CN101992128B - Regeneration method of ammoxidation fluid catalyst - Google Patents

Regeneration method of ammoxidation fluid catalyst Download PDFInfo

- Publication number

- CN101992128B CN101992128B CN200910057792A CN200910057792A CN101992128B CN 101992128 B CN101992128 B CN 101992128B CN 200910057792 A CN200910057792 A CN 200910057792A CN 200910057792 A CN200910057792 A CN 200910057792A CN 101992128 B CN101992128 B CN 101992128B

- Authority

- CN

- China

- Prior art keywords

- catalyst

- potassium

- molybdenum

- fluid

- ammoxidation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

- Y02P20/52—Improvements relating to the production of bulk chemicals using catalysts, e.g. selective catalysts

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

- Y02P20/584—Recycling of catalysts

Landscapes

- Catalysts (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Abstract

The invention relates to a regeneration method of an ammoxidation fluid catalyst, which mainly solves the problem that sublimation of the Mo element and loss of the K element result in the decrease of catalyst activity in the use process of the current Mo, Bi and Fe oxide system catalysts in an industrial device. The invention adopts the technical scheme of supplementing the corresponding contents of molybdenum and kalium according to the composition requirement of a fresh body catalyst of the ammoxidation fluid equilibrium catalyst, and calcining and activating at the temperature of 550-700 DEG C for 0.5-12 hours to obtain the regenerated catalyst. The technical scheme better solves the problem and can be used for the industrial production of an acrylonitrile or methacrylonitrile device by ammoxidation.

Description

Technical field

The present invention relates to a kind of renovation process of ammonoxidizing fluid bed catalyst,, be used for the renovation process that propylene, isobutene ammonia oxidizing are produced the fluid catalyst of acrylonitrile, methacrylonitrile particularly about with Mo, Bi, Fe oxide being main active component.

Background technology

The acrylonitrile commercial production realizes that through the ammoxidation of propylene reaction process this technical process is invented in the sixties in last century by BP company at present.This process is used the multicomponent composite oxide catalysts of a kind of key component as Mo, Bi, Fe oxide.Catalyst technology is one of core technology of this technology, and through Continual Improvement for many years, catalyst performance has obtained large increase, and the fresh catalyst single-pass yield of acrylonitrile can reach more than 80% at present.After the long-time use of commercial plant; Catalyst Mo element distillation in the commercial plant use, K element run off, and catalyst activity descends gradually, generally use 2 years after; The catalyst single-pass yield of acrylonitrile descends about 2 percentage points, influences the benefit of industrial installation.Because catalyst costs an arm and a leg, whole tower is changed because of the less employing of economic cause.Usually adopt the type of the adding catalyst through adding specific composition in the industry or the catalyst that activity descends kept reactivity worth more from birth.

The active decline of ammoxidation catalyst mainly contains following reason: 1. in the use some component of catalyst such as Mo at high temperature and reaction atmosphere particularly under the steam effect; The distillation loss; K runs off under the erosion of high linear speed material; Changed the composition of catalyst, made it depart from best ratio range.2. in the catalyst some component with redox property by over reduction, as Mo, Bi, Fe oxide all can be in various degree reduction.3. the catalyst activity phase structure changes in course of reaction gradually.4. catalyst grain size distributes to change and causes that fluidized state changes.5. catalyst duct carbon distribution etc.These factors all can cause catalyst performance to descend, and to above reason, need take certain measures to recover catalyst activity.

Generally comprise following measure: 1. some component of make-up catalyst is recovered the original composition of catalyst, as replenishing the Mo element.2. under particular atmosphere, improve catalyst oxidation reducing condition and active phase structure through high-temperature roasting.3. control catalyst grain size distribution optimization device fluidized state.The catalyst that activity is descended like the clear 63-33903 of Japanese Patent Laid take out and replenish molybdenum component after drop into reactor again; US3882159 directly adds the inert microspheres thing that molybdenum oxide or load have molybdenum oxide in reactor; US4425255 adopt earlier with activity descend catalyst roasting under the reducing atmosphere then under air atmosphere the method for roasting can optimize the catalyst oxidation reducing condition, improve catalyst selectivity; CN1110193A is through replenishing ammonium molybdate and regenerated catalyst under nitrogen air Mixture atmosphere.US4609635 and US4052332 all adopt catalyst that activity is descended through the solution impregnation that contains some composition of the catalyst method of roasting then; US4590011 regularly extracts catalyst in reactor out, and sieve goes the loss of putting back to reactor behind the coarse granule or adding fine grained inert particle post-reactor finely grained catalyst, and the holdout device fluidized state is stable.The catalyst mechanical disintegration that special clear 63-30065 will use for a long time increases fine grain content; CN1061163A adopts the catalyst of adding of specific composition, and distributes through the control catalyst grain size and to prolong industrial catalyst service life.

The problem that prior art exists mainly shows: the reaction bed catalyst is drawn off carry out mechanical disintegration or with the solution impregnation of some composition, will cause in solution amount and can't evenly flood more after a little while, and that solution amount increases the rear catalyst swelling is broken, operability is poor; The catalyst of existing in addition renovation process gained is because of reckoning without the loss of K element, and regenerated catalyst does not really return to the composition of fresh catalyst on prescription, still comparatively fast decline, poor effect of acrylonitrile yield after the long-time running.

Summary of the invention

The Mo that technical problem prior art to be solved by this invention exists, Bi, Fe oxide bulk the series catalysts distillation of Mo element, K element in commercial plant run off; Cause the problem of catalyst activity reduction, a kind of renovation process of new ammonoxidizing fluid bed catalyst is provided.This method has can make equilibrium catalyst replenish Mo and K component rapidly, thereby makes catalyst recover active rapidly, and more stable advantage.

For solving the problems of the technologies described above; The technical scheme that the present invention adopts is following: a kind of renovation process of ammonoxidizing fluid bed catalyst; Through ammonoxidizing fluid bed equilibrium catalyst being pressed the composition requirement of fresh bulk catalyst; After replenishing corresponding molybdenum and potassium content,, get the regenerated catalyst finished product 550~700 ℃ roasting temperature activation 0.5~12 hour.

In the technique scheme, the raw material preferred version that replenishes molybdenum in the catalyst regeneration process is selected from ammonium heptamolybdate, ammonium tetramolybdate or molybdenum oxide, and more preferably scheme is selected from ammonium heptamolybdate; The raw material preferred version that replenishes potassium is selected from potassium nitrate, potassium acetate, potash or potassium hydroxide, and more preferably scheme is selected from potassium nitrate; The sintering temperature preferable range is 570~650 ℃, and more preferably scope is 570~620 ℃; The roasting time preferable range is 1~4 hour, and more preferably scope is 1~2 hour.

Regenerative process is following: will contain Mo and K component and add the active equilibrium catalyst that descends and mix, and under calcination atmosphere, obtain regenerated catalyst through the converter roasting.

Molybdenum component: ammonium heptamolybdate, ammonium tetramolybdate crystal etc.; Ammoniun Heptamolybdate Solution; Molybdenum oxide.Preferred ammonium heptamolybdate crystal.Potassium component: potassium nitrate, potassium acetate, potash or potassium hydroxide etc., preferred potassium nitrate crystals.

Sintering temperature: 550~650 ℃, preferred 570~620 ℃.

Roasting time: 0.5~4 hour, preferred 1~2 hour.

In the following embodiment that provides, be to the investigation appreciation condition of catalyst:

Reactor: fluidized-bed reactor, 38 millimeters of internal diameters

Catalyst filling amount: 550 grams

Reactor top pressure: 0.084MPa (gauge pressure)

Reaction temperature: 440 ℃

Reaction time: 4 hours

Raw material ratio: propylene/ammonia/air=1/1.2/9.5

WWH:0.06 hour

-1

Product absorbs with 0 ℃ of diluted acid, with gas-chromatography and chemical analysis binding analysis product.

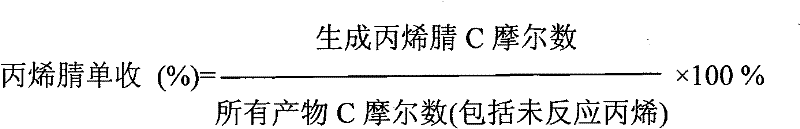

Propylene conversion, acrylonitrile yield and optionally be defined as:

Adopt renovation process of the present invention to be used for ammonoxidizing fluid bed catalyst when regeneration, not only can make the composition of catalyst really return to the proportioning of fresh catalyst, reduction components returns to high valence state, and the catalyst oxidation ability strengthens, and propylene conversion improves; The surface acid alkalescence of catalyst improves simultaneously, and the acrylonitrile selectivity rises, and has solved catalyst effectively and has run off because of Mo, K component, and the problem of catalyst activity reduction has obtained better technical effect.

Through embodiment the present invention is done further elaboration below.

[embodiment 1]

The specific embodiment

According to fresh body acrylonitrile fluidized-bed catalyst (Mo

12Bi

2.0Fe

2.5Ni

5.5Mg

1.8La

0.8K

0.05Cs

0.05Na

0.05+ 50%SiO

2) composition requirement, with equilibrium catalyst (Mo

11.3Bi

2.0Fe

2.5Ni

5.5Mg

1.8La

0.8K

0.041Cs

0.05Na

0.05+ 50%SiO

2) molybdenum and the potassium component of replenishing corresponding content, mix, by table 1,2 process conditions catalyst is carried out roasting regeneration.The result shows: the catalyst single-pass yield of acrylonitrile can reach more than 82%, improves more than 6 percentage points than regeneration forward horizontal stand catalyst.

The different molybdenums of table 1 source regeneration effect

| Component | Single-pass yield of acrylonitrile (%) | Propylene conversion (%) | Acrylonitrile selectivity (%) |

| Poising agent | 77.0 | 94.7 | 81.4 |

| Do not mend molybdenum | 79.2 | 95.6 | 82.8 |

| Ammonium tetramolybdate | 80.1 | 95.7 | 83.7 |

| Ammonium heptamolybdate | 80.7 | 97.0 | 83.2 |

| Molybdenum oxide | 81.1 | 95.5 | 84.9 |

| Molybdenum oxide, potassium nitrate | 81.6 | 96.4 | 84.6 |

| Ammonium heptamolybdate, potassium nitrate | 82.2 | 96.8 | 84.9 |

| Molybdenum oxide, potassium acetate | 81.3 | 96.2 | 84.5 |

| Ammonium heptamolybdate, potassium acetate | 81.9 | 96.7 | 84.7 |

| Molybdenum oxide, potash | 81.5 | 96.1 | 84.8 |

| Molybdenum oxide, potassium hydroxide | 80.8 | 97.3 | 83.0 |

* note 1:AN acrylonitrile, ACN acetonitrile, ACHO, methacrylaldehyde, HCN hydrogen cyanide.

* note 2: roasting condition is air atmosphere, 580 ℃, 1 hour.

The different roasting condition regeneration effects of table 2

| Roasting condition | Single-pass yield of acrylonitrile (%) | Propylene conversion (%) | Acrylonitrile selectivity (%) |

| 570℃ | 81.4 | 97.3 | 83.7 |

| 590℃ | 81.9 | 96.5 | 84.9 |

| 610℃ | 81.2 | 96.2 | 84.4 |

| 620℃ | 80.8 | 95.9 | 84.3 |

| 0.5 hour | 81.7 | 97.8 | 83.5 |

| 1.0 hour | 82.2 | 96.8 | 84.9 |

| 1.5 hour | 82.0 | 96.4 | 85.1 |

| 2.0 hour | 81.1 | 95.7 | 84.7 |

* note 3: roasting condition is an air, and catalyst is ammonium heptamolybdate, the potassium nitrate that equilibrium catalyst replenishes corresponding molybdenum and potassium content.

* note 4: without the roasting time of indicating is that 1 hour, sintering temperature are 580 ℃.

Claims (5)

1. the renovation process of an ammonoxidizing fluid bed catalyst; Through ammonoxidizing fluid bed equilibrium catalyst being pressed the composition requirement of fresh bulk catalyst; After replenishing corresponding content molybdenum and potassium,, get the regenerated catalyst finished product 550~700 ℃ roasting temperature activation 0.5~12 hour.

2. the renovation process of fluid catalyst according to claim 1 is characterized in that the raw material that replenishes molybdenum in the catalyst regeneration process is selected from ammonium heptamolybdate, ammonium tetramolybdate or molybdenum oxide; The raw material that replenishes potassium is selected from potassium nitrate, potassium acetate, potash or potassium hydroxide.

3. the renovation process of fluid catalyst according to claim 2 is characterized in that the raw material that replenishes molybdenum in the catalyst regeneration process is selected from ammonium heptamolybdate; The raw material that replenishes potassium is selected from potassium nitrate.

4. the renovation process of fluid catalyst according to claim 1 is characterized in that sintering temperature is 570~650 ℃ in the catalyst regeneration process, and roasting time is 1~4 hour.

5. the renovation process of fluid catalyst according to claim 4 is characterized in that sintering temperature is 570~620 ℃ in the catalyst regeneration process; Roasting time is 1~2 hour.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200910057792A CN101992128B (en) | 2009-08-31 | 2009-08-31 | Regeneration method of ammoxidation fluid catalyst |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200910057792A CN101992128B (en) | 2009-08-31 | 2009-08-31 | Regeneration method of ammoxidation fluid catalyst |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101992128A CN101992128A (en) | 2011-03-30 |

| CN101992128B true CN101992128B (en) | 2012-09-05 |

Family

ID=43783169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200910057792A Active CN101992128B (en) | 2009-08-31 | 2009-08-31 | Regeneration method of ammoxidation fluid catalyst |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101992128B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113509965B (en) * | 2021-06-24 | 2021-12-07 | 潍坊中汇化工有限公司 | Regeneration method of catalyst for process of preparing acetonitrile by acetic acid ammoniation method |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4609635A (en) * | 1984-04-18 | 1986-09-02 | Enichem Sintesi S.P.A. | Method for the regeneration of ammoxidation catalysts |

| CN1061163A (en) * | 1990-11-05 | 1992-05-20 | 中国石油化工总公司 | The method of catalyst activity of acrylonitrile fluidized bed long-term stability |

| CN1110193A (en) * | 1994-04-11 | 1995-10-18 | 上海石油化工股份有限公司 | Reactivating or regenerating method for molybdenum-bismuth-iron system ammoxidation catalyst |

| CN1128680A (en) * | 1995-02-09 | 1996-08-14 | 中国石化齐鲁石油化工公司 | Regeneration method of carbon monoxide sulfur-tolerant shift catalyst |

| CN1226461A (en) * | 1997-12-05 | 1999-08-25 | 标准石油公司 | Improvement of performance of used molybdenum based catalysts by addition of ammonium dimolybdate |

-

2009

- 2009-08-31 CN CN200910057792A patent/CN101992128B/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4609635A (en) * | 1984-04-18 | 1986-09-02 | Enichem Sintesi S.P.A. | Method for the regeneration of ammoxidation catalysts |

| CN1061163A (en) * | 1990-11-05 | 1992-05-20 | 中国石油化工总公司 | The method of catalyst activity of acrylonitrile fluidized bed long-term stability |

| CN1110193A (en) * | 1994-04-11 | 1995-10-18 | 上海石油化工股份有限公司 | Reactivating or regenerating method for molybdenum-bismuth-iron system ammoxidation catalyst |

| CN1128680A (en) * | 1995-02-09 | 1996-08-14 | 中国石化齐鲁石油化工公司 | Regeneration method of carbon monoxide sulfur-tolerant shift catalyst |

| CN1226461A (en) * | 1997-12-05 | 1999-08-25 | 标准石油公司 | Improvement of performance of used molybdenum based catalysts by addition of ammonium dimolybdate |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101992128A (en) | 2011-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101062898B (en) | Isophthalonitrile catalytic hydrogenation method | |

| CN101690900A (en) | Method for preparing catalyst for acrolein and acrylic acid | |

| CN100566829C (en) | Catalyst for preparing acrylonitrile by ammonia oxidizing method | |

| CN102371156B (en) | Unsaturated nitrile fluidized bed catalyst prepared by ammoxidation and its preparation method | |

| CN101992091B (en) | Fluidized bed catalyst for preparing unsaturated nitrile by ammoxidation and preparation method thereof | |

| CN103418406A (en) | Low-temperature high-load catalyst for olefin ammoxidation reaction | |

| CN103418405B (en) | Replenishment catalyst for maintaining stabilization production of acrylonitrile device | |

| CN101468311B (en) | Catalyst for methanation of coal gas and preparation method thereof | |

| CN101121131B (en) | Ammoxidation method to manufacturing unsaturated nitrile fluid-bed catalyst | |

| CN101992128B (en) | Regeneration method of ammoxidation fluid catalyst | |

| CN104624197B (en) | Deoxygenating and desulfurization double-function fine desulfurization agent and preparation method thereof | |

| CN100506377C (en) | Fluidized bed catalyst for ammoxidating propylene to produce acrylonitrile | |

| CN101147867B (en) | Fluidized bed catalyst for oxidation of propene ammonia | |

| CN101767013B (en) | Fluidized bed catalyst for preparing acrylonitrile by ammonia oxidation method | |

| CN101767020A (en) | Regeneration method of ammoxidation fluid catalyst | |

| CN103418400A (en) | Fluidized-bed catalyst for preparing unsaturated nitrile by ammoxidation | |

| CN101811058B (en) | Unsaturated nitrile fluid catalyst prepared by ammoxidation | |

| CN111036268A (en) | Alumina composite material, preparation method and application thereof, and synthetic method of n-valeronitrile | |

| CN103894203B (en) | High-load catalyst for olefin ammoxidation reactions | |

| CN100408172C (en) | Acrylonitrile fluid bed catalyst | |

| CN105618091A (en) | Supported catalyst for synthesizing pyridine by tetrahydrofurfuryl alcohol gas-solid phase catalysis and preparation method thereof | |

| CN100358630C (en) | Fluid-bed catalyst for propylene ammoxidation to prepare acrylonitrile | |

| CN101768091A (en) | Method for improving acrylonitrile device reaction yield | |

| CN101279264B (en) | High load fluidized bed catalyst for preparing acrylonitrile | |

| CN100368082C (en) | Fluidized bed catalyst for prodn. of acrylonitrile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |