CN103474445A - Miniaturized LED integrated array device and preparation method thereof - Google Patents

Miniaturized LED integrated array device and preparation method thereof Download PDFInfo

- Publication number

- CN103474445A CN103474445A CN2013103536105A CN201310353610A CN103474445A CN 103474445 A CN103474445 A CN 103474445A CN 2013103536105 A CN2013103536105 A CN 2013103536105A CN 201310353610 A CN201310353610 A CN 201310353610A CN 103474445 A CN103474445 A CN 103474445A

- Authority

- CN

- China

- Prior art keywords

- wire

- bottom electrode

- top electrode

- luminescence chip

- diaphragm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Led Device Packages (AREA)

Abstract

The invention discloses a miniaturized LED integrated array device and a preparation method thereof, and relates to the technical field of luminescence display. With the device and method, the problem of limited use due to bending incapability of a conventional planar LED micro-display device can be solved. The working process of the miniaturized LED integrated array device is as follows: current is injected from an upper electrode and flows out of a lower electrode, so that an electric field is formed in the device, and positive and negative carriers emit light at a luminescent layer in a composite manner; a part of the light is oriented upwards, passes through an euphotic layer and comes out of a micro-lens; and a part of the light is oriented downwards, reaches a reflection layer, is reflected by the reflection layer, passes through the luminescent layer and the euphotic layer, and then comes out of the micro-lens. The luminescent device is based on the luminescence principle of composite luminescence of the carriers in a p-n structure and has the non-linear characteristics of the current and voltage of a diode so that the luminescent brightness also has the non-linear characteristics according to the size of the injected current. The brightness of pixel elements is controlled through a circuit so that luminescence display is realized.

Description

Technical field

The present invention relates to the LED technical field, be specifically related to a kind of miniature LED integrated array device and preparation method.

Background technology

At present, micro-display device has relied on its unique advantage to become the focus that each science and technology power pays close attention to.The LED micro-display has advantages of many uniquenesses, as active illuminating, super brightness, long-life, operating voltage is low, luminous efficiency is high, fast response time, stable and reliable for performance, operating temperature range is wide etc.Traditional manufacture method is that a plurality of single tube LED chips are arranged on pedestal, then goes between, encapsulates.Be subject to the impact of pedestal, the Pixel Dimensions of the display device that the method is made is difficult to do little, so resolution is subject to certain limitation, and inadaptable miniaturization from now on, the development need of sharpening.Semiconductor process techniques is combined with MOEMS three-dimensional fine process technology, and its suitability for industrialized production does not need extra wholesale investment, therefore, has wide industrialization prospect.

Summary of the invention

The present invention exists the Pixel Dimensions of LED to be difficult to do little for solving the existing LED of making micro-display, causes resolution to be restricted, and the problem that can't meet the needs of, and a kind of miniature LED integrated chip and manufacture method are provided.

Miniature LED integrated array device, comprise photic zone, luminescent layer, reflector, substrate, top electrode, top electrode lead-in wire, bottom electrode, bottom electrode lead-in wire, diaphragm, lenticule, adhesives and substrate, described photic zone, luminescent layer, reflector, substrate and lenticule form the LED luminescence unit; Be followed successively by luminescent layer, photic zone and lenticule above described reflector, the following of reflector is substrate; A plurality of LED luminescence units composition array of light emitting cells of evenly arranging, be diaphragm between luminescence unit, and described diaphragm makes each luminescence unit connect successively and realize the isolation of luminescence unit; Euphotic upper surface is placed with top electrode, the upper surface of diaphragm is placed with the top electrode lead-in wire, top electrode in same a line is connected successively with the top electrode lead-in wire, underside view of part at substrate has bottom electrode, underside view of part at diaphragm has the bottom electrode lead-in wire, bottom electrode in same row and bottom electrode lead-in wire is connected successively, the lower lead-in wire row that described bottom electrode forms with the bottom electrode lead-in wire and top electrode and top electrode go between the upper lead-in wire of composition capable on direction antarafacial vertical; Substrate is fixed in the lower surface of array of light emitting cells by adhesives.

The preparation method of miniature LED integrated array device, the method is realized by following steps:

The thinning back side of step 1, luminescence chip,

Step one by one, select luminescence chip, described luminescence chip is comprised of photic zone, luminescent layer, reflector and substrate;

The pixel segmentation of step 5, luminescence chip, obtain a plurality of LED luminescence units;

Step May Day, remove upper screening glass and bonding agent in step 1 three, expose the diaphragm that is positioned at the luminescence chip upper surface;

Lower screening glass and the bonding agent of the lower surface of the substrate of step 9, removal luminescence chip, make circuit lead, completes the LED element manufacturing.

The course of work of miniature LED integrated array device of the present invention is that the electric current utmost point from power on injects, and from bottom electrode, flows out, and forms electric field in device, makes positive negative carrier at the luminescent layer recombination luminescence.Wherein part light upwards, through photic zone, penetrates from lenticule; Part light arrives reflector downwards, is reflected layer reflection, through luminescent layer, photic zone, from lenticule, penetrates.Because the principle of luminosity of this luminescent device is the charge carrier recombination luminescence in p-n junction, there is the nonlinear characteristic of diode current voltage, luminosity also has nonlinear characteristic with the size of Injection Current.The present invention controls the bright dark of phase primitive element by circuit, realizes luminescence display.

Beneficial effect of the present invention: the present invention has adopted inorganic active illuminating diode chip for backlight unit to prepare flexible micro-display device, simple in structure, firm, response is fast; And overcome that organic light-emitting device life period is short and drive current is low and the problem of restriction light output intensity, thereby provide a kind of self-luminous, volume is little, low in energy consumption and based on high brightness luminescent chip micro-display device and preparation method thereof.This micro-display device can be applied to a plurality of fields such as medicine equipment, micro sensor devices manufacture.

The accompanying drawing explanation

The design sketch that Fig. 1 is miniature LED integrated array device of the present invention;

In Fig. 2, Fig. 2 a and Fig. 2 b are respectively principal section figure and the left profile figure of miniature LED integrated array device of the present invention;

Fig. 3 adopts the luminescence unit distribution map of square luminescence unit in miniature LED integrated array device of the present invention.

In Fig. 4, Fig. 4 a to Fig. 4 e is five kinds of top electrodes and the top electrode pin configuration schematic diagram that adopts square luminescence unit in miniature LED integrated array device of the present invention;

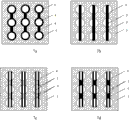

In Fig. 5, Fig. 5 a to Fig. 5 d is four kinds of bottom electrodes and the bottom electrode pin configuration schematic diagram that adopts square luminescence unit in miniature LED integrated array device of the present invention;

Fig. 6 adopts the luminescence unit distribution map of circular luminous unit in miniature LED integrated array device of the present invention;

Four kinds of top electrodes of the employing circular luminous unit that in Fig. 7,7a to 7d is miniature LED integrated array device of the present invention and top electrode pin configuration schematic diagram;

In Fig. 8,8a to 8c is three kinds of bottom electrodes and the bottom electrode pin configuration schematic diagram that adopts the circular luminous unit in miniature LED integrated array device of the present invention.

In Fig. 9, Fig. 9 a to Fig. 9 g is the elevation cross-sectional view of the miniature LED integrated array device of preparation; Fig. 9 h to Fig. 9 m is the left pseudosection of the miniature LED integrated array device of preparation, left pseudosection and elevation cross-sectional view that Fig. 9 n and Fig. 9 o are the pel array that completes.

Embodiment

Embodiment one, in conjunction with Fig. 1 to Fig. 8, present embodiment is described, miniature LED integrated array device comprises: photic zone 1, luminescent layer 2, reflector 3, substrate 4, top electrode 5, top electrode lead-in wire 9, bottom electrode 6, bottom electrode lead-in wire 10, diaphragm 7, lenticule 8 and substrate 11.Photic zone 1, luminescent layer 2, reflector 3, substrate 4 and lenticule 8 form the LED luminescence unit.Being followed successively by luminescent layer 2, photic zone 1 and lenticule 8 above reflector 3, is substrate 4 below reflector 3.The LED luminescence unit composition array of light emitting cells of evenly arranging.Between luminescence unit, be diaphragm 7, diaphragm 7 makes each luminescence unit connect successively and realize the isolation of pixel.The upper surface of photic zone 1 is placed with top electrode 5, the upper surface of diaphragm 7 is placed with top electrode lead-in wire 9, top electrode 5 in same row is connected successively with top electrode lead-in wire 9, underside view of part at substrate 4 has bottom electrode 6, underside view of part at diaphragm 7 has bottom electrode lead-in wire 10, bottom electrode 6 in same row and bottom electrode lead-in wire 10 is connected successively, the lower lead-in wires row that bottom electrode 6 forms with bottom electrode lead-in wire 10 and top electrode 5 and top electrode go between the upper lead-in wires of 9 compositions capable on direction antarafacial vertical.Substrate 11 is fixed in the lower surface of array of light emitting cells by adhesives 12.

The described LED luminescence unit of present embodiment is that luminescence unit is square, rectangle, circle or other shapes.That top electrode 5 is shaped as is back-shaped, annular, wall scroll shape, two bar shaped or other shape.Bottom electrode 6 be shaped as rectangle, circle, wall scroll shape, two bar shaped or other shape.

The described photic zone 1 of present embodiment, luminescent layer 2, reflector 3, substrate 4 are the general AlGaInPLED epitaxial wafer material of being made by traditional handicraft.The material of the top electrode lead-in wire 9 that the top electrode 5 on luminescence unit and luminescence unit are outer is Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au or Al or Cu, or the composite membrane formed by Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au and Cu or Au, by film vapor deposition and the preparation of photoetching corrosion forming technology, for improving the reliability of top electrode and top electrode lead-in wire, or make thick membrane electrode by techniques such as evaporated film, the standby mask of optical graving and electroforming.The material of bottom electrode 6, bottom electrode lead-in wire 10 is Cr/AuTi/Pt/Au or Ti/Mo/Au or AuGeNi/Au or Al or Cu, or the composite membrane formed by Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au and Cu or Au, by film vapor deposition and the preparation of photoetching corrosion forming technology, for improving the reliability of bottom electrode and bottom electrode lead-in wire, or make thick membrane electrode by techniques such as evaporated film, the standby mask of optical graving and electroforming.Diaphragm 7 material diaphragm materials need meet following 3 requirements, and the one, good insulating, can realize the electric isolation between pixel so better; The 2nd, light tight, guarantee that the bright dipping between pixel not there will be crosstalk phenomenon; The 3rd, certain adhesive is arranged, make the LED pixel connect to an integral body.The material of lenticule 8 is hard epoxy or other high permeability material.

Embodiment two, in conjunction with Fig. 9, present embodiment is described, the preparation method that present embodiment is the described miniature LED integrated array device of embodiment one; Present embodiment has adopted manufacture method from bottom to top, first makes structure, then, then protects structure, prepares Facad structure.In manufacturing process, by the filling flexible material and make special pattern by lithography, to realize the making of flexible electrode.

A. the thinning back side of luminescence chip:

A) host material that the present invention uses is luminescence chip, and luminescence chip used consists of photic zone, luminescent layer, reflector and substrate, as shown in Fig. 9 a.

B) carry out the cleaning of luminescence chip.Then at the upper surface of luminescence chip, the photic zone upper surface prepares layer protecting film, as shown in Fig. 9 b.

C) use bonding agent screening glass on the diaphragm upper surface is pasted, as shown in Fig. 9 c.

D) lower surface of whole luminescence chip carried out to attenuate, after being thinned to desired thickness, carry out polishing, as shown in Fig. 9 d.

B. form back side island structure: at first, the lower surface of the substrate after attenuate prepares one deck masking layer.Then, at masking layer surface-coated photoresist, by photoetching, etching process, make masking layer output window, window shape is identical with flexible region.Finally, substrate is carried out to selective etch, to obtain the island structure of lower surface, as shown in Fig. 9 e.

C. prepare bottom electrode, bottom electrode lead-in wire:

Remove lower masking layer, then, prepare film bottom electrode and bottom electrode lead-in wire; Or thick film bottom electrode and bottom electrode lead-in wire, as shown in Fig. 9 f.

D. the luminescence chip back side is fixed: protected for the luminescence chip lower surface to preparing back side flexible material, it is fixed on lower screening glass to the elevation cross-sectional view that Fig. 9 g has been the fixing luminescence chip in the back side with bonding agent.

E. the pixel segmentation of luminescence chip:

A) remove upper screening glass and bonding agent, expose the diaphragm that is positioned at the luminescence chip upper surface, as Fig. 9 h.

B) to its cleaned, photoetching and corrosion protection film, expose the flexible region window.Under the sheltering of diaphragm and photoresist, the luminescence chip upper surface is carried out to the ICP etching, remove the luminescence chip material of flexible region fully, realize the pixel segmentation of luminescence chip, as shown in Fig. 9 i.

F. prepare the diaphragm zone between luminescence unit:

A) apply the diaphragm material at the luminescence chip upper surface of realizing pixel separation, and carry out precuring, as shown in Fig. 9 j.

B) remove the diaphragm material of photic zone upper surface by photoetching and etching process.Complete the fully curing of diaphragm material.

C) remove diaphragm, as Fig. 9 k.

G. prepare top electrode and top electrode lead-in wire: the luminescence chip upper surface that completes flexible region in preparation completes the making of top electrode and top electrode lead-in wire by techniques such as photoetching, evaporation and electroforming, as shown in Fig. 9 l.

H. prepare microlens array: the polymeric layer of the high adhesion of preparation on the luminescence chip that completes top electrode and top electrode lead-in wire obtains the micro polymer lens by hot melt.As shown in Fig. 9 m.

I. remove screening glass and the bonding agent at the luminescence chip back side, the left pseudosection of resulting pel array and elevation cross-sectional view are as shown in Fig. 9 n and 9o.Make circuit lead, complete element manufacturing.

The preparation method that embodiment three, present embodiment are the described miniature LED integrated array device of embodiment two, realized by following steps:

A. the thinning back side of luminescence chip:

A) the described luminescence chip of present embodiment is the AlGaInP-LED epitaxial wafer, photic zone, luminescent layer, reflector and substrate, consists of, and the thickness of luminescence chip is at 200 μ m~1000 μ m.The lower surface that adopts mechanical reduction and polishing or chemical reduction and polishing or machinery to combine with chemical method to luminescence chip carries out attenuate and polishing, and the luminescence chip after attenuate is 20~300 μ m.

B) the diaphragm material prepared at the upper surface of luminescence chip is composite membrane or metal or organic material or inorganic material or other thin-film material that can play a protective role that silicon dioxide or silicon nitride or silicon dioxide and silicon nitride form.The diaphragm preparation method is electron beam evaporation or radio frequency sputtering or magnetron sputtering or sol-gal process or other film growth method.

C) adhesive material is photoresist or heat-curable glue or ultra-violet curing glue or other adhesives.The material of upper screening glass is silicon or glass or quartz or pottery or aluminium or titanium or other inorganic material or organic material or metal material.

D) method of attenuate is mechanical reduction or chemical reduction, and finishing method is mechanical polishing or chemical polishing.

B. form back side island structure:

A) composite membrane or metal or organic material or inorganic material or other thin-film material that can play a protective role that the masking layer material that prepared by the lower surface of the substrate after attenuate is silicon dioxide or silicon nitride or silicon dioxide and silicon nitride composition.

B), at masking layer surface-coated photoresist, carry out the window of front baking, exposure, development and rear baking formation and the identical figure of flexible region.

C) under the protection of photoresist, masking layer is corroded or etching, make the masking layer of substrate lower surface output window.

D) substrate being carried out to selective etch, to take the method for the island structure that obtains lower surface be dry etch process or the wet corrosion techniques such as ICP or RIE.The island structure figure is square or rectangle or circular or other shape, identical with the luminescence unit shape.Also can adopt lift-off technique to complete.

C. prepare bottom electrode, bottom electrode lead-in wire:

A) remove lower masking layer by wet etching or dry etching.Prepare film bottom electrode and bottom electrode lead-in wire by lift-off technique or plated film-photoetching-etching process, or prepare thick film bottom electrode and bottom electrode lead-in wire by techniques such as thick resist lithography, evaporation and electroforming thickenings.

The material of bottom electrode and bottom electrode lead-in wire is Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au or Al or Cu, or the composite membrane be comprised of Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au and Cu or Au.The film vapor deposition mode is electron beam evaporation or radio frequency sputtering or magnetron sputtering.

The preparation method of described thick film bottom electrode and bottom electrode lead-in wire has two kinds: one, at first carry out thick resist lithography and obtain the thick photoresist figure contrary with the bottom electrode figure, evaporation bottom electrode film again, bottom electrode selects Au or AuGeNi/Au or Ti/Pt/Au or Ti/Mo/Au or other and substrate to have the metal of good ohmic contact performance.After peeling off, carry out electroforming, make the electrode thickening.The thin-film material of electroforming material and evaporation is identical or different.

Two, evaporation bottom electrode film at first, bottom electrode selects Au or AuGeNi/Au or Ti/Pt/Au or Ti/Mo/Au or other and substrate to have the metal of good ohmic contact performance.Then carry out thick resist lithography and obtain the thick photoresist figure contrary with the bottom electrode figure.Electroforming makes the electrode thickening, and the thin-film material of electroforming material and evaporation is identical or different.Finally, remove thick photoresist and obtain thick membrane electrode.

D. the luminescence chip back side is fixed: adhesive material is photoresist or heat-curable glue or ultra-violet curing glue or other adhesives.Lower screening glass material is silicon or glass or quartz or pottery or aluminium or titanium or other metal materials or inorganic material or organic material.

E. the pixel segmentation of luminescence chip:

A) remove the bonding agent between upper screening glass and diaphragm by wet method or dry method, screening glass is separated with luminescence chip, expose the diaphragm that is positioned at the luminescence chip upper surface.

B) step for preparing the diaphragm regional window is: form diaphragm zone photoresist graph window on diaphragm by photoetching process, under the protection of photoresist by the be protected graph window of film of dry etching or wet corrosion technique.Photoresist thickness is 0.2 μ m-15 μ m, under the sheltering of diaphragm and photoresist, the luminescence chip upper surface is carried out to the ICP etching, and etching depth is that photic zone, luminescent layer, reflector, substrate etching is saturating, arrives bottom electrode, realizes the pixel segmentation of luminescence chip.

C) adopt wet etching or dry etch process to remove diaphragm.

F. prepare the diaphragm zone between luminescence unit:

A) the diaphragm material applied at the luminescence chip upper surface of realizing pixel separation is that the pixel connecting material is that polyimides or flexible-epoxy or dimethyl silicone polymer (PDMS) or other can apply the flexible organic material of film forming.The precuring mode is for being heating and curing or normal temperature cure.

B) remove the diaphragm material of photic zone upper surface by photoetching and wet corrosion technique.Then remove photoresist, and carry out anticaustic with corrosive agent or specific solvent, make the formation concave shape of formed packing material upper surface.

G. prepare top electrode and top electrode lead-in wire: prepare film top electrode and top electrode lead-in wire by lift-off technique or plated film-photoetching-etching process, or prepare thick film top electrode and top electrode lead-in wire by techniques such as thick resist lithography, evaporation and electroforming thickenings.

The material of top electrode and top electrode lead-in wire is Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au or Al or Cu, or the composite membrane be comprised of Cr/Au or Ti/Pt/Au or Ti/Mo/Au or AuGeNi/Au and Cu or Au.The film vapor deposition mode is electron beam evaporation or radio frequency sputtering or magnetron sputtering.

The preparation method of described thick film top electrode and top electrode lead-in wire has two kinds: one, at first carry out thick resist lithography and obtain the thick photoresist figure contrary with the top electrode figure, evaporation upper electrode film again, top electrode selects Au or AuGeNi/Au or Ti/Pt/Au or Ti/Mo/Au or other and substrate to have the metal of good ohmic contact performance.After peeling off, carry out electroforming, make the electrode thickening.The thin-film material of electroforming material and evaporation is identical or different.

Two, evaporation upper electrode film at first, top electrode selects Au or AuGeNi/Au or Ti/Pt/Au or Ti/Mo/Au or other and substrate to have the metal of good ohmic contact performance.Then carry out thick resist lithography and obtain the thick photoresist figure contrary with the top electrode figure.Electroforming makes the electrode thickening, and the thin-film material of electroforming material and evaporation is identical or different.Finally, remove thick photoresist and obtain thick membrane electrode.

H. prepare microlens array: apply the one layer of polymeric colloid on the luminescence chip that completes top electrode and top electrode lead-in wire, according to design and processes, experiment determines concrete thickness; Polymeric colloid is carried out to ultra-violet curing or hot curing, obtain having the polymeric layer of higher adhesion; The certain thickness photoresist of spin coating on polymer after solidifying, after front baking, exposure, development, adopt hot melt to make the photoresist lenticule; Adopt again reactive ion etching that the photoresist lenticule is transferred on aforesaid polymer, obtain the micro polymer lens.The polymer lens material is polyimides or epoxy resin or SU-8 photoresist.

Claims (10)

1. miniature LED integrated array device, comprise photic zone (1), luminescent layer (2), reflector (3), substrate (4), top electrode (5), top electrode lead-in wire (9), bottom electrode (6), bottom electrode lead-in wire (10), diaphragm (7), lenticule (8), adhesives (12) and substrate (11); It is characterized in that,

Described photic zone (1), luminescent layer (2), reflector (3), substrate (4) and lenticule (8) form the LED luminescence unit, be followed successively by luminescent layer (2), photic zone (1) and lenticule (8) above described reflector (3), the following of reflector (3) is substrate (4), a plurality of LED luminescence units composition array of light emitting cells of evenly arranging, be diaphragm (7) between luminescence unit, and described diaphragm (7) makes each luminescence unit connect successively and realize the isolation of luminescence unit, the upper surface of photic zone (1) is placed with top electrode (5), the upper surface of diaphragm (7) is placed with top electrode lead-in wire (9), top electrode in same a line (5) is connected successively with top electrode lead-in wire (9), underside view of part at substrate (4) has bottom electrode (6), underside view of part at diaphragm (7) has bottom electrode lead-in wire (10), bottom electrode in same row (6) is connected successively with bottom electrode lead-in wire (10), the lower lead-in wire row that described bottom electrode (6) and bottom electrode lead-in wire (10) forms and the upper lead-in wire of top electrode (5) and top electrode lead-in wire (9) composition capable on direction antarafacial vertical, substrate (11) is fixed in the lower surface of array of light emitting cells by adhesives (12).

2. miniature LED integrated array device according to claim 1, is characterized in that, described luminescence unit be shaped as square, rectangle or circle; Described bottom electrode (6) be shaped as rectangle, circle, wall scroll shape or two bar shaped; That described top electrode (5) is shaped as is three-back-shaped, annular, wall scroll shape or two bar shaped.

3. prepare the method for miniature LED integrated array device claimed in claim 1, it is characterized in that, the method is realized by following steps:

The thinning back side of step 1, luminescence chip,

Step one by one, select luminescence chip, described luminescence chip is comprised of photic zone (1), luminescent layer (2), reflector (3) and substrate (4);

Step 1 two, luminescence chip is cleaned, then the euphotic upper surface at luminescence chip prepares layer protecting film;

Step 1 three, adopt bonding agent screening glass on the diaphragm upper surface is pasted, the lower surface attenuate to the substrate of luminescence chip, then carry out polishing;

Step 2, formation luminescence chip back side island structure; The lower surface of the substrate of the luminescence chip after attenuate prepares one deck masking layer; At masking layer surface-coated photoresist, by photoetching, etching process, make masking layer output window, window shape is identical with flexible region; Substrate (4) is carried out to selective etch, obtain the island structure at the luminescence chip back side;

Step 3, prepare bottom electrode (6) and bottom electrode lead-in wire (10); Remove lower masking layer, prepare bottom electrode (6) and bottom electrode lead-in wire (10); Then, the lower surface at substrate (4) prepares flexible material;

Step 4, the luminescence chip back side are fixed; The lower surface that adopts bonding agent will prepare the substrate (4) of the luminescence chip of back side flexible material is fixed on lower screening glass;

The pixel segmentation of step 5, luminescence chip, obtain a plurality of LED luminescence units;

Step May Day, remove upper screening glass and bonding agent in step 1 three, expose the diaphragm that is positioned at the luminescence chip upper surface;

Step 5 two, to step described luminescence chip on May Day cleaned, photoetching and corrosion protection film, expose the diaphragm window; Under the sheltering of diaphragm and photoresist, the luminescence chip upper surface is carried out to the ICP etching, remove the luminescence chip material of flexible region fully, realize the pixel segmentation of luminescence chip;

Step 6, prepare the diaphragm zone between luminescence unit; Realizing that the luminescence chip upper surface that luminescence unit separates applies the diaphragm material, carry out precuring, remove the diaphragm material of photic zone (1) upper surface by photoetching and etching process, and by the formation concave shape of removing photoresist and corrosion makes the upper surface of formed flexible material again; Complete the fully curing of diaphragm material, remove the diaphragm of photic zone (1) upper surface;

Step 7, prepare top electrode (5) and top electrode lead-in wire (9);

Step 8, prepare lenticule (8); On the luminescence chip that completes top electrode (5) and top electrode lead-in wire (9), the polymeric layer of the high adhesion of preparation, obtain the micro polymer lens by hot melt;

Lower screening glass and the bonding agent of the lower surface of the substrate of step 9, removal luminescence chip, make circuit lead, completes the LED element manufacturing.

4. the preparation method of miniature LED integrated array device according to claim 3, it is characterized in that, the material of described top electrode (5), top electrode lead-in wire (9), bottom electrode (6) and bottom electrode lead-in wire (10) is any one in Cr/Au, Ti/Pt/Au, Ti/Mo/Au, AuGeNi/Au, Al or Cu, or be the composite membrane formed by Cr/Au, Ti/Pt/Au, Ti/Mo/Au or AuGeNi/Au and Cu, or be the composite membrane formed by Cr/Au, Ti/Pt/Au, Ti/Mo/Au or AuGeNi/Au and Au.

5. the preparation method of miniature LED integrated array device according to claim 3, it is characterized in that, the method for preparing top electrode (5), top electrode lead-in wire (9), bottom electrode (6) and bottom electrode lead-in wire (10) is: prepare film bottom electrode and bottom electrode lead-in wire by lift-off technique or plated film, photoetching and etching process, or prepare thick film bottom electrode and bottom electrode lead-in wire by thick resist lithography, evaporation and electroforming process for upsetting.

6. the preparation method of miniature LED integrated array device according to claim 5, it is characterized in that, the described concrete grammar for preparing thick film top electrode, top electrode lead-in wire, bottom electrode and bottom electrode lead-in wire is: at first carry out thick resist lithography and obtain the thick photoresist figure contrary with top electrode or bottom electrode figure, evaporation top electrode or bottom electrode film again, after peeling off, carry out electroforming, make the electrode thickening; The thin-film material of electroforming material and evaporation is identical or different.

7. the preparation method of miniature LED integrated array device according to claim 5, it is characterized in that, the described concrete grammar for preparing thick film top electrode, top electrode lead-in wire, bottom electrode and bottom electrode lead-in wire is: at first evaporation top electrode or bottom electrode film, then carry out thick resist lithography and obtain the thick photoresist figure contrary with top electrode or bottom electrode figure; Electroforming makes the electrode thickening, and the thin-film material of electroforming material and evaporation is identical or different; Finally, remove thick photoresist and obtain thick membrane electrode.

8. the preparation method of miniature LED integrated array device according to claim 3, it is characterized in that, the detailed process for preparing lenticule (8) is: apply the one layer of polymeric colloid layer on the LED luminescence unit that completes top electrode (5) and top electrode lead-in wire (9), according to design and processes, experiment determines the thickness of described colloid layer; The polymeric colloid layer is carried out to ultra-violet curing or hot curing, obtain having the polymeric layer of higher adhesion; On polymer after solidifying, glue is carved in spin coating, after front baking, exposure, development, adopts hot melt to make the photoresist lenticule; Adopt again reactive ion etching that the photoresist lenticule is transferred on described polymeric layer, obtain micro polymer lens (8).

9. the preparation method of miniature LED integrated array device according to claim 3, is characterized in that, the composite membrane that the material of described upper protective film and lower diaphragm is silicon dioxide or silicon nitride or silicon dioxide and silicon nitride composition.

10. the preparation method of miniature LED integrated array device according to claim 3, is characterized in that, after the lower surface attenuate to the substrate (4) of the luminescence chip described in step 1 three, the thickness of luminescence chip is 20~300 μ m.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310353610.5A CN103474445B (en) | 2013-08-14 | 2013-08-14 | Miniature LED integrated array device and preparation method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310353610.5A CN103474445B (en) | 2013-08-14 | 2013-08-14 | Miniature LED integrated array device and preparation method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN103474445A true CN103474445A (en) | 2013-12-25 |

| CN103474445B CN103474445B (en) | 2016-01-13 |

Family

ID=49799237

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310353610.5A Active CN103474445B (en) | 2013-08-14 | 2013-08-14 | Miniature LED integrated array device and preparation method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103474445B (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103400849A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array device for displaying and lighting and preparation method |

| CN105283971A (en) * | 2014-05-09 | 2016-01-27 | 釜庆大学校产学协力团 | LED chip having hybrid sensor and method for manufacturing same |

| CN105489716A (en) * | 2016-01-05 | 2016-04-13 | 中国科学院半导体研究所 | Preparation method for flexible LED array based on inorganic semiconductor material |

| CN107579143A (en) * | 2017-08-30 | 2018-01-12 | 歌尔股份有限公司 | LED component and preparation method thereof |

| CN107895543A (en) * | 2017-11-27 | 2018-04-10 | 福州大学 | A kind of high-integrated semiconductor display system |

| CN109037260A (en) * | 2017-06-09 | 2018-12-18 | 美商晶典有限公司 | Micro- light-emitting diode display module and its manufacturing method |

| CN110196503A (en) * | 2018-02-27 | 2019-09-03 | 印芯科技股份有限公司 | Light emitting devices |

| WO2020192528A1 (en) * | 2019-03-28 | 2020-10-01 | 京东方科技集团股份有限公司 | Array substrate manufacturing method, array substrate, and display device |

| CN113078145A (en) * | 2021-03-30 | 2021-07-06 | 厦门乾照半导体科技有限公司 | Array type light emitting diode device and manufacturing method thereof |

| CN114038953A (en) * | 2021-10-09 | 2022-02-11 | 重庆康佳光电技术研究院有限公司 | Micro light-emitting diode display and manufacturing method |

| CN114665047A (en) * | 2022-05-20 | 2022-06-24 | 镭昱光电科技(苏州)有限公司 | Display device and method of manufacturing the same |

| WO2023082325A1 (en) * | 2021-11-10 | 2023-05-19 | 惠州华星光电显示有限公司 | Display panel and method for preparing same |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060110839A1 (en) * | 2003-02-05 | 2006-05-25 | Dawson Martin D | Micro-leds |

| US20090078955A1 (en) * | 2007-09-26 | 2009-03-26 | Iii-N Technlogy, Inc | Micro-Emitter Array Based Full-Color Micro-Display |

| CN102130242A (en) * | 2010-09-28 | 2011-07-20 | 映瑞光电科技(上海)有限公司 | Single-color LED (light-emitting diode) chip and method for forming single-color LED chip |

| CN102386200A (en) * | 2010-08-27 | 2012-03-21 | 财团法人工业技术研究院 | Light emitting unit array and projection system |

| CN102790144A (en) * | 2012-07-23 | 2012-11-21 | 中国科学院长春光学精密机械与物理研究所 | Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure |

| CN103400915A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array chip |

| CN103400849A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array device for displaying and lighting and preparation method |

-

2013

- 2013-08-14 CN CN201310353610.5A patent/CN103474445B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060110839A1 (en) * | 2003-02-05 | 2006-05-25 | Dawson Martin D | Micro-leds |

| US20090078955A1 (en) * | 2007-09-26 | 2009-03-26 | Iii-N Technlogy, Inc | Micro-Emitter Array Based Full-Color Micro-Display |

| CN102386200A (en) * | 2010-08-27 | 2012-03-21 | 财团法人工业技术研究院 | Light emitting unit array and projection system |

| CN102130242A (en) * | 2010-09-28 | 2011-07-20 | 映瑞光电科技(上海)有限公司 | Single-color LED (light-emitting diode) chip and method for forming single-color LED chip |

| CN102790144A (en) * | 2012-07-23 | 2012-11-21 | 中国科学院长春光学精密机械与物理研究所 | Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure |

| CN103400915A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array chip |

| CN103400849A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array device for displaying and lighting and preparation method |

Non-Patent Citations (1)

| Title |

|---|

| 尹悦: "LED微显示集成阵列芯片的设计及关键技术研究", 《中国优秀硕士学位论文全文数据库》, 15 January 2013 (2013-01-15) * |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103400849A (en) * | 2013-08-14 | 2013-11-20 | 中国科学院长春光学精密机械与物理研究所 | Minitype LED array device for displaying and lighting and preparation method |

| CN103400849B (en) * | 2013-08-14 | 2016-01-13 | 中国科学院长春光学精密机械与物理研究所 | For the Minitype LED array device that shows and throw light on and preparation method |

| CN105283971A (en) * | 2014-05-09 | 2016-01-27 | 釜庆大学校产学协力团 | LED chip having hybrid sensor and method for manufacturing same |

| CN105283971B (en) * | 2014-05-09 | 2017-08-25 | 釜庆大学校产学协力团 | It is integrated with the LED chip and its manufacture method of hybrid sensor |

| CN105489716A (en) * | 2016-01-05 | 2016-04-13 | 中国科学院半导体研究所 | Preparation method for flexible LED array based on inorganic semiconductor material |

| CN105489716B (en) * | 2016-01-05 | 2017-10-13 | 中国科学院半导体研究所 | The preparation method of flexible led array based on inorganic semiconductor material |

| CN109037260A (en) * | 2017-06-09 | 2018-12-18 | 美商晶典有限公司 | Micro- light-emitting diode display module and its manufacturing method |

| CN107579143A (en) * | 2017-08-30 | 2018-01-12 | 歌尔股份有限公司 | LED component and preparation method thereof |

| CN107579143B (en) * | 2017-08-30 | 2019-06-25 | 歌尔股份有限公司 | LED component and preparation method thereof |

| CN107895543A (en) * | 2017-11-27 | 2018-04-10 | 福州大学 | A kind of high-integrated semiconductor display system |

| CN110196503A (en) * | 2018-02-27 | 2019-09-03 | 印芯科技股份有限公司 | Light emitting devices |

| WO2020192528A1 (en) * | 2019-03-28 | 2020-10-01 | 京东方科技集团股份有限公司 | Array substrate manufacturing method, array substrate, and display device |

| US11482545B2 (en) | 2019-03-28 | 2022-10-25 | Beijing Boe Display Technology Co., Ltd. | Method of forming array substrate, array substrate and display device |

| CN113078145A (en) * | 2021-03-30 | 2021-07-06 | 厦门乾照半导体科技有限公司 | Array type light emitting diode device and manufacturing method thereof |

| CN113078145B (en) * | 2021-03-30 | 2022-06-21 | 厦门乾照半导体科技有限公司 | Array type light emitting diode device and manufacturing method thereof |

| CN114038953A (en) * | 2021-10-09 | 2022-02-11 | 重庆康佳光电技术研究院有限公司 | Micro light-emitting diode display and manufacturing method |

| CN114038953B (en) * | 2021-10-09 | 2023-04-18 | 重庆康佳光电技术研究院有限公司 | Micro light-emitting diode display and manufacturing method |

| WO2023082325A1 (en) * | 2021-11-10 | 2023-05-19 | 惠州华星光电显示有限公司 | Display panel and method for preparing same |

| CN114665047A (en) * | 2022-05-20 | 2022-06-24 | 镭昱光电科技(苏州)有限公司 | Display device and method of manufacturing the same |

| CN114665047B (en) * | 2022-05-20 | 2022-09-23 | 镭昱光电科技(苏州)有限公司 | Display device and method of manufacturing the same |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103474445B (en) | 2016-01-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103474445B (en) | Miniature LED integrated array device and preparation method | |

| CN103474425B (en) | The miniature flexible LED area array device of high uniformity of luminance and preparation method | |

| CN103400850B (en) | For flexible led array device and the manufacture method of micro-display and illumination | |

| CN103400918B (en) | Transparent-electrodhigh-density high-density flexible LED micro-display array device and manufacture method | |

| US8172632B2 (en) | Method of making white LED package structure having a silicon substrate | |

| CN103390613A (en) | Densely arranged LED area array device with high luminance uniformity and preparation method | |

| CN102473818B (en) | The LED that color reduces about the change of angle | |

| CN109923683B (en) | Micro light-emitting diode and manufacturing method thereof | |

| CN101728470B (en) | Light-emitting diode device and method for fabricating the same | |

| CN103400849B (en) | For the Minitype LED array device that shows and throw light on and preparation method | |

| CN104282814A (en) | Light emitting diode packaging structure | |

| CN103400915A (en) | Minitype LED array chip | |

| CN103400924B (en) | Miniature flexible LED array device and preparation method | |

| CN102347436A (en) | LED (Light-emitting Diode) device and wafer-level LED device as well as packaging structure of LED device and wafer-level LED device | |

| CN104409585A (en) | Vertical LED structure and manufacturing method thereof | |

| CN105914275B (en) | Inverted light-emitting diode (LED) and preparation method thereof | |

| CN102222749A (en) | Light emitting component and module thereof | |

| CN103426875B (en) | Transparent-electrodflexible flexible LED micro-display array device and preparation method | |

| CN104538514B (en) | Flip LED chips structure and preparation method thereof | |

| KR20140111905A (en) | Wafer Level Chip Scale Light Emitting Diode Package | |

| CN104183678A (en) | LED flip chip and patterned substrate and manufacturing method of LED flip chip | |

| CN204596828U (en) | A kind of flip LED chips | |

| CN104966777A (en) | Semiconductor light-emitting device and method of manufacturing the same | |

| CN108493306B (en) | Preparation method of high-voltage high-power GaN-based LED array chip | |

| CN109461753B (en) | Large-injection flip micron LED chip and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |