collides and stops, a clamping cylinder receives a signal to push a rectangular tooth clamping plate to clamp and fix the battery groove from the lower part;

then, a power cylinder in the overturning power mechanism provides torque for the power rod to realize overturning of the battery groove; in the overturning process of the battery tank, acid liquor in the battery tank overflows outwards and drops into an arc acid liquor collecting device at the lower part of the overturning power mechanism, when the battery overturning power mechanism is in butt joint with a vibrating tank notch in the vibrating and separating integrated machine, most of acid liquor in the battery overturning power mechanism is separated, only a small amount of acid liquor is attached to the inner wall of the shell and adsorbed on the cluster part, and meanwhile, the cut opening of the battery tank is downward, and only an external plastic tank body and an internal cluster part of the battery tank are left;

and finally, the battery clamping mechanism loosens the clamped battery groove, and the battery groove enters the vibration separating mechanism to separate the plastic groove body from the cluster group under the pushing of the air cylinder.

The invention relates to a transition mechanism of a cutting machine and vibration separation integrated mechanism, which effectively solves the problems of line feeding and overturning of a battery tank, realizes mechanical automatic production and avoids the harm of waste acid liquid in the battery tank to the environment and the body of workers.

Drawings

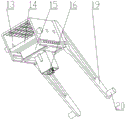

FIG. 1 is a diagram (perspective view) of the installation structure of a turnover and wire feeding device of a waste lead-acid battery disclosed by the invention;

fig. 2 is a schematic diagram (perspective view) of the whole structure of the turnover and wire-feeding device of the waste lead-acid battery disclosed by the invention;

FIG. 3 is a schematic diagram of a battery clamping mechanism of the waste lead-acid battery flipping and feeding device of the present invention;

FIG. 4 is a schematic view of a rectangular tooth sandwich structure of the present disclosure;

FIG. 5 is a schematic diagram of a vibration isolation integrated mechanism disclosed in the present invention;

FIG. 6 is a schematic diagram of a battery compartment flipping module of the present disclosure prior to flipping;

FIG. 7 is a schematic diagram of a battery compartment flipping module of the present disclosure in a flipped state;

FIG. 8 is a schematic diagram of the battery well flipping motion of the present disclosure;

FIG. 9 is a top view of the power rod 8 of the present invention;

FIG. 10 is a front view of FIG. 9;

fig. 11 is a left side view of fig. 9.

In fig. 1-11, the reference numerals correspond as follows:

| reference numerals | Name of the name |

| 1 | Vibration separation integrated |

| 2 | Acid |

| 3 | Battery overturning and wire feeding device |

| 4 | Roller conveyor belt |

| 5 | Cylinder |

| 6 | Rotary shaft |

| 7 | |

| 8 | Power rod |

| 8-1 | Main push rod |

| 8-2 | Auxiliary push rod |

| 8-3 | |

| 9 | |

| 10 | Cylinder fixing hinged |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | Rectangular tooth splint |

| 15-1 | Bottom plate |

| 15-2 | |

| 16 | Clamping |

| 17 | Vibration tank |

| 17-1 | Notch of |

| 18 | |

| 19 | |

| 20 | Hinge shaft of |

| 21 | Suspended |

| 22 | Fixing arm |

Detailed Description

The technical scheme of the invention is described in detail below with reference to fig. 1-11.

Fig. 2-8 show a waste lead-acid battery turning and feeding device 3 for treating cut waste lead-acid batteries, which mainly comprises the following components: the turnover machine frame 7, the battery clamping mechanism 12, the turnover power mechanism and the pushing mechanism; a battery clamping mechanism 12, a turnover power mechanism and a pushing mechanism are arranged below the turnover frame 7, and the battery clamping mechanism 12 is connected with the turnover power mechanism and realizes turnover action under the action of the turnover power mechanism; the battery clamping mechanism 12 is positioned below the pushing mechanism in the initial state, and when the overturning power mechanism overturns to the horizontal height corresponding to the pushing mechanism, the pushing mechanism acts to push out the waste lead-acid batteries clamped in the battery clamping mechanism 12.

As shown in fig. 1, the front end procedure of the battery overturning and wire feeding device 3 is in linear butt joint with a roller conveyor belt 4, the cut battery is conveyed into a battery clamping mechanism 12 through the roller conveyor belt 4, and an arc acid liquid collecting device 3 is arranged on a running track below the battery clamping mechanism 12 and used for collecting dumped sulfuric acid liquid in the overturning process of the battery; the rear end of the battery overturning and wire feeding device 3 is in butt joint with the vibration separation integrated machine 1, the vibration separation integrated machine 1 and the suspended plate 21 are located at the same horizontal height, and a battery groove after liquid pouring is pushed into the vibration separation integrated machine 1 through a push plate arranged at the suspended plate 21 to carry out a follow-up vibration separation process.

The specific structure of the pushing mechanism shown in fig. 1-2 comprises an air cylinder 5 and a suspension plate 21, wherein the suspension plate 21 is L-shaped, the vertical end of the L-shape is fixed below the turnover frame 7, the horizontal end of the L-shape extends out of the space below the turnover frame 7 in a suspension manner, the air cylinder 5 is horizontally fixed on the horizontal end of the L-shape of the suspension plate 21, a push plate is arranged at the end head of a piston rod of the air cylinder 5, and the push plate is vertically arranged at the vertical position perpendicular to the horizontal end of the L-shape. When the battery clamping mechanism 12 is turned over from the bottom, one end of the notch of the transition groove shell 13 corresponds to the vibration separation integrated machine 1 at the other end corresponding to the push plate, so that the air cylinder 5 can push out the battery in the transition groove shell 13 into the vibration separation integrated machine 1 through the push plate.

As shown in fig. 2-4, the battery clamping mechanism 12 is composed of a transition groove shell 13, a transition roller 14, a rectangular tooth clamping plate 15, a clamping cylinder 16 and a protruding arm 19: the transition housing 13 has a horizontal upper cover and two vertically parallel opposite side walls, forming a clamping cavity with a transition drum 14 mounted to the bottom surface of the transition housing. The clamping cylinder 16 is fixed at the bottom of the transition groove shell 13, and pushes the rectangular tooth clamping plate 15 to move upwards to clamp the cut battery in the clamping cavity. The rectangular tooth clamping plate 15 comprises a plurality of rectangular teeth 15-2 which are arranged in parallel at intervals, and the rectangular teeth 15-2 are fixed on a clamping cylinder 16 through a bottom plate 15-1. The rectangular tooth clamping plate 15 is fixed to the clamping cylinder 16, is placed below the transition roller 14 inside the transition housing 13, and protrudes in the gap of the transition roller 14 to clamp or retract the cut battery back to the original state with the action of the clamping cylinder. The projecting arm 19 projects from one side face of the transition housing 13 in an outward obliquely downward direction and is held at a set angle to the vertical direction.

As shown in fig. 1 and 6-8, the turnover power mechanism comprises a combination of a double rocker part and a crank block part:

the double-rocker mechanism comprises a turnover frame 7, a power rod 8, a rocker 11 and a battery clamping mechanism 12, wherein the upper end of the rocker 11 is hinged to a rotating shaft 6 through a hinge point F, the rotating shaft 6 is fixed below the turnover frame 7, the lower end of the rocker 11 is rotationally fixed on one side of a transition groove shell 13 of the battery clamping mechanism 12, which is not provided with an extension arm 19, the battery clamping mechanism 12 is integrally positioned at a connecting rod position, and the lower part of the extension arm 19 of the battery clamping mechanism 12 is hinged to the power rod 8 through an extension arm hinge shaft 20 at a hinge point D; when the power rod 8 rotates by 80 degrees anticlockwise, the battery clamping mechanism 12 turns 180 degrees, and the transition groove shell 13 just is in butt joint with the vibration groove notch 17-1 in the vibration separation integrated machine 1;

the crank block part comprises a power cylinder 9 as a block module and a power rod 8; as shown in fig. 1 and 6-11, the power rod 8 is a V-shaped crank, two branches (a main push rod 8-1 and a push arm 8-3) of the V-shaped crank are arranged in unequal length and have a V-shaped included angle greater than 90 degrees (preferably 100 degrees in the embodiment of fig. 10), the two branches of the V-shaped crank are connected with the main push rod 8-1 and the push arm 8-3 through a secondary push rod 8-2, wherein the main push rod 8-1 is arranged perpendicular to the secondary push rod 8-2, and the push arm 8-3 is arranged perpendicular to the secondary push rod 8-2; for balancing the force, two push arms 8-3 are arranged in parallel at intervals; the power rod 8 is hinged on the overturning frame 7 through one branch 8-3 of the two branches (hinged at a hinge point C through a lower suspension fixing arm 22 fixed on the overturning frame 7), the tail end of the branch 8-3 is hinged with the battery clamping mechanism 12 at a hinge point D, and the tail end of the other branch 8-1 of the V-shaped crank is hinged with the free end of the power cylinder 9 at a hinge point B, so that required torque is provided for overturning the battery clamping mechanism 12. The power cylinder 9 is hinged to the tilting frame 7 at a hinge point a by a cylinder fixed hinge support 10.

The air cylinder is fixed between the hinged support 10 (i.e. the hinge point A) and the air cylinder 9, between the air cylinder 9 and the power rod 8, between the power rod 8 and the battery clamping mechanism 12, between the battery clamping mechanism 12 and the rocker 11, and between the rocker 11 and the turnover frame 7 (i.e. the hinge point F corresponding part) all have corresponding bearings to reduce friction between rotating parts.

The method for overturning and feeding the waste lead-acid battery is characterized by comprising the following specific steps of:

firstly, the cut battery jar (comprising acid liquor, an external plastic jar body and an internal cluster) is opened upwards, enters the transition jar shell 13 after being accelerated by the roller conveyor belt 4 and then is stopped by collision, and the clamping air cylinder 16 of the battery clamping mechanism 12 receives a signal to push the rectangular tooth clamping plate 15 to clamp and fix the battery jar from the lower part.

Then, the power cylinder 9 in the turnover power mechanism provides torque for the power rod 8 to realize the turnover of the battery tank, during the turnover process of the battery tank, acid liquor in the battery tank overflows outwards and drips into the arc-shaped acid liquor collecting device 2 (such as an arc-shaped tank in fig. 1) at the lower part of the battery turnover and wire feeding device 3, when the battery clamping mechanism 12 is in butt joint with the vibration tank notch 17-1 in the vibration separation integrated machine 1, most of the acid liquor is separated, only a small amount of acid liquor is attached to the inner wall of the outer plastic shell and adsorbed to the cluster part, and meanwhile, the cut opening of the battery tank is downward, and the transition tank shell 13 is aligned with the vibration separation integrated machine 1, so that the battery tank only remains the outer plastic tank body and the inner cluster part.

Finally, the battery clamping mechanism 12 releases the clamped battery jar, and enters the vibration separation integrated machine 1 under the pushing of the air cylinder 5 of the pushing mechanism to separate the external plastic jar body from the internal clusters.

The overturning power mechanism specifically acts as follows:

the power cylinder 9 performs telescopic movement, so that the power cylinder 9 pushes the power rod 8 to rotate around a hinge point C on the turnover frame 7 at a hinge point B, the power rod 8 drives the battery clamping mechanism 12 serving as a connecting rod to move, the battery clamping mechanism 12 pulls the rocker 11 to turn the transition groove shell 13 at an initial position (shown in fig. 6) before the rocker 11 turns over by 180 degrees, the transition groove shell 13 is turned to be in butt joint with the vibration groove notch 17-1 of the vibration separation integrated machine by being in butt joint with the conveying belt 4 of the cutting machine, and at the moment, the transition groove shell 13 corresponds to a push plate of the pushing mechanism at the same time, so that the push plate can push a battery into the vibration groove 17 of the vibration separation integrated machine (the vibration groove 17 is fixed on the vibration separation frame 18).

The foregoing is merely illustrative of the present invention, and the present invention is not limited thereto, and any changes or substitutions easily contemplated by those skilled in the art within the scope of the present invention should be included in the present invention. Therefore, the protection scope of the present invention should be defined by the claims.

Claims (7)

1. The utility model provides a old and useless lead acid battery upset device of going up for overturn and go up line to old and useless lead acid battery after cutting, its characterized in that mainly includes: the device comprises a turnover frame, a battery clamping mechanism, a turnover power mechanism and a pushing mechanism; the battery clamping mechanism, the turnover power mechanism and the pushing mechanism are arranged below the turnover frame, and the battery clamping mechanism is connected with the turnover power mechanism and realizes turnover under the action of the turnover power mechanism; the battery clamping mechanism is positioned below the pushing mechanism in the initial state, and when the overturning power mechanism overturns to the horizontal height corresponding to the pushing mechanism, the pushing mechanism acts to push out the waste lead-acid batteries clamped in the battery clamping mechanism;

the pushing mechanism comprises a cylinder and a suspension plate, the lateral section of the suspension plate is L-shaped, the vertical end of the L-shape is fixed below the overturning frame, the horizontal end of the L-shape extends out of the space below the overturning frame in a suspending way, the cylinder is horizontally fixed on the horizontal end of the L-shape of the suspension plate, a push plate is arranged at the end of a piston rod of the cylinder, and the push plate is vertically arranged perpendicular to the horizontal end of the L-shape; when the battery clamping mechanism is turned over from the lower part, one end of the battery clamping mechanism corresponds to the pushing plate, and the other end of the battery clamping mechanism corresponds to the vibration separation integrated machine, so that the air cylinder can push out the battery in the battery clamping mechanism into the vibration separation integrated machine through the pushing plate;

the battery clamping mechanism consists of a transition groove shell, a transition roller, a rectangular tooth clamping plate, a clamping cylinder and an extending arm: the transition groove shell is provided with a horizontal upper cover and two vertical parallel opposite side walls, and a rectangular clamping cavity is formed by the transition groove shell and a transition roller arranged on the bottom surface of the transition groove shell; the clamping cylinder is fixed at the bottom of the transition groove shell and pushes the rectangular tooth clamping plate to move upwards to clamp the cut battery in the clamping cavity; the extending arm extends out from one side surface of the transition groove shell in the outward inclined downward direction and keeps a set angle with the vertical direction; in the initial clamping position, the transition roller is in linear butt joint with the roller conveyor belt, and when the battery clamping mechanism just turns over 180 degrees, the transition groove shell is in butt joint with a vibration groove notch and a push plate in the vibration separation integrated machine;

the overturning power mechanism comprises a combination of a double rocker part and a crank block part:

the double-rocker mechanism comprises a turnover frame, a power rod, a rocker and a battery clamping mechanism, wherein the upper end of the rocker is hinged on the turnover frame, the lower end of the rocker is hinged on one side of a transition groove shell of the battery clamping mechanism, which is not provided with an extension arm, the whole battery clamping mechanism is positioned at a connecting rod position, and the lower part of the extension arm of the battery clamping mechanism is hinged with the power rod through a hinge shaft of the extension arm; when the power rod rotates by 80 degrees anticlockwise, the battery clamping mechanism turns over by 180 degrees, and the transition groove shell just is in butt joint with a vibration groove opening in the vibration separation integrated machine;

the crank slide block part comprises a power cylinder as a slide block module and a power rod; the power rod 8 is a V-shaped crank, and two branches of the V-shaped crank are a main push rod and a push arm; the two branches of the V-shaped crank are arranged in unequal length and form a V-shaped included angle larger than 90 degrees, the two branches of the V-shaped crank are connected through an auxiliary push rod, the main push rod is vertically arranged with the auxiliary push rod, and the push arm is vertically arranged with the auxiliary push rod; the power rod is hinged on the overturning frame through one of the two branches, namely the pushing arm, the tail end of the branch is hinged with the battery clamping mechanism, and the other branch of the V-shaped crank, namely the tail end of the main pushing rod is hinged with the free end of the power cylinder; the power cylinder is hinged on the overturning frame through a cylinder fixed hinged support.

2. The waste lead-acid battery overturning and wire-feeding device according to claim 1, wherein: the front end of the waste lead-acid battery overturning and wire feeding device is in linear butt joint with a roller conveyor belt, the cut battery is conveyed in through the roller conveyor belt and put into a battery clamping mechanism, and an acid liquid collecting device is arranged on a running track below the battery clamping mechanism and used for collecting dumped sulfuric acid liquid in the overturning process of the battery; the battery overturning and feeding device is in butt joint with the vibration separation integrated machine, and when the notch of the battery clamping mechanism is in butt joint with the notch of the vibration groove of the vibration separation integrated machine, the pushing mechanism acts to push the battery groove of the battery clamping mechanism after pouring liquid into the vibration separation integrated machine for subsequent separation vibration.

3. The waste lead-acid battery overturning and wire-feeding device according to claim 1, wherein: the rectangular tooth clamping plate comprises a plurality of rectangular teeth which are arranged in parallel at intervals, and the rectangular teeth are fixed on the clamping cylinder through a bottom plate; the rectangular tooth clamping plate is fixed on the clamping cylinder, is placed below the transition roller in the transition groove shell, and is arranged to clamp or retract the cut battery back to the initial state in the gap of the transition roller along with the action of the clamping cylinder.

4. The waste lead-acid battery overturning and wire-feeding device according to claim 1, wherein: two pushing arms are arranged in parallel at intervals.

5. The turnover online device for waste lead-acid batteries according to claim 4, wherein: the power rod is hinged on the lower suspension fixing arm through one of the two branches, namely the pushing arm, and the lower suspension fixing arm is suspended and fixed on the overturning frame.

6. The turnover online device for waste lead-acid batteries according to claim 5, wherein: the corresponding bearings are arranged between the power cylinder and the power rod, between the power rod and the connecting rod, between the connecting rod and the rocker, and between the rocker and the base support part so as to reduce friction between rotating parts.

7. A method for overturning and feeding a battery by adopting the waste lead-acid battery overturning and feeding device as claimed in any one of claims 1 to 6, which is characterized by comprising the following specific steps:

firstly, a battery groove enters a transition groove shell after being accelerated by a roller conveyor belt and then collides and stops, a clamping cylinder receives a signal to push a rectangular tooth clamping plate to clamp and fix the battery groove from the lower part;

then, a power cylinder in the overturning power mechanism provides torque for the power rod to realize overturning of the battery groove; in the overturning process of the battery tank, acid liquor in the battery tank overflows outwards and drops into an arc acid liquor collecting device at the lower part of the overturning power mechanism, when the battery overturning power mechanism is in butt joint with a vibrating tank notch in the vibrating and separating integrated machine, most of acid liquor in the battery overturning power mechanism is separated, only a small amount of acid liquor is attached to the inner wall of the shell and adsorbed on the cluster part, and meanwhile, the cut opening of the battery tank is downward, and only an external plastic tank body and an internal cluster part of the battery tank are left;

and finally, the battery clamping mechanism loosens the clamped battery groove, and the battery groove enters the vibration separating mechanism to separate the plastic groove body from the cluster group under the pushing of the air cylinder.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711054523.4A CN107706479B (en) | 2017-11-01 | 2017-11-01 | Turnover online device and method for waste lead-acid batteries |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711054523.4A CN107706479B (en) | 2017-11-01 | 2017-11-01 | Turnover online device and method for waste lead-acid batteries |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107706479A CN107706479A (en) | 2018-02-16 |

| CN107706479B true CN107706479B (en) | 2023-06-16 |

Family

ID=61177418

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711054523.4A Active CN107706479B (en) | 2017-11-01 | 2017-11-01 | Turnover online device and method for waste lead-acid batteries |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN107706479B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108539313B (en) * | 2018-05-18 | 2021-02-05 | 瑞安市智造科技有限公司 | Waste lead-acid battery separating and collecting device |

| CN108461766B (en) * | 2018-06-28 | 2024-04-05 | 惠州华科技术研究院有限公司 | Battery overturning core-closing device |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009178651A (en) * | 2008-01-30 | 2009-08-13 | Kanichi Tamura | Waste battery treating vibration apparatus, waste battery treating system using it and waste battery treating method |

| CN103515667A (en) * | 2013-08-23 | 2014-01-15 | 浙江晨龙锯床股份有限公司 | Production line for sawing, sorting, and recycling waste storage batteries |

| CN105261804A (en) * | 2015-11-20 | 2016-01-20 | 贵州岑祥资源科技有限责任公司 | Spent lead-acid storage battery separating and collecting device and method |

| CN105304968A (en) * | 2015-11-20 | 2016-02-03 | 贵州岑祥资源科技有限责任公司 | C-shape overturn and crank rocker vibration separator and method thereof |

| CN105304970A (en) * | 2015-11-20 | 2016-02-03 | 襄阳远锐资源工程技术有限公司 | Method and device for using four-separation head gap mechanism for processing waste and old lead-acid batteries |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009526649A (en) * | 2006-02-13 | 2009-07-23 | ハルキー − ロバーツ コーポレイション | Apparatus and method for using tetrazine-based energy materials |

-

2017

- 2017-11-01 CN CN201711054523.4A patent/CN107706479B/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009178651A (en) * | 2008-01-30 | 2009-08-13 | Kanichi Tamura | Waste battery treating vibration apparatus, waste battery treating system using it and waste battery treating method |

| CN103515667A (en) * | 2013-08-23 | 2014-01-15 | 浙江晨龙锯床股份有限公司 | Production line for sawing, sorting, and recycling waste storage batteries |

| CN105261804A (en) * | 2015-11-20 | 2016-01-20 | 贵州岑祥资源科技有限责任公司 | Spent lead-acid storage battery separating and collecting device and method |

| CN105304968A (en) * | 2015-11-20 | 2016-02-03 | 贵州岑祥资源科技有限责任公司 | C-shape overturn and crank rocker vibration separator and method thereof |

| CN105304970A (en) * | 2015-11-20 | 2016-02-03 | 襄阳远锐资源工程技术有限公司 | Method and device for using four-separation head gap mechanism for processing waste and old lead-acid batteries |

Also Published As

| Publication number | Publication date |

|---|---|

| CN107706479A (en) | 2018-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107706479B (en) | Turnover online device and method for waste lead-acid batteries | |

| CN103447615A (en) | Band sawing machine for cutting waste lead-acid storage batteries | |

| CN105304970A (en) | Method and device for using four-separation head gap mechanism for processing waste and old lead-acid batteries | |

| CN209530972U (en) | One kind scrapping controller for electric vehicle reclaimer | |

| CN2930897Y (en) | Horizontal shell breaking machine for waste batteries | |

| CN203119053U (en) | Device allowing 12AH storage battery plate groups to enter turnover boxes | |

| CN205025951U (en) | Connection structure of breaker home roll axle and power drive axle | |

| CN204675406U (en) | Full automaticity melting charger | |

| CN207441909U (en) | A kind of waste lead acid battery overturns eedle threader | |

| CN204449474U (en) | A kind of lead direct-forming device | |

| CN207615740U (en) | A kind of aluminium flake cutter | |

| CN206511466U (en) | A kind of new type carting station | |

| CN213304220U (en) | Lead plaster recycling device for lead-acid battery | |

| CN109830771A (en) | A kind of junked-auto battery dismantling machine | |

| CN211246927U (en) | Hydrodynamic scraper | |

| CN208627504U (en) | A kind of environmental protection machinery process equipment being crushed for solid waste | |

| CN204741046U (en) | Novel waste battery's recovery processing device | |

| CN208234164U (en) | Transport device is used in a kind of processing of health care product | |

| CN210058375U (en) | Concrete raw material preprocessing device | |

| CN208262224U (en) | A kind of linkage press-loading device | |

| CN210846512U (en) | High strength glass retrieves reducing mechanism | |

| CN209401794U (en) | A kind of junked-auto battery dismantling machine | |

| CN216093909U (en) | Crushing equipment for scrap iron regeneration | |

| CN108504869B (en) | Fine disassembling device for busbar of lead-acid storage battery | |

| CN206653424U (en) | A kind of SMT material strips automatic belt cutting machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |