CN107062026B - Compound total reflection LED shot-light lens - Google Patents

Compound total reflection LED shot-light lens Download PDFInfo

- Publication number

- CN107062026B CN107062026B CN201710203537.1A CN201710203537A CN107062026B CN 107062026 B CN107062026 B CN 107062026B CN 201710203537 A CN201710203537 A CN 201710203537A CN 107062026 B CN107062026 B CN 107062026B

- Authority

- CN

- China

- Prior art keywords

- total reflection

- light

- refraction

- light incident

- lens

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V5/00—Refractors for light sources

- F21V5/04—Refractors for light sources of lens shape

- F21V5/046—Refractors for light sources of lens shape the lens having a rotationally symmetrical shape about an axis for transmitting light in a direction mainly perpendicular to this axis, e.g. ring or annular lens with light source disposed inside the ring

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

Abstract

The invention discloses a composite total reflection LED spotlight lens which comprises a refraction convex lens structure, a refraction-total reflection-refraction structure and a refraction-total reflection-refraction structure, wherein the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure are arranged around the refraction convex lens structure in a centrosymmetric manner; the convex lens structure comprises a first light incident surface and a first light emitting surface, the refraction-total reflection-refraction structure comprises a second light incident surface, a first total reflection surface and a second light emitting surface, and the refraction-total reflection-refraction structure comprises the second light incident surface, the second total reflection surface and the second light emitting surface. The invention has small integral size, light weight and high optical utilization rate.

Description

Technical Field

The invention belongs to the technical field of LED spotlight lenses, and particularly relates to a composite total reflection LED spotlight lens.

Background

The application of the lighting lamp light comprises ambient lighting and key lighting, the ambient lighting provides basic illumination required by vision, and the key lighting improves the illumination of key areas through light condensation design and is used for highlighting key display articles. The light-gathering design mainly adjusts the large-angle light beam of the light-emitting source into a small-angle light beam, and the light-gathering design mainly comprises two schemes, namely an optical reflector and an optical lens.

For example, CN201510081535.0 discloses a design method of a double-free-form-surface LED collimating lens, which realizes refraction and light condensation of a convex lens through the change of curvatures of an inner surface (light incident surface) and an outer surface (light emergent surface). CN201210550997.9 discloses a design method of an LED collimating lens, which realizes the design of light gathering by the cooperation of three curved surfaces, namely an inner surface (light incident surface), a total internal reflection surface of the lens, and a light emergent surface. CN01805486.2 discloses another condenser lens structure, which divides a light beam of a light source into two parts, wherein one part realizes light condensation through a biconvex lens structure in the middle part, and the other part enters light through a curved surface of an inner side wall, and emits light from an annular plane on the upper surface of the lens after total internal reflection of the outer side wall. CN201110128186.5 discloses a compact non-imaging LED collimation system, wherein a light beam of a light source is divided into two parts, one part emits light through a middle refraction structure, the other part refracts to an annular position on the upper surface of a lens through a light incident surface to generate a first total internal reflection, and the other part reflects to the lower surface of the lens to generate a second reflection, and emits the light from the annular position on the upper surface after changing the direction.

In the above multiple design schemes of the condenser lens, in order to realize the small-angle (50% beam angle is less than 15 degrees) condenser design, CN201510081535.0 only depends on the refraction scheme, the size of the lens is large, the weight is also large, and the optical efficiency is low; CN201210550997.9 and CN01805486.2 adopt a refraction scheme and a one-time total internal reflection scheme, and under the same size, the optical efficiency is improved compared with a simple refraction scheme; CN201110128186.5 and CN201610073520.4 achieve reduction of the height of the lens size, but most (70%) of the light beams emit light after three internal reflections, resulting in low optical efficiency, and meanwhile, since the LED light source has a certain size, a small portion of the light emitted from different positions of the LED does not exit from an ideal light path according to the design, and becomes invalid light, and also causes the bad phenomena of stray light and glare.

Therefore, the lens to be designed for realizing small-angle light condensation is further improved, so that the lens is small in size, light in weight and high in optical efficiency, and the phenomena of stray light and glare are effectively avoided.

Disclosure of Invention

The invention aims to overcome the defects of the prior art and provides the composite total reflection LED spotlight lens which is small in size, light in weight, high in optical efficiency and capable of effectively avoiding the phenomena of stray light and glare.

The technical scheme of the invention is realized as follows: a composite total reflection LED spotlight lens comprises a refraction convex lens structure, a refraction-total reflection-refraction structure and a refraction-total reflection-refraction structure, wherein the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure are arranged around the refraction convex lens structure in a central symmetry manner;

the convex lens structure comprises a first light incident surface and a first light emergent surface, the refraction-total reflection-refraction structure comprises a second light incident surface, a first total reflection surface and a second light emergent surface, and the refraction-total reflection-refraction structure comprises a second light incident surface, a second total reflection surface and a second light emergent surface;

the second light incident surface comprises a plane part and a curved surface part connected with the plane part, the curved surface part is connected with the first light incident surface, and the plane part is connected with the first total reflection surface; the first total reflection surface is connected with the second total reflection surface, prismatic protrusions are uniformly arranged on the outer surface of the second total reflection surface, and ridge lines of the prismatic protrusions are curves; the first light-emitting surface and the second light-emitting surface are positioned on the same plane, and the first light-emitting surface is positioned in the center of the first light-emitting surface;

incident light with an included angle of more than or equal to 0 degree and less than or equal to 35 degrees with the central axis of the first light incident surface is refracted by the first light incident surface and then refracted by the first light emergent surface to be emitted;

incident light with an included angle of more than 35 degrees and less than 52 degrees with the central axis of the first light incident surface directly enters from the curved surface part of the second light incident surface, is refracted by the second light incident surface, is refracted to the second light emitting surface to generate first total reflection at the second light emitting surface, is directly reflected to the second total reflection surface to generate second and third total reflections through the prismatic protrusions of the second total reflection, and is finally refracted and emitted from the second light emitting surface;

incident light rays with an included angle of more than or equal to 52 degrees and less than or equal to 80 degrees with the central axis of the first light incident surface are incident from the plane part of the second light incident surface and are refracted, and then are reflected to the first total reflection surface for the first time and are refracted and emitted through the second light emitting surface; in the light irradiation process, the light energy distribution proportion of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure is 36 +/-5%: 34 +/-5%: 30. 5 percent.

Preferably, the first incident light surface is a convex structure formed by facet sheets.

Preferably, the first total reflection surface is a total internal reflection surface and is in a sectional curved surface shape formed by patch sheets.

Preferably, the first light emitting surface is a plane, and a micro-bump array is arranged on the surface of the first light emitting surface.

Preferably, the second light-emitting surface is a plane mirror surface.

Preferably, the light energy distribution proportion of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure is 36%:34%:30 percent.

The first light emitting surface and the second light emitting surface form a circular bottom surface, the diameter of the circular bottom surface is 40.40 +/-1 mm, the height of the whole lens is 11.43 +/-1 mm, the distance from the highest point of the first light incident surface to the circular bottom surface is 5.12 +/-0.5 mm, and the diameter of the first light incident surface is 10.40 +/-0.5 mm; the second light incident surface, the first total reflection surface and the second total reflection surface are arranged around a circle formed by the first light incident surface in a central symmetry mode, the width from the second light incident surface to the first total reflection surface is 6.21 +/-0.05 mm, and the width from the second total reflection surface to the edge is 9.30 +/-0.05 mm.

The invention has the beneficial effects that: the invention adopts a structure comprising a refraction convex lens, a refraction-total reflection-refraction structure and a refraction-total reflection-refraction structure, light rays are totally reflected in the whole lens for multiple times, so that the optical utilization rate is greatly improved, and meanwhile, the second light incident surface in the refraction-total reflection-refraction structure consists of a plane part and a curved surface part, and the design of the curved surface part improves the optical utilization rate; the second total reflection surface of the refraction-total reflection-refraction structure is uniformly provided with prismatic protrusions, ridge lines of the prismatic protrusions are curves, the prismatic protrusion structure has the advantage of ultrathin short focus, the total amount of all incident light passing through the prismatic protrusion structure is less than 40%, and the integral optical efficiency of the lens is guaranteed to be higher than 80%; the invention has small integral size, light weight and high optical utilization rate.

Drawings

Fig. 1 is a schematic view (bottom view) of an embodiment of an overall structure of a composite total reflection LED reflector lens according to the present invention.

Fig. 2 is a sectional view taken along the H-H plane in fig. 1.

Fig. 3 is a schematic view of an overall structure of a composite total reflection LED spotlight lens according to an embodiment of the invention.

Fig. 4 is a schematic overall structure diagram (top view) of an embodiment of a composite total reflection LED reflector lens according to the present invention.

Fig. 5 is a schematic view (side view) of an overall structure of an embodiment of a composite total reflection LED reflector lens of the present invention.

Fig. 6 is a partially enlarged view of a portion B in fig. 5.

Fig. 7 is a partially enlarged view of portion E of fig. 5.

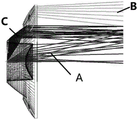

Fig. 8 is a diagram of paths of all incident light rays in a first embodiment of a composite total reflection LED reflector lens according to the present invention.

Fig. 9 is a diagram of a light path of a part of incident light in a composite total reflection LED reflector lens according to an embodiment of the present invention (the included angle between the central axis of the first light incident surface and the incident light is greater than or equal to 0 degrees and less than or equal to 35 degrees).

Fig. 10 is a partial incident light path diagram (an angle between the central axis of the first light incident surface and the incident light beam is greater than 35 degrees and less than 52 degrees) of an embodiment of a composite total reflection LED reflector lens according to the present invention.

Fig. 11 is a partial incident light path diagram (an angle between the central axis of the first light incident surface and the incident light beam is greater than or equal to 52 degrees and less than or equal to 80 degrees) of an embodiment of a composite total reflection LED spotlight lens according to the invention.

FIG. 12 is an optical effect diagram of the composite total reflection LED spotlight lens assembled on an LED light source.

FIG. 13 is a light distribution curve diagram of a composite total reflection LED spotlight lens assembled on an LED light source.

Fig. 14 is a schematic view (cross-sectional view) of an overall structure of a second embodiment of a composite total reflection LED reflector lens according to the present invention.

Fig. 15 is a schematic view (cross-sectional view) of the overall structure of a third embodiment of the composite total reflection LED reflector lens of the present invention.

Reference numbers corresponding to the names of the respective components: the light source comprises a first light incident surface-1, a second light incident surface-2, a plane part-21, a curved surface part-22, a first total reflection surface-3, a second total reflection surface-4, a second light emitting surface-5 and a first light emitting surface-6.

Detailed Description

The following further describes embodiments of the present invention with reference to the accompanying drawings:

example one

As shown in fig. 1-7, a compound total reflection LED spotlight lens includes a refraction convex lens structure, a refraction-total reflection-refraction structure, and a refraction-total reflection-refraction structure, both of which are disposed in central symmetry around the refraction convex lens structure;

the convex lens structure comprises a first light incident surface 1 and a first light emergent surface 6, the refraction-total reflection-refraction structure comprises a second light incident surface 2, a first total reflection surface 3 and a second light emergent surface 5, and the refraction-total reflection-refraction structure comprises the second light incident surface 2, a second total reflection surface 4 and the second light emergent surface 5;

the second light incident surface 2 comprises a plane part 21 and a curved surface part 22 connected with the plane part, the plane part is connected with the first total reflection surface, and the curved surface 22 is connected with the first light incident surface 1, so that the curved surface design of the curved surface part can effectively improve the optical utilization rate, and the optical efficiency is improved by 5%; the second total reflection surface 4 is connected with the first total reflection surface 3, the outer surface of the second total reflection surface 4 is uniformly provided with prismatic protrusions, ridge lines of the prismatic protrusions are curves, and the curve radius range of the ridge lines is as follows: the curvature radius is 6mm to 1000mm, in this embodiment, the curvature radius is 10mm, according to the curvature change of the ridge line, the light can produce different light distribution angles, and the light distribution angle produced in this embodiment is 24 degrees. In addition, the design of the prismatic protrusion structure has the advantage of ultrathin short focus, the total quantity of all incident light passing through the prismatic protrusion structure is less than 40%, and the integral optical efficiency of the lens is ensured to be higher than 80%. The first light-emitting surface 6 and the second light-emitting surface 5 are positioned on the same plane, and the first light-emitting surface is positioned in the center of the first light-emitting surface;

specifically, the first light incident surface 1 is a convex structure formed by patches. The first total reflection surface 3 is a total internal reflection surface and is in a sectional curved surface shape formed by surface patches, and the sectional curved surface shape has a light condensation effect. The first light emitting surface 6 is a plane, and a micro-convex point array is arranged on the surface of the first light emitting surface. The second light-emitting surface is a plane mirror surface.

The lens product has the characteristic of small size, and the specific size is as follows: the first light emitting surface 6 and the second light emitting surface 5 form a circular bottom surface, the diameter of the circular bottom surface is 40.40 +/-1 mm, the height of the whole lens is 11.43 +/-1 mm, the distance from the highest point of the first light incident surface 1 to the circular bottom surface is 5.12 +/-0.5 mm, and the diameter of the first light incident surface 1 is 10.40 +/-0.5 mm; the second light incident surface 2, the first total reflection surface 3 and the second total reflection surface 4 are arranged around a circle formed by the first light incident surface 1 in a centrosymmetric manner, the width from the second light incident surface 2 to the first total reflection surface 3 is 6.21 +/-0.05 mm, and the width from the second total reflection surface 4 to the edge is 9.30 +/-0.05 mm.

As shown in fig. 8 and 9, incident light, which forms an included angle with the central axis of the first light incident surface 1 of 0 degree or more and 35 degrees or less (a part of light rays in fig. 8), is refracted by the first light incident surface 1 and then refracted by the first light emitting surface 6 to be emitted;

as shown in fig. 8 and 10, the incident light (part B of light in fig. 8) having an included angle of more than 35 degrees and less than 52 degrees with the central axis of the first light incident surface 1 directly enters from the curved surface portion 22 of the second light incident surface 2, is refracted by the second light incident surface 2, is refracted to the second light emitting surface 5 to generate a first total reflection at the second light emitting surface 5, is directly reflected into the second total reflection surface 4 to generate a second total reflection and a third total reflection through the prismatic protrusions of the second total reflection surface 4, and is finally refracted and emitted from the second light emitting surface 5;

as shown in fig. 8 and 11, the incident light (part C of light in fig. 8) having an included angle of 52 degrees or more and 80 degrees or less with the central axis of the first light incident surface 1 directly enters from the plane portion 21 of the second light incident surface 2 and is refracted, and the first total reflection surface 3 generates a first total reflection, and is refracted and emitted through the second light emitting surface 5;

in the light irradiation process, the light energy distribution proportion of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure is 36 +/-5%: 34 +/-5%: 30 plus or minus 5 percent.

In this embodiment, the light energy distribution ratio of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure, and the refraction-total reflection-refraction structure is 36%:34%:30 percent.

After the LED light source is assembled above an LED light source, wherein the LED light source adopts a 5mmx5 mm-sized patch lamp bead, the lens is assembled with the size of 43mm and the assembly height of 12mm, the realized optical effect is shown in figure 12, and the illumination distribution diagram is uniform in gradual change of illumination and free of stray light spots at the position of 1 meter.

As shown in fig. 12, in the light distribution graph, the 50% luminous intensity angle is 13.4 degrees, and the central luminous intensity value: the lumen value was 13.6.

The size of the lens product is adjusted according to the size of the light source and the specific assembly structure, different fixing devices are adopted for installation, and the width size of the whole installation device is different.

Example two

As shown in fig. 14, the present embodiment is different from the first embodiment in that the curved radius range of the ridge line is 1000mm, and the generated light distribution angle is 12 degrees.

EXAMPLE III

As shown in fig. 15, the difference between the present embodiment and the first and second embodiments is that the curved radius of the ridge line is 5mm, and the generated light distribution angle is 36 degrees.

Variations and modifications to the above-described embodiments may occur to those skilled in the art based upon the disclosure and teachings of the above specification. Therefore, the present invention is not limited to the specific embodiments disclosed and described above, and some modifications and variations of the present invention should fall within the scope of the claims of the present invention. Furthermore, although specific terms are employed herein, they are used in a generic and descriptive sense only and not for purposes of limitation.

Claims (7)

1. A compound total reflection LED spotlight lens is characterized by comprising a refraction convex lens structure, a refraction-total reflection-refraction structure and a refraction-total reflection-refraction structure, wherein the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure are arranged around the refraction convex lens structure in a central symmetry manner;

the refraction-total reflection-refraction structure comprises a second light incident surface, a second total reflection surface and a second light emitting surface;

the second light incident surface comprises a plane part and a curved surface part connected with the plane part, the curved surface part is connected with the first light incident surface, and the plane part is connected with the first total reflection surface; the first total reflection surface is connected with the second total reflection surface, prismatic protrusions are uniformly arranged on the outer surface of the second total reflection surface, ridge lines of the prismatic protrusions are curves, and the curvature radius range of the ridge lines is as follows: 5mm to 1000mm; the first light-emitting surface and the second light-emitting surface are positioned on the same plane, and the first light-emitting surface is positioned in the center of the first light-emitting surface;

incident light with an included angle of more than or equal to 0 degree and less than or equal to 35 degrees with the central axis of the first light incident surface is refracted by the first light incident surface and then refracted by the first light emergent surface to be emitted;

incident light with an included angle of more than 35 degrees and less than 52 degrees with the central axis of the first light incident surface directly enters from the curved surface part of the second light incident surface, is refracted by the curved surface part of the second light incident surface, is refracted to the second light emitting surface to generate first total reflection at the second light emitting surface, is directly reflected to the second total reflection surface to generate second and third total reflections through the prismatic protrusions of the second total reflection, and is finally refracted and emitted from the second light emitting surface;

incident light rays with an included angle of more than or equal to 52 degrees and less than or equal to 80 degrees with the central axis of the first light incident surface enter from the plane part of the second light incident surface and are refracted, and then the incident light rays are reflected to the first total reflection surface for the first time and are refracted and emitted through the second light emitting surface; in the light irradiation process, the light energy distribution proportion of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure is 36 +/-5%: 34 +/-5%: 30 plus or minus 5 percent.

2. The compound total reflection LED spot lens of claim 1, wherein the first light incident surface has a convex structure formed by a surface sheet.

3. The compound total reflection LED reflector lens of claim 1, wherein said first total reflection surface is a total internal reflection surface in a shape of a piecewise curved surface composed of facets.

4. The lens of claim 1, wherein the first light-emitting surface is a plane surface with an array of micro-bumps disposed thereon.

5. The compound total reflection LED spotlight lens according to claim 1, wherein the second exit surface is a planar mirror surface.

6. The compound total reflection LED reflector lens of claim 1, wherein the light energy distribution ratio of the light source beam in the refraction convex lens structure, the refraction-total reflection-refraction structure and the refraction-total reflection-refraction structure is 36%:34%:30 percent.

7. The lens of claim 1, wherein the first light emitting surface and the second light emitting surface form a circular bottom surface, the diameter of the circular bottom surface is 40.40 ± 1mm, the height of the entire lens is 11.43 ± 1mm, the distance from the highest point of the first light incident surface to the circular bottom surface is 5.12 ± 0.5mm, and the diameter of the first light incident surface is 10.40 ± 0.5mm; the second light incident surface, the first total reflection surface and the second total reflection surface are arranged around a circle formed by the first light incident surface in a central symmetry mode, the width from the second light incident surface to the first total reflection surface is 6.21 +/-0.05 mm, and the width from the second total reflection surface to the edge is 9.30 +/-0.05 mm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710203537.1A CN107062026B (en) | 2017-03-30 | 2017-03-30 | Compound total reflection LED shot-light lens |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710203537.1A CN107062026B (en) | 2017-03-30 | 2017-03-30 | Compound total reflection LED shot-light lens |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107062026A CN107062026A (en) | 2017-08-18 |

| CN107062026B true CN107062026B (en) | 2022-12-27 |

Family

ID=59602366

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201710203537.1A Active CN107062026B (en) | 2017-03-30 | 2017-03-30 | Compound total reflection LED shot-light lens |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN107062026B (en) |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01130578A (en) * | 1987-11-17 | 1989-05-23 | Iwasaki Electric Co Ltd | Light emitting diode |

| JP3729012B2 (en) * | 2000-02-24 | 2005-12-21 | 松下電工株式会社 | LED module |

| US6896381B2 (en) * | 2002-10-11 | 2005-05-24 | Light Prescriptions Innovators, Llc | Compact folded-optics illumination lens |

| US8016451B2 (en) * | 2007-10-26 | 2011-09-13 | Fraen Corporation | Variable spot size lenses and lighting systems |

| JP5228217B1 (en) * | 2012-06-19 | 2013-07-03 | 鈴木 優一 | Lens, illumination device, light receiving device, and optical device |

| CN102748712B (en) * | 2012-07-13 | 2014-04-16 | 惠州元晖光电股份有限公司 | Optical lens and mining cap lamp |

| CN207080826U (en) * | 2017-03-30 | 2018-03-09 | 佛山指南针光学科技有限公司 | A kind of compound total reflection LED spotlight lens |

-

2017

- 2017-03-30 CN CN201710203537.1A patent/CN107062026B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN107062026A (en) | 2017-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20140321116A1 (en) | LED Device for Wide Beam Generation and Method of Making the Same | |

| CN100399061C (en) | Fresnel lens and lighting apparatus provided with the fresnel lens | |

| US20110141734A1 (en) | Lens generating a batwing-shaped beam distribution, and method therefor | |

| US20110292670A1 (en) | Vehicular lamp | |

| EP3273144B1 (en) | Led spotlight | |

| CN102654268A (en) | LED (Light-Emitting Diode) lens device, LED lens device module and LED lamp device | |

| TW201344248A (en) | Lens and light source module | |

| US20130083541A1 (en) | Optical lens, light-emitting diode optical component and light-emitting diode illumination lamp | |

| KR101189652B1 (en) | LED array type for the lighting lens and the lens using the same | |

| EP2034237B1 (en) | Energy-saving lampshade with even light distribution | |

| US10738969B2 (en) | Light-emitting structure and light-emitting system with the same | |

| US20200011511A1 (en) | Zoom lamp lens group | |

| CN215954056U (en) | Combined light source collector | |

| JP2013012440A (en) | Optical element for lighting device, and lighting device | |

| TWI452231B (en) | A lighting device withGPP brightening film | |

| CN105156990B (en) | LED street lamp lens unit, LED street lamp lens module and street lamp with LED street lamp lens module | |

| CN107062026B (en) | Compound total reflection LED shot-light lens | |

| CN114440142B (en) | LED optical system for forming special-shaped outline light spots based on micro-lens array | |

| CN203363991U (en) | LED (light-emitting diode) secondary optical lens | |

| CN214948814U (en) | Airport taxiway lamp | |

| JP2015118818A (en) | Lighting appliance | |

| KR101464277B1 (en) | Tilt type Compound Refractive Lens for Lighting Unit and Street Light Apparatus Comprising the same | |

| CN113701065A (en) | Combined light source collector and design method thereof | |

| CN107062156B (en) | Wash pinup lens, have this light emitting module who washes pinup lens and wash pinup | |

| CN217482671U (en) | Optical lens and lighting device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |