CN103761936A - Ramp wave driving circuit and ramp wave obliquity control method - Google Patents

Ramp wave driving circuit and ramp wave obliquity control method Download PDFInfo

- Publication number

- CN103761936A CN103761936A CN201110460309.5A CN201110460309A CN103761936A CN 103761936 A CN103761936 A CN 103761936A CN 201110460309 A CN201110460309 A CN 201110460309A CN 103761936 A CN103761936 A CN 103761936A

- Authority

- CN

- China

- Prior art keywords

- voltage

- adjustment component

- driving circuit

- temperature self

- adaptation adjustment

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Control Of Indicators Other Than Cathode Ray Tubes (AREA)

- Control Of Gas Discharge Display Tubes (AREA)

Abstract

The invention provides a ramp wave driving circuit and a ramp wave obliquity control method. The ramp wave driving circuit includes a signal generating component which is used for generating voltage reference signals, a temperature adaptive adjustment component which is used for adjusting the amplitude of the voltage reference signals under different temperatures so as to obtain voltage control signals, a driving voltage generating component which is used for generating output voltage at the output end of the ramp wave driving circuit according to the voltage control signals which are obtained through adjustment; and the obliquity of the output voltage changes in a predetermined range under the control of the voltage control signals. With the ramp wave driving circuit and the ramp wave obliquity control method of the invention adopted, a problem of a requirement for a large quantity of waveform setting in order to adapt to changes of ramp wave obliquity under different temperatures in the prior art can be solved, such that waveform design can be simplified, and therefore, the reliability of a PDP module can be improved, and the display effect of the PDP module can be ensured.

Description

Technical field

The present invention relates to PDP (Plasma Display Panel, plasma display panel) module field, in particular to the control method of a kind of oblique wave driving circuit and ramp slopes.

Background technology

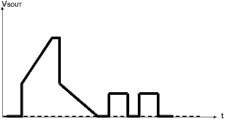

Along with growing in intensity of flat panel products market competition, low cost, high reliability are the emphasis that PDP product is pursued always.PDP module is at varying environment temperature, the characteristic of screen itself can change, particularly the parameter of circuit devcie can change, and a Main Function of drive waveforms is exactly at varying environment temperature, the parameter of adaptive circuit device changes, by adjusting waveform setting, to realize the optimization of PDP at varying environment temperature, show.But, current PDP module design, great majority are to arrange by waveform, adapt to the variation of the RAMP slope that module causes because of device temperature characteristic variations under different temperatures environment, PDP module adapts to the variation of the slope of RAMP (oblique wave) by the driving circuit in Fig. 1, but, temperature characterisitic at varying environment temperature dropper part also can change, and then the slope of RAMP is exerted an influence, particularly the temperature characterisitic of the power tube of RAMP circuit control is very large on the impact of RAMP slope, caused at varying environment temperature, RAMP slope variation is very large, as shown in Figure 2, when temperature raises, it is large that the slope of RAMP becomes, therefore, in order to adapt to above-mentioned RAMP slope variation, Waveform Matching just need to be done a large amount of work waveform is set, distinguish more temperature ranges, multiple waveforms are set and could realize the optimum demonstration of PDP module.Therefore,, at varying environment temperature, setting brings a lot of drawbacks to waveform by waveform setting, to adapt to the variation of RAMP slope.

Summary of the invention

The invention provides the control method of a kind of oblique wave driving circuit and ramp slopes, with at least solve in correlation technique under different temperatures, for adapting to the variation needs of RAMP slope, do the problem that a large amount of waveforms arranges.

According to an aspect of the present invention, provide a kind of oblique wave driving circuit, it comprises: signal generator part, for generation of voltage reference signal; Temperature self-adaptation adjustment component, obtains voltage control signal for the amplitude of adjusting voltage reference signal under different temperatures; Driving voltage generates parts, for the voltage control signal obtaining according to adjustment, at the output terminal of oblique wave driving circuit, produces output voltage, and wherein, the slope of output voltage is subject to changing in the predetermined scope of being controlled at of voltage control signal.

Preferably, temperature self-adaptation adjustment component is arranged in the bleeder circuit between signal generator part and driving voltage generation parts.

Preferably, one end of temperature self-adaptation adjustment component is connected to the output terminal as the optocoupler of signal generator part by resistance, and is connected to by resistance the grid that generates the switching tube of parts as driving voltage; The other end of temperature self-adaptation adjustment component is connected to the source electrode of switching tube and the output terminal of oblique wave driving circuit by resistance.

Preferably, the resistance parameter of temperature self-adaptation adjustment component reduces along with the rising of temperature, makes the lower voltage between grid and the source electrode of switching tube.

Preferably, temperature self-adaptation adjustment component comprises: thermistor.

Preferably, the variation range of resistance parameter of temperature self-adaptation adjustment component and the predetermined scope of the slope of output voltage are corresponding.

According to a further aspect in the invention, provide a kind of control method of ramp slopes, it comprises: by signal generator part, produce voltage reference signal; The amplitude of adjusting voltage reference signal by temperature self-adaptation adjustment component under different temperatures obtains voltage control signal; By driving voltage, generate the voltage control signal that parts obtain according to adjustment and produce output voltage at the output terminal of oblique wave driving circuit, wherein, the slope of output voltage is subject to changing in the predetermined scope of being controlled at of voltage control signal.

Preferably, temperature self-adaptation adjustment component is arranged in the bleeder circuit between signal generator part and driving voltage generation parts, wherein, one end of temperature self-adaptation adjustment component is connected to the output terminal as the optocoupler of signal generator part by resistance, and is connected to by resistance the grid that generates the switching tube of parts as driving voltage; The other end of temperature self-adaptation adjustment component is connected to the source electrode of switching tube and the output terminal of oblique wave driving circuit by resistance.

Preferably, the resistance parameter of temperature self-adaptation adjustment component reduces along with the rising of temperature, makes the lower voltage between grid and the source electrode of switching tube.

Preferably, temperature self-adaptation adjustment component comprises: thermistor.

In the present invention, the amplitude of adjusting voltage reference signal by temperature self-adaptation adjustment component under different temperatures is to obtain voltage control signal, by driving voltage, generate the voltage control signal generation output voltage that parts obtain according to adjustment again, and then being controlled at of voltage control signal, make the slope of output voltage change in predetermined scope, realized under different temperatures, the slope of controlling output voltage changes in predetermined scope, reduced the variation of ramp slopes, avoided under different temperatures, by a large amount of waveform settings, adapt to the variation of ramp slopes, thereby simplified Waveform Design, improved the reliability of PDP module, guaranteed the display effect of PDP module.

Accompanying drawing explanation

Accompanying drawing described herein is used to provide a further understanding of the present invention, forms the application's a part, and schematic description and description of the present invention is used for explaining the present invention, does not form inappropriate limitation of the present invention.In the accompanying drawings:

Fig. 1 is according to the schematic diagram of the oblique wave driving circuit of correlation technique;

Fig. 2 is according to the temperature variant schematic diagram of the ramp slopes of correlation technique;

Fig. 3 is the preferred schematic diagram of one according to the oblique wave driving circuit of the embodiment of the present invention;

Fig. 4 is according to the preferred schematic diagram of the temperature variant one of the voltage control signal of the switching tube of the embodiment of the present invention;

Fig. 5 is according to the preferred schematic diagram of the temperature variant one of the ramp slopes of the embodiment of the present invention;

Fig. 6 is according to the preferred process flow diagram of the one of the control method of the ramp slopes of the embodiment of the present invention.

Embodiment

Hereinafter with reference to accompanying drawing, also describe the present invention in detail in conjunction with the embodiments.It should be noted that, in the situation that not conflicting, the feature in embodiment and embodiment in the application can combine mutually.

Embodiment 1

Fig. 3 is the preferred schematic diagram of one according to the oblique wave driving circuit of the embodiment of the present invention, and as shown in Figure 3, this oblique wave driving circuit comprises: signal generator part 302, for generation of voltage reference signal; Temperature self-adaptation adjustment component 304, is connected with signal generator part 302, for the amplitude of adjusting voltage reference signal under different temperatures, obtains voltage control signal; Driving voltage generates parts 306, be connected with temperature self-adaptation adjustment component 304, for the voltage control signal obtaining according to adjustment, at the output terminal of oblique wave driving circuit, produce output voltage, wherein, the slope of output voltage is subject to changing in the predetermined scope of being controlled at of voltage control signal.

In above preferred embodiment, the amplitude of adjusting voltage reference signal by temperature self-adaptation adjustment component 304 under different temperatures is to obtain voltage control signal, by driving voltage, generate the voltage control signal generation output voltage that parts obtain according to adjustment again, and then being controlled at of voltage control signal, make the slope of output voltage change in predetermined scope, realized under different temperatures, the slope of controlling output voltage changes in predetermined scope, reduced the variation of ramp slopes, avoided under different temperatures, by a large amount of waveform settings, adapt to the variation of ramp slopes, thereby simplified Waveform Design, improved the reliability of PDP module, guaranteed the display effect of PDP module.

On the basis of above preferred embodiment, as shown in Figure 3, temperature self-adaptation adjustment component 304 can be arranged on signal generator part 302 and driving voltage generates in the bleeder circuit between parts 306, with the amplitude that makes temperature self-adaptation adjustment component 304 adjust voltage reference signal in the mode of dividing potential drop, obtain voltage control signal, and then the size of control output voltage, with the slope of controlling output voltage, in predetermined scope, change.

On the basis of above-mentioned each preferred embodiment, as shown in Figure 3, the concrete connected mode of temperature self-adaptation adjustment component 304 in oblique wave driving circuit can be: one end of temperature self-adaptation adjustment component 304 is connected to the output terminal as the optocoupler of signal generator part 302 by resistance, and is connected to by resistance the grid that generates the switching tube Q1 of parts as driving voltage; The other end of temperature self-adaptation adjustment component 304 is connected to the source electrode of switching tube and the output terminal of oblique wave driving circuit by resistance.In the present embodiment, temperature self-adaptation adjustment component 304 is connected to signal generator part 302 in parallel in realization and driving voltage generates in the bleeder circuit between parts 306, make to adjust by temperature self-adaptation adjustment component 304 amplitude of voltage reference signal, the voltage control signal changing to be met oblique wave.

On the basis of above-mentioned each preferred embodiment, in conjunction with Fig. 3, can analyze and draw, the resistance parameter of temperature self-adaptation adjustment component 304 reduces along with the rising of temperature, thereby make the lower voltage VGS between grid and the source electrode of switching tube Q1, and then the slope of controlling oblique wave diminishes, make the variation range of resistance parameter of temperature self-adaptation adjustment component 304 and the predetermined scope of the slope of output voltage corresponding, in the present embodiment, along with temperature is different, there is different variations in the resistance parameter by temperature self-adaptation adjustment component 304, so that the voltage between grid and the source electrode of switching tube Q1 is also changed along with different temperatures, therefore, can realize the slope along with the difference control output voltage of temperature.

In force, as shown in Figure 4, when temperature raises, the resistance parameter of temperature self-adaptation adjustment component 304 reduces along with the rising of temperature, by the dividing potential drop effect of temperature self-adaptation adjustment component 304, the voltage VGS between grid and the source electrode of switching tube Q1 is reduced, realize and make switching tube Q1 in conducting state with lower forward voltage, can be understood as the easier conducting of rising switching tube Q1 along with temperature, with lower forward voltage, make switching tube Q1 in conducting state.

In an embodiment, when temperature self-adaptation adjustment component 304 is connected in the bleeder circuit between signal generator part 302 and driving voltage generation parts 306, under different temperatures, the slope that can effectively control oblique wave changes in less scope, as shown in Figure 5, after temperature self-adaptation adjustment component 304 is determined, under different temperatures, the resistance parameter of temperature self-adaptation adjustment component 304 can change according to the variation of temperature, and then the size of change output voltage, the variation of the output voltage causing because of temperature variation with other devices in compensating circuit, the slope of realizing control output voltage changes in less scope, even, can realize under different temperatures, keep the slope of output voltage constant, be not variation with temperature and changing of ramp slopes, or under different temperatures, there is less variation in ramp slopes, to guarantee the display effect of PDP module.

On the basis of above-mentioned each preferred embodiment, temperature self-adaptation adjustment component 304 can be that any resistance parameter varies with temperature and the device that changes, preferably, temperature self-adaptation adjustment component 304 is thermistor, certainly, the selection of thermistor can be selected the thermistor of negative temperature coefficient or the thermistor of positive temperature coefficient (PTC) as required, and the resistance that it is also conceivable that thermistor varies with temperature and the speed that changes.

On the basis of Fig. 3-5, the invention provides a kind of control method of preferred ramp slopes, as shown in Figure 6, the control method of this ramp slopes comprises:

S602: produce voltage reference signal by signal generator part;

S604: the amplitude of adjusting voltage reference signal by temperature self-adaptation adjustment component under different temperatures obtains voltage control signal;

S606: generate by driving voltage the voltage control signal that parts obtain according to adjustment and produce output voltage at the output terminal of oblique wave driving circuit, wherein, the slope of output voltage is subject to changing in the predetermined scope of being controlled at of voltage control signal.

In above preferred embodiment, the amplitude of adjusting voltage reference signal by temperature self-adaptation adjustment component under different temperatures is to obtain voltage control signal, by driving voltage, generate the voltage control signal generation output voltage that parts obtain according to adjustment again, and then being controlled at of voltage control signal, make the slope of output voltage change in predetermined scope, realized under different temperatures, the slope of controlling output voltage changes in predetermined scope, reduced the variation of ramp slopes, avoided under different temperatures, by a large amount of waveform settings, adapt to the variation of ramp slopes, thereby simplified Waveform Design, improved the reliability of PDP module, guaranteed the display effect of PDP module.

On the basis of above-described embodiment, temperature self-adaptation adjustment component is arranged in the bleeder circuit between signal generator part and driving voltage generation parts, particularly, as shown in Figure 3, one end of temperature self-adaptation adjustment component is connected to the output terminal as the optocoupler of signal generator part by resistance, and is connected to by resistance the grid that generates the switching tube of parts as driving voltage; The other end of temperature self-adaptation adjustment component is connected to the source electrode of switching tube and the output terminal of oblique wave driving circuit by resistance.In the present embodiment, temperature self-adaptation adjustment component is connected to signal generator part in parallel in realization and driving voltage generates in the bleeder circuit between parts, make to adjust by temperature self-adaptation adjustment component the amplitude of voltage reference signal, the voltage control signal changing to be met oblique wave.

On the basis of above-mentioned each preferred embodiment, in conjunction with Fig. 3, can analyze and draw, the resistance parameter of temperature self-adaptation adjustment component reduces along with the rising of temperature, thereby the voltage VGS between grid and the source electrode of switching tube is reduced, and then the slope of controlling oblique wave diminishes, make the variation range of resistance parameter of temperature self-adaptation adjustment component and the predetermined scope of the slope of output voltage corresponding, in the present embodiment, along with temperature is different, there is different variations in the resistance parameter by temperature self-adaptation adjustment component, so that the voltage VGS between grid and the source electrode of switching tube is also changed along with different temperatures, therefore, can realize the slope along with the difference control output voltage of temperature.

In force, as shown in Figure 4, when temperature raises, the resistance parameter of temperature self-adaptation adjustment component reduces along with the rising of temperature, by the dividing potential drop effect of temperature self-adaptation adjustment component, the voltage VGS between grid and the source electrode of switching tube is reduced, realize and make switching tube in conducting state with lower forward voltage, can be understood as the easier conducting of rising switching tube along with temperature, with lower forward voltage, make switching tube in conducting state.

In an embodiment, when temperature self-adaptation adjustment component is connected in the bleeder circuit between signal generator part and driving voltage generation parts, under different temperatures, the slope that can effectively control oblique wave changes in less scope, as shown in Figure 5, after temperature self-adaptation adjustment component is selected, under different temperatures, the resistance parameter of temperature self-adaptation adjustment component can change according to the variation of temperature, and then the size of change output voltage, the variation of the output voltage causing because of temperature variation with other devices in compensating circuit, the slope of realizing control output voltage changes in less scope, even, can realize under different temperatures, keep the slope of output voltage constant, it is not variation with temperature and changing of ramp slopes, or under different temperatures, there is less variation in ramp slopes, to guarantee the display effect of PDP module.

On the basis of above-mentioned each preferred embodiment, temperature self-adaptation adjustment component can be that any resistance parameter varies with temperature and the device that changes, preferably, temperature self-adaptation adjustment component is thermistor, certainly, the selection of thermistor can be selected the thermistor of negative temperature coefficient or the thermistor of positive temperature coefficient (PTC) as required, and the resistance that it is also conceivable that thermistor varies with temperature and the speed that changes.

Obviously, those skilled in the art should be understood that, above-mentioned of the present invention each module or each step can realize with general calculation element, they can concentrate on single calculation element, or be distributed on the network that multiple calculation elements form, alternatively, they can be realized with the executable program code of calculation element, thereby, they can be stored in memory storage and be carried out by calculation element, and in some cases, can carry out shown or described step with the order being different from herein, or they are made into respectively to each integrated circuit modules, or the multiple modules in them or step are made into single integrated circuit module to be realized.Like this, the present invention is not restricted to any specific hardware and software combination.

The foregoing is only the preferred embodiments of the present invention, be not limited to the present invention, for a person skilled in the art, the present invention can have various modifications and variations.Within the spirit and principles in the present invention all, any modification of doing, be equal to replacement, improvement etc., within all should being included in protection scope of the present invention.

Claims (10)

1. an oblique wave driving circuit, is characterized in that, comprising:

Signal generator part, for generation of voltage reference signal;

Temperature self-adaptation adjustment component, obtains voltage control signal for the amplitude of adjusting described voltage reference signal under different temperatures;

Driving voltage generates parts, for the voltage control signal obtaining according to adjustment, at the output terminal of described oblique wave driving circuit, produces output voltage, and wherein, the slope of described output voltage is subject to changing in the predetermined scope of being controlled at of described voltage control signal.

2. oblique wave driving circuit according to claim 1, is characterized in that, described temperature self-adaptation adjustment component is arranged on described signal generator part and described driving voltage generates in the bleeder circuit between parts.

3. oblique wave driving circuit according to claim 2, it is characterized in that, one end of described temperature self-adaptation adjustment component is connected to the output terminal as the optocoupler of described signal generator part by resistance, and is connected to by resistance the grid that generates the switching tube of parts as described driving voltage; The other end of described temperature self-adaptation adjustment component is connected to the source electrode of switching tube and the output terminal of described oblique wave driving circuit by resistance.

4. oblique wave driving circuit according to claim 3, is characterized in that, the resistance parameter of described temperature self-adaptation adjustment component reduces along with the rising of temperature, makes the lower voltage between grid and the source electrode of described switching tube.

5. according to the oblique wave driving circuit described in any one in claim 1 to 4, it is characterized in that, described temperature self-adaptation adjustment component comprises: thermistor.

6. according to the oblique wave driving circuit described in any one in claim 1 to 4, it is characterized in that, the variation range of resistance parameter of described temperature self-adaptation adjustment component and the predetermined scope of the slope of described output voltage are corresponding.

7. a control method for ramp slopes, is characterized in that, comprising:

By signal generator part, produce voltage reference signal;

The amplitude of adjusting described voltage reference signal by temperature self-adaptation adjustment component under different temperatures obtains voltage control signal;

By driving voltage, generate the voltage control signal that parts obtain according to adjustment and produce output voltage at the output terminal of oblique wave driving circuit, wherein, the slope of described output voltage is subject to changing in the predetermined scope of being controlled at of described voltage control signal.

8. method according to claim 7, it is characterized in that, described temperature self-adaptation adjustment component is arranged in the bleeder circuit between described signal generator part and described driving voltage generation parts, wherein, one end of described temperature self-adaptation adjustment component is connected to the output terminal as the optocoupler of described signal generator part by resistance, and is connected to by resistance the grid that generates the switching tube of parts as described driving voltage; The other end of described temperature self-adaptation adjustment component is connected to the source electrode of switching tube and the output terminal of described oblique wave driving circuit by resistance.

9. method according to claim 8, is characterized in that, the resistance parameter of described temperature self-adaptation adjustment component reduces along with the rising of temperature, makes the lower voltage between grid and the source electrode of described switching tube.

10. according to the method described in any one in claim 7 to 9, it is characterized in that, described temperature self-adaptation adjustment component comprises: thermistor.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201110460309.5A CN103761936A (en) | 2011-12-31 | 2011-12-31 | Ramp wave driving circuit and ramp wave obliquity control method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201110460309.5A CN103761936A (en) | 2011-12-31 | 2011-12-31 | Ramp wave driving circuit and ramp wave obliquity control method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103761936A true CN103761936A (en) | 2014-04-30 |

Family

ID=50529166

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201110460309.5A Pending CN103761936A (en) | 2011-12-31 | 2011-12-31 | Ramp wave driving circuit and ramp wave obliquity control method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103761936A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1404026A (en) * | 2001-01-12 | 2003-03-19 | 株式会社Upd | Apparatus for and method of driving surface discharge plasma display screen |

| CN1855195A (en) * | 2005-04-19 | 2006-11-01 | 三星Sdi株式会社 | Method of driving plasma display panel (PDP) |

| US20080143701A1 (en) * | 2006-12-15 | 2008-06-19 | Hak-Ki Choi | Driving device for plasma display panel and plasma display device including the driving device |

| US20080204442A1 (en) * | 2007-02-23 | 2008-08-28 | Hak-Ki Choi | Driving device of plasma display panel and method |

| CN101404137A (en) * | 2007-10-04 | 2009-04-08 | 三星Sdi株式会社 | Plasma display and driving method |

-

2011

- 2011-12-31 CN CN201110460309.5A patent/CN103761936A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1404026A (en) * | 2001-01-12 | 2003-03-19 | 株式会社Upd | Apparatus for and method of driving surface discharge plasma display screen |

| CN1855195A (en) * | 2005-04-19 | 2006-11-01 | 三星Sdi株式会社 | Method of driving plasma display panel (PDP) |

| US20080143701A1 (en) * | 2006-12-15 | 2008-06-19 | Hak-Ki Choi | Driving device for plasma display panel and plasma display device including the driving device |

| US20080204442A1 (en) * | 2007-02-23 | 2008-08-28 | Hak-Ki Choi | Driving device of plasma display panel and method |

| CN101404137A (en) * | 2007-10-04 | 2009-04-08 | 三星Sdi株式会社 | Plasma display and driving method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107453593B (en) | Switching tube driving circuit and driving method thereof | |

| US8570268B2 (en) | Driving method of liquid crystal display | |

| CN103903572B (en) | Backlight drive device and use the liquid crystal display of this backlight drive device | |

| CN102314846B (en) | Corner-cutting circuit in LCD (Liquid Crystal Display) driving system | |

| CN102129845A (en) | Liquid crystal panel driving circuit and liquid crystal display device | |

| CN105548997A (en) | Active compensation for phase alignment errors in time-of-flight cameras | |

| TWI408882B (en) | Control device for buck-boost converter | |

| EP1858143A3 (en) | Switching power supply, electronic apparatus, and method of controlling switching power supply circuit | |

| CN103366706A (en) | Voltage compensation circuit and method of grid electrode driver and liquid-crystal display device | |

| EP2383893A3 (en) | Integrated circuit, communication unit and method for improved amplitude resolution of an RF-DAC | |

| US9530378B2 (en) | Driving circuit of display apparatus | |

| CN105265021B (en) | Deviation proportion controlled actuator circuit | |

| CN103021365A (en) | Device and method for adjusting gamma curve and liquid crystal display device | |

| CN102468828A (en) | Pulse edge control device for waveform generator | |

| JP2013081079A5 (en) | ||

| CN102136259B (en) | Chamfering circuit for generating chamfering voltage of liquid crystal display and method thereof | |

| TW201338619A (en) | Laser diode drive device and drive method, and optical transmission system using same | |

| CN201607919U (en) | Backlight adjusting control circuit and television | |

| CN102723658B (en) | Constant current source power supplying circuit of laser | |

| CN103761936A (en) | Ramp wave driving circuit and ramp wave obliquity control method | |

| CN103259415B (en) | Constant-current switch power source and constant-current controller thereof | |

| CN102436794B (en) | Method and system for realizing clock control by use of pulse modulation | |

| EP2341408A3 (en) | Voltage regulator which provides sequentially and arbitrarily shaped regulated voltage and related method | |

| WO2013030105A3 (en) | Assembly having a potential-isolated electrical power supply device | |

| CN103337229B (en) | A kind of device that automatically can regulate plasma scope preparatory stage waveform slope |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20140430 |