CN102499405B - Preparation method for asparagus compound cereal fermentation type functional beverage - Google Patents

Preparation method for asparagus compound cereal fermentation type functional beverage Download PDFInfo

- Publication number

- CN102499405B CN102499405B CN201110356754.7A CN201110356754A CN102499405B CN 102499405 B CN102499405 B CN 102499405B CN 201110356754 A CN201110356754 A CN 201110356754A CN 102499405 B CN102499405 B CN 102499405B

- Authority

- CN

- China

- Prior art keywords

- asparagus

- juice

- fermentation

- temperature

- preparation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Non-Alcoholic Beverages (AREA)

Abstract

The invention belongs to the field of food processing, and specifically discloses a preparation method for an asparagus compound cereal fermentation type functional beverage. According to the preparation method, asparagus offcuts are adopted as raw materials. The method is characterized in that the asparagus offcuts are subjected to treatments of crushing juicing, enzymolysis and concentration to prepare into an asparagus juice; the asparagus juice is mixed with a compound cereal comprising rice, rhubarb rice and broomcorn millet; and the resulting mixture is subjected to treatments of saccharification, enzymolysis, fermentation and blending to prepare into the fermentation type functional beverage. According to the present invention, the asparagus and the compound cereal comprising the rice, the rhubarb rice and the broomcorn millet are mixed, and are subjected to the treatments of saccharification, enzymolysis and fermentation to prepare into the fermentation type functional beverage, the product has characteristics of moderate sour and sweet taste, harmony and gracefulness, the unique yeast aroma of the beverage attracts the consumers, and the consumers love the beverage.

Description

(1) technical field

The invention belongs to food processing field, particularly a kind of preparation method of asparagus compound cereal fermentation type functional beverage.

(2) background technology

Fast development along with national economy, improving constantly of people's living standard, having there is radical change in people's nutrition and health care consciousness, is being satisfied with under the prerequisite of having enough, having drunk cuisines, and nutrition dietary affects problem to the national national life quality whether feature that become to healthy; Nutrition simultaneously is also familiar with by consumer to people's health effect, government and consumer need to reach urgent and strong stage to green health, nutritional health food, how by occupying people, live the drink, food of main status on traditional basis, produce the drink, the food that become not only nutrition and health care but also there is certain function extremely urgent.

Asparagus is the dioecious herbaceos perennial of Liliaceae Asparagus, claim its asparagus to be because mainly edible tender stem is as tender stem and the bamboo shoots of reed, asparagus is with its higher nutritive value, medical value, very popular, becomes the high-grade health-care vegetable of international popular.Asparagus spear can be eaten raw and process, and root can be used as medicine, and its taste fragrance is delicious, soft good to eat, can improve a poor appetite, and helps digest; Asparagus is rich in the trace elements such as multivitamin and amino acid and selenium, molybdenum, manganese, energy balance the body organism metabolism and enhancing immunocompetence, the prevention of hypertension, heart disease and cancer and treatment are had to special pharmacological action, the effect that normal food has antifatigue, promotes longevity.

In recent years, asparagus has been processed with development faster, and quick-frozen asparagus, canned asparagus spear, asparagus wine are come out one after another, and the production technology of asparagus juice has also had certain progress, and asparagus allotment juice, the turbid juice of asparagus etc. have appearred in market in succession.Further investigation reveals that, though these products have certain nutritive value, market reaction is flat, can not meet taste and preference, trace it to its cause, and be first sensory issues, secondly the peculiar bitter substance of asparagus is difficult to adapt to consumer taste.

(3) summary of the invention

The present invention is in order to make up the deficiencies in the prior art, and the preparation method that a kind of unique flavor, quality are good, process unique asparagus compound cereal fermentation type functional beverage is provided

The present invention is achieved through the following technical solutions:

A kind of preparation method of asparagus compound cereal fermentation type functional beverage, take asparagus leftover bits and pieces as raw material, it is characterized in that: asparagus leftover bits and pieces is made to asparagus juice through broken juice, enzymolysis, after concentrated, mix through saccharification, enzymolysis, fermentation, allotment and make fermented type drinks with the composite cereal being formed by rice, Radix Et Rhizoma Rhei rice, milled glutinous broomcorn millet.

The present invention mainly comprises the steps:

(1) asparagus leftover bits and pieces is placed in to water and adds multivariate table surface-active agent, vitamin C and citric acid cleaning, after cleaning, with the citric acid water of heating, complete;

(2) the cooled asparagus leftover bits and pieces that will complete is broken for the particle of 1 ~ 15mm, adds citric acid, sodium ascorbate and maceration enzyme simultaneously, is then squeezed the juice, filters;

(3) juice after filtering is pumped in enzymolysis cylinder, add the natural clarifying agent of 0.003% compound dispersion chestnut STERM layer current potential to stir and evenly mix, standing 1.5 ~ 2 hours, separation of supernatant, filtered through diatomite filter;

(4) asparagus juice filtration being obtained adopts quadruple effect falling film type evaporation concentrated, then pump in enzymolysis cylinder, at 50 ~ 55 ℃, add ZTE natural clarifying agent, pectase, Ludox, tannin, gelatin to stir, within standing 1.5 ~ 2 hours, carry out secondary enzymolysis clarification, finally filter;

(5) adopt quadruple effect falling film type evaporation concentrator to carry out rear concentrated, in concentrated last effect device, cooling Titian is set and returns fragrant device, add the ethanol of-18 ~-15 ℃ to carry out cooling, be cooled to 5 ~ 10 ℃ of Titians;

(6) under 40 ~ 45 ℃, the vacuum of 400 ~ 500mm mercury column, concentrated asparagus juice is carried out degassed, then by the rear ultra high temperature sterilization of 80 ~ 95 ℃ preheat, be cooled to 28 ~ 32 ℃ after low tempertaure storage, obtain concentrating asparagus Normal juice;

(7) composite cereal is added to water-wet, impurity elimination, fragmentation, in mixing tank, add concentrated asparagus Normal juice and pure water, under the state stirring, slowly add broken good composite cereal, make it to mix;

(8) material mixing is put into digester, heat while stirring, boiling temperature is 95 ~ 98 ℃, be incubated 50 ~ 70 minutes after cooling, add saccharifying agent to stir, insulation saccharification;

(9) by the good aroma-producing yeasts of seed selection, first the test tube slant culture medium made from brewer's wort carries out preservation, adjusting wort concentration is 7 ° of Be, pH value is 4.5 ~ 5, agar 2%, 0.1MPa sterilizing 30min, temperature is controlled at 26 ~ 28 ℃, cultivate after 3d, in 4 ℃ of left and right preservations, inoculation in 3 months is transplanted once;

The purebred cultivation in laboratory: large triangular flask (1L) the Ka Shi tank (10L) of the little triangular flask of slant strains (250ml);

The purebred cultivation in workshop: Ka Shi tank (10L) first class seed pot (100L) secondary seed tank (1000L).

(10) saccharified liquid is squeezed into fermentation tank, access prior cultured distiller's yeast, inoculum concentration is not less than converted mash 10%, temperature controlled fermentation, and after pol drops to 15~18Brix, stuck fermentation immediately, sterilization treatment;

(11) zymotic fluid is carried out to little fire and distill slowly, low temperature is plucked wine, after separated, still residue is proceeded to horizontal screw centrifuge, and the clear liquid that centrifugation goes out adds the standing clarification of fining agent, obtains asparagus fermenation raw liquid, filter, obtain asparagus composite cereal zymotic fluid;

(12) toward adding acidity agent, sweetener and stabilizing agent in asparagus composite cereal zymotic fluid, stir, hyperfiltration, ultra high temperature short time sterilization, finally obtains product.

Its preferred technical scheme is:

In step (1), the vitamin C of multivariate table surface-active agent, 0.8 ~ 1 ‰ of oedema condition 0.2 ‰ and 0.3 ‰ citric acid when asparagus leftover bits and pieces cleans, the raw material after cleaning completes three minutes with 95 ℃, 0.3% citric acid water.

In step (2), in shattering process, add 0.03 ‰ citric acid, 0.15% sodium ascorbate and 0.005% maceration enzyme.

In step (4), enzymolysis clarification is, adds 0.03 ‰ ZTE natural clarifying agent, 0.03 ‰ pectase, 0.007 ‰ Ludox, 0.003 ‰ tannin and 0.005 ‰ gelatin; During the quadruple effect of asparagus juice concentrates, an effect temperature is 60 ~ 62 ℃, and vacuum is 600mm mercury column, two effect temperature are 40 ~ 42 ℃, and vacuum is 650 ~ 700mm mercury column, and triple effect temperature is 50 ~ 55 ℃, vacuum is 600 ~ 650mm mercury column, and quadruple effect temperature is 40 ~ 42 ℃, and vacuum is 700 ~ 750mm mercury column.

In step (7), the weight proportion of concentrated asparagus Normal juice, rice, Radix Et Rhizoma Rhei rice, milled glutinous broomcorn millet, pure water is 10:10:15:15:50.

In step (8), boiling gelatinization point is 103 ~ 105 ℃, and the time is 30 minutes; Saccharification temperature is 60 ℃, and the time is 72h, and saccharifying agent is carbohydrase and root aspergillus, saccharifying agent consumption Wei300 unit/g.

In step (10), fermentation temperature is 26 ~ 28 ℃, and the time is 4 ~ 5 days.

In step (11), while plucking wine, first separately pinch and get 0.5 ~ 1kg foreshot, pluck wine to 50 ~ 55%(v/v) time, change atmosphere and knock into the back, pinch and get wine tail and deposit separately, when wine tail wine degree is less than 5%, stop pinching a wine, atmosphere acid discharge, after 10 minutes, stops distillation, carries out separation.

In step (12), the operation differential static pressure of hyperfiltration is 0.2 ~ 1MPa.

The present invention adopts pure biotechnology brew, there are vegetables that better nutritivity health care is worth and nutritious cereal is fused in the production technology of fermented beverage by asparagus is this, produce a kind of have pure and sweet asparagus fragrance, taste salubrious high-quality drinks, the nutrition and the functional component that have retained to the full extent asparagus and cereal, have good nutrition and health care effect; Product color is yellowish, and clear, fragrance is strong, mouthfeel is mellow, has anti-cancer, reducing blood lipid, toxin expelling diuresis, strong kidney, strengthens the effect of immunity.

The present invention is mixedly together with rice, Radix Et Rhizoma Rhei rice, milled glutinous broomcorn millet through saccharification, enzymolysis, fermentation, to make a kind of Fermented drinks by asparagus and composite cereal, this product sour and sweet palatability, harmonious graceful, and its unique yeast fragrance deep breath has drawn consumer, enjoys great kindness.

(4) accompanying drawing explanation

Below in conjunction with accompanying drawing, the present invention is further illustrated.

Fig. 1 is process chart prepared by the concentrated asparagus Normal juice of the present invention;

Fig. 2 is the process chart of asparagus composite cereal fermentation of the present invention;

Fig. 3 is that under different conditions of cooking, viscosity number changes schematic diagram;

Fig. 4 is that under different conditions of cooking, pol changes schematic diagram;

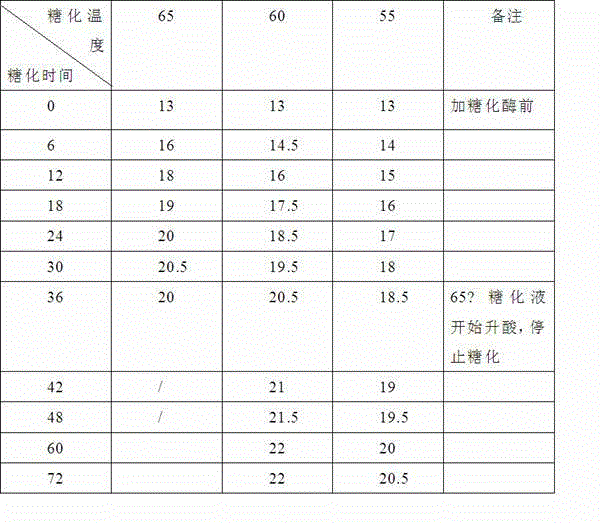

Fig. 5 is different saccharification temperature pol change curve schematic diagrames.

(5) specific embodiment

Embodiment:

One, asparagus inspissated juice preparatory phase

(1) pretreatment of raw material:

Clean: the leftover bits and pieces of choosing in the outer asparagus of non-rot grade and canned asparagus spear, quick-frozen asparagus production is made raw material, raw material is strictly washed, to remove microorganism, sand, dead leaf and the part agricultural chemicals etc. of raw material surface attachment with the stability of assurance product quality.

In cleaning fluid, add the vitamin C of 0.2 ‰ multivariate table surface-active agent, 0.8 ~ 1 ‰ and 0.3 ‰ citric acid, to improve clean effect, remove copper and other heavy metal in bactericide.

Complete: the raw material after cleaning will complete three minutes with 95 ℃, 0.3 ‰ citric acid waters, this process of completing can keep the activity of Normal juice color and inactive enzyme to prevent occurring brown stain and microbial spoilage phenomenon in each road manufacturing procedure afterwards, simultaneously can remove portion bitter taste.

(2) broken juice:

Broken: the cooled material that completes will carry out fragmentation in time, and broken fineness is 1 ~ 15mm, and adds 0.03 ‰ citric acid in shattering process simultaneously, 0.15% sodium ascorbate and 0.005% maceration enzyme, effectively decompose the colloidal substance in asparagus, reduce viscosity, improve crushing juice rate.Shattering process will be taked cold crush method, and this method can reduce in shattering process ascorbic destruction.

Squeeze the juice: raw material is with squeezing the juice with spiral juice extractor after crusher in crushing.The process of squeezing the juice also should keep low temperature, and low temperature can keep stronger pectinase activity, and the clarity of asparagus juice is improved.The juice of squeezing out is filtered through 150 order ternary vibratory sieves.

(3) enzymolysis clarification: the juice (55 ~ 65 ℃) after filtering is pumped into rapidly in enzymolysis cylinder, the natural clarifying agent that adds 0.003% compound dispersed particle STERM layer current potential, stir and evenly mix, static 1.5 ~ 2 hours, main tannic acid, protein, resin, the wax isocolloid labile element removed, eliminate its on active ingredient in asparagus juice as the impact of alkaloid, glycoside, saponins, terpene, polysaccharide, amino acid, polypeptide, vitamin, mineral matter and other components.

Diatomite filtration: be that supernatant is squeezed into Diatomeae filter and filtered by the asparagus juice of enzymolysis clarification, filter adopts drum type vacuum filter, first carry out coarse filtration, filter is hung in native process, vacuum is 900 ~ 950mm mercury column, pre-hung diatomite layer thickness is 4 ~ 5cm, scraper is adjusted into 0.5 ~ 0.8 mm, the diatomite filter that asparagus juice after filtration is squeezed into positive press filtration again filters, asparagus juice technical indicator after filtration is, light transmittance (625nm) 95.6%, colour (425nm) 50%, turbidity 4 ~ 5NTU.Under enzymolysis, precipitated liquid is with pumping into diatomite filtration after horizontal screw centrifuge separation.

(4) just concentrated: the concentrated quadruple effect falling film type evaporation that adopts is concentrated, and it is 18Brix (compound microcapsule) that asparagus juice is concentrated into 5 times, then pump into and in enzymolysis cylinder, carry out secondary enzymolysis clarification.Adopting temperature is 50 ~ 55 ℃, separately adds 0.03 ‰ ZTC natural clarifying agent, 0.03 ‰ pectase, and 0.007 ‰ Ludox, 0.003 ‰ tannin and 0.005 ‰ gelatin, stir, and then after static 1.5 ~ 2 hours, filters.Filter type adopts diatomite filtration and hyperfiltration machine to filter.

During the quadruple effect of asparagus juice concentrates, one effect temperature is 60 ~ 62 ℃, vacuum is 600mm mercury column, and two effect temperature are 40 ~ 42 ℃, and vacuum is 650 ~ 700mm mercury column, triple effect is 50 ~ 55 ℃, vacuum is 600 ~ 650mm mercury column, and quadruple effect temperature is 40 ~ 42 ℃, and vacuum is 700 ~ 750mm mercury column, wherein, it is cooling that concentrator adopts secondary spraying formula.

Diatomite filtration: adopt diatomite filter to filter juice.First diatomite filter is carried out to precoating and make to form a kind of diatomite coating on stainless steel filtration disk, liquid to be filtered is by precoated shet under pump pressure effect, and particle and macromolecule are just trapped within precoated shet.This law is bright through experiment repeatedly, show that best precoated shet thickness is 5mm left and right.

(5) concentrated after: to adopt quadruple effect falling film type evaporation concentrator.In concentration process, Hui Xiang is also a main link, asparagus contains special aromatic substance, its typical fragrance matter delicate fragrance is graceful, slightly bitter, in concentration process, it can volatilize with the evaporation of moisture, for this reason in concentrated last effect device, cooling Titian is set and returns fragrant device, add 70% the ethanol of-18 ~-15 ℃ to carry out cooling, be cooled to 5 ~ 10 ℃, extract the aromatic substance in asparagus.

(6) degassed, sterilizing: at 40 ~ 45 ℃, carry out degassed to concentrated asparagus Normal juice under the vacuum of 400 ~ 500mm mercury column.This project adopts vacuum degassing technology, for fully removing the oxygen in Juice, should make the interior juice temperature of degassing tank higher than the corresponding boiling point of vacuum in degassing tank, and definite optimum temperature can make degassed beverage have 2% ~ 3% evaporation capacity.Asparagus juice after degassed, by 80 ~ 95 ℃ preheat, adopts the ultra high temperature sterilization of 121 ℃, and holding the temperature time is 45 ~ 50s, and cooling procedure for being cooled to 28 ~ 32 ℃ after 60 ~ 75 ℃ pre-cooled again.After finishing, sterilizing proceeds to hold-up tank low tempertaure storage, in order to the use of secondary fermentation stage.

Two, composite cereal processing stage

(7) spice: cereal impurity elimination is eluriated clean rear broken, in mixing tank, add asparagus inspissated juice and pure water, open and stir, slowly add broken good composite cereal (rice, Radix Et Rhizoma Rhei rice and milled glutinous broomcorn millet), asparagus inspissated juice, rice, Radix Et Rhizoma Rhei rice, milled glutinous broomcorn millet, pure water, its ratio is 10:10:15:15:50, notes stirring and charging rate, make it to mix, must not have caking or sink to the bottom phenomenon to occur.

(8) boiling: will pour in digester than the base-material preparing by optimum proportion, heat while stirring, carry out boiling gelatinization, note controlling heating and mixing speed, prevent precipitation or be burned at the end, boiling temperature is selected respectively 95 ~ 98 ℃ and 103 ~ 105 ℃, and temperature retention time is got respectively 15,30,45,60 minutes, detect its viscosity number and pol value and change, to determine best conditions of cooking.

Under different boiling temperature conditions, viscosity number and pol value change as shown in the table

By upper table and accompanying drawing 3,4, can be found out, best conditions of cooking should be: 103 ~ 105 ℃ of temperature, 30 minutes time;

Three, mix the saccharification stage

(9) saccharification: after boiling finishes, the saccharification of can lowering the temperature.Reach after saccharification temperature requirement, add carbohydrase, the saccharifying agents such as root aspergillus, stir, insulation saccharification.Meanwhile, note recording pol situation of change, and PH variation, reach after regulation requirement, can stop saccharification, cooling fermentation.

A, saccharification temperature time effects: saccharification temperature is got respectively 65,60,55 ℃, add the carbohydrase of 300 units/g, and insulation saccharification, measures its pol situation of change and reach the highest pol time, to determine best saccharification temperature and saccharificatinn period.

Under different saccharification temperature conditions, pol situation of change is as shown in the table

By showing above and accompanying drawing 5 can be found out, best saccharification temperature and saccharificatinn period are determined and be: 60 ℃ of saccharification temperatures, time 72h;

B, saccharifying agent select impact: can select respectively 1. carbohydrase 2. carbohydrase+root inulinase 3. root inulinase 4. in heat wine Qu Jinhang mashing test, to determine best saccharifying agent combination.Consumption can add according to its saccharifying power ,An 300 units/g.

Best saccharifying agent combination is determined: carbohydrase+root inulinase

C, the impact of saccharifying agent consumption: respectively in the ratio of saccharifying power 100,150,200,300, 400 units/g, add saccharifying agent and carry out mashing test, record pol situation of change, to determine optimal proportion.

Best saccharifying agent Determination of quantity: 300 units/g

D, by orthogonal experiment, determine best saccharification condition

On mashing test basis above, in order to obtain best saccharification condition, on saccharification temperature, saccharificatinn period, saccharifying agent combination, saccharifying agent consumption, these affect the key process parameter of saccharification result respectively, carry out orthogonal test, to determine best saccharification condition.

Best Saccharification Parameters: 60 ℃ of saccharification temperatures, time 72h; Saccharifying agent: carbohydrase and root aspergillus; Saccharifying agent consumption: 300 units/g.

Four, the inoculation fermentation stage

(10) Yeast Cultivation

A, yeast screening assay: by from market purchasing and University Of Yantai's food fermentation research institute seed selection and preservation several primary yeasts: the XYNo109 of University Of Yantai yeast, new aroma-producing yeasts greatly, Angel aroma-producing yeasts, beneficial aroma-producing yeasts of a specified duration, beneficial friend's aroma-producing yeasts, yellow rice wine dry ferment, with the direct broken juice of fresh asparagus, recording pol is 3 ° of Brix, with brewer's wort sugar addition, be 7 ° of Brix, respectively above all kinds of yeast are inoculated in 100ml asparagus Normal juice by identical inoculum concentration, in constant incubator, temperature control ferments, observe fermentation situation, emphasis is aerogenesis speed, rise sour speed, fragrance forms, to determine best kind.

The yeast strain of the most applicable asparagus fermentation:

B, barms preservation: by the good aroma-producing yeasts of seed selection, the test tube slant culture medium of first making with brewer's wort carries out preservation.Adjusting wort concentration is 7 ° of Be, and pH value is 4.5 ~ 5, agar 2%, and 0.1MPa sterilizing 30min, temperature is controlled at 26~28 ℃, cultivates after 3d, and in 4 ℃ of left and right preservations, inoculation in 3 months is transplanted once.

The purebred cultivation in laboratory:

Flow process: large triangular flask (1L) the Ka Shi tank (10L) of the little triangular flask of slant strains (250ml)

The purebred cultivation in workshop:

Flow process: Ka Shi tank (10L) first class seed pot (100L) secondary seed tank (1000L)

Distiller's yeast culture process technical conditions

(11) fermentation: after saccharified liquid cools to inoculation temperature, squeeze into fermentation tank, access prior cultured distiller's yeast, inoculum concentration is not less than converted mash 10%, temperature controlled fermentation.After pol drops to 15~18Brix, stuck fermentation immediately, sterilization treatment.Adopt respectively different fermentation temperatures to ferment, carry out pol in sweat, total acid, temperature, pH value change records, to determine optimal conditions of fermentation.

Best technological condition for fermentation: optimum fermentation temp is 26 ~ 28 ℃, 4 ~ 5 days time.

Five, the separating and filtering stage

(12) distillation: by the zymotic fluid after fermentation ends, squeeze in boiler, open steam, distill.During distillation, will note controlling distillation speed, accomplish that little fire steams slowly, low temperature is plucked wine.While plucking wine, to note leaving out the beginning and the end, pinch and get 0.5 ~ 1kg foreshot first separately, pluck wine to 50 ~ 55%(v/v) time, change atmosphere and knock into the back, pinch and get wine tail and deposit separately, get that pot is multiple to be steamed ready.Until wine tail wine degree, be less than 5%(v/v) time, stopping pinching wine, atmosphere acid discharge, after 10 minutes, stops distillation, carries out separation.

Separated: still residue to be proceeded to horizontal screw centrifuge, carry out centrifugation.After separated, residue is deposited separately, and standby proferment vinegar is used; Separated clear liquid proceeds to hold-up tank, clarifying treatment.

Clarification: the separated clear liquid of horizontal screw centrifuge is added respectively to the fining agents such as pectase, cellulase, bentonite, stir, standing clarifying treatment.

Filter: the asparagus fermenation raw liquid that lower glue is clarified, get supernatant and filter.Filter and use horizontal disc diatomite filter, with 616 types and 821 type diatomite that Qingdao Samsung filter aid factory produces, make filter aid, filter aid addition is by each 616 type+821 type=1.5kg+1.5kg, and filter pressure is 0.15 ~ 0.3Mpa, and precoating thickness of filter bed is not less than 1cm.It is standby that filtration finishes rear clarified solution storage, and turbid solution and precipitation residue proceed to horizontal screw centrifuge centrifugation again.

Six, the allotment tinning stage

(13) allotment: mainly adjust the sugar-acid ratio of beverage, give prominence to feeling of freshness and the refrigerant sense of asparagus health drink, and fully demonstrate the original feature of asparagus juice.Before batching, first prepare syrup, granulated sugar is dissolved and filter, make certain density syrup.Batching is carried out in batches, according to every batch of dosage, according to the proportioning of the different cultivars raw material of formula regulation, calculates the consumption of Juice.Then adjust sugar-acid ratio, various Juices used or slurry are put into blend tank to be uniformly mixed, according to soluble solid content and the dosage of the soluble solid content of the mixed juice slurry of measuring, juice slurry consumption, product beverage, calculate granulated sugar consumption, and by the syrup concentration of preparation, calculate syrup consumption.After calculating, syrup used is put into blend tank, add water to the ormal weight of every batch of batching, be further uniformly mixed.Measure the acidity of beverage in blend tank, calculate and need supplementary Citric Acid Dosage, acid is mixed with to acid solution and adds in blend tank.Finally add thickener, stabilizing agent, and will add micro-colouring agent, essence etc. as required, fully stir.

Hyperfiltration: the particle and the large molecule that utilize hyperfiltration membrane filtration 5 ~ 100nm.Operation differential static pressure is 0.2 ~ 1MPa.

Sterile filling: 8 grades of air cleanings of racking room, wash, local 5 grades of air cleanings (primary standard is 100 grades) in filling, inside back cover position all-in-one.The equipment of all contact fruit drinks, article even space all must be through strict sterilizings.Bottle adopts the chlorine dioxide disinfection liquid of 250ppm to soak 30s; Bubble bottle machine is done local 5 grades of purifications; Disinfectant has the automatic recovery and concentration determination system, guarantees that decontaminant concentration is stable; After bottle sterilization, be delivered to bottling department, with sterilized water, disinfectant residual in bottle rinsed well, then dried up with filtrated air, guarantee that residual disinfectancy agent can not exert an influence to material.Lid sterilization can adopt ozone fumigating system, in ozone disinfection cabinet, carries out, and ozone concentration is 1% left and right, and the time is 25 ~ 30 minutes.Ozone disinfection cabinet is placed in aseptic, and the lid after sterilizing is directly gone up bottle placer.To fruit juice, sterilization is to adopt UHT ultra high temperature short time sterilization, temperature 135 ~ 150 to cold-aseptic filling

0c, time 3 ~ 5 seconds.Material heated time is short, and nutritional labeling is lost seldom, and quality and mouthfeel do not have significant change yet.

Claims (9)

1. the preparation method of an asparagus compound cereal fermentation type functional beverage, take asparagus leftover bits and pieces as raw material, it is characterized in that: asparagus leftover bits and pieces is made to asparagus juice through broken juice, enzymolysis, after concentrated, mix through saccharification, enzymolysis, fermentation, allotment and make fermented type drinks with the composite cereal being formed by rice, milled glutinous broomcorn millet; Mainly comprise the steps:

(1) asparagus leftover bits and pieces is placed in to water and adds multivariate table surface-active agent, vitamin C and citric acid cleaning, after cleaning, with the citric acid water of heating, complete;

(2) the cooled asparagus leftover bits and pieces that will complete is broken for the particle of 1 ~ 15mm, adds citric acid, sodium ascorbate and maceration enzyme simultaneously, is then squeezed the juice, filters;

(3) juice after filtering is pumped in enzymolysis cylinder, add 0.003% natural clarifying agent that meets the current potential of dispersed particle STERM layer to stir and evenly mix, standing 1.5 ~ 2 hours, separation of supernatant, filtered through diatomite filter;

(4) asparagus juice filtration being obtained adopts quadruple effect falling film type evaporation concentrated, then pump in enzymolysis cylinder, at 50 ~ 55 ℃, add ZTC natural clarifying agent, pectase, Ludox, tannin, gelatin to stir, within standing 1.5 ~ 2 hours, carry out secondary enzymolysis clarification, finally filter;

(5) adopt quadruple effect falling film type evaporation concentrator to carry out rear concentrated, in concentrated last effect device, cooling Titian is set and returns fragrant device, add the ethanol of-18 ~-15 ℃ to carry out cooling, be cooled to 5 ~ 10 ℃ of Titians;

(6) under 40 ~ 45 ℃, the vacuum of 400 ~ 500mm mercury column, concentrated asparagus juice is carried out degassed, then by the rear ultra high temperature sterilization of 80 ~ 95 ℃ preheat, be cooled to 28 ~ 32 ℃ after low tempertaure storage, obtain concentrating asparagus Normal juice;

(7) composite cereal is added to water-wet, impurity elimination, fragmentation, in mixing tank, add concentrated asparagus Normal juice and pure water, under the state stirring, slowly add broken good composite cereal, make it to mix;

(8) material mixing is put into digester, heat while stirring, boiling temperature is 95 ~ 98 ℃, be incubated 50 ~ 70 minutes after cooling, add saccharifying agent to stir, insulation saccharification;

(9) by the good aroma-producing yeasts of seed selection, the test tube slant culture medium of first making with brewer's wort carries out preservation, and adjusting wort concentration is 7 ° of Be, and pH value is 4.5 ~ 5, agar 2%, 0.1MPa sterilizing 30min, temperature is controlled at 26 ~ 28 ℃, cultivate after 3d, in 4 ℃ of preservations, inoculation in 3 months is transplanted once;

(10) saccharified liquid is squeezed into fermentation tank, access prior cultured distiller's yeast, inoculum concentration is not less than converted mash 10%, temperature controlled fermentation, and after pol drops to 15~18Brix, stuck fermentation immediately, sterilization treatment;

(11) zymotic fluid is carried out to little fire and distill slowly, low temperature is plucked wine, after separated, still residue is proceeded to horizontal screw centrifuge, and the clear liquid that centrifugation goes out adds the standing clarification of fining agent, obtains asparagus fermenation raw liquid, filter, obtain asparagus composite cereal zymotic fluid;

(12) toward adding acidity agent, sweetener and stabilizing agent in asparagus composite cereal zymotic fluid, stir, hyperfiltration, ultra high temperature short time sterilization, finally obtains product.

2. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, it is characterized in that: in step (1), when asparagus leftover bits and pieces cleans, in water, add the vitamin C of 0.2 ‰ multivariate table surface-active agent, 0.8 ~ 1 ‰ and 0.3 ‰ citric acid, the raw material after cleaning completes three minutes with 95 ℃, 0.3% citric acid water.

3. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, is characterized in that: in step (2), add 0.03 ‰ citric acid, 0.15% sodium ascorbate and 0.005% maceration enzyme in shattering process.

4. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, it is characterized in that: in step (4), enzymolysis clarification is, adds 0.03 ‰ ZTC natural clarifying agent, 0.03 ‰ pectase, 0.007 ‰ Ludox, 0.003 ‰ tannin and 0.005 ‰ gelatin; During the quadruple effect of asparagus juice concentrates, an effect temperature is 60 ~ 62 ℃, and vacuum is 600mm mercury column, two effect temperature are 40 ~ 42 ℃, and vacuum is 650 ~ 700mm mercury column, and triple effect temperature is 50 ~ 55 ℃, vacuum is 600 ~ 650mm mercury column, and quadruple effect temperature is 40 ~ 42 ℃, and vacuum is 700 ~ 750mm mercury column.

5. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, is characterized in that: in step (7), the weight proportion of concentrated asparagus Normal juice, rice, milled glutinous broomcorn millet, pure water is 10:10:30:50.

6. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, is characterized in that: in step (8), saccharification temperature is 60 ℃, and the time is 72h, and saccharifying agent is carbohydrase and root aspergillus, saccharifying agent consumption Wei300 unit/g.

7. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, is characterized in that: in step (10), fermentation temperature is 26 ~ 28 ℃, and the time is 4 ~ 5 days.

8. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, it is characterized in that: in step (11), while plucking wine, first pinch and get 0.5 ~ 1kg foreshot separately, pluck wine to 50 ~ 55%(v/v) time, change atmosphere and knock into the back, pinch and to get wine tail and deposit separately, when wine tail wine degree is less than 5%, to stagnate and pinch wine, atmosphere acid discharge is after 10 minutes, stop distillation, carry out separation.

9. the preparation method of asparagus compound cereal fermentation type functional beverage according to claim 1, is characterized in that: in step (12), the operation differential static pressure of hyperfiltration is 0.2 ~ 1MPa.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201110356754.7A CN102499405B (en) | 2011-11-11 | 2011-11-11 | Preparation method for asparagus compound cereal fermentation type functional beverage |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201110356754.7A CN102499405B (en) | 2011-11-11 | 2011-11-11 | Preparation method for asparagus compound cereal fermentation type functional beverage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102499405A CN102499405A (en) | 2012-06-20 |

| CN102499405B true CN102499405B (en) | 2014-02-26 |

Family

ID=46211586

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201110356754.7A Active CN102499405B (en) | 2011-11-11 | 2011-11-11 | Preparation method for asparagus compound cereal fermentation type functional beverage |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102499405B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104012945B (en) * | 2013-09-12 | 2016-08-17 | 菏泽巨鑫源食品有限公司 | The preparation method of solid Germinatus Phragmitis ferment |

| CN103992897B (en) * | 2013-10-11 | 2015-08-26 | 菏泽巨鑫源食品有限公司 | The preparation method of asparagus gas water beverage |

| CN108850800A (en) * | 2018-06-20 | 2018-11-23 | 云南农业大学 | A kind of asparagus rice and preparation method thereof |

| CN110150523A (en) * | 2019-06-14 | 2019-08-23 | 扬州大学 | A kind of novel fermentation asparagus beverage preparation method |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101579136A (en) * | 2009-06-12 | 2009-11-18 | 菏泽巨鑫源食品有限公司 | Concentrated cloudy juice prepared from waste asparagus and processing technology thereof |

| CN101643691A (en) * | 2009-09-01 | 2010-02-10 | 周长生 | Asparagus beer and brewing method thereof |

| CN101748029A (en) * | 2008-12-09 | 2010-06-23 | 秦刚 | Production technology of black rice wine |

| CN101946936A (en) * | 2010-08-24 | 2011-01-19 | 菏泽巨鑫源食品有限公司 | Process for preparing concentrated asparagus clear juice |

-

2011

- 2011-11-11 CN CN201110356754.7A patent/CN102499405B/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101748029A (en) * | 2008-12-09 | 2010-06-23 | 秦刚 | Production technology of black rice wine |

| CN101579136A (en) * | 2009-06-12 | 2009-11-18 | 菏泽巨鑫源食品有限公司 | Concentrated cloudy juice prepared from waste asparagus and processing technology thereof |

| CN101643691A (en) * | 2009-09-01 | 2010-02-10 | 周长生 | Asparagus beer and brewing method thereof |

| CN101946936A (en) * | 2010-08-24 | 2011-01-19 | 菏泽巨鑫源食品有限公司 | Process for preparing concentrated asparagus clear juice |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102499405A (en) | 2012-06-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102488013B (en) | Preparation method of asparagus and natto health drink | |

| CN102488267B (en) | Asparagus-pawpaw functional drink and its production method | |

| CN102492601B (en) | Asparagus healthcare vinegar and preparation process | |

| CN105211880B (en) | Preparation method of fig enzymes | |

| CN104593219A (en) | Fermented kiwi fruit vinegar and brewing method thereof | |

| CN104774700B (en) | Cherokee rose fruit craft beer and preparation method thereof | |

| CN107557224A (en) | A kind of honey raisin tree health lycium chinense and its brewing method | |

| CN102499405B (en) | Preparation method for asparagus compound cereal fermentation type functional beverage | |

| CN102864059B (en) | Full-juice fermented yam wine and preparation method thereof | |

| CN102524863B (en) | Asparagus corn fermented beverage and preparation method thereof | |

| CN101381664A (en) | Honeymead and honey vinegar brewed by natural plant spice and preparation method thereof | |

| JP2008194040A (en) | Method for producing alcoholic beverage using cultured root of mountain ginseng | |

| CN105482982B (en) | A method of producing high-quality fruit vinegar using navel orange slag multi-cultur es liquid submerged fermentation | |

| CN109181976B (en) | Low-alcohol green plum wine and production method thereof | |

| CN102871187B (en) | Preparation method of seaweed-strawberry fermented drink | |

| CN105670872A (en) | Directly brewed health fresh purple sweet potato wine and production process therefor | |

| CN107904075A (en) | A kind of preparation method of Chinese data wine | |

| CN102293437A (en) | Method for preparing grosvener siraitia composite plant drink without fishy smell | |

| JP2007135415A (en) | Method for producing food and drink using buckwheat as raw material | |

| CN104013056B (en) | A kind of preparation method of asparagus pachyrhizus fermented beverage | |

| CN106962716B (en) | Lucid ganoderma germinated brown rice fruit and vegetable beverage and preparation method thereof | |

| TW200415995A (en) | Method for producing yam juice, method for producing beverage, and beverage | |

| PotdarVrushali et al. | Optimum parameters for wine production from fig fruit (Ficus Carica) juice | |

| CN108936492A (en) | Preparation method of grape skin jam with round leaves | |

| CN109181922A (en) | A kind of brewing method of Chinese pear beer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20190415 Address after: 274000 West Side of Qinghe North Road and Songhua River Road Intersection in Cao County, Heze City, Shandong Province Patentee after: Shandong Juxinyuan Agricultural Technology Co., Ltd. Address before: 274400 Jinzhuang Industrial Development Zone, Suji Town, Cao County, Heze City, Shandong Province Patentee before: Heze Jvxinyuan Food Co., Ltd. |