CN1048919C - Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction - Google Patents

Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction Download PDFInfo

- Publication number

- CN1048919C CN1048919C CN95116599A CN95116599A CN1048919C CN 1048919 C CN1048919 C CN 1048919C CN 95116599 A CN95116599 A CN 95116599A CN 95116599 A CN95116599 A CN 95116599A CN 1048919 C CN1048919 C CN 1048919C

- Authority

- CN

- China

- Prior art keywords

- catalyst

- reaction

- clorox

- strong oxidizer

- acetylene

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000003054 catalyst Substances 0.000 title claims abstract description 51

- 238000006243 chemical reaction Methods 0.000 title claims abstract description 34

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 title abstract description 53

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 title abstract description 17

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 title abstract description 17

- 238000011069 regeneration method Methods 0.000 title abstract description 6

- 239000002002 slurry Substances 0.000 title abstract description 6

- 230000002194 synthesizing effect Effects 0.000 title abstract description 3

- DLDJFQGPPSQZKI-UHFFFAOYSA-N but-2-yne-1,4-diol Chemical compound OCC#CCO DLDJFQGPPSQZKI-UHFFFAOYSA-N 0.000 title abstract 2

- 239000007800 oxidant agent Substances 0.000 claims abstract description 16

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 10

- 238000001035 drying Methods 0.000 claims abstract description 4

- 239000007791 liquid phase Substances 0.000 claims abstract description 4

- 238000000034 method Methods 0.000 claims description 30

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 27

- 239000010949 copper Substances 0.000 claims description 27

- 229910052802 copper Inorganic materials 0.000 claims description 27

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 claims description 18

- 229910052797 bismuth Inorganic materials 0.000 claims description 12

- JCXGWMGPZLAOME-UHFFFAOYSA-N bismuth atom Chemical compound [Bi] JCXGWMGPZLAOME-UHFFFAOYSA-N 0.000 claims description 12

- SUKJFIGYRHOWBL-UHFFFAOYSA-N sodium hypochlorite Chemical compound [Na+].Cl[O-] SUKJFIGYRHOWBL-UHFFFAOYSA-N 0.000 claims description 9

- 238000009418 renovation Methods 0.000 claims description 7

- 239000007787 solid Substances 0.000 claims description 7

- 230000035484 reaction time Effects 0.000 claims description 5

- 239000007864 aqueous solution Substances 0.000 claims description 4

- 239000000203 mixture Substances 0.000 claims description 3

- 239000007788 liquid Substances 0.000 claims description 2

- 230000001172 regenerating effect Effects 0.000 claims description 2

- 238000000926 separation method Methods 0.000 claims description 2

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims 3

- 229910052801 chlorine Inorganic materials 0.000 claims 3

- 239000000460 chlorine Substances 0.000 claims 3

- 230000001590 oxidative effect Effects 0.000 abstract description 5

- 239000002699 waste material Substances 0.000 abstract description 2

- 150000001345 alkine derivatives Chemical class 0.000 description 11

- QPLDLSVMHZLSFG-UHFFFAOYSA-N Copper oxide Chemical compound [Cu]=O QPLDLSVMHZLSFG-UHFFFAOYSA-N 0.000 description 8

- 239000000243 solution Substances 0.000 description 8

- 239000002253 acid Substances 0.000 description 7

- -1 alkynes copper complex Chemical class 0.000 description 6

- 230000003197 catalytic effect Effects 0.000 description 5

- 238000005516 engineering process Methods 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 229960004643 cupric oxide Drugs 0.000 description 4

- WQYVRQLZKVEZGA-UHFFFAOYSA-N hypochlorite Chemical compound Cl[O-] WQYVRQLZKVEZGA-UHFFFAOYSA-N 0.000 description 4

- 230000008929 regeneration Effects 0.000 description 4

- 239000005749 Copper compound Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- VLTRZXGMWDSKGL-UHFFFAOYSA-N perchloric acid Chemical compound OCl(=O)(=O)=O VLTRZXGMWDSKGL-UHFFFAOYSA-N 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- 238000011084 recovery Methods 0.000 description 3

- XTEGARKTQYYJKE-UHFFFAOYSA-M Chlorate Chemical compound [O-]Cl(=O)=O XTEGARKTQYYJKE-UHFFFAOYSA-M 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 238000013019 agitation Methods 0.000 description 2

- 229910000416 bismuth oxide Inorganic materials 0.000 description 2

- TYIXMATWDRGMPF-UHFFFAOYSA-N dibismuth;oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[Bi+3].[Bi+3] TYIXMATWDRGMPF-UHFFFAOYSA-N 0.000 description 2

- 239000012535 impurity Substances 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 159000000000 sodium salts Chemical class 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 229930040373 Paraformaldehyde Natural products 0.000 description 1

- 238000003723 Smelting Methods 0.000 description 1

- QAAXRTPGRLVPFH-UHFFFAOYSA-N [Bi].[Cu] Chemical compound [Bi].[Cu] QAAXRTPGRLVPFH-UHFFFAOYSA-N 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 238000001354 calcination Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- XTEGARKTQYYJKE-UHFFFAOYSA-N chloric acid Chemical compound OCl(=O)=O XTEGARKTQYYJKE-UHFFFAOYSA-N 0.000 description 1

- 229940005991 chloric acid Drugs 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 150000004699 copper complex Chemical class 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- QWPPOHNGKGFGJK-UHFFFAOYSA-N hypochlorous acid Chemical compound ClO QWPPOHNGKGFGJK-UHFFFAOYSA-N 0.000 description 1

- 230000002779 inactivation Effects 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- VMGAPWLDMVPYIA-HIDZBRGKSA-N n'-amino-n-iminomethanimidamide Chemical compound N\N=C\N=N VMGAPWLDMVPYIA-HIDZBRGKSA-N 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 238000005839 oxidative dehydrogenation reaction Methods 0.000 description 1

- 229920002866 paraformaldehyde Polymers 0.000 description 1

- VLTRZXGMWDSKGL-UHFFFAOYSA-M perchlorate Inorganic materials [O-]Cl(=O)(=O)=O VLTRZXGMWDSKGL-UHFFFAOYSA-M 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000011027 product recovery Methods 0.000 description 1

- BOLDJAUMGUJJKM-LSDHHAIUSA-N renifolin D Natural products CC(=C)[C@@H]1Cc2c(O)c(O)ccc2[C@H]1CC(=O)c3ccc(O)cc3O BOLDJAUMGUJJKM-LSDHHAIUSA-N 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- 239000011949 solid catalyst Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Landscapes

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Catalysts (AREA)

Abstract

The invention relates to a regeneration method of a catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in a slurry bed reaction, which comprises the steps of carrying out oxidation reaction on a waste catalyst and a strong oxidant in a liquid phase, and then separating and drying to obtain the regenerated catalyst.

Description

The present invention relates to a kind of renovation process of catalyst, more particularly, relate to a kind of slurry-bed reaction that is used for and synthesize 1 by formaldehyde and acetylene, the 4-butynediols renovation process of catalyst.

Utilize formaldehyde and acetylene to synthesize 1, the 4-butynediols can adopt technologies such as Reppe method trickle bed, suspension bed and slurry bed.Advantages such as synthesising reacting speed is fast, pressure is low because slurry bed technology has, handling safety, catalyst replacing convenience have become at present and have synthesized 1, one of main method of 4-butynediols.

The slurry bed method synthesizes 1, and the 4-butynediols uses the copper bismuth catalyst mostly.Main component cupric oxide in this type of catalyst, generate the alkynes copper complex with formaldehyde and acetylene reaction, PARA FORMALDEHYDE PRILLS(91,95) and acetylene synthesize 1, and the 4-butynediols plays catalytic action, and the main effect of bismuth oxide component wherein then is the acetylene polymerization side reaction that produces in the inhibitory reaction process.Owing to be subjected to the influence of impurity in the raw material, operating condition and accessory substance acetylene polymer, its catalytic performance can reduce above-mentioned catalyst gradually in process of production.In order to keep high catalytic activity and stable production, must regularly replace or add at any time catalyst, therefore can produce a large amount of dead catalyst, contain a large amount of very unsettled in this dead catalyst, the alkynes copper compound of decomposition explosion takes place in chance heat, friction or bump, brings very big difficulty to handling and recycle catalyst.

The dead catalyst that normally will contain alkynes copper takes underground buried method to handle, and this kind method has not only caused the waste of a large amount of non-ferrous metal copper and bismuth, and can cause more serious pollution to environment.

Many experts and scholars are seeking practicable recovery method, solve the problem of outlet of useless alkynes copper catalyst.For example smelting method, mainly be metallic copper and the bismuth that reclaims in the catalyst, but this method danger is bigger, and the technology more complicated, and the practical application difficulty is bigger.Acid hydrolyzation for example is after utilizing strong acid and the effect of alkynes copper compound to generate salt, prepare new catalyst more again, but this method removal process to be long again, consume a large amount of strong acid, and recovery cost is very high.Up to now, also do not see having with this dead catalyst regeneration, the technology of reusing.

U.S. Pat 4,311,611 have announced that a kind of oxidizing process reclaims the method for catalyst, this catalyst is a kind of oxide that contains metals such as iron, antimony, copper, cobalt, nickel, magnesium, is mainly used on the technologies such as oxidation, ammoxidation and oxidative dehydrogenation of hydrocarbon.This method is to utilize H

2O

2As oxidant, with the dead catalyst effect, and then after filtration, steps such as drying, calcining, make dead catalyst obtain regeneration.But do not provide the renovation process that contains the copper scrap bismuth catalyst of explosive alkynes copper compound of the present invention in this patent.

Purpose of the present invention is exactly the defective that exists in the above-mentioned prior art in order to overcome, and proposes a kind of slurry-bed reaction that is used for and synthesizes 1 by formaldehyde and acetylene, the 4-butynediols renovation process of catalyst.

The inventor has proposed a kind of slurry-bed reaction that is used for and has synthesized 1, the renovation process of 4-butynediols copper scrap bismuth catalyst by formaldehyde and acetylene through research for many years.

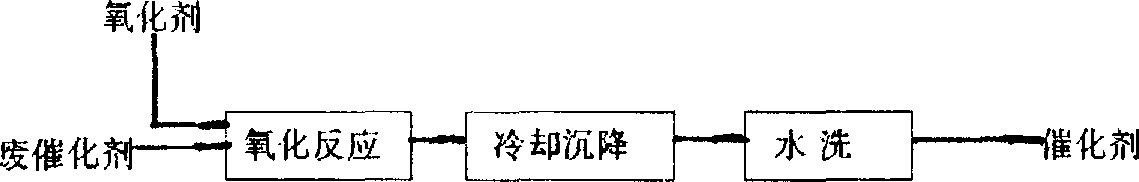

Dead catalyst and strong oxidizer are carried out oxidation reaction in liquid phase, carry out Separation of Solid and Liquid then, the solid matter that obtains is washed to remove water-solubility impurity, obtain the black powder solid after the drying, it promptly is the oxide of copper and bismuth, that is to say that being used for of obtaining regenerating is synthetic 1, the catalyst of 4-butynediols.

Be used for slurry-bed reaction and synthesize 1 by formaldehyde and acetylene, 4-butynediols catalyst for reaction is the mixture of cupric oxide and bismuth oxide, and the weight ratio between copper and the bismuth is 100: 1~100: 40, and general carrier-free exists.After being used for slurry-bed reaction, cupric oxide in the catalyst and formaldehyde and acetylene reaction generate the alkynes copper complex, and to synthesizing 1, the 4-butynediols has reacted catalytic action.In said method, alkynes copper complex in the decaying catalyst and strong oxidizer reaction generate cupric oxide, make catalyst obtain regeneration.

Oxidation reaction is the key of whole regenerative process, and its quality directly influences the performance of catalyst, and it mainly is performance, oxidant consumption, the influence in sharp reaction time of reaction temperature of oxidant.

Above-mentioned dead catalyst is synthetic 1 by formaldehyde and acetylene, and the 4-butynediols is used for the catalyst of inactivation behind the slurry-bed reaction.

Above-mentioned strong oxidizer can be selected from hydrogen peroxide, perchloric acid, perchlorate, chloric acid, chlorate, hypochlorous acid, a kind of in the hypochlorite or their mixture; Be preferably hypochlorite; The best is hypochlorous sodium salt.Wherein the ratio of dead catalyst and clorox (in Cl) weight of material is within 1: 0.5~1: 5.0 scope; 1: 2.0~1: 4.5 comparatively suitable; 1: 3.0~1: 4.0 is best.

Above-mentioned hypochlorous sodium salt is 1~13.5% the aqueous solution, wherein adds a certain amount of NaOH, makes solution be alkalescence, helps oxidation reaction, and the addition of NaOH is 0.1~20% of a solution, is preferably 1~15%, is preferably 2~3%.

Above-mentioned oxidation reaction is carried out in two steps, and the step reaction temperature is 30 ℃~90 ℃, in 10~50 minutes reaction time, is preferably 20~30 minutes; The second step reaction temperature is 100 ℃~108 ℃, and the reaction time is 20~60 minutes, is preferably 30~40 minutes.Wherein first step reaction temperature is controlled by the speed of dropping oxidizing agent.

The present invention has the following advantages:

(1) in the present invention because oxidation reaction is to carry out in liquid phase, so solved the safety problem of handling easily the alkynes copper catalyst that decomposes, explodes;

(2) strong oxidizer used in the present invention is simple and easy to, the product recovery rate height, and processing procedure is simple, convenient.

(3) the regenerate catalyst of gained of the present invention has the catalytic performance identical with raw catalyst, and it is synthetic 1 to have reduced the slurry bed method, and the production cost of 4-butynediols has reduced the pollution to environment.

Embodiment:

Example 1: with dead catalyst 55.0 grams of cupric 42.16% and bismuth 5.85%, put into one 3000 milliliters beaker, under condition of stirring, in beaker, drip 2280.0 grams and (contain [Cl] 12.41%, NaOH2.64%) liquor natrii hypochloritis, in temperature is under 50~70 ℃, adds in 20 minutes; Under agitation boiled 30 minutes in 100~108 ℃, tell solid after the cooling and wash, obtain black solid catalyst (oxidation state) 31.9337 grams after the oven dry, wherein copper 70.986%, and bismuth 9.9% is 97.83% in the metal rate of recovery.

Example 2: in 500 milliliters of glass there-necked flasks that have stirring and condenser, dead catalyst 10.0 grams that add cupric 42.3% and bismuth 6.3%, (contain [Cl] 12.41%, liquor natrii hypochloritis NaOH2.64%) added in 20 minutes to drip 400.0 grams at 50~60 ℃; Under agitation continue to react 30 minutes in 107 ℃, the copper complex formazan content of alkynes is 0 in the assaying reaction product, and the copper loss mistake is 0.41% in the solution.Under similarity condition, the temperature in the time of only will feeding in raw material changes 90~95 ℃ into, and the copper loss mistake is 0.27% in the solution.

Example 3: the condition identical with example 2, only changing charge ratio (alkynes copper/[Cl]) is 1: 2.48 and 1: 4.96, and the former has alkynes copper to exist and acid non-soluble substance, and the copper loss mistake is 0.68% in the solution, and the latter does not have existence of alkynes copper and acid non-soluble substance, and the copper loss mistake is 0.34% in the solution.

Example 4: the condition identical with example 2, charge ratio (alkynes copper/[Cl]) is 1: 4.96, changes clorox concentration, and clorox [Cl] is respectively 12.41% and 5.76%, the no alkynes copper in reaction back exists and acid non-soluble substance, and copper loss is lost and is respectively 0.34% and 0.48% in the solution.

Example 5: the condition identical with example 2, charge ratio (alkynes copper/[Cl]) is 1: 4.96, the content that changes NaOH among the liquor natrii hypochloritis is respectively 0.28%, 0.78% and 3.84%, the no alkynes copper in reaction back exists and acid non-soluble substance, and copper loss is lost and is respectively 0.48%, 0.34% and 0.12% in the solution.

Example 6: the regenerated catalyst of example 1 gained is used for formaldehyde and acetylene synthetic 1, the slurry-bed reaction of 4-butynediols, reaction condition is: under 90 ℃, normal pressure, reacted 7 hours, raw material formalin/catalyst is 9: 1 (weight ratio), and the concentration of formalin is 35.84wt%.Reaction result is: the conversion ratio of formaldehyde: 88.52%, and space-time yield 14.42g/g.d, selectivity 97.42%.

Example 7: it is synthetic 1 that raw catelyst is used for formaldehyde and acetylene, and the slurry-bed reaction of 4-butynediols, reaction condition are with example 6, and reaction result is: the conversion ratio of formaldehyde: 90.0%, and space-time yield 14.22g/g.d, selectivity 96.60%.

By the test data of example 6 and example 7 more as can be seen, it is synthetic 1 to utilize the catalyst of regeneration to be used for formaldehyde and acetylene, the slurry-bed reaction of 4-butynediols can obtain the reaction result identical with raw catelyst.

Claims (6)

- The renovation process of the catalyst that 1, a kind of slurry-bed reaction is synthetic 1, the 4-butynediols is used is characterized in that it comprises following step:(1) copper scrap bismuth catalyst and strong oxidizer are carried out oxidation reaction in liquid phase; Wherein said oxidation reaction is carried out in two steps, and first step reaction temperature is 30 ℃~90 ℃, and the reaction time is 10~50 minutes; The second step reaction temperature is 100 ℃~108 ℃, and the reaction time is 20~60 minutes; Described dead catalyst and strong oxidizer are 1: 0.5~1: 5.0 by the weight ratio of the clorox of chlorine;(2) mixture that reaction is obtained carries out Separation of Solid and Liquid, obtains solids;(3) solids of step (2) gained is washed, being used for of obtaining after the drying regenerating is synthetic 1, the catalyst of 4-butynediols.

- 2, method according to claim 1 is characterized in that, described strong oxidizer clorox is 1~13.5% the aqueous solution, wherein contains 0.1~20% NaOH.

- 3, method according to claim 1 is characterized in that, contains 1~15% NaOH in the aqueous solution of described strong oxidizer clorox.

- 4, method according to claim 1 is characterized in that, contains 2~3% NaOH in the aqueous solution of described strong oxidizer clorox.

- 5, method according to claim 1 is characterized in that, described copper scrap bismuth catalyst and strong oxidizer are 1: 2.0~1: 4.5 by the weight ratio of the clorox of chlorine.

- 6, method according to claim 1 is characterized in that, described copper scrap bismuth catalyst and strong oxidizer are 1: 3.0~1: 4.0 by the weight ratio of the clorox of chlorine.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN95116599A CN1048919C (en) | 1995-10-27 | 1995-10-27 | Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN95116599A CN1048919C (en) | 1995-10-27 | 1995-10-27 | Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1132114A CN1132114A (en) | 1996-10-02 |

| CN1048919C true CN1048919C (en) | 2000-02-02 |

Family

ID=5080974

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN95116599A Expired - Fee Related CN1048919C (en) | 1995-10-27 | 1995-10-27 | Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1048919C (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105413711A (en) * | 2015-11-20 | 2016-03-23 | 苏英慧 | Regeneration preparing method for supported copper-bismuth catalyst |

| CN108069825B (en) * | 2016-11-11 | 2020-11-10 | 中国石油化工股份有限公司抚顺石油化工研究院 | Method for prolonging service cycle of catalyst for preparing 1, 4-butynediol through reaction of formaldehyde and acetylene |

| CN111229785A (en) * | 2020-03-04 | 2020-06-05 | 河南理工大学 | Method for treating industrial catalytic waste of copper acetylide |

| CN115945228A (en) * | 2022-12-12 | 2023-04-11 | 巴斯夫公司 | Regeneration method for preparing 1,4-butynediol catalyst through alkyne hydroformylation reaction |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4311611A (en) * | 1978-12-05 | 1982-01-19 | Nitto Chemical Industry, Co., Ltd. | Process for regenerating an antimony containing oxide catalyst |

| JPS63137755A (en) * | 1986-11-28 | 1988-06-09 | Nippon Shokubai Kagaku Kogyo Co Ltd | Reactivation of catalyst |

| CN1051683A (en) * | 1989-11-16 | 1991-05-29 | 甘肃省刘家峡化肥厂 | The recovery method of waste copper-series catylist |

| DE4200006A1 (en) * | 1992-01-02 | 1993-07-08 | Tech Hochschule C Schorlemmer | Activating molybdenum-contg. mixed oxide catalyst for propene ammoxidation - by treating with readily-dispersed bismuth-III cpd. at 300-600 deg.C |

-

1995

- 1995-10-27 CN CN95116599A patent/CN1048919C/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4311611A (en) * | 1978-12-05 | 1982-01-19 | Nitto Chemical Industry, Co., Ltd. | Process for regenerating an antimony containing oxide catalyst |

| JPS63137755A (en) * | 1986-11-28 | 1988-06-09 | Nippon Shokubai Kagaku Kogyo Co Ltd | Reactivation of catalyst |

| CN1051683A (en) * | 1989-11-16 | 1991-05-29 | 甘肃省刘家峡化肥厂 | The recovery method of waste copper-series catylist |

| DE4200006A1 (en) * | 1992-01-02 | 1993-07-08 | Tech Hochschule C Schorlemmer | Activating molybdenum-contg. mixed oxide catalyst for propene ammoxidation - by treating with readily-dispersed bismuth-III cpd. at 300-600 deg.C |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1132114A (en) | 1996-10-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1052664C (en) | Unsupported catalyst for producing 1, 4-butynediol and preparation method and application thereof | |

| US4212991A (en) | Single-stage process for the preparation of terephthalic acid | |

| US2587858A (en) | Production of oxygenated compounds | |

| CN113429295A (en) | Method for preparing m-phenylenediamine by continuous catalytic hydrogenation based on fixed bed microreactor | |

| CN1048920C (en) | Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction | |

| US4077800A (en) | Method for the recovery of platinum from spent catalysts | |

| CN111484395B (en) | Method for recovering bisphenol A by catalyzing polycarbonate to carry out methanol alcoholysis by composite metal oxide | |

| CN1048919C (en) | Regeneration method of catalyst for synthesizing 1, 4-butynediol from formaldehyde and acetylene in slurry bed reaction | |

| US3816337A (en) | Process for preparing a catalytic cobalt carbonyl reaction product | |

| Benvenuto et al. | Industrial Catalysis | |

| CN1054765A (en) | Continuous process for synthesizing oxalate by gas phase catalysis | |

| EP0307869B1 (en) | Process for producing ammonia and sulfur dioxide | |

| CA1068073A (en) | Alkali metal hydride formation | |

| CN1063354C (en) | Ruthenium regenerating catalyst | |

| US3558272A (en) | Treatment of thiosulfate-containing solutions with hydrogen in the presence of a nickel sulfide catalyst | |

| CN110872208A (en) | Cyclohexanol preparation method by coupling cyclohexane mixture dehydrogenation technology | |

| JPH0780309A (en) | Catalyst for production of hydrocarbon and production of hydrocarbon | |

| US3663626A (en) | Hydrogenation of arylaldehydes | |

| CA1298311C (en) | Preparation process of (meth)acrylamide | |

| US4017584A (en) | Process for the recovery of aluminum trichloride | |

| EP0046056A2 (en) | Process for preparation or reactivation of metal catalysts | |

| CN101602647A (en) | A kind of method of sulphur removal of coking benzene | |

| CA1085879A (en) | Continuous process for the removal of non-paraffinic hydrocarbons from paraffinic hydrocarbons | |

| CN113248355B (en) | Preparation method of p-chlorobenzaldehyde | |

| JPS6333421B2 (en) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20000202 Termination date: 20111027 |